GaN device with mixed polarity

A mixed polarity and device technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of increasing device preparation time, deterioration of ohmic contact characteristics, and increasing process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

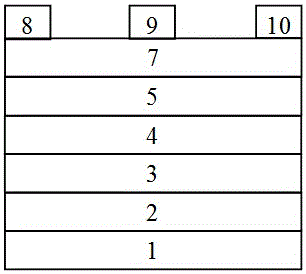

[0025] In this embodiment, the mixed polarity GaN / AlGaN Schottky barrier field effect transistor MESFET device is taken as an example, combined with the attached figure 1 Embodiments of the present invention are described in detail. The MESFET device described in this embodiment includes from bottom to top: substrate layer 1, N-polarGaN buffer layer 2, Al composition x First N-polarAl of incremental gradient x GaN layer 3, Al composition x Keep the second N-polarAl constant x GaN layer 4, Al composition x The third N-polarAl of the decreasing gradient x GaN layer 5 , Ga-polarGaN channel layer 7 ; source 8 , gate 9 and drain 10 are provided on the upper surface of Ga-polarGaN channel layer 7 .

[0026] It should be pointed out that in this embodiment: the substrate layer 1 can be a sapphire substrate, a silicon carbide substrate or a silicon substrate; the thickness of the N-polarGaN buffer layer 2 is between 1-3 μm; the Al components x Incremental Gradient Al x The GaN...

Embodiment 2

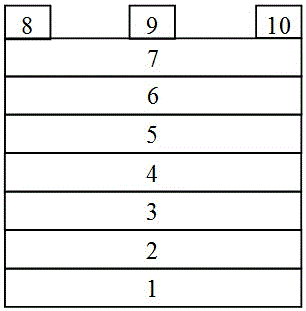

[0028] In this embodiment, the mixed-polarity GaN / AlGaN high electron mobility transistor HEMT device is taken as an example, and the attached figure 2 Embodiments of the present invention are described in detail. In this embodiment, the HEMT device includes from bottom to top: substrate layer 1, N-polarGaN buffer layer 2, Al composition x First N-polarAl of incremental gradient x GaN layer 3, Al composition x Keep the second N-polarAl constant x GaN layer 4, Al composition x The third N-polarAl of the decreasing gradient x GaN layer 5, N-polarAlN insertion layer 6, Ga-polarGaN channel layer 7; the upper surface of the Ga-polarGaN channel layer 7 is provided with a source 8, a gate 9, and a drain 10.

[0029] It should be noted that, in this embodiment: the substrate layer 1 may be a sapphire substrate, a silicon carbide substrate or a silicon substrate. The GaN buffer layer is N-polar with a thickness between 1 μm and 3 μm. The Al composition x Incremental Gradient A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com