Cleaning component, cleaning method of coater, cleaning device and manufacture method of component for display

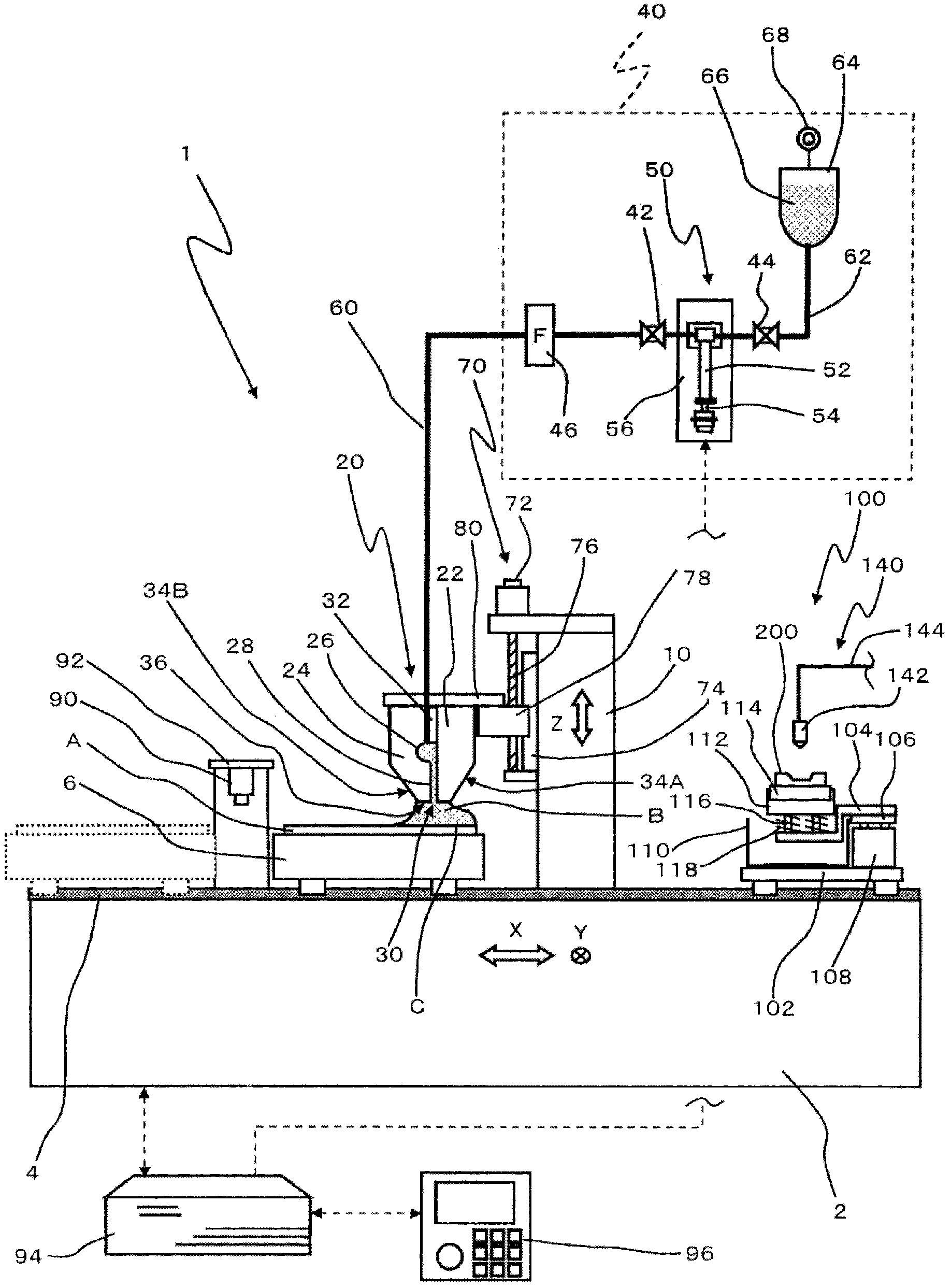

A technology of applicators and components, which is applied in the direction of surface coating liquid devices, instruments, coatings, etc., can solve problems such as coating defects, achieve high coating film thickness accuracy, high yield film thickness accuracy, The effect of shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

