Patents

Literature

154results about How to "Solve the problem of volatility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyester paint of high solid for coiled material and lithographed sheet

InactiveCN1415682AIncreased irregularitySmall molecular weightLiquid surface applicatorsPolyester coatingsChemistryBoiling point

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

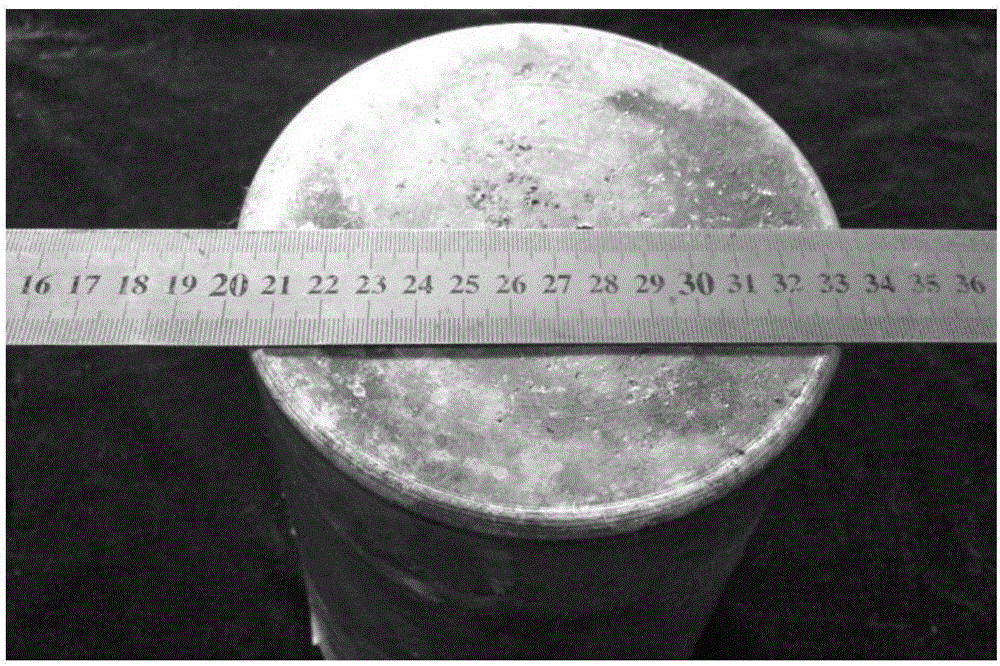

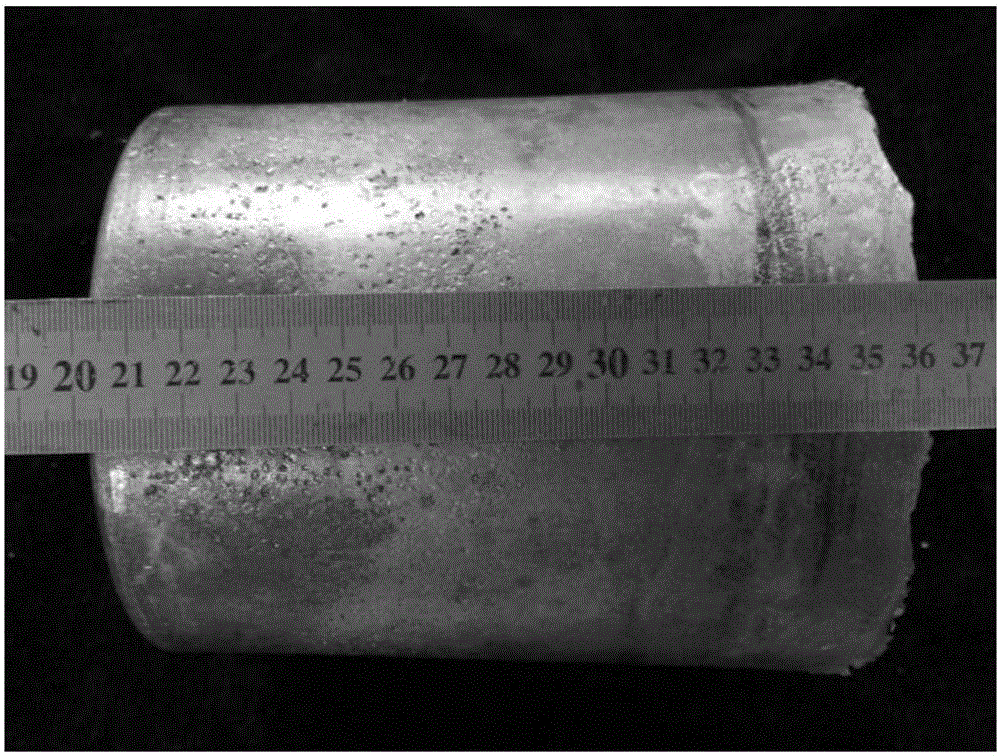

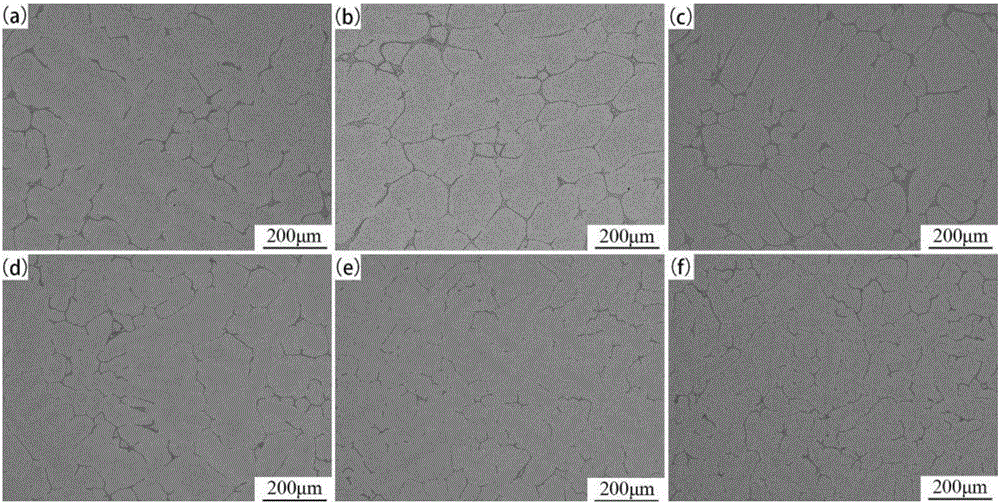

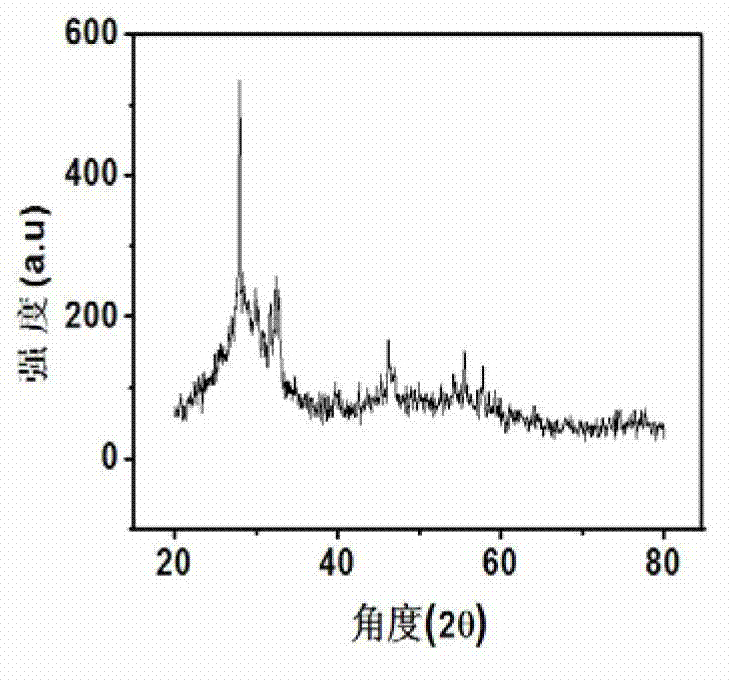

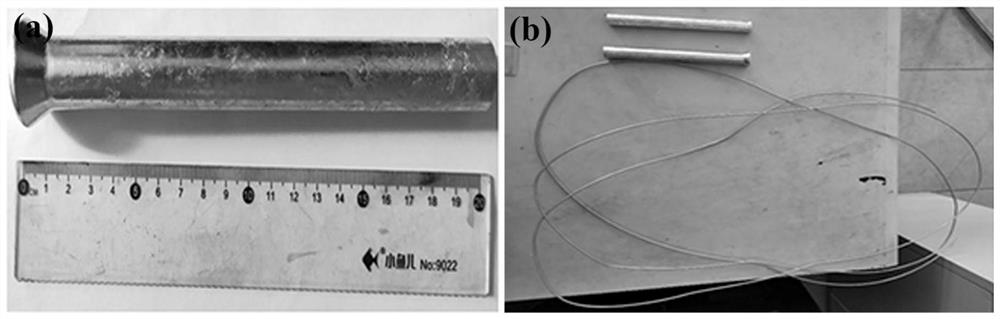

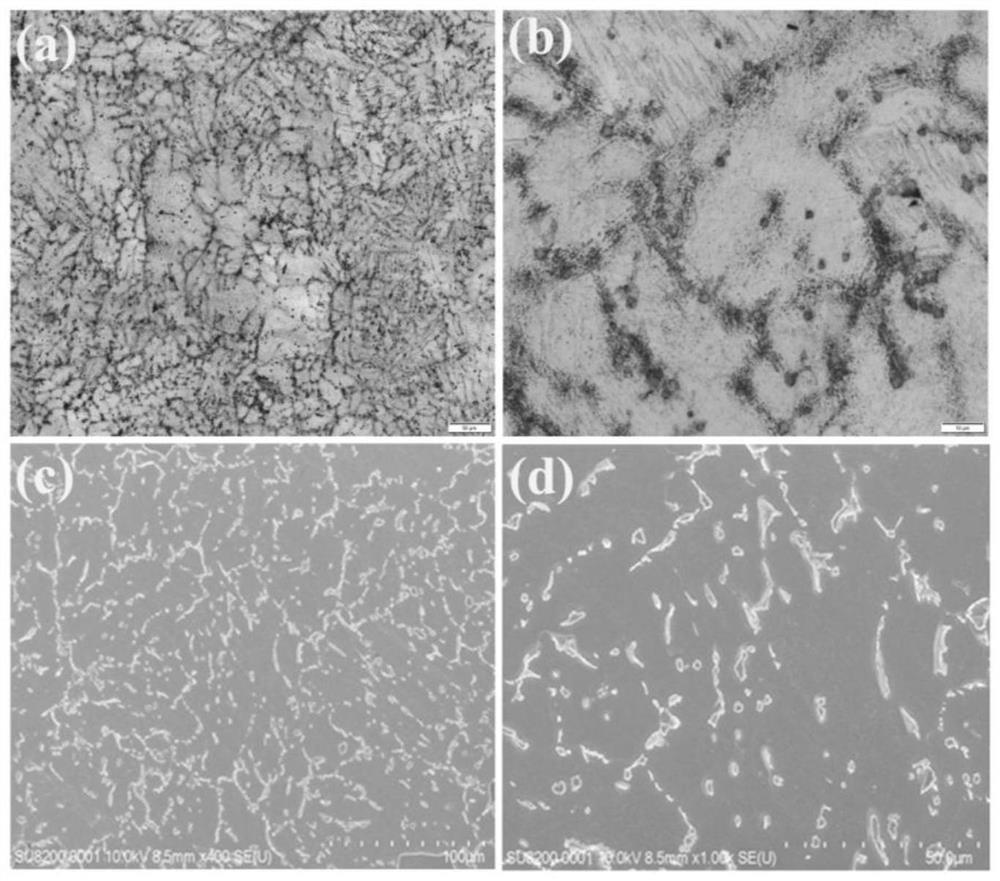

Method for preparing Al0.5CoCrFeNi high-entropy alloy

ActiveCN106756412AReduce volatilityGuaranteed compositional uniformityHigh entropy alloysSmelting process

The invention discloses a method for preparing an Al0.5CoCrFeNi high-entropy alloy. An intermediate alloy serves as a raw material, and volatilization of a low-melting-point element Al in the smelting process is greatly reduced. Meanwhile, a vacuum induction heating device is adopted, the electromagnetic stirring effect of the induction heating device is utilized, and therefore the component uniformity of a cast ingot is guaranteed. According to the method, the melting point difference between the lowest-melting-point metal Al and the highest-melting-point metal Cr is indirectly reduced, the problem of excessive volatilization of the low-melting-point Al simple substance in the smelting process is solved, and the component uniformity of the multi-element high-entropy alloy is guaranteed through the electromagnetic stirring effect existing in induction heating. Through reasonable designing of the atmosphere, the air pressure, the die preheating temperature, the smelting temperature, the heat preservation time, the casting speed and other parameters in the smelting process, a large Al0.5CoCrFeNi high-entropy alloy cast ingot is successfully prepared.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Plant antibacterial component based slow-releasing antibacterial fresh-keeping carton and production method thereof

InactiveCN104943992ASuitable for antibacterial and fresh-keepingInhibition of growth and reproductionLinings/internal coatingsContainers preventing decayDistilled waterCarton

The invention discloses a plant antibacterial component based slow-releasing antibacterial fresh-keeping carton and a production method thereof and relates to the field of fresh keeping of agricultural products. The slow-releasing antibacterial fresh-keeping carton comprises a corrugated board and an antibacterial coating which coats the corrugated board, and the antibacterial coating is prepared from, by weight, 0.2-3% of clove extract, 0.4-4% of thymus serpyllum extract, 0.3-3% of lemon grass extract, 0.3-2% of prickly ash extract, 6-16% of moisture sensitive resin, 2-6% of beta-cyclodextrin, 0.02-2% of emulgator and 80-90% of distilled water. The production method includes: firstly, proportionally mixing all the components of the antibacterial coating with heating and stirring to produce a slow-releasing antibacterial coating solution; secondly, coating the corrugated board with the slow-releasing antibacterial coating solution to obtain the slow-releasing antibacterial corrugated board; finally, subjecting the antibacterial corrugated board to die cutting and creasing to produce the slow-releasing antibacterial fresh-keeping carton. The slow-releasing antibacterial fresh-keeping carton is applicable to fresh keeping of the agricultural products such as fruits and vegetables, and storage period of the fruits and vegetables can be prolonged by three to eight times.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Artificial quartz stone and preparation method thereof

The invention relates to an artificial quartz stone and a preparation method thereof. The quartz stone is composed of the main raw materials of, by mass: 3-10% of aqueous resin, a curing agent with a mass accounting for 5-200% of that of the aqueous resin, 55-65% of quartz sand, glass sand and mirror glass sand, 25-35% of quartz powder, a coupling agent with a mass accounting for 0.05-0.2% of the total mass of quartz sand, glass san, mirror glass sand, and quartz powder, and 1% of a color paste. The preparation method comprises the steps that: the raw materials are fetched according to mass percentages; the curing agent, the coupling agent, and the color paste are added into aqueous resin, and the mixture is uniformly dispersed; the mixture is mixed with already uniformly mixed quartz sand, glass sand and mirror glass sand; the mixture is well mixed; quartz powder is added; the mixture is well mixed by stirring, such that a half-dry material is obtained; the material is distributed by using a mold; and vacuuming, molding, curing, thickness setting, and polishing are carried out, such that a finished product is obtained. According to the invention, aqueous resin and a water solvent are used for replacing oleiferous resin and an organic solvent, such that the harm to the environment caused by evaporation of the organic solvent is solved, viscosity is reduced, and manufacturability is improved.

Owner:WUHAN UNIV OF TECH

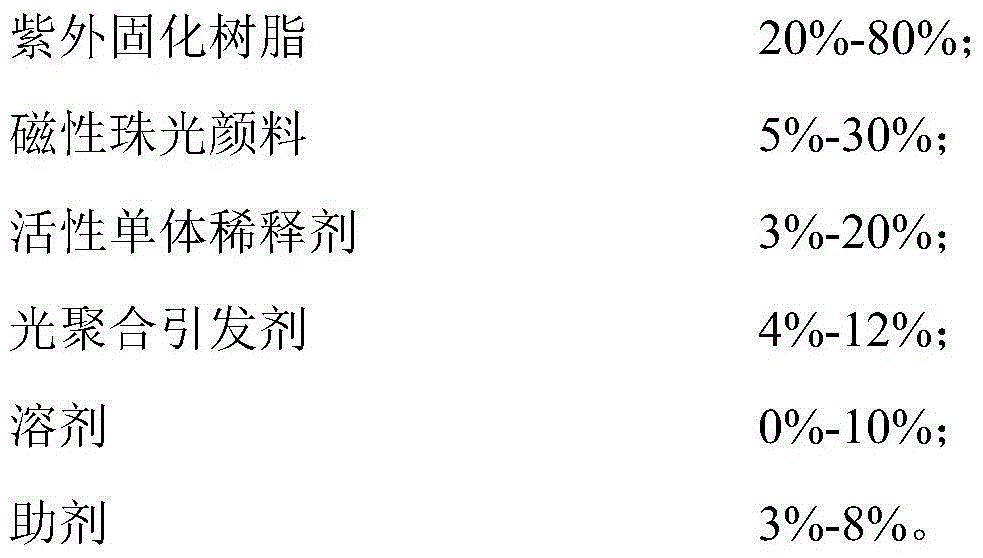

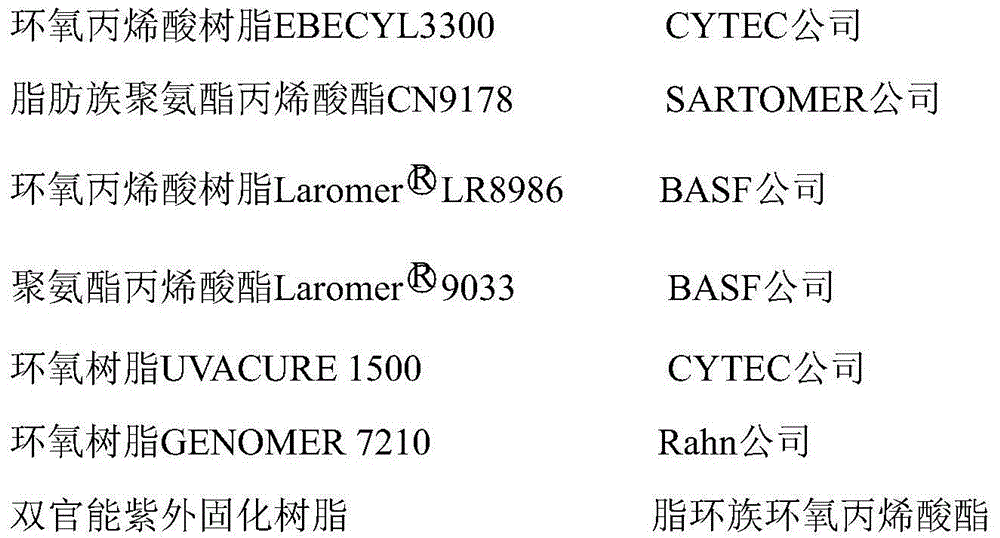

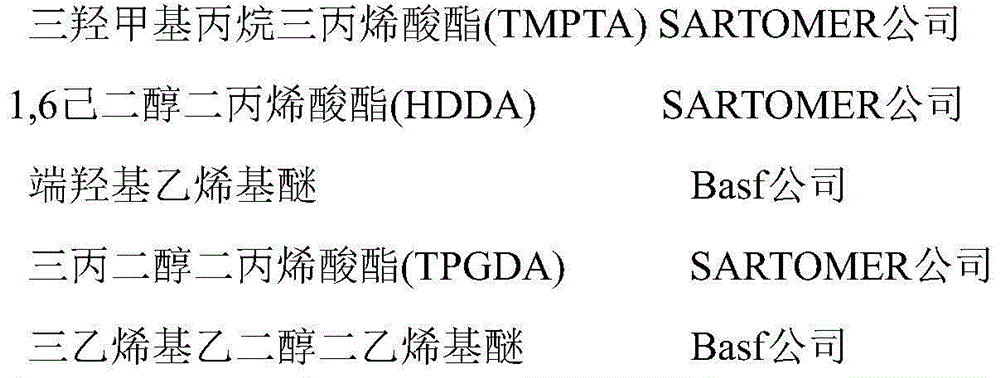

Cationic-radical UV (Ultraviolet)-cured magnetic pearly-luster silk screen ink and preparation method thereof

The invention discloses a cationic-radical UV (Ultraviolet)-cured pearly-luster silk screen ink and a preparation method thereof. The ink is prepared from the following components in percentage by weight: 20 to 80% of UV-cured resin, 5 to 30% of magnetic pearly-luster pigment, 3 to 20% of active monomer diluents, 4 to 12% of photoplymerization, 0 to 10% of solvent, and 3 to 8% of additive. The cationic-radical UV-cured magnetic pearly-luster silk screen ink has a dynamic optical effect that pear luster changes as the change changes and is easily recognized by the public; in addition, the ink has a post-curing characteristic through which the problem of easy falling and bubbling of the surface of an ink film at the part in which sheet-shaped magnetic pigments are vertically arranged can be solved.

