Nitride semiconductor light emitting element and method for manufacturing nitride semiconductor

A nitride semiconductor and light-emitting element technology, applied in semiconductor devices, electrical components, nano-optics, etc., can solve the problems of deterioration of the crystal quality of the p-type semiconductor layer, hindering the p-type semiconductor layer from being p-typed, and increasing the number of manufacturing processes. The effect of improving external luminous efficiency, reducing forward voltage Vf, and alleviating deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

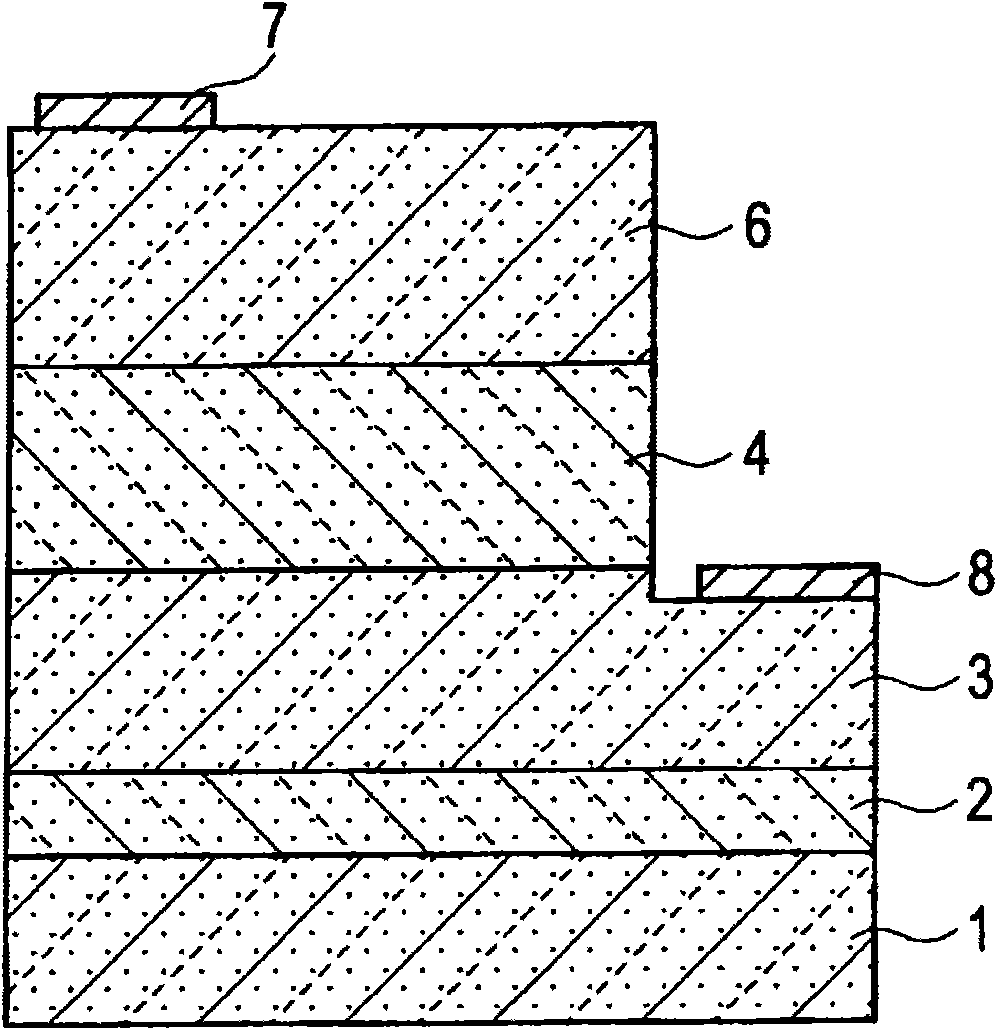

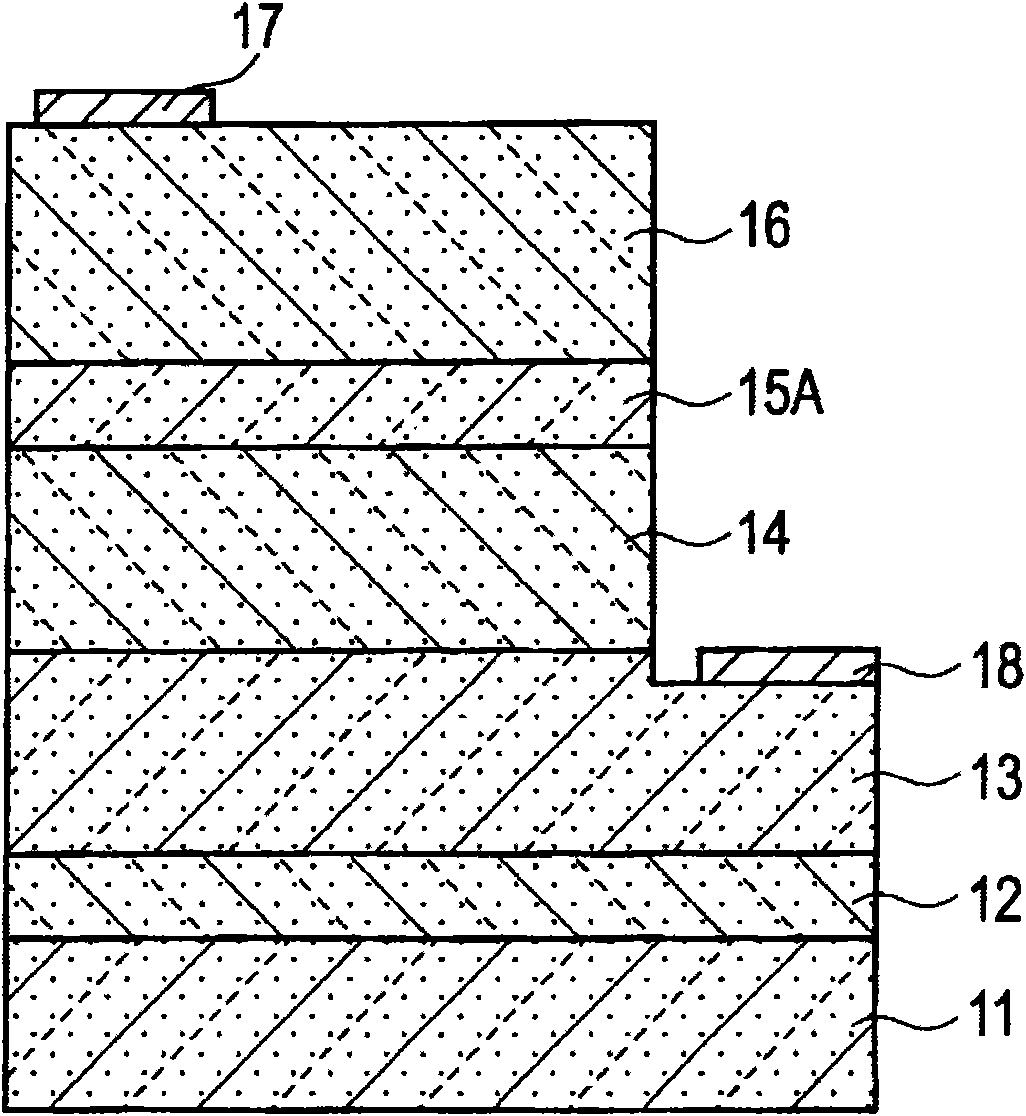

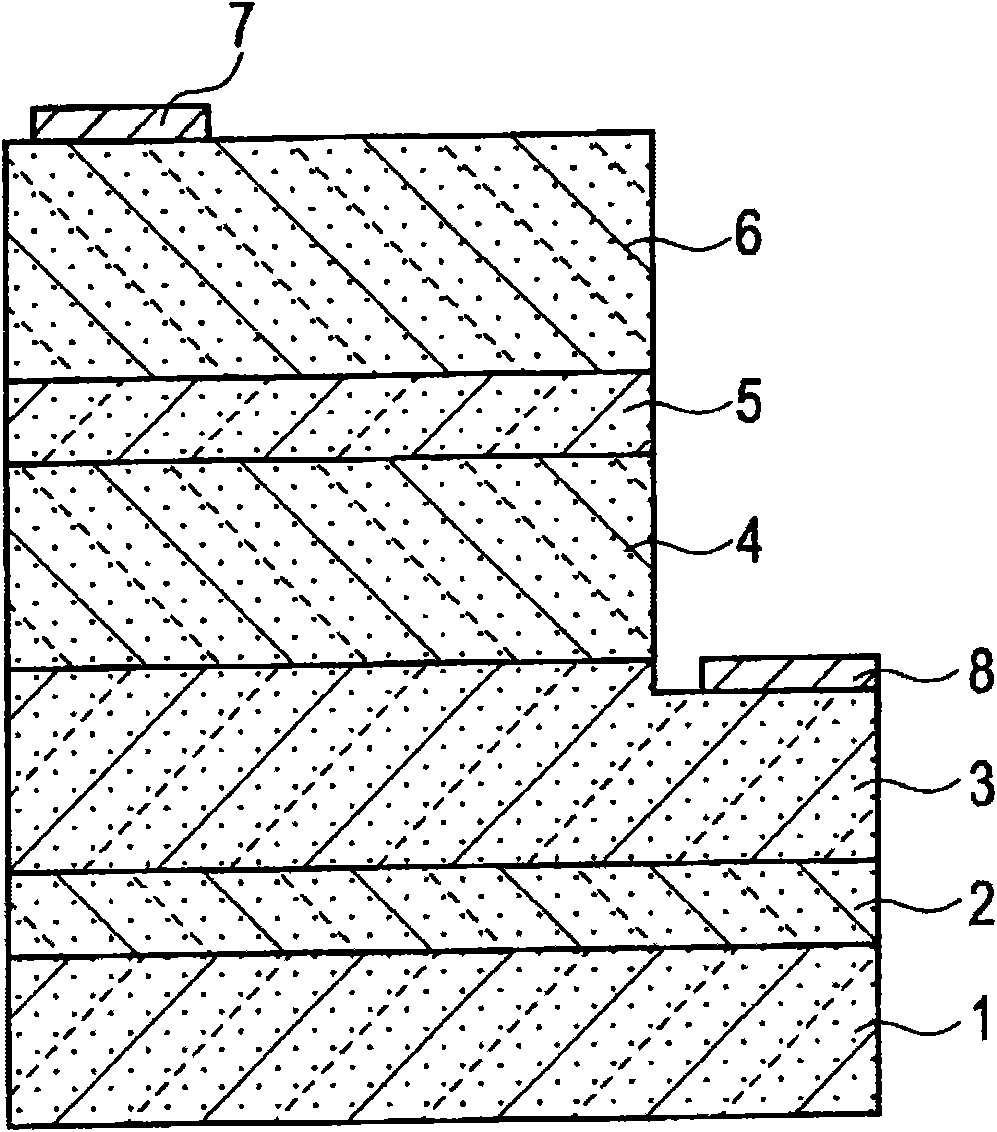

[0086] An embodiment of the present invention will be described below with reference to the drawings. figure 1 An example of the structure of the nitride semiconductor light-emitting device of the present invention is shown.

[0087] A sapphire substrate 1 is used as a growth substrate, an AlN buffer layer 2 is formed on the sapphire substrate 1, and an n-type AlGaN layer 3, an InGaN / GaN active layer 4, and a p-type GaN layer 6 are sequentially stacked thereon. Nitride semiconductors. This nitride semiconductor is formed by a known MOCVD method or the like. Nitride semiconductors are represented as AlGAAlNN quaternary mixed crystals, known as so-called III-V nitride semiconductors, which can be Al x Ga y In z N (x1+y1+z1=1, 0≤x1≤1, 0≤y1≤1, 0≤z1≤1) represents.

[0088] Mesa etching is performed until n-type AlGaN layer 3 is exposed from p-type GaN layer 6 , and n-electrode 8 is formed on the exposed surface of n-type AlGaN layer 3 . On the other hand, p-electrode 7 is for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com