Preparation method of topology insulator/ferromagnet heterostructure film

A topological insulator and heterostructure technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of high energy consumption, high cost, expensive equipment, etc. Reduced requirements and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

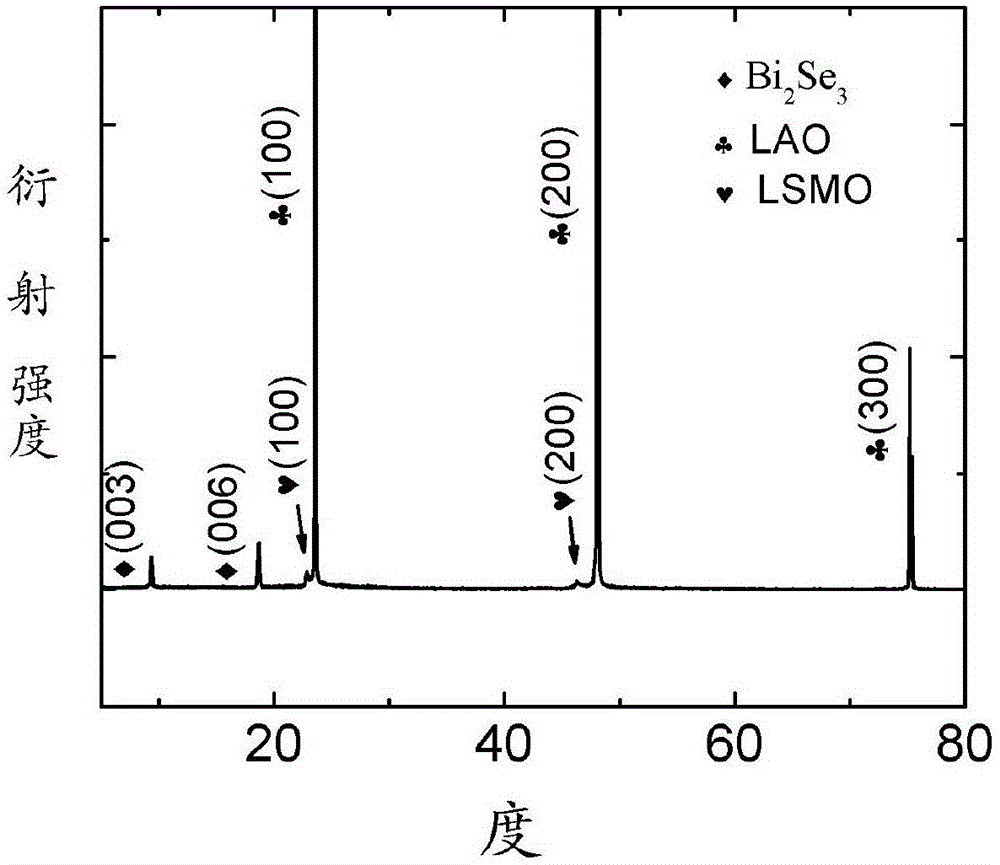

[0030] A kind of preparation method of topological insulator / ferromagnet heterostructure film, its step is:

[0031] a. Preparation of La 0.7 Sr 0.3 MnO 3 Thin film: Dissolve lanthanum nitrate, strontium nitrate and manganese nitrate in N,N-dimethylformamide according to the proportion of lanthanum, strontium and manganese ions in the ratio of 7:3:10 to form La 0.7 Sr 0.3 MnO 3 solution; in La 0.7 Sr 0.3 MnO 3 The mass added to the solution is the La 0.7 Sr 0.3 MnO 3 3% polyvinylpyrrolidone K30 of the solution quality forms a colloid; then the colloid is spin-coated on lanthanum aluminate LaAlO 3 On the single crystal substrate, place it in an infrared drying oven to dry; place the dried substrate sheet in a tube furnace, heat it at 200°C for 8 minutes, slowly heat it to 520°C for 18 minutes, then hold it at 850°C for 1 hour, and anneal Processing, that is, La 0.7 Sr 0.3 MnO 3 film;