Owner:CHINA BANKNOTE INK +1

Glass fiber reinforced poly(ethylene terephthalate)/polycarbonate alloy

The invention relates to a glass fiber reinforced poly(ethylene terephthalate) / polycarbonate alloy and a preparation method thereof. The alloy has the innovation point that the glass fiber reinforced poly(ethylene terephthalate) / polycarbonate alloy is prepared by employing a liquid-phase chemical deposition method to cover a rare earth compound layer on surfaces of glass fiber and glass microspheres, and processing with poly(ethylene terephthalate), polycarbonate, a flexibilizer, a nucleating agent and an anti-oxidant in a melt blending manner by a double-screw extrusion machine. The alloy can be subjected to injection molding at a mold temperature of 60 DEG C, has the characteristics of being low in warping property, free of micromolecule volatile matter during spraying, excellent in mechanical properties, high in thermal deformation temperature, stable in dimension and the like, and is applicable to injection molding of vehicle doors, wind shields, tyre guard boards and even whole vehicle bodies.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

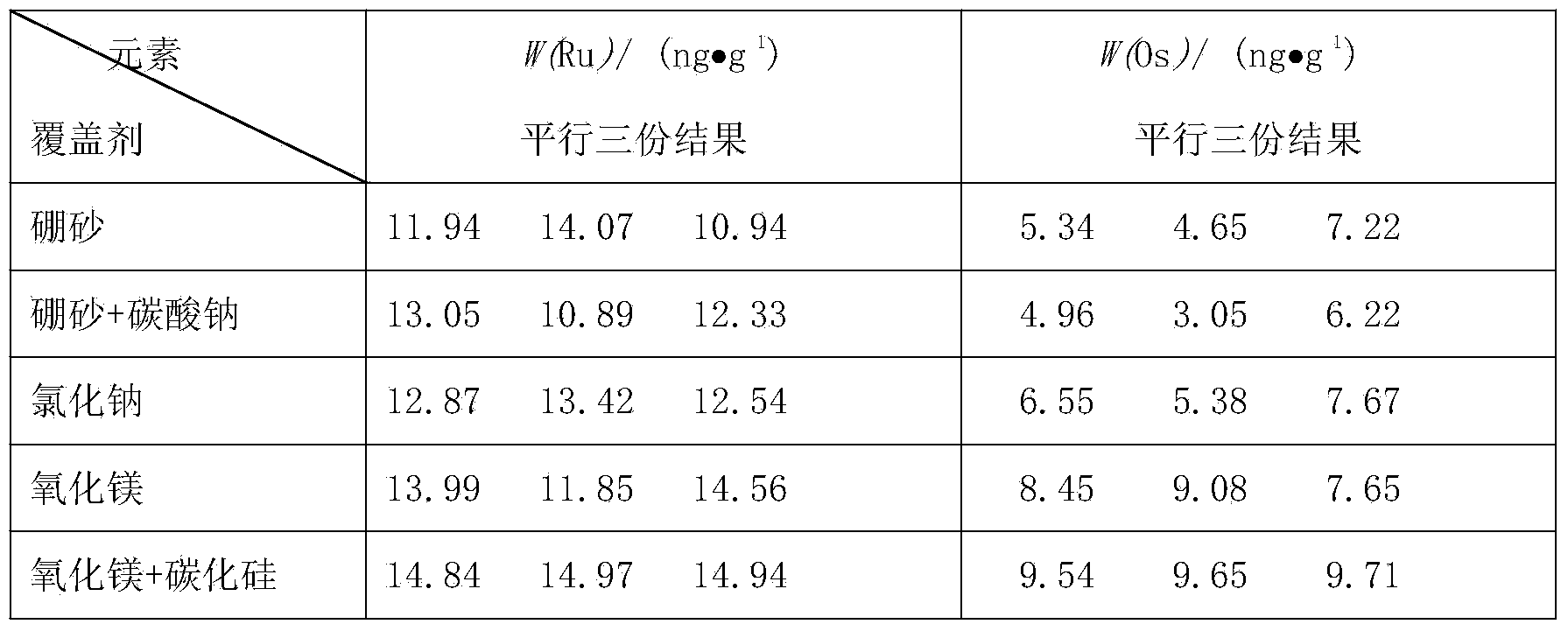

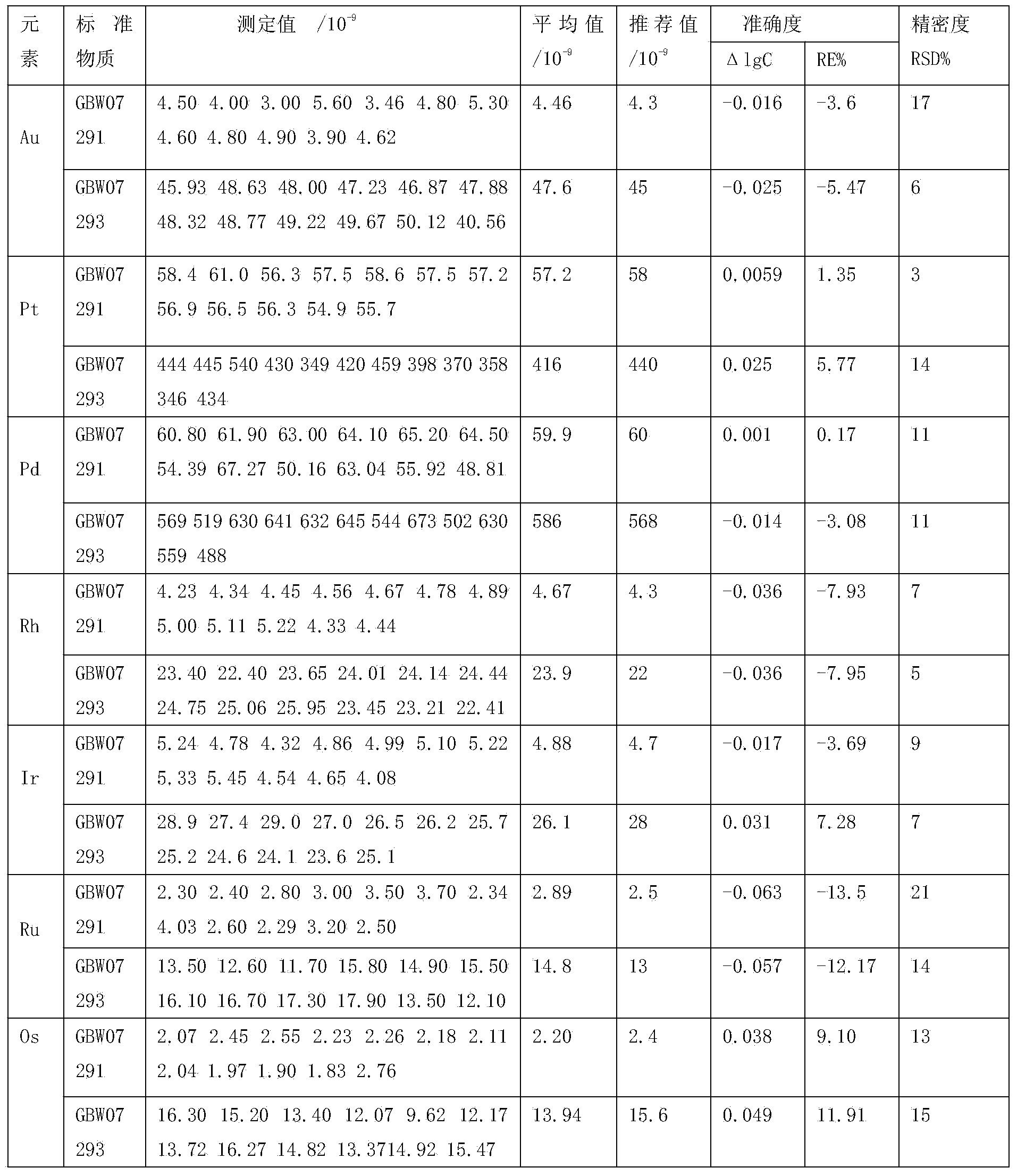

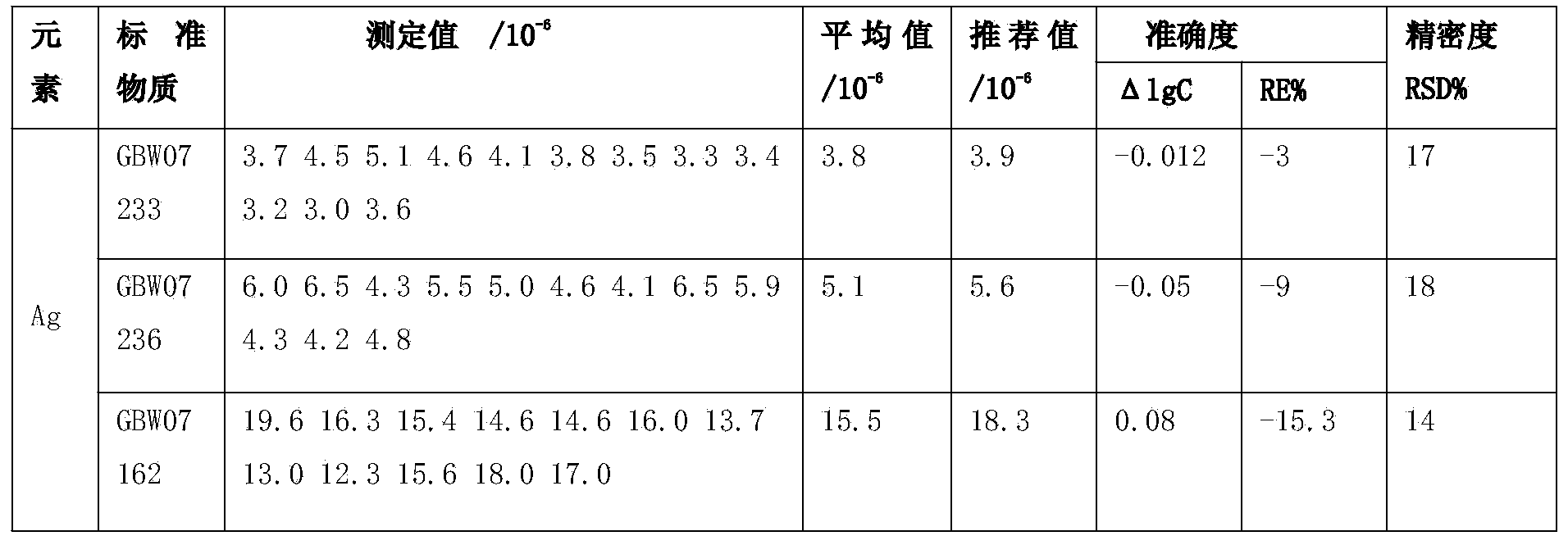

Method for determining content of noble metal in rock ores by fire assaying method

InactiveCN103884769AQuantitative captureSolve the problem of volatilityPreparing sample for investigationMaterial analysis by electric/magnetic meansAnalysis methodMaterials science

The invention discloses a method for determining the content of noble metal in rock ores by a fire assaying method. The method takes light magnesium oxide and silicon carbide which have reducing actions as covering agents so as to realize an analysis method for determining eight noble metal elements in a rock ore sample by primary separation. The method disclosed by the invention can be accurate and efficient and is suitable for a technology for analysis and testing work of the noble metal elements in various rock ore samples.

Owner:河南省岩石矿物测试中心

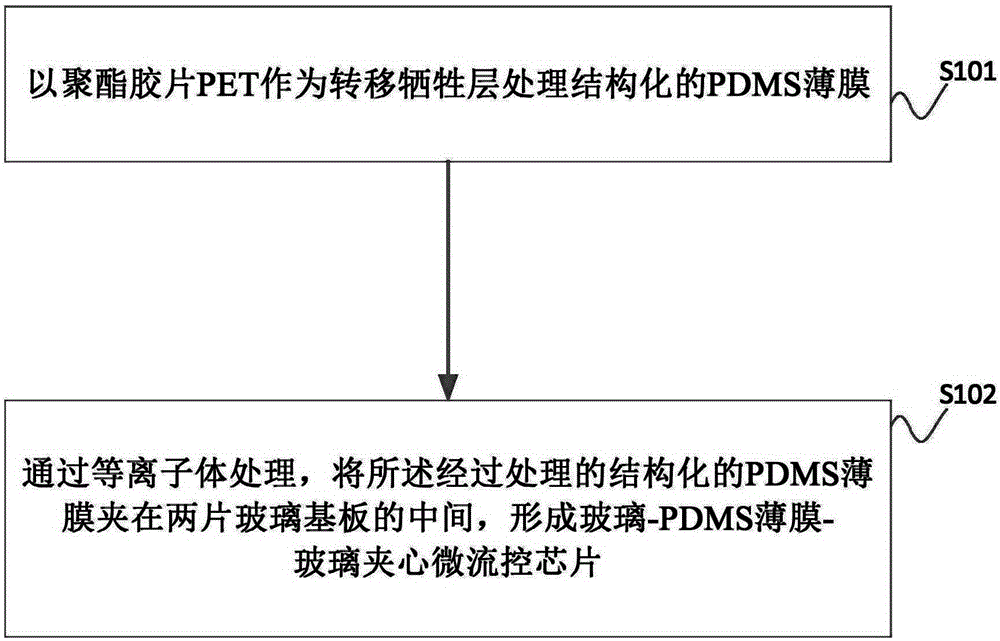

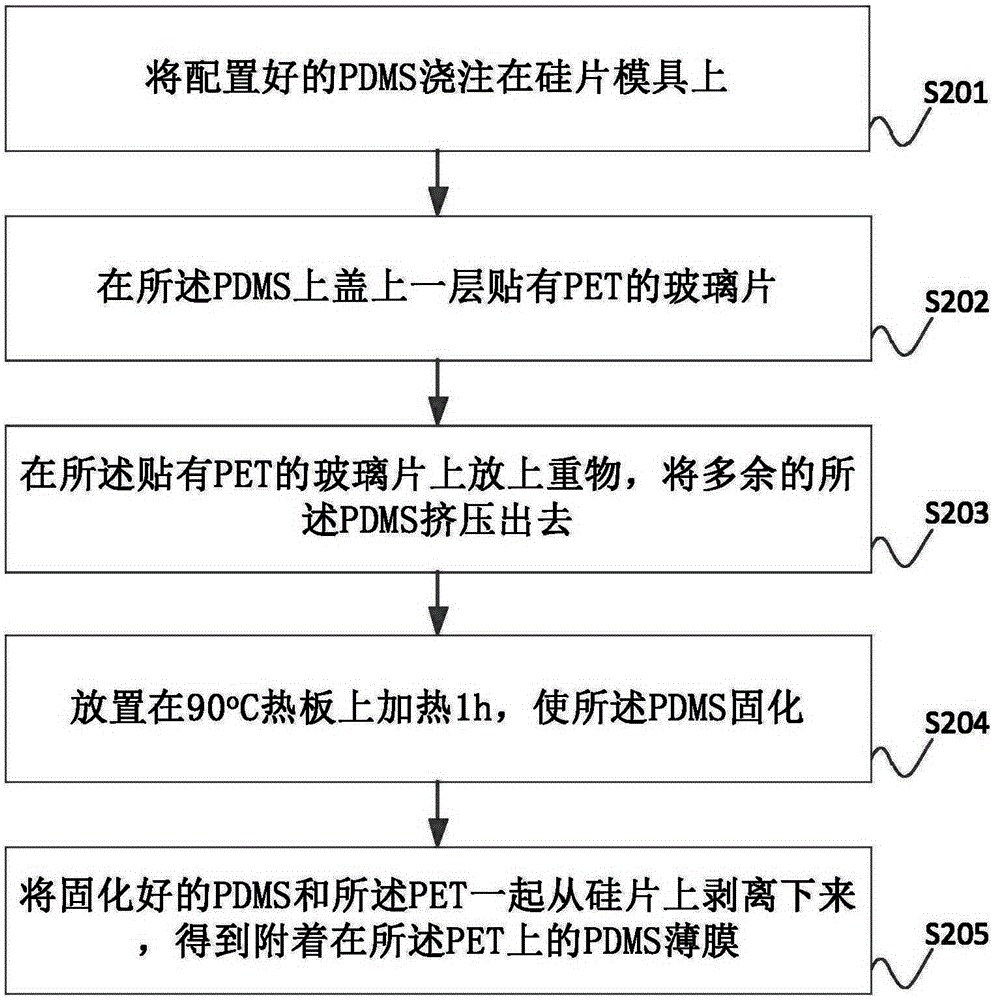

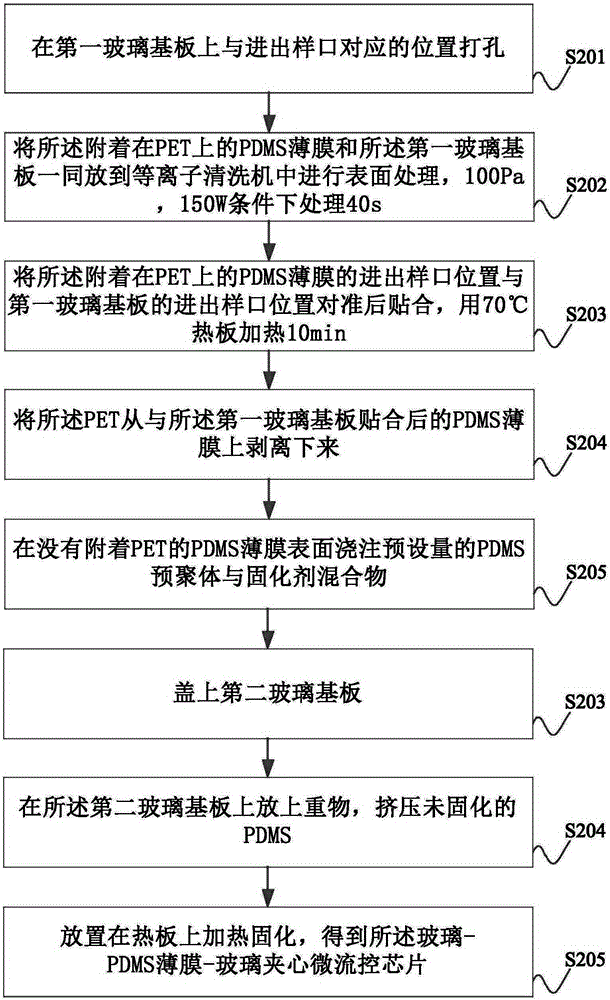

Glass-PDMS film-glass sandwich microfluidic chip manufacturing method

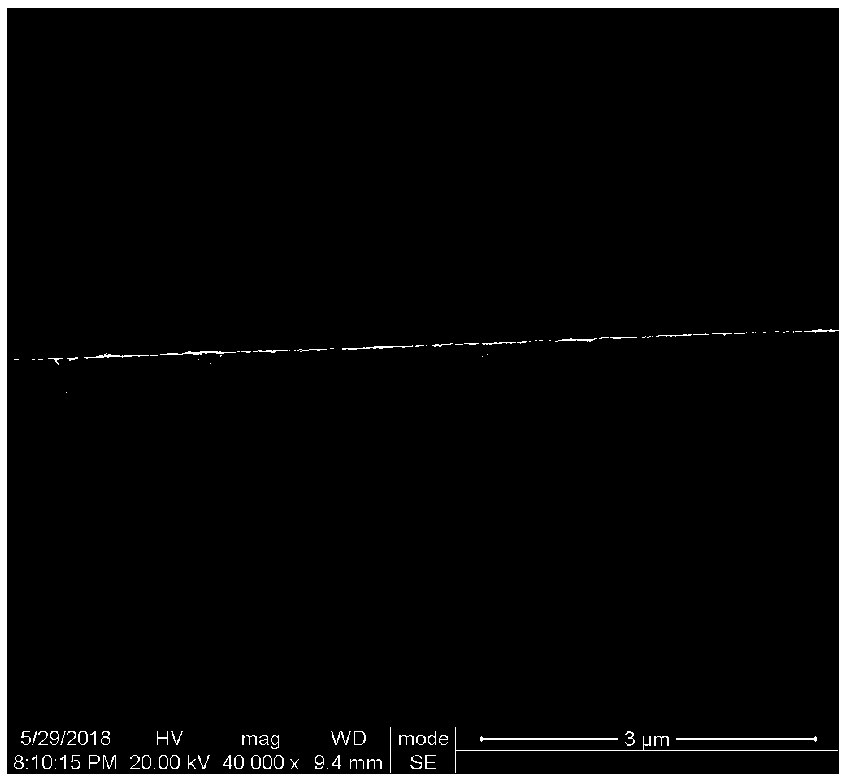

ActiveCN105233888AThe production process is simpleReduce volatilityLaboratory glasswaresPolyesterThin membrane

