Titanium cylinder electrolysis machine

A technology of electrolysis machine and titanium cylinder, applied in electrolysis process, electrolysis components, electrodes, etc., can solve the problems of short service life, low electrolysis efficiency, long running time, etc., and achieve improved corrosion resistance, high electrolysis efficiency, and anti-corrosion Good corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The best embodiment of the present invention will be further described in detail below.

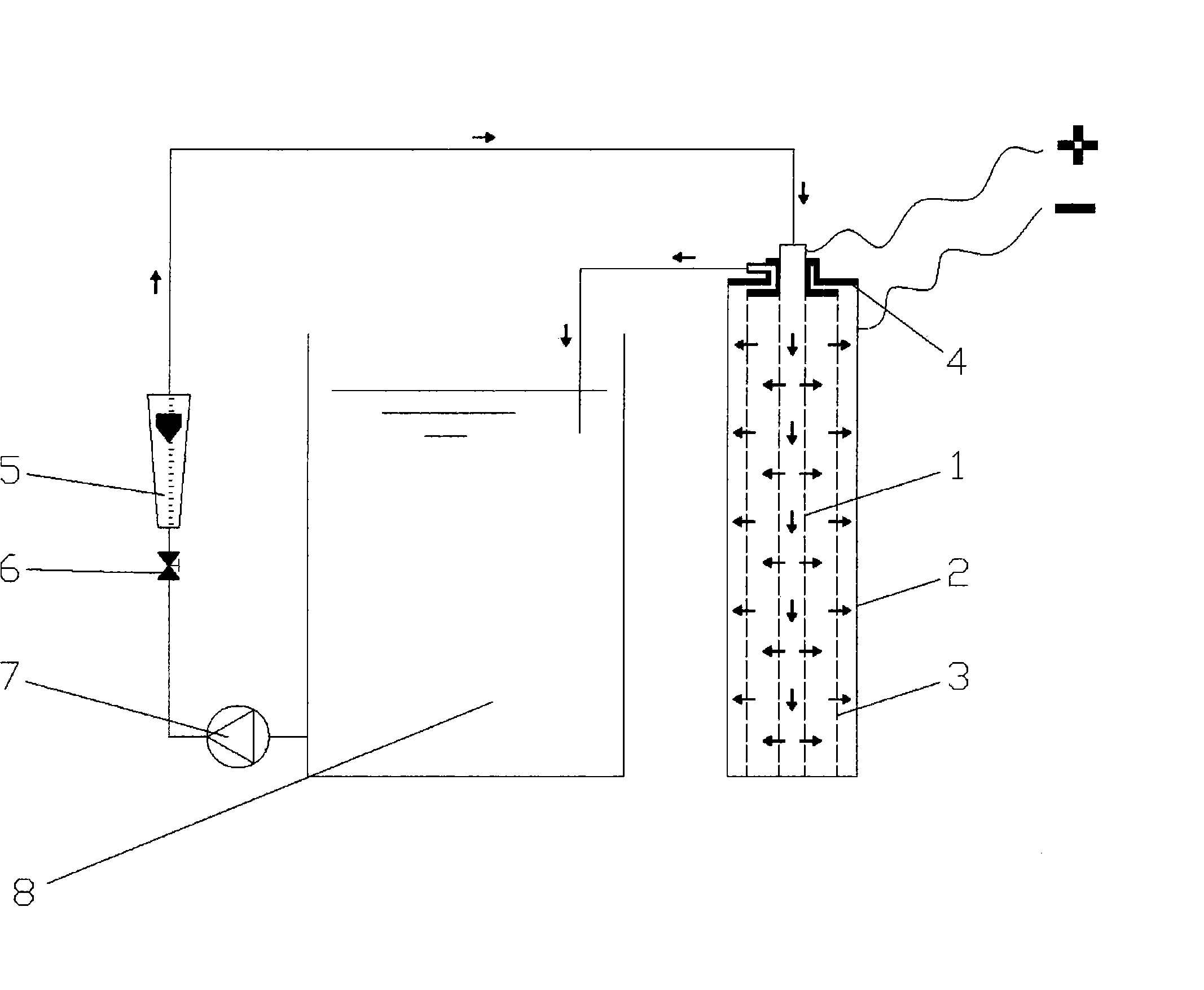

[0025] Such as figure 1 As shown, the titanium cylinder electrolysis machine includes an anode perforated titanium tube 1, a cathode titanium cylinder 2, and a gold-containing waste liquid storage tank 8. The anode perforated titanium tube 1 and cathode titanium cylinder 2 constitute an electrolytic cell, and the electrolytic cell passes through The pipeline is connected to the gold-containing waste liquid storage tank 8, and the bottom of the gold-containing waste liquid storage tank 8 is connected to the anode perforated titanium tube 1 of the electrolytic cell through a pipeline, and the gold-containing waste liquid is discharged from the pipeline at the bottom of the gold-containing waste liquid storage tank 8 The anode perforated titanium tube 1 flowing into the electrolytic cell is decomposed in the electrolytic cell and then flows back to the gold-containing waste liquid sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com