Patents

Literature

413 results about "Strontium nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strontium nitrate is an inorganic compound made of the elements strontium and nitrogen with the formula Sr(NO₃)₂. This colorless solid is used as a red colorant and oxidizer in pyrotechnics.

Desensitizing bleaching gel

InactiveUS6458340B1Easy and fast fashionImprove stabilityCosmetic preparationsBiocideAlkaline earth metalGlycerol

A substantially anhydrous gel useful for bleaching teeth comprising: (i) at least 25% by weight of organic polyol; (ii) less than 3% by weight polyacrylic acid thickening agent; (iii) at least 10% by weight carbamide peroxide (or a chemically equivalent amount of another bleaching agent, such as 3% by weight hydrogen peroxide); (iv) neutralizing agent; (v) chelating agents; (vi) desensitizing agent; and (vii) miscellaneous ingredients such as Cirtoxain(R) and flavorants. The organic polyol is preferably glycerin. The polyacrylic acid thickening agent is preferably a carbomer. The desensitizing agent is preferably potassium nitrate, strontium chloride, potassium citrate, strontium nitrate, or a similarly effective alkali or alkaline earth metal salt of an organic or inorganic acid.

Owner:RANIR LLC

Extinguishment combination with hot gas sol

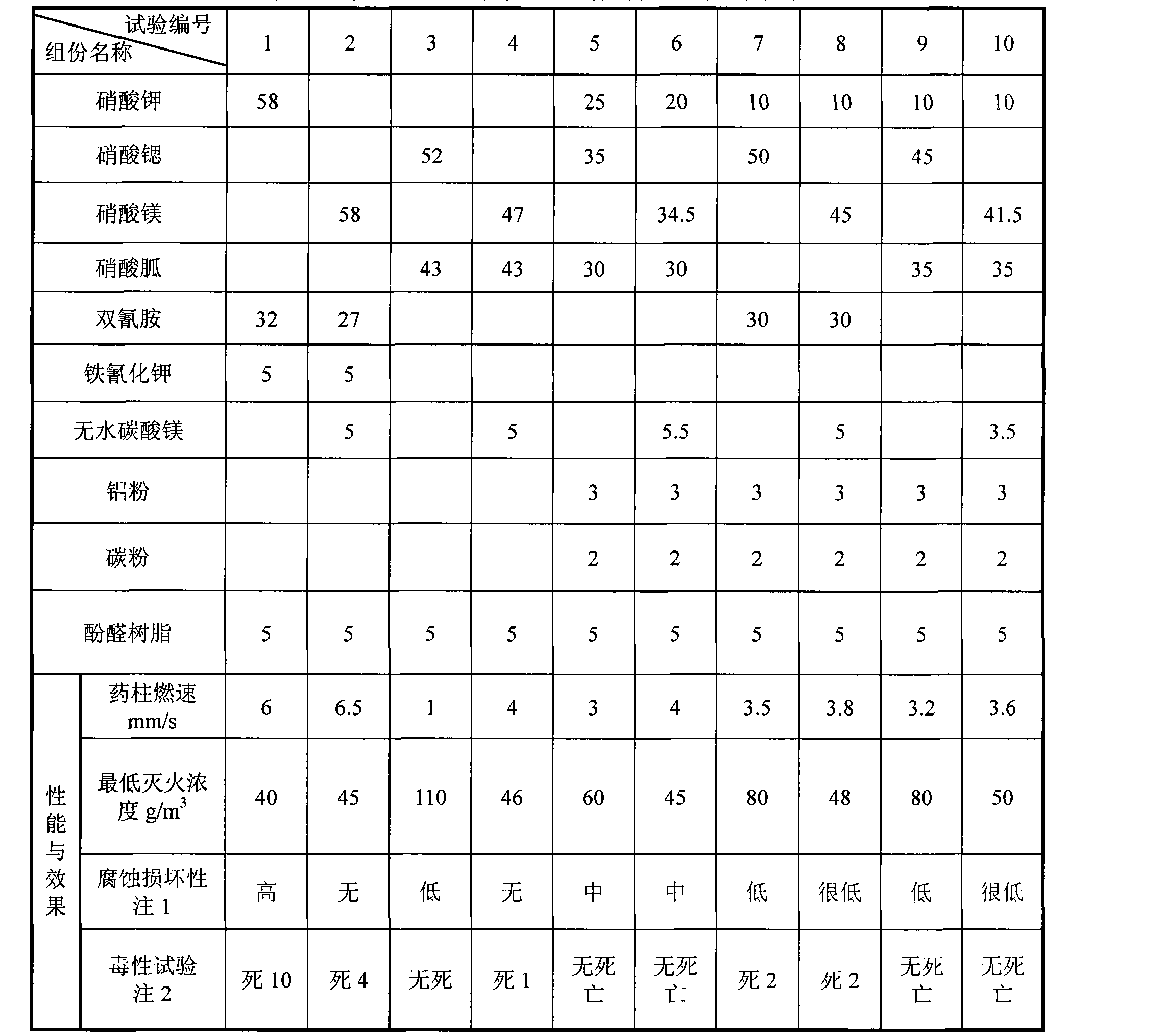

The invention provides ''a hot aerosol fire-extinguishing composition'' and relates to an oxidative magnesium salt hot aerosol fire-extinguishing composition represented by anhydrous magnesium nitrate. The composition is characterized in that the composition can be magnesium nitrate, magnesium carbonate, or other magnesium salt, and can also be a compound of magnesium nitrate, or other magnesium salt with potassium nitrate, strontium nitrate, or other potassium salt or strontium salt; a reducer can be one of or the combination of a plurality of ammonium carbamidine, dicyandiamide, red prussiate of potash, formamine, triazole, and tetrazole; a capability improver can be magnesium carbonate, manganous carbonate, aluminium powder, powdered carbon, magnesium hydrate, metal oxide, etc.; and the bond adopts phenolic resin, etc. The preparation of the magnesium salt comprises the continuous steps: medium temperature and low pressure dehydration, spray under the protection of nitrogen-oxygen flow or ultrafine grinding of grinded colloid, and microencapsulated hydrophobic treatment, etc. Compared with the prior art, the fire-extinguishing composition has the advantages of low price, extensive source, fire-extinguishing capability of K-type composition, and low causticity and toxicity of the ultimate product of combustion.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

Fire-extinguishing aerosol without toxicity and corrosion for electric appliance

InactiveCN1386554AAvoid corrosionWon't happenFire extinguisherHazardous substancePotassium ferrocyanide

A fire-extinguishing aerosol not generating harmful substance for electric equipment (computer, communication equipment, electric generator, etc) is prepared from oxidant (strontium nitrate or strontium nitrate / potassium nitrate), reducer (guanidine nitrate or dicyandiamide) and modifier (potassium ferrocyanide, aluminium powder, carbon powder and phenolic resin). After it is ignited by sensor, alot of fire-extinguishing particles are generated to cover on the object to be protected while the inert gas is generated for extinguishing fire.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

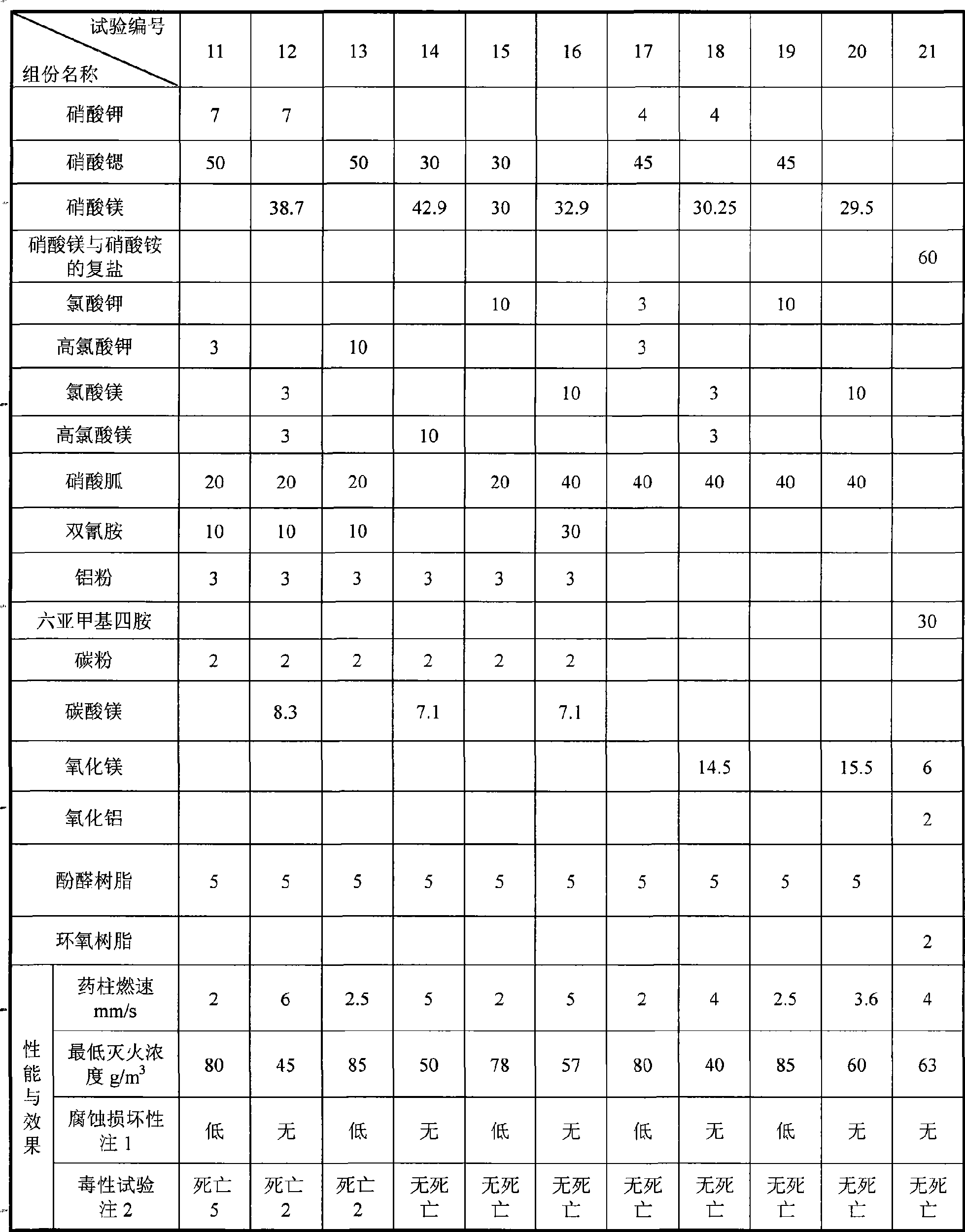

Compound type aerosol extinguishing agent

InactiveCN101862517ALow fire extinguishing concentrationImprove corrosion resistanceFire extinguisherSucroseNuclear chemistry

The invention discloses a compound type aerosol extinguishing agent comprising the following components in percentage by weight: 30-75 percent of oxidizing agent, 20-50 percent of reducing agent, 2-15 percent of performance regulating agent and no more than 2 percent of binding agent. The oxidizing agent is prepared by matching any two or three matched components selected from potassium nitrate, strontium nitrate and magnesium nitrate; the reducing agent is prepared by matching two or more components selected from polyhexose, glucose, starch, sorbitol, xylitol, lactose, dicyandiamide, melamine, carbamide and sucrose; the performance regulating agent is prepared by matching one or more component selected from carbon powder, light magnesium carbonate, magnesium stearate, aluminium nitrate, hexamethylenetetramine, aluminium oxide, magnesium oxide and light metal oxide; and the binding agent is prepared by matching water or 20-30 percent of ethanol added into the water. In the invention, production raw materials have a wide source and low cost, can be constantly obtained and are safe and reliable, and burnt residues have no toxicity and good environmental protection performance.

Owner:湖南省金鼎消防器材有限公司

Fire-extinguishing aerosol without toxicity and corrosion for electric appliance

InactiveCN1150952CStrong fire extinguishing functionRealize total flooding fire extinguishingFire extinguisherHazardous substancePotassium ferrocyanide

A fire-extinguishing aerosol not generating harmful substance for electric equipment (computer, communication equipment, electric generator, etc) is prepared from oxidant (strontium nitrate or strontium nitrate / potassium nitrate), reducer (guanidine nitrate or dicyandiamide) and modifier (potassium ferrocyanide, aluminium powder, carbon powder and phenolic resin). After it is ignited by sensor, a lot of fire-extinguishing particles are generated to cover on the object to be protected while the inert gas is generated for extinguishing fire.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

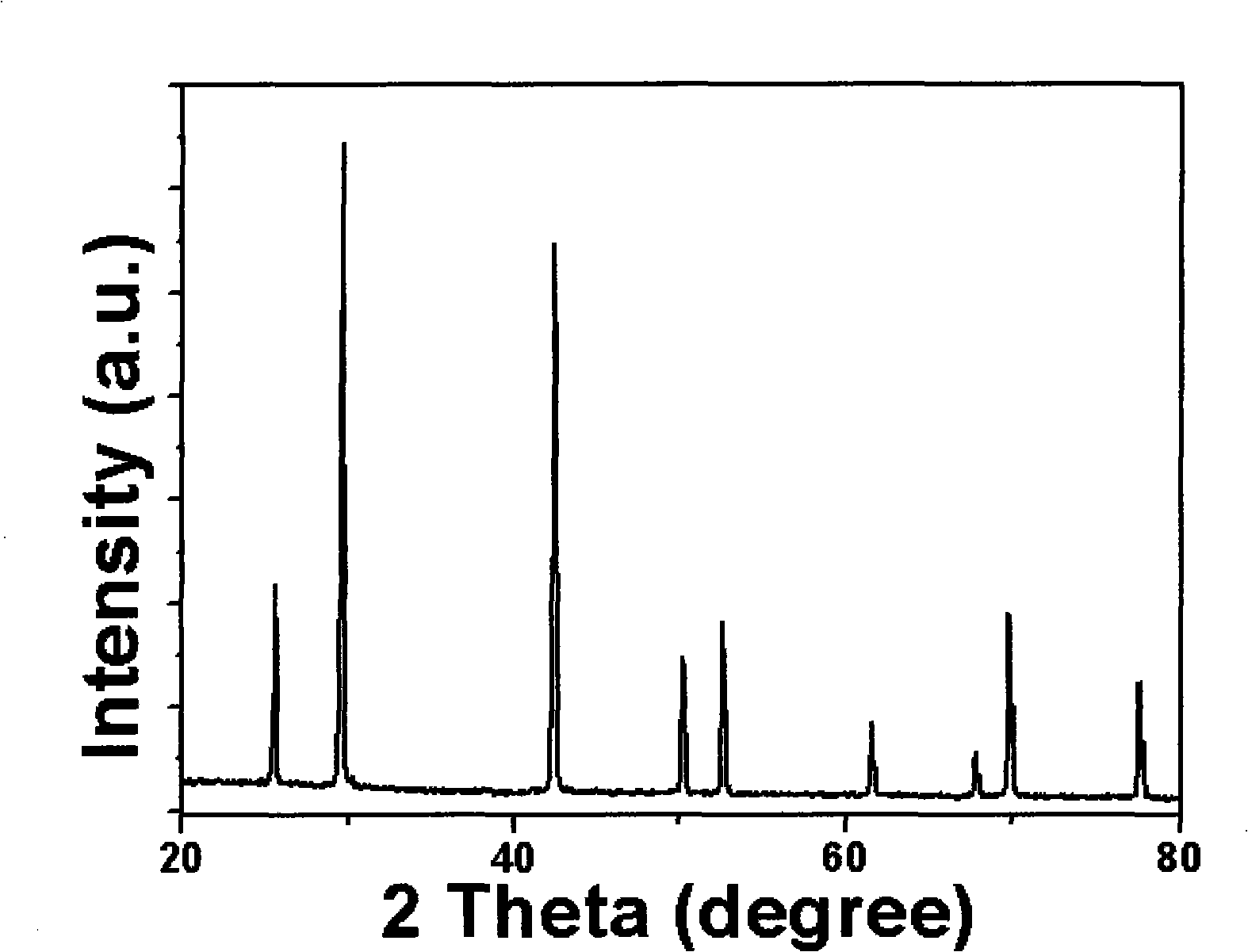

La doped SrTiO3 base oxide pyroelectric material and preparation method

InactiveCN101423243AStoichiometric ratio is accurateUniform compositionTitanium compoundsThermoelectric materialsStrontium titanate

A La-doped strontium titanate (SrTiO3)-based oxide thermoelectric material and a preparation method thereof, belonging to the technical field of energy materials. The method is divided into two parts of powder synthesis and forming of bulk materials. The powder synthesis adopts the sol-gel method, takes tetrabutyl titanate, strontium nitrate and lanthanum nitrate as raw materials, takes deionized water and ethanol as solvents and takes acetic acid and glycerol as a catalyst and a chelating agent to prepare SrTiO3 gel with different La doping amount, and the temperature is kept at the temperature of 500-560 DEG C for 1-2 hours to obtain precursor powder. The bulk forming adopts the spark plasma sintering method, and the sintering conditions are as follows: the vacuum degree is 2-10Pa, the pressure is 40-50MPa, the heating rate is 100 DEG C / min, the sintering temperature is 900-1000 DEG C, and the holding time is 5-10min. The method synthesizes the La-doped SrTiO3-based bulk thermoelectric material with high chemical homogeneity, uniform and fine grains and single-phase perovskite structure under the conditions of lower reaction temperature and shorter reaction time. The preparation method has the advantages of simple and convenient process, short synthesis and forming time, and the like.

Owner:UNIV OF SCI & TECH BEIJING

Mixing fireworks and producing method thereof

A mixed 'firecracker-fireworks' having the effects of firecracker and fireworks and generating 5 colors is prepared from potassium perchlorate, Mg-Al alloy powder, strontium carbonate, phenolic resin, polyvinyl chloride, strontium nitrate, sulfur, glutinous rice flour, etc. Its advantages are simple preparing process, dual effect, multiple color and long perdurability.

Owner:黄远清 +1

Combined chemical for fireworks and its prepn process

InactiveCN1810741AReasonable ratio of material selectionImprove thermal stabilityExplosivesSlagFireworks

The present invention is one kind of combined chemical for fireworks and its preparation process, and aims at providing one kind of combined chemical for fireworks possessing high heat stability, high mechanical sensitivity and high safety for compounding, producing, storing and transporting. It is ignited only in burning its fuse. The combined chemical consists of oxidant of barium nitrate and / or potassium nitrate; and inflammable including one or several of sulfur, aluminum powder, Al-Mg alloy powder, charcoal powder, titanium powder, coal powder, alumina slag, iron slag, carbon slag, resin and starch dextrin in the ratio of 100 to 10-120. It may also contain coloring agent of barium nitrate, strontium nitrate, copper carbonate and / or sodium oxalate; and effect chemical comprising sounder and color bead.

Owner:邵兴宾

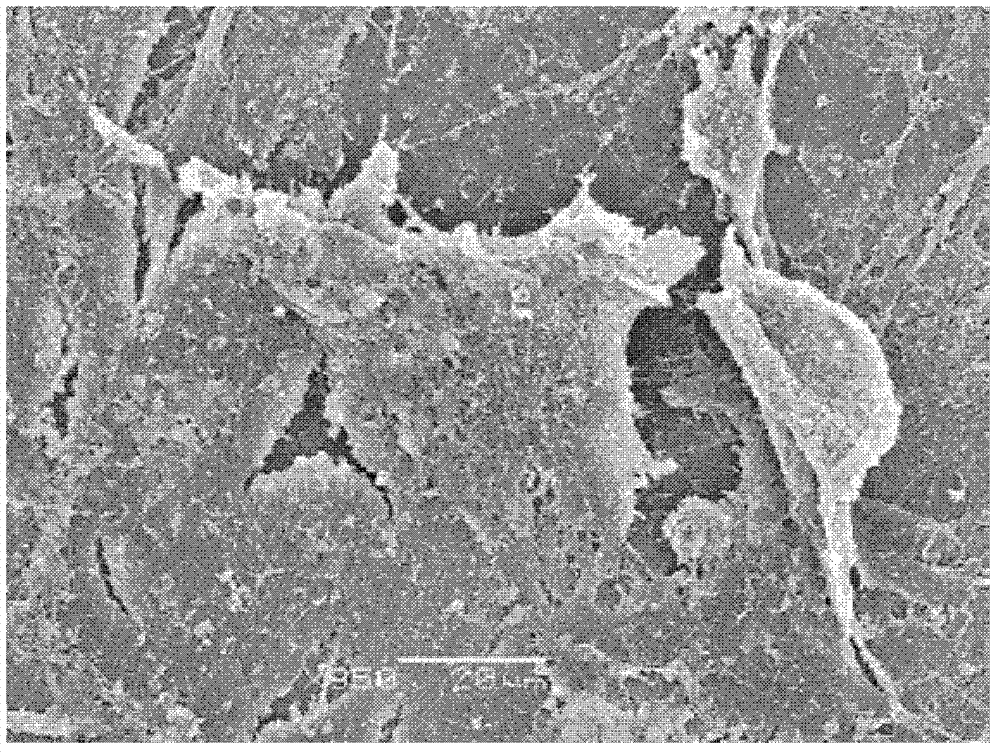

Method for preparing strontium-containing hydroxyapatite coating on surface of biodegradable magnesium alloy

InactiveCN104888271AGood biocompatibilitySimple processMetallic material coating processesProsthesisCalcium nitrate tetrahydrateCalcium phosphate coating

The invention relates to a method for preparing a strontium-containing hydroxyapatite coating on the surface of a biodegradable magnesium alloy. The method comprises the following steps: polishing a magnesium alloy matrix to remove a surface oxidation layer, and cleaning; preparing a hydrothermal solution from calcium nitrate tetrahydrate, EDTA-2 Na, sodium dihydrogen phosphate dihydrate and strontium nitrate; and placing the well treated magnesium alloy matrix into the hydrothermal solution for hydrothermal reaction to obtain the strontium-containing hydroxyapatite coating, a biomimetic calcium phosphate coating, wrapping the magnesium alloy matrix. Compared with the prior art, as the hydrothermal method is adopted to prepare hydroxyapatite, not only is the degradation rate of the magnesium alloy in a human body effectively slowed down, but also the biocompatibility of the magnesium alloy is further improved. As strontium element is added into the hydroxyapatite coating, and as one of trace elements of the human body, strontium has the functions of promoting bone formation and inhibiting bone breakage, both the biological activity and the biocompatibility are improved.