The invention provides a glass-PDMS film-glass sandwich microfluidic chip manufacturing method. A polyester PET sheet is used as a transferring sacrificial layer to treat a structured PDMS film, and through plasma processing, the treated structured PDMS film is sandwiched between two glass substrates so that a glass-PDMS film-glass sandwich microfluidic chip is formed. Through ingeniously use of PET as a carrier for transferring a treated delicate structured PDMS film so that high efficiency transferring of the structured PDMS film is realized, a structured PDMS film manufacturing process is simplified and technology difficulty and a time cost are reduced. Through plasma processing, the structured PDMS film is sandwiched between two glass substrates so that the glass-PDMS film-glass sandwich microfluidic chip is formed. A glass material has low permeability so that the chip has low solvent volatility and the problem of PDMS microfluidic chip solvent volatilization is solved.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

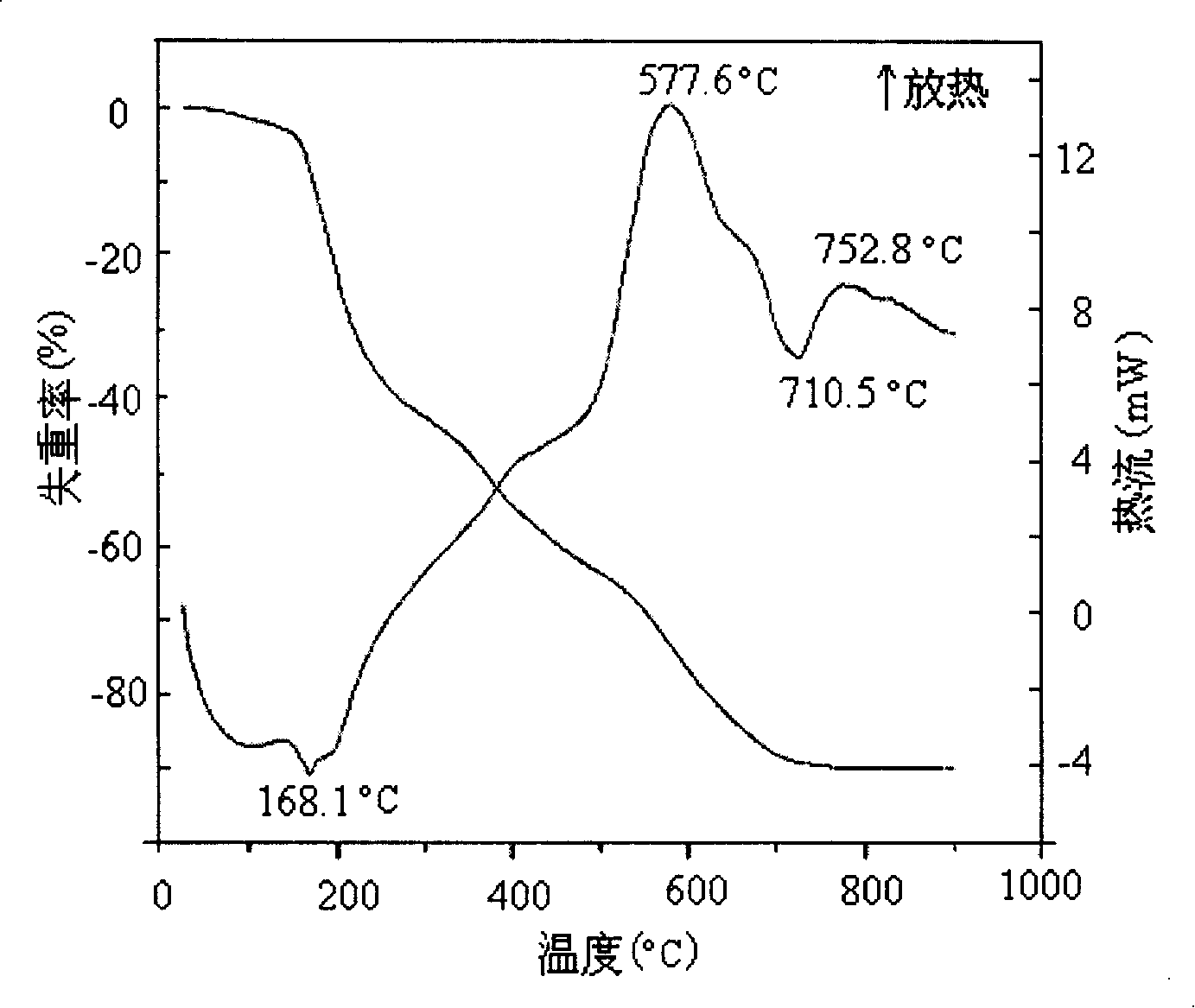

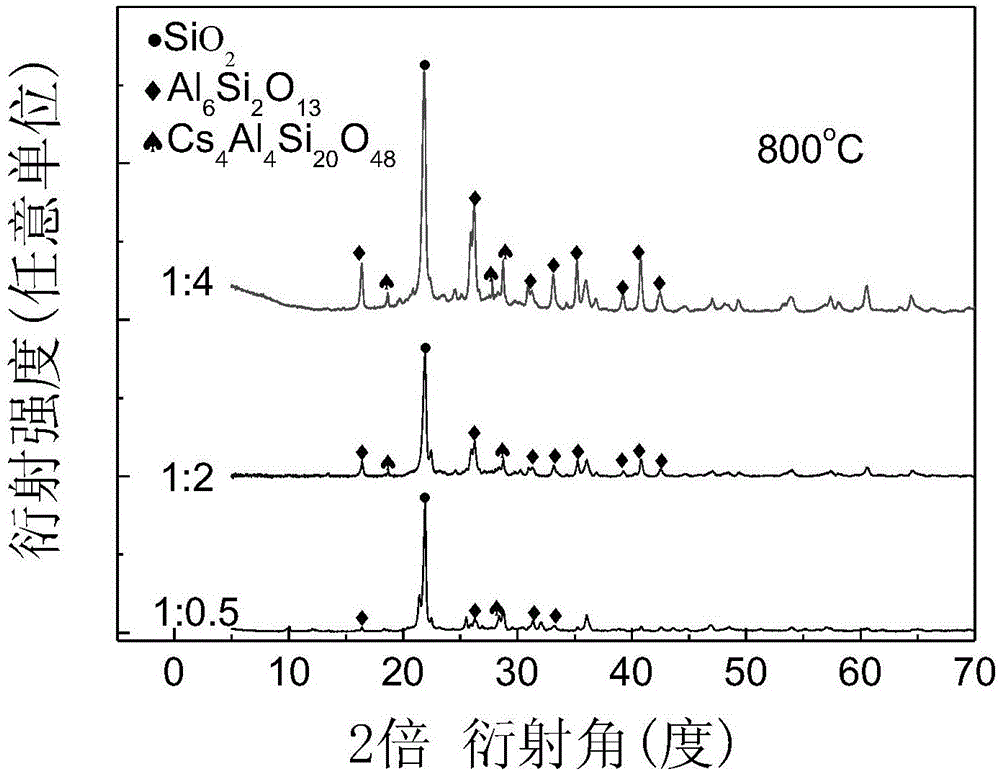

Preparation method for strontium-cesium co-solidified body

ActiveCN102208223AReduce volatilitySolve the problem of volatilityRadioactive decontaminationCaesium nitrateRoom temperature

The invention belongs to the technical field of industrial treatment of nuclear waste and discloses a preparation method for a strontium-cesium co-solidified body. In the method, a modified ZSM-5 zeolite serves as a substrate to adsorb Sr and Cs; and the method comprises the following steps of: treating the ZSM-5 zeolite with a HNO3 solution; preparing a mixed solution of a strontium nitrate solution and a cesium nitrate solution in a ratio of 5 to 15 weight percent of strontium oxide and 5 to 15 weight percent of cesium oxide based on the strontium-cesium co-solidified body, adding the modified ZSM-5 zeolite, stirring, aging, standing, stirring, evaporating, and drying to obtain a strontium-cesium co-solidified precursor; and heating and calcining the strontium-cesium co-solidified precursor according to a certain process and cooling naturally to the room temperature to obtain a strontium-cesium solidified polycrystal. High-temperature calcining for preparing the co-solidified body is avoided, so that the problem of Cs volatilization is solved, the aim of solidifying Sr at the same time is fulfilled and the experimental safety and operability under a radioactive condition are ensured; and the method is applicable for solidifying the strontium solution and the cesium solution which are separated from the unclear waste.

Owner:TSINGHUA UNIV

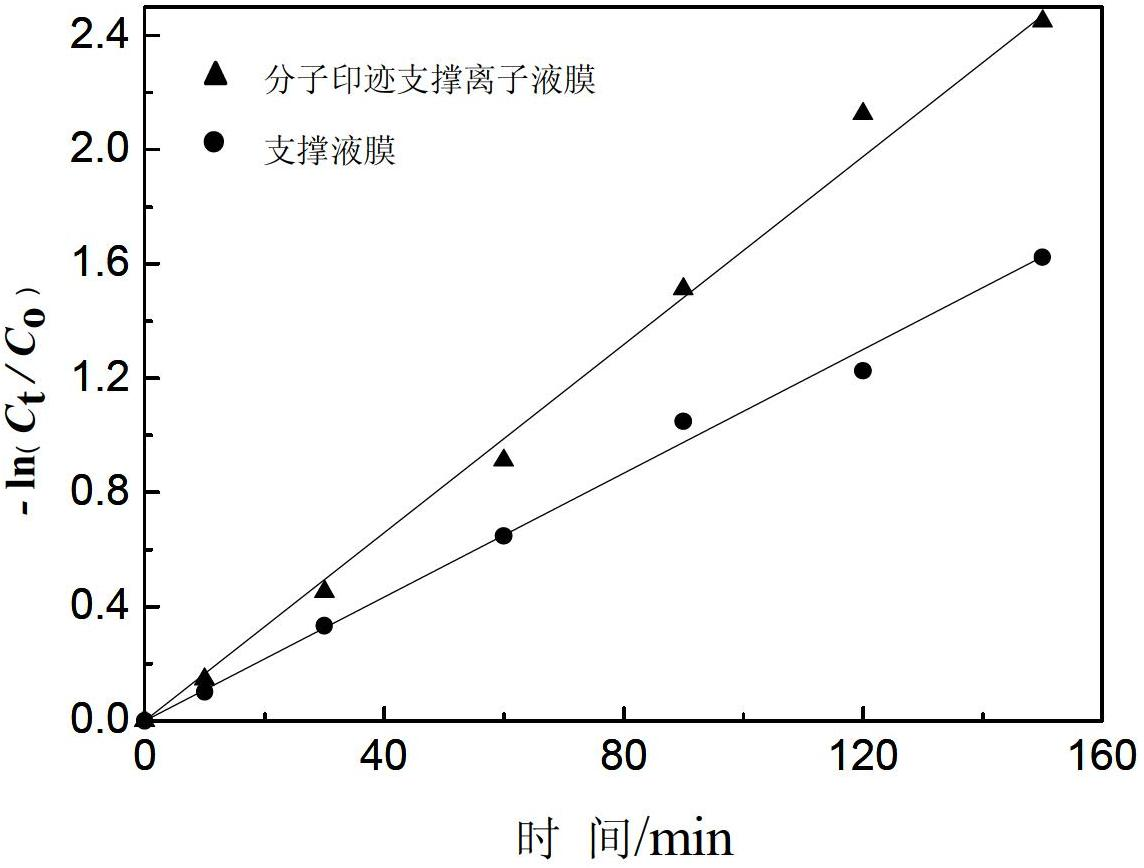

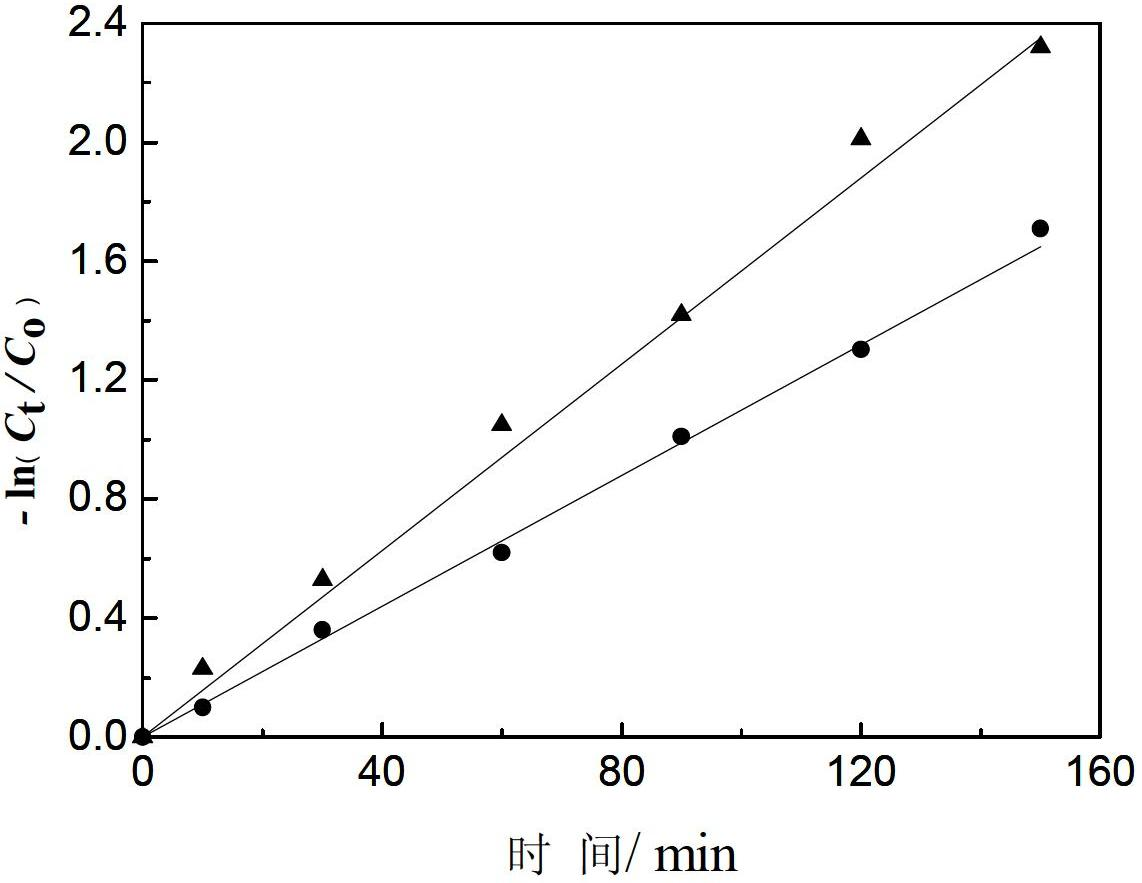

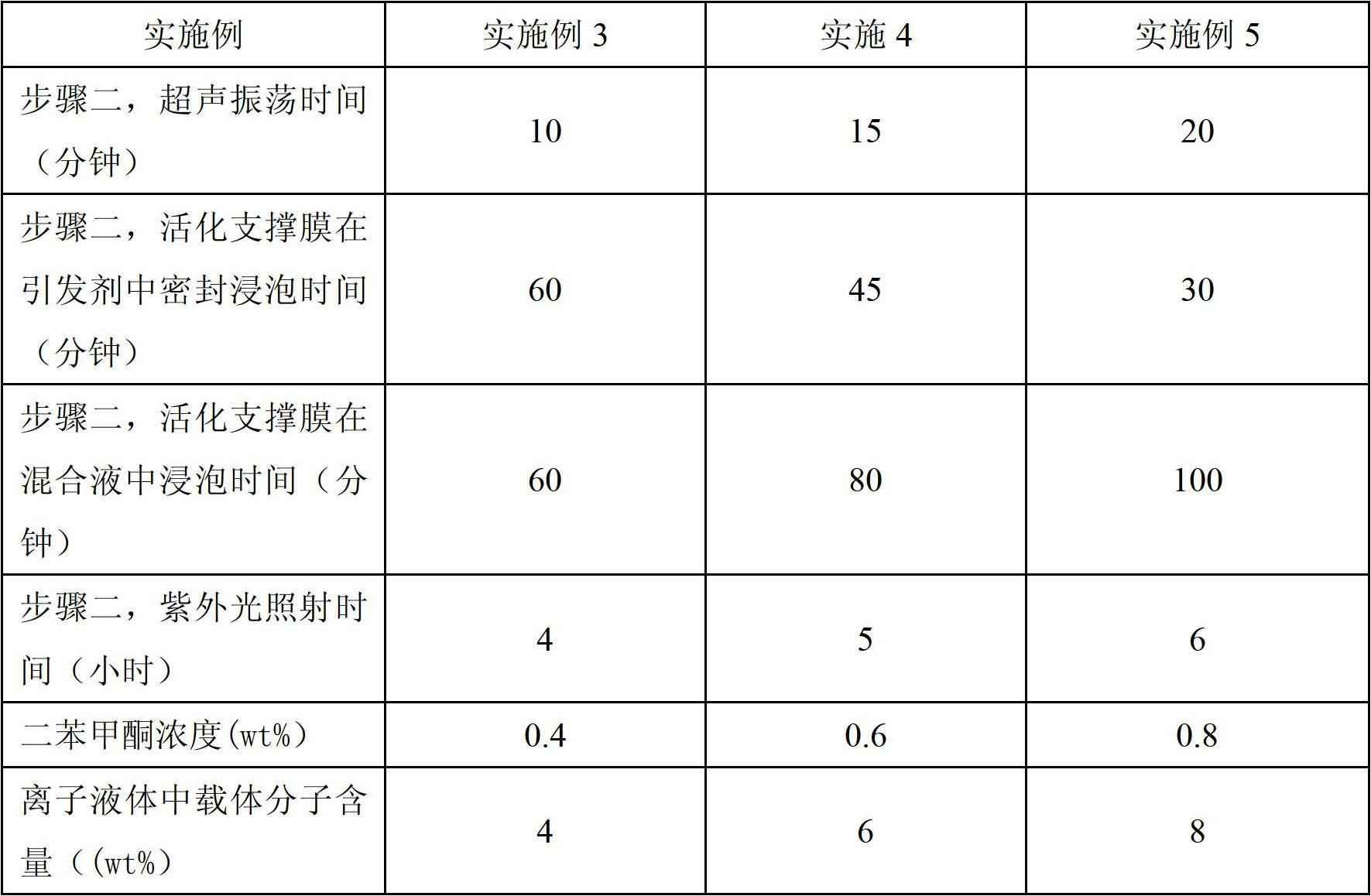

Method for preparing modified supported liquid membrane

InactiveCN102688696AHigh selectivityHigh mass transfer fluxSemi-permeable membranesCross-linkFunctional monomer

A method for preparing a modified supported liquid membrane is characterized in that an activation support membrane is soaked in an initiating agent and then is placed in a mixed solution containing template molecules, functional monomers, porogen and cross-linking agents for soaking, afterwards, the activation support membrane is taken out and reacts under irradiation of ultraviolet light to obtain a molecular imprinting support membrane, and after template molecules are removed, the molecular imprinting support membrane is soaked in ionic liquid to obtain a molecular imprinting support ionic liquid membrane. According to the invention, molecular imprinting and ionic liquid are combined to obtain the molecular imprinting support ionic liquid membrane; through the characteristics of the molecular imprinting technology and ionic liquid at ambient temperature, a modification technology is adopted to perform molecular imprinting molecular modification to the surface of a porous support body, and then a layer of dense film having special selectivity to template molecules can be formed, so that not only can the stability of the supported liquid membrane be improved, but also the selectivity, the mass transfer rate and the pollution-resistant capability of the supported liquid membrane can be improved.

