Patents

Literature

125 results about "Lanthanum titanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

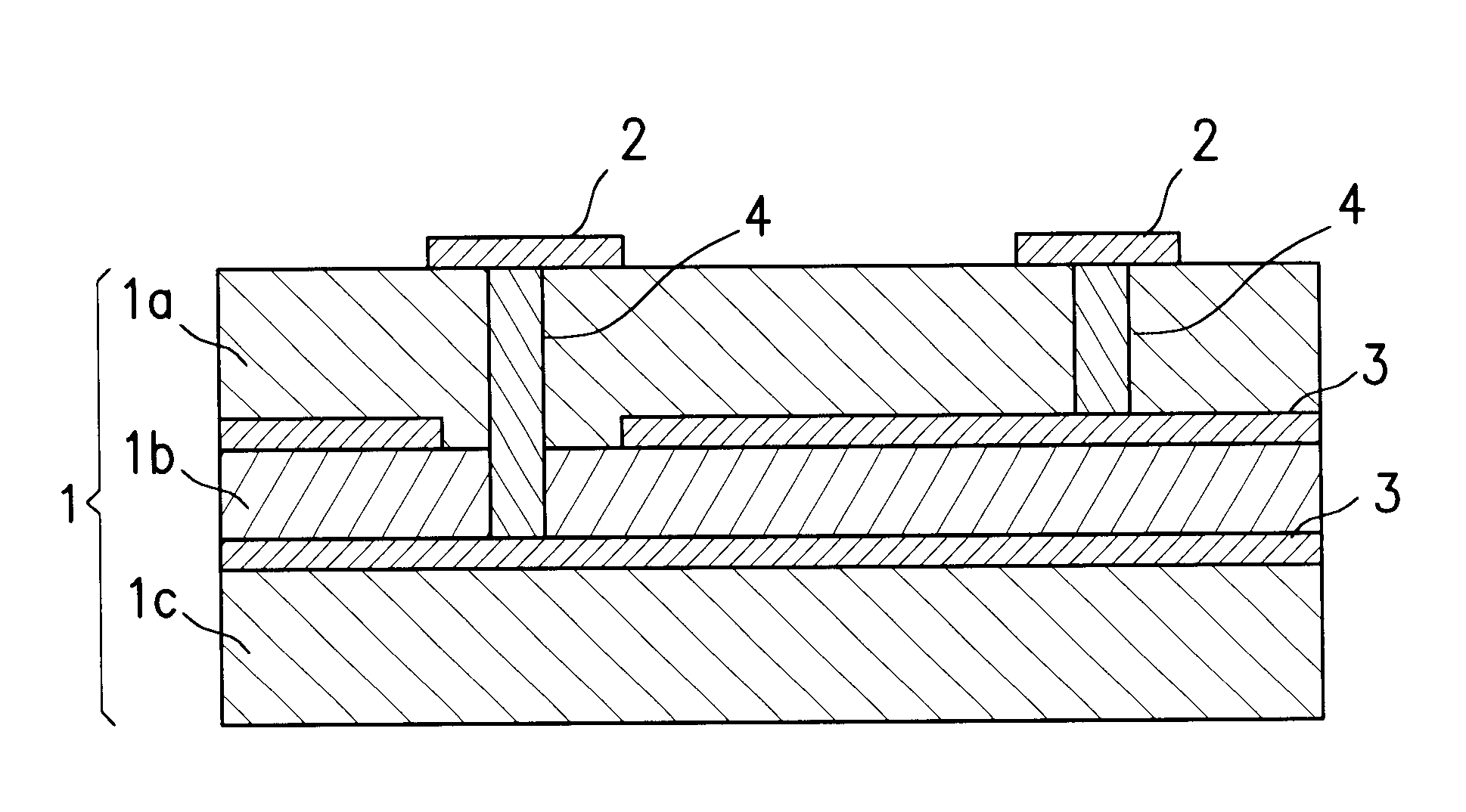

Amorphous dielectric capacitors on silicon

InactiveUS6255122B1Improve conformityReduce leakage currentTransistorSemiconductor/solid-state device manufacturingLead zirconate titanateMaterials science

High-capacity capacitors and gate insulators exhibiting moderately high dielectric constants with surprisingly low leakage using amorphous or low temperature films of perovskite type oxides including a titanate system material such as barium titanate, strontium titanate, barium strontium titanate (BST), lead titanate, lead zirconate titanate, lead lanthanum zirconate titanate, barium lanthanum titanate, a niobate, aluminate or tantalate system material such as lead magnesium niobate, lithium niobate lithium tantalate, potassium niobate and potassium tantalum niobate, a tungsten-bronze system material such as barium strontium niobate, lead barium niobate, barium titanium niobate, and Bi-layered perovskite system material such as strontium bismuth tantalate, bismuth titanate deposited directly on a silicon surface at temperatures about 450° C. or less.

Owner:GLOBALFOUNDRIES INC

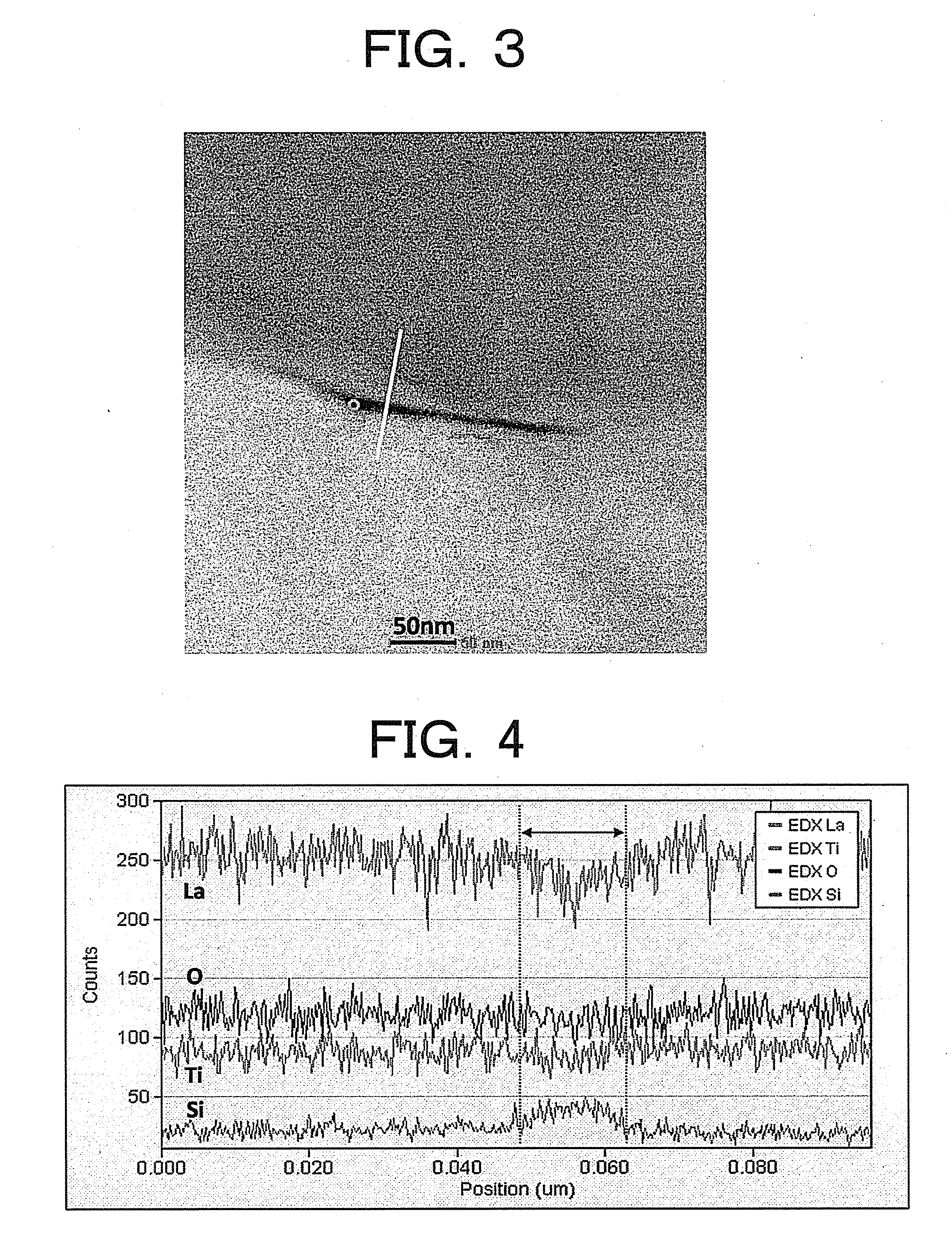

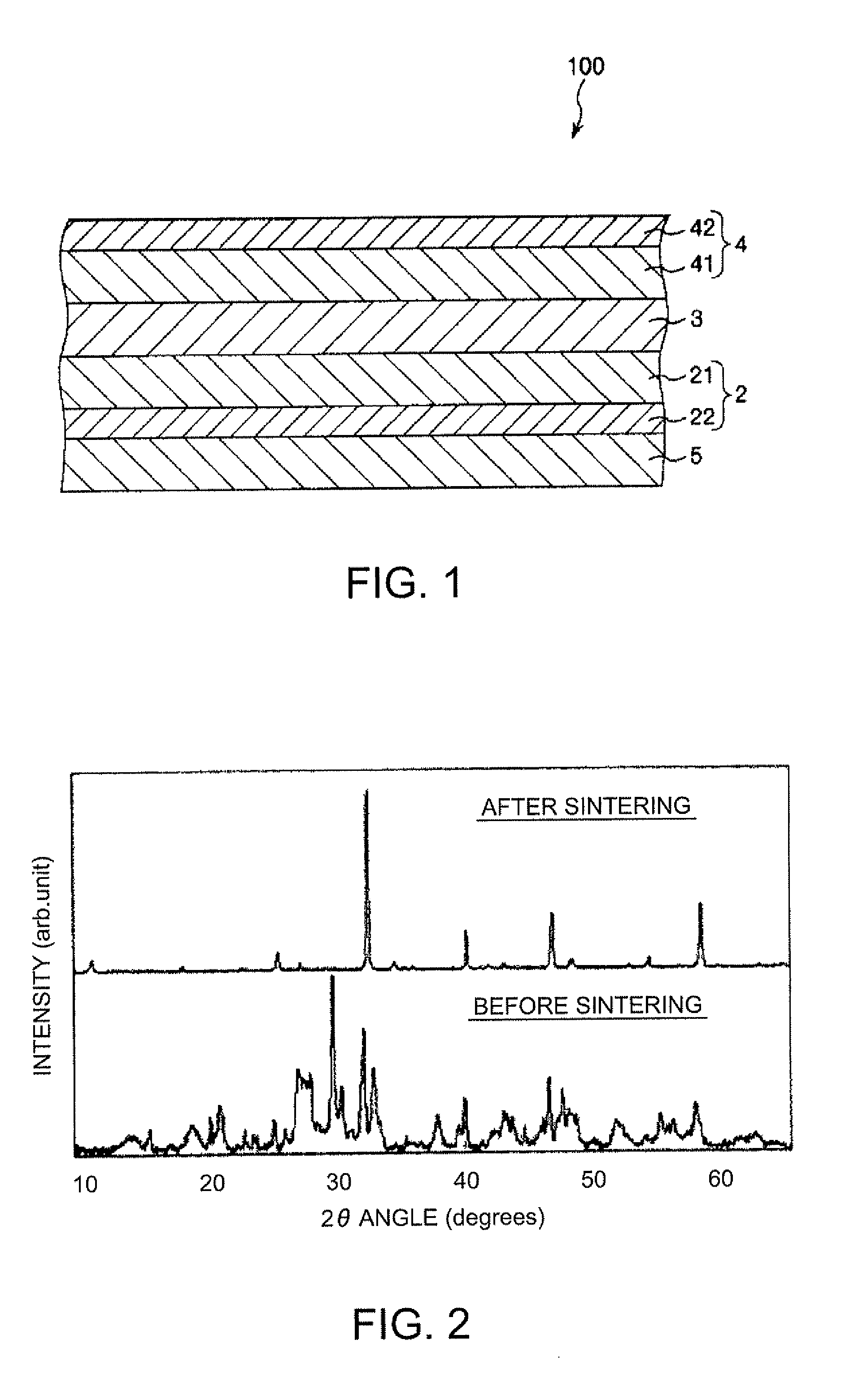

Li-la-ti-o composite solid electrolyte material containing silicon and synthesizing method thereof

ActiveUS20110059369A1Easy to implementImprove conductivitySecondary cellsSolid electrolyte cellsExperimental methodsAmorphous silicon

The invention relates to a lithium lanthanum titanate composite solid electrolyte material containing silicon in which amorphous Si or an amorphous Si compound exist in a grain boundary between crystal grains, and a method of producing the same, and belongs to a field of a lithium ion battery. According to the invention, the amorphous Si or the amorphous Si compound exist in the grain boundary between the crystal grains of the lithium lanthanum titanate. The amorphous Si or the amorphous Si compound are introduced into the grain boundary by employing a wet chemical method. In the wet chemical method, the inexpensive organosilicon compound is used as an additive, and the organosilicon compound is added into the lithium lanthanum titanate solid electrolyte material. Thus, it is possible to synthesize the lithium lanthanum titanate composite solid electrolyte material containing silicon by performing sintering when the ratio of mass of the Si or mass of the Si calculated based on mass of the Si compound to mass of the lithium lanthanum titanate is 0.27% to 1.35%. Grain boundary conductivity thereof is significantly improved, and therefore, total conductivity is improved. In addition, processes of the experimental method are simple and easily performed. Also, an experimental period is greatly reduced, a synthesis temperature is reduced, and energy consumption and production cost are reduced.