Owner:TONGJI UNIV

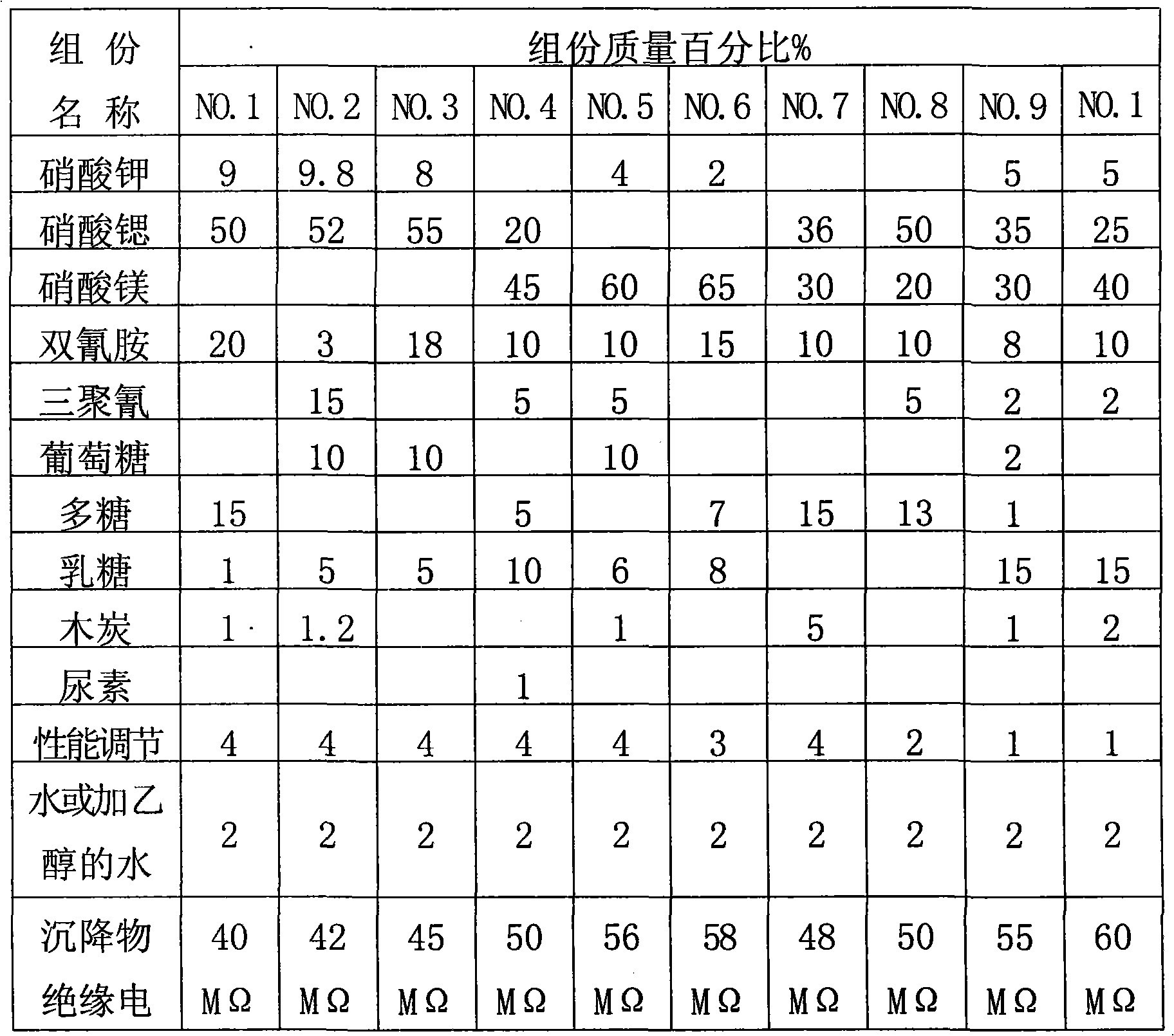

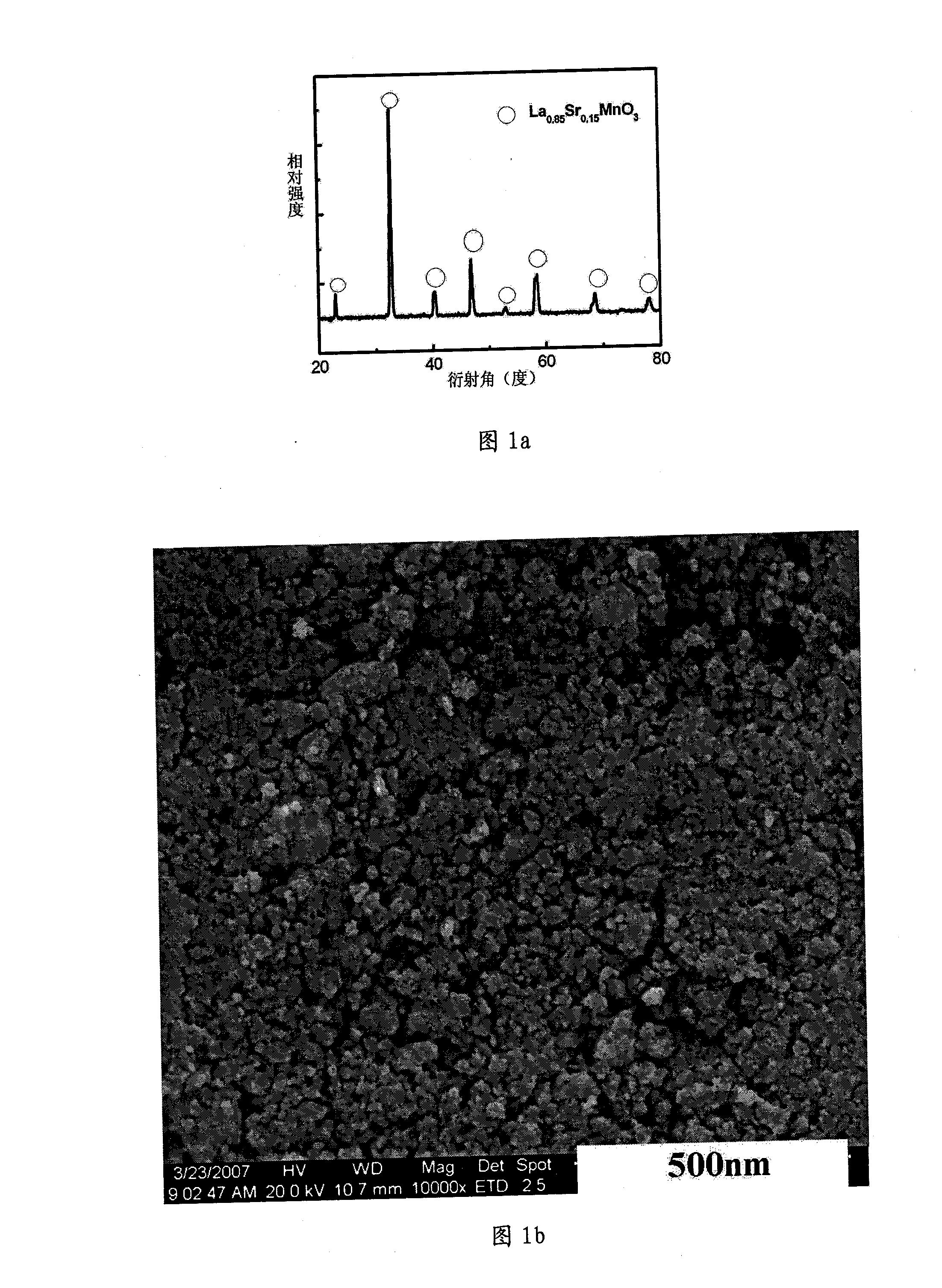

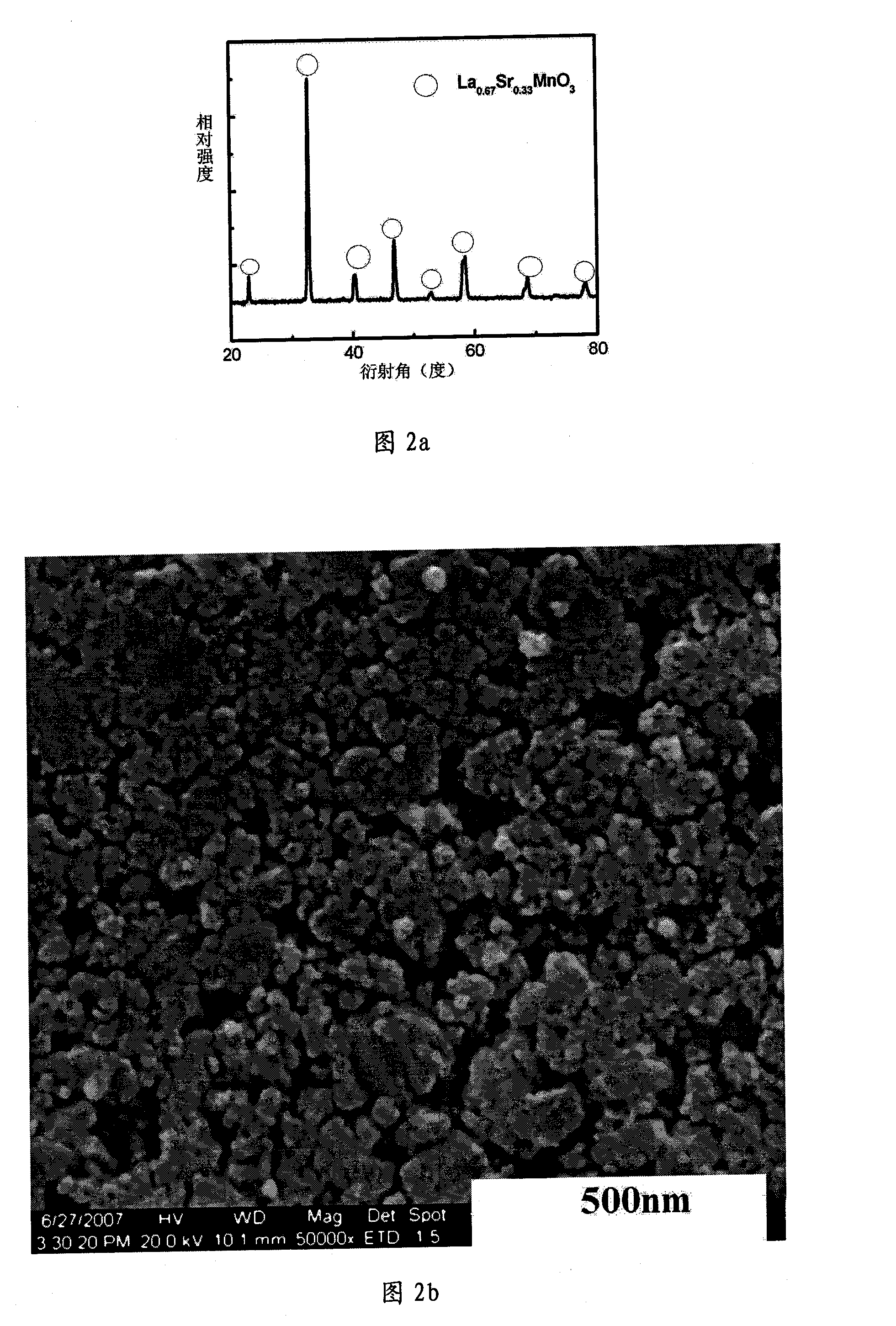

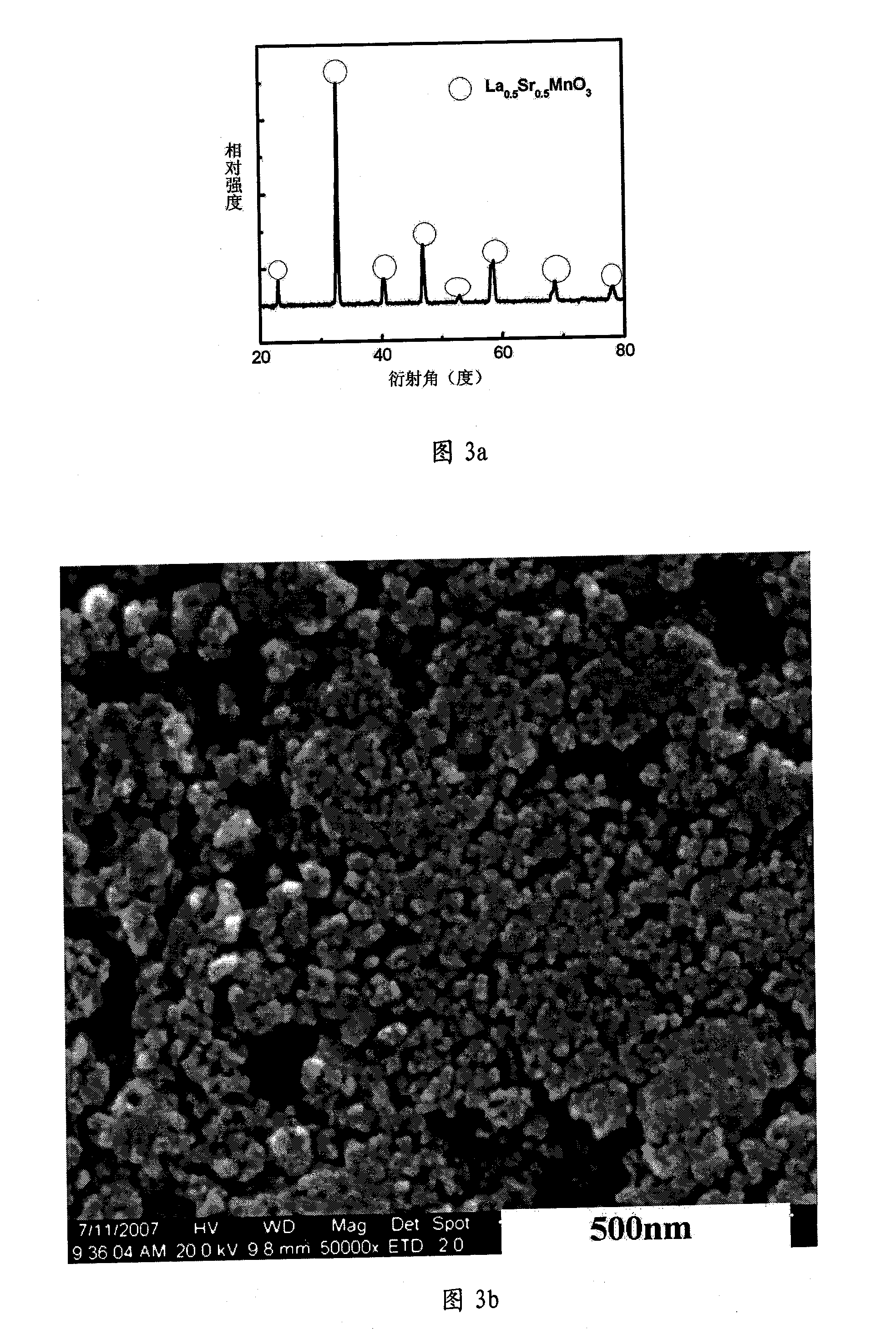

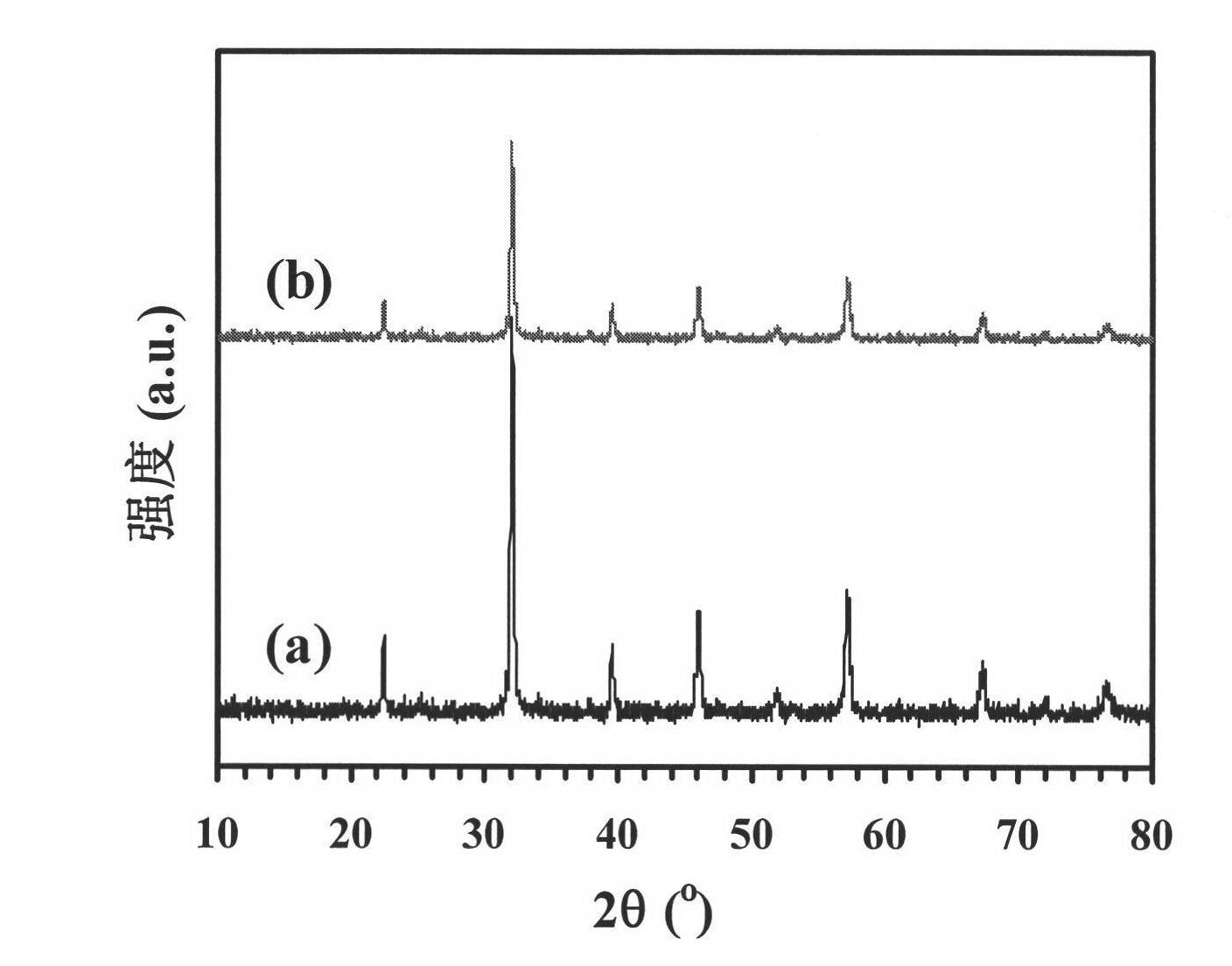

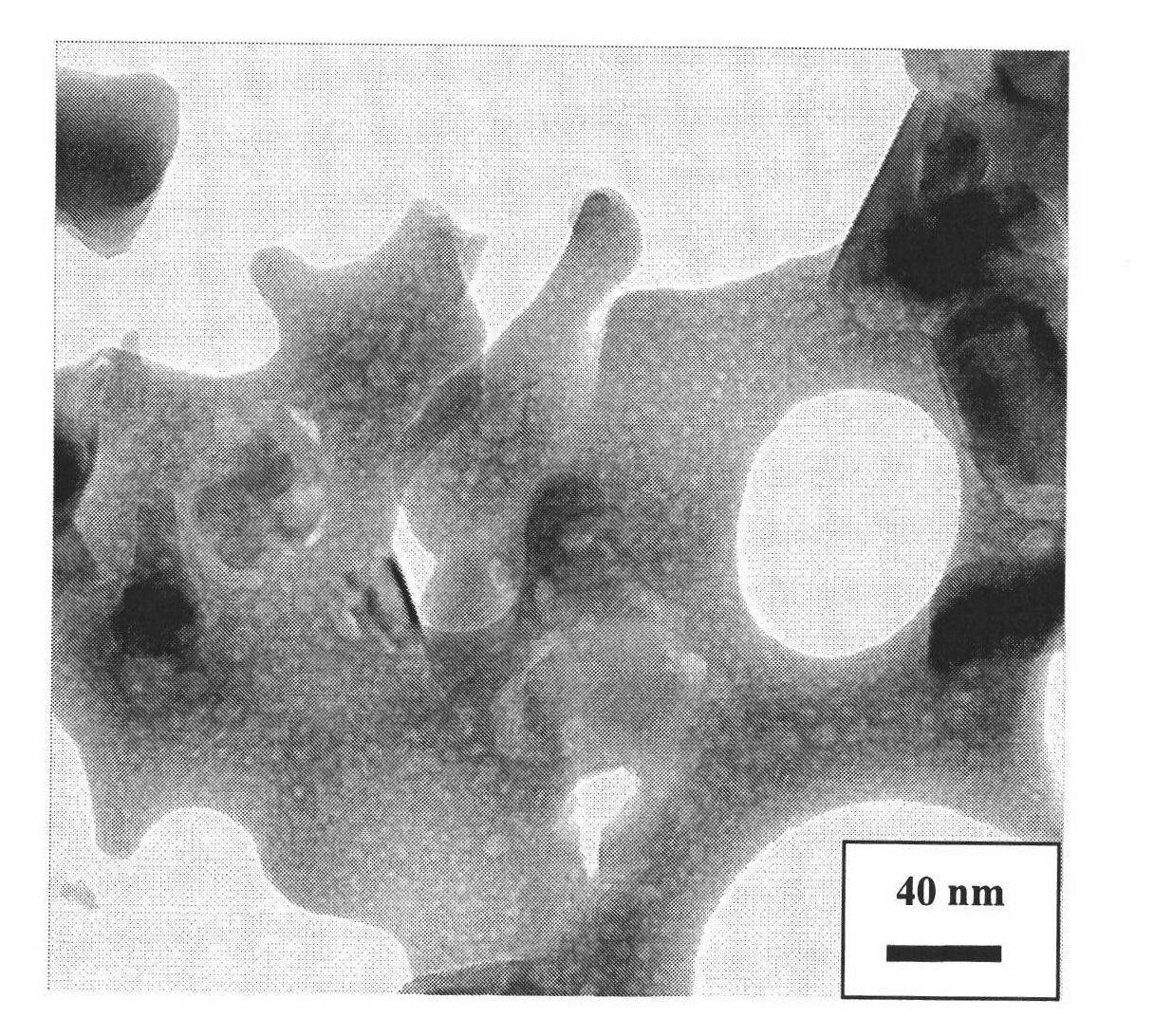

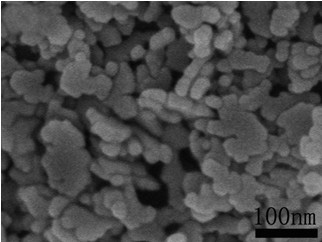

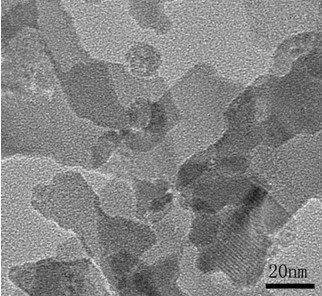

Method for preparing nano lanthanum-strontium-manganese oxide

The invention provides a method for preparing nanometer lanthanum strontium manganese oxide (La1-xSrxMnO3) powder, which dissolves lanthana, strontium nitrate and manganous nitrate which are taken as raw materials into a nitric acid solution, then adopts ammonia water as a precipitant to carry out precipitation reaction at room temperature: the precipitate is heat-treated at the temperature of 600-700 DEG C to obtain nanometer perovskite structure lanthanum strontium manganese oxide (La1-xSrxMnO3) polycrystalline powder. The lanthanum strontium manganese oxide oxide powder with different grain sizes (20-35nm) can be obtained by changing the temperature and time of the heat treatment. The method has the advantages that the reaction is moderate, the grain diameter of the oxide powder is uniform, the structure is compact and the performance is stable; the preparation technique is simple, the production cost is low and the invention is suitable for industrial production and so on.