Owner:XIAN UNIV OF TECH

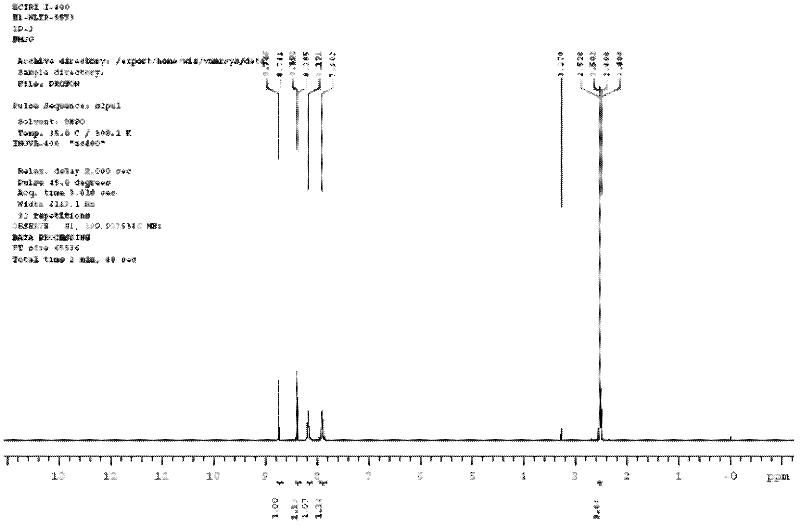

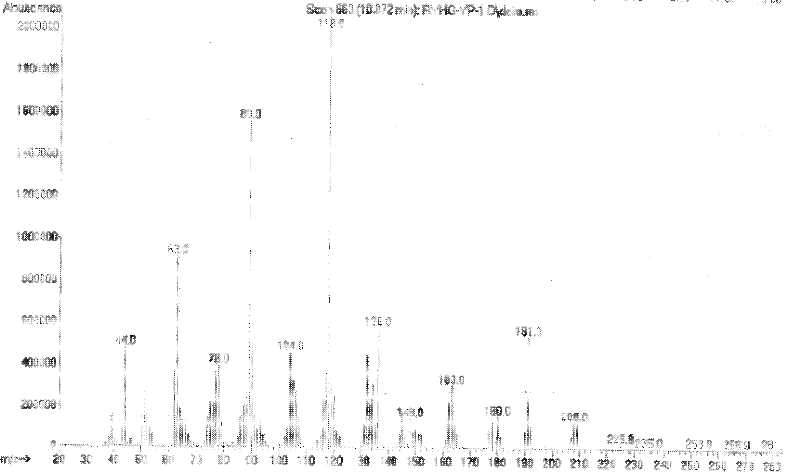

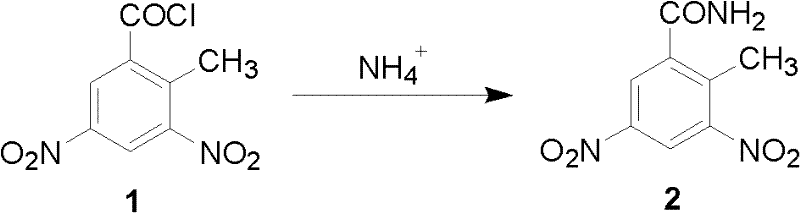

Preparation method of 3, 5-binitro-2-methyl benzamide

InactiveCN102531945AEasy to quantitative controlSolve the problem of volatilityOrganic compound preparationCarboxylic acid amides preparationSynthesis methodsBenzoyl chloride

The invention discloses a preparation method of 3, 5-binitro-2-methyl benzamide, which includes the following steps: 3, 5-binitro-2-methyl benzoyl chloride is slowly and dropwise added to ammonium salt aqueous solution with the mass concentration of 10% to 40%, reaction is conducted for 0.5 hour to 3 hours at the temperature of 10 DEG C to 50 DEG C, after reaction is finished, reaction liquid is filtered, and filter cake is dried to obtain 3, 5-binitro-2-methyl benzamide. The time for dropping 3, 5-binitro-2-methyl benzoyl chloride is 0.5 hour to 3 hours, and the proportion of the amount of 3, 5-binitro-2-methyl benzoyl chloride to the amount of an ammonium salt feeding material is 1:1-6. The preparation method of 3, 5-binitro-2-methyl benzamide uses ammonium salt aqueous solution as an amination reagent, thereby facilitating quantitative control of feeding volume, saving cost, avoiding the problem of ammonia volatilization, and being an environment-friendly, green and efficient synthesis method of Zoalene.

Owner:ZHEJIANG RONGYAO CHEM

Impregnating-reinforced composite floorboard as well as preparation method and equipment thereof

InactiveCN101585202ASolve the problem of volatilityWood veneer joiningPressure impregnationPolymer scienceSingle plate

The invention provides a preparation method of an impregnating-reinforced composite floorboard. The floorboard comprises a basal board and a surface board which is arranged on the basal board and formed by compounding one or more layers of veneers. The floorboard is prepared by the following steps: providing one or more layers of veneers and an impregnating solution comprising 100 portions of polymer monomer, 0-0.5 portion of initiator, 0-10 portions of oil soluble dye and 0-10 portions of floorboard addition agent by weight portion; providing a closed space and impregnating one or more layers of veneers in the impregnating solution in the closed space to trigger the polymerization of the polymer monomer and obtain the impregnating surface board; and gluing the surface board and the basal board to obtain the impregnating-reinforced composite floorboard. The preparation method of the impregnating-reinforced composite floorboard can improve the utilization rate of the monomer, solves the problem of environmental pollution caused by monomer volatilization and enhances the performance of the floorboard in hardness, surface impact, abrasion resistance, and the like.

Owner:SHANGHAI FINE FURNITURE

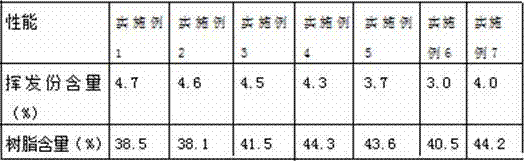

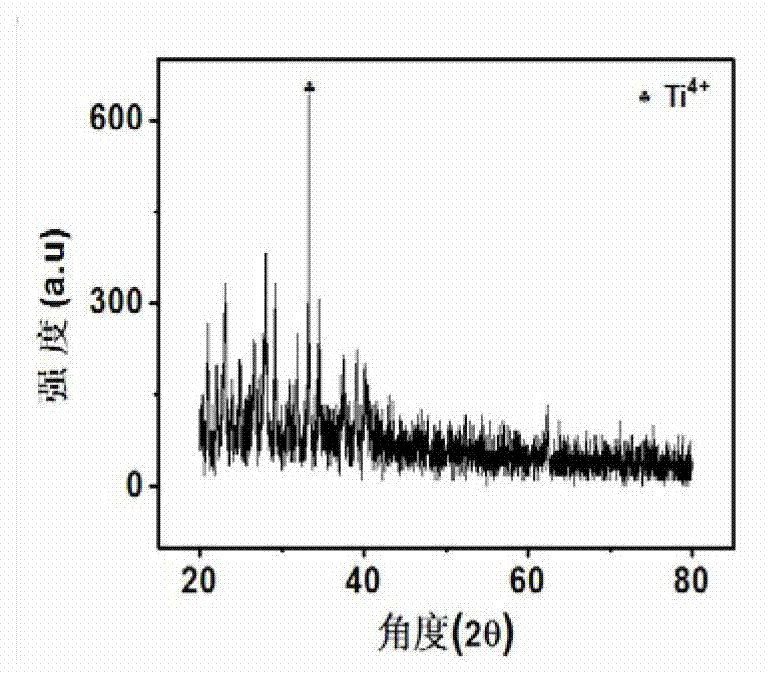

Phenolic resin prepreg and method for preparing phenolic composite material from same

ActiveCN107446304AHigh molecular weightImprove product qualitySynthetic resin layered productsLaminationVacuum pumpingMoisture permeability

The invention discloses a phenolic resin prepreg and a method for preparing a phenolic composite material from the phenolic resin prepreg. The prepreg comprises the following components by weight: 50 to 65 parts of a fabric, 20 to 48 parts of phenolic resin and 1 to 5 parts of a thickening agent. A vacuum bag molding and curing process is employed for preparation of the phenolic composite material from the phenolic resin prepreg. A microporous membrane is adopted in the process, and the microporous membrane has a micropore diameter of 0.1 to 10 [mu]m, a thickness of between 2 to 300 [mu]m and porosity of 50% to 80%; since the micropore diameter is tens of thousands of times the diameter of a liquid molecule and is several hundred times smaller than the diameter of a water droplet, the microporous membrane has excellent moisture permeability, air permeability and droplet permeation resitance, so volatile gas is drawn out while liquid resin components are not drawn out during vacuum pumping; and thus, the problem of nonuniform distribution of resin caused by drawing-out of resin is avoided, and wasting of materials and the amount of produced waste are reduced.

Owner:陈精明

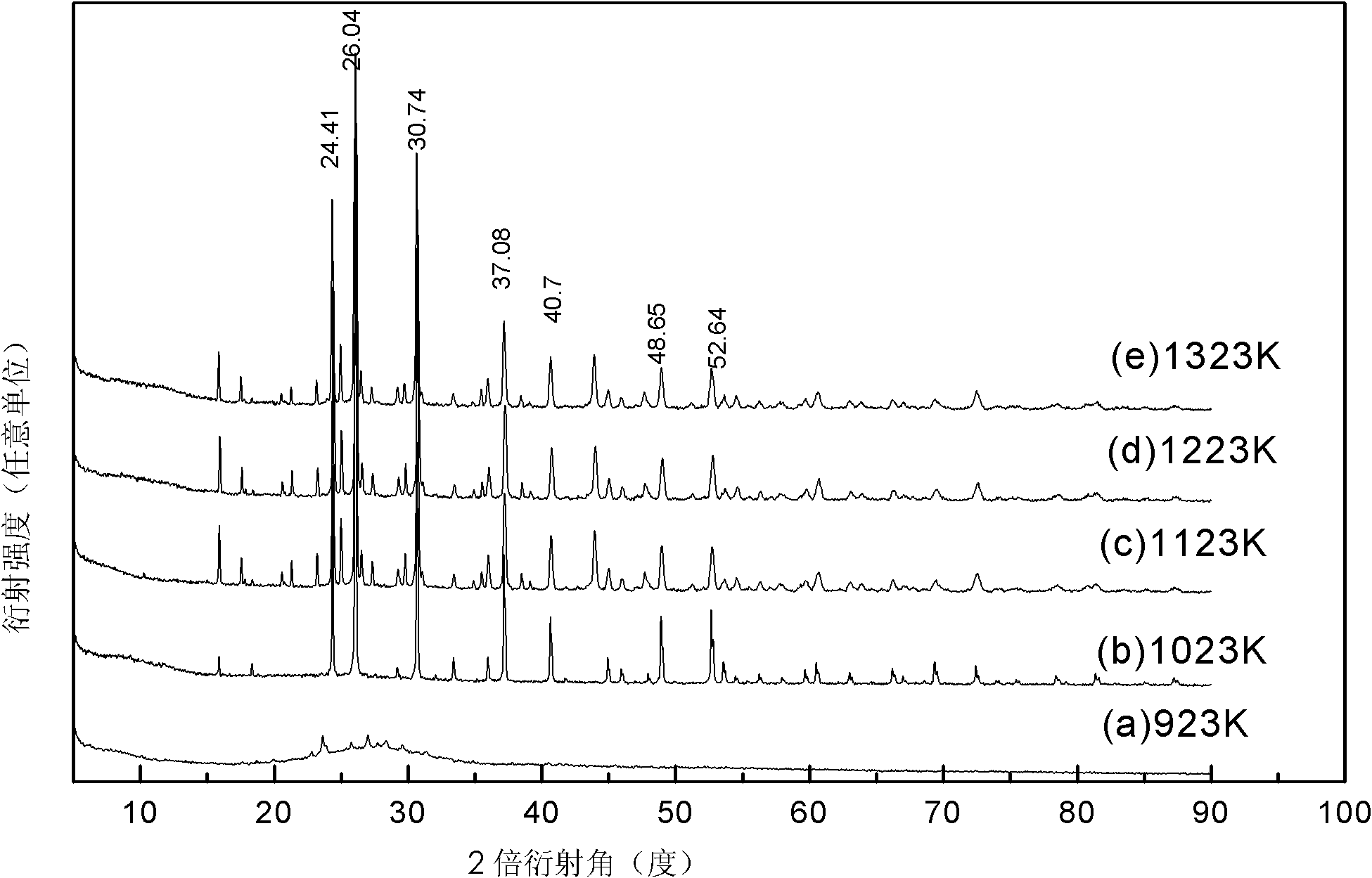

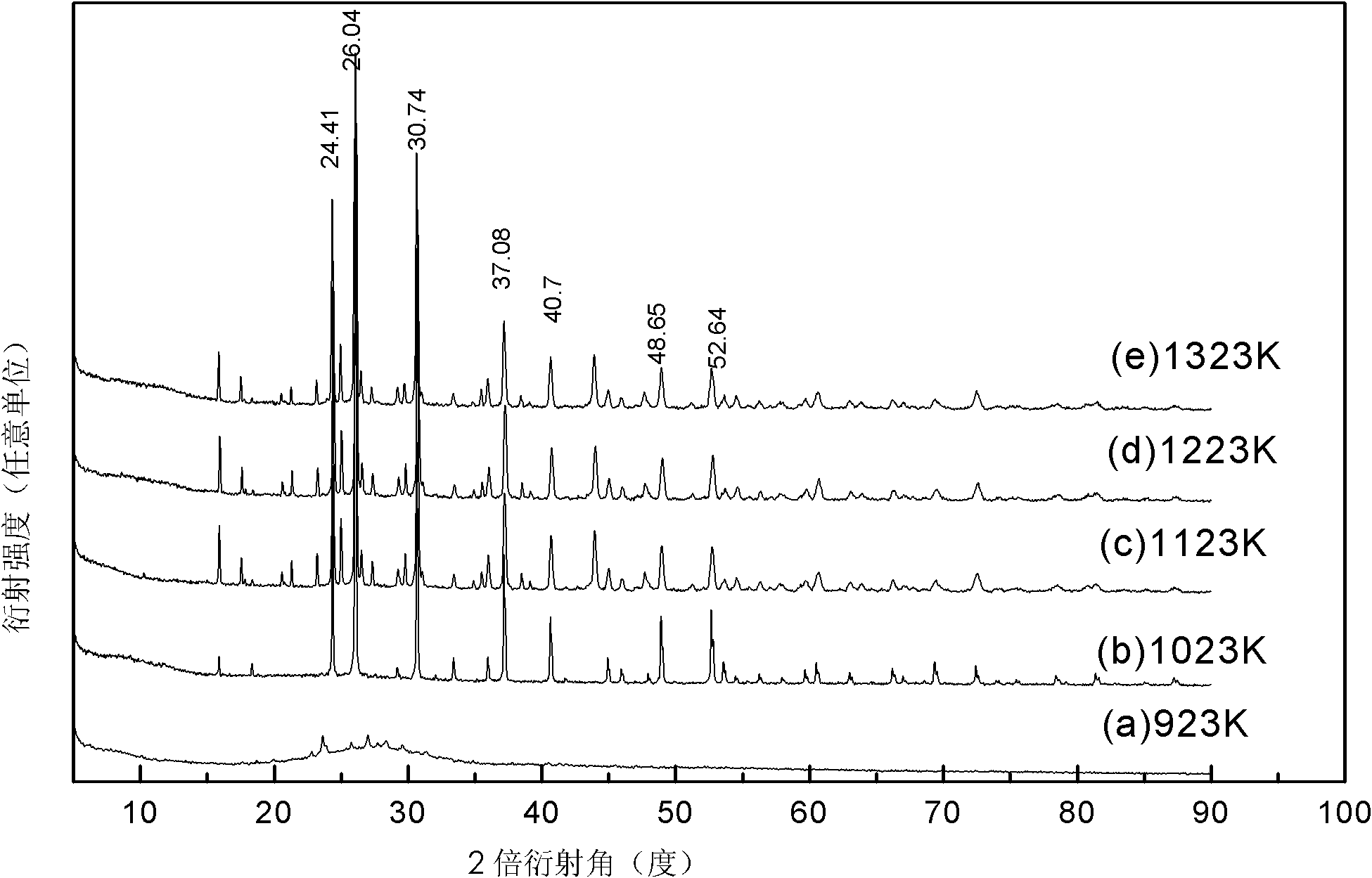

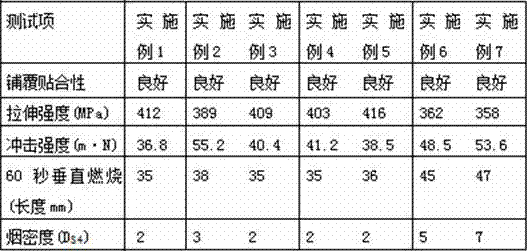

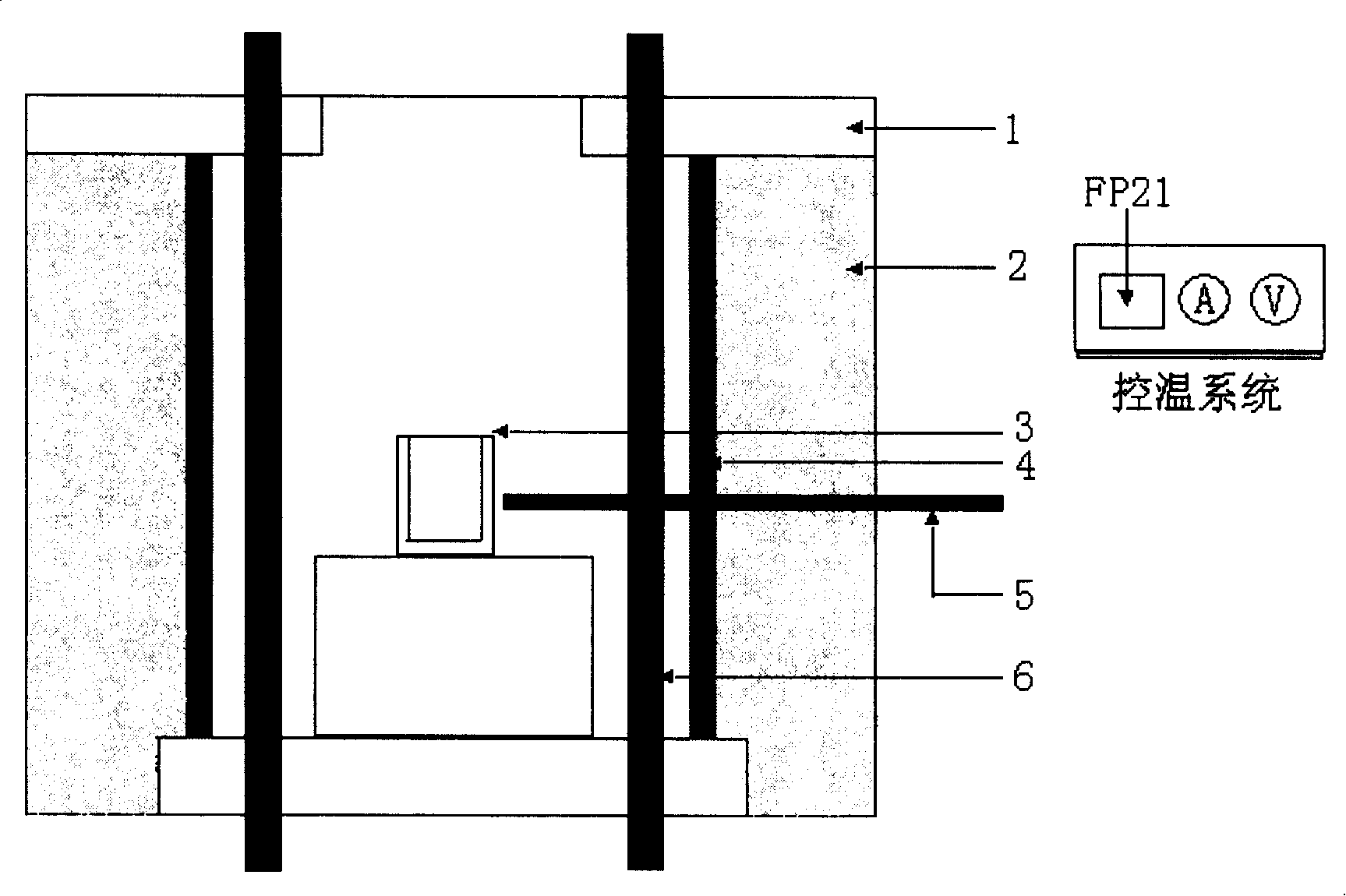

Environment-coordinating method for preparing titanate piezoelectric ceramic powder

