Preparation method of thin film of diffusion impervious layer

A technology of barrier layer and thin film, which is applied in the direction of coating, metal material coating process, semiconductor/solid-state device manufacturing, etc., can solve the problem of inability to effectively block copper diffusion, and achieve the effect of improving performance and increasing working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

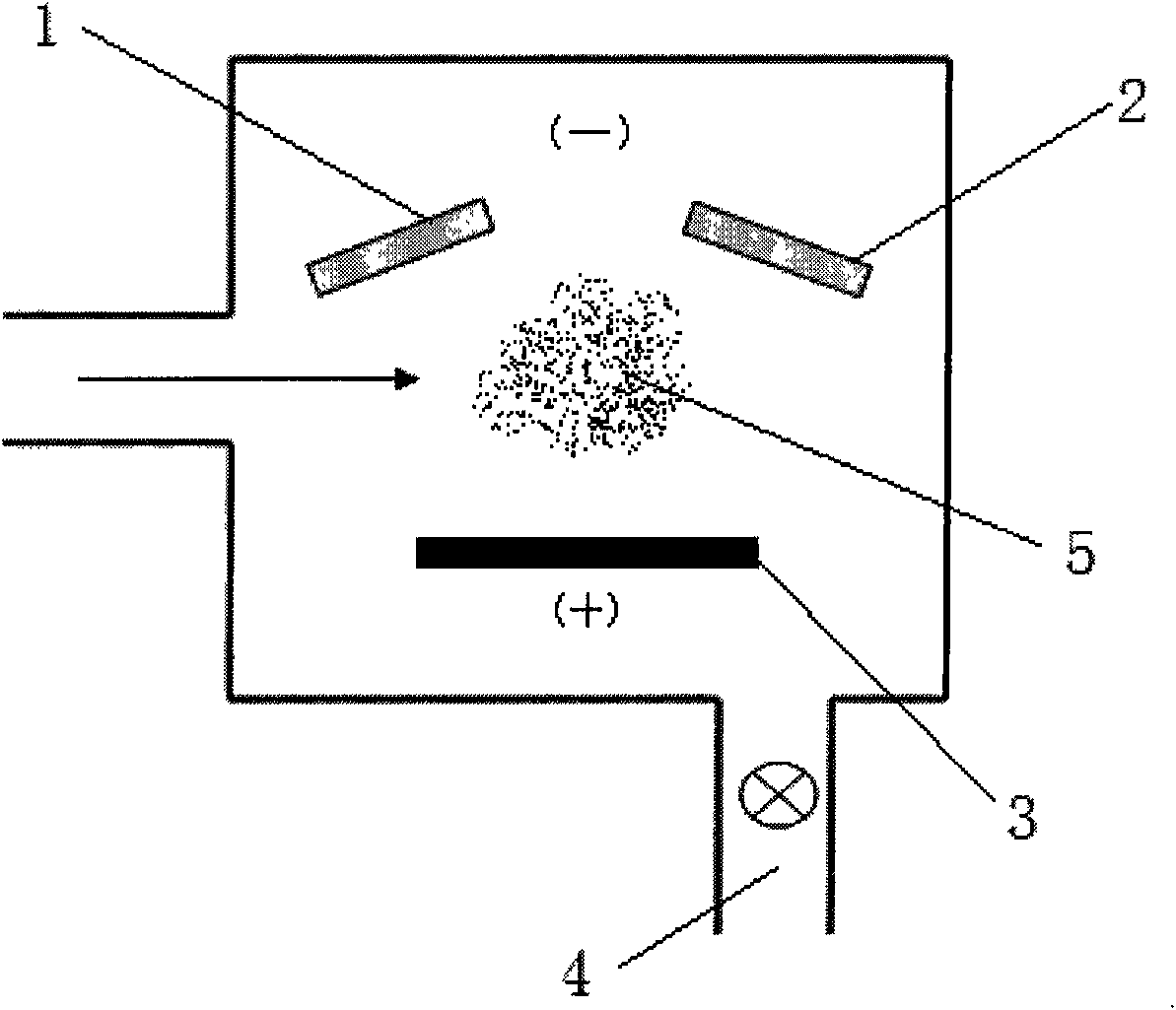

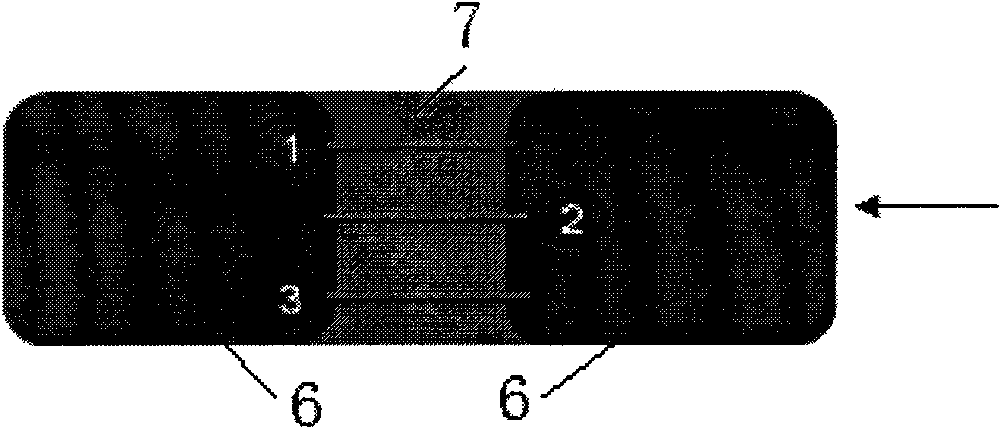

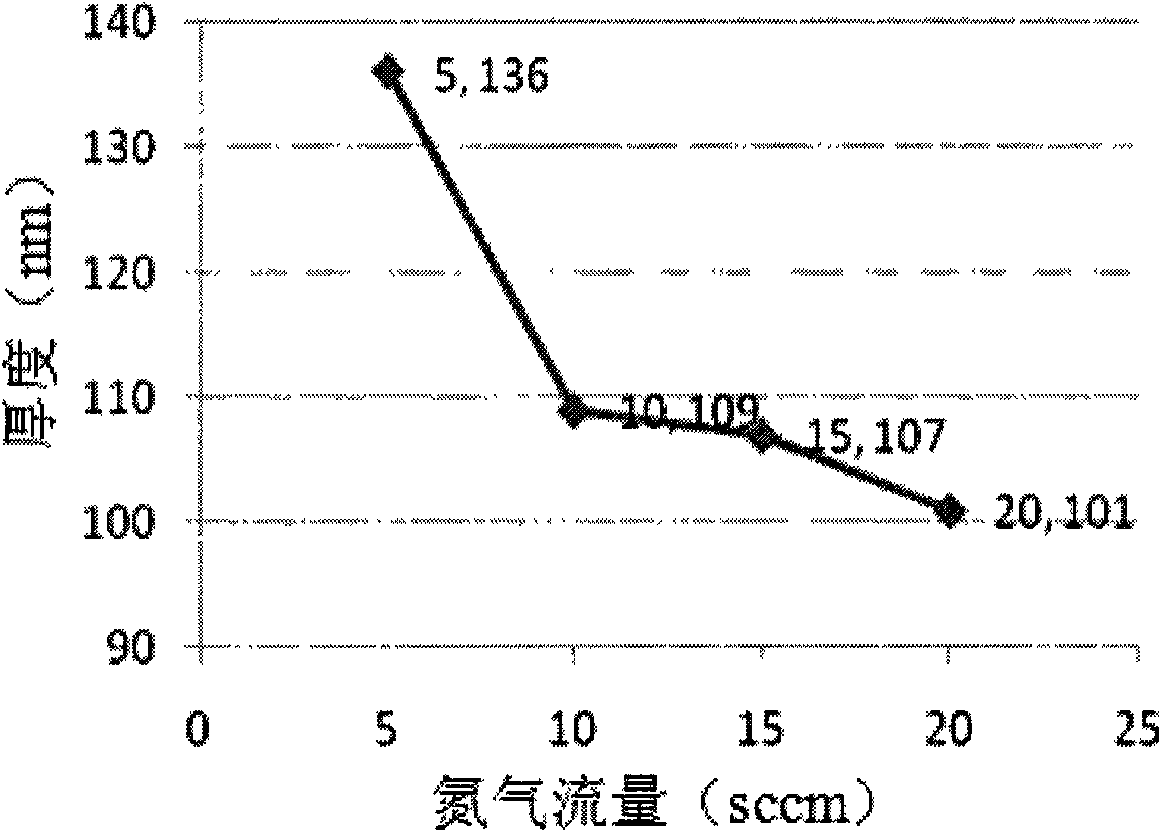

[0007] Specific embodiment one: the preparation method of the diffusion barrier film in the present embodiment is realized by following steps: one, silicon substrate is put into the vacuum chamber of magnetron sputtering coating equipment, utilize plasma to silicon substrate Sputtering cleaning; 2. Under the atmosphere of nitrogen and argon, use ruthenium and titanium as the target cathode and adopt the magnetron co-sputtering method to carry out the deposition process on the silicon substrate processed by step 1 for 600s (obtain the deposited state on the silicon substrate. thin film), wherein during the deposition process, the sputtering power of target cathode ruthenium is 100W, the sputtering power of target cathode titanium is 100-220W, the flow rate of argon gas is 10-25 sccm, the flow rate of nitrogen gas is 5-20 sccm, and the working pressure Fixed at 10mTorr; 3. Heat up to 400-700°C at a heating rate of 10°C / min, heat the silicon substrate treated in step 2 for 60 minu...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment differs from Embodiment 1 in that the silicon substrate described in step 1 is a single crystal silicon polished wafer. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0024] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the sputtering power of the target cathode titanium (Ti) in step 2 is 130-190W. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com