Preparation method for strontium-cesium co-solidified body

A solidified body, strontium and cesium technology, applied in the direction of radioactive purification, nuclear engineering, etc., can solve the problems of easy volatilization, small Cs/Sr inclusion capacity, etc., to reduce volatilization, solve volatilization problems, ensure safety and operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

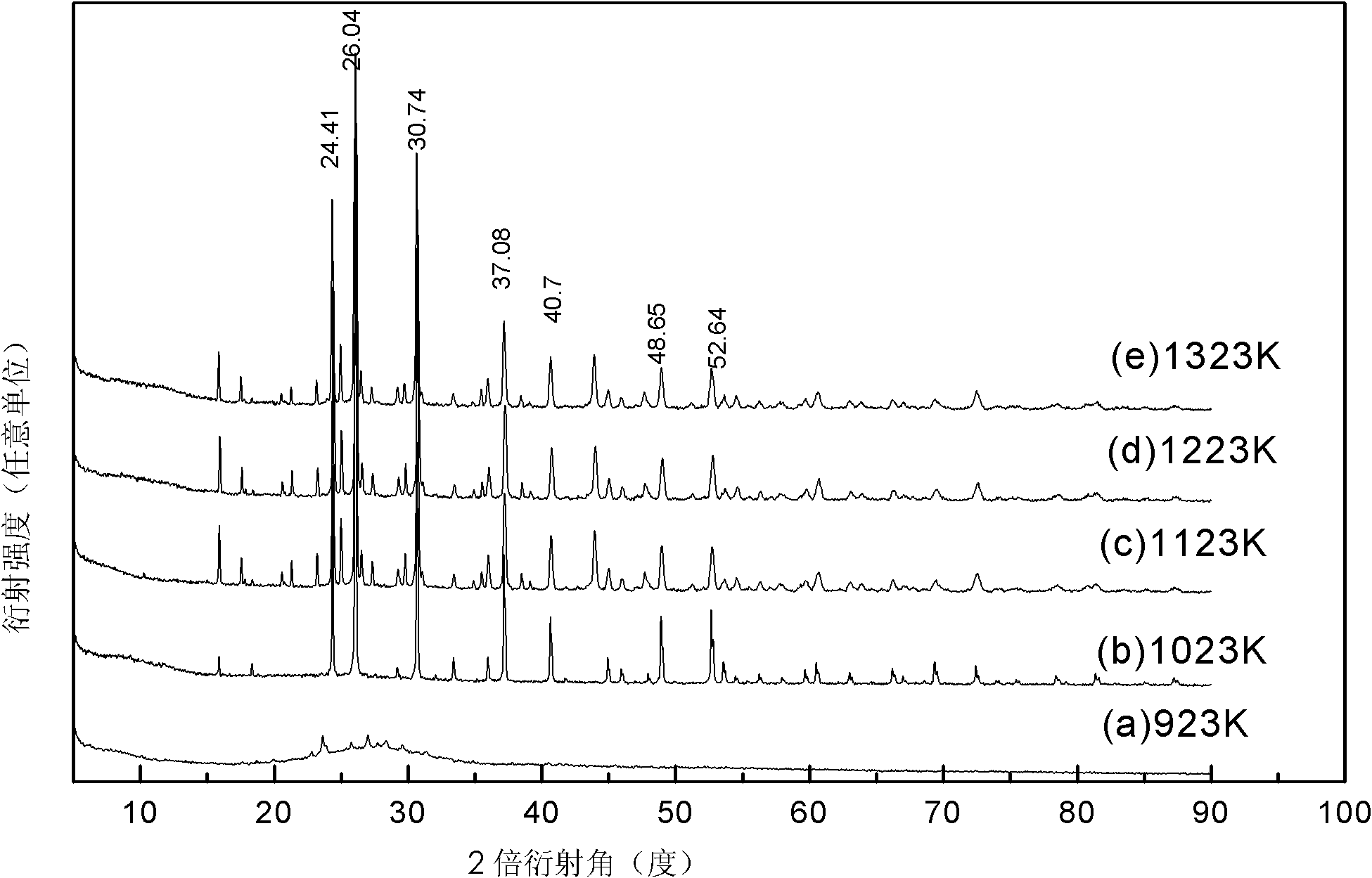

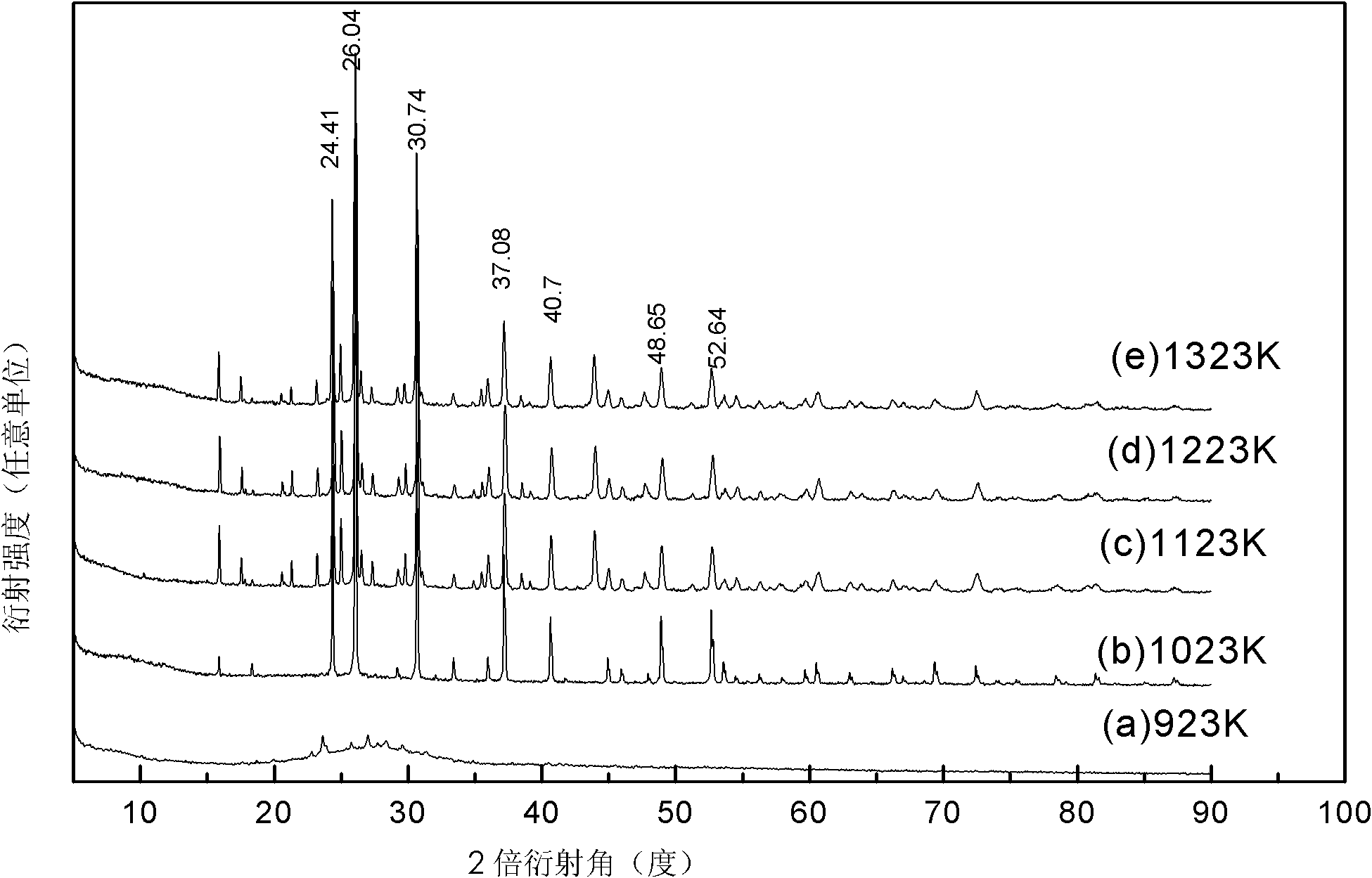

Image

Examples

Embodiment 1

[0021] Dissolve strontium nitrate and cesium nitrate in deionized water respectively, prepare 0.5 mol / L strontium nitrate solution and 0.1 mol / L cesium nitrate solution, and prepare 0.1 mol / L nitric acid solution. In a beaker at room temperature, add 0.1mol / L HNO at a liquid-solid ratio of 10:1 3 and ZSM-5A molecular sieve, stirred for 10 hours, and centrifuged to obtain improved ZSM-5A molecular sieve; in a beaker, add 0.1mol / L of HNO 3Solution, add 0.5mol / L strontium nitrate solution according to the weight ratio of strontium oxide to the whole strontium-cesium co-solidified body as 5%, add 0.5mol / L cesium nitrate according to the weight ratio of cesium oxide to the whole strontium-cesium co-solidified body as 15% Solution, prepared as a mixed solution and placed in a beaker, then added improved ZSM-5A molecular sieve, wherein the solid-to-liquid ratio of ZSM-5A molecular sieve to the mixed solution was 1:3, stirred and left to stand for 10 hours, then stirred and evaporated...

Embodiment 2