InactiveCN102898147AAvoid defectsGo greenPiezoelectric/electrostrictive/magnetostrictive devicesSpontaneous combustionElectricity

The invention discloses an environment-coordinating method for preparing titanate piezoelectric ceramic powder, and the method is characterized in that lactic acid is chelating agent, swelling agent and pore-forming agent, sol is prepared under the normal temperature by utilizing a sol-gel method, after the pH value is adjusted, the sol is vacuum concentrated or removed with solvent under constant pressure to obtain gel, the gel is processed through unique swelling process and spontaneous combustion way under the temperature of 180 DEG C to 200 DEG C to obtain a nano pyrophoric material, and the pyrophoric material is pre-burned to obtain nano powder under the temperature of 550DEG C to 600DEG C; and the powder is processed through procedures such as granulating, tabletting, plastic releasing and the like to obtain a green sheet, the green sheet is sintered for 1 to 2h under the condition of 950DEG C to 1025DEG C to obtain a ceramic sheet, and the ceramic sheet is polarized in normal-temperature silicon oil to obtain the titanate piezoelectric ceramic powder after standing. The method has important practical significance for traditional piezoelectric ceramic production process to realize high quality, low energy consumption, low cost and environmental friendliness; and meanwhile, an important innovation effect for the titanate compound application field seeking no conglobation and having ultra-large specific surface area can be achieved.

Owner:CHINA WEST NORMAL UNIVERSITY

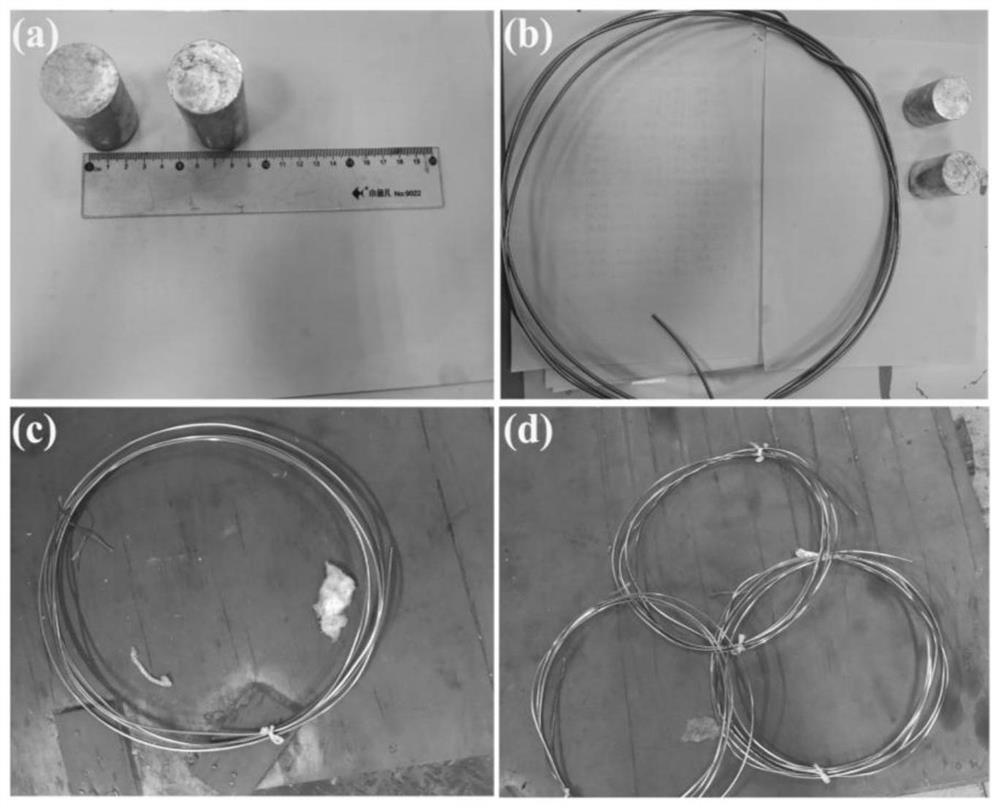

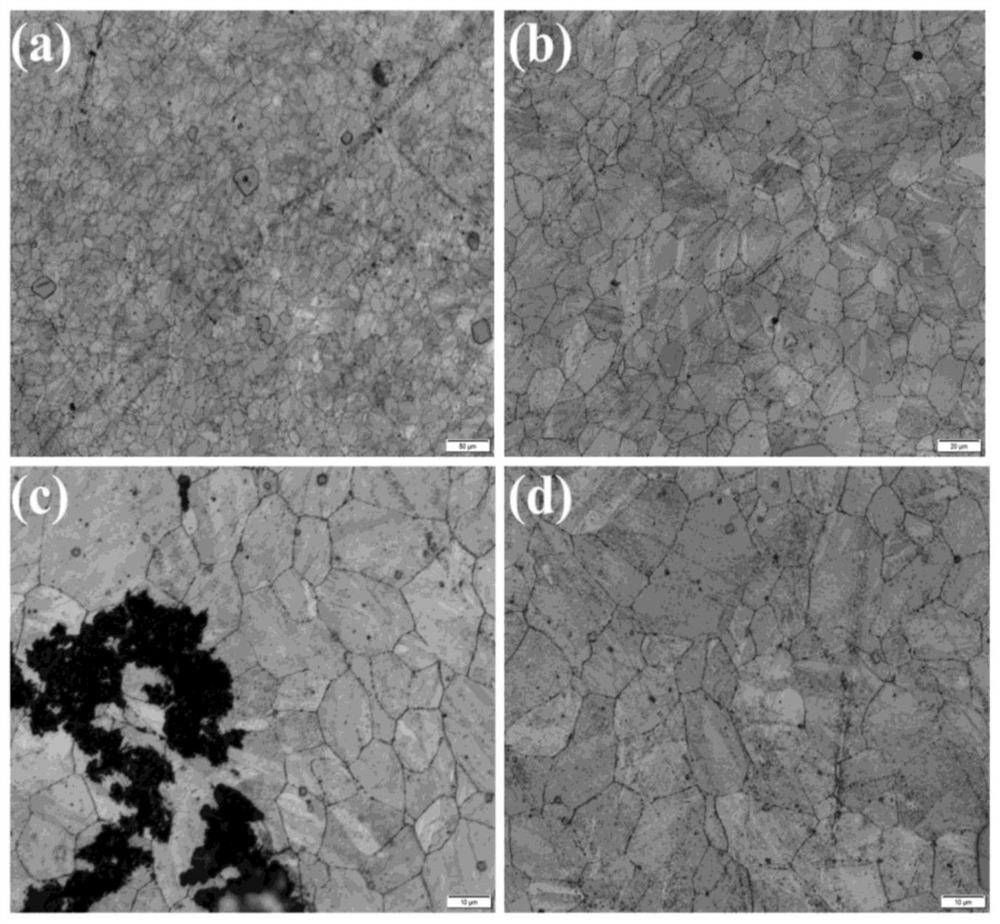

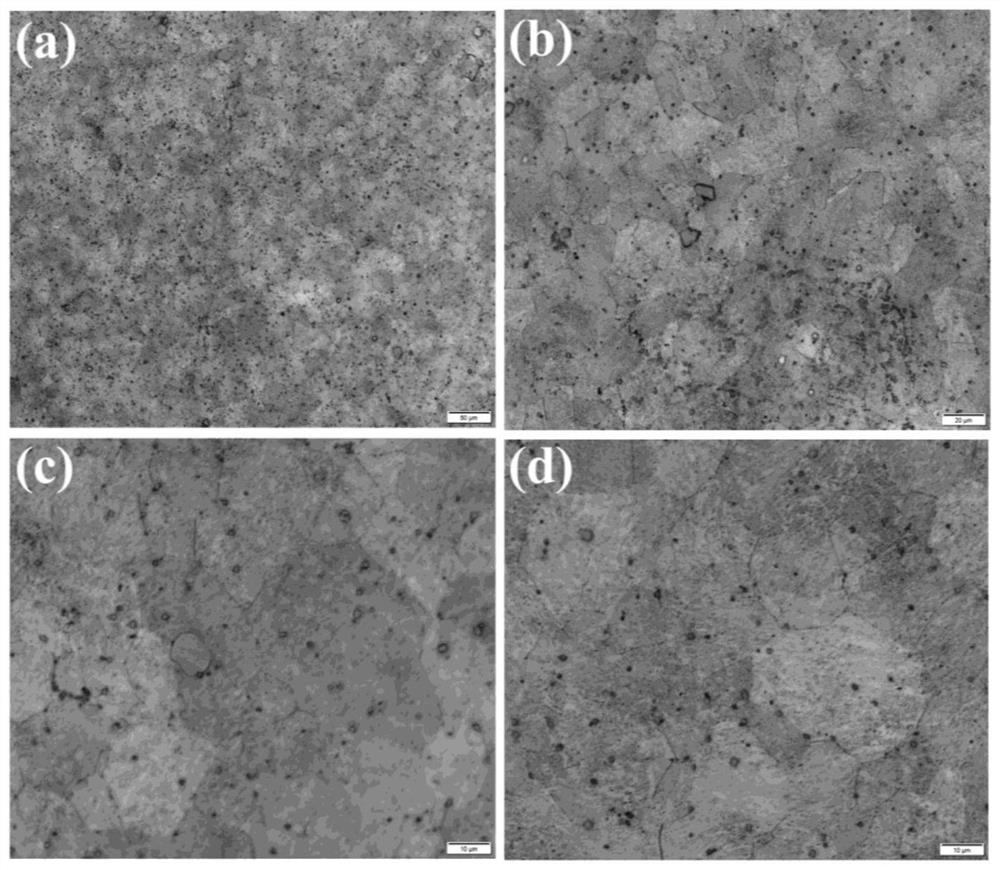

Preparation method of 3 mm Zn-Cu-Ti alloy wire for spraying

InactiveCN112143923ASolve the problem of volatilityReduce production processMolten spray coatingExtrusion diesElectric arc furnaceSmelting process

Owner:CHINA UNIV OF MINING & TECH

Method for preparing protolignin by using corn cob residues

The invention discloses a method for preparing protolignin by using corn cob residues, by which lignin in corn cob residues are effectively separated by taking high-boiling alcohol as a solvent and under the action of a catalyst. According to the invention, the biomass resources of waste gas are fully used, and lignin in corn cob residues is effectively separated. By detecting, the ash content of obtained lignin is low, the molecular weight of the lignin is about 5000, and the dispersancy index of the lignin is about 1, so that the obtained lignin is high in purity, good in activity, and narrow in molecular weight distribution, therefore, the lignin is a high-quality lignin. According to the invention, the problems of environmental pollution and cost raise caused by the volatilization of low-boiling-point solvents are solved; and because used solvents are high-boiling-point solvents and water, the problems of volatilization and cycle use of the solvents are effectively solved. The method disclosed by the invention solves the problem of corn cob residue resource waste, and the extraction rate of lignin in corn cob residues is 60-75%.

Owner:ZHENJIANG BIO INNOVA BIOTECH

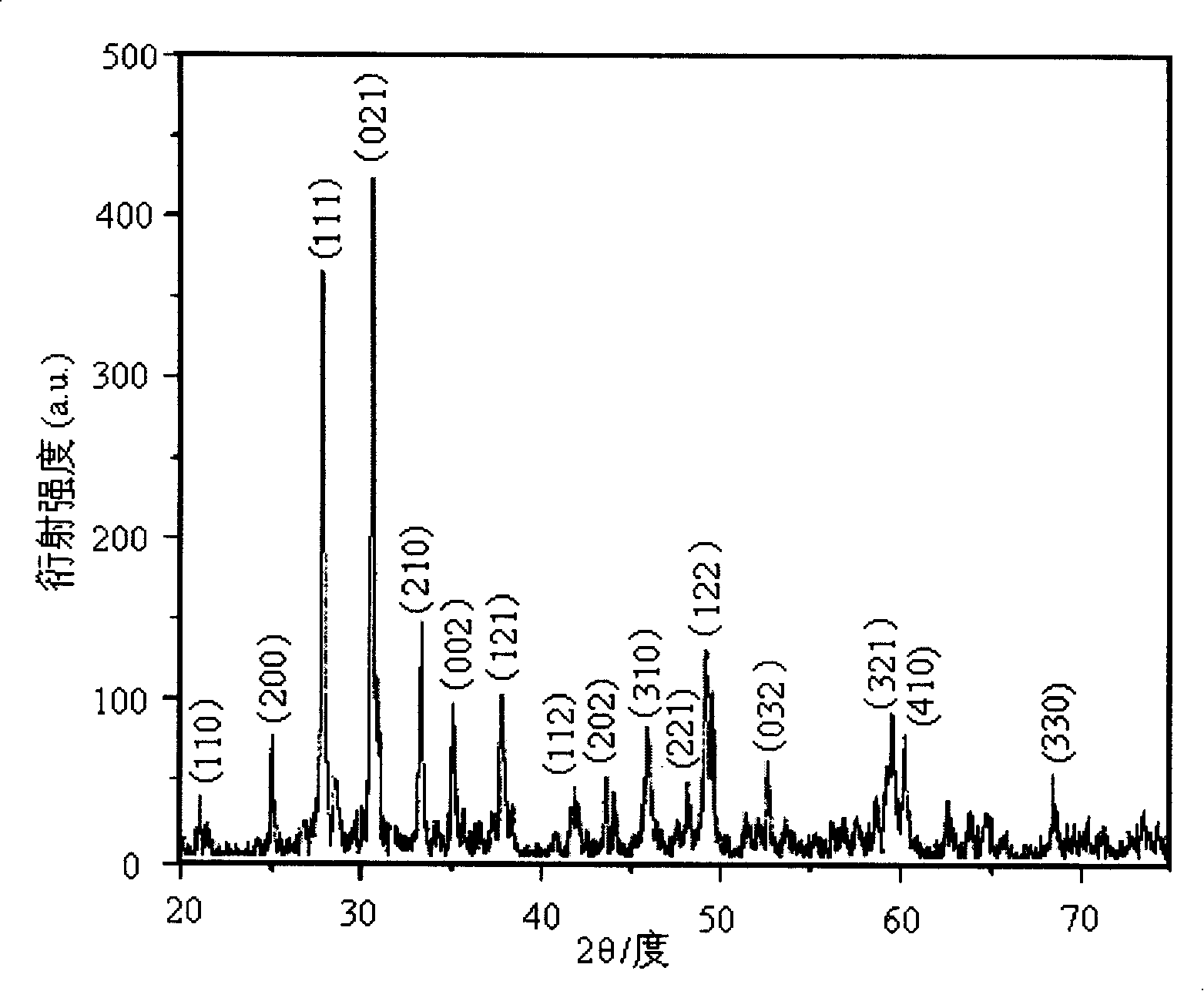

Method for preparing gallium lanthanum niobate series nano powder

InactiveCN101190798AHigh puritySolve the problem of volatilityGallium/indium/thallium compoundsRare earth metal compoundsHydrofluoric acidCITRATE ESTER

A preparation method of nanometer powder of langanite series pertains to the technical field of the preparation of crystal growth material. The nanometer powder series comprises La3Ga5.5Nb0.5O14 (LGN), La3Ga5.5Ta0.5O14 (LGT) and La3Ga5SiO14 (LGS). The invention adopts citrate gel method to prepare the nanometer powder at a low temperature. Nb2O5, Ta2O5 or SiO2 is dissolved in concentrated hydrofluoric acid and then ammonium oxalate and ammonia are added to form sediment which is then dissolved in citrate solution. Gallium nitrate solution and lanthanum nitrate solution are then added and next the citrate is added and mixed evenly; then the gel is obtained after the solution is heated; the gel is kept at certain temperature to obtain foam-shaped fluffy solid which is calcined to obtain the nanometer powder. The synthesis of the method of the invention can be done at the low temperature to obtain the nanometer powder of langanite series with comparatively higher purity as the raw material for crystal growth, which dramatically improves the uniformity of the components of the crystal and reduces the cost of crystal growth.

