Cracking furnace

A cracking furnace and furnace technology, used in cracking, non-catalytic thermal cracking, petroleum industry, etc., can solve the problems of poor uniformity of heating of the outlet pipe, large floor space, low space utilization, etc., and achieve uniformity of heat flux distribution. Good, easy to install and repair construction, not easy to coking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

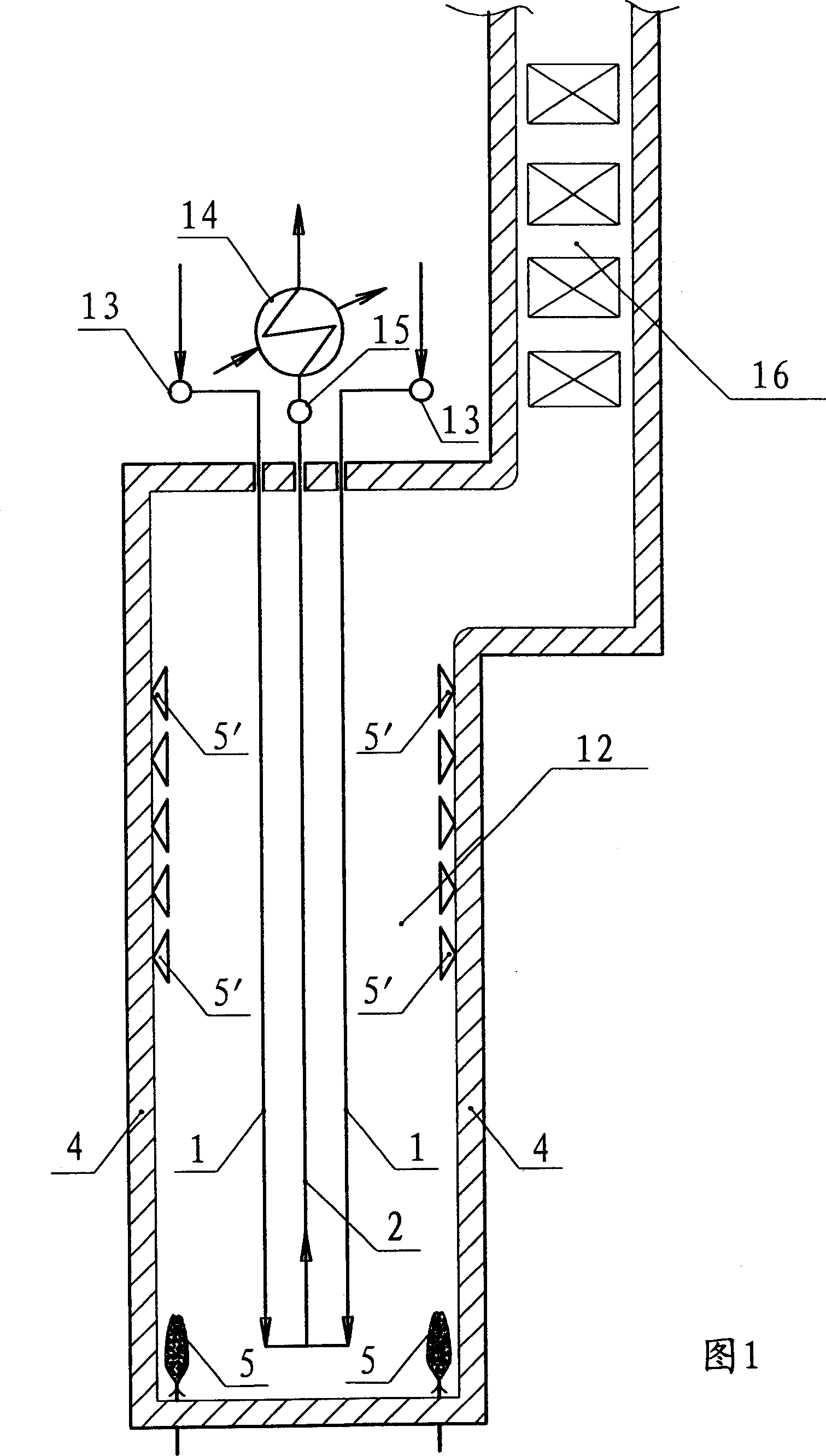

[0047] Referring to Fig. 1, be the simple structural representation of cracking furnace of the present invention, wherein, comprise: radiant section hearth 12; Be arranged in the burner 5,5 ' that is arranged in row in this fire hearth; Form a flame by at least a row of above-mentioned burner combustion Radiant surface 11, each furnace comprises at least two above-mentioned flame radiant surfaces 11; Radiant section reactor tube 1, 2 vertically arranged in the middle of above-mentioned every two flame radiant surfaces 11; An inlet manifold 13; a quenching heat exchanger 14 arranged outside the furnace, and a reaction tube outlet manifold 15 for connecting the outlets of the plurality of reaction tubes to the quenching heat exchanger 14.