comparative test 1

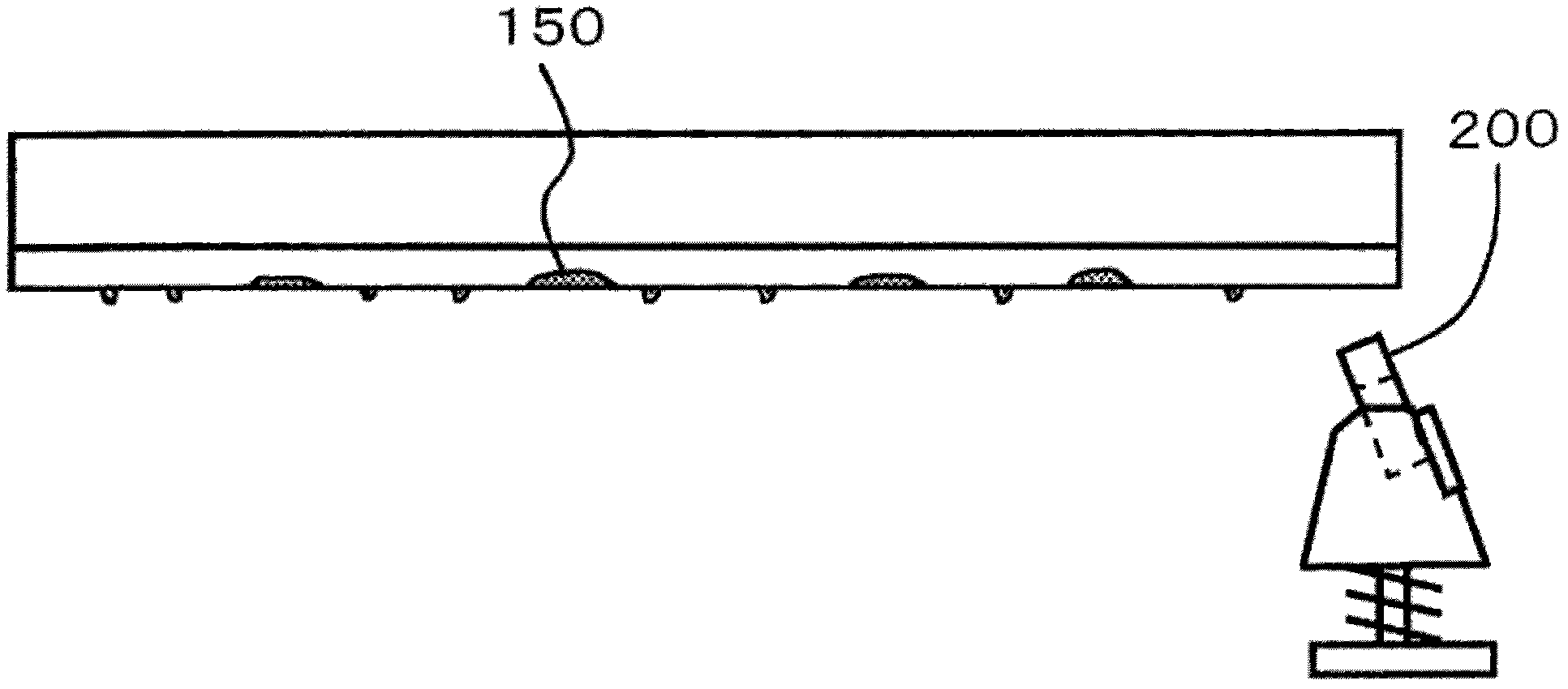

[0214] In the configuration of the comparative test piece 1, the notch 220 was removed from the test piece 1 (wiping member 300). Using this comparative test piece 1, cleaning and coating were performed under exactly the same conditions as the test piece 1, and evaluations 1 to 4 of the same cleaning ability and coating were performed.