Owner:TOYOTA JIDOSHA KK +1

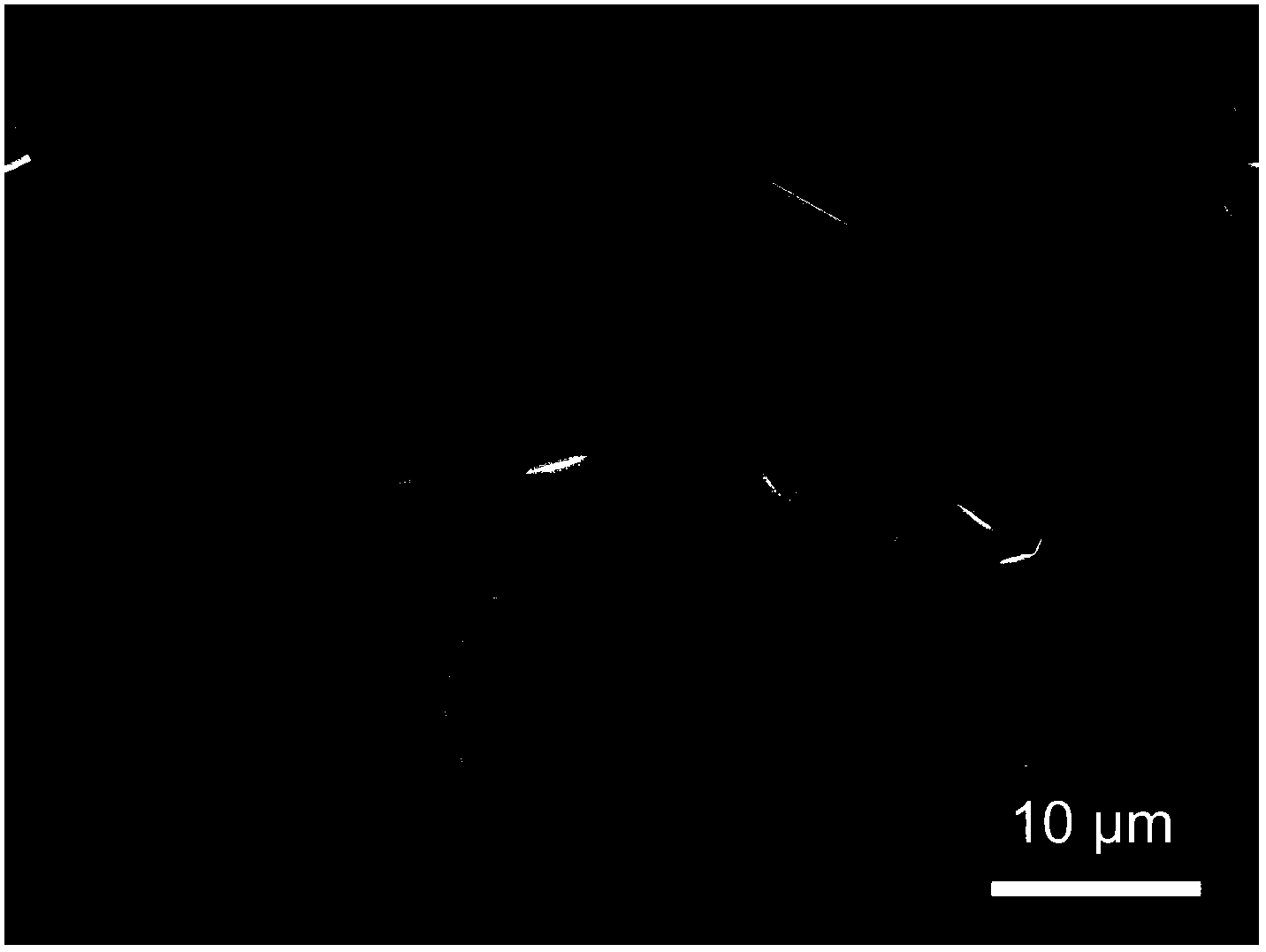

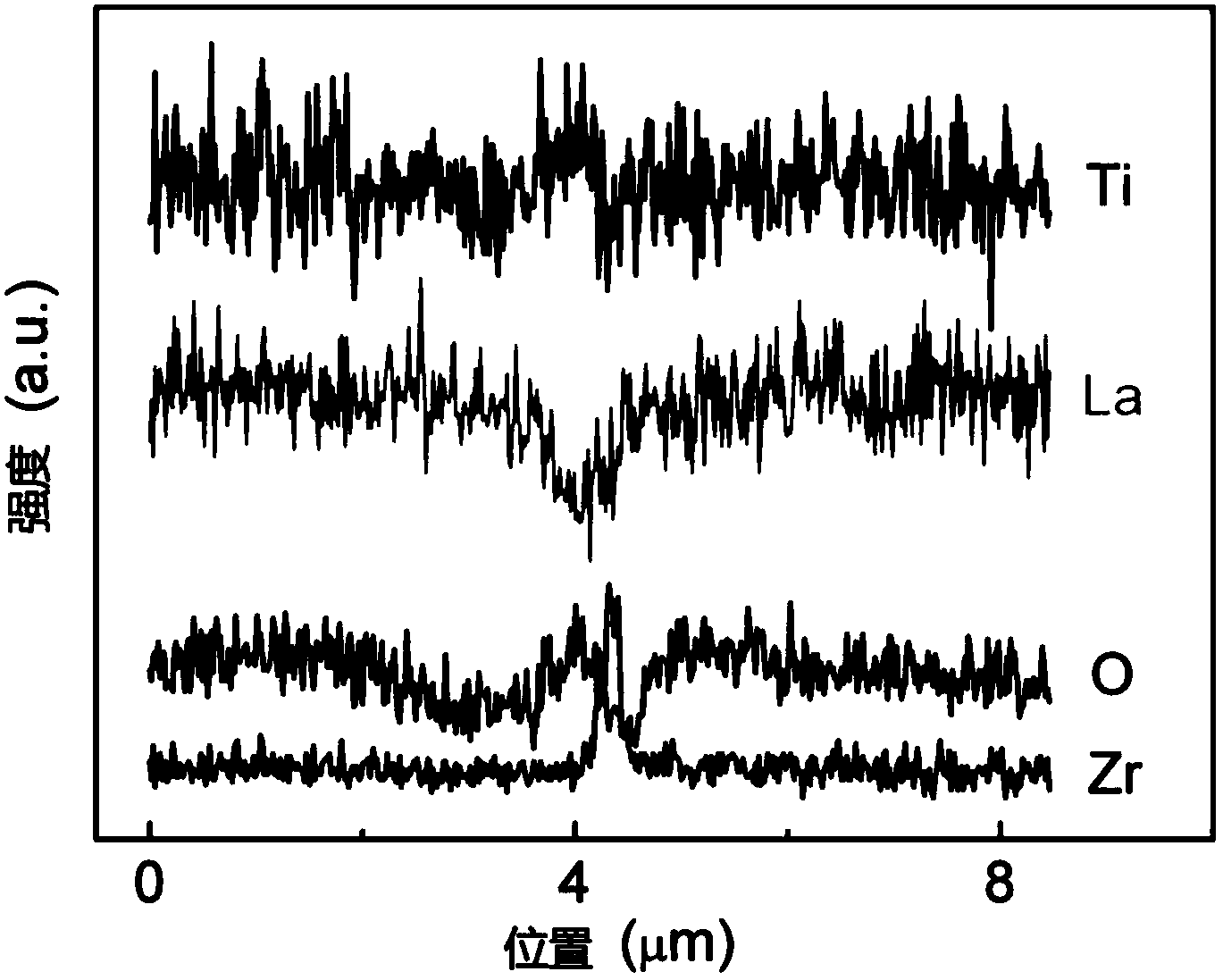

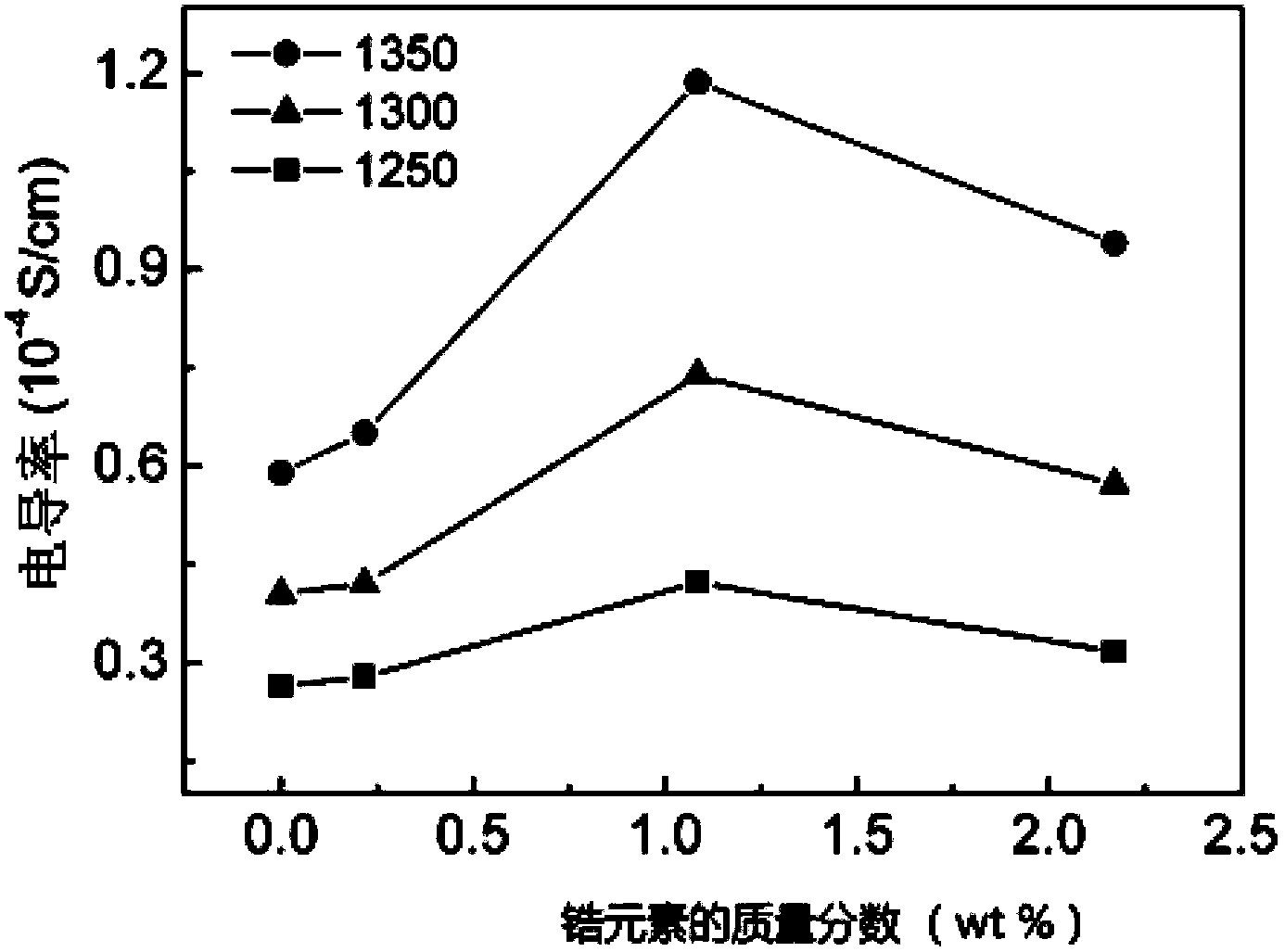

Lithium lanthanum titanate (LLTO) composite solid-state lithium ion electrolyte material, preparation method and application thereof

InactiveCN104051782AImprove grain boundary conductivityImprove overall conductivityFinal product manufactureElectrolytesPhysical chemistryBoundary conductivity

An embodiment of the invention provides a lithium lanthanum titanate (LLTO) composite solid-state lithium ion electrolyte material which is composed of Li<3x>La<2 / 3-x>TiO3 and zirconium which is enriched in a crystal boundary layer of the Li<3x>La<2 / 3-x>TiO3, wherein 0<x<0.16. The material is of excellent crystal boundary conductivity and total conductivity and is simple in a preparation technology. The embodiment of the invention also provides a preparation method of the LLTO composite solid-state lithium ion electrolyte material. A precursor powder of the composite solid-state lithium ion electrolyte material is prepared in a manner of coating LLTO by a lithium-lanthanum-zirconium-oxygen sol and then performing a sintering process to obtain the LLTO composite solid-state lithium ion electrolyte material. The LLTO is increased in crystal boundary conductivity and total conductivity. The preparation method is simple. In addition, the embodiment of the invention provides an application of the LLTO composite solid-state lithium ion electrolyte material in a lithium ion battery.