Owner:SHANDONG UNIV

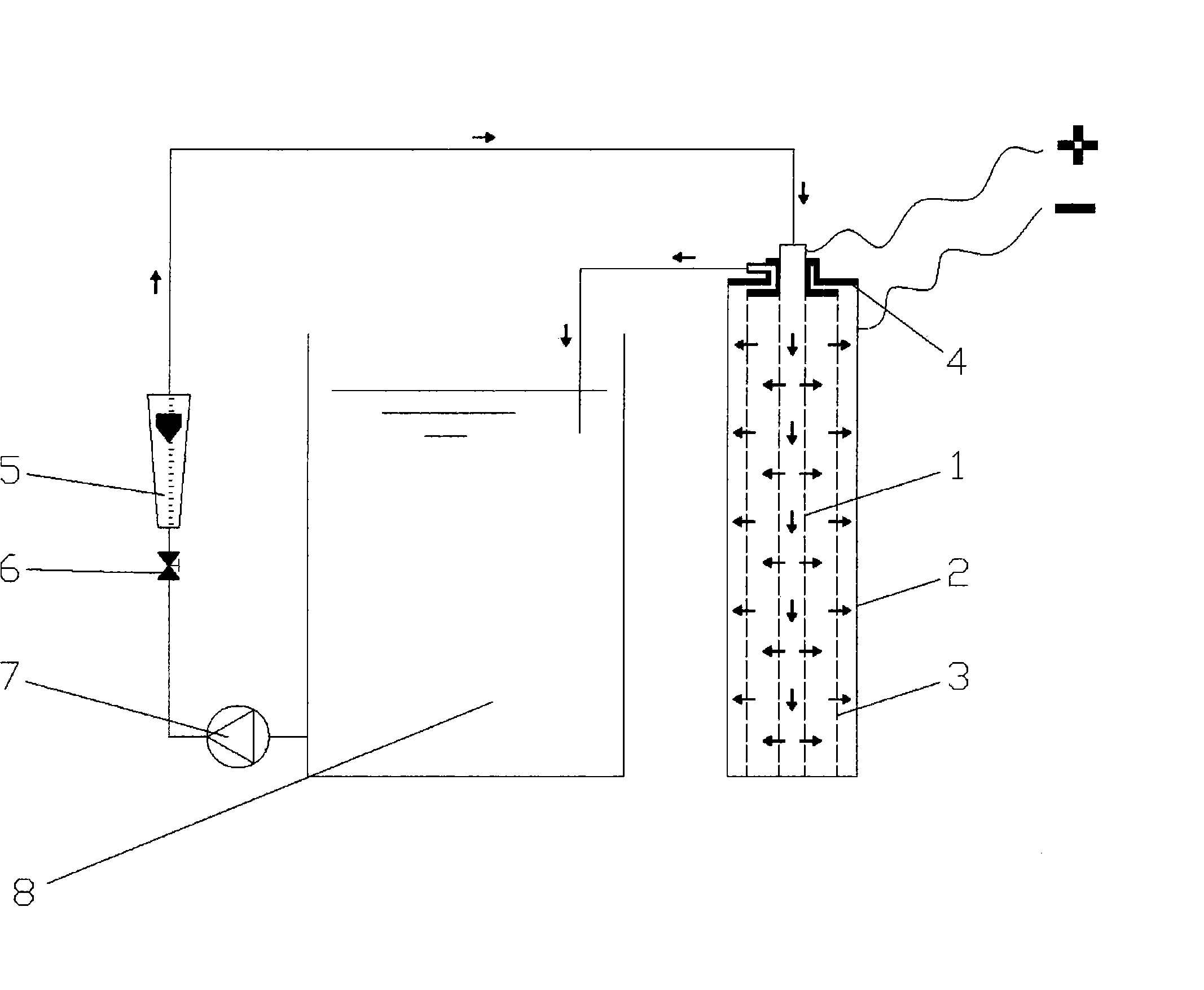

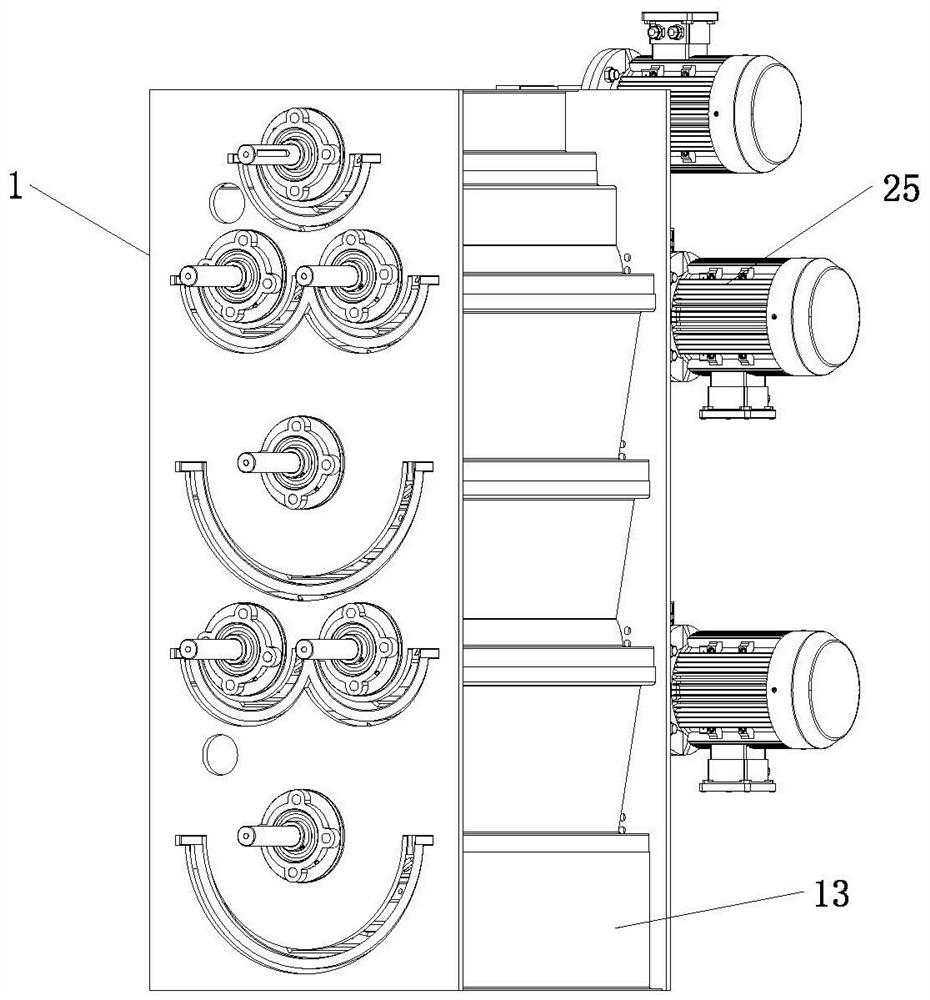

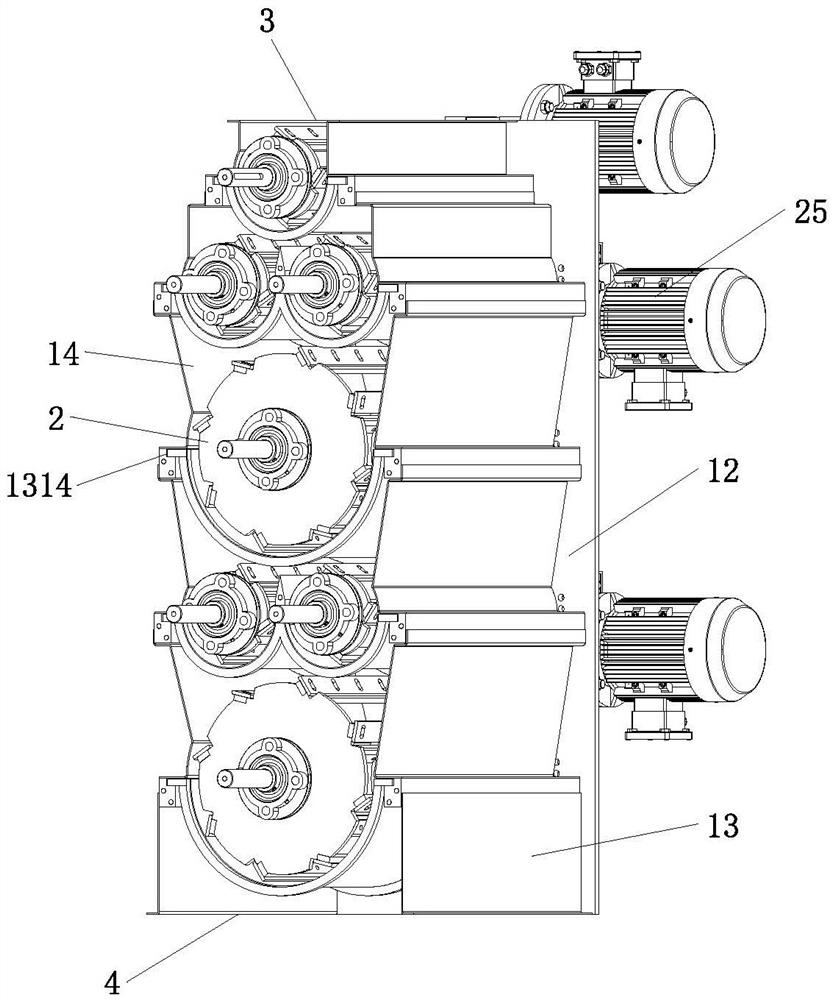

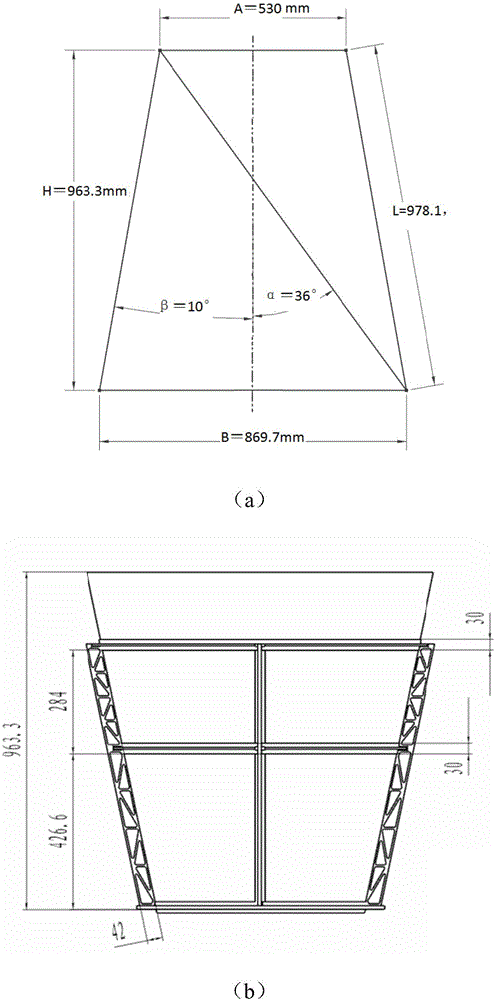

Titanium cylinder electrolysis machine

ActiveCN103361673AArrangement scienceSimple structurePhotography auxillary processesElectrodesElectrolysisLiquid storage tank

The invention discloses a titanium cylinder electrolysis machine including an anode perforated titanium tube, a cathode titanium cylinder and a gold bearing waste liquid storage tank. An electrolysis tank is formed by the anode perforated titanium tube and the cathode titanium cylinder, the electrolysis tank is connected to the gold bearing waste liquid storage tank through a pipeline, and the bottom of the gold bearing waste liquid storage tank is connected to the anode perforated titanium tube of the electrolysis tank through a pipeline to which a circulation pump, a regulation valve and a flow meter are successively connected. The cathode titanium cylinder is a titanium-material cylinder-shaped structure, the center position of the cathode titanium cylinder is provided with the titanium-material anode perforated titanium tube, and the anode perforated titanium tube is a hollow circular structure with the side wall thereof provided with through holes. The top end of the cathode titanium cylinder is sealed by a sealing cover. The titanium cylinder electrolysis machine has the advantages of simple structure, scientific electrode arrangement, high electrolysis efficiency and short electrolysis time, good corrosion resistance, long service life and reduced cost of electrolysis.

Owner:KANFORT JIANGMEN ENVIRONMENTAL TECH CO LTD

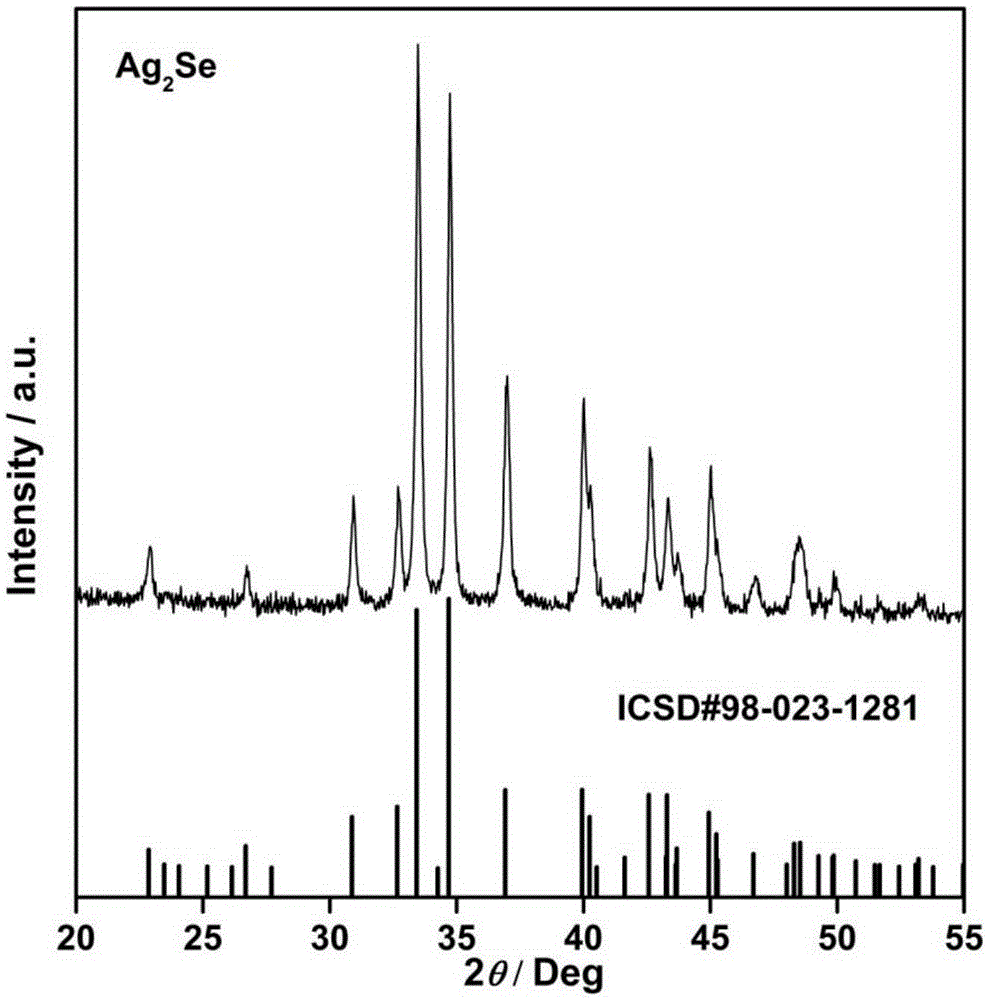

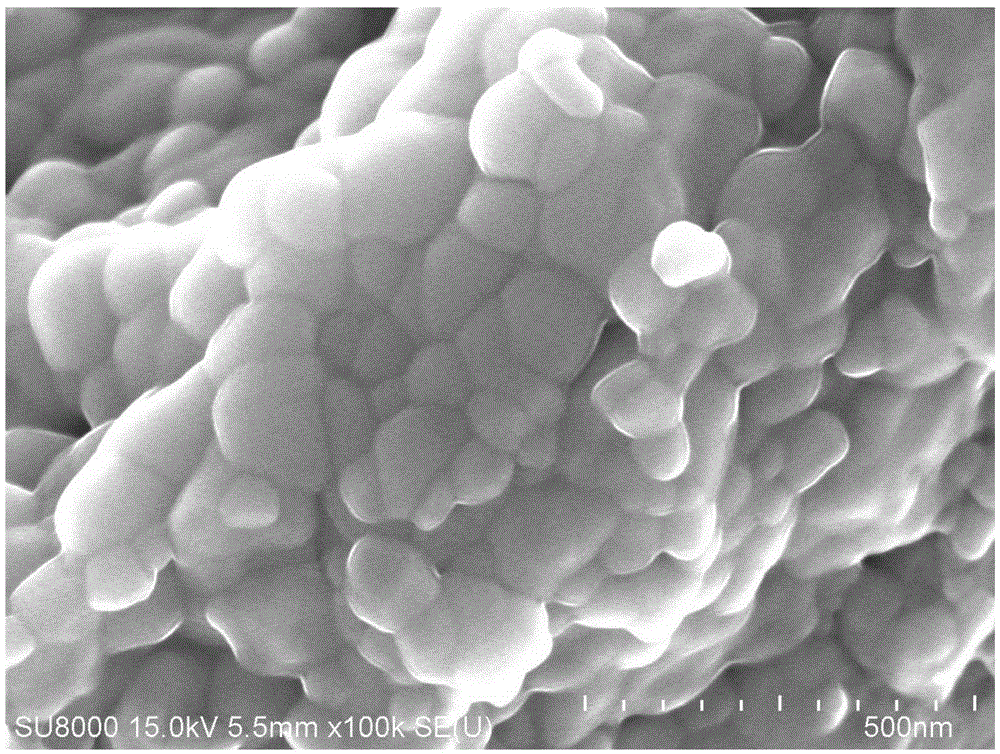

Ultrafast synthetic method of Ag2X block thermoelectric material

ActiveCN105420529ASimple preparation processSuitable for large-scale productionThermoelectric device junction materialsPolymer scienceMixed materials

The invention discloses an ultrafast synthetic method of a Ag2X block thermoelectric material. The ultrafast synthetic method is characterized in that Ag and an X elementary substance are taken as raw materials, high pressure is applied at the normal temperature after the raw materials are mixed uniformly, the mixed materials react and are densified by one step, and the Ag2X block thermoelectric material is prepared, wherein X is Se or Te. The densities of Ag2Se and Ag2Te blocks prepared by the ultrafast synthetic method are above 97%; the relevant preparation time is short, and a technology is simple; in addition, the problem of element volatilization in high-temperature synthetic processes of selenide and telluride is solved; accurate control on components and a microstructure is realized; the thermoelectric properties of obtained products are superior to those of products prepared by the traditional preparation method; ZTmax of obtained Ag2Se is equal to 0.65@107 DEG; ZTmax of obtained Ag2Te is equal to 0.7@127 DEG; and the ultrafast synthetic method lays a good foundation for large-scale preparation and large-scale application of Ag2Seand Ag2Te thermoelectric materials.

Owner:WUHAN UNIV OF TECH

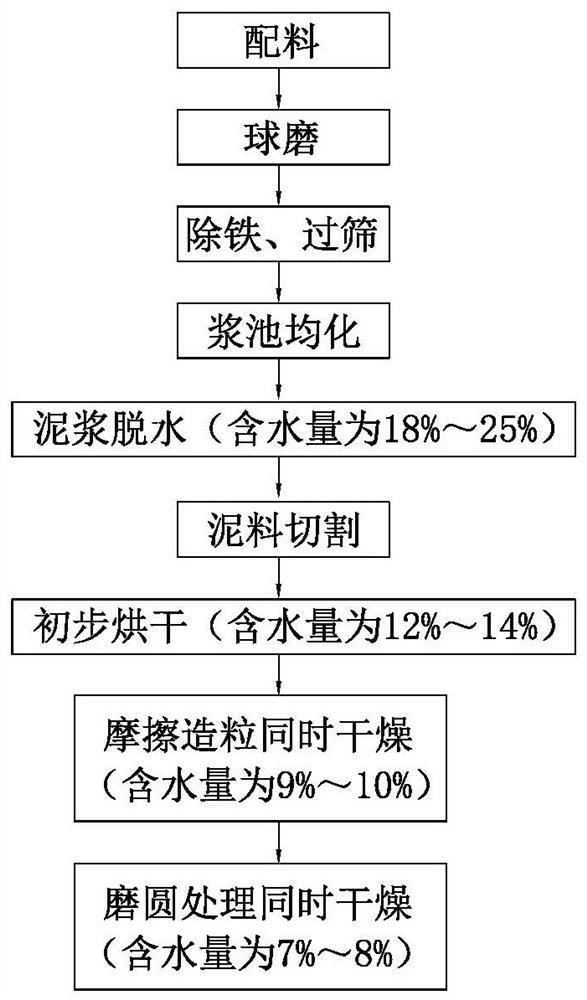

Ceramic powder preparation process and system

PendingCN112321303AReduced time to dry mud clodsSpeed up dryingDrying solid materials with heatDrying gas arrangementsWater contentPowder

The invention relates to the technical field of ceramic wet powder preparation, in particular to a ceramic powder preparation process and system. The ceramic powder preparation process comprises the following steps: S1, drying mud to obtain mud blocks with the water content of 12%-14%; s2, rubbing the mud blocks with more than two screens which are sequentially arranged layer by layer, reducing the apertures of screen holes of the screens layer by layer, and reducing the particle sizes of the mud blocks when the mud blocks pass through the screen holes of the screens layer by layer; meanwhile,hot air is introduced below the screen so that the mud blocks are repeatedly heated and dried by the flowing hot air in the friction movement and falling process, and finally powder particles with the particle size being smaller than 1.5 mm and the water content being 9%-10% are obtained; according to the invention, the drying of the mud is decomposed into three processes of preliminary drying, granulation and rounding which are carried out step by step, and the specific surface area of powder particles is rapidly increased in the later two processes so that the rapid volatilization of wateris facilitated, the drying speed is increased, and the energy consumption is reduced.