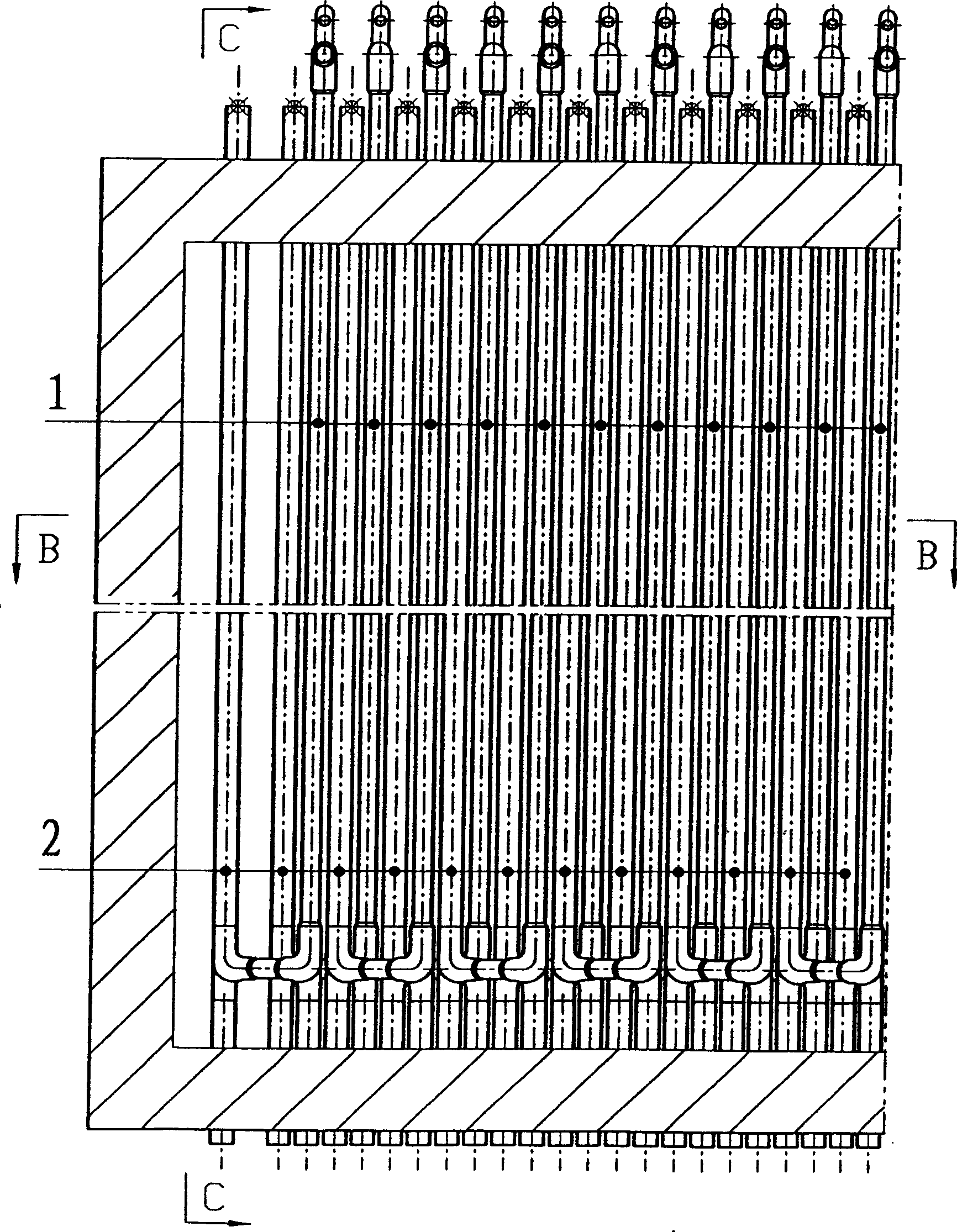

[0048] Figure 2, Figure 3, Figure 4, Figure 5 The reference diagram of a preferred embodiment of the cracking furnace of the present invention is shown. In this example, the reaction tube is a two-pass reducing tube, and both the outlet tube...