Owner:HUAWEI TECH CO LTD +1

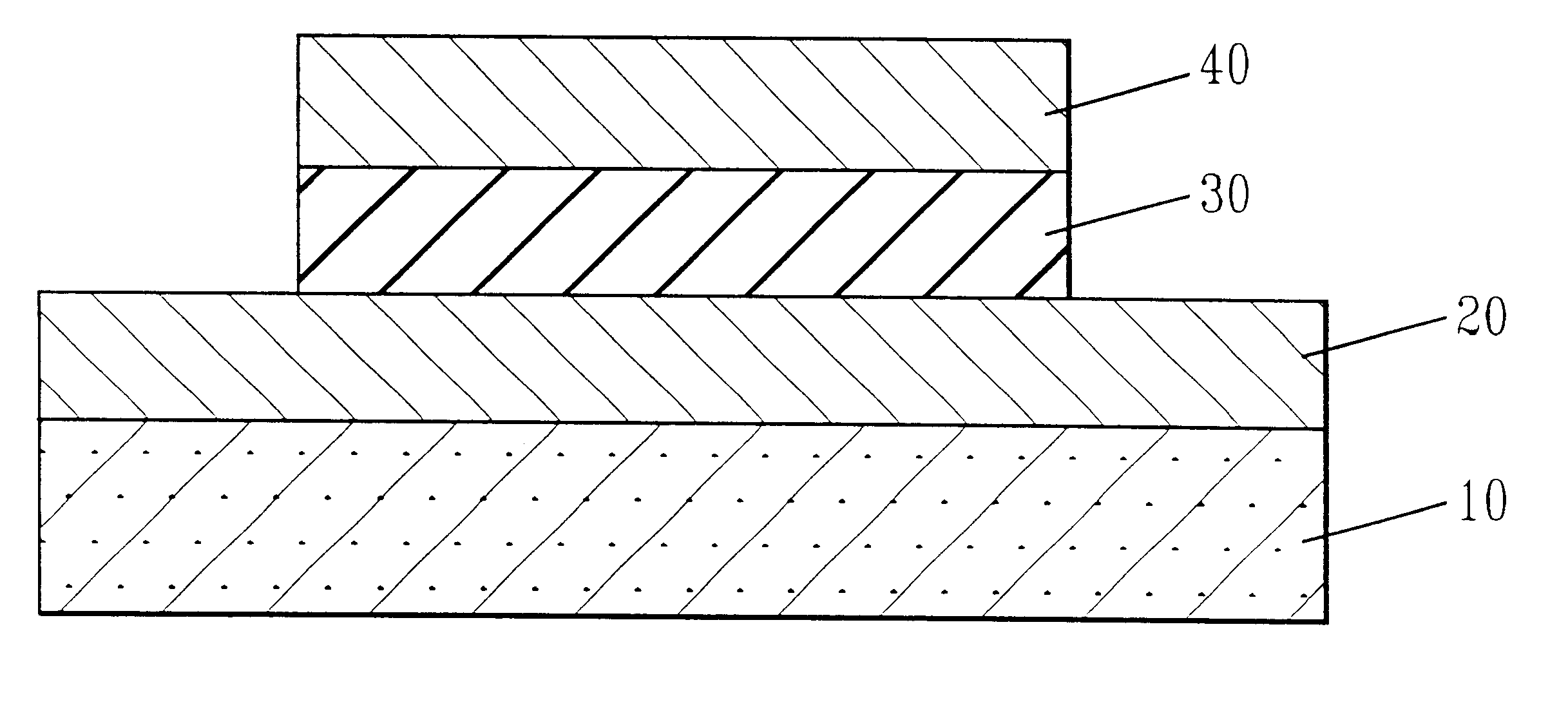

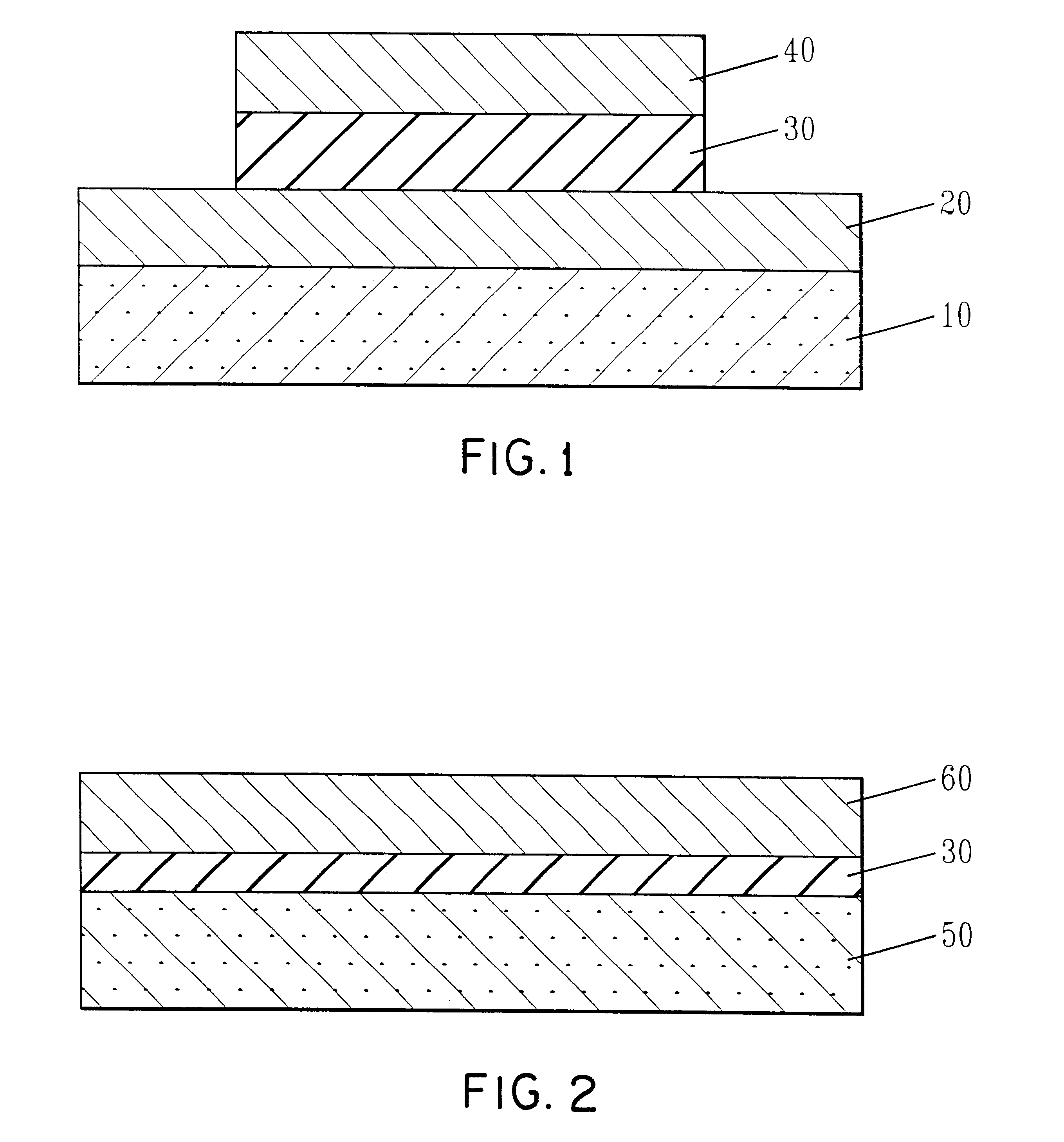

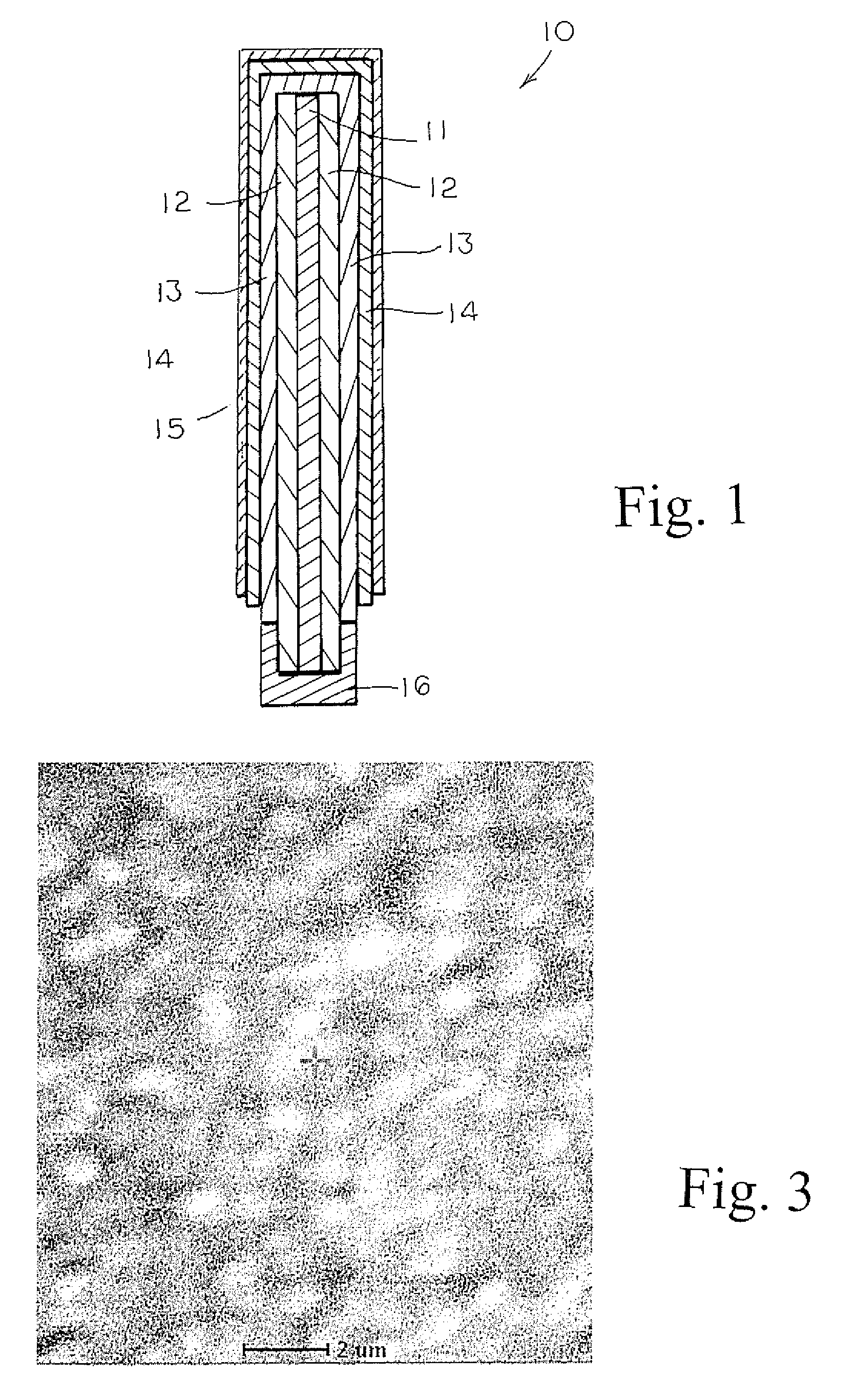

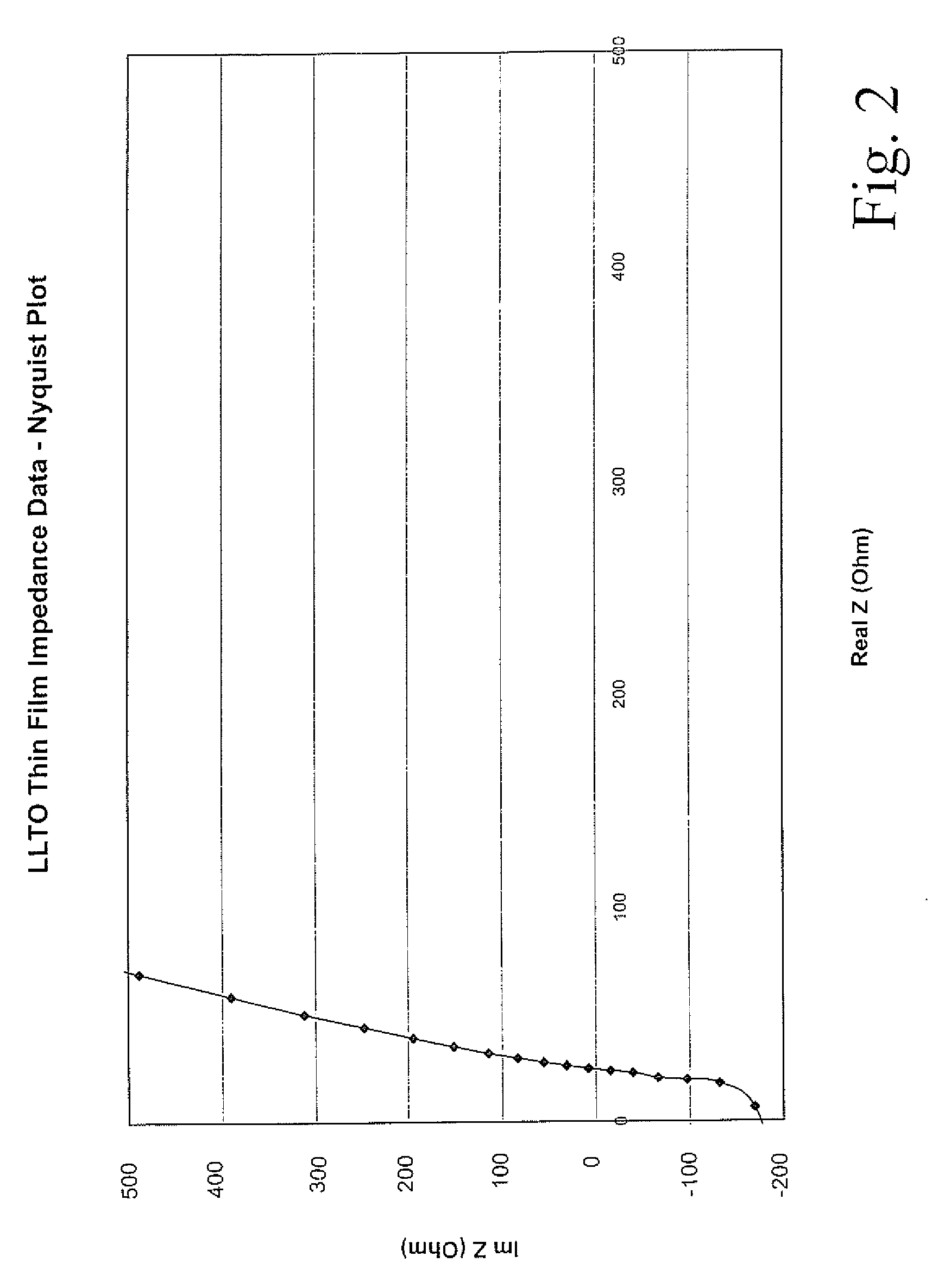

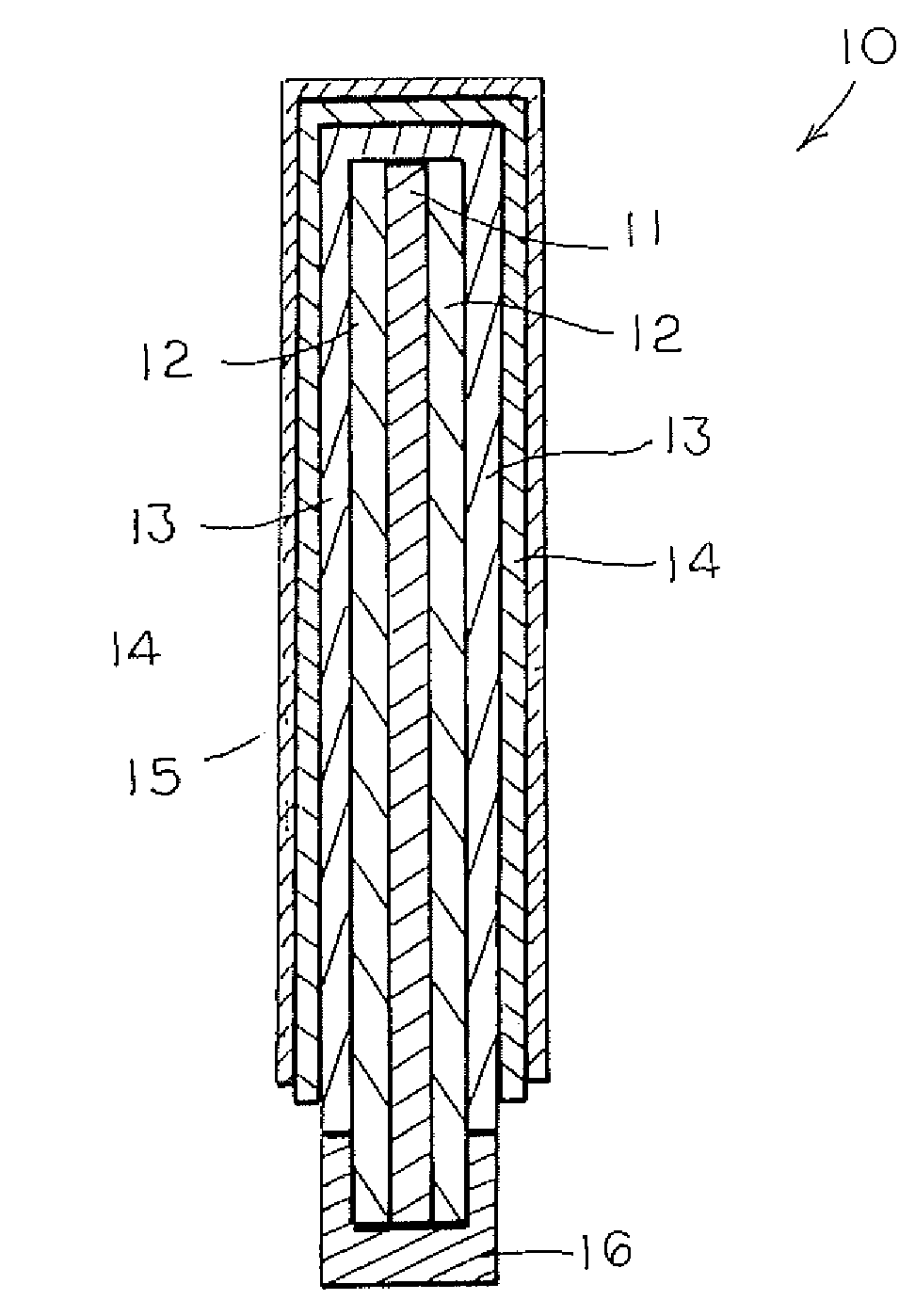

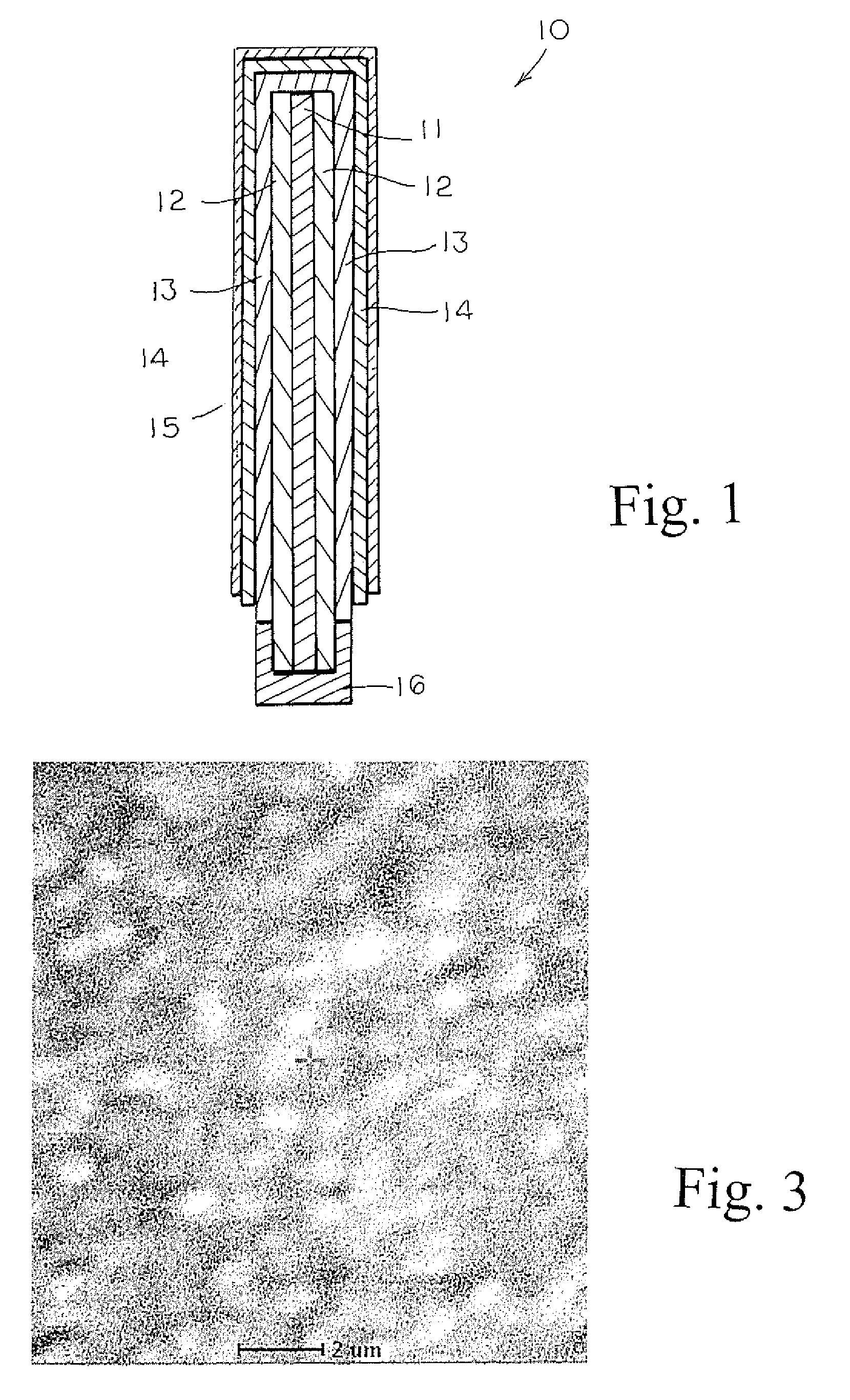

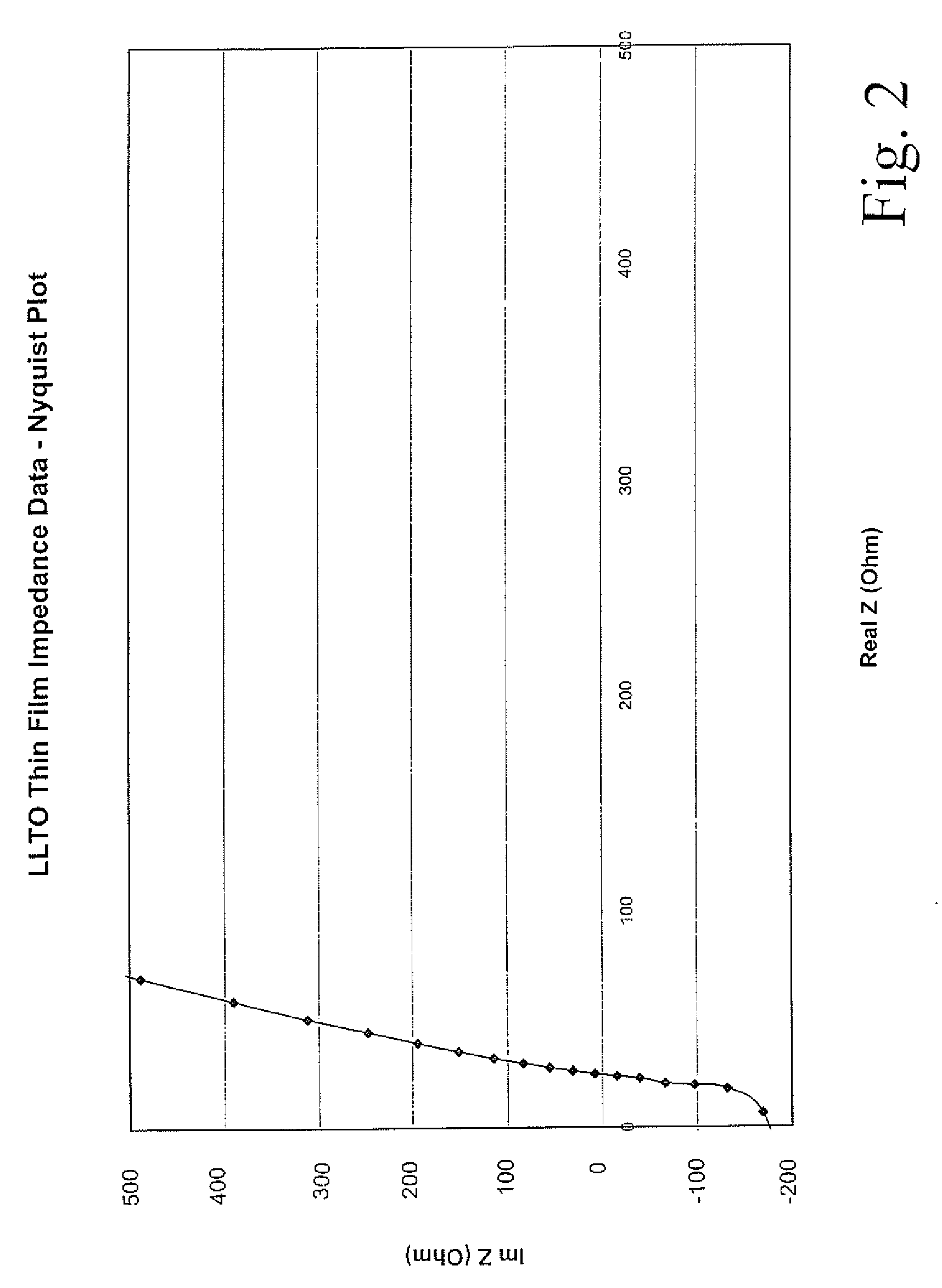

Amorphous lithium lanthanum titanate thin films manufacturing method

An amorphous lithium lanthanum titanate (LLTO) thin film is produced by the sol-gel method wherein a polymer is mixed with a liquid alcohol to form a first solution. A second solution is then prepared by mixing a lanthanum alkoxide with an alcohol. The first solution is then mixed with the lanthanum based second solution. A lithium alkoxide and a titanium alkoxide are then also added to the lanthanum based second solution. This process produces a batch of LLTO precursor solution. The LLTO precursor solution is applied to a substrate to form a precursor layer which is then dried. The coating techniques that may be used include spin coating, spraying, casting, dripping, and the like, however, the spin coating technique is the preferred method recited herein.

Owner:JOHNSON IP HLDG LLC

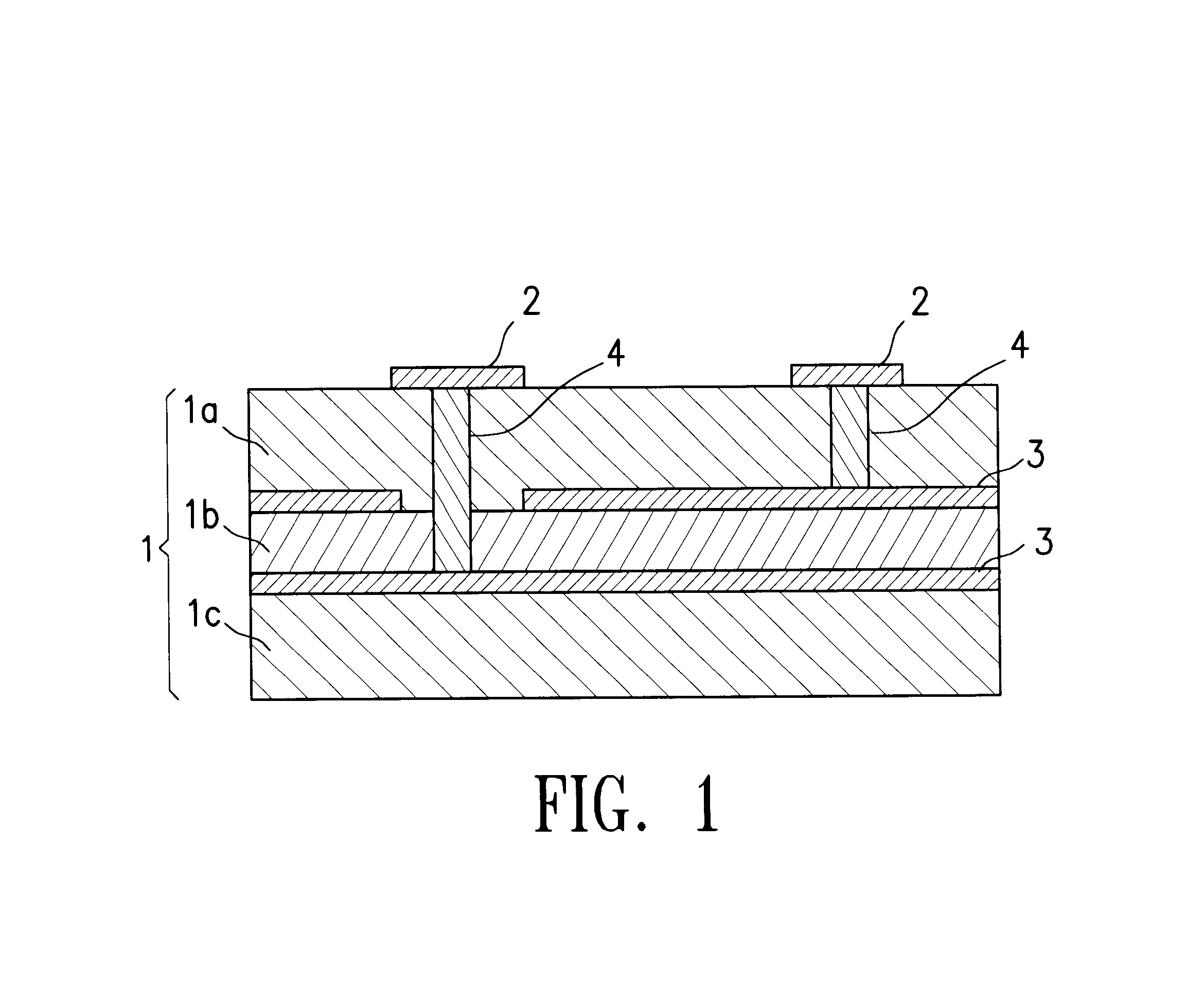

Ceramic wiring board

InactiveUS6447888B2Easy laminationReduce the differenceSemiconductor/solid-state device detailsPrinted circuit aspectsCeramic sinteringThermal expansion

A ceramic wiring board provided with an insulating layer of a high dielectric constant formed of a ceramic sintered product having a high dielectric constants wherein the ceramic sintered product contains a crystal phase of lanthanum titanate and a glass phase present on the grain boundaries of the crystal phase, and has a coefficient of thermal expansion at 40 to 400.degree. C. of not smaller than 8.times.10.sup.-6 / .degree. C. and a specific inductive capacity at 1 MHz of not smaller than 10. The wiring board contains a capacitor and is very useful in realizing various electric circuit devices in small sizes, and can be further reliably mounted on a printed board that uses an organic resin as an insulating material.