Owner:SOUTHWEST JIAOTONG UNIV

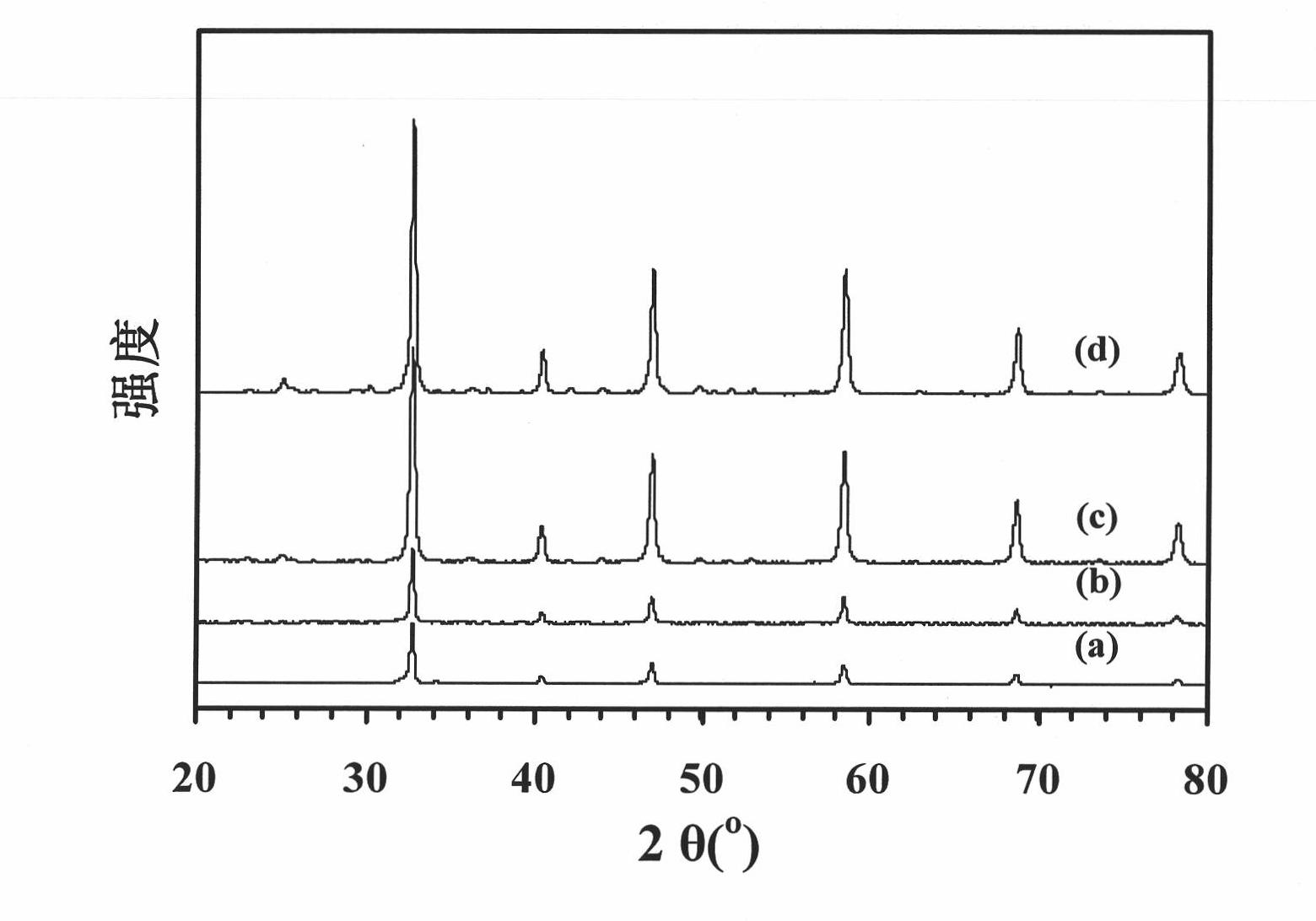

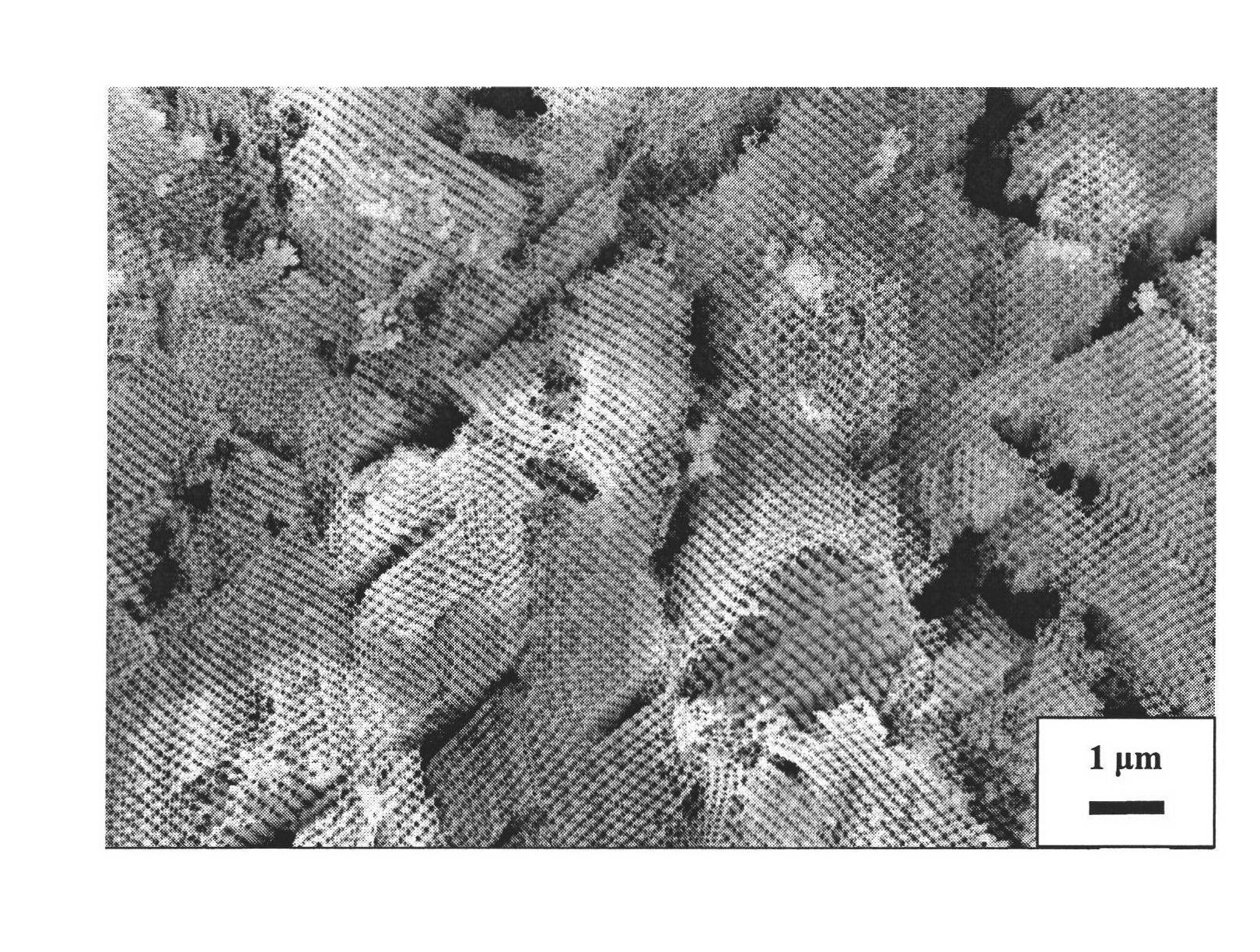

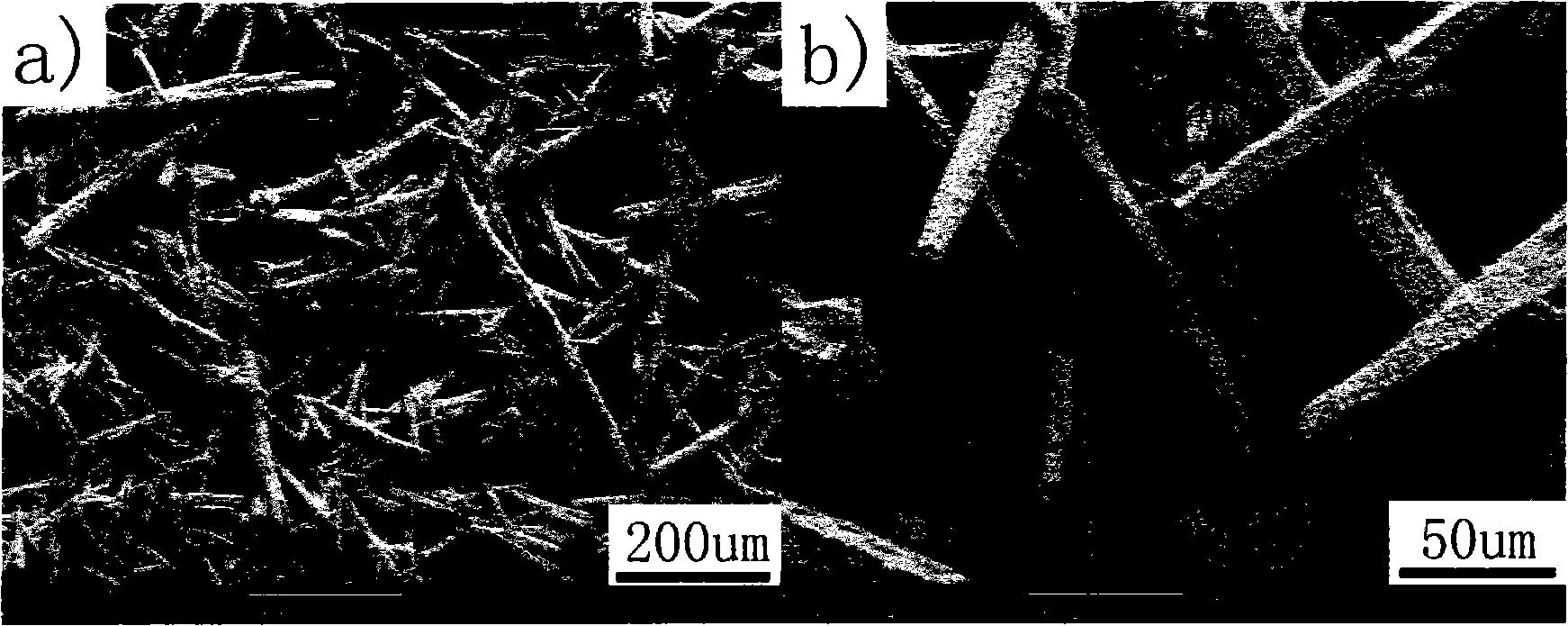

New method for preparing polycrystalline SrFeO3 with three-dimensional ordered macroporous structure

InactiveCN102010011AThe macroporous structure hasHigh crystallinityIron compoundsAir atmosphereFiltration

The invention discloses a new method for preparing polycrystalline SrFeO3 with a three-dimensional ordered macroporous structure. The new method comprises the following steps of: dissolving strontium nitrate and iron nitrate in water according to the molar ratio of 1 to 1, adding citric acid to form complexing solution, and controlling metal ion concentration to be about 1.5mol / L, wherein an additive or a carbon source such as lysine, sugar or the like can be introduced into the solution; pouring a polymethyl methacrylate (PMMA) microsphere template into the solution, impregnating, performingsuction filtration and drying; placing the mixture into a tubular furnace; and heating to the temperature of 600 DEG C in a nitrogen atmosphere at the rate of 1 DEG C per minute, keeping the constanttemperature for 2 hours, switching to an air atmosphere after cooling to below 70 DEG C, heating to the temperature of 300 DEG C at the rate of 1 DEG C per minute, keeping the constant temperature for 1 hour, continuously heating to the temperature of 750 DEG C and keeping the constant temperature for 3 hours to obtain the perovskite type polycrystalline oxide SrFeO3 with the three-dimensional ordered macroporous structure. The prepared polycrystalline oxide SrFeO3 material with the three-dimensional ordered macroporous structure has the advantages of high crystallinity, cheap and readily available raw materials and high thermal stability of a product.

Owner:BEIJING UNIV OF TECH

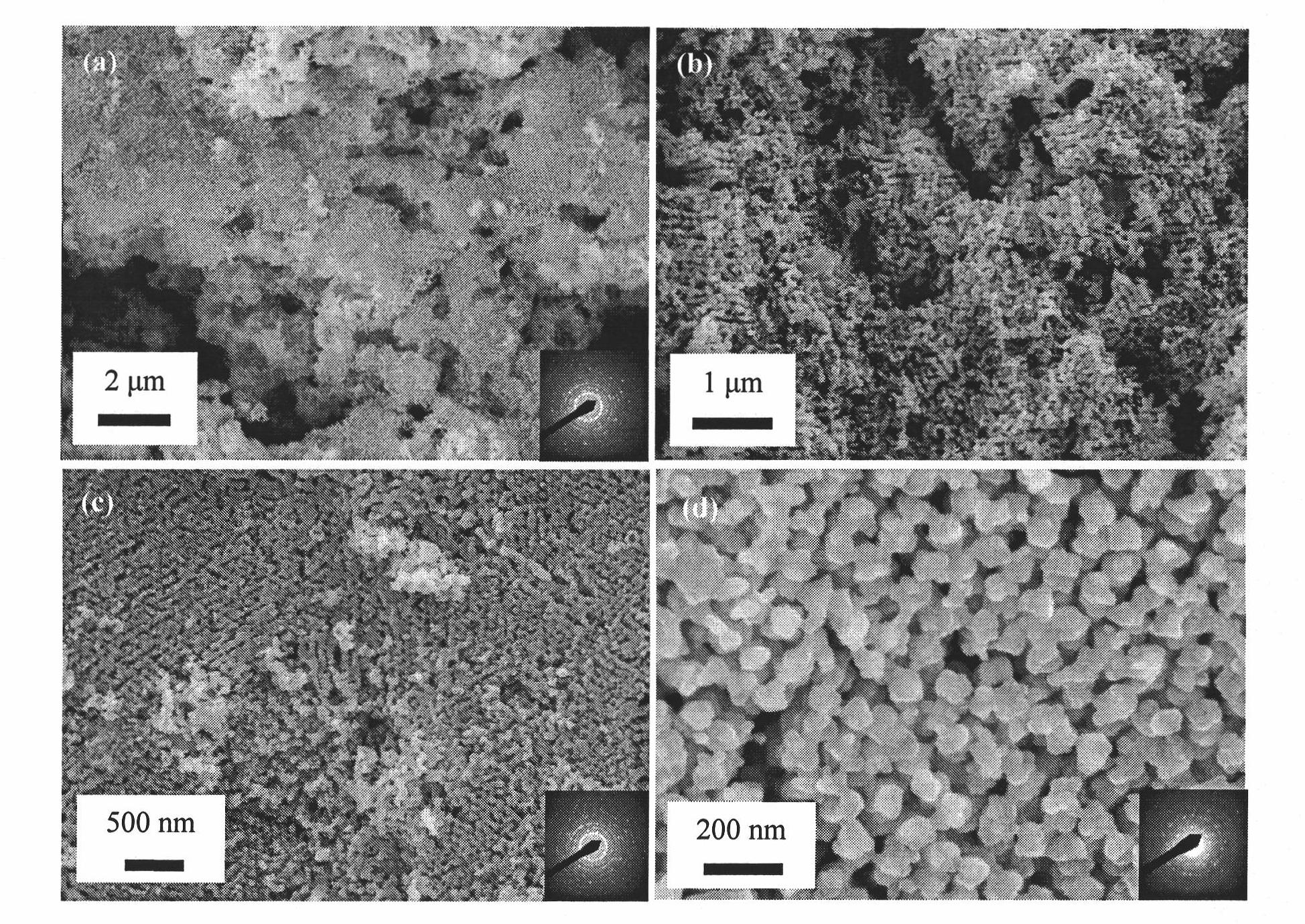

Preparation method of three-dimensional ordered macroporous La1-xSrxCrO3 with mesoporous pore wall

The invention discloses a preparation method of three-dimensional ordered macroporous La1-xSrxCrO3 (x=0, 0.4) with a mesoporous pore wall. The preparation method comprises the following steps of: dissolving lanthanum nitrate and chromium nitrate in mixed liquid of polyethylene glycol 400 and absolute methanol in the molar ratio of 1:1 or dissolving lanthanum nitrate, strontium nitrate and chromium nitrate in mixed liquid of polyethylene glycol 400, absolute methanol and deionized water in the molar ratio of 0.6:0.4:1; adding citric acid in the molar ratio of 1:1 of chromium nitrate to citric acid; performing ultrasonic treatment; adding absolute methanol solution of P123 and performing ultrasonic treatment so as to form homogeneous solution; adjusting metal ion concentration to be 2.0 mol / L; and pouring a polymethyl methacrylate (PMMA) microsphere template into the solution, soaking, performing suction filtration, drying and baking the obtained substance in two steps. The La1-xSrxCrO3prepared by the preparation method has high degree of crystallization, controllable particle shape and pore size, readily available raw materials, high product stability, high electrical conductivityand good application prospect.