Owner:FOSHAN LANZHIJING SCI & TECH CO LTD

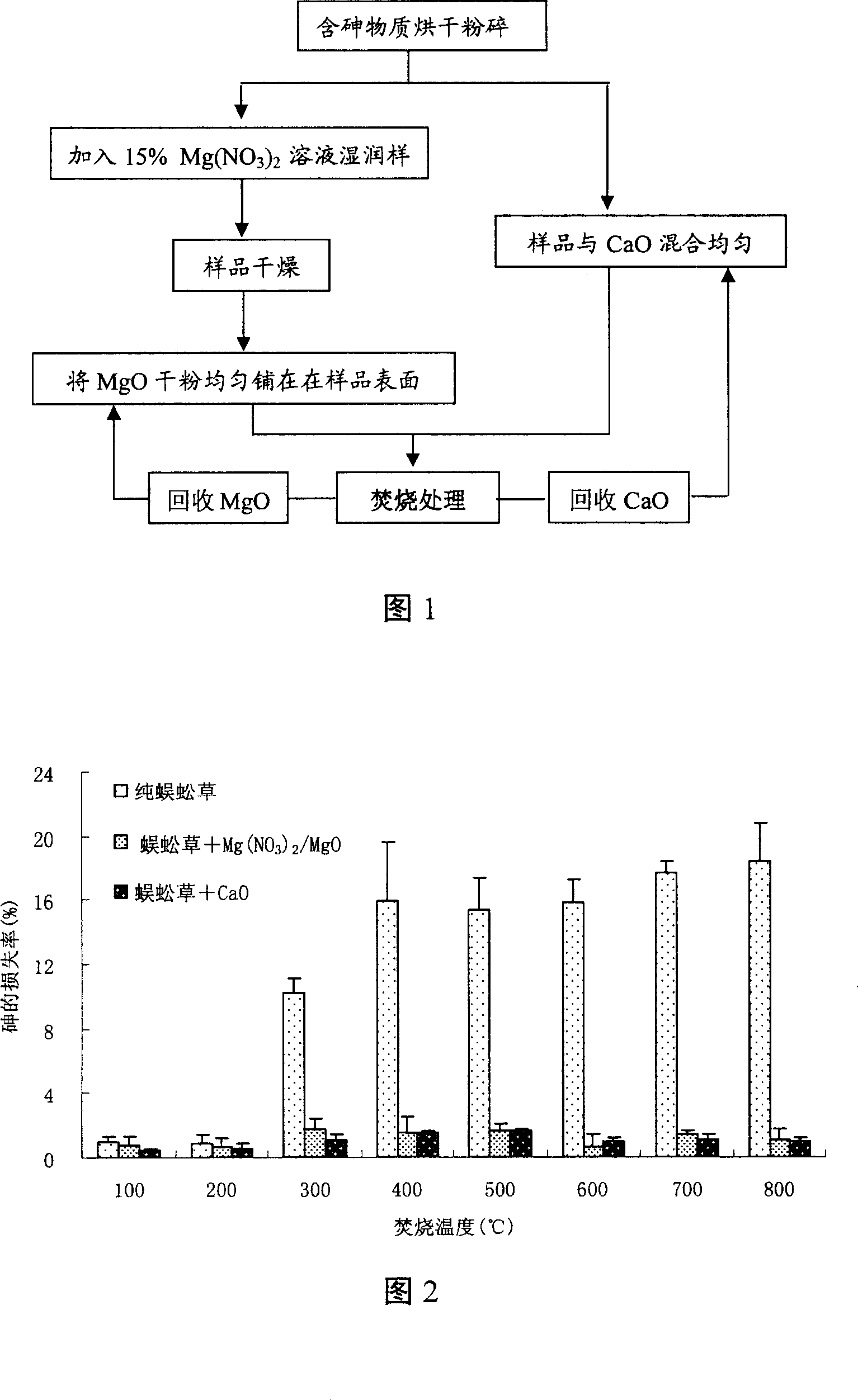

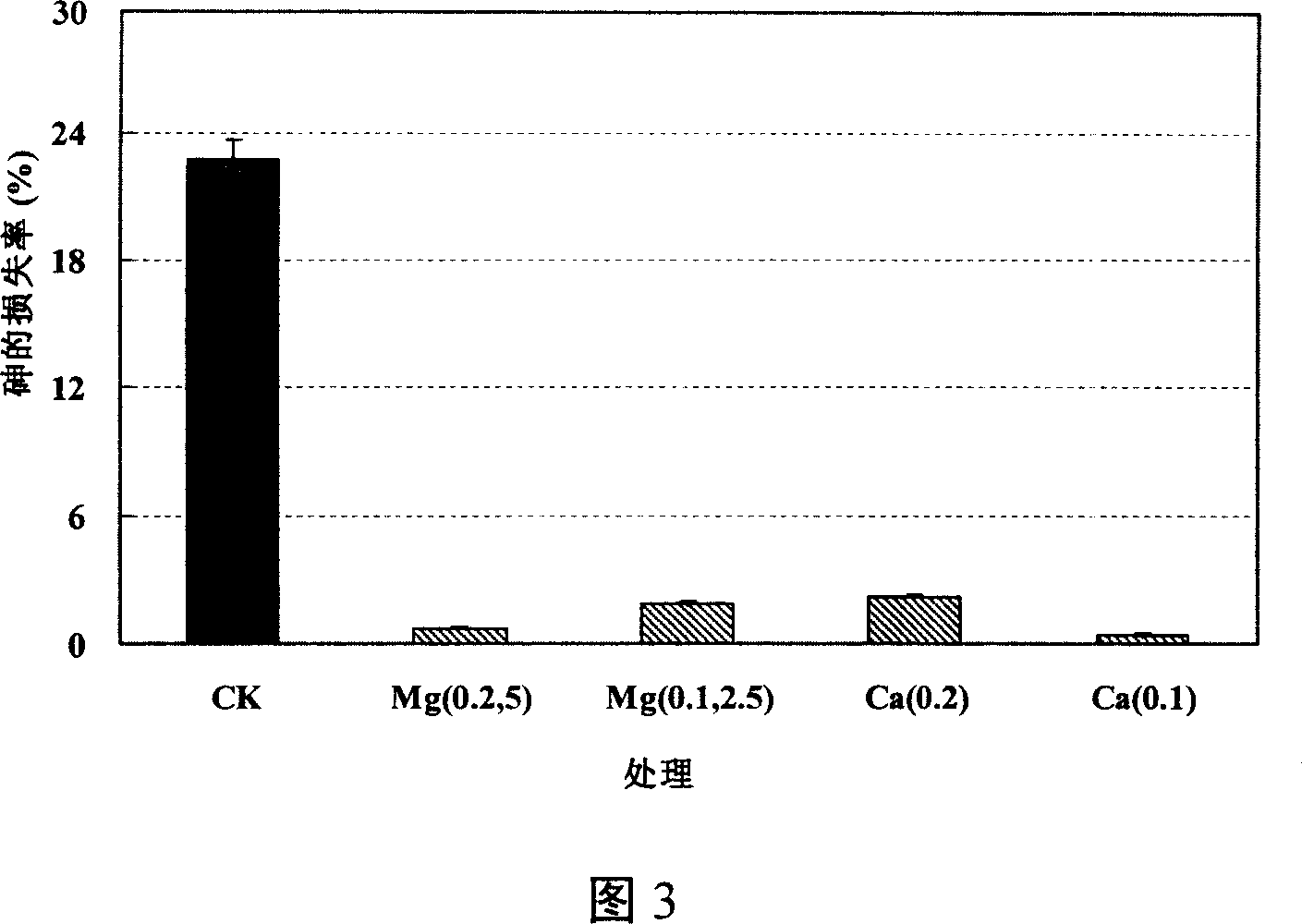

Safety burning method for matter containing arsenic

The invention relates to arsenic bearing material safe burning method. It includes the following steps: wetting the pulverized arsenic bearing material by 15% Mg(NO3)2; drying; mixing with the MgO powder as the 2-4:1(W / W); or directly mixing the pulverized one with the CaO as 2-4:1(W / W); burning at 300-800 degree centigrade; reclaiming the extra MgO or CaO. The method can effectively prevent arsenic from volatilizing, and greatly reduce pending material and next disposing cost. The arsenic solidifying agent can avoid its leaching while processing to reduce secondary pollution risk. This method can be used in burning for arsenic bearing plant, arsenic bearing conserving agent processed wood, high arsenic coal etc.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

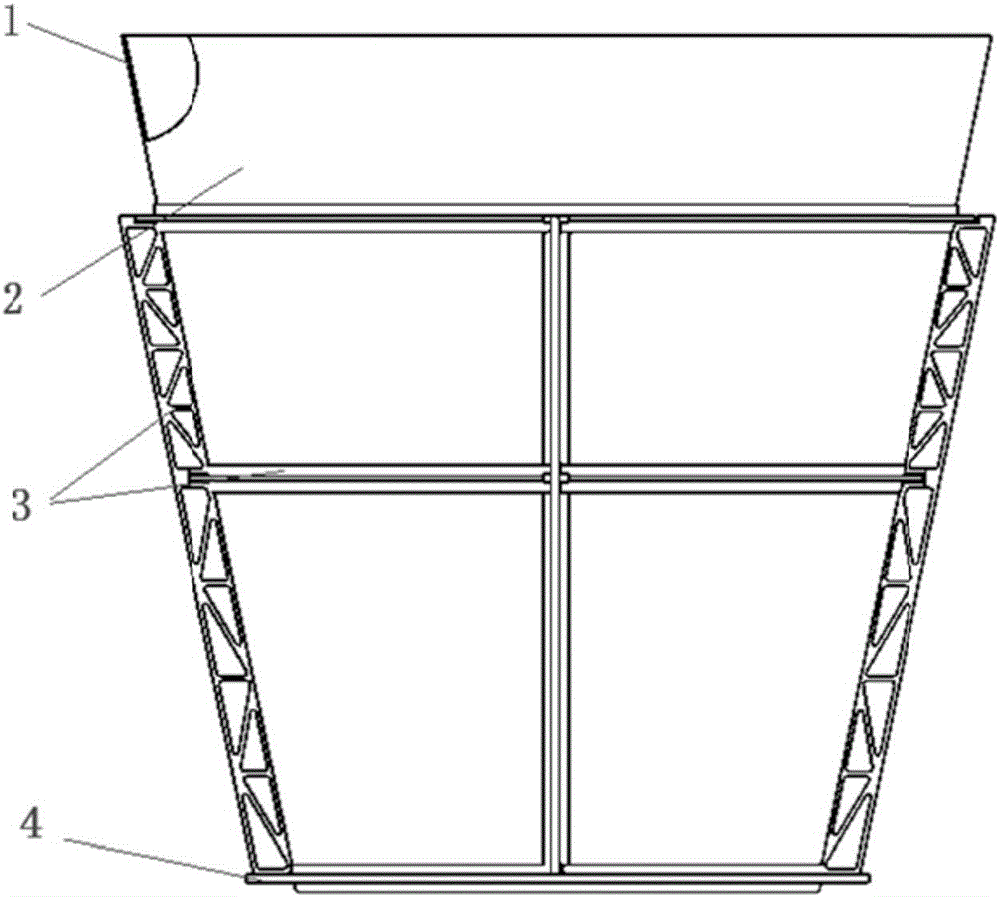

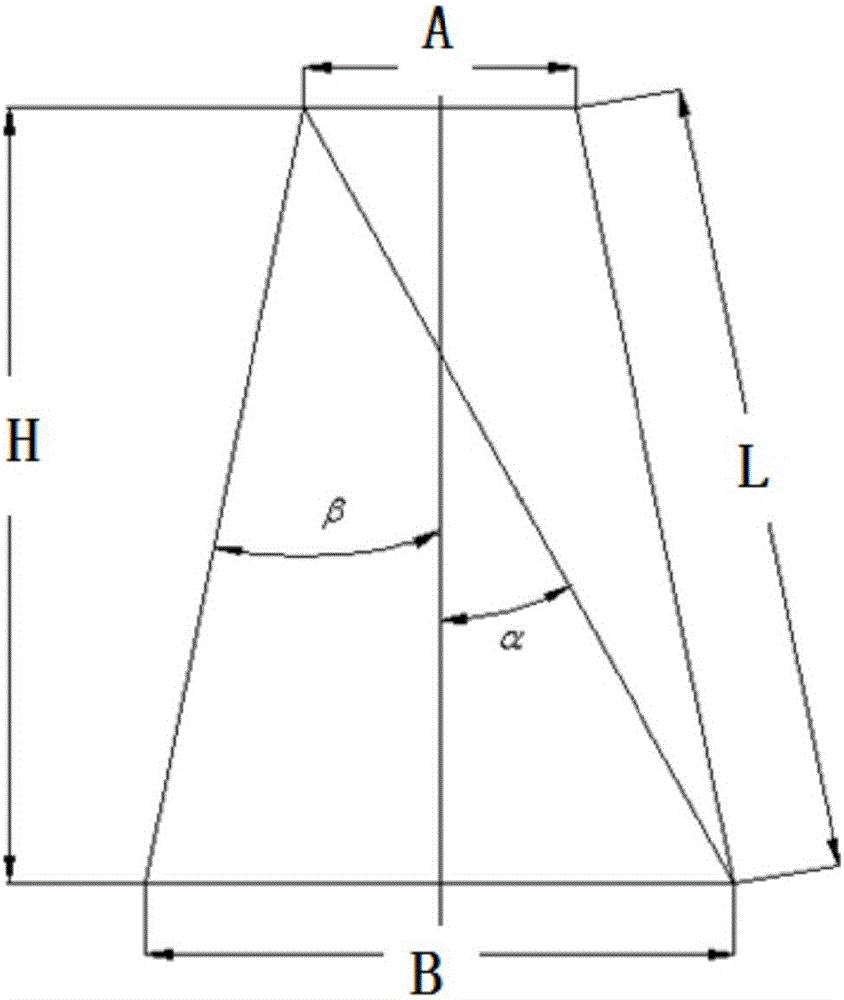

Metal outer light shield used for earth synchronous orbit space optical remote sensor

InactiveCN106482770ASolve the problem of volatilityPlay the role of eliminating stray lightMeasurement apparatus housingsSynchronous orbitSpace environment

The invention discloses a metal outer light shield used for an earth synchronous orbit space optical remote sensor. The metal outer light shield is formed by a cylinder wall, a diaphragm, an outer support truss and an installation flange, which are made of aluminium alloy. The diaphragm is connected with the cylinder wall in welding, riveting and bonding manners. The cylinder wall is connected with the outer support truss in a riveting manner. The outer support truss is subjected to the lightweight design, so the rigidity of a thin wall aluminum structure is improved. An installation through hole or an installation countersink is arranged in the installation flange at the bottom. The whole assembly is installed on the main body of a space remote sensor through riveting or threads. Inorganic paint is painted on the outer surface of the whole light shield. Parasitic light eliminating paint is painted on the inner surface of the light shield. The metal outer light shield is advantageous in that: pollution possibly to space load by high-temperature high-vacuum degassing is avoided; andthe metal outer light shield has quite good specific stiffness and is suitable for space environment.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

A method for separating lignin from nut shells by using high boiling alcohol

The invention discloses a method for separating lignin from nut shells by using high-boiling alcohol. The high-boiling alcohol solution is used as a solvent to effectively separate lignin from nut shell biomass with dense structure under the action of a catalyst. The invention makes full use of waste biomass resources. The obtained lignin has low ash content, the hydroxyl value is 197.2mgKOH / g, the number average and weight average molecular weight are around 5000, and the polydispersity index of lignin is around 1, so it can be seen that the obtained lignin has high purity, good activity, The range of molecular weight distribution is narrow, and it is high-quality lignin. The invention solves the environmental pollution and cost increase caused by the volatilization of low-boiling solvents, and the solvents used are high-boiling solvents and water, effectively solving the problems of solvent volatilization and recycling. The invention solves the problem of low lignin yield due to the compact structure of the nut shell biomass, and can make the lignin extraction rate in the nut shell within the range of 56.9-74.6%.

Owner:CHANGCHUN UNIV OF TECH

Dipping solution formula of industrial canvas and preparation process thereof

ActiveCN103757932ASolve the problem of volatilityStrong ability to accept methyleneFibre treatmentOrganic solventThiazole

The invention aims to provide a dipping solution formula of an industrial canvas and a preparation process thereof. The dipping solution formula comprises a first bath formula and a second bath formula. The dipping solution formula and the preparation process have the beneficial effects that 2-chloromethylthiobenzothiazole is added to a two-bath dipping solution, so that unreacted resorcinol is etherified through etherification reaction, thus the content of free resorcinol is less than 1% and the harms to workshop workers and the environment are reduced; during dipping solution preparation, an organic solvent serves as a carrier to form a solvent type dipping system, so that high tenacity of the canvas can be ensured while endowing the canvas with high degree of adhesion, thus forming a product with high added values; release of toxic substances in the dipping process is reduced and the environment is protected by adopting the environment-friendly dipping system.

Owner:ANHUI HUAYE ADVANCED MATERIALS CO LTD

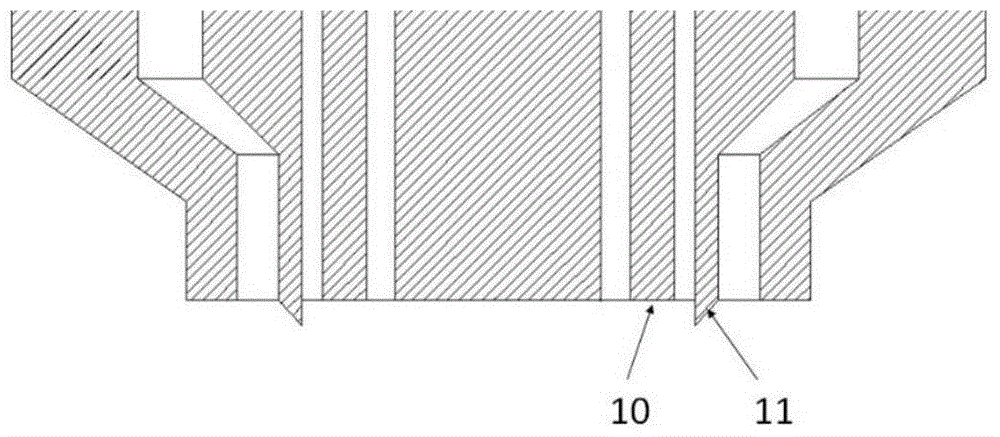

Internal and external circular air assisted electrospinning nozzle unit

ActiveCN104928768AEvenly distributedPrevent volatilizationFilament/thread formingElectrospinningNanofiber

The invention belongs to the field of electrospinning and relates to an internal and external circular air assisted electrospinning nozzle unit, comprising a nozzle body and a positive electrode. The nozzle body is composed of a first component, a second component, a third component and a fourth component nested to one another and detachably arranged from inside to outside. The four components of the nozzle body form an internal circular air passage, an external circular air passage, a middle circular liquid passage and an internal circular air inlet; an external circular air outlet and an external circular liquid outlet are concentrically circular; a guide plate is disposed within the middle circular liquid passage. The positive electrode extends into the middle circular liquid passage and contacts liquid. The nozzle unit is assisted by both internal and external air flows, is simple in structure, high in controllability and good in airtightness, helps avoid volatilizing of solvents in the liquid during spinning, has the yield up to ten times as high as the needle type, roller type or spiral type electrospinning unit, and is suitable for continuous industrial production of nanofibers.