Owner:KYOCERA CORP

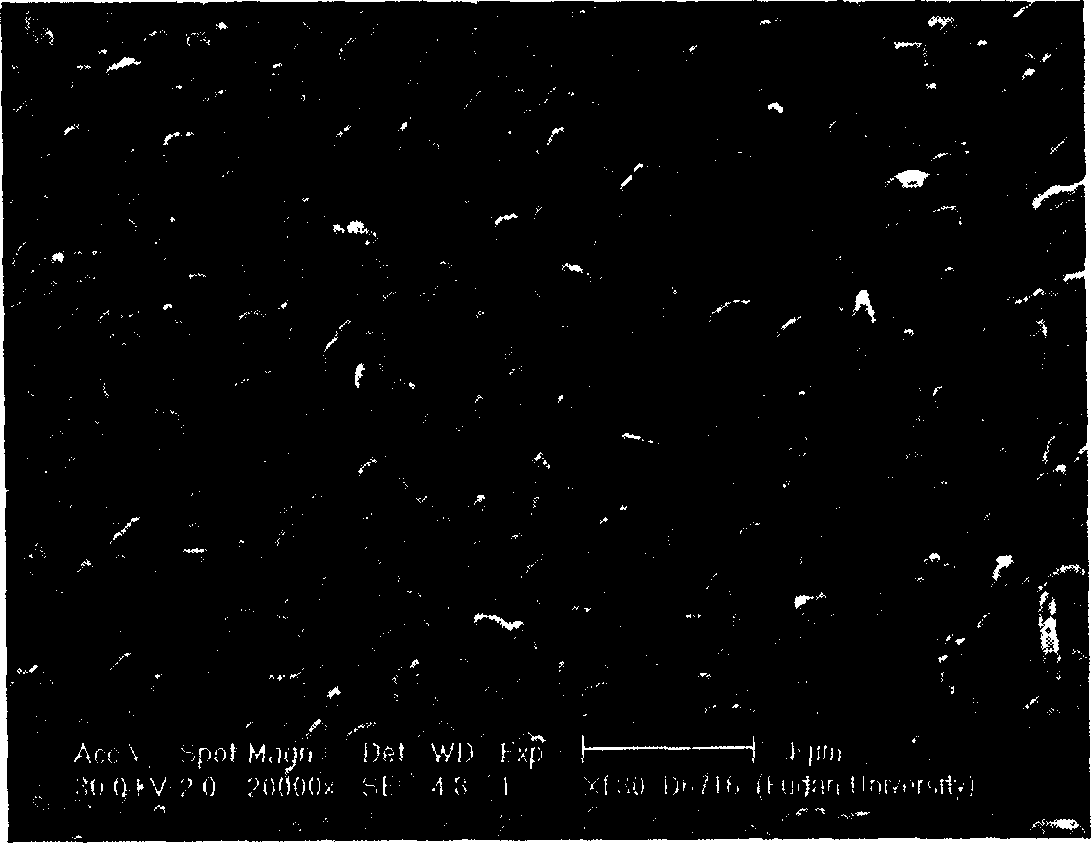

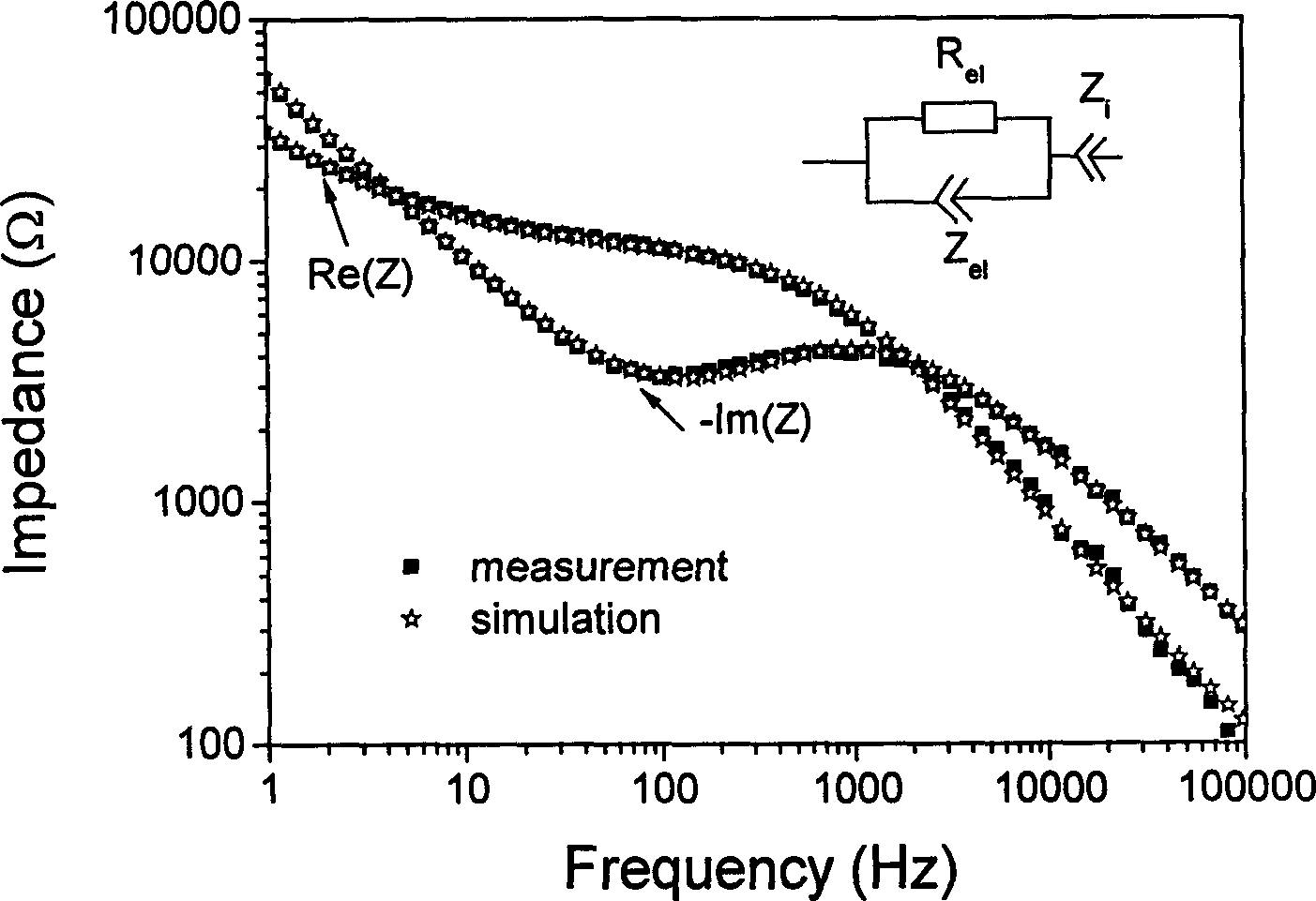

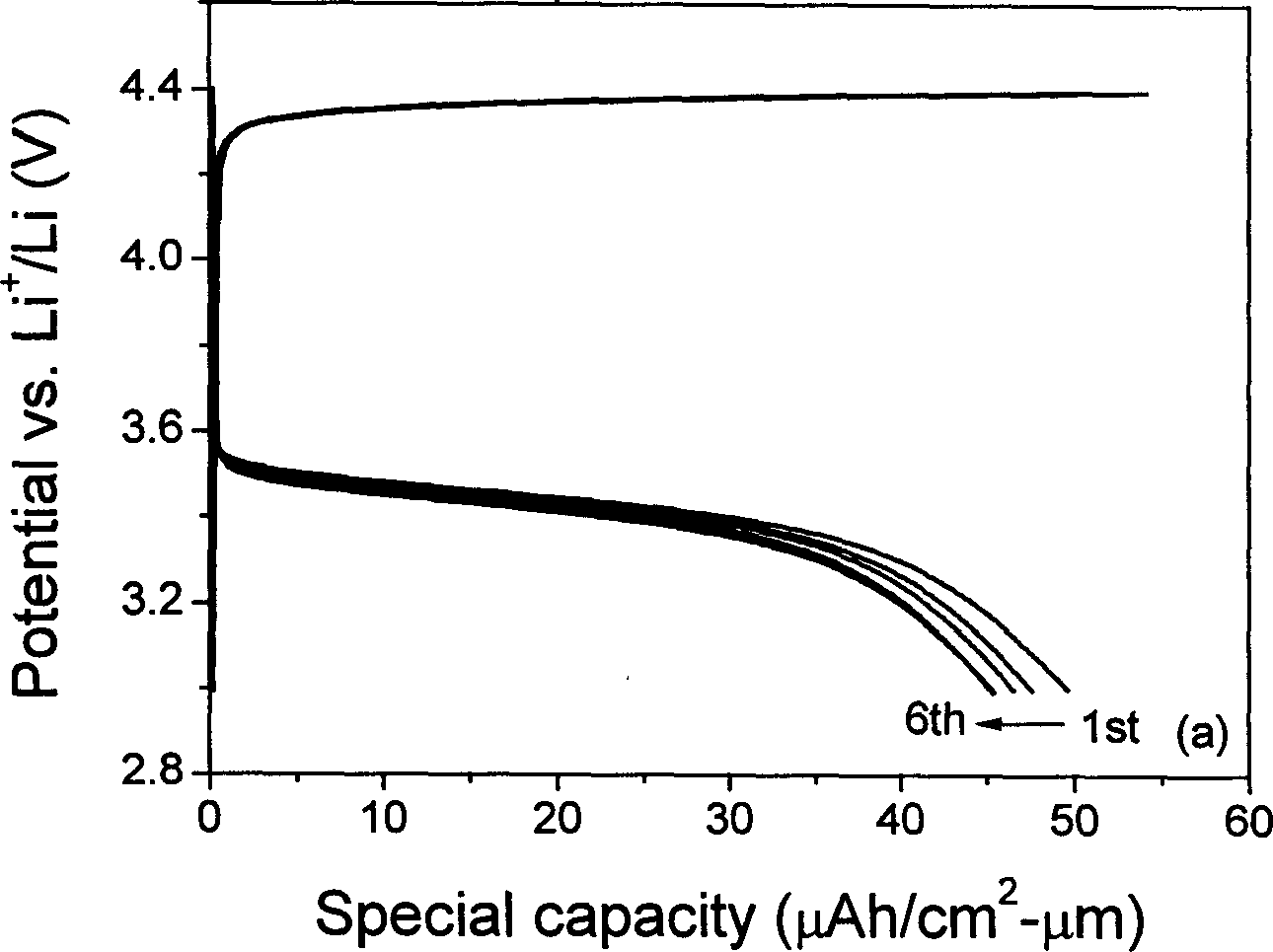

Method for preparing LLTO(lithium lanthanum titanate) film by electron beam heat evaporation

InactiveCN1789483AImprove charge and discharge performanceVacuum evaporation coatingSputtering coatingMetallic lithiumSolid state electrolyte

The invention, belonging to lithium ion hull cell technical field, relates the method for preparation of LLTO used for solid state thin film lithium battery. The invention adopts the electron-beam vapor deposition method to prepare LLTO, comprising the following characteristics: large film deposit area, big deposition rate, and lithium ion ionic conductivity being 2í‡10-7S / cm. The LiCoO2 or LiMn2O4, LiPON and antiabrasion layer film, which are made with the method of radio-frequency magnetic control sputtering, and the metallic lithium anode film made with the method of vacuum heat evaporation are assembled to solid state thin film lithium battery. The specific capacity of cell is 45mAh / cm2-ª–m and 24mAh / cm2-ª–m, and the cycle index is up to 150 times. So the LLTO solid state electrolyte thin film made by the method of electron-beam evaporation can be used in solid state thin film lithium battery.

Owner:FUDAN UNIV

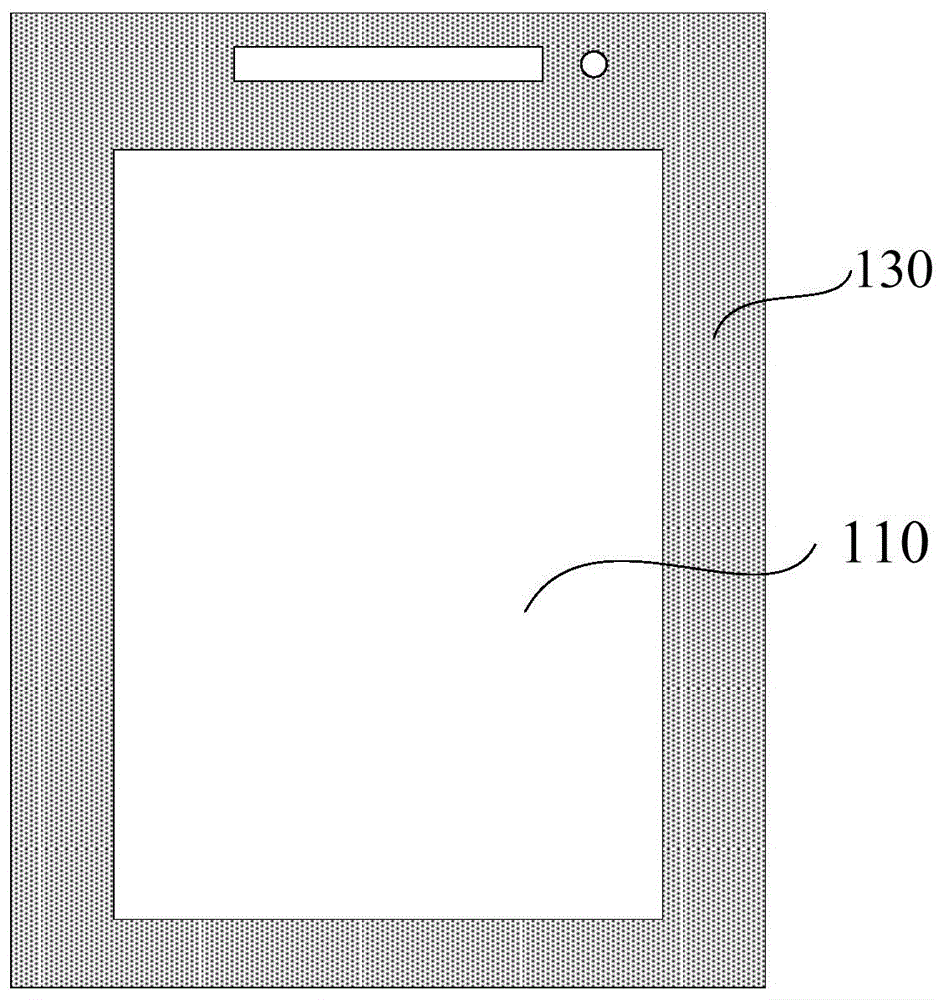

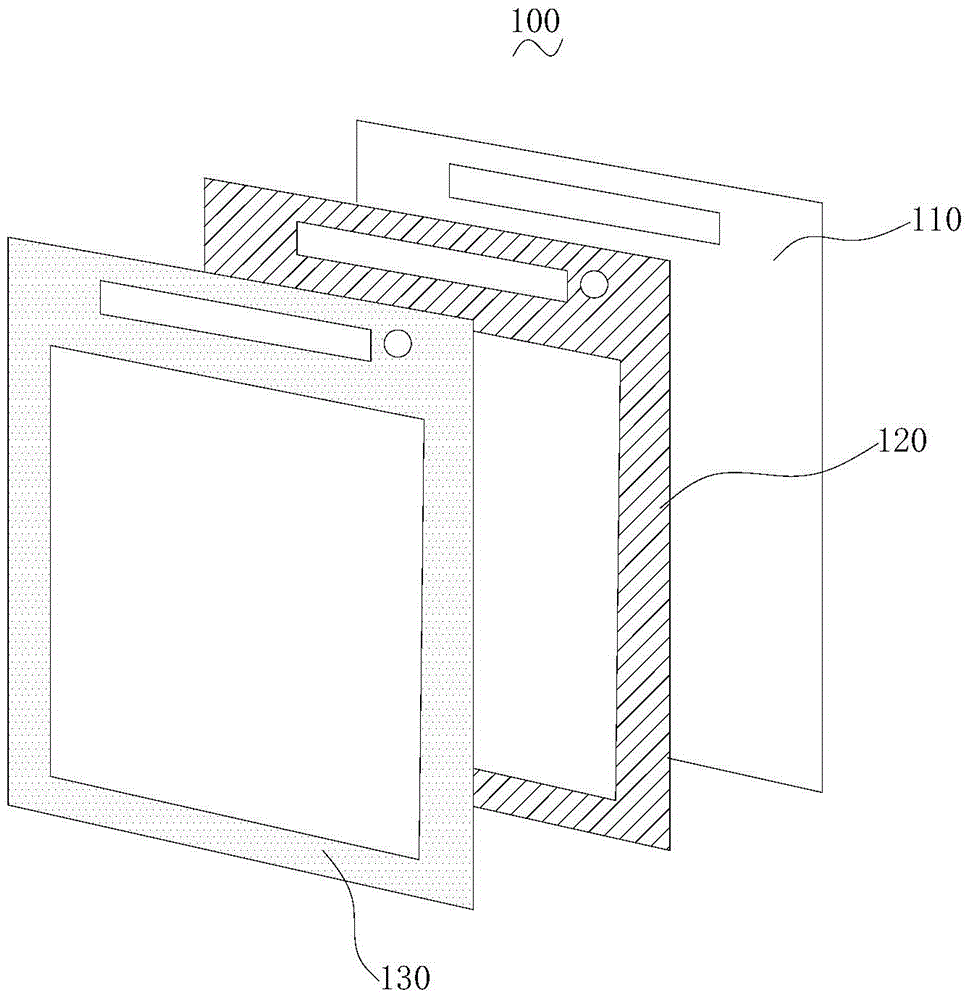

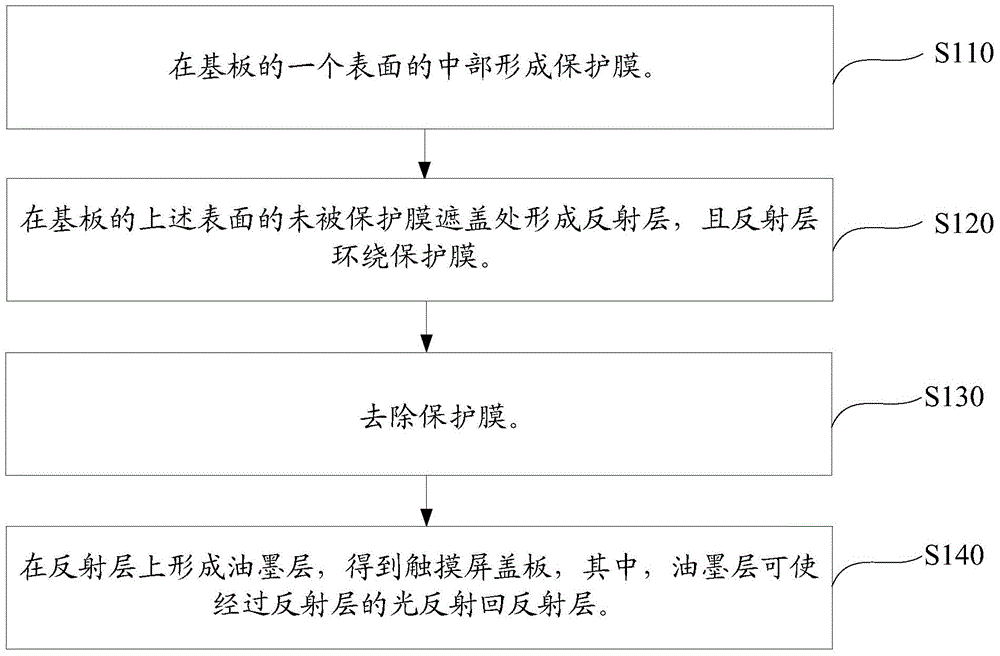

Touch screen cover plate and manufacturing method thereof

InactiveCN106033288AHigh glossImprove reflectivityInput/output processes for data processingZinc selenideBarium titanate

The invention relates to a touch screen cover plate and a manufacturing method thereof. The touch screen cover plate comprises a substrate, a reflecting layer, and an ink layer. The reflecting layer is formed on one surface of the substrate. The reflecting layer is arranged on the periphery of the edge of the substrate. The reflecting layer is a metal elemental film or a compound film. The compound film is one selected from an oxide film, a fluoride film, a zinc sulfide film, a zinc selenide film, a titanium nitride film, a silicon carbide film, a lanthanum titanate film, a barium titanate film, a strontium titanate film, a praseodymium titanate film, and a cadmium sulfide film. The ink layer is on the reflecting layer, and the ink layer can reflect light which passes through the reflecting layer back to the reflecting layer. The touch screen cover plate has relatively high reflectivity, so glossiness of the touch screen cover plate is good.