Owner:BEIJING UNIV OF TECH

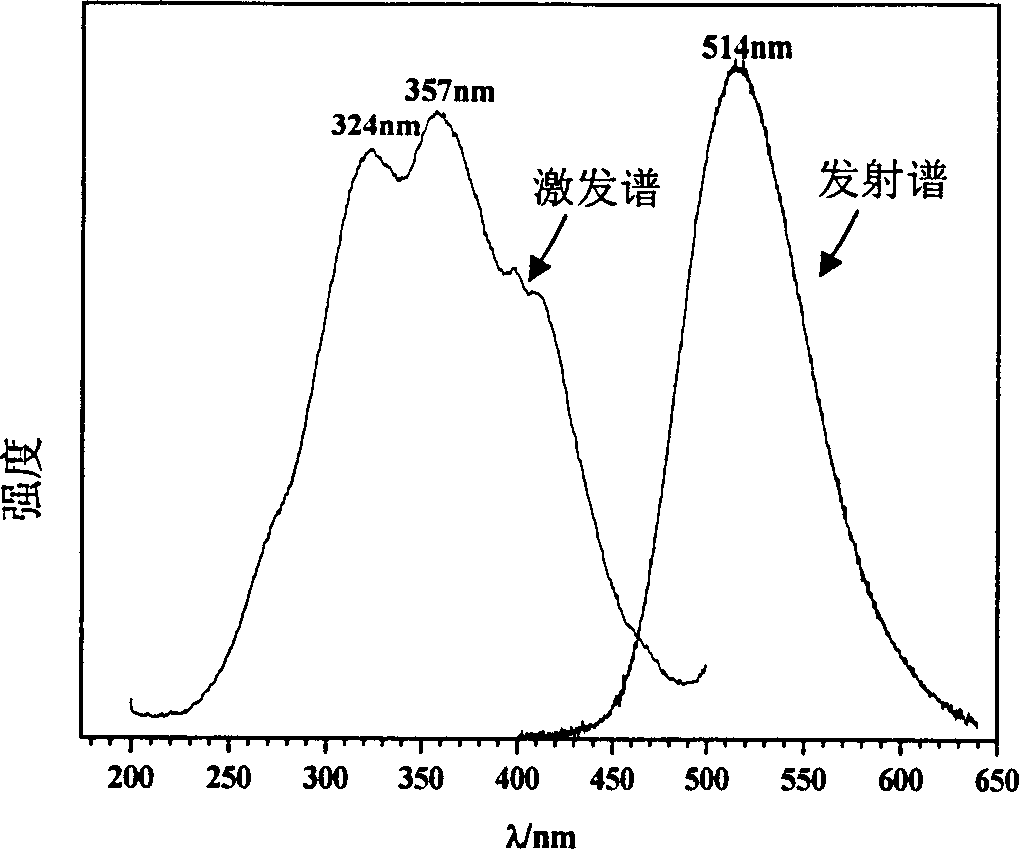

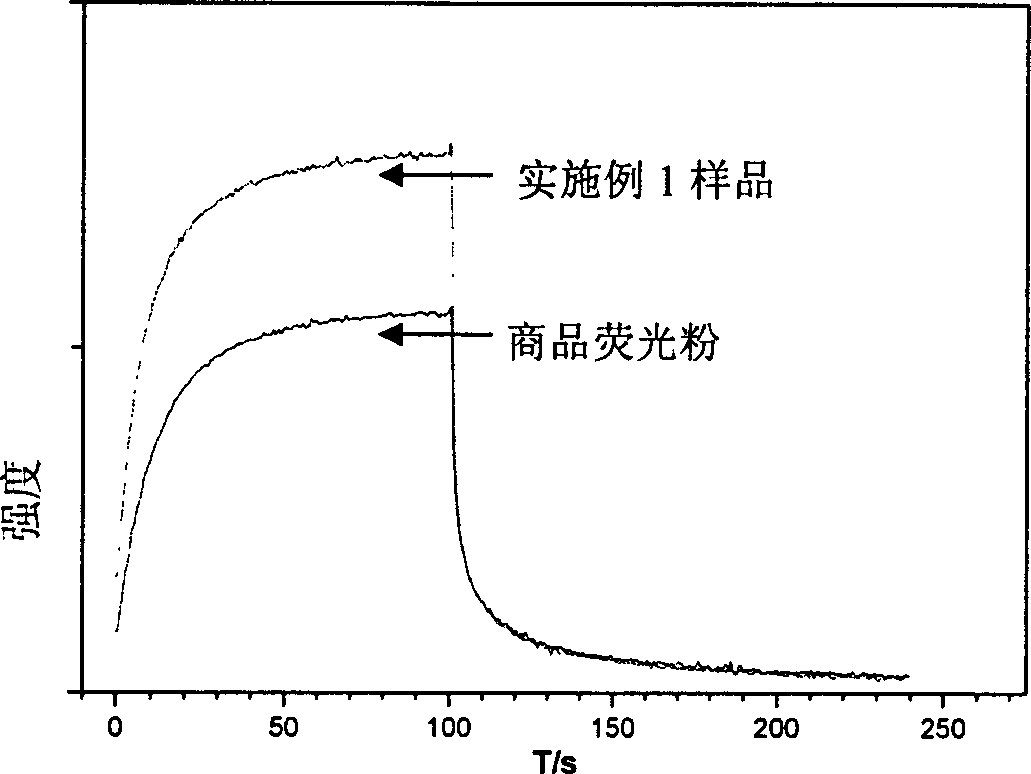

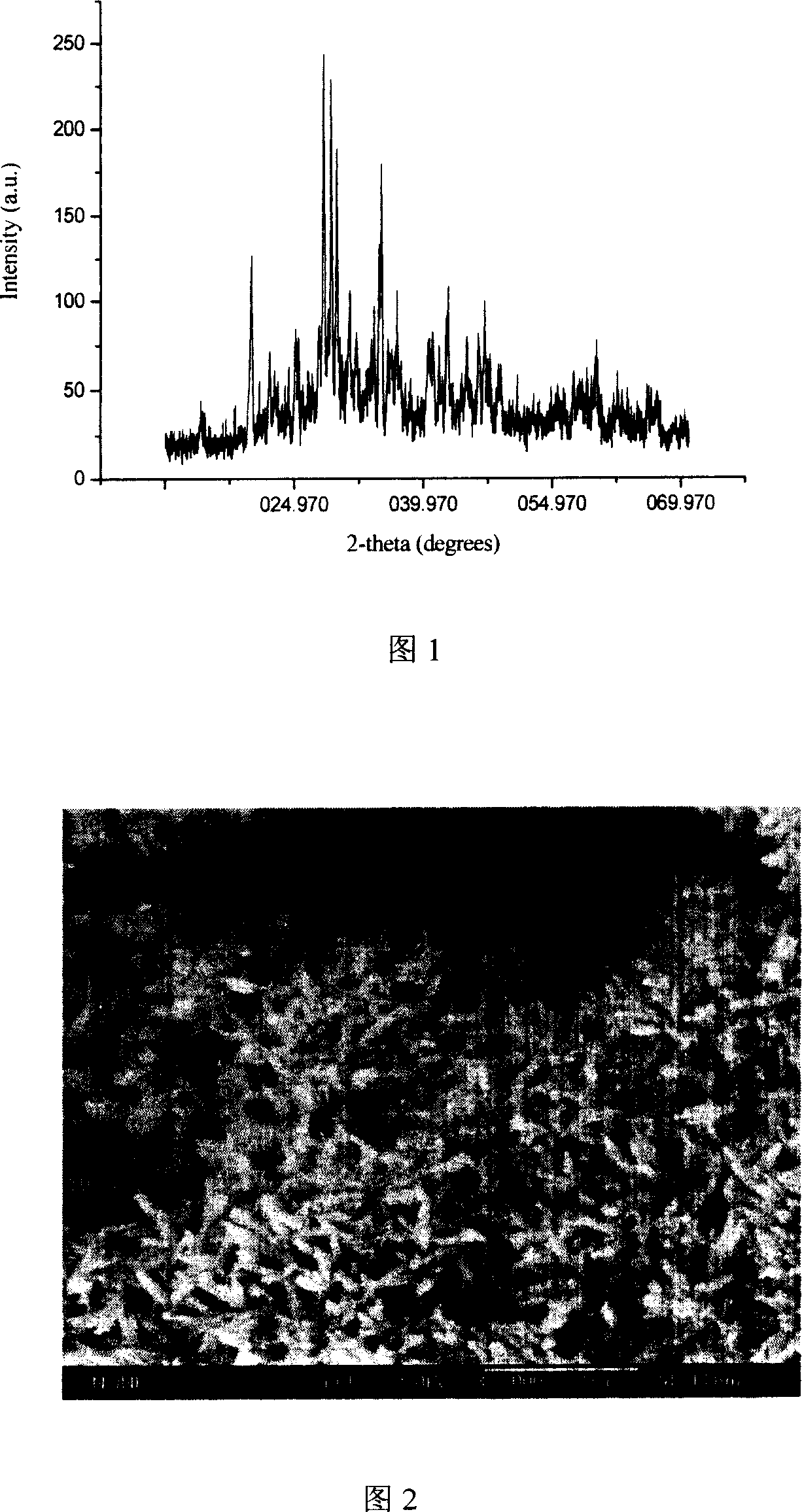

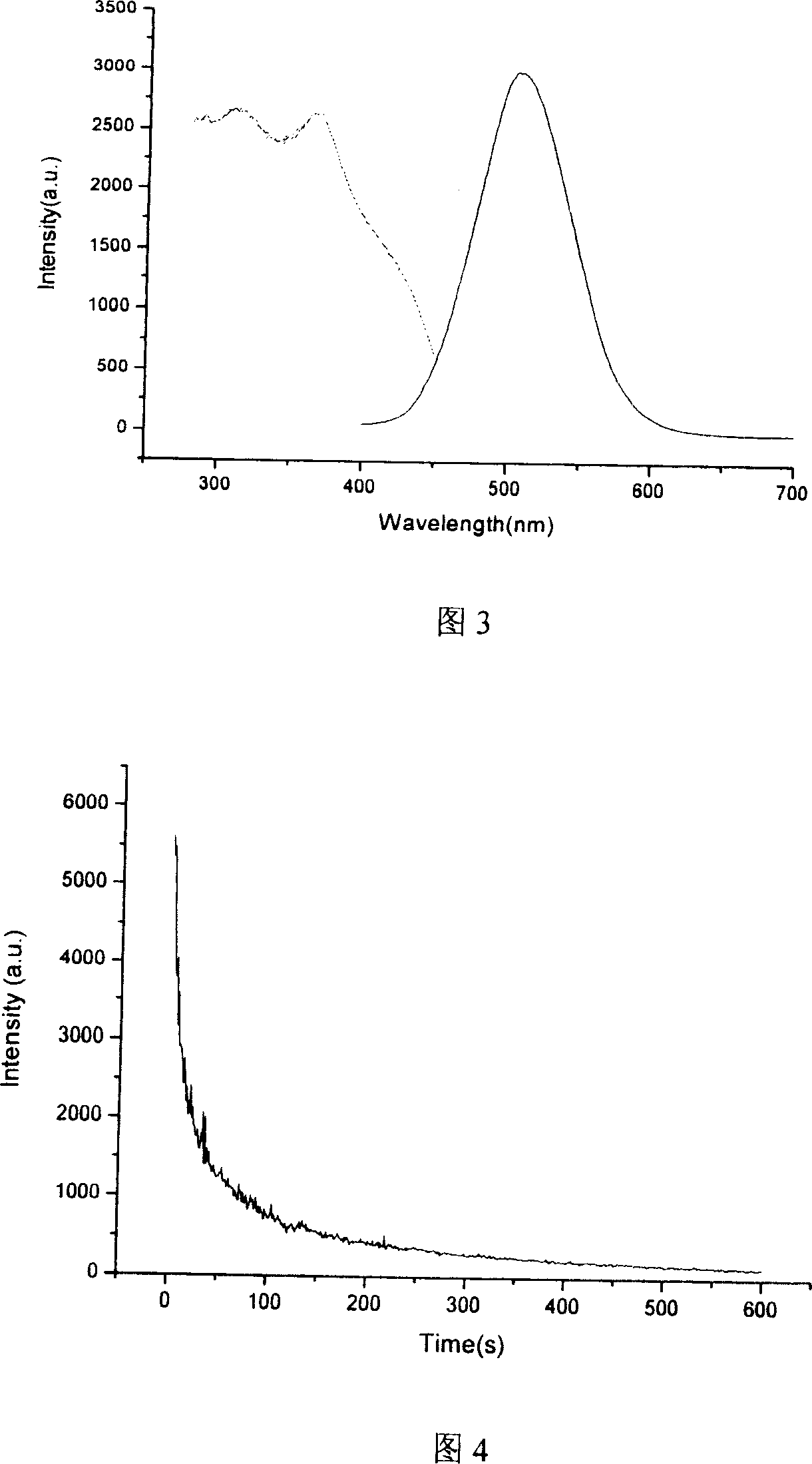

Preparation of red strontium sulphide long afterglow material

InactiveCN101328405AEasy to controlWell mixedLuminescent compositionsSolubilitySurface-active agents

The invention discloses a method for preparing a red strontium sulphide long afterglow material, comprising a hydrothermal coprecipitation method which comprises the following steps that: (a) water-solubility strontium salt, water-solubility europium salt, water-solubility dysprosium salt, carbamide and water are weight according to the mol ratio of 1: between 0.01 and 0.05: between 0.01 and 0.05: between 4 and 6: between 28 and 32 and are put inside a container to be stirred and dissolved, the mixture is insulated in a sealing state at a temperature of between 80 and 160 DEG C for 5 to 24 hours so that a precursor is obtained; (b) the precursor is subject to filtering and annealing at a temperature of between 900 and 1200 DEG C in the reaction environment for 0. 5 to 2 hours so that the red strontium sulphide long afterglow material is prepared; the water-solubility strontium salt is strontium nitrate or strontium chloride or strontium acetate, the water-solubility europium salt is europium nitrate, europium chloride or polyimide, the water-solubility dysprosium salt is dysprosium nitrate or dysprosium chloride or dysprosium acetate, and a surface active agent is added according to the mol ratio of the water-solubility strontium salt to the surface active agent of 1: between 0.0001 and 0.0003. The method is widely applied to the fields such as building decoration, traffic transportation, military facilities, fire emergency service and goods for everyday consumption.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

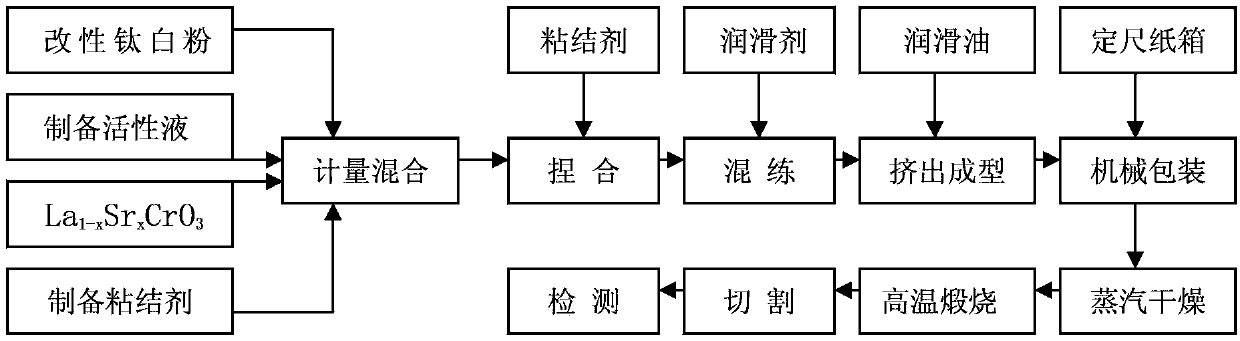

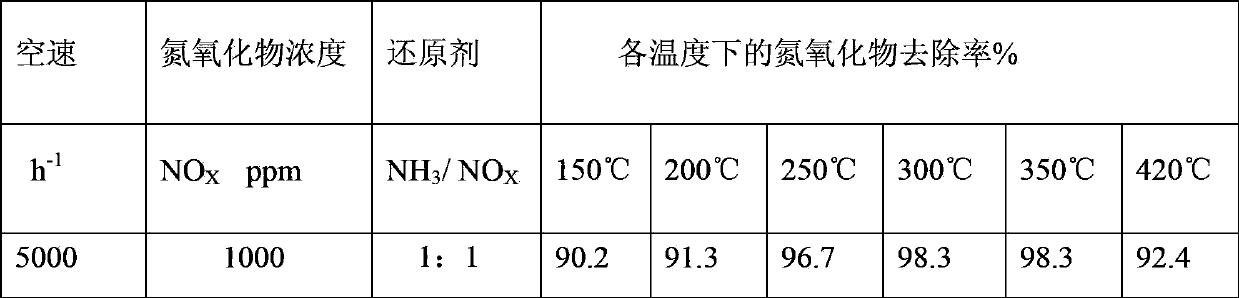

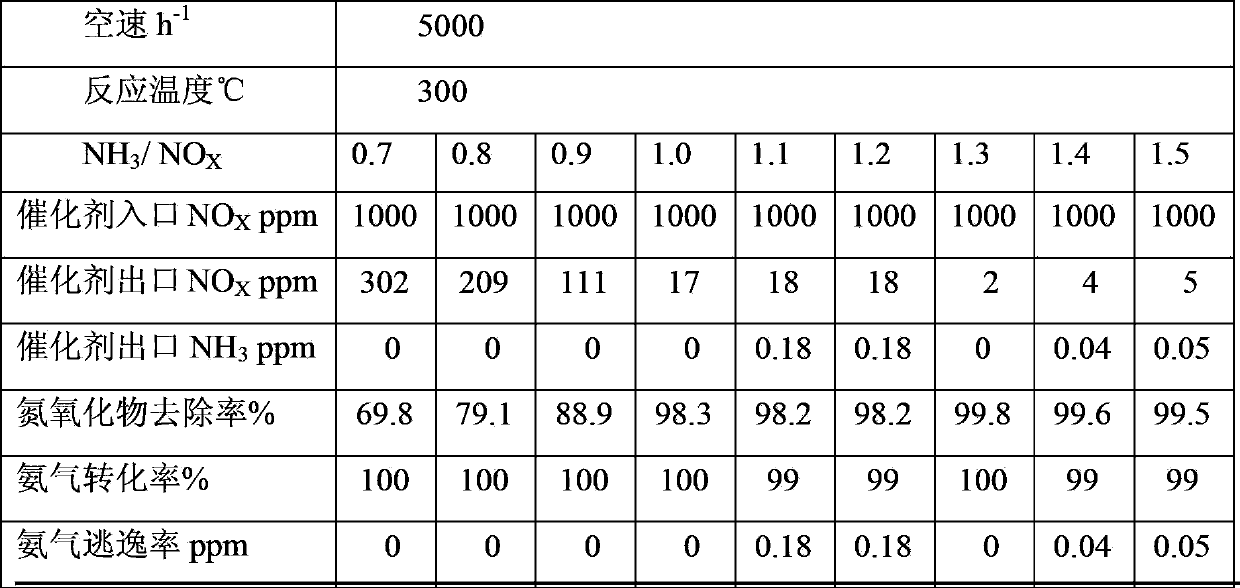

Perovskite-type substance La<1-x>Sr<x>CrO<3>, heat-engine plant denitration composite catalyst, and preparation methods of perovskite-type substance La<1-x>Sr<x>CrO<3> and heat-engine plant denitration composite catalyst

InactiveCN103861581AImprove performanceUltra-fine crystal shape lowDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPhosphateHoneycomb like

The invention discloses perovskite-type substance La<1-x>SrCrO<3>, a heat-engine plant denitration composite catalyst, and preparation methods of the perovskite-type substance La<1-x>SrCrO<3> and the heat-engine plant denitration composite catalyst, and belongs to the technical field of flue gas denitrification catalyst. The preparation method of the perovskite-type substance La<1-x>SrCrO<3> is used for solving a problem that existing preparation method of the perovskite-type substance is complex. According to the preparation method of the perovskite-type substance La<1-x>SrCrO<3>, lanthanum nitrate, strontium nitrate, and chromium nitrate are taken as raw material precursors, and are dissolved in water, and then are subjected to high-temperature roasting so as to obtain finished products. The preparation methods of the heat-engine plant denitration composite catalyst is used for solving a problem of existing denitration catalyst that ammonia is released in denitration processes. According to the preparation methods of the heat-engine plant denitration composite catalyst, a titanium dioxide mixture, an active liquid, water, glycerin, ethylene glycol, glass fiber, and aluminium dihydrogen phosphate are subjected to kneading so as to obtain ceramic clay; the ceramic clay is subjected to vacuum extrusion so as to obtain honeycomb ceramic blank; and the honeycomb ceramic blank is subjected to steam drying and roasting so as to obtain products. The heat-engine plant denitration composite catalyst is high in denitration rate, and is capable of solving a problem of ammonia escaping.

Owner:SHANGHAI LANGT ELECTRIC POWER ENVIRONMENTAL PROTECTION TECH +1

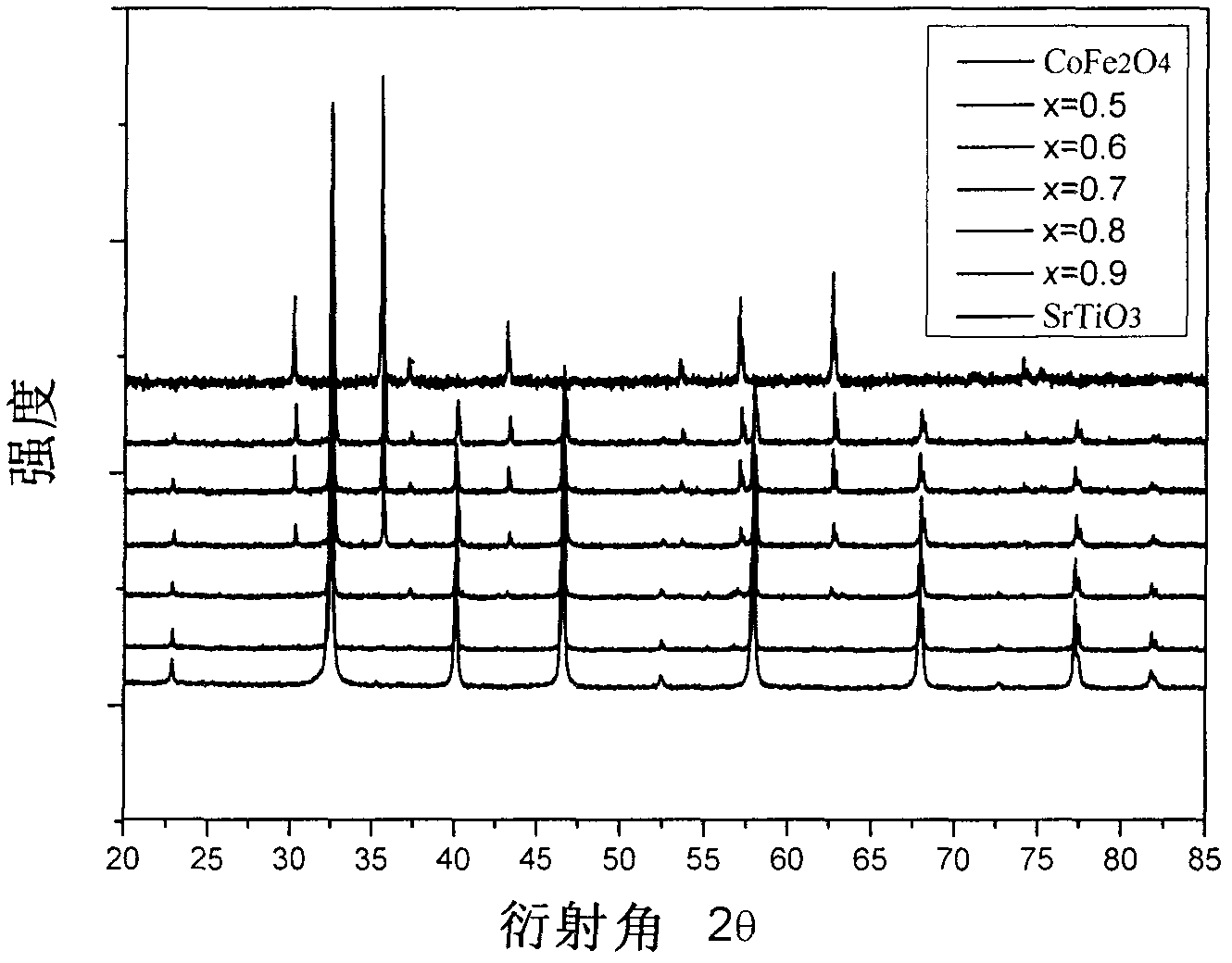

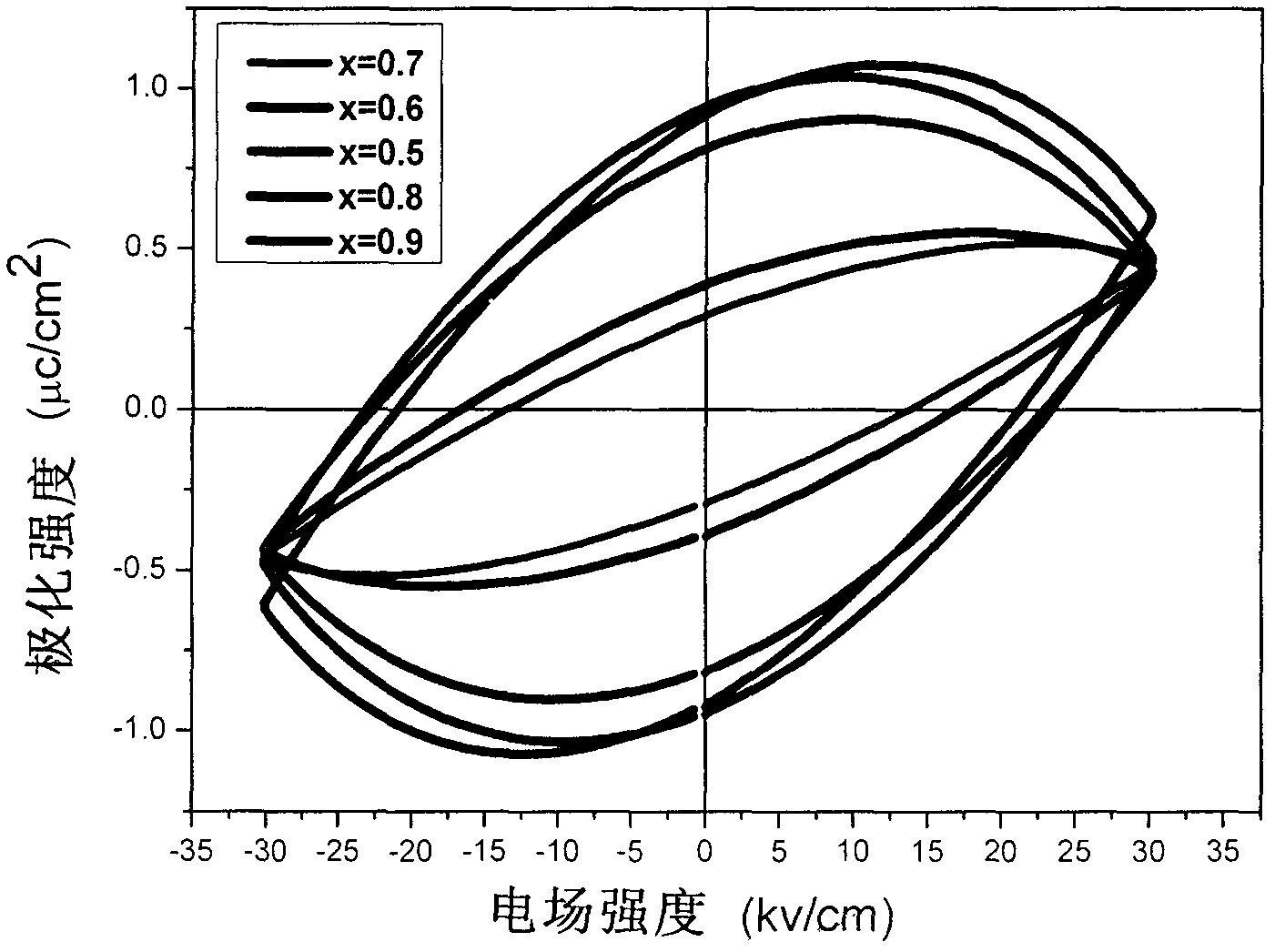

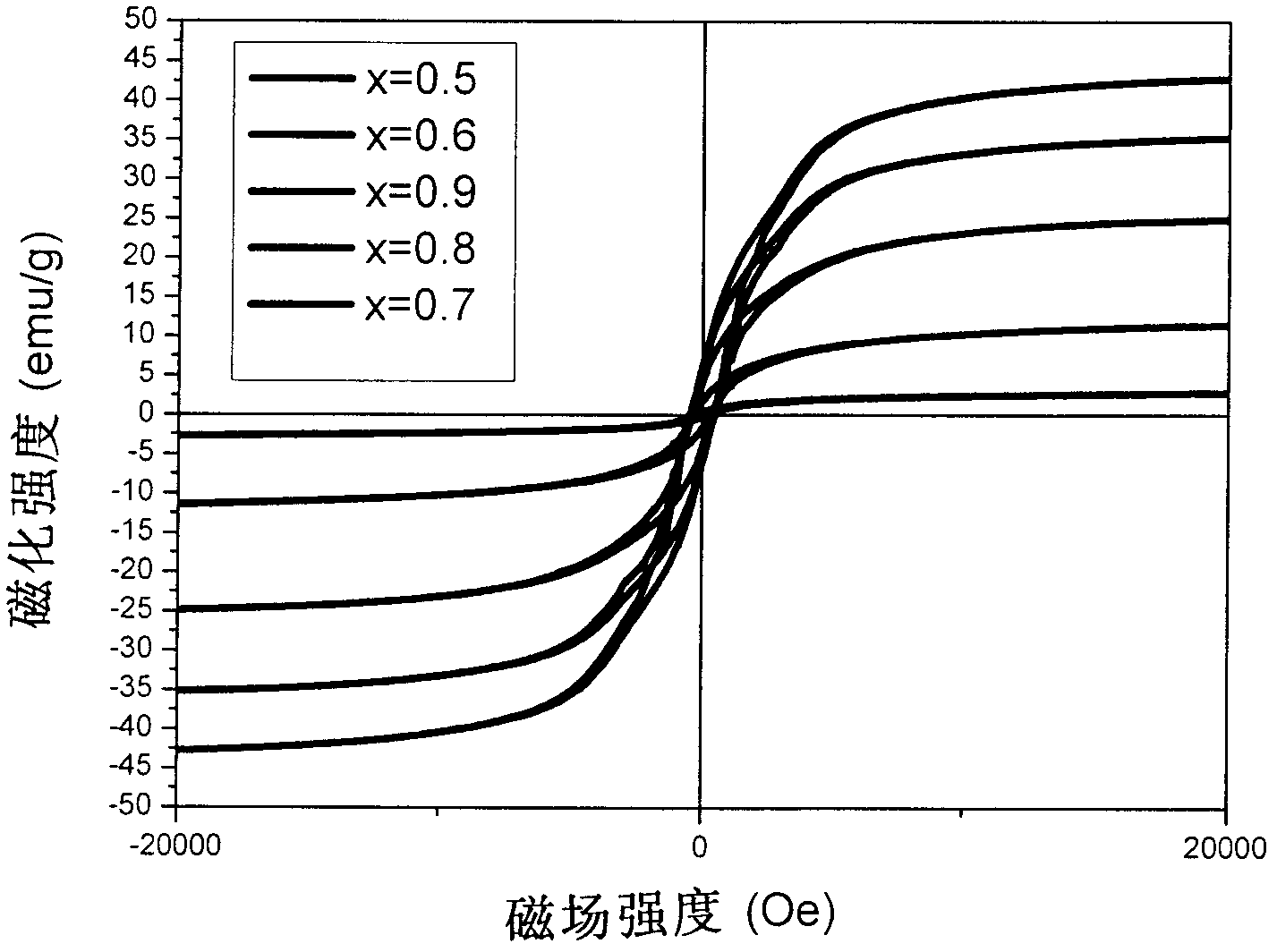

Xsrtio3-(1-x) cofe2o4 composite material and preparation method thereof

InactiveCN102643088AGood calcination temperatureHelpful for practical applicationComposite ceramicCobalt

The invention discloses an xSrTiO3-(1-x) CoFe2O4 composite material having ferromagnetism and ferroelectricity and a preparation method thereof. In the formula, x ranges from 0.5 or 0.6 or 0.7 or 0.8 or 0.9. Compared with single-phase ceramics, the composite ceramics have certain changes in ferroelectricity and ferromagnetism. The preparation method is an improved sol gel method and uses strontium nitrate, citric acid, cobalt nitrate, butyl titanate, absolute ethyl alcohol, glacial acetic acid and ferric nitrate as raw materials. The preparation method simplifies compound steps, effectively avoids outside affecting factors of particle compound, and reduces material compound temperature. The ferroelectricity of the xSrTiO3-(1-x) CoFe2O4 composite material is improved compared with single-phase SrTiO3, and a ferroelectric hysteresis loop tending to be saturated is obtained. The ferromagnetism has regularity along with increase of content of cobalt ferrite, and therefore actual application of composite materials is facilitated.

