Layered all-solid-state lithium ion battery and preparation method thereof

A lithium-ion battery, all-solid-state technology, applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the complex preparation process of all-solid-state thin-film batteries, which hinders product marketization and commercial application, and solid-state battery capacity Small and other problems, to achieve the effect of good compactness, short holding time, and solve the problem of volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

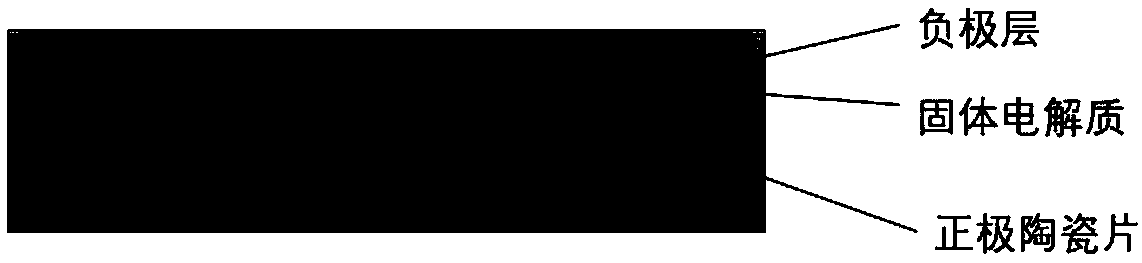

[0036] In order to solve the first technical problem of the present invention, the preparation method of the layered all-solid lithium ion battery comprises:

[0037] a. Prepare positive or negative electrode ceramic sheets, polish the surface of the ceramic sheets, and set aside;

[0038] b. prepare lithium lanthanum titanate sol solution by sol-gel method;

[0039] c. Spin coating the lithium lanthanum titanyl oxide sol solution on the polished ceramic sheet in step a, then bake the ceramic sheet to volatilize the organic matter, and finally anneal at a high temperature to obtain a lithium lanthanum titanic oxide film on the surface of the ceramic sheet; The high-temperature annealing process is as follows: first, the temperature is raised to 350-450°C, and the heat treatment is performed for 5-15 minutes; then, the temperature is rapidly raised to 600-900°C, and the annealing treatment is performed for 5-15 minutes.

[0040] Preferably, the method further includes: d. repe...

Embodiment 1

[0058] Step 1: Preparation of LiCoO 2 Positive ceramic sheet

[0059] ① Granulation: Weigh an appropriate amount of lithium cobalt oxide (LiCoO 2 ) powder is granulated, wherein the adhesive is 10% PVA by mass fraction;

[0060] ② Tablet: Weigh 0.6g of LiCoO after granulation 2 The powder is compressed into tablets, wherein the pressure is 10MPa, and the holding time is 3min;

[0061] ③ Debinding: Heating from room temperature to 400°C after 7 hours, then heating from 400°C to 650°C after 10 hours, keeping it warm for 2 hours, and then cooling with the furnace;

[0062] ④ Sintering: LiCoO obtained after debinding 2 Sintering at 1000°C and holding for 3h to obtain LiCoO 2 Anode ceramic sheet;

[0063] ⑤ Polishing: first use 600#, 800#, 1000#, 1200#, 1400#, 1600#, 1800#, 2000# metallographic sandpaper to LiCoO 2 The ceramic piece is polished, and then W 0.5 , W 0.25 diamond polishing fluid for polishing until LiCoO 2 The surface of the ceramic sheet reaches a mirror le...

Embodiment 2

[0076] Step 1: Preparation of lithium titanate (Li 4 Ti 5 o 12 ) Negative ceramic sheet

[0077] ① Granulation: Weigh an appropriate amount of lithium titanate (Li 4 Ti 5 o 12 ) powder is granulated, wherein the adhesive is 10% PVA by mass fraction;

[0078] ② Tablet pressing: Weigh 0.6g of Li after granulation 4 Ti 5 o 12 The powder is compressed into tablets, wherein the pressure is 10MPa, and the holding time is 3min;

[0079] ③ Debinding: Heating from room temperature to 400°C after 7 hours, then heating from 400°C to 650°C after 10 hours, keeping it warm for 2 hours, and then cooling with the furnace;

[0080] ④ Sintering: the Li obtained after debinding 4 Ti 5 o 12 Sintered at 800°C and kept for 5h to obtain Li 4 Ti 5 o 12 Negative electrode ceramic sheet;

[0081] ⑤Polishing: first use 600#, 800#, 1000#, 1200#, 1400#, 1600#, 1800#, 2000# metallographic sandpaper on Li 4 Ti 5 o 12 Negative electrode ceramic sheet is polished, and then W 0.5 , W 0.25 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com