Owner:NANCHANG O FILM OPTICAL TECH +3

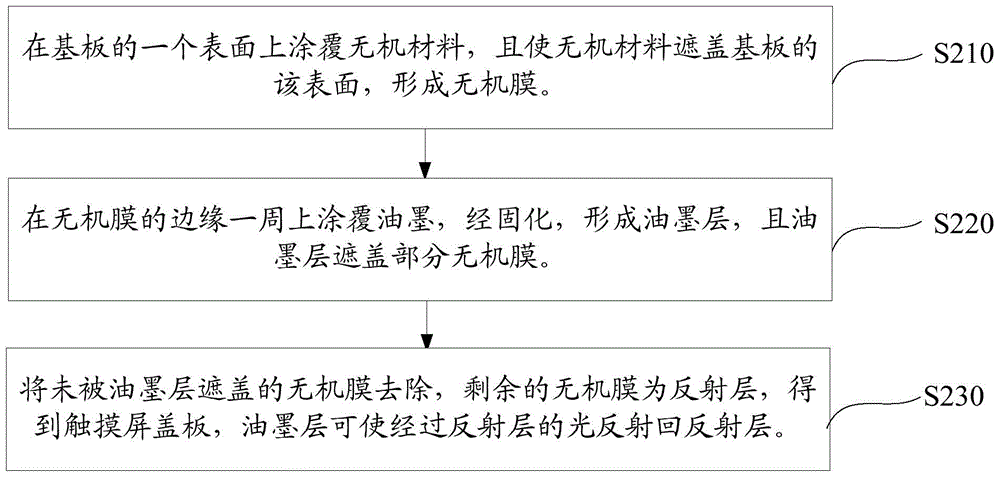

Manufacturing method for touch screen cover plate

InactiveCN106033273AHigh glossIncrease reflectionInput/output processes for data processingLanthanum titanateOxide

The invention relates to a manufacturing method for a touch screen cover plate. The manufacturing method for a touch screen cover plate comprises the following steps: forming a protection film on the middle part of a surface of a substrate; forming a reflecting layer on the position which is not covered by the protection film on the surface of the substrate, and the reflecting layer surrounding the protection film, the reflecting layer being a metal elemental layer, a metal alloy layer, a compound layer, or a silicon layer, the compound layer being one or more selected from an oxide layer, a fluoride layer, a zinc sulfide layer, a zinc selenide layer, a titanium nitride layer, a silicon carbide layer, a lanthanum titanate layer, a barium titanate layer, a strontium titanate layer, a praseodymium titanate layer, and a cadmium sulfide layer; removing the protection film; forming an ink layer on the reflecting layer, to obtain a touch screen cover plate. The ink layer can make light through the reflecting layer reflected back to the reflecting layer. The manufacturing method is simple in operation, and the manufactured touch screen cover plate has relatively good glossiness.

Owner:NANCHANG O FILM OPTICAL TECH +3

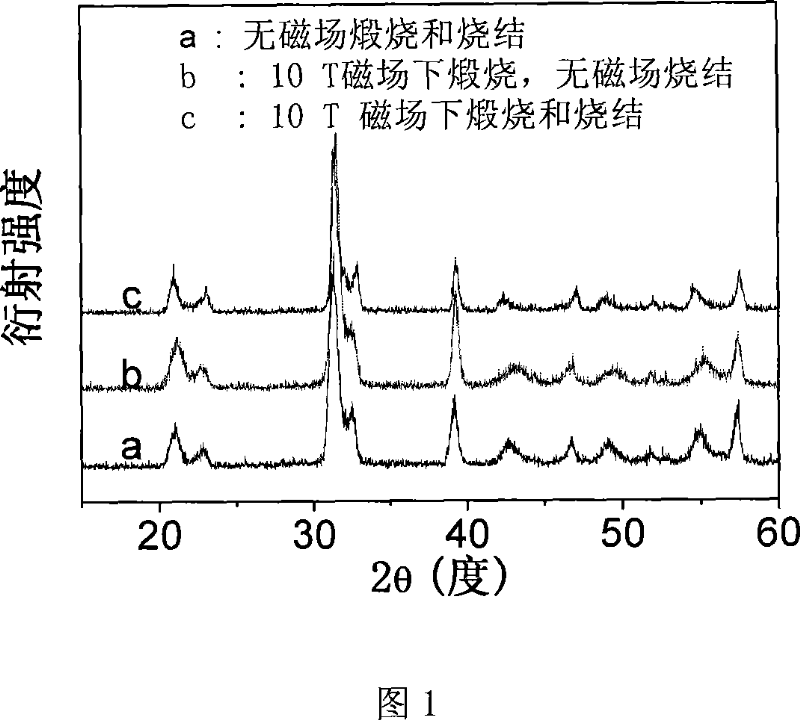

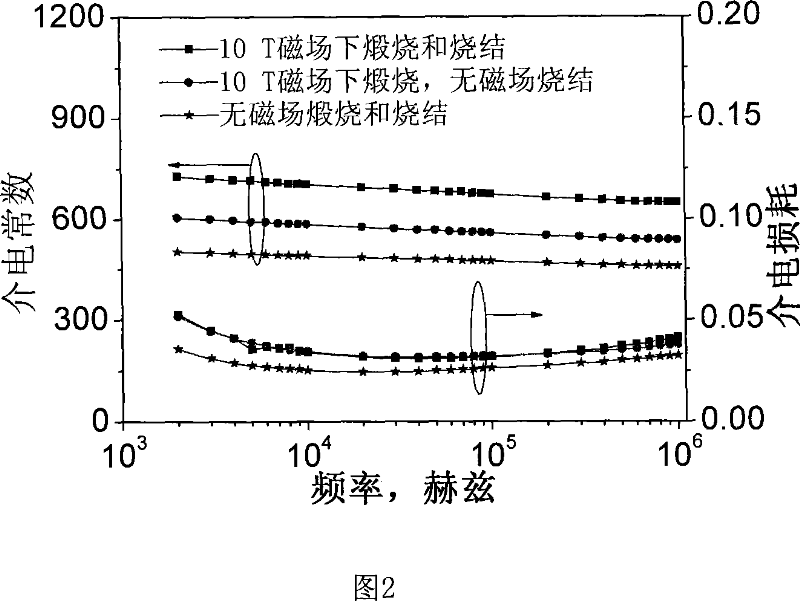

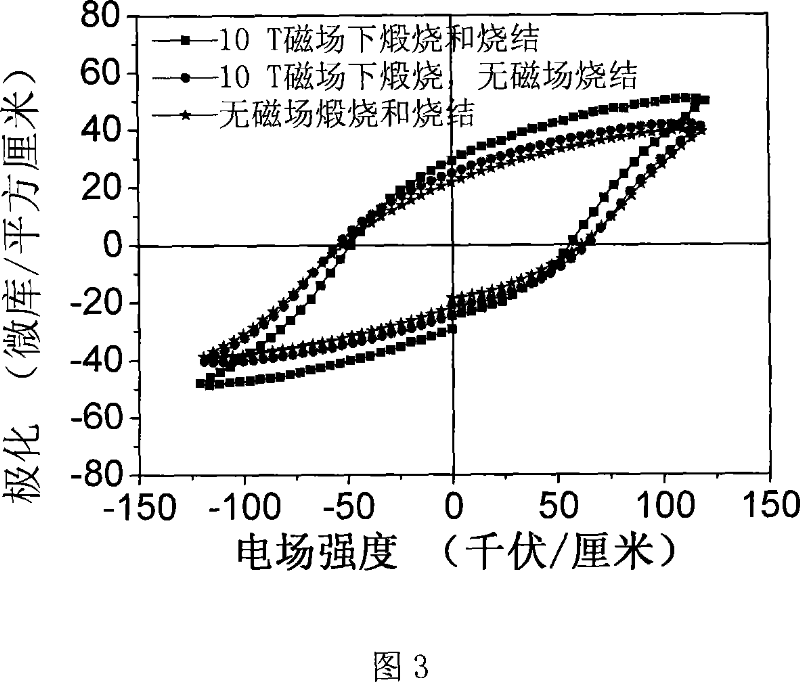

Method for preparing ferrite bismuth lanthanum-titanate lead solid solution ceramic under strong magnetic field action

The invention relates to a method for producing ferric acid bismuth lanthanum-lead titanate solid solution ceram in an intense magnetic field, belonging to the technical field of inorganic non-metal material and solid solution ceram material. The designed chemical formula of ferric acid bismuth lanthanum-lead titanate solid solution ceram is: (1-x)(Bil-yLay)FeO3-xPbTiO3; wherein: 0.2<=x<=0.6, y=0-0.4; weighing and preparing materials according to the chemical dosage rate of the chemical formula; weighing and mixing the Bi2O3, La2O3, Fe2O3, PbCO3 and TiO2 powder with a purity more than 99.9%, adding ethanol as abrasive, zirconia grain as abrasing medium; ball milling for 24 hours in the ball mill, mixing sufficiently and levigating; calcining and synthesizing in 750 DEG C in the magnetic intensity of 7-14T for 24 hours; ball milling for 24 hours; then doing a secondary ball milling; then prilling, tabletting; finally sintering the pressed compact in 1080-1100 DEG C, meanwhile introducing the intense magnetic field and obtaining the ferro-electricity ferromagnetism ceramic material.

Owner:SHANGHAI UNIV

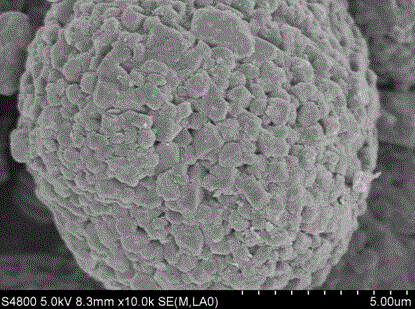

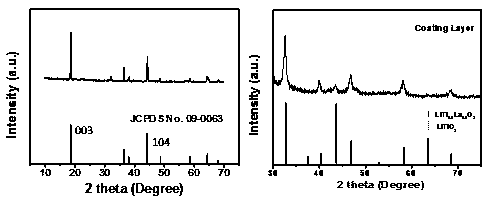

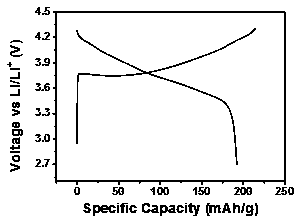

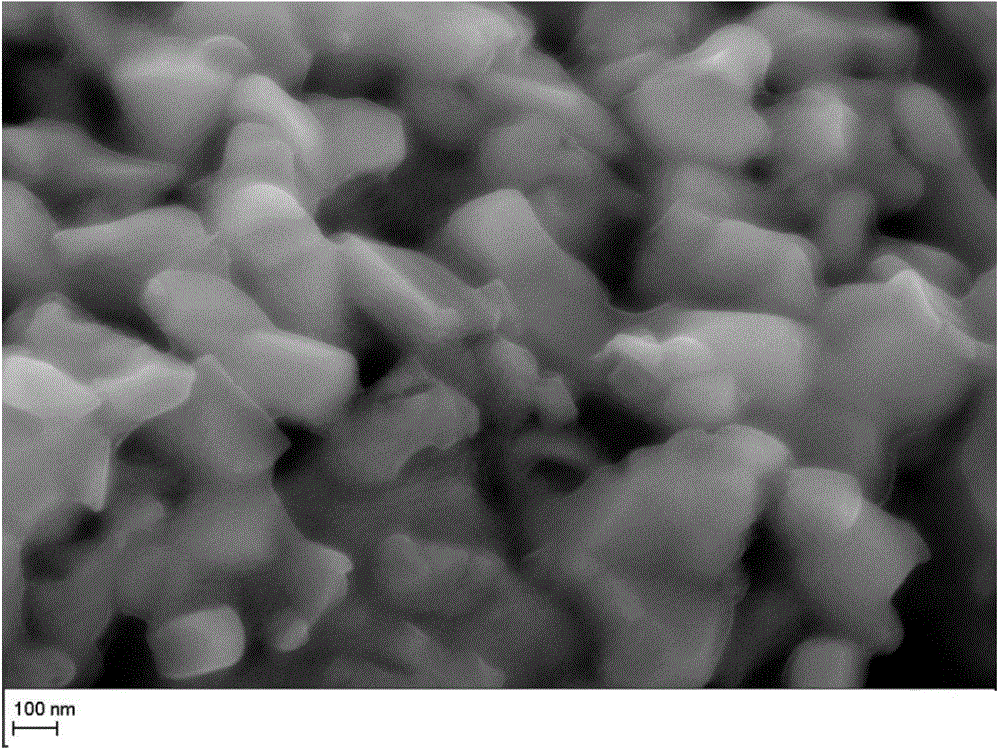

Nickel cobalt lithium manganate composite anode material of lithium ion battery and preparation method of nickel cobalt lithium manganate composite anode material

ActiveCN104835955AImproved magnification performanceImprove cycle performanceCell electrodesManganateConductive materials

The invention relates to a nickel cobalt lithium manganate composite anode material of a lithium ion battery and a preparation method of the nickel cobalt lithium manganate composite anode material, and belongs to the technical field of anode materials of lithium ion batteries. The composite anode material comprises nickel cobalt lithium manganate and lithium lanthanum titanate wrapping the surface of the nickel cobalt lithium manganate. The chemical formula of the composite anode material is LiNixCoyMn(1-x-y) O2 / LizLa (2-z) / 3TiO3, x is greater than 1 and smaller than 1, y is greater than 0 and smaller than 1, (x+y) is greater than 1 and smaller than 1, z is greater than or equal to 0.5 and smaller than or equal to 1.5, and the mass percent of the lithium lanthanum titanate is 0.5-1.5%wt. A layer of stable conductive materials which are the lithium lanthanum titanate wraps the surface of the nickel cobalt lithium manganate composite anode material. On one hand, the structure of the nickel cobalt lithium manganate composite anode material is quite stable; and on the other hand, the ionic conductivity of the nickel cobalt lithium manganate material is quite high, so that dissolution of the nickel cobalt lithium manganate material is restrained, the conductivity is improved, and the rate capability and the recycling performance of the material are greatly improved.