Owner:HEBEI NORMAL UNIV

Preparation method for special pigment for aqueous printing ink

The invention relates to a preparation method for special pigment for aqueous printing ink. The method comprises the following steps of: (1), preparing diazotization liquid by a diazotization process for later use; (2), preparing coupling fluid; and (3), coupling, namely a, adding the diazotization liquid into the coupling fluid at the flow speed of 25 minutes, and controlling the pH value to be 10 and the temperature to be below 15 DEG C; b, continuing stirring for one hour and adding rosin fluid; c, reacting for 60 minutes and then adding 60 kilograms of 95 percent anhydrous calcium chloride; and d, raising the temperature to 85 DEG C after one hour, adding 40 kilograms of strontium nitrate dissolved with water with the temperature of 70 DEG C, raising the temperature to 90 DEG C, regulating the pH value to be 6 to 6.5 by using aluminum sulphate fluid, adding 7 kilograms of dissolved rosin amine, stirring for 60 minutes, and filtrating, rinsing, drying and crushing. The method has the advantages of use of aqueous solvent, simple process and low cost. Furthermore, the environmentally-friendly aqueous printing ink has low mammalian toxicity, no pollution, good flocculability, and good stability in an aqueous medium.

Owner:WUJIANG TUNCUN PIGMENT PLANT

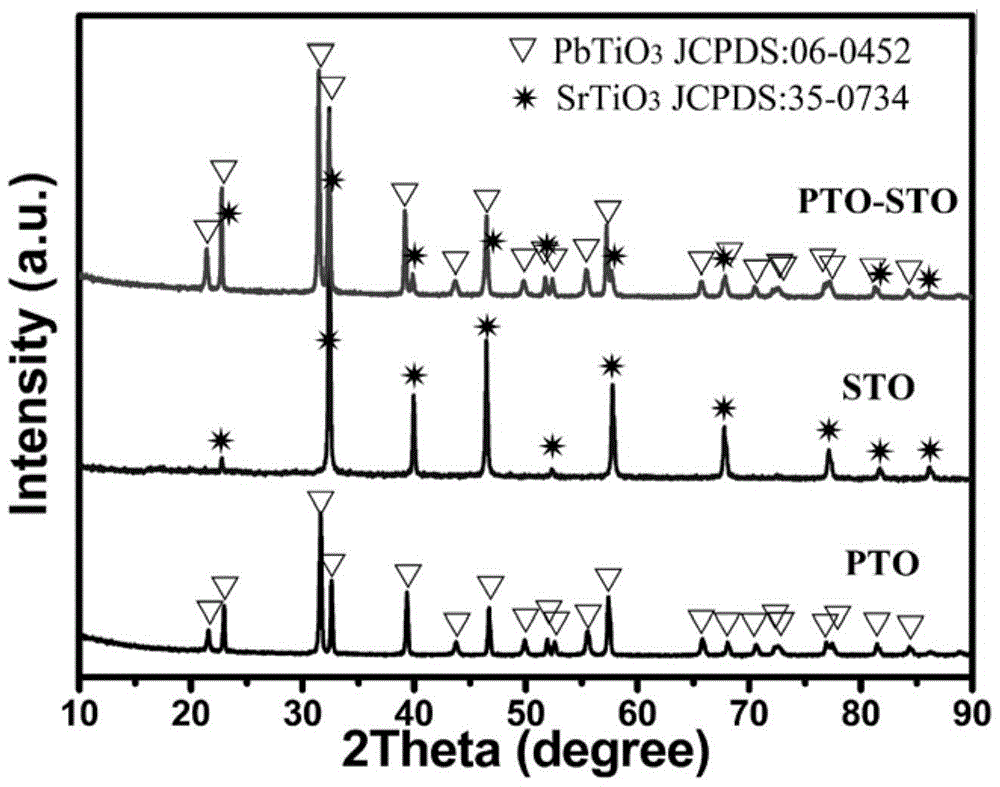

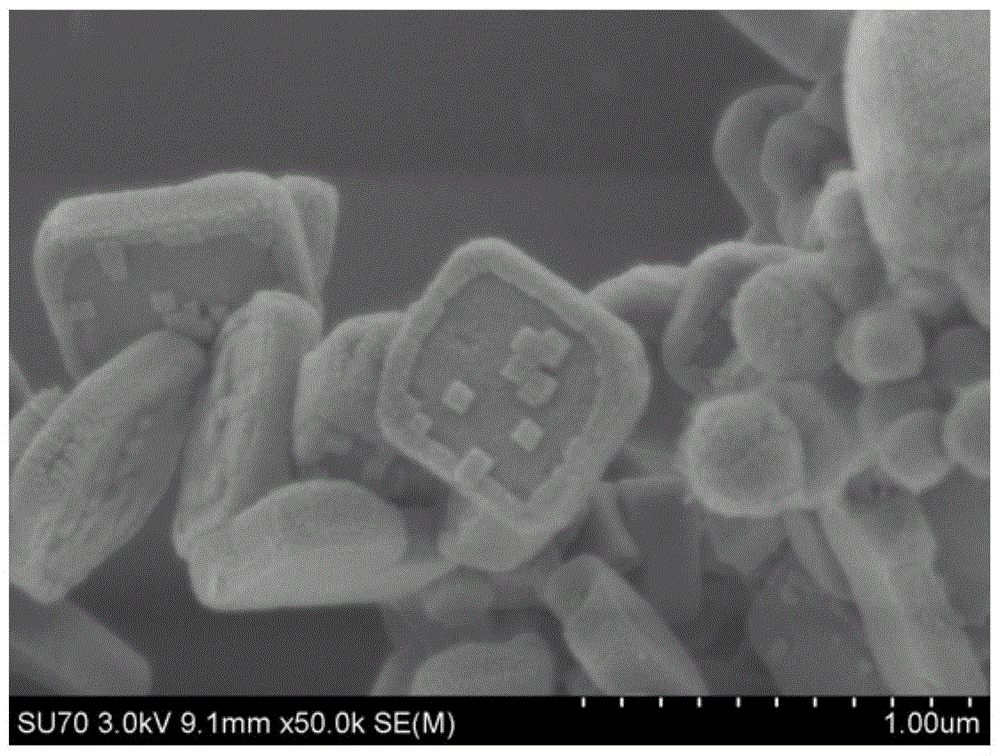

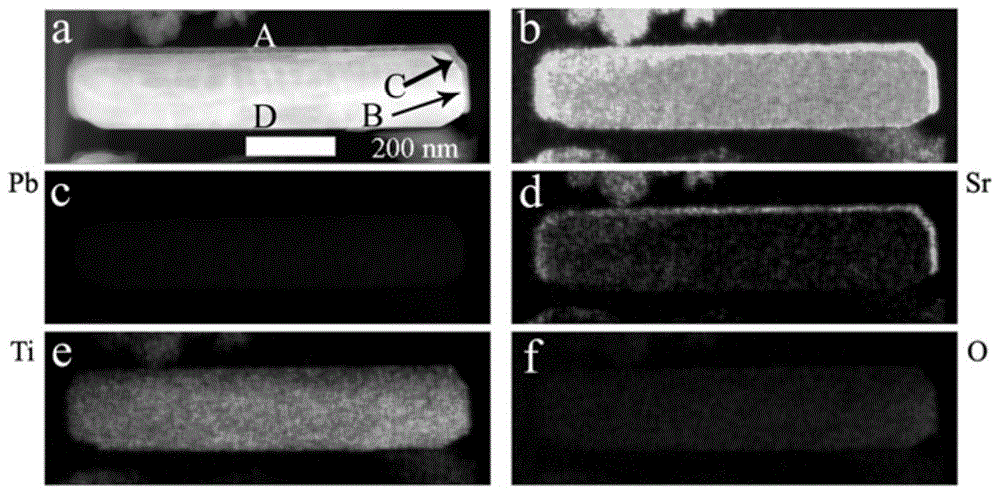

Preparation method of lead titanate-strontium titanate monocrystal nanometer material with core-shell structure

ActiveCN105040090ASimple processEasy to controlPolycrystalline material growthFrom normal temperature solutionsStrontium titanateSingle crystal

The invention relates to a preparation method of a perovskite phase lead titanate-strontium titanate monocrystal nanometer material with a core-shell structure. The preparation method comprises the steps of taking a monocrystal single-domain perovskite phase lead titanate nanosheet as a template and a raw material, taking tetrabutyl titanate as a titanium source, taking strontium nitrate as a strontium source, taking sodium hydroxide as a precipitant and a mineralizing agent, and preparing precursor mixed turbid liquid for a hydrothermal reaction under the condition of magnetic stirring; sealing the precursor mixed turbid liquid into a stainless steel reaction still having a teflon liner, and obtaining a core-shell structure perovskite phase lead titanate-strontium titanate monocrystal nanometer composite structure through subjecting to hydro-thermal treatment at the temperature of 160 to 220 DEG C for 4 to 24 hours. The preparation method provided by the invention is simple in technical process, easy to control, free of pollution, low in cost, and easy for mass production. The prepared perovskite phase lead titanate-strontium titanate monocrystal nanometer composite structure has a clear core-shell structure, and has an interface with atomic resolution.

Owner:ZHEJIANG UNIV

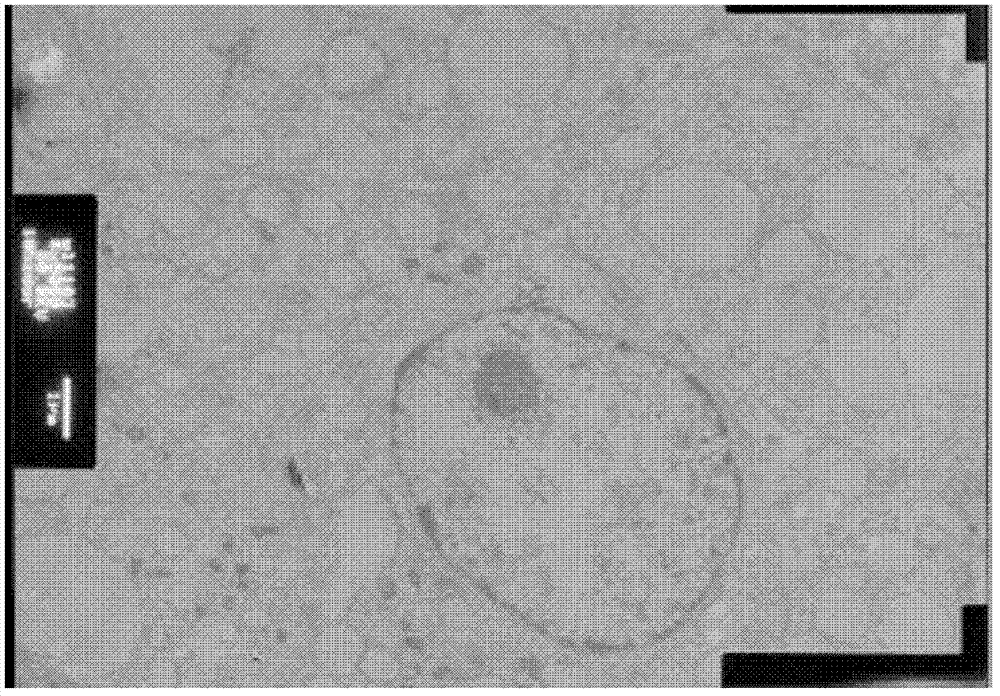

Preparation method of nanometer strontium hydroxyapatite and application thereof

InactiveCN103086337APromote degradationGuaranteed biodegradabilityNanotechnologyPhosphorus compoundsFreeze-dryingDiammonium phosphate

The invention discloses a preparation method of nanometer strontium hydroxyapatite, which comprises the following steps: preparing a strontium nitrate aqueous solution and a diammonium phosphate aqueous solution with certain concentrations, adjusting the pH value of the strontium nitrate aqueous solution, mixing the strontium nitrate and the diammonium phosphate aqueous solutions to generate a nanometer strontium hydroxyapatite precipitate, standing and aging, filtering to remove the upper supernatant, washing and filtering the nanometer strontium hydroxyapatite precipitate to be neutral, performing centrifugal dewatering and freeze drying to finally obtain the nanometer strontium hydroxyapatite. When compared with nanometer hydroxyapatite, the nanometer strontium hydroxyapatite obtained in the preparation method has better biodegradability and better osteoinductivity; meanwhile, the preparation process avoids high temperature process, so the biodegradability is further ensured; The nanometer strontium hydroxyapatite obtained in the preparation method has good prospects in the application of bone repair materials.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

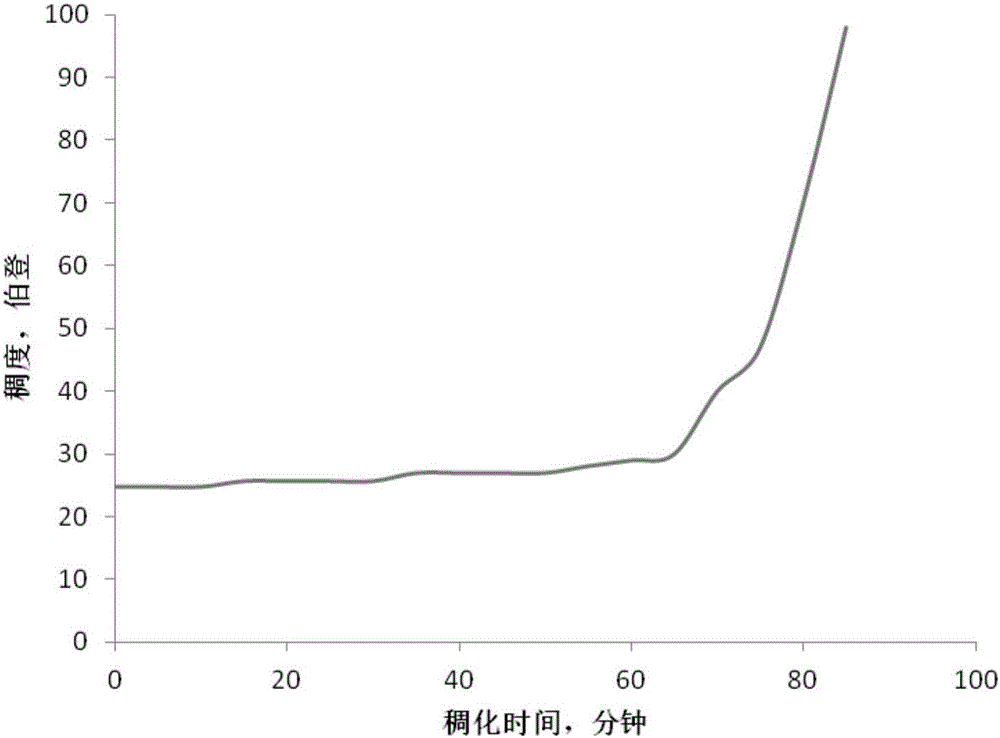

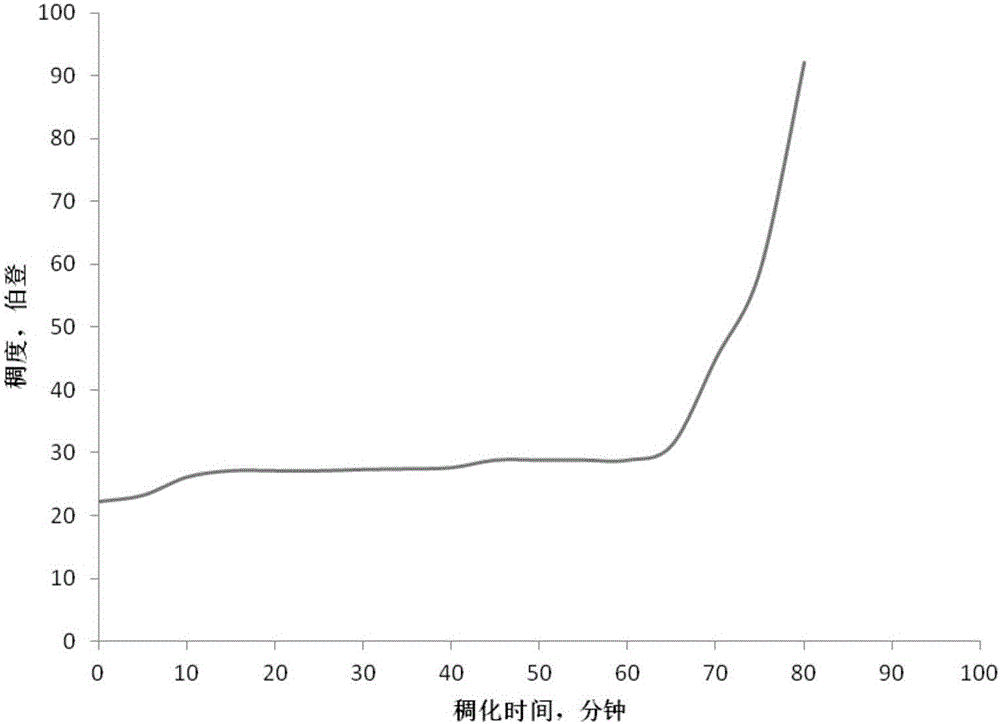

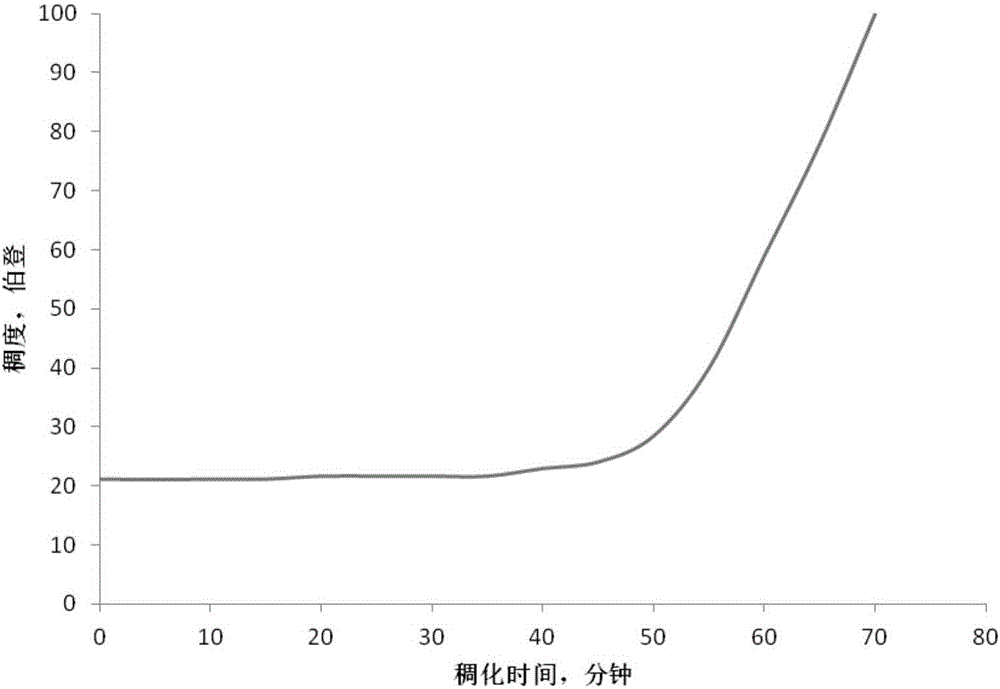

Wide spectrum chlorine-free coagulation accelerating early strength agent for oil field oil well cement

ActiveCN106186777AImprove anti-channeling abilityImprove top strengthDrilling compositionOXALIC ACID DIHYDRATEApatite

The invention relates to a wide spectrum chlorine-free coagulation accelerating early strength agent for oil field oil well cement. The early strength agent comprises the following raw materials in parts by weight: 1 to 1.5 parts of sodium salts, 1 to 1.5 parts of calcium salts, 1 to 1.5 parts of aluminum salts, and 1 to 1.5 parts of other materials, wherein other materials are one or more of hydroxyl apatite, meta-kaolin, magnesium trisilicate, magnesium oxide, strontium sulfate, strontium carbonate, strontium nitrate, lithium carbonate, and oxalic acid. The provided early strength agent is stable, and has an excellent coagulation accelerating performance and early strength property; the early strength is high, the strength development is fast, the thickening transition time and primary-final setting transition time are short; and the early strength agent is suitable for various cement slurry systems such as cement slurry system with a wide temperature range and large temperature difference, AMPS cement slurry system, and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