[0024] Dissolve strontium nitrate and cesium nitrate in deionized water respectively to prepare 0.1mol / L strontium nitrate solution and 0.5mol / L cesium nitrate solution, and then prepare two nitric acid solutions of 0.01mol / L and 0.05mol / L. In a beaker at room temperature, add 0.05mol / L of HNO at a liquid-solid ratio of 10:1 3 solution and ZSM-5A molecular sieve, stirred for 8 hours, and centrifuged to obtain improved ZSM-5A molecular sieve; in a beaker, add 0.01mol / L of HNO 3 Solution, add 0.1mol / L strontium nitrate solution according to the weight ratio of strontium oxide to the whole strontium-cesium co-solidified body as 10%, add 0.5mol / L cesium nitrate according to the weight ratio of cesium oxide to the whole strontium-cesium co-solidified body Solution, prepared as a mixed solution and placed in a beaker, then added improved ZSM-5A molecular sieve, wherein the solid-to-liquid ratio of ZSM-5A molecular sieve to the mixed solution was 1:3, stirred and left to stand for 15...

Embodiment 3

[0026] Dissolve strontium nitrate and cesium nitrate in deionized water respectively to prepare 0.3 mol / L strontium nitrate solution and 0.3 mol / L cesium nitrate solution, and then prepare 0.05 mol / L and 0.08 mol / L nitric acid solutions. In a beaker at room temperature, add 0.08mol / L of HNO at a liquid-solid ratio of 10:1 3 solution and ZSM-5A molecular sieve, stirred for 7 hours, and centrifuged to obtain improved ZSM-5A molecular sieve; in a beaker, add 0.05mol / L of HNO 3 Solution, add 0.3mol / L strontium nitrate solution according to the weight ratio of strontium oxide to the whole strontium-cesium co-solidified body as 5%, add 0.3mol / L cesium nitrate according to the weight ratio of cesium oxide to the whole strontium-cesium co-solidified body as 15% solution, mix and place in a beaker, then add improved ZSM-5A molecular sieve, wherein the solid-to-liquid ratio of ZSM-5A molecular sieve to the mixed solution is 1:3, stir and age for 18 hours, then stir and evaporate, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com