Owner:中国东方电气集团有限公司

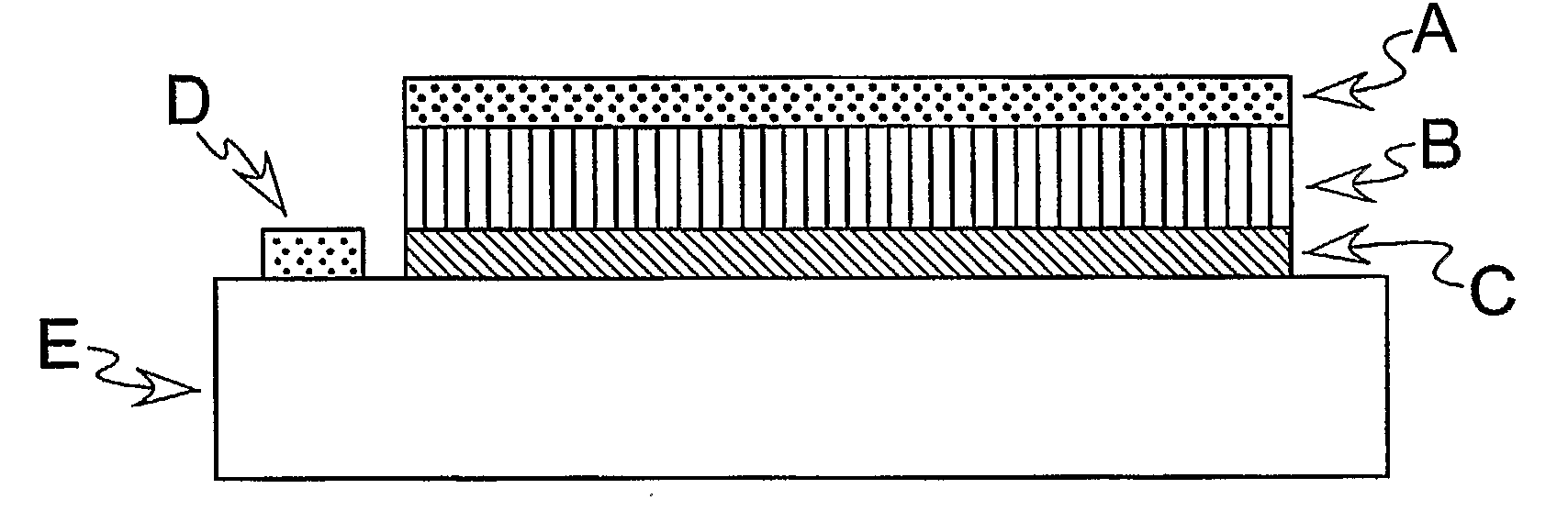

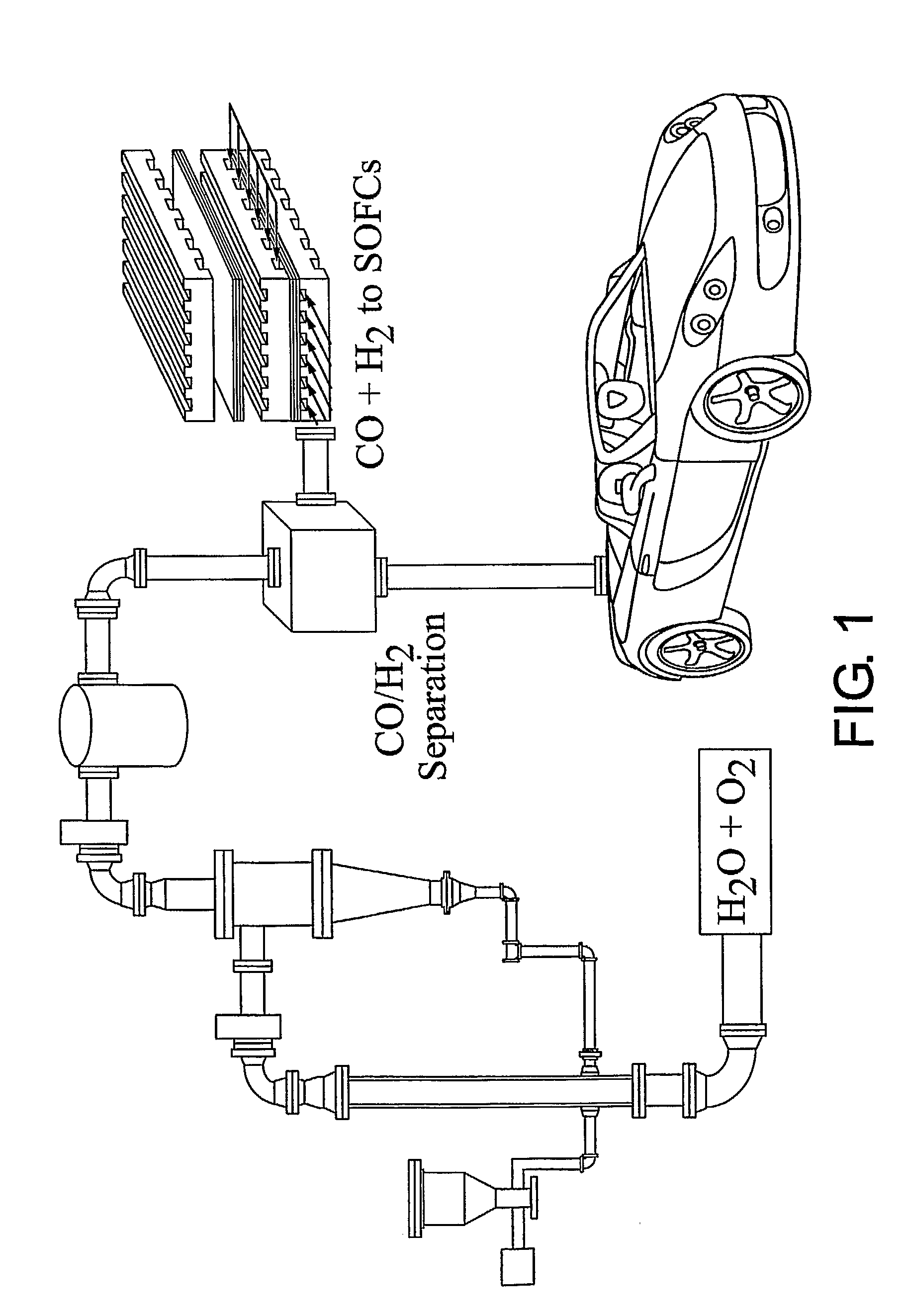

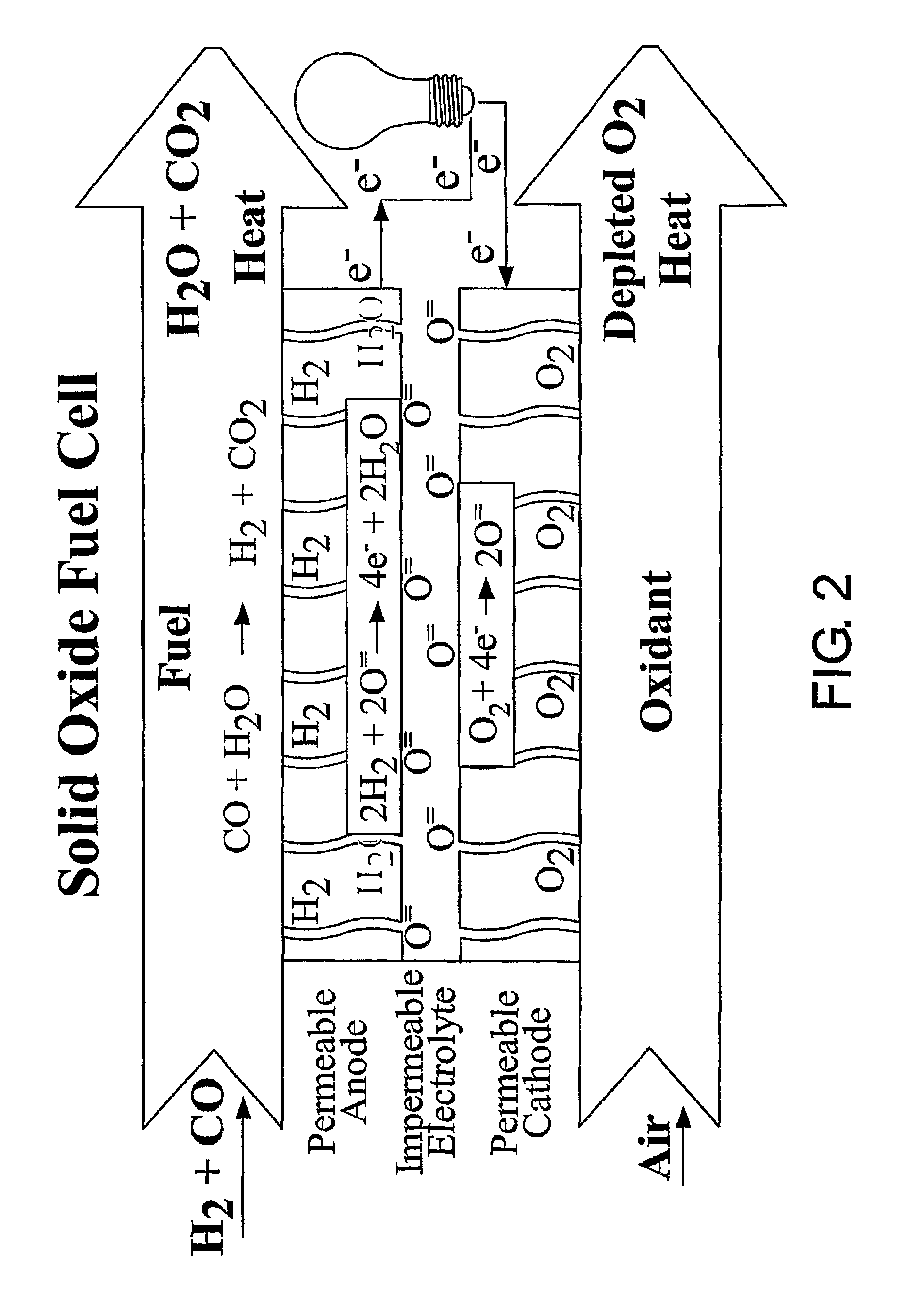

Sulphur-Tolerant Anode For Solid Oxide Fuel Cell

InactiveUS20080138669A1Efficiently oxidizedHigh densityFuel cell auxillariesNegative electrodesStrontium titanateLanthanum

An anode for a solid oxide fuel cell. The anode is not harmed by sulfur-containing compounds, nor is its resistance increased thereby. The anode has two layers, including a “protective” layer (A) and a layer (B) that oxidizes molecular hydrogen The protective layer has a diffusion rate for molecular hydrogen that exceeds its diffusion rate for sulfur-containing compounds, and has an oxidation rate for sulfur-containing compounds that exceeds its oxidation rate for molecular hydrogen. The first anode layer can be selected fro the group of Lanthanum Strontium Titanate (LST) and Lanthanum Strontium Vanadate (LSV), and the second anode layer is made of Gadolinium Doped Cerium oxide (GDC) and nickel. The first layer can include Yttria Stabilized Ziroonia (YSZ), and the second layer can include YSZ interspersed throughout the layer as a separate phase.

Owner:OHIO UNIV

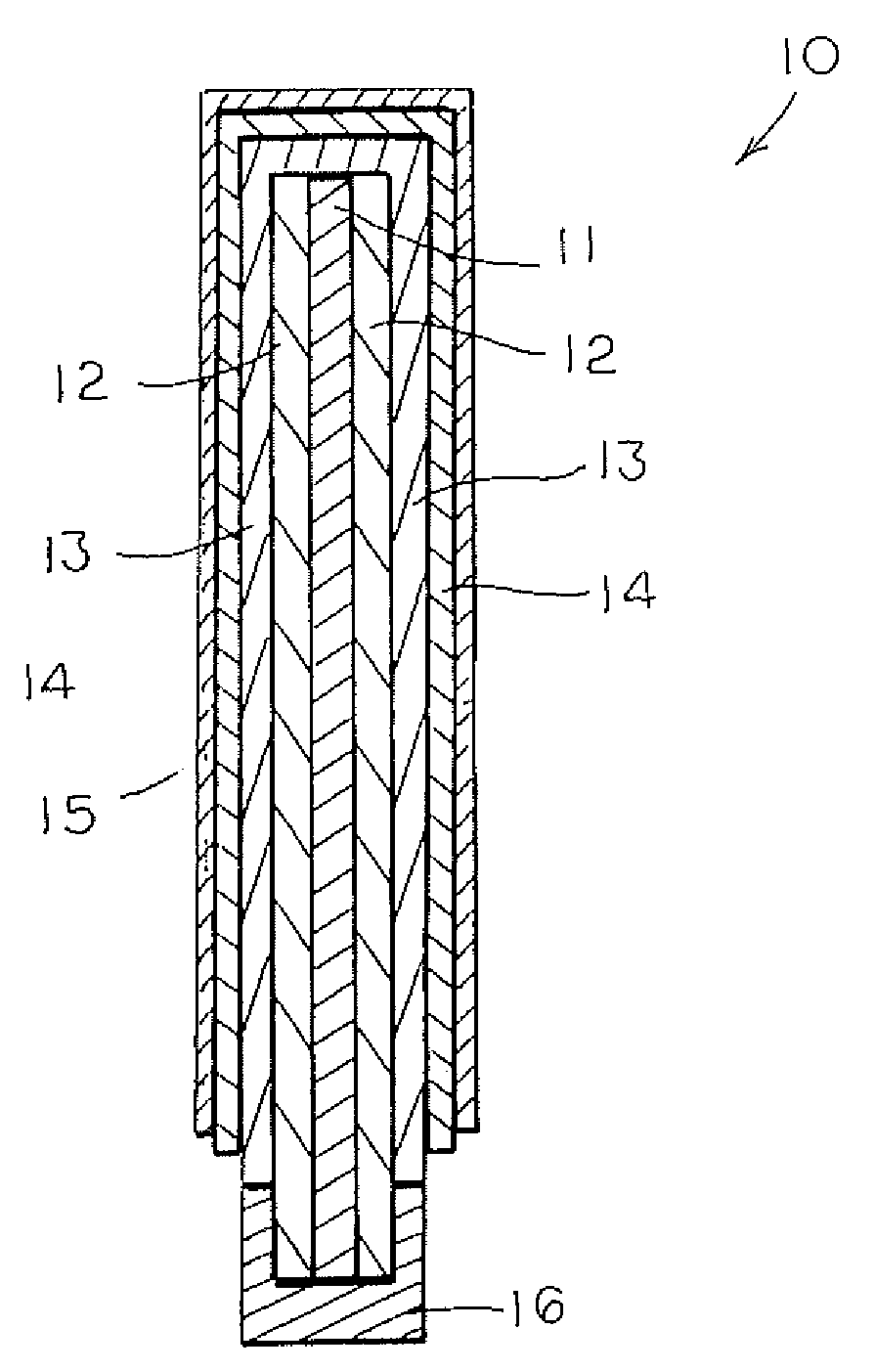

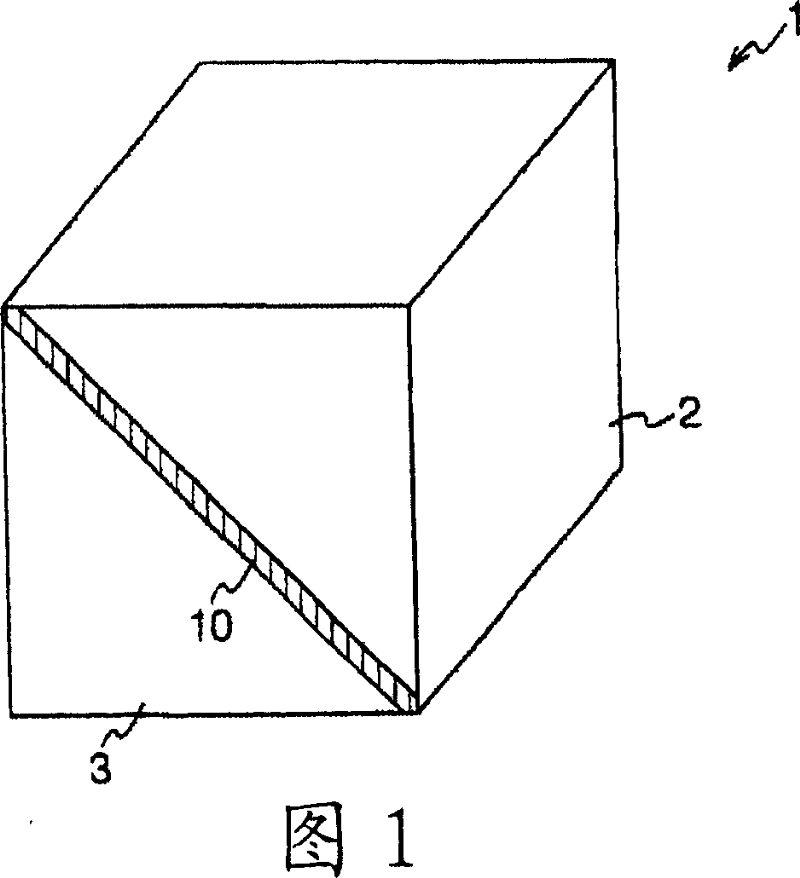

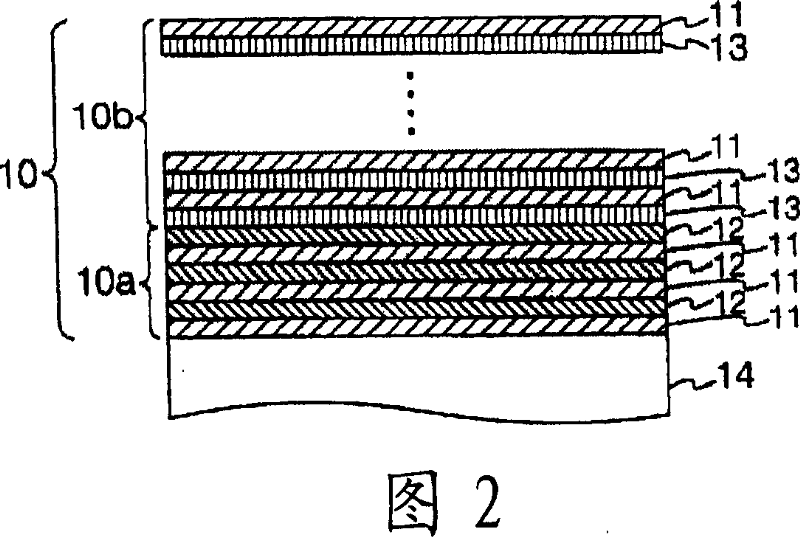

Polarized light splitting device and method for manufacturing the same

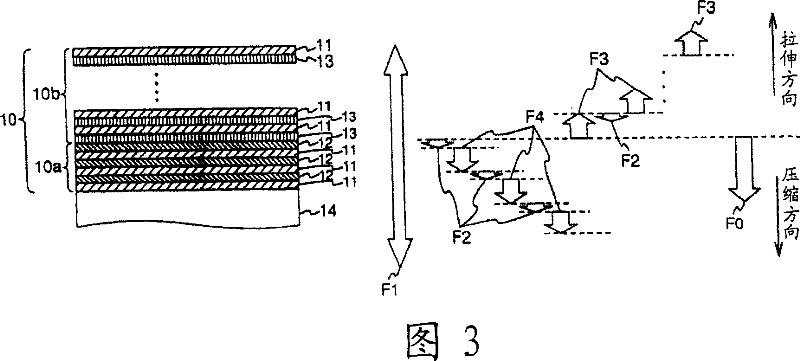

To provide a polarized beam splitter free from peeling of a polarized light splitting film or cracks on an interface with a prism.The polarized light beam splitter 1 comprises two right triangular prisms bonded to each other at inclined surfaces thereof via a polarized light splitting film 10, wherein the polarized light splitting film 10 comprises a first polarized light splitting film layer 10a formed by alternately laminating SiO2coatings 12 having compressive stress and lanthanum titanate films 11, and a second polarized light splitting film layer 10b formed by alternately laminating MgF2films 13 having tensile stress and lanthanum titanate films 11.