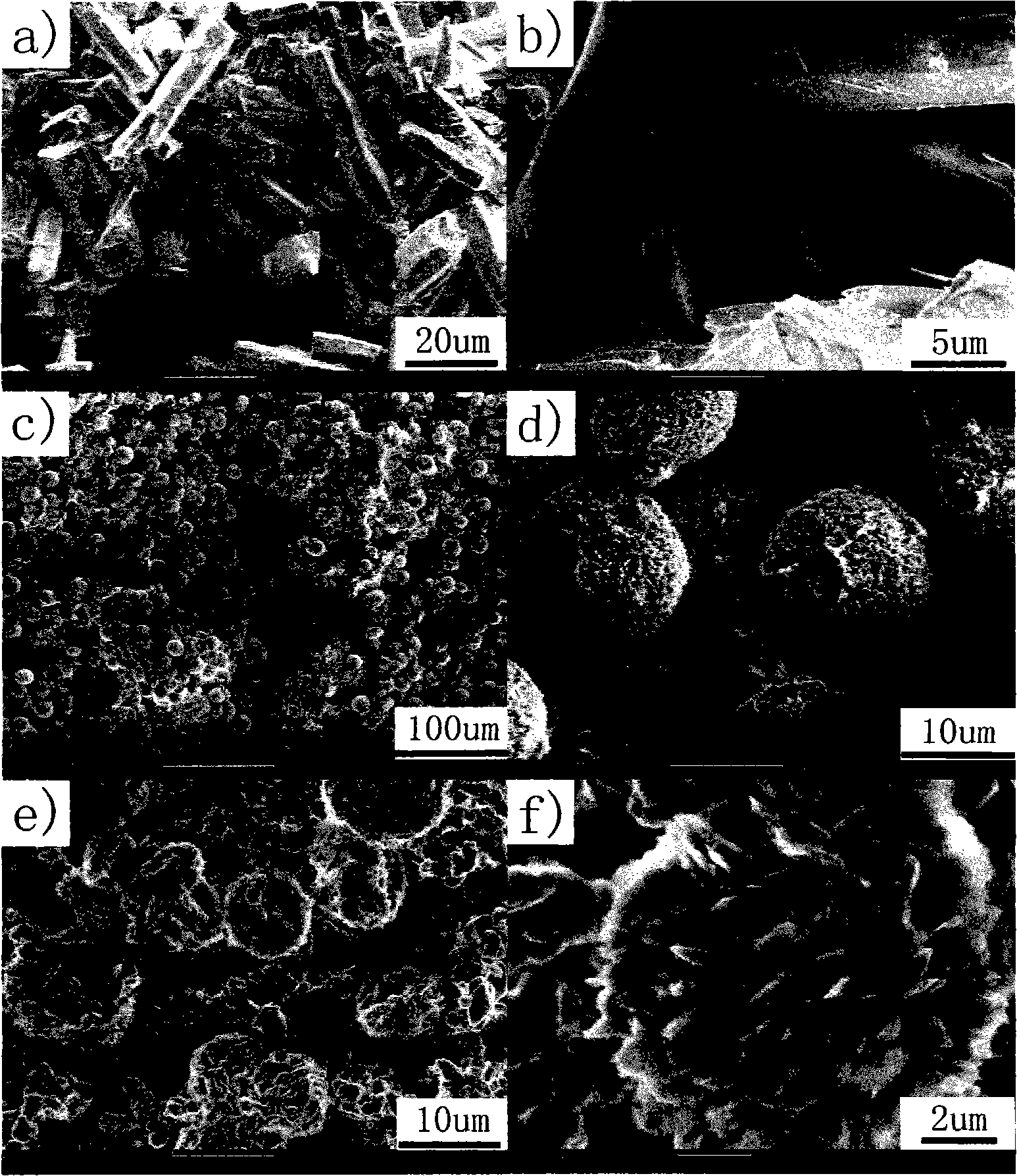

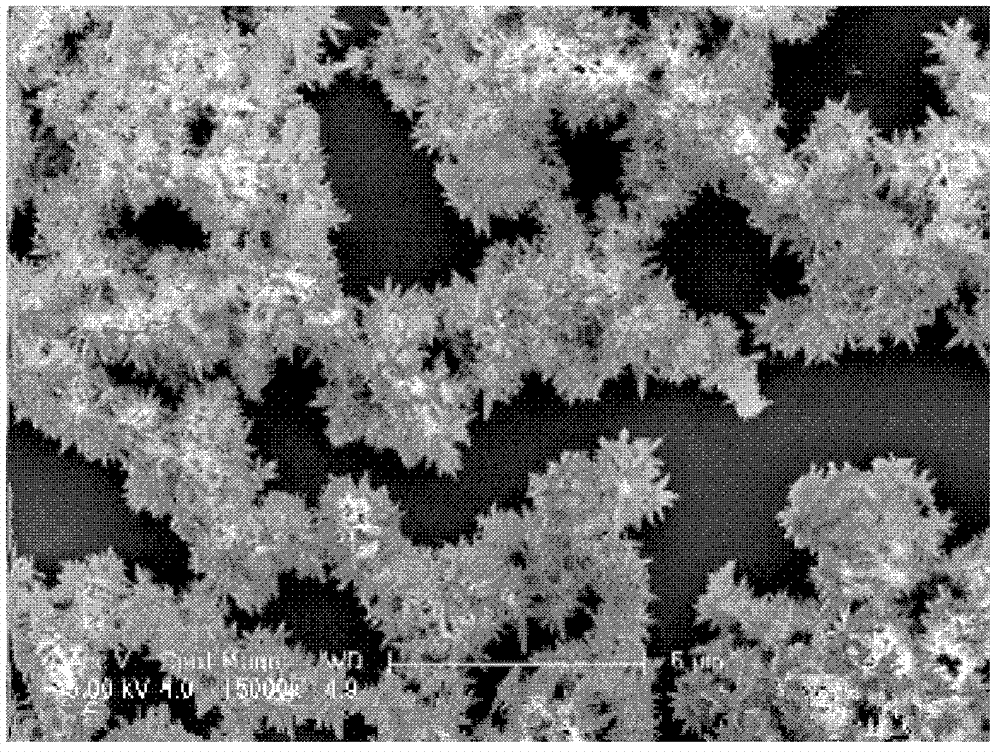

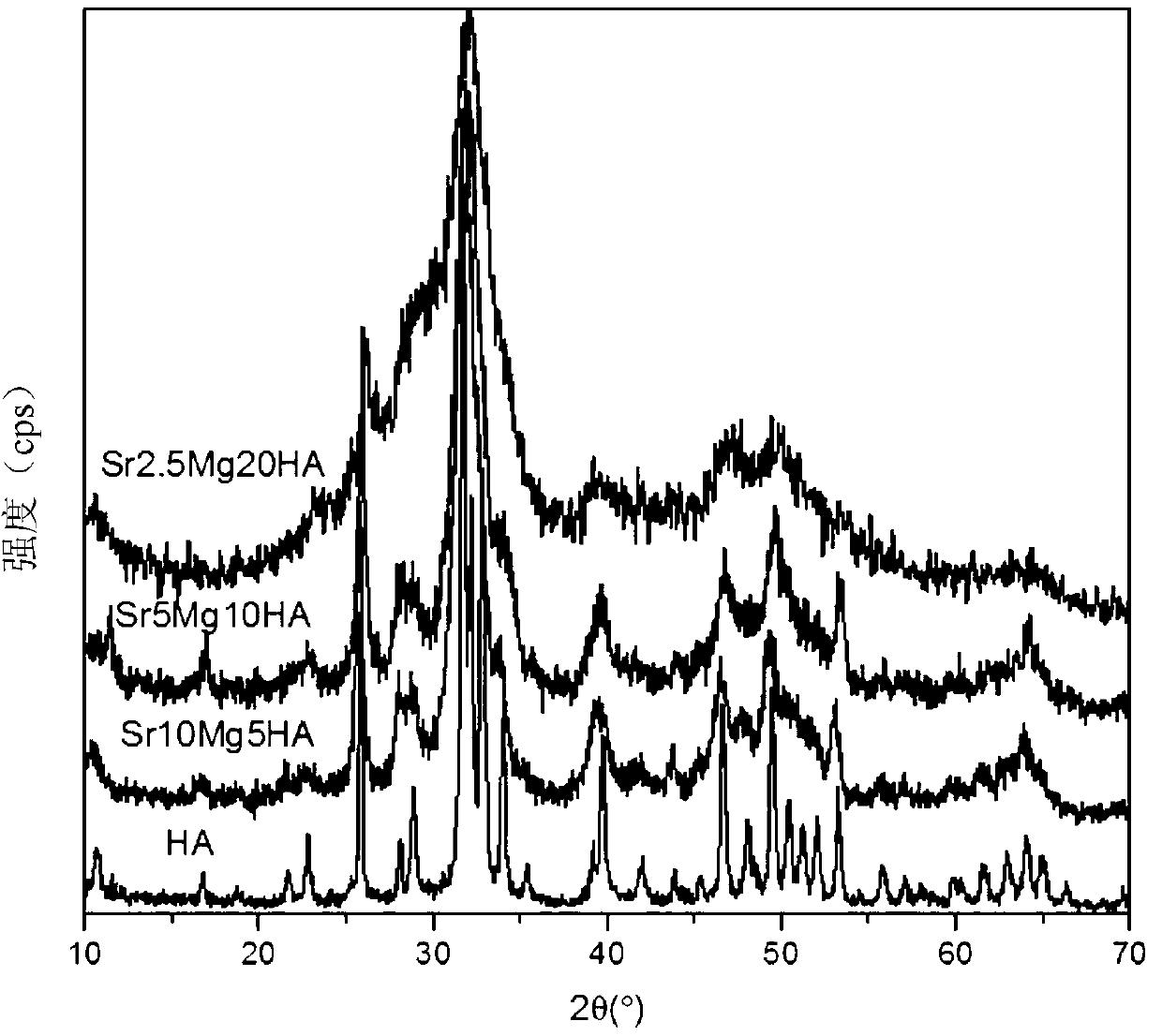

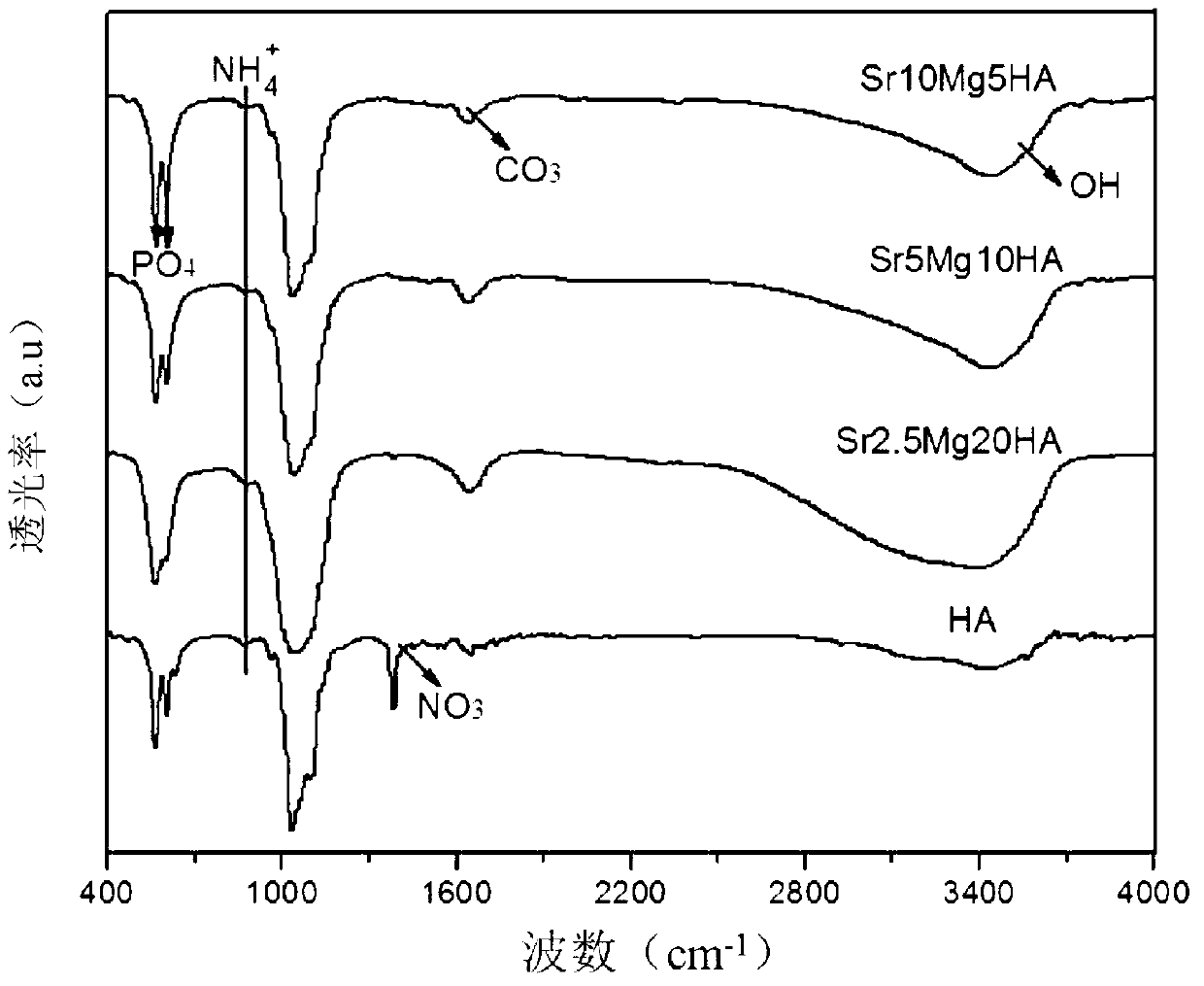

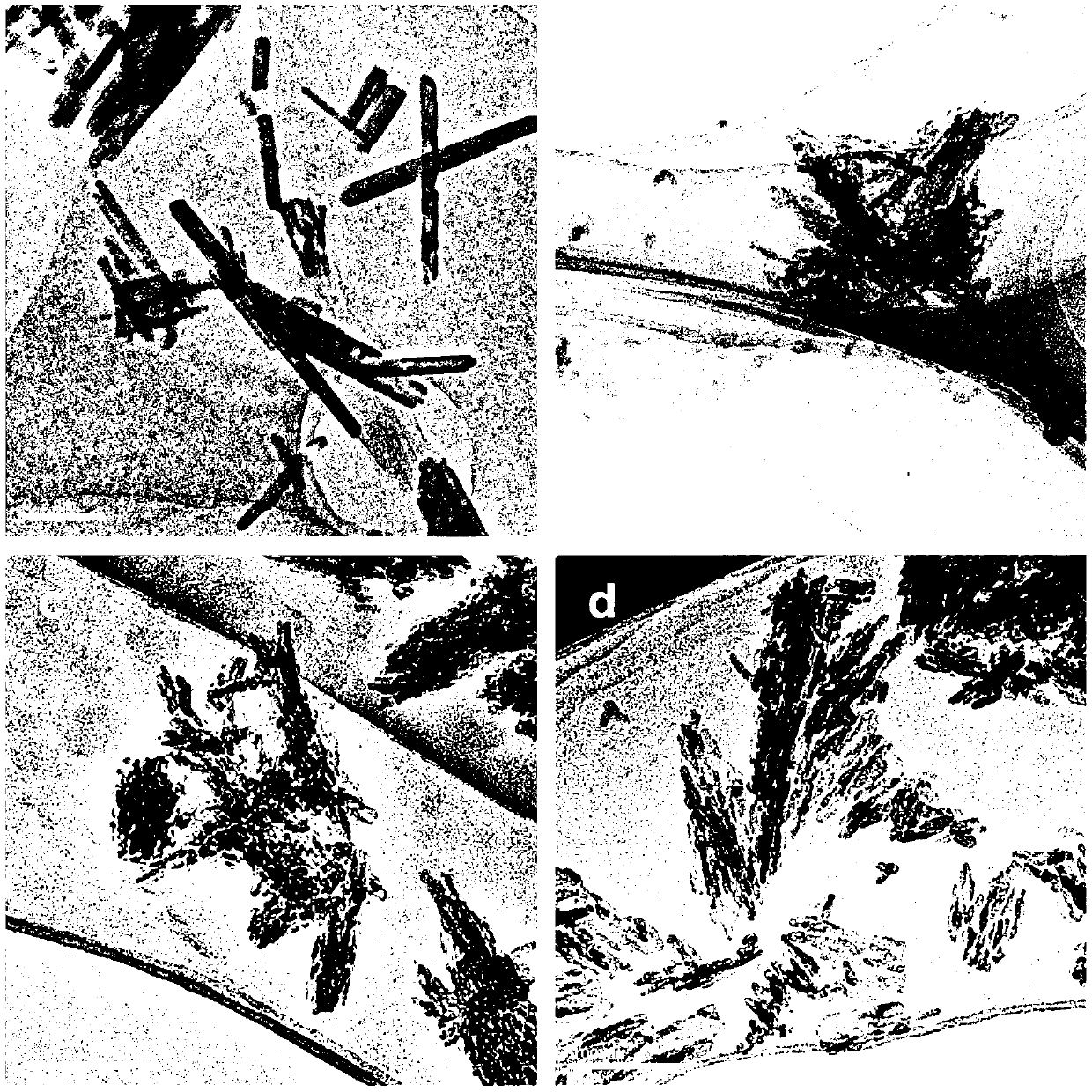

Strontium magnesium-doped nano-hydroxyapatite and preparation method thereof

The invention discloses strontium magnesium-doped nano-hydroxyapatite and a preparation method thereof. The method comprises the following steps of: simultaneously and slowly adding a strontium nitrate liquor, a magnesium nitrate liquor and an ammonium hydrogen phosphate liquor by a predetermined molar ratio to a nitric acid liquor at 80-90 DEG C; adjusting pH value to 7-8 by ammonia water under continuous stirring; reacting for 2-3 hours, and standing for 24-48 hours; filtering and washing the precipitate; placing the precipitate in a reaction kettle for reaction for 4-6 hours at 80-90 DEG C; and cleaning and drying the slurry obtained to obtain the rod-like strontium magnesium-doped nano-hydroxyapatite free from solvent residue with small particle diameter. The strontium magnesium-doped nano-hydroxyapatite can be used as a novel biological material for repairing hard tissues, better simulates natural bone, and has the capacity of shortening the bone repairing period.

Owner:MICRO STRUCTURE ANALYTICAL LAB

Preparation method of high-purity strontium carbonate

InactiveCN101987736AHigh purityLow costCalcium/strontium/barium carbonatesStrontium carbonateDistilled water

The invention belongs to a preparation method of high-purity strontium carbonate, comprising the following steps: (1) ammonium carbonate solution preparation; (2) strontium nitrate purification: placing the strontium nitrate into distilled water; heating the mixture to 60-70 DEG C; dissolving, filtering, and concentrating; controlling the relative density to be 18-20 Be; drying after cooling and crystallizing to obtain the purified strontium nitrate for later use; (3) impurity barium ions removing: placing the purified strontium nitrate into the distilled water; heating mixture to 40-50 DEG C; dissolving, adding sulfuric acid, stirring, precipitating for 2-3h, and filtering to obtain filter liquor; and (4) high-purity strontium carbonate synthesis: heating the filter liquor obtained in the step (3) to 60-70 DEG C; adding the ammonium carbonate solution obtained in the step (1); controlling the pH value at 8.5-9; and standing for 4-5h to obtain strontium nitrate precipitation; drying after pumping to dry to obtain the high-purity strontium carbonate finish product. The prepared strontium carbonate finish product has high purity and low impurity content, and the preparation process has simple process steps and higher production efficiency.

Owner:TIANJIN CHEM REAGENT RES INST

Gas generating agent for automobile safe gasbag and preparing method thereof

InactiveCN101234943AEasy to mold and releaseImprove adsorption capacityPressure gas generationCarboxymethyl celluloseSesquioxide

The invention discloses an automobile airbag gas generating agent and a preparation method thereof. The invention is characterized in that 30 to 50 percent of guanidine nitrate, 5 to 20 percent of basic cupric nitrate, 10 to 25 percent of strontium nitrate, 3 to 10 percent of ammonium perchlorate, 2 to 6 percent of iron sesquioxide, 2 to 10 percent of sodium carboxymethyl cellulose and 2 to 5 percent of caoline taken in accordance with the weight percentages are mixed thoroughly; after distilled water is added, the mixture is heated and kneaded and cooled for granulation; obtained particles are then dried and sieved to get the gas generating agent. Raw materials for products to be made with the method of the invention are easy to acquire and have low prices. The production process is safe and conducive to safety of automobile occupants and also to environment protection.