Embodiment 2

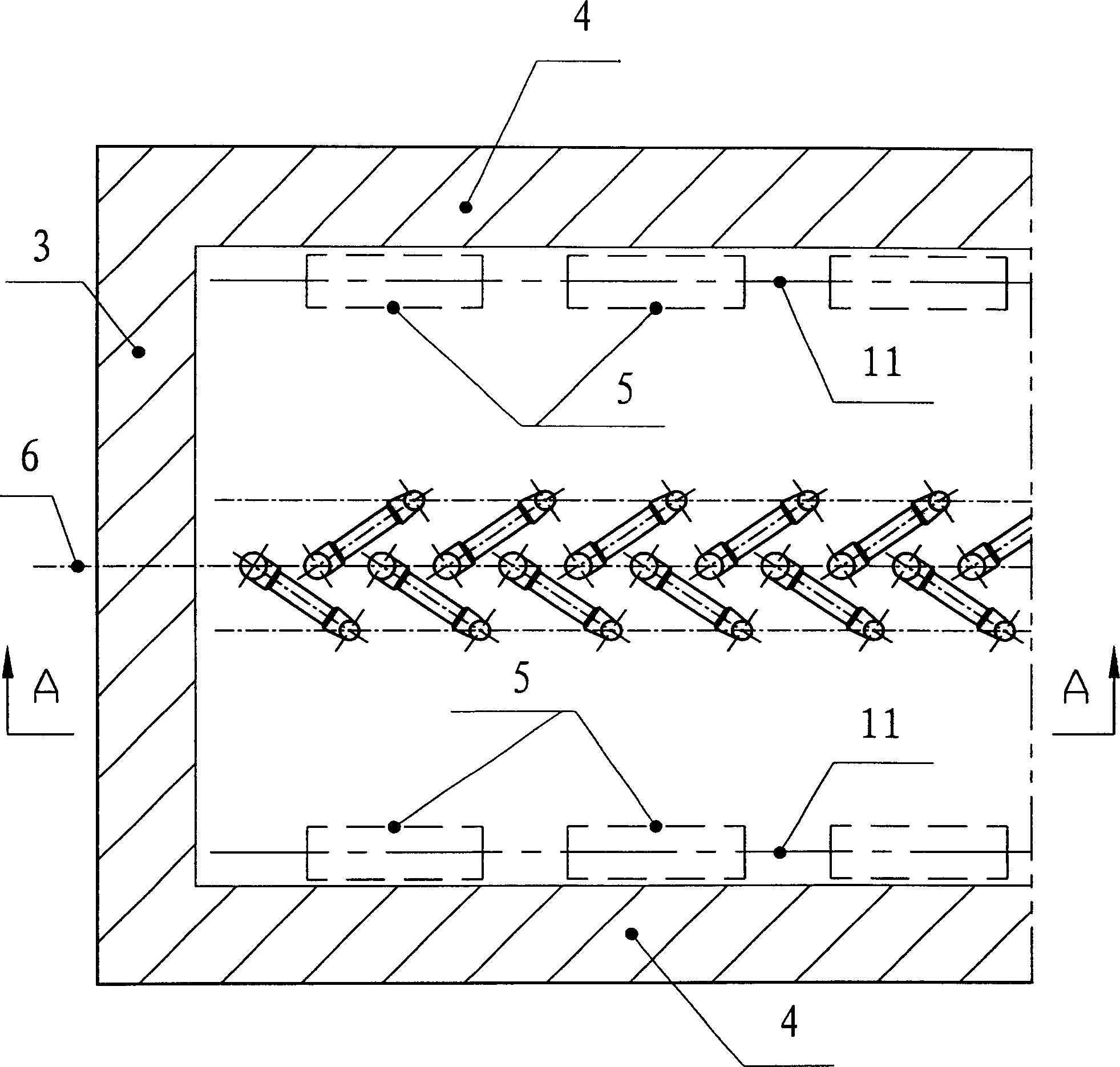

[0051] Referring to Fig. 7, in this example, the reaction tube is still a two-pass reducing tube, and both the outlet and inlet pipes are single-channel. This is the same as the first embodiment. The difference from Embodiment 1 is: in this example, the outlet pipes 2 are arranged in two rows, and are symmetrically arranged on both sides of the horizontal centerline 6 of the two flame radiation surfaces, and the two rows deviate from the centerline 6 a certain distance. Considering the uniformity of heating, the distance should be as small as possible. Compared with the first embodiment, the distance between the adjacent outlet pipes 2 in this example can be larger, and they are not easy to collide with each other, and it can also bring certain convenience for installation and maintenance. Generally speaking, as long as the two rows of outlet pipes 2 are located between the two rows of inlet pipes 1, it can be said that although the heating uniformity of the outlet pipes may...

Embodiment 3

[0053] Figure 8 , Fig. 9, Fig. 10, are the simplified schematic diagrams of the third embodiment of the cracking furnace of the present invention. In this example, the reaction tube is still a two-pass reducing tube, but the inlet tube 1 is a double channel, and the outlet tube 2 is a single channel, that is, the process fluid passes through two parallel inlet tubes 1 and enters a connected outlet tube at the bottom of the furnace 2. Between a pair of radiation surfaces 11, the reaction tubes are arranged in three rows, the outlet tubes 2 are located in the middle row, and the inlet tubes 1 are divided into two rows, located on both sides of the row where the outlet tubes 2 are located. The reaction tubes can be arranged in three rows in a staggered manner, as shown in Figure 9, or they can be aligned (see Figure 11 ) or cross columns (see Figure 12 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com