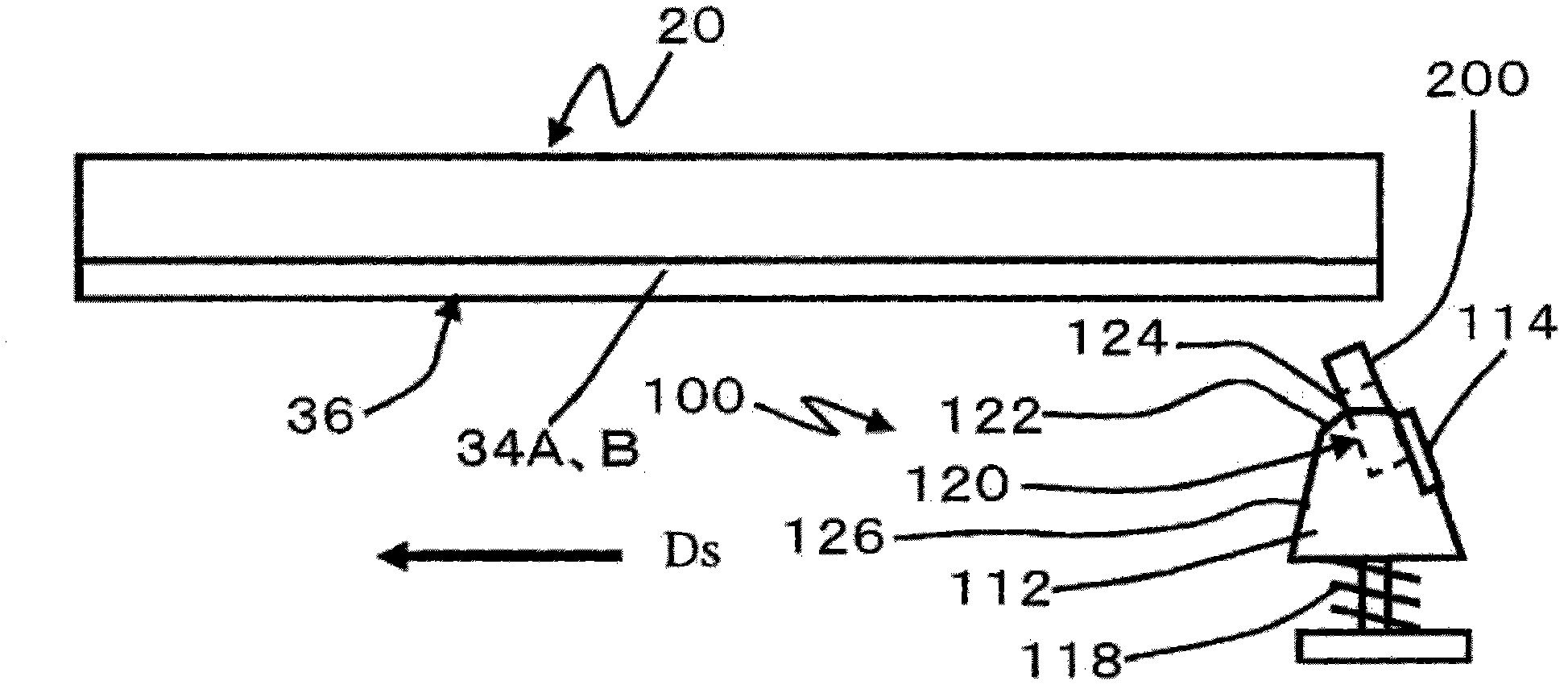

[0215] In Evaluation 1, with regard to the test piece 1, after cleaning 10 times and after cleaning 100 times, the coating liquid for R color did not remain on the discharge port surface 36 and the lip slopes 34A and 34B. As a result, no wear of the wiping member 300 was observed. In addition, in the comparative test piece 1, although the R color coating liquid did not remain on the discharge port surface 36, the R color coating liquid remained on the upper parts of the lip slopes 34A and 34B along the entire longitudinal direction of the slit nozzle 20. cloth liquid. The line width of the residual R-color coating liquid was 1 mm after clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com