Owner:烟台安泰德汽车安全系统有限公司

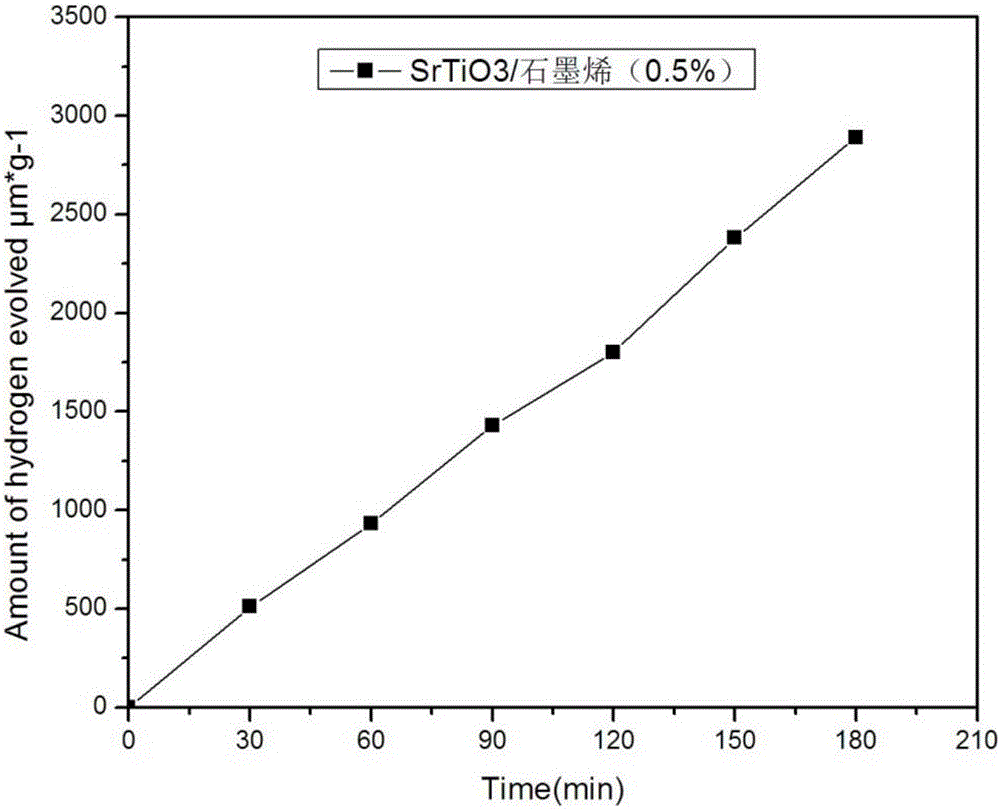

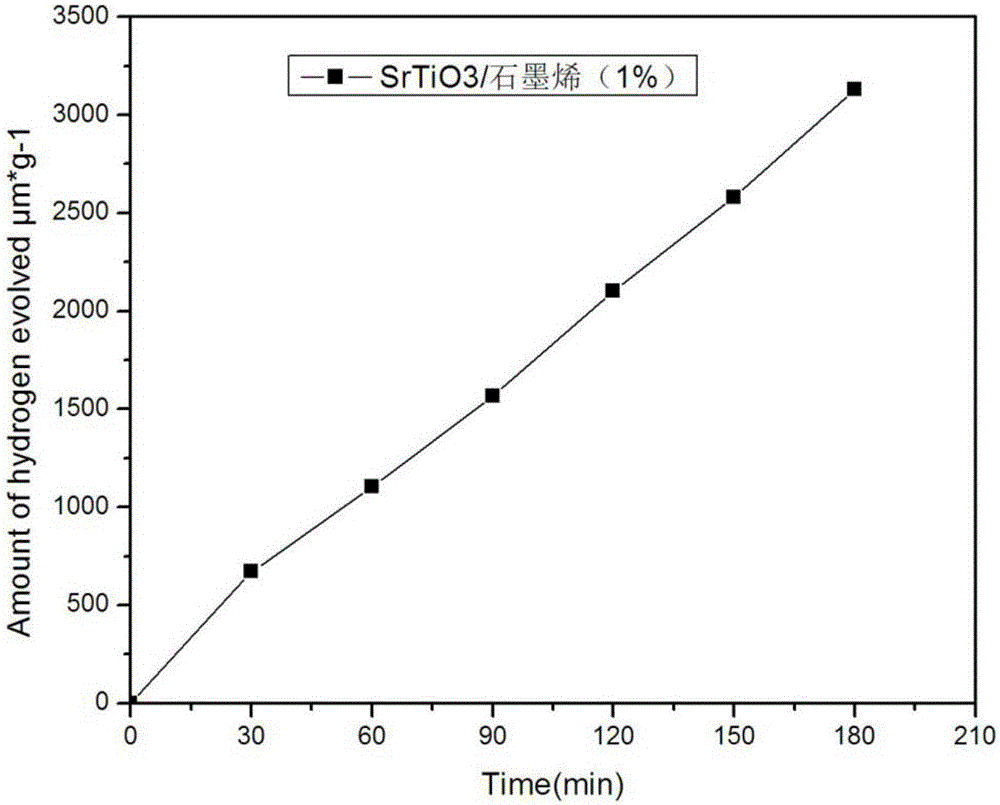

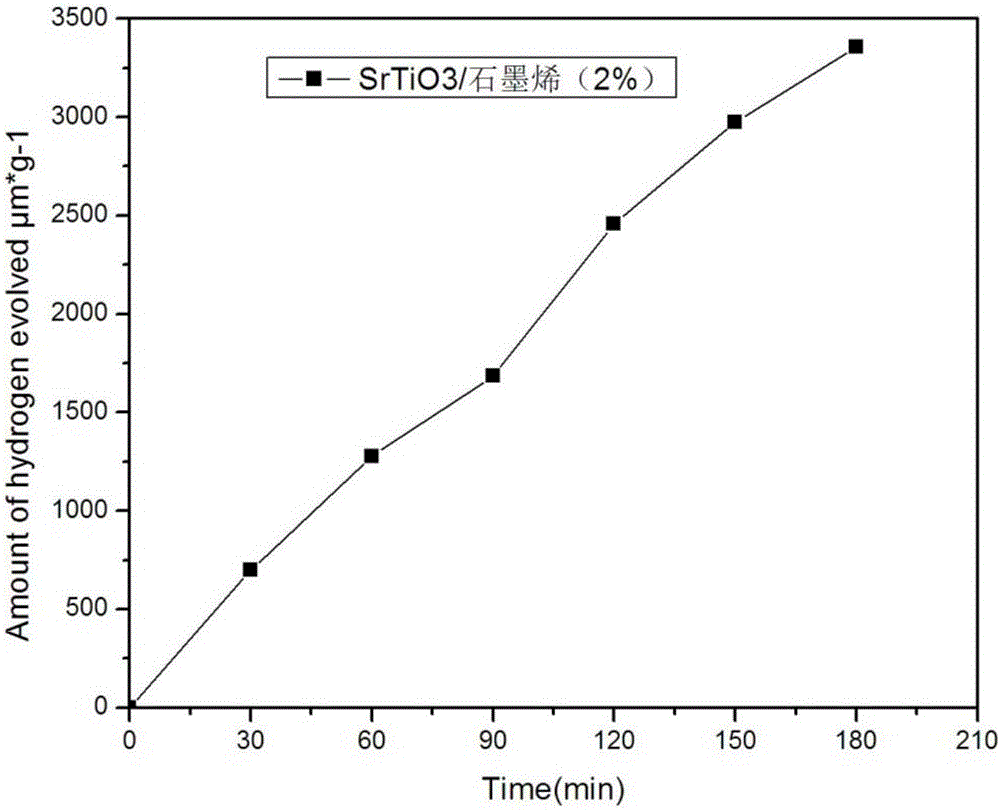

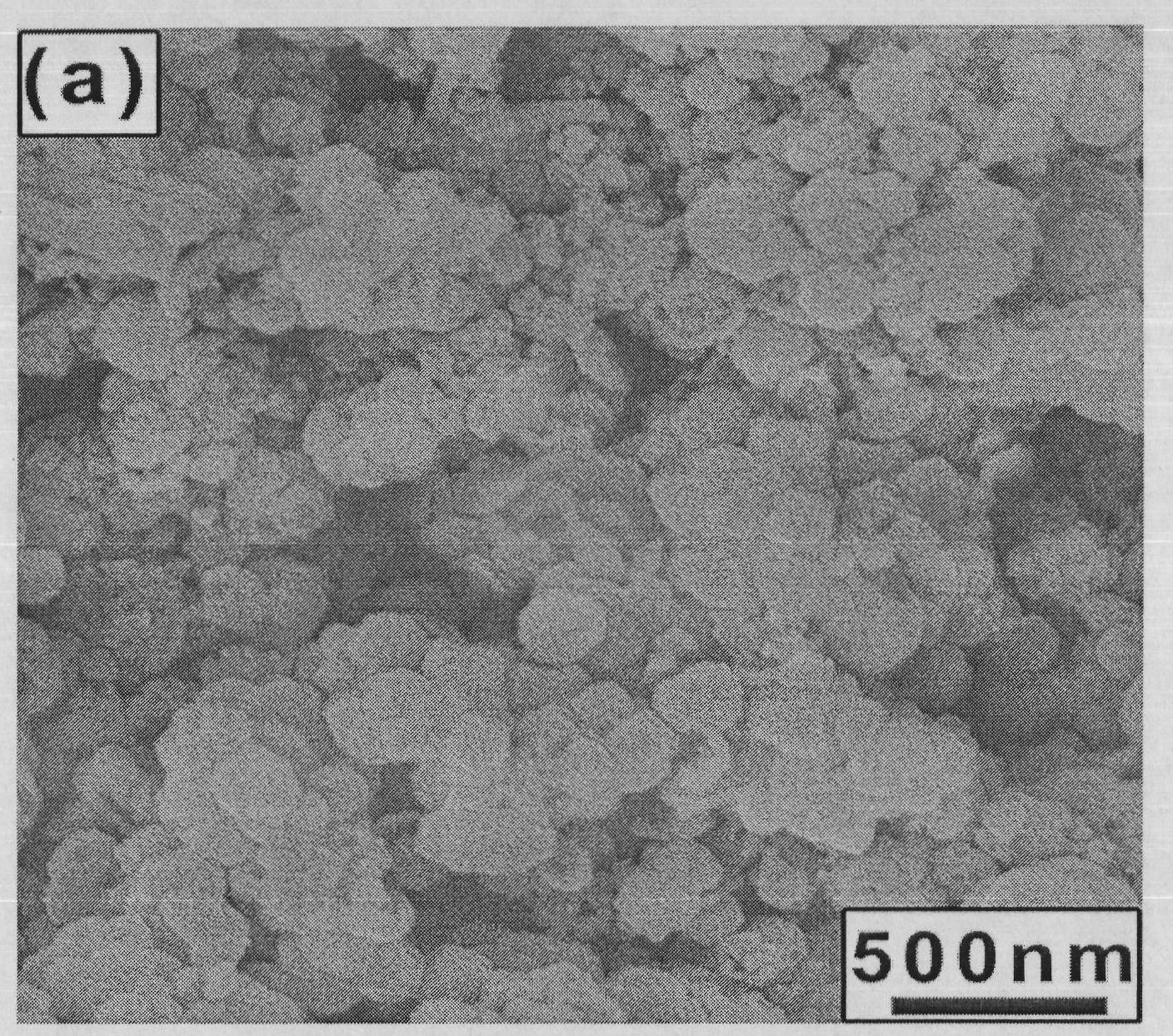

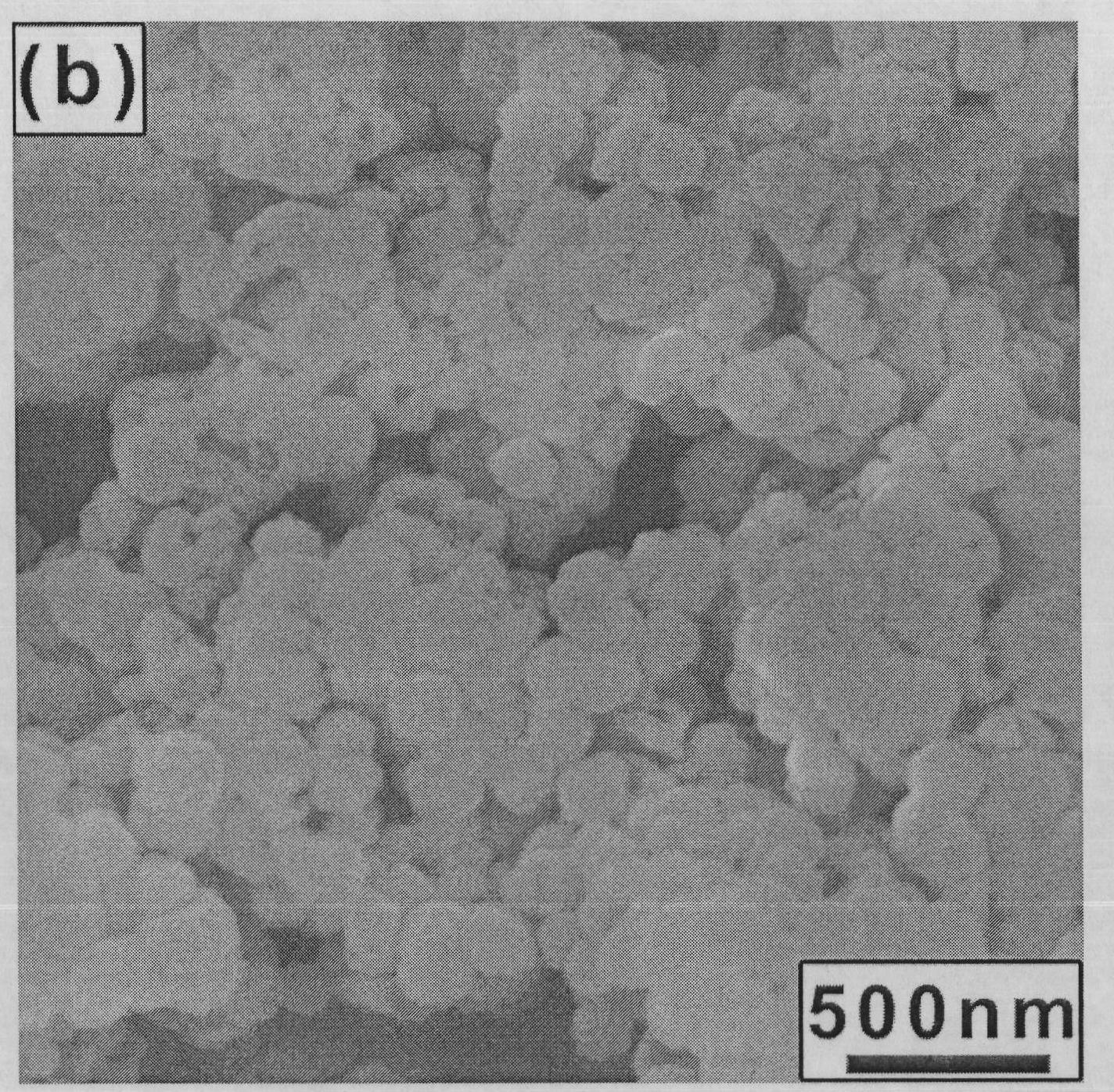

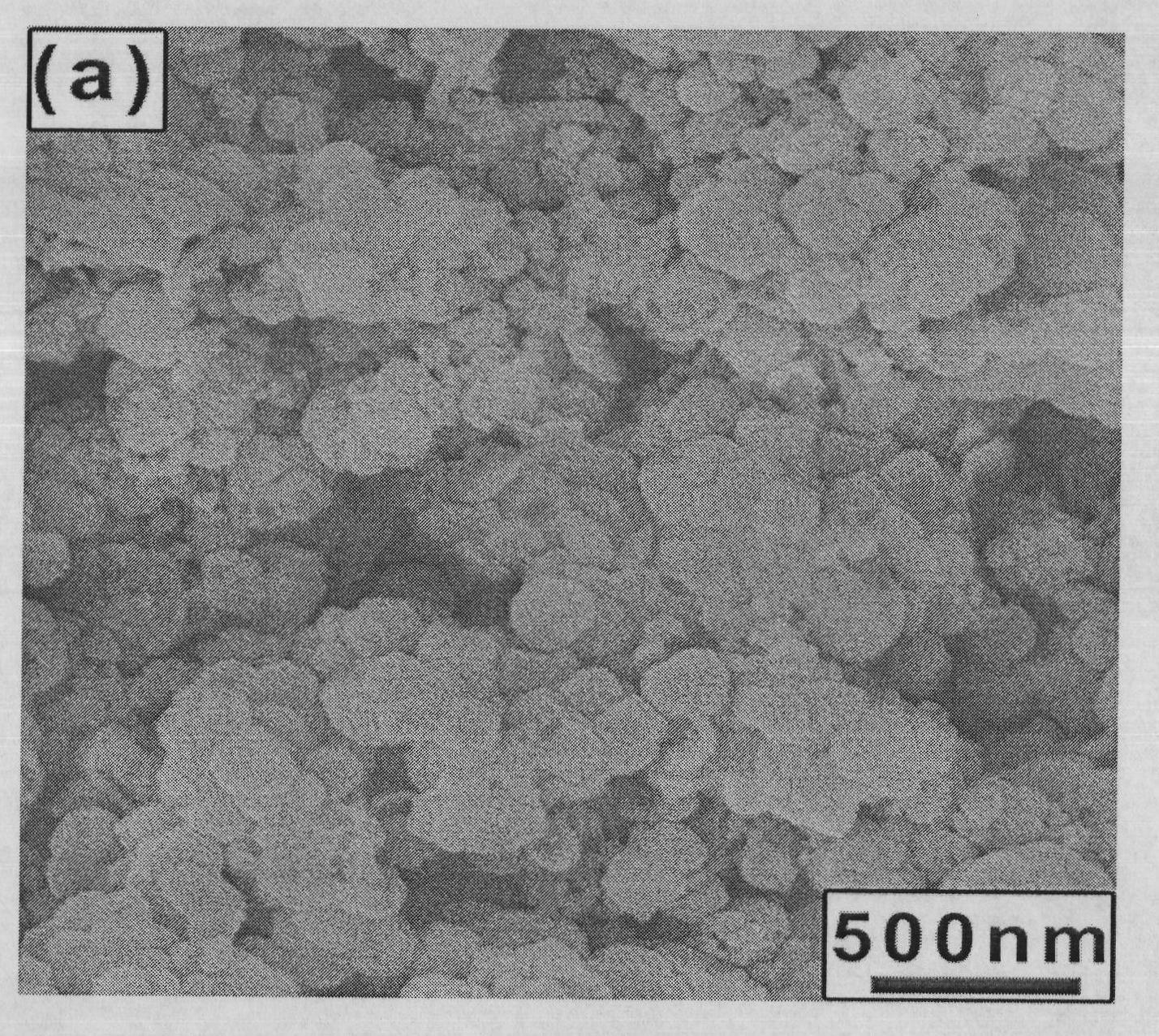

SrTiO3/graphene composite catalyst as well as preparation method and application thereof

InactiveCN105817217AGood dispersionGood chemical stabilityHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsHigh pressureUltrasonic dispersion

The invention discloses a SrTiO3 / graphene composite catalyst for photocatalytically decomposing water as well as a preparation method and application thereof. The SrTiO3 / graphene composite catalyst is prepared from SrTiO3 and graphene, wherein the SrTiO3 is loaded on the surface of the graphene. The preparation method of the catalyst comprises the following steps: firstly, adding tetrabutyl titanate into a graphene oxide dispersion solution; adding glacial acetic acid, and stirring and dissolving to obtain a solution A; weighing strontium nitrate and adding into de-ionized water, and stirring and dissolving to obtain a solution B; dropwise adding the solution B into the solution A and stirring uniformly; continually carrying out ultrasonic dispersion to form homogenized sol; adjusting the pH value to 13-14; and transferring the homogenized sol into a high-pressure reaction kettle, carrying out high-temperature treatment, and then cooling to obtain the SrTiO3 / graphene composite catalyst. The SrTiO3 / graphene composite catalyst integrates photocatalytic activity of SrTiO3, high specific surface area, chemical stability, and adsorption property of graphene, and high conducting property.

Owner:WUHAN YUANFANG SCI & TECH CO LTD OF CHINA SANJIANG SPACE GRP

Method for preparing nano barium-strontium titanate powder by adopting hydrothermal method

InactiveCN101786887AUniform particle size distributionAvoid grain growthBarium strontium titanateBarium titanate

The invention discloses a method for preparing nano barium-strontium titanate powder by adopting a hydrothermal method, which is used for solving the technical problem of large granularity of the barium-strontium titanate powder prepared by a method of the prior art. The method comprises the following steps of: adding strontium nitrate, barium nitrate, anatase phase titanium oxide and a mineralizer into a high-pressure kettle; then adding deionized water and stirring; later on, raising the temperature to a hydrothermal temperature according to a certain speed and preserving heat; after heat preservation time arrives, furnace cooling to room temperature; and then repeatedly washing and filtering by using deionized water and drying. Because the barium-strontium titanate powder is prepared by adopting the hydrothermal method, the barium-strontium titanate powder with uniform size distribution is obtained through controlling different barium-titanium proportions, and moreover, the defects of grain growth, impurity mixing, and the like easily caused in a sintering process are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