Owner:TOYO TSUSHINKI

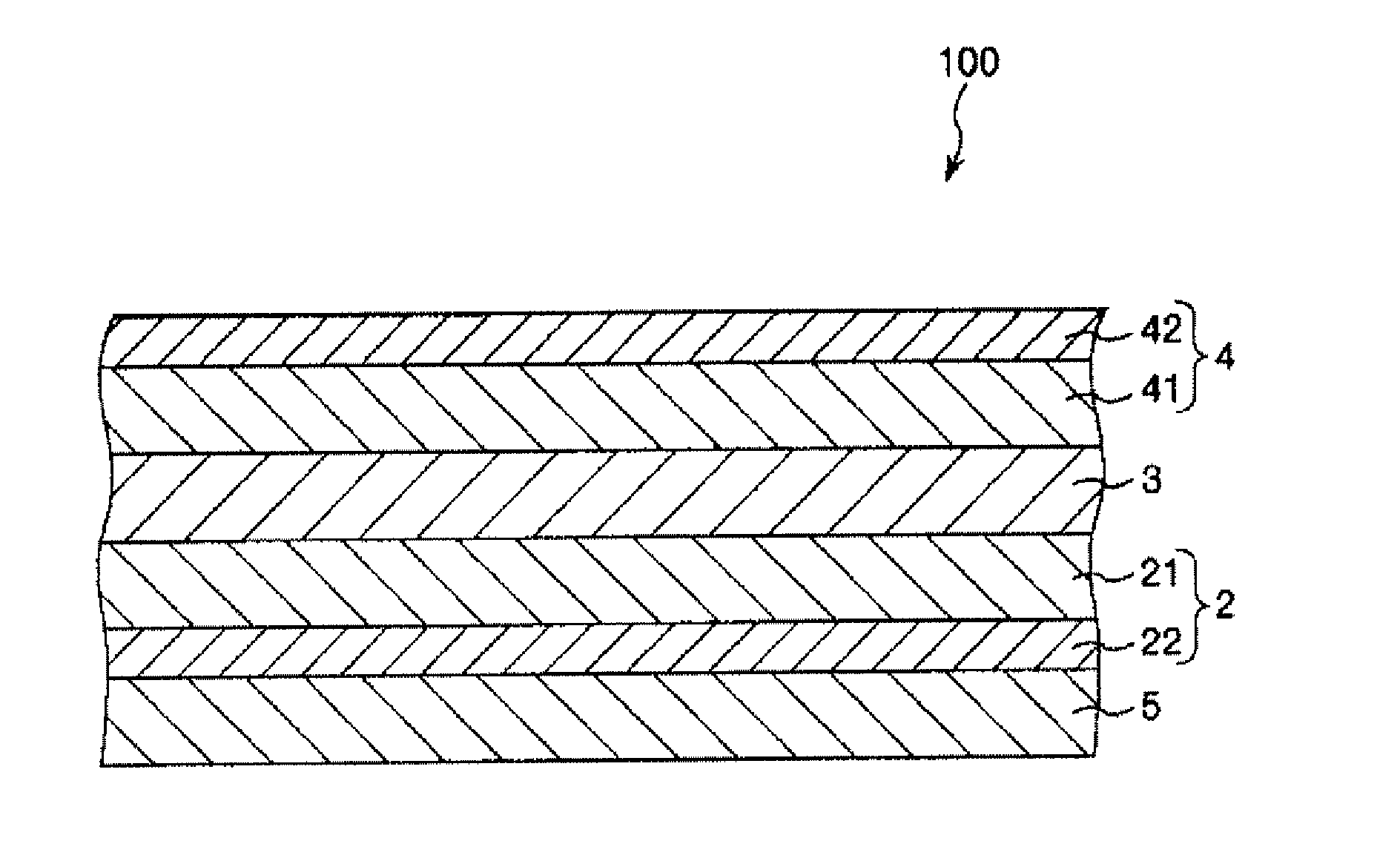

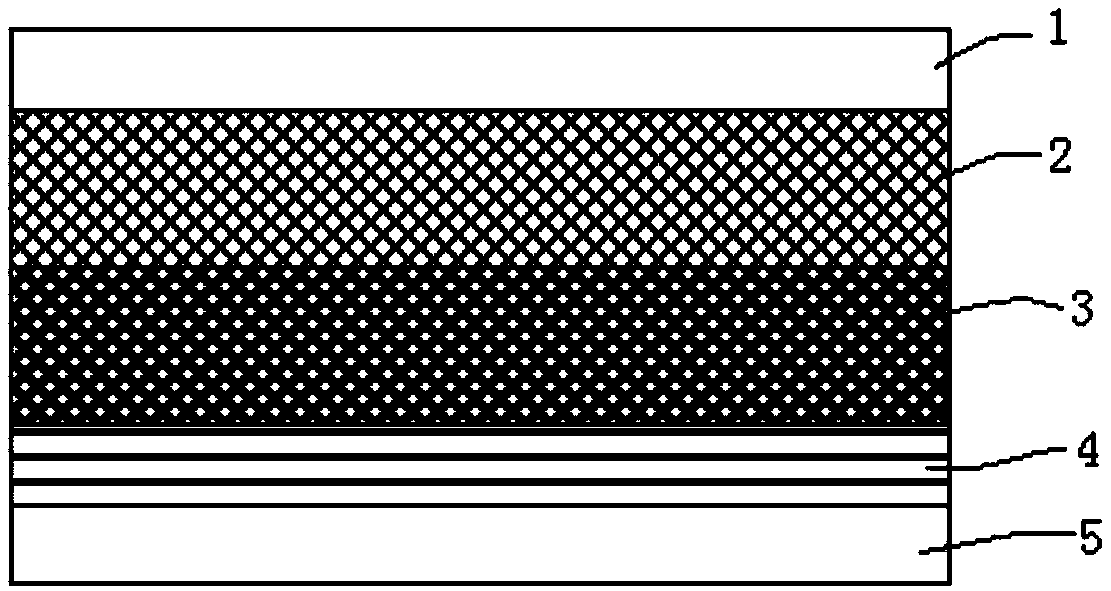

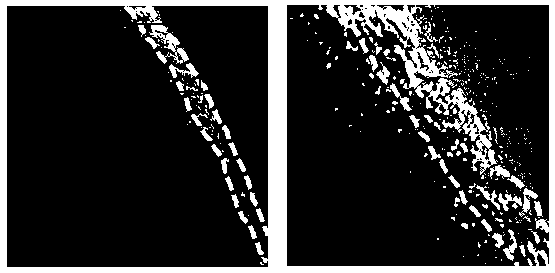

Lithium secondary battery cell structure

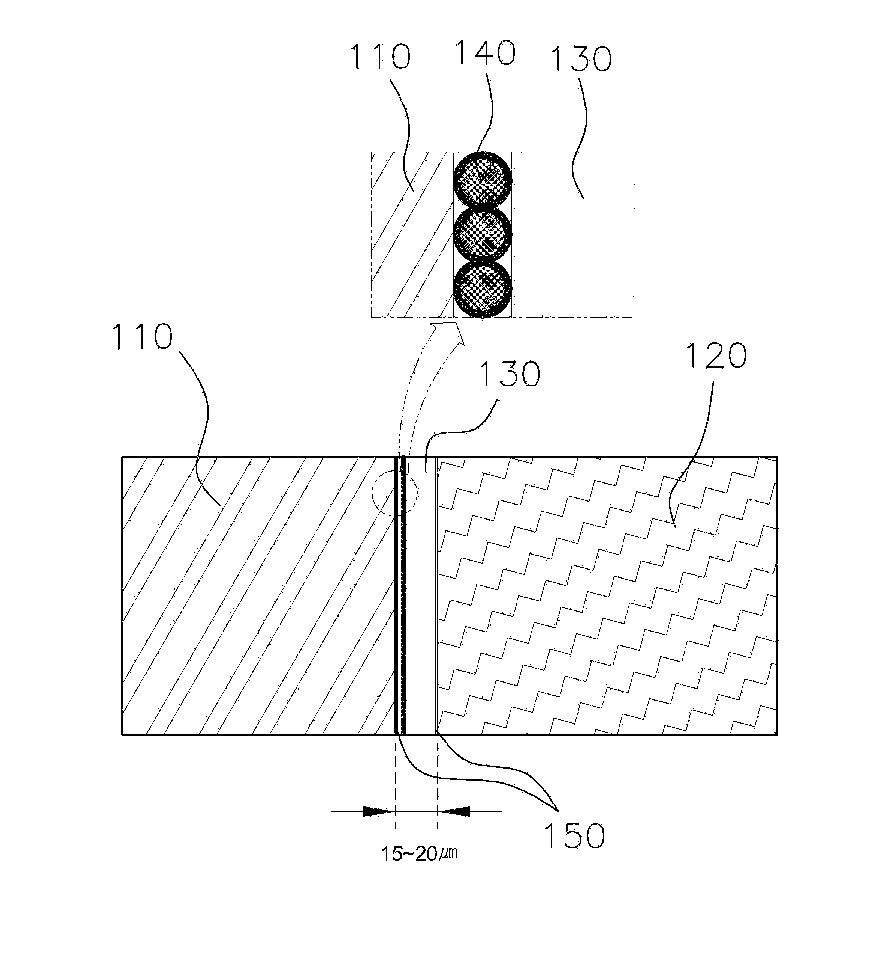

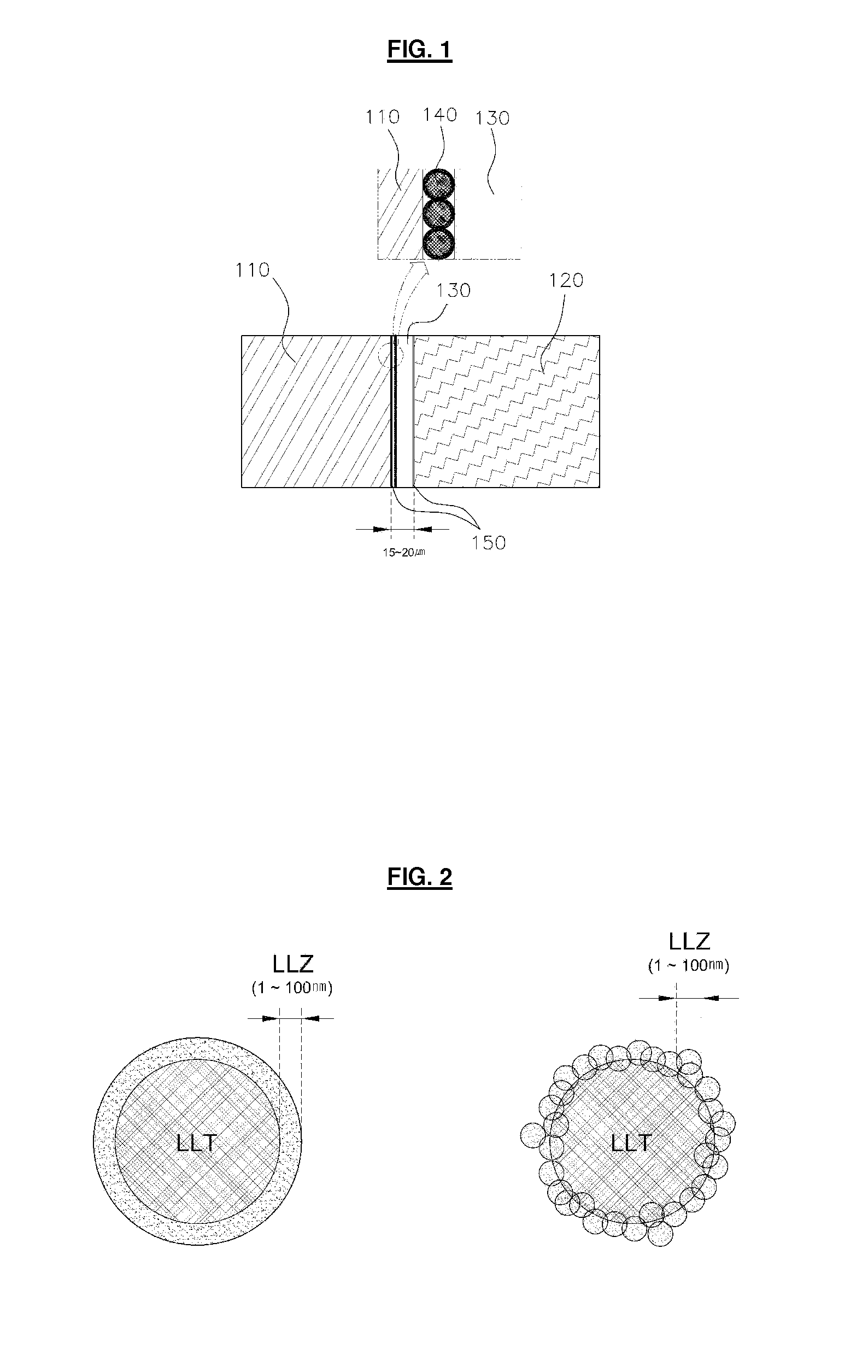

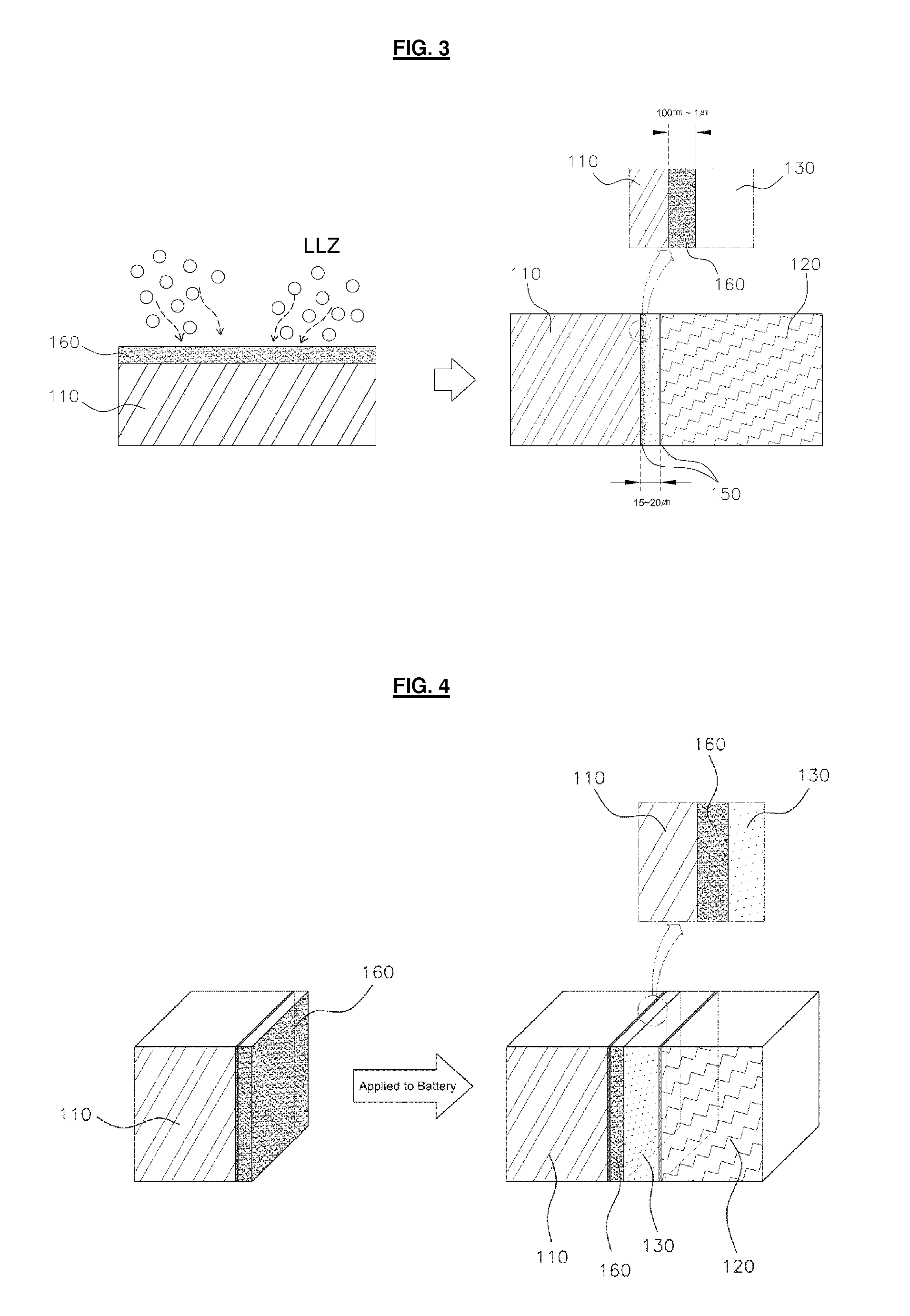

ActiveUS20140186678A1Good chemical stabilityImprove lithium ion conductivityNuclear energy generationFinal product manufactureLanthanum titanateLanthanum

A lithium secondary battery that has a battery cell structure, with improved electrochemical stability between an electrode and an electrolyte. In addition, the lithium secondary battery improves ion conductivity while applying a solid electrolyte. More specifically, a lithium secondary battery comprising a separator formed by an electrolyte between the cathode and the anode, wherein a composite coated layer of lithium-lanthanum-titanate (LixLayTiO3) and lithium-lanthanum-zirconium-oxide (Li7La3Zr2O12) is formed on the interface of the anode and the electrolyte.

Owner:HYUNDAI MOTOR CO LTD

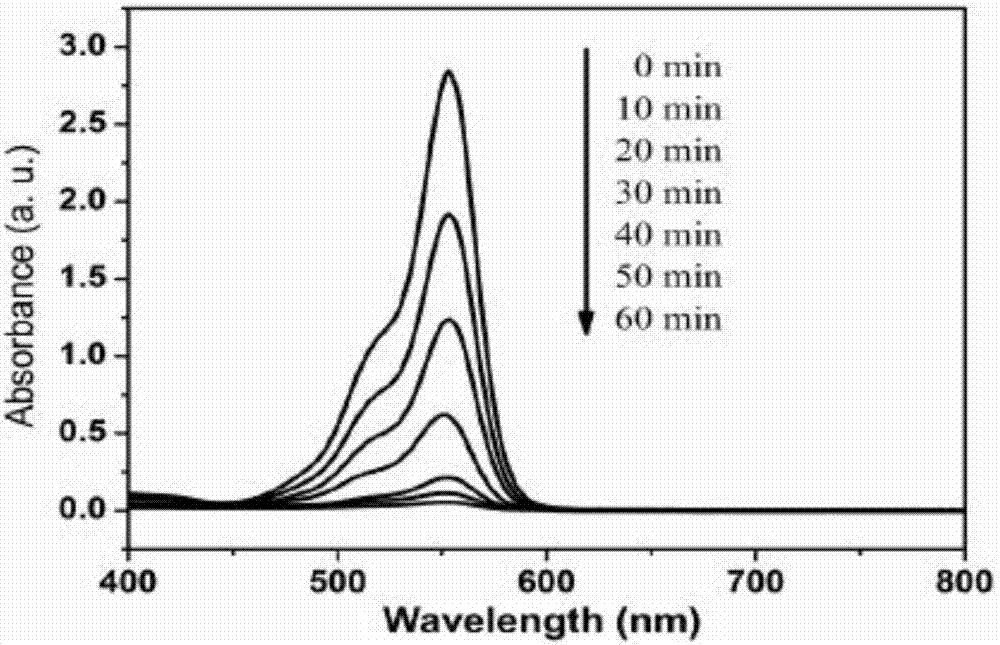

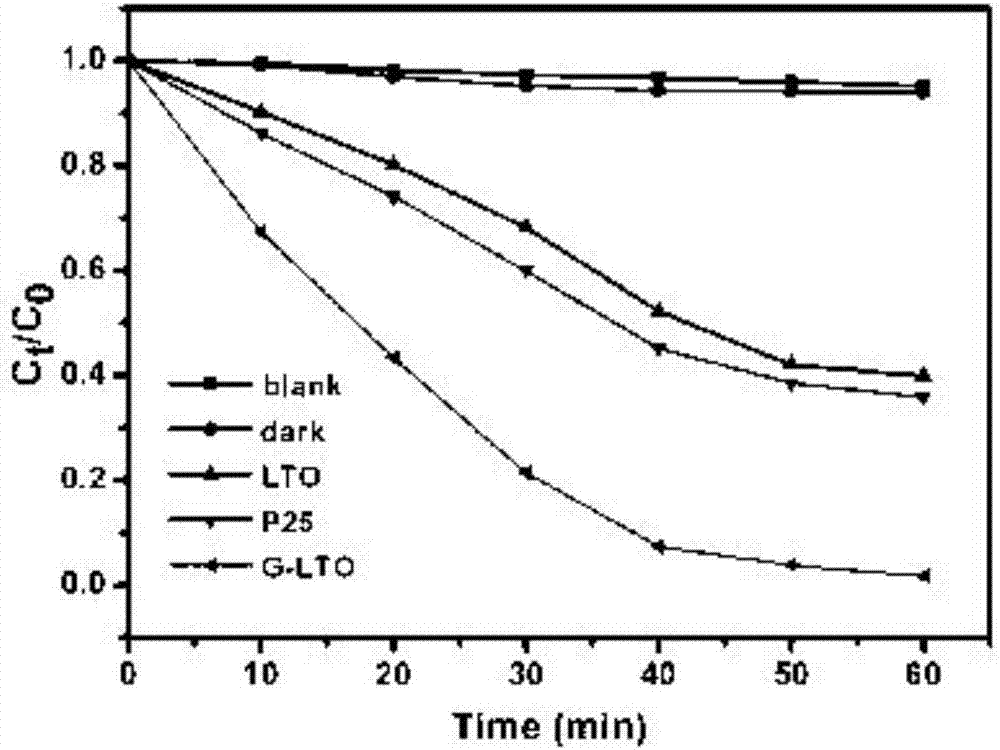

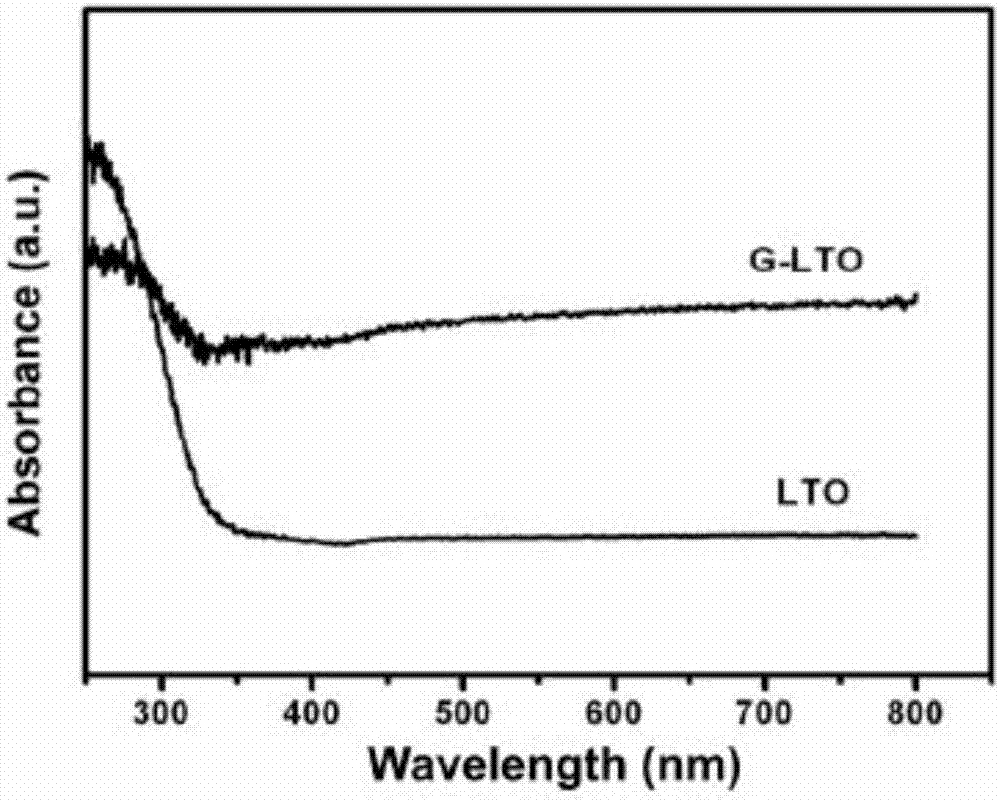

Preparation method of photocatalyst material based on graphene

InactiveCN107020073AReduce defectsImprove light absorption efficiencyCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsChlorideLanthanum

The invention relates to a preparation method of a photocatalyst material based on graphene. The preparation method comprises the following steps: taking lanthanum chloride, a titanium source and the graphene as raw materials; carrying out precipitation aeration reaction and rice flour heating and aeration reaction to obtain a lanthanum titanate material; carrying out ultrasonic and illumination reaction on the lanthanum titanate material and the graphene to obtain a graphene-lanthanum titanate material. According to the preparation method provided by the invention, the graphene is further reduced by utilizing an in-situ photocatalytic reduction capability of a La2Ti2O7 nano material and defects of the graphene material are reduced; meanwhile, a direction relation between the graphene and the La2Ti2O7 nano material is increased and the light absorption efficiency of the La2Ti2O7 nano material is improved.