Owner:烟台森森环保科技有限公司 +1

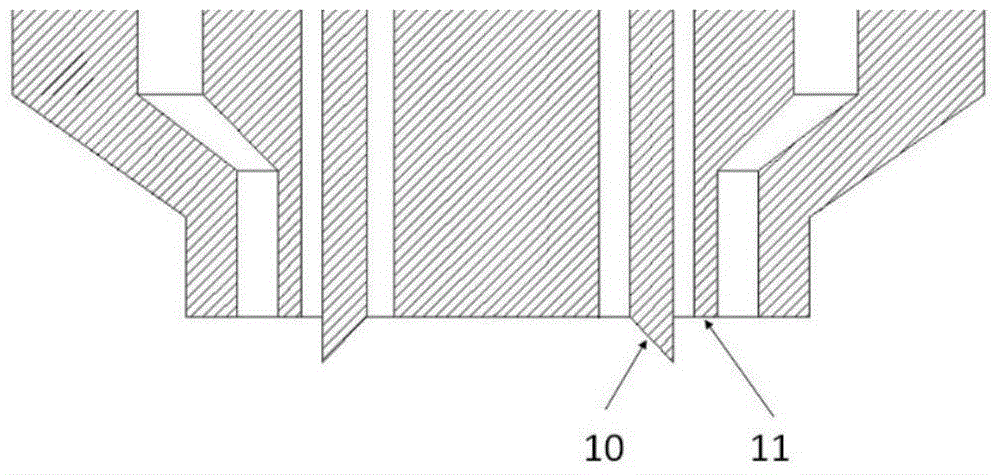

Preparation method of zinc-copper-titanium alloy for corrosion prevention

The invention discloses a preparation method of zinc-copper-titanium alloy for corrosion prevention. The preparation method comprises the following steps: 1, weighing first-grade sponge titanium and pure copper blocks in a mass ratio of 1:1 and smelting through an electric arc smelting furnace to prepare a copper-titanium alloy ingot; 2, performing single-roller rotary quenching and rapid solidification on the copper-titanium alloy ingot to prepare a copper-titanium alloy amorphous strip; 3, putting pure zinc into a resistance furnace, pressing the copper-titanium alloy amorphous strip into zinc melt, and then pouring the zinc melt into a graphite mold with the inner diameter of 20 mm; 4, heating the zinc-copper-titanium alloy cast ingot and preserving heat, and performing rolling deformation treatment by seven times; and after a rod material is subjected to heat preservation for 10-20 minutes at a temperature of 180-200 DEG C, performing rolling deformation for four times to obtain azinc-copper-titanium alloy wire with a diameter being 3 mm. According to the preparation method disclosed by the invention, on one hand, the problem of zinc volatilization in the smelting process is solved, on the other hand, the copper-titanium alloy amorphous strip is easier to diffuse into the zinc melt, so that smelting time of the zinc alloy is greatly shortened; and more importantly, the copper-titanium amorphous strip has no crystal structure, so that corrosion resistance of the zinc-copper-titanium alloy is improved.

Owner:CHINA UNIV OF MINING & TECH

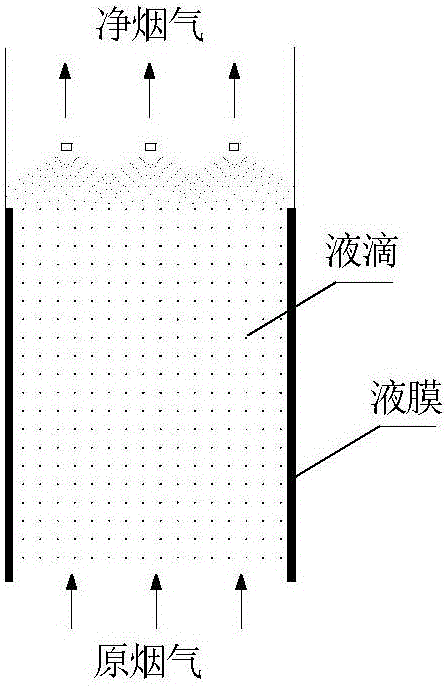

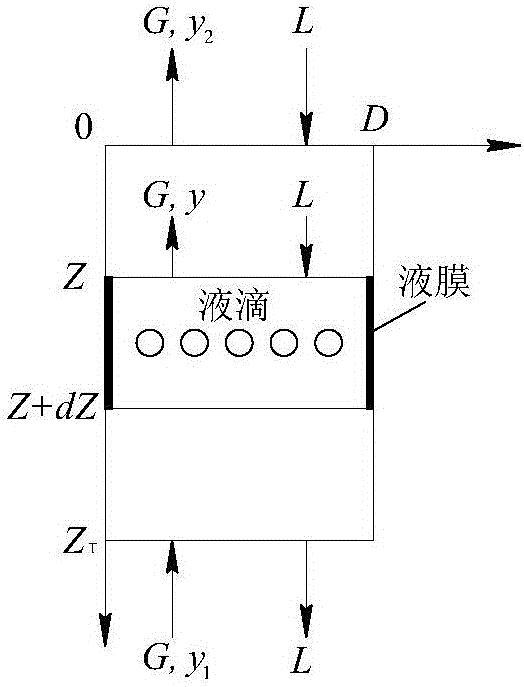

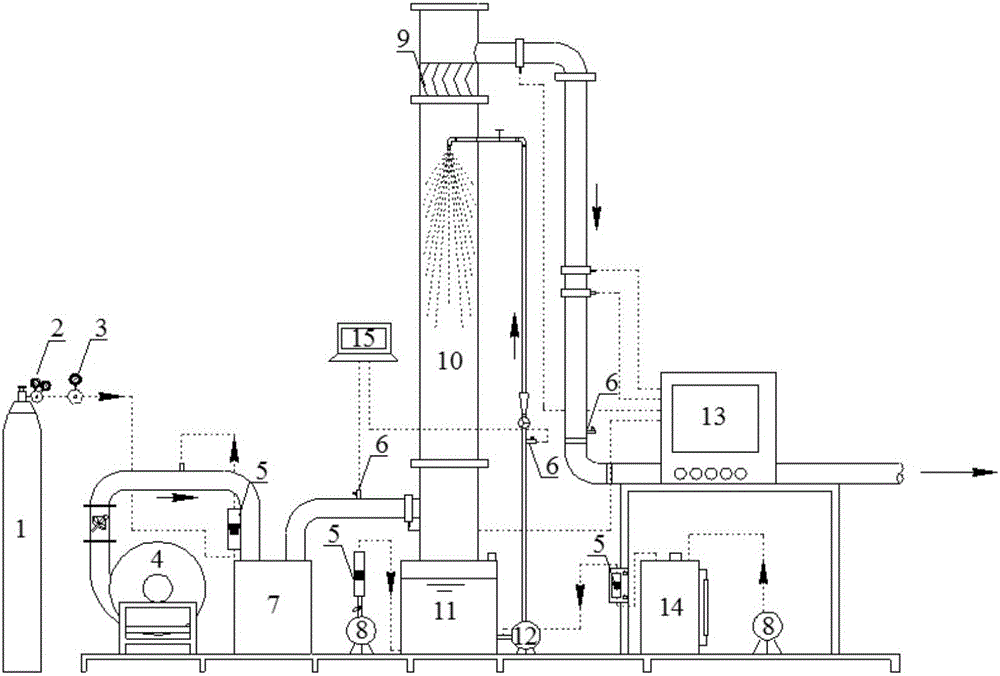

Ammonia process desulfurization spraying tower system and method for determining SO2 absorption mass transfer coefficient

ActiveCN106000041ASolve the problem of volatilityImprove desulfurization efficiencyGas treatmentDispersed particle separationSpray towerChemistry

The invention discloses an ammonia process desulfurization spraying tower system and a method for determining SO2 absorption mass transfer coefficient, and belongs to the technical field of ammonia process flue gas desulfurization. The invention is based on the characteristics of spraying tower ammonia process flue gas desulfurization process. The pH value, gas velocity ug and liquid-gas ratio L / Q of slurry in the spraying tower are selected as parameters; absorption mass transfer coefficient ky of ammonia process desulfurization under different conditions of pH value, gas velocity ug and liquid-gas ratio L / Q are calculated; then a numerical fitting method is employed to construct an universal expression formula of absorption mass transfer coefficient ky' of ammonia process desulfurization. The SO2 mass transfer coefficient of ammonia process desulfurization obtained by the method can fully and accurately reflect the effects of process operation conditions on SO2 mass transfer absorption process, and has general applicability; the invention provides theoretical guidance to the optimization of the design and operation of ammonia process desulfurization absorption tower, and has strong practical significance and application value; and the error between the calculated result and experimental result is less than 14.77%.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

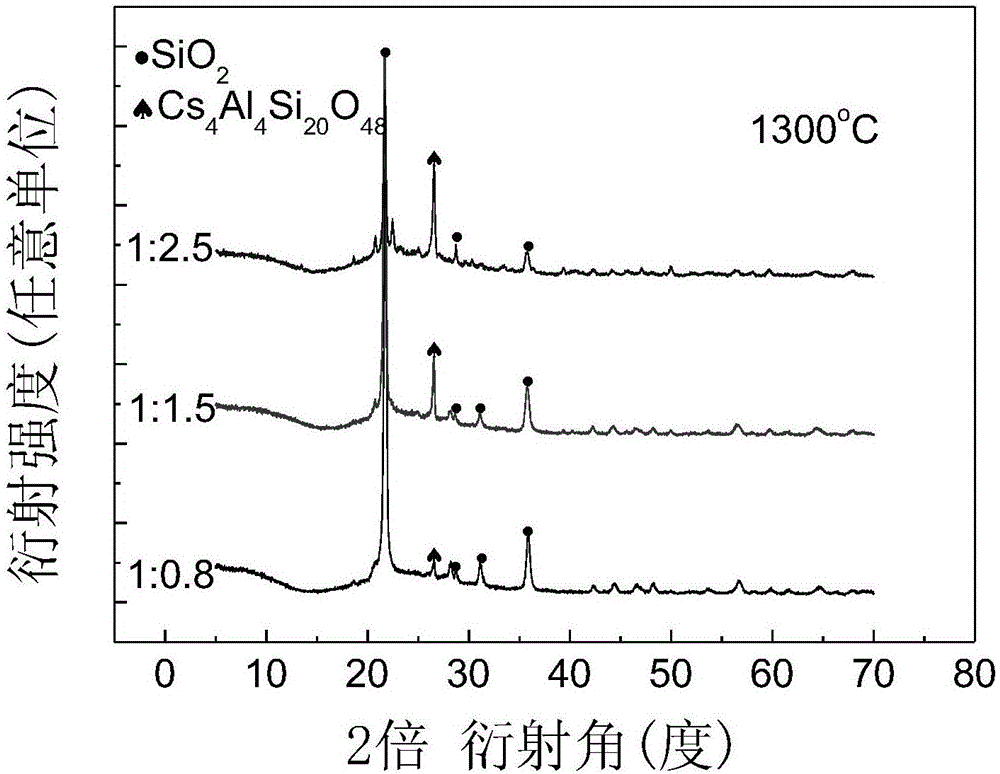

Method for preparing solidified bodies on basis of cesium-adsorbed silicon-based heteropolyacid salt composite adsorbents

The invention discloses a method for preparing solidified bodies on the basis of cesium-adsorbed silicon-based heteropolyacid salt composite adsorbents. The method includes particular steps of firstly, mixing solidifying base materials and the cesium-adsorbed silicon-based heteropolyacid salt composite adsorbents with one another to obtain mixtures and uniformly grinding the mixtures; secondly, carrying out static-pressure molding on the ground mixtures to obtain molded blanks; thirdly, calcining the molded blanks at the high temperatures of 800-1500 DEG C for 2-5 hours and annealing the molded blanks until the temperatures of the molded blanks reach the room temperature to obtain the cesium-containing ceramic solidified bodies. The solidifying base materials are selectively one or two types of allophane or zeolite materials. The method has the advantages that the solidifying materials such as allophane or zeolite are low in price and are easily available, processes for preparing the solidified bodies are simple, good cesium immobilization effects can be realized by the solidified bodies, the solidified bodies are high in strength and low in leaching rate, the method is applicable to solidifying and treating cesium-containing radioactive waste, and the like.

Owner:SHANGHAI JIAO TONG UNIV

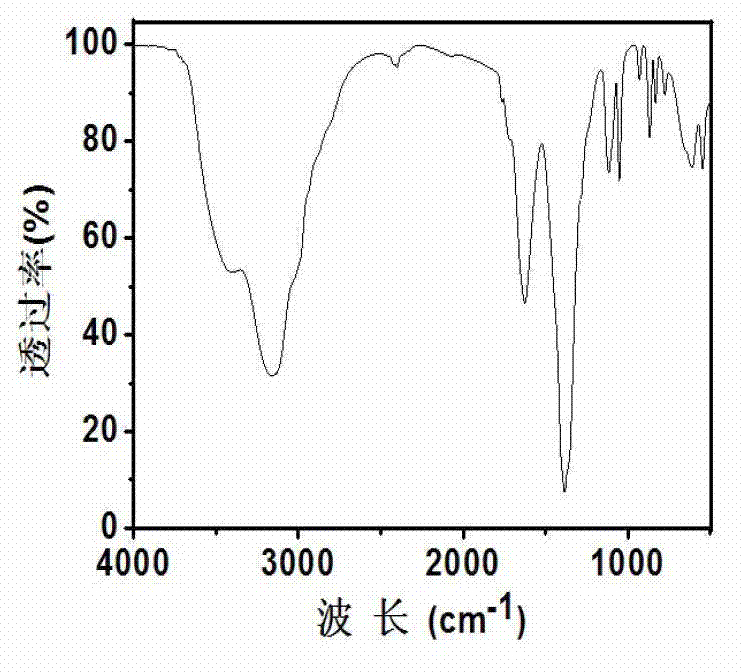

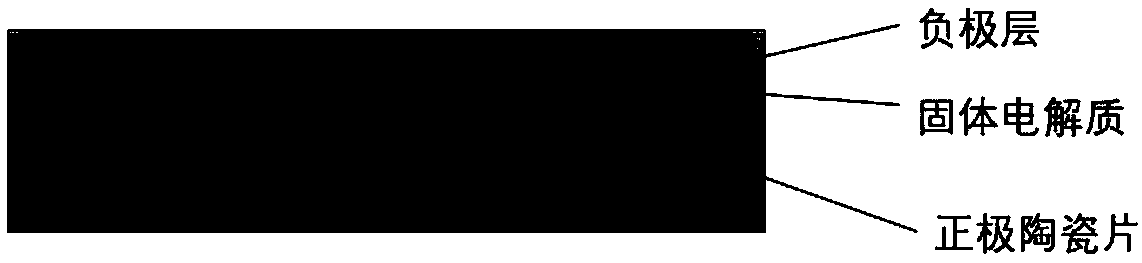

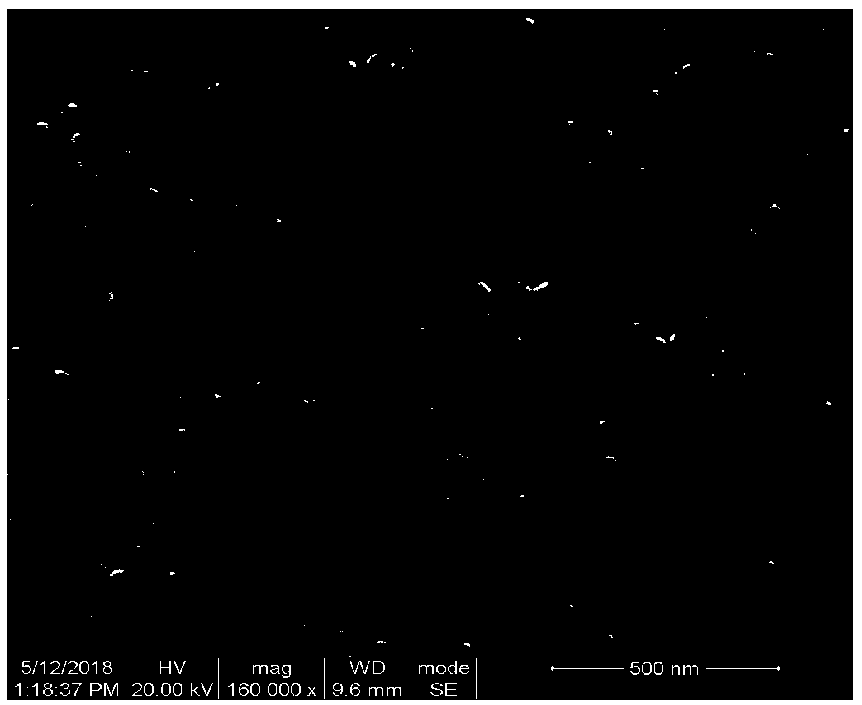

Layered all-solid-state lithium ion battery and preparation method thereof

ActiveCN109103505ASimple processLow costMaterial nanotechnologyFinal product manufactureOxygenLanthanum

The invention relates to a layered all-solid-state lithium ion battery and a preparation method thereof, belonging to the technical field of all-solid-state lithium ion batteries. The preparation method of the layered all-solid-state lithium ion battery comprises the following steps: a. preparing a positive electrode or a negative electrode ceramic sheet, polishing the surface of the ceramic sheetfor standby; B. preparing a lithium lanthanum titanium oxide sol solution by a sol-gel method; (c) applying the lithium lanthanum titanium oxide sol liquid on the polished ceramic sheet in step (a) through spin coating, baking the ceramic sheet to volatilize organic matter, and finally annealing at high temperature to obtain a lithium lanthanum titanium oxide thin film on the surface of the ceramic sheet. The high temperature annealing process is to increase temperature to 350-450 DEG C and perform heat treatment for 5-15min, and then rapidly increase temperature to 600-900 DEG C and performannealing for 5-15 min. The preparation method of the invention does not require polymer auxiliary deposition and expensive vacuum equipment, and has the advantages of simple process, low cost and lowinterface impedance. A lithium lanthanum titanium oxide thin film is obtain, that particles of the lithium lanthanum titanium oxide thin film are nano-scale, the density is good, and the problem of the volatilization of Li in the preparation process of the lithium lanthanum titanium oxide thin film is sol due to the short holding time of the lithium lanthanum titanium oxide thin film.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Process method for absorbing sulfur dioxide in flue gas by using aqueous carboxylate solution and regenerating absorbent at same temperature

InactiveCN107297123ARegeneration is gentle and easyLow priceGas treatmentDispersed particle separationFiltrationResource utilization

The invention discloses a process method for absorbing sulfur dioxide in flue gas by using an aqueous carboxylate solution and regenerating an absorbent at the same temperature. The process method comprises the following steps: with the aqueous carboxylate solution as the absorbent, under the conditions that the absorbing temperature is 25-60 DEG C and the concentration of the sulfur dioxide in the flue gas is 100-10000ppm, absorbing the sulfur dioxide gas in the flue gas, and then at the temperature equal to the absorbing temperature, under the stirring condition, inflating hydrogen sulfide, reacting with the sulfur dioxide in the absorbent to produce sulfur, recycling the sulfur through filtration or centrifugation to regenerate the absorbent, and reusing the regenerated absorbent. The process method has the advantages as follows: the absorbent is low in cost, pollution-free, good in stability and low in regeneration energy consumption; resource utilization of the sulfur dioxide is achieved.

Owner:TAIYUAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com