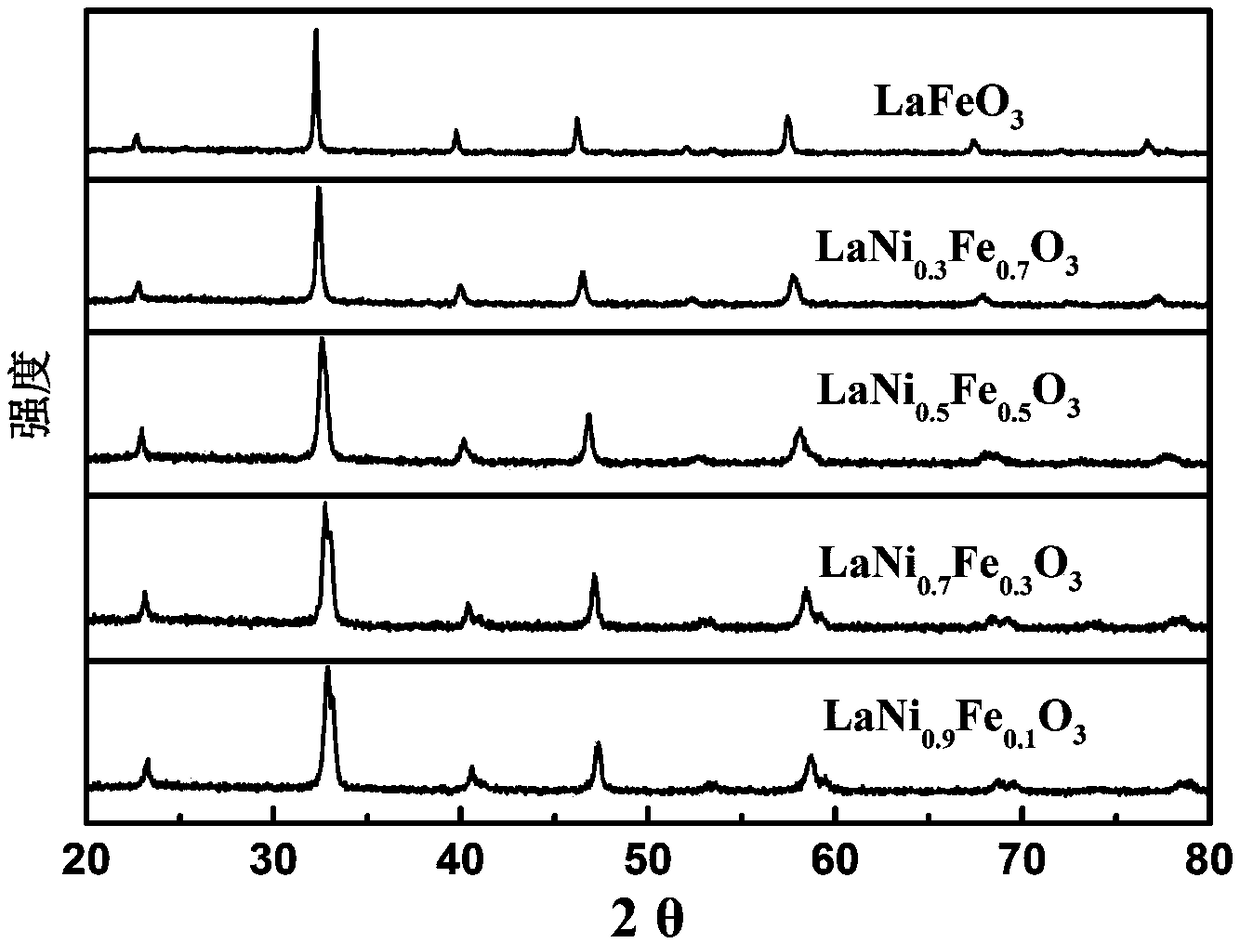

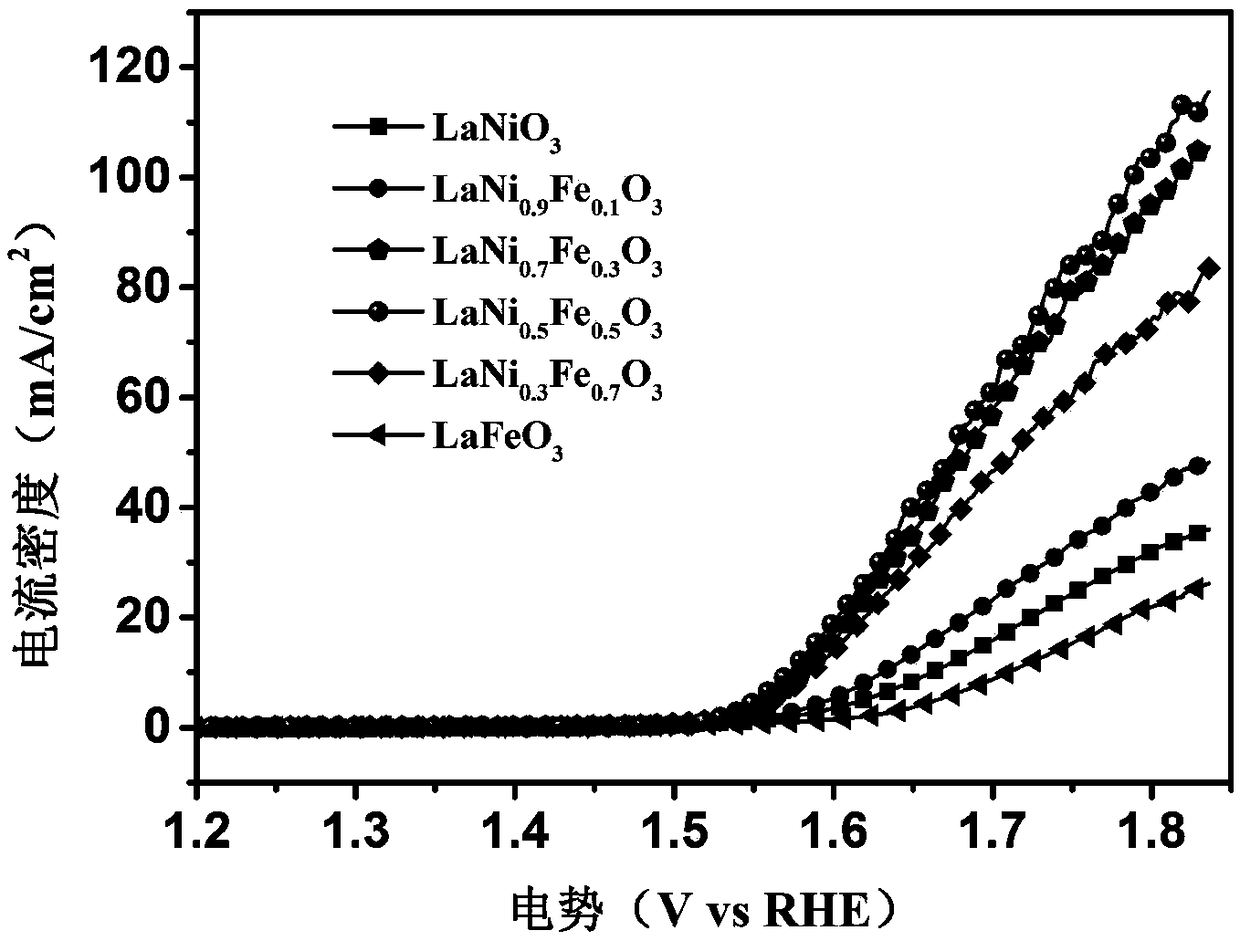

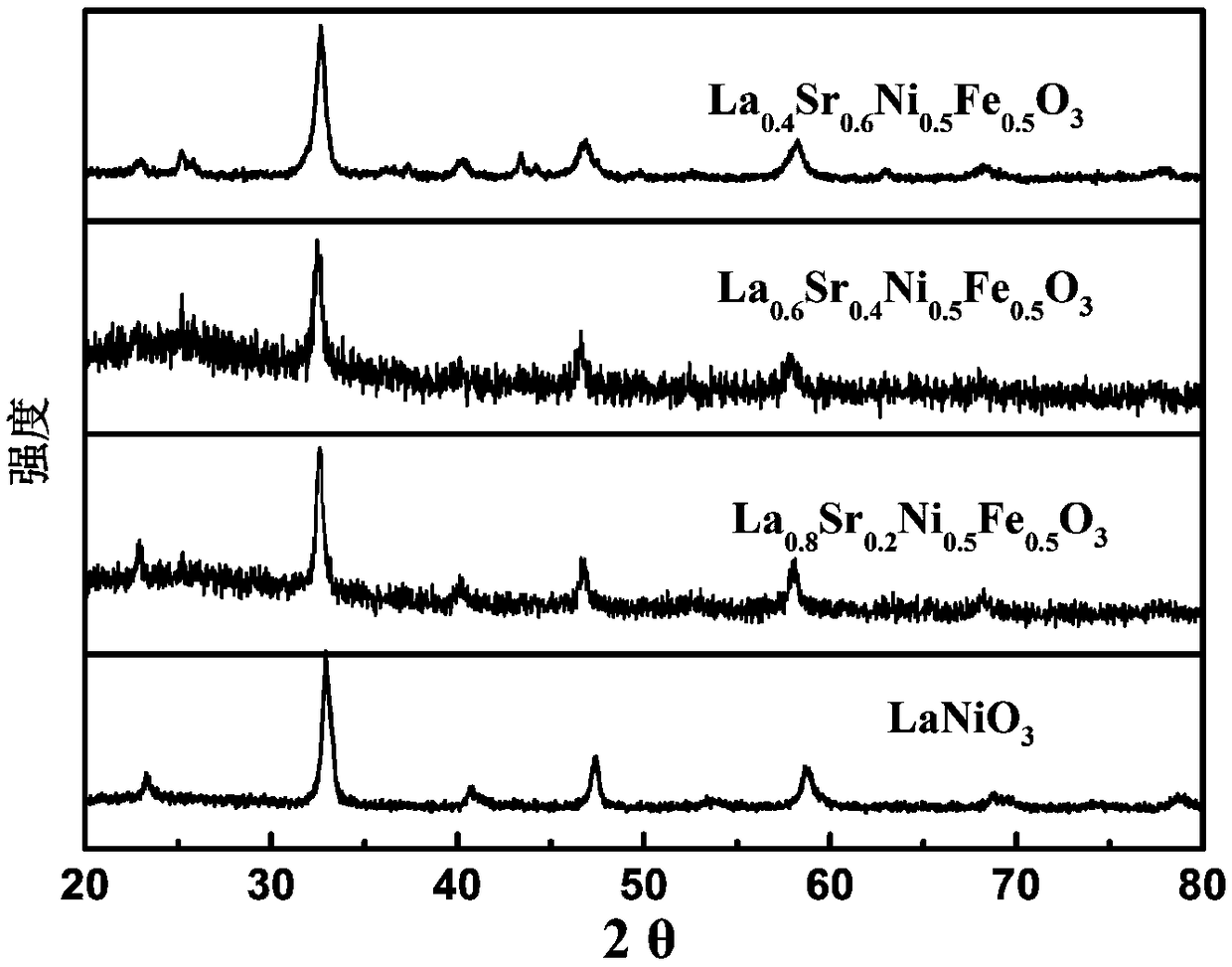

Preparation method and application of bifunctional perovskite type oxide oxygen electrode catalyst

InactiveCN109390598ABifunctional electrocatalytic performance is goodImproved Oxygen Reduction (ORR) Catalytic PerformanceCell electrodesWater bathsOxygen

The invention relates to a preparation method and an application of a bifunctional perovskite type oxide oxygen electrode catalyst. The method comprises the following steps: mixing aqueous solutions of lanthanum nitrate, strontium nitrate, nickel nitrate and ferric nitrate, then adding ethanediol, adding the mixture into a citric acid solution, heating a water bath to 70-90 DEG C until a gel is formed; finally raising the temperature of the gel to 650-800 DEG C, preserving heat for 6-9 hours; finally obtaining a La(1-x)SrxNi(1-y)FeyO3 powder, namely the bifunctional perovskite type oxide oxygen electrode catalyst. The catalyst is used for catalyzing the oxygen evolution reaction (OER) and the oxygen reduction reaction (ORR) of a fuel cell and an electrolytic tank. The main ingredients of the bifunctional perovskite type oxide oxygen electrode catalyst are from rich transition metal materials, and the cost is low.

Owner:HEBEI UNIV OF TECH

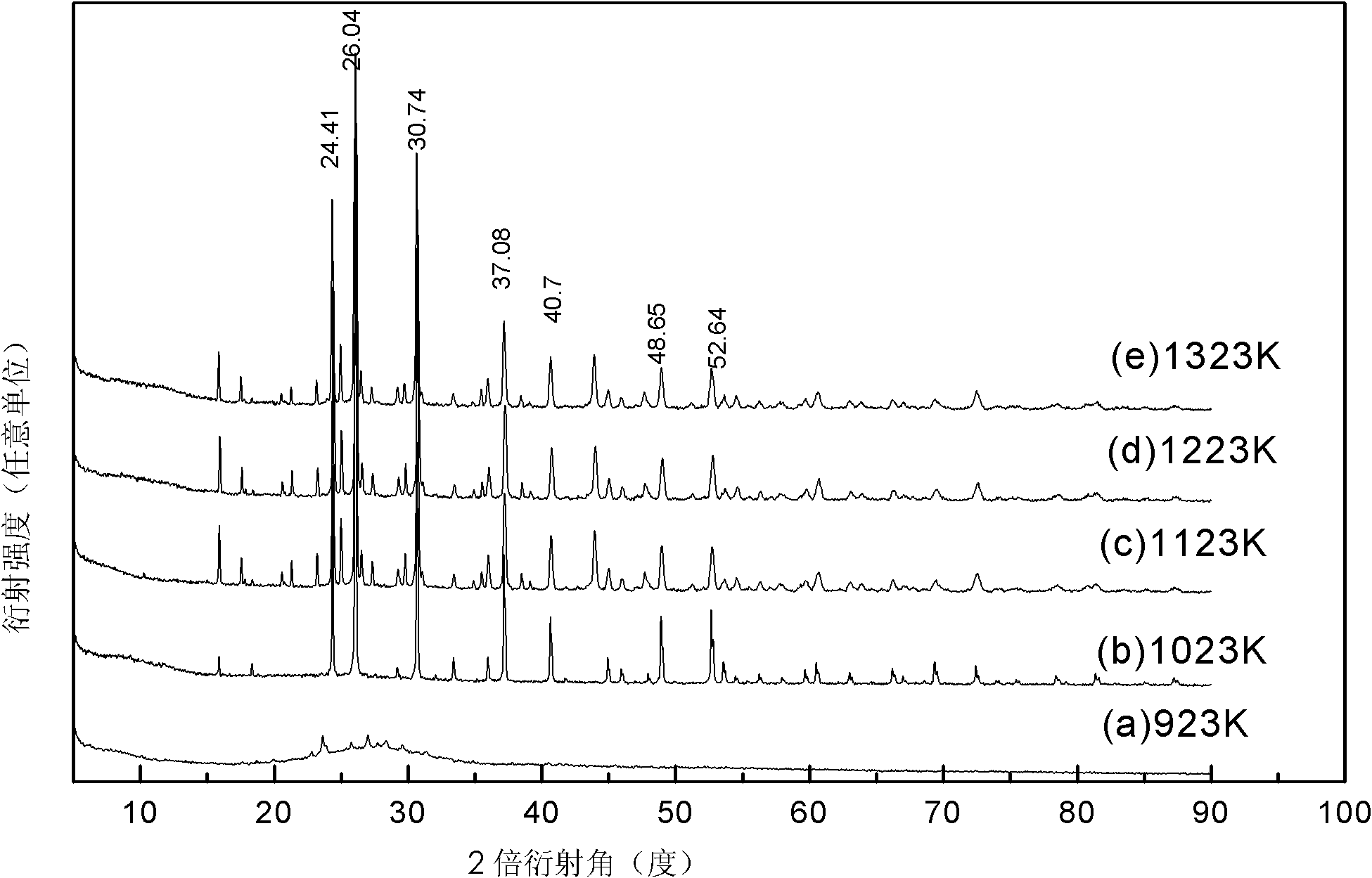

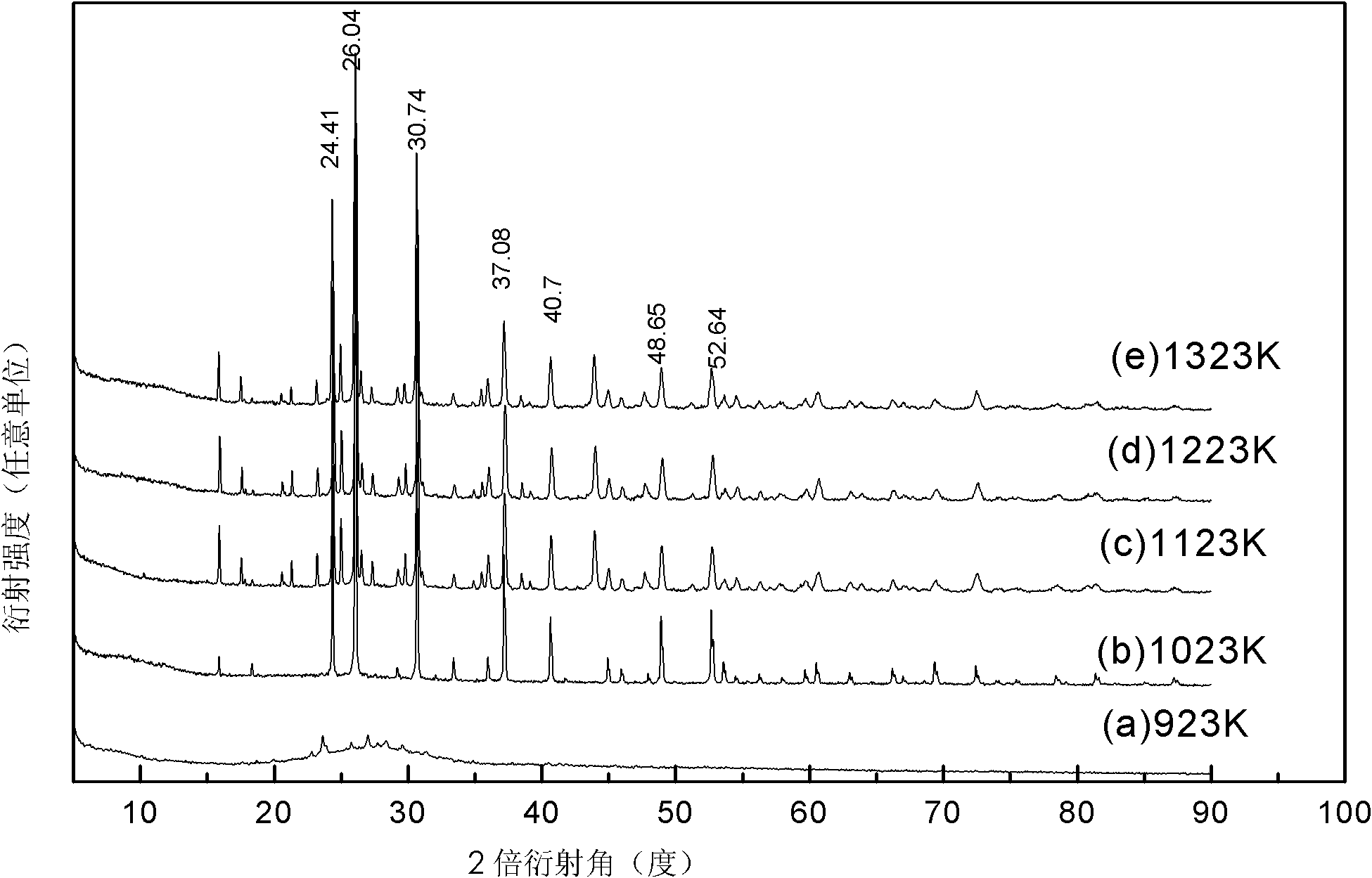

Process for preparing rare-earth excited strontium aluminate long afterglow fluorescent powder

InactiveCN1900216AWell mixedImprove luminous brightnessLuminescent compositionsInorganic saltsNitrate

The present invention discloses process of preparing RE excited long afterglow strontium aluminate fluorescent powder. The process includes the following steps: 1. preparing mixed solution of strontium nitrate, aluminum nitrate and lanthanide RE nitrate in the molar ratio of 29.6-39.5 to 59.2-69.2 to 0.65-1.8, regulating the pH value of solution to 2-8, and adding sol forming agent through stirring at 80-120 deg.c for 1-24 to form sol; 2. heating the sol at 300-900 deg.c for 1.5-30 hr to obtain solid pre-baked matter; and 3. grinding the solid pre-baked matter, adding inorganic salt, igniting at 800-1400 deg.c in reducing atmosphere, and washing to obtain the RE excited long afterglow strontium aluminate fluorescent powder. The present invention has simple technological process, high product performance and important industrial application value.

Owner:PEKING UNIV

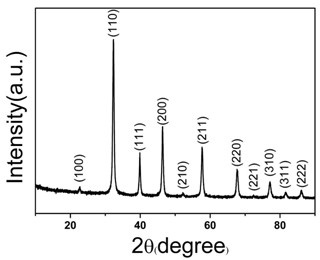

Preparation method for strontium-cesium co-solidified body

ActiveCN102208223AReduce volatilitySolve the problem of volatilityRadioactive decontaminationCaesium nitrateRoom temperature

The invention belongs to the technical field of industrial treatment of nuclear waste and discloses a preparation method for a strontium-cesium co-solidified body. In the method, a modified ZSM-5 zeolite serves as a substrate to adsorb Sr and Cs; and the method comprises the following steps of: treating the ZSM-5 zeolite with a HNO3 solution; preparing a mixed solution of a strontium nitrate solution and a cesium nitrate solution in a ratio of 5 to 15 weight percent of strontium oxide and 5 to 15 weight percent of cesium oxide based on the strontium-cesium co-solidified body, adding the modified ZSM-5 zeolite, stirring, aging, standing, stirring, evaporating, and drying to obtain a strontium-cesium co-solidified precursor; and heating and calcining the strontium-cesium co-solidified precursor according to a certain process and cooling naturally to the room temperature to obtain a strontium-cesium solidified polycrystal. High-temperature calcining for preparing the co-solidified body is avoided, so that the problem of Cs volatilization is solved, the aim of solidifying Sr at the same time is fulfilled and the experimental safety and operability under a radioactive condition are ensured; and the method is applicable for solidifying the strontium solution and the cesium solution which are separated from the unclear waste.

Owner:TSINGHUA UNIV

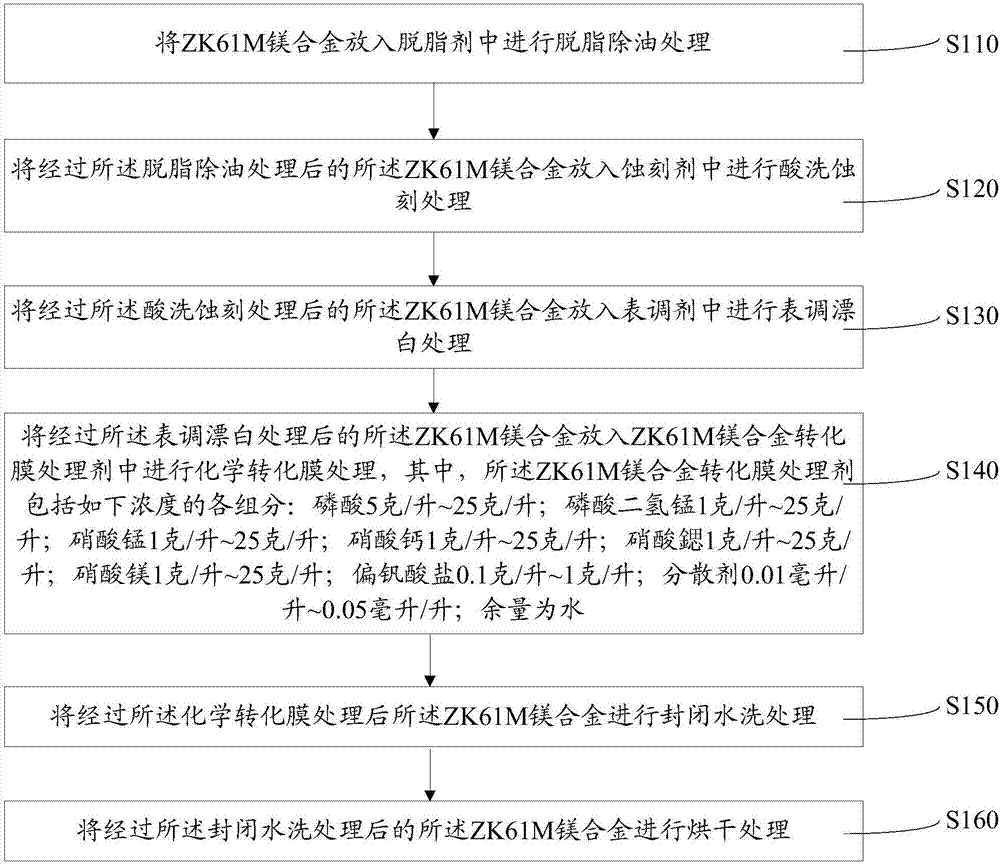

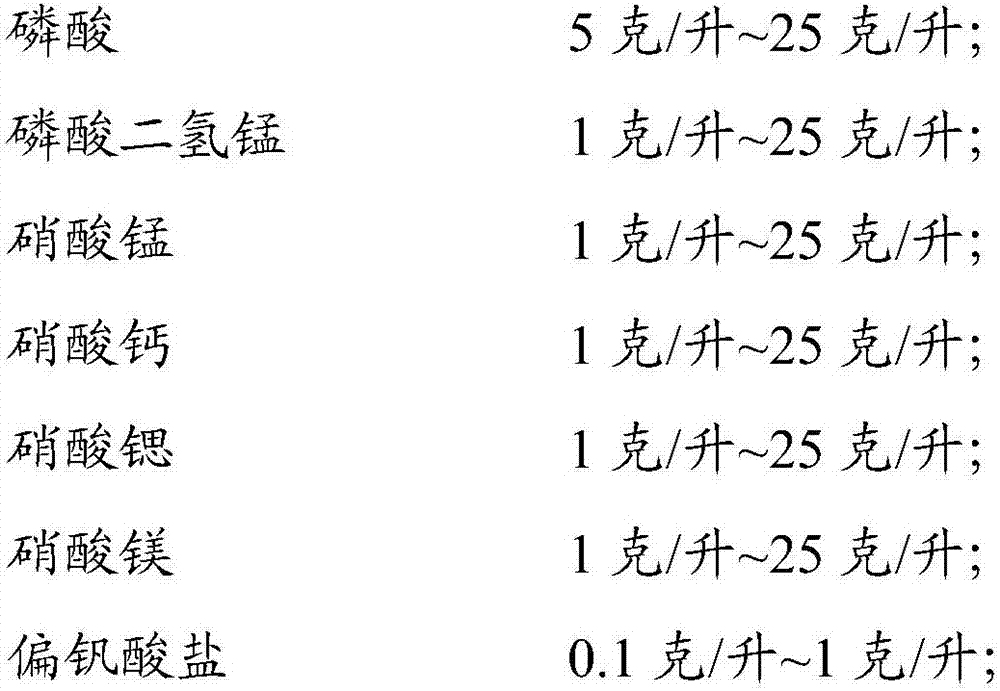

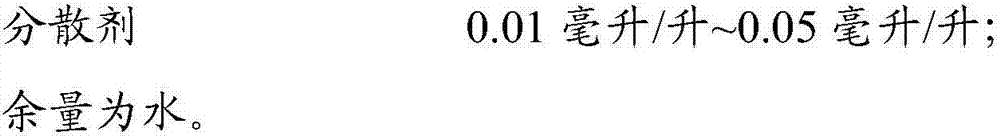

ZK61M magnesium alloy conversion film treatment agent and conversion film treatment method

InactiveCN107130233AImprove adhesionHigh degree of corrosion resistanceMetallic material coating processesNitratePhosphate

The invention relates to a ZK61M magnesium alloy conversion film treatment agent and a ZK61M magnesium alloy conversion film treatment method. The ZK61M magnesium alloy conversion film treatment agent comprises the following components by concentrations: 5-25 g / l of phosphoric acid, 1-25 g / l of manganous dihydrogen phosphate, 1-25 g / l of manganese nitrate, 1-25 g / l of calcium nitrate, 1-25 g / l of strontium nitrate, 1-25 g / l of magnesium nitrate, 0.1-1 g / l of metavanadate, 0.01-0.05 ml / l of dispersing agent, and the balance of water. The ZK61M magnesium alloy conversion film treatment agent performs the chemical conversion film treatment on the surface of a ZK61M magnesium alloy to form a conversion film with good adhesion, high corrosion resisting degree, salt mist resistance and good film forming uniformity.

Owner:广东东明新材科技有限公司

Preparation method of strontium titanate nanometer piece

InactiveCN102583517AImprove crystal qualityLarge specific surface areaNanotechnologyTitanium compoundsStrontium titanatePotassium hydroxide

The invention relates to a preparation method of a strontium titanate nanometer piece. According to the invention, butyl titanate is taken as a titanium source, strontium nitrate is taken as a strontium source, and ammonia water is taken as a precipitating agent. The preparation method comprises the following steps of: firstly, adopting ammonia water to deposit titanium salt so as to obtain titanic hydroxyl hydrogen oxide deposition to be as a solvent hot reaction material with the strontium nitrate, using glycol as a reaction system solvent to form a solvent thermosynthesis perovskite structure strontium titanate self assembly nanometer piece at 150 DEG C-240 DEG C. The preparation method provided by the invention has the advantages of simple technical process, no pollution, low cost, and is easy to control and is easy to perform large-scale production; the crystallizing quantity of the prepared product is stable, and the specific area is large; and the preparation method has wide application prospect on the fields such as electro-optical devices, memory devices, oxygen sensors, photocatalysts, solar batteries and the like.

Owner:ZHEJIANG UNIV

Fast synthesizing process of strontium aluminate rare earth long afterglow luminescent powder

The fast synthesis process of long afterglow RE strontium aluminate powder includes mixing aluminum nitrate, strontium nitrate, boric acid and composite RE activator; and microwave heating the mixture inside one sandwiched container with carbon black or other microwave absorbing material filled in the sandwich at 1000-1700 deg.c to react for 10-60 min. The composite RE activator consists of nitrates of Eu, Dy, Nd and / or La. The product of the long afterglow RE strontium aluminate powder is monoclinic crystal in the nanometer size.

Owner:ANHUI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com