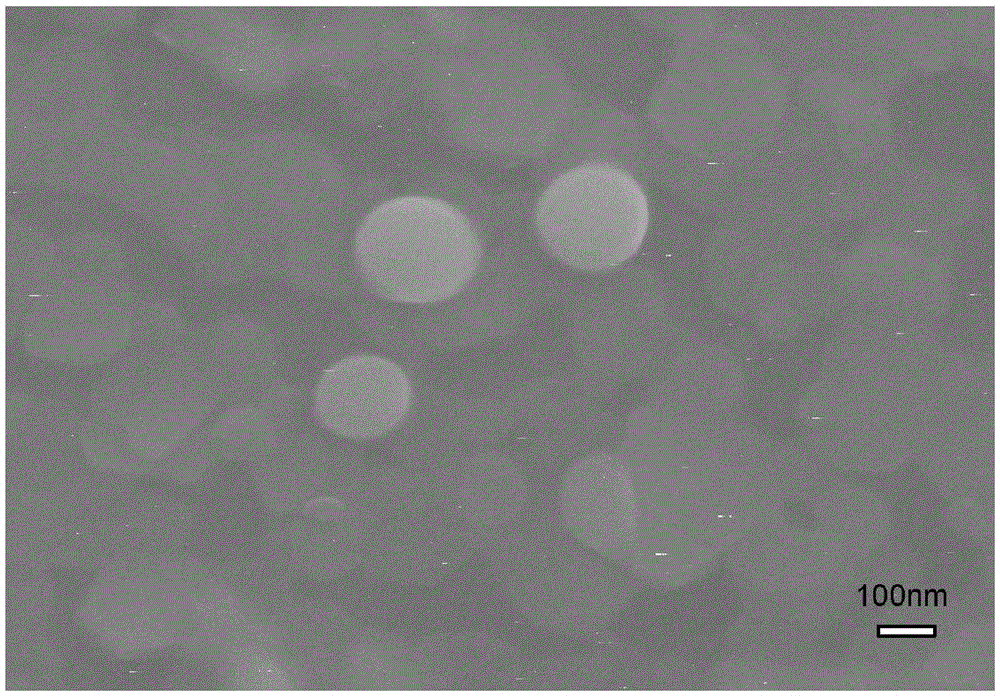

[0032] b. Deposition of Bi 2 Se 3 Thin film: the La prepared in step a 0.7 ...

Embodiment 2

[0040] A kind of preparation method of topological insulator / ferromagnet heterostructure film, its step is:

[0041] a. Preparation of La 0.7 Sr 0.3 MnO 3 Thin film: Dissolve lanthanum nitrate, strontium nitrate and manganese nitrate in N,N-dimethylformamide according to the proportion of lanthanum, strontium and manganese ions in the ratio of 7:3:10 to form La 0.7 Sr 0.3 MnO 3 solution; in La 0.7 Sr 0.3 MnO 3 The mass added to the solution is the La 0.7 Sr 0.3 MnO 3 5% polyvinylpyrrolidone K30 of the solution quality forms a colloid; then the colloid is spin-coated on lanthanum aluminate LaAlO 3 On the single crystal substrate, place it in an infrared drying oven to dry; place the dried substrate sheet in a tube furnace, heat it at 200°C for 8 minutes, slowly heat it to 520°C for 18 minutes, and hold it at 830°C for 1 hour, annealing , that is, La 0.7 Sr 0.3 MnO 3 film;

[0042] b. Deposition of Bi 2 Se 3 Thin film: the La prepared in step a 0.7 Sr 0.3 MnO ...