Owner:孝感双华应用科技开发有限公司

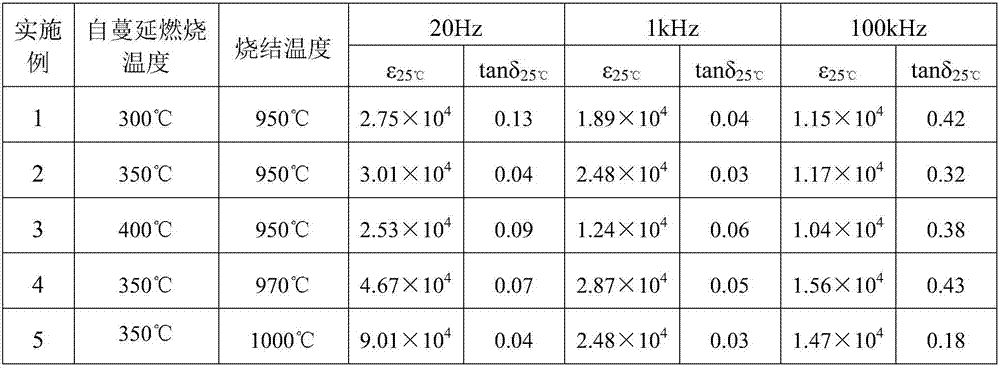

Method for preparing sodium bismuth copper lanthanum titanate dielectric material based on sol-gel method

InactiveCN107573058AExcellent dielectric propertiesLow dielectric lossCopper nitrateGreek letter sigma

The invention discloses a method for preparing sodium bismuth copper lanthanum titanate dielectric material based on a sol-gel method. The method comprises the following steps of firstly, preparationof a solution 1: dissolving butyl titanate and bismuth nitrate into ethylene glycol according to a molar ratio of 10:1 under the condition of adding acetylacetone as a stabilizer, wherein the volume ratio of the ethylene glycol to the butyl titanate to the acetylacetone is 10:10:1; then, preparation of a solution 2: dissolving lanthanum nitrate, sodium nitrate and copper nitrate into a water solution of citric acid when the molar ratio of Na (sodium), Bi (mismuth), La (lanthanum) to Cu (copper) to Ti (titanium) is 5:4:1:30:40, wherein the mass ratio of citric acid to water is 1:2; evaporatingthe water at the temperature of 80 DEG C until the volume of the solution is not changed; mixing the solution 1 and the solution 2, so as to obtain gel; performing self-propagation combustion reactionon the gel at the temperature of 300 to 450 DEG C, so as to obtain the sodium bismuth copper lanthanum titanate nanometer powder material; after the powder is granulated, pressing into a blank, and sintering the blank at the temperature of 950 to 1000 DEG C, so as to obtain the sodium bismuth copper lanthanum titanate material. The method has the advantages that the dielectric loss tan-sigma is lower and is 0.04, and the huge dielectric constant epsilon is 9.01*10<4> at the temperature of 25 DEG C; the cost of the raw material is low, and the sintering temperature of the ceramic is effectively reduced.

Owner:TIANJIN UNIV

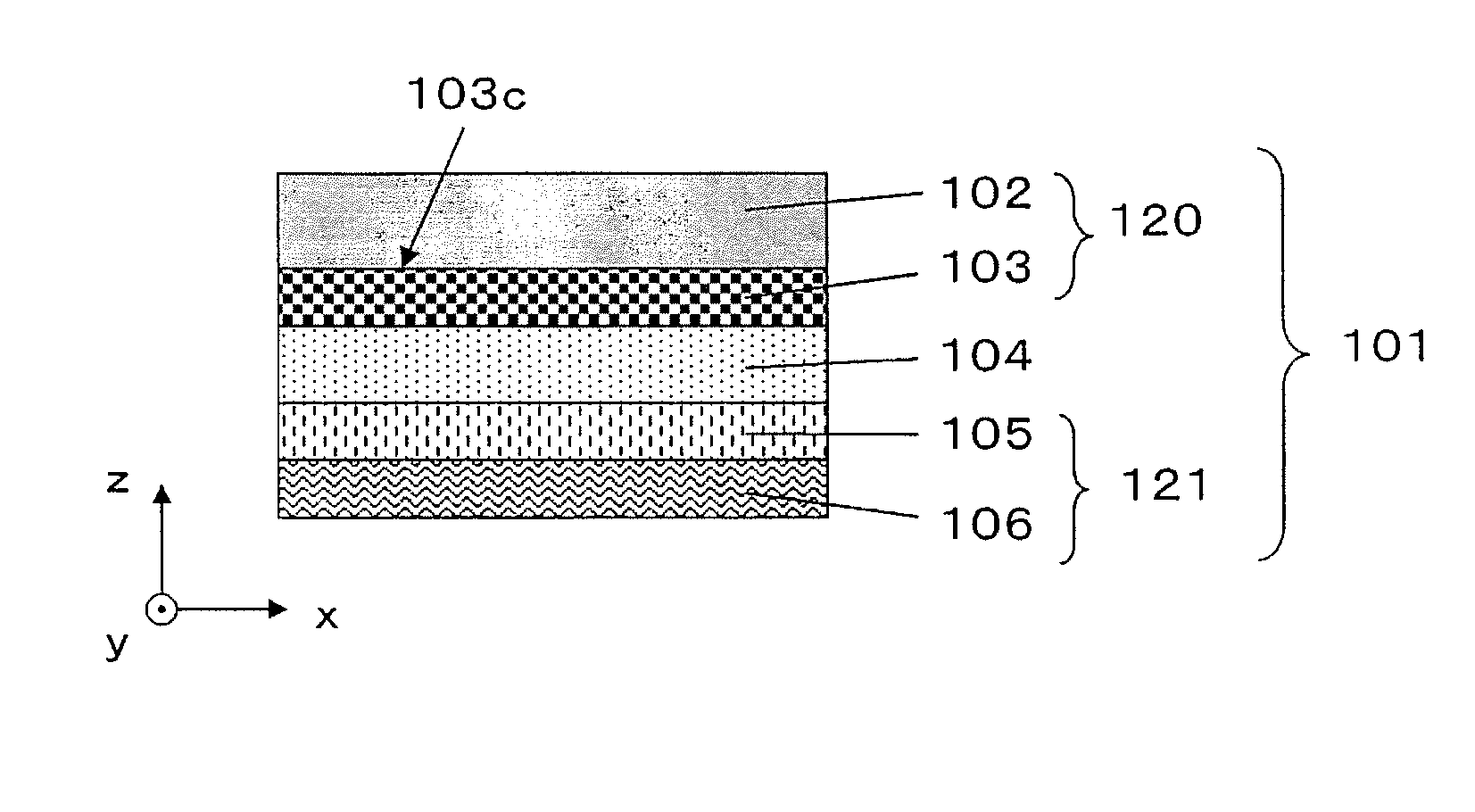

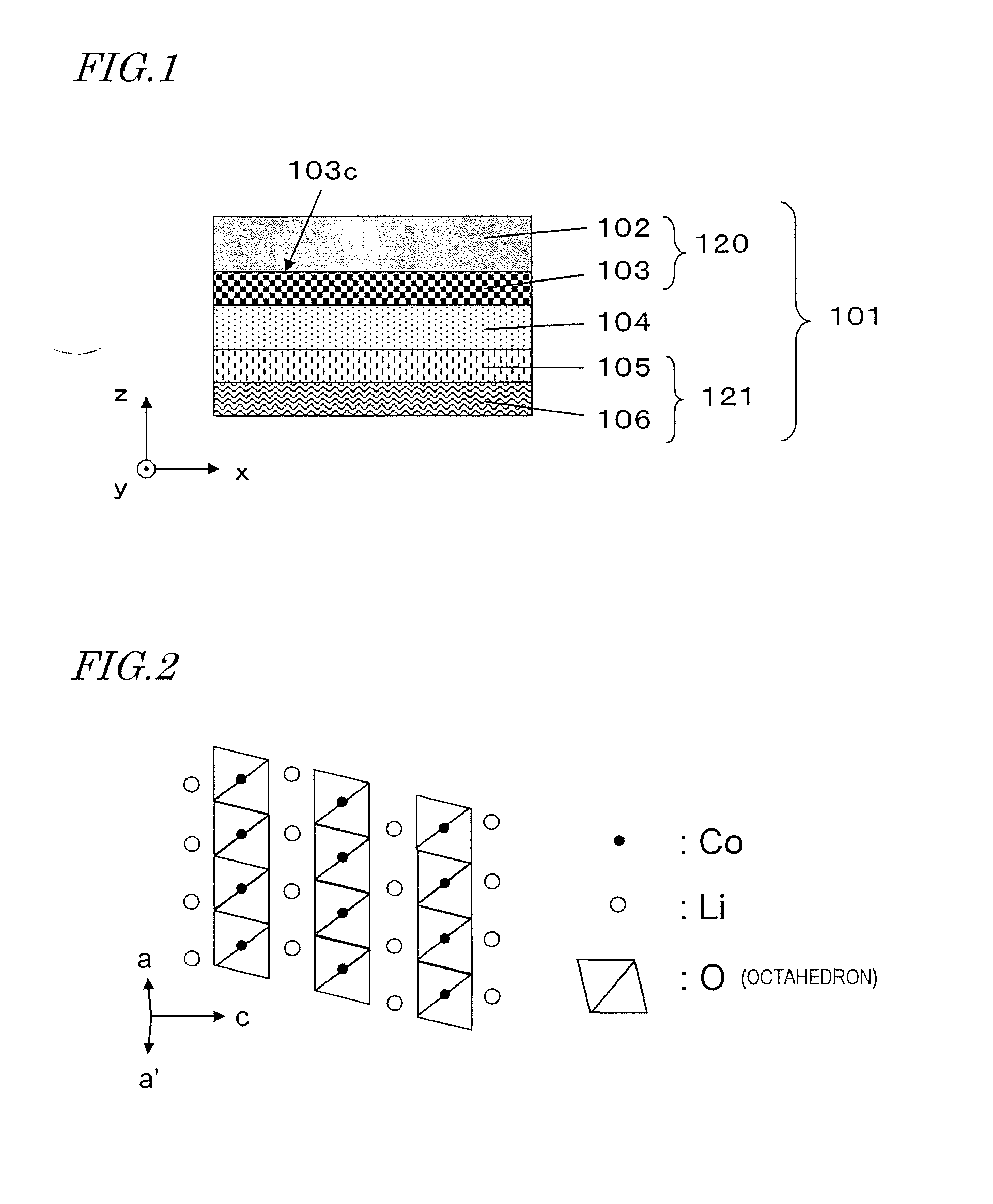

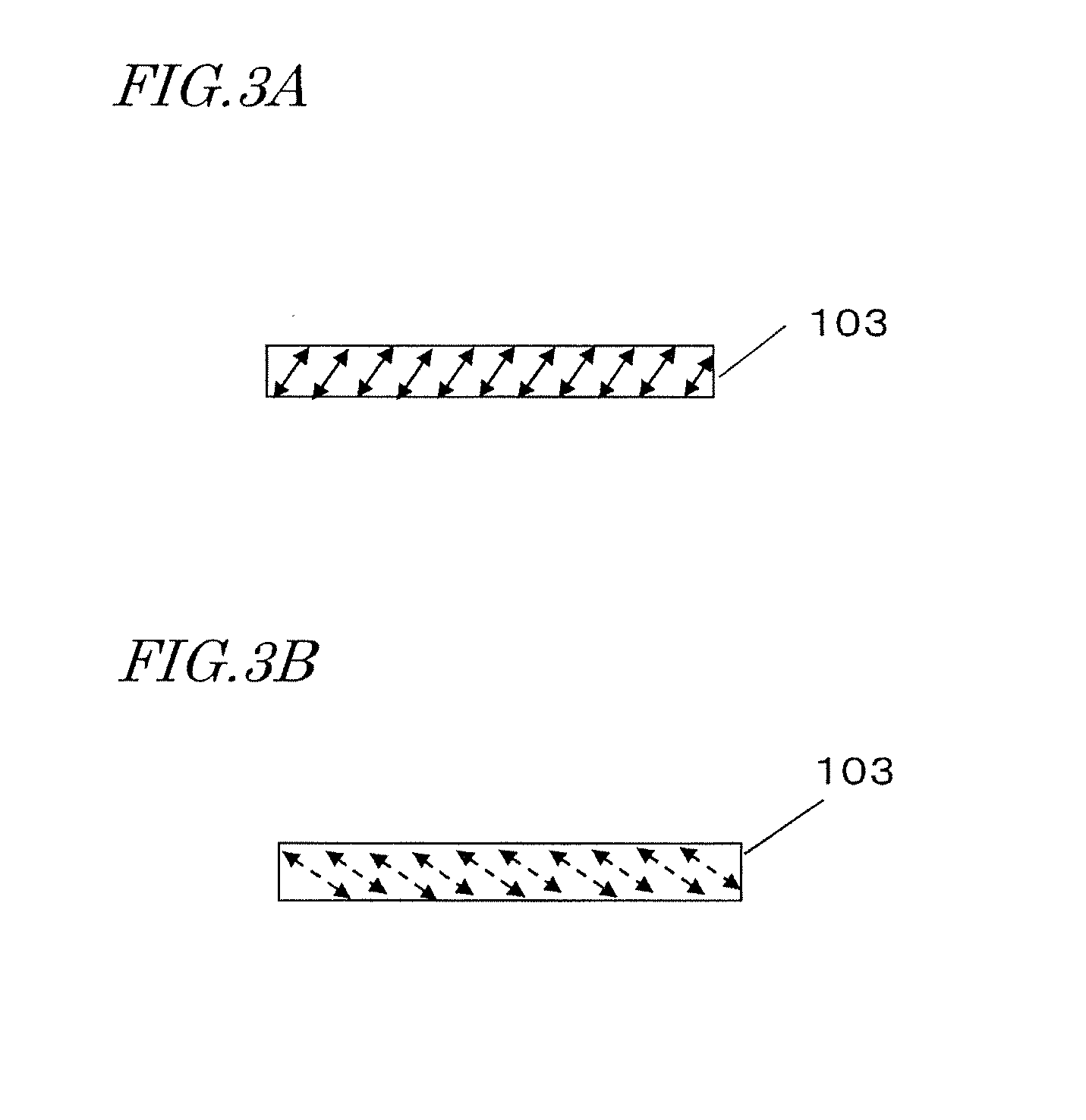

All-solid lithium secondary battery

ActiveUS20150236374A1Improve featuresImprove output characteristicsFinal product manufactureElectrode carriers/collectorsCrystal structureElectrolyte

An exemplary all-solid lithium secondary battery includes a positive electrode including a positive-electrode active substance layer, a negative electrode, and a solid electrolyte layer interposed between the positive electrode and the negative electrode. The positive-electrode active substance layer is composed of lithium cobaltate, and has an α—NaFeO2 type crystal structure. The positive-electrode active substance layer has a (018) plane oriented in a normal direction of a principal face of the positive-electrode active substance layer. The solid electrolyte layer is composed of lithium lanthanum titanate and has a tetragonal perovskite-type crystal structure. The solid electrolyte layer has a (110) plane or a (102) plane oriented in a normal direction of a principal face of the solid electrolyte layer.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Composition for forming solid electrolyte layer, method for forming solid electrolyte layer, solid electrolyte layer, and lithium ion secondary battery

ActiveUS20130122376A1Improve reliabilityEfficiently formedMaterial nanotechnologySolid electrolyte cellsPhysical chemistryElectrolyte

A composition for forming a solid electrolyte layer for use in the formation of a solid electrolyte layer of a lithium ion secondary battery contains first particles made of a lanthanum titanate and second particles made of a lithium titanate. It is preferable that the first particles have an average particle size of 50 nm or more and 300 nm or less. It is preferable that the second particles have an average particle size of 10 nm or more and 50 nm or less.

Owner:SEIKO EPSON CORP

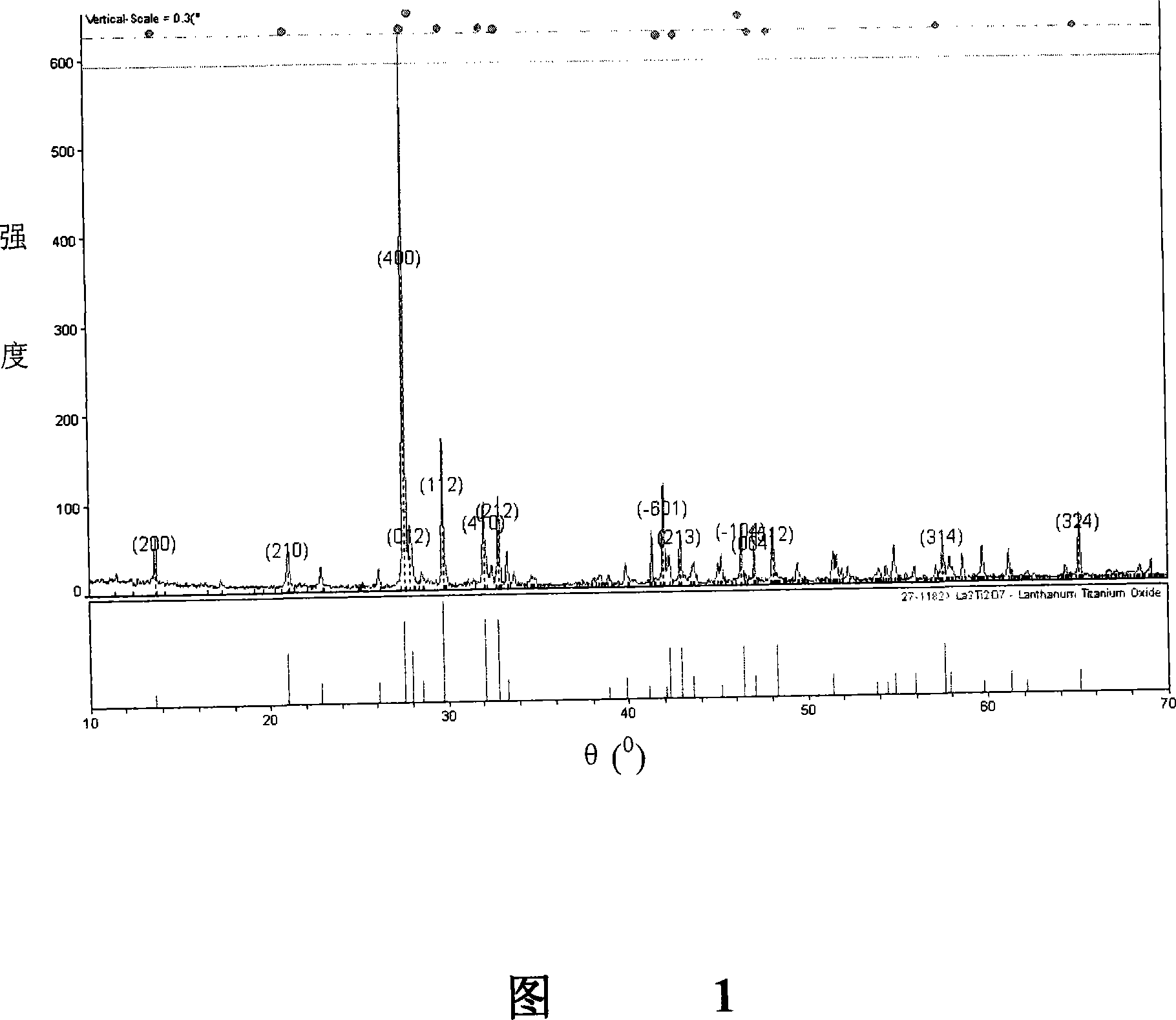