Embodiment 3

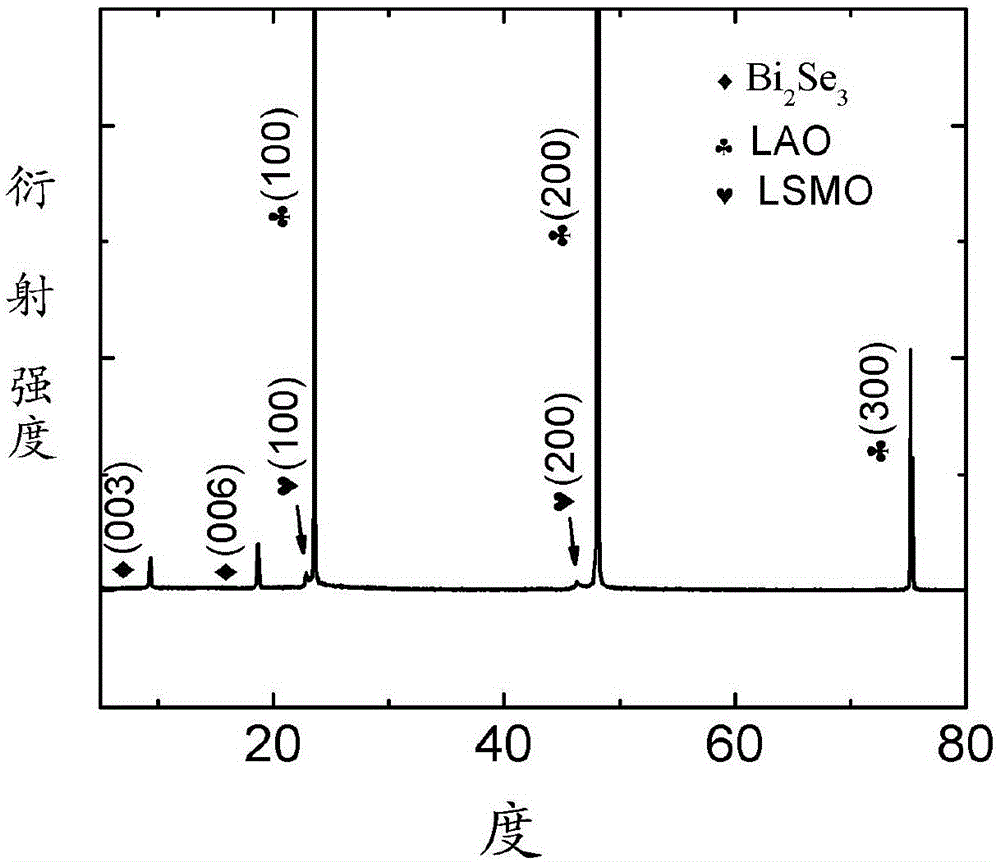

[0050] A kind of preparation method of topological insulator / ferromagnet heterostructure film, its step is:

[0051] a. Preparation of La 0.7 Sr 0.3 MnO 3 Thin film: Dissolve lanthanum nitrate, strontium nitrate and manganese nitrate in N,N-dimethylformamide according to the proportion of lanthanum, strontium and manganese ions in the ratio of 7:3:10 to form La 0.7 Sr 0.3 MnO 3 solution; in La 0.7 Sr 0.3 MnO 3 The mass added to the solution is the La 0.7 Sr 0.3 MnO 3 7% polyvinylpyrrolidone K30 of the solution quality forms a colloid; then the colloid is spin-coated on lanthanum aluminate LaAlO 3 On the single crystal substrate, dry in an infrared drying oven; place the dried substrate in a tube furnace, heat at 200°C for 12 minutes, slowly heat to 520°C for 22 minutes, hold at 850°C for 2 hours, and anneal , that is, La 0.7 Sr 0.3 MnO 3 film;

[0052] b. Deposition of Bi 2 Se 3 Thin film: the La prepared in step a 0.7Sr 0.3 MnO 3 The film is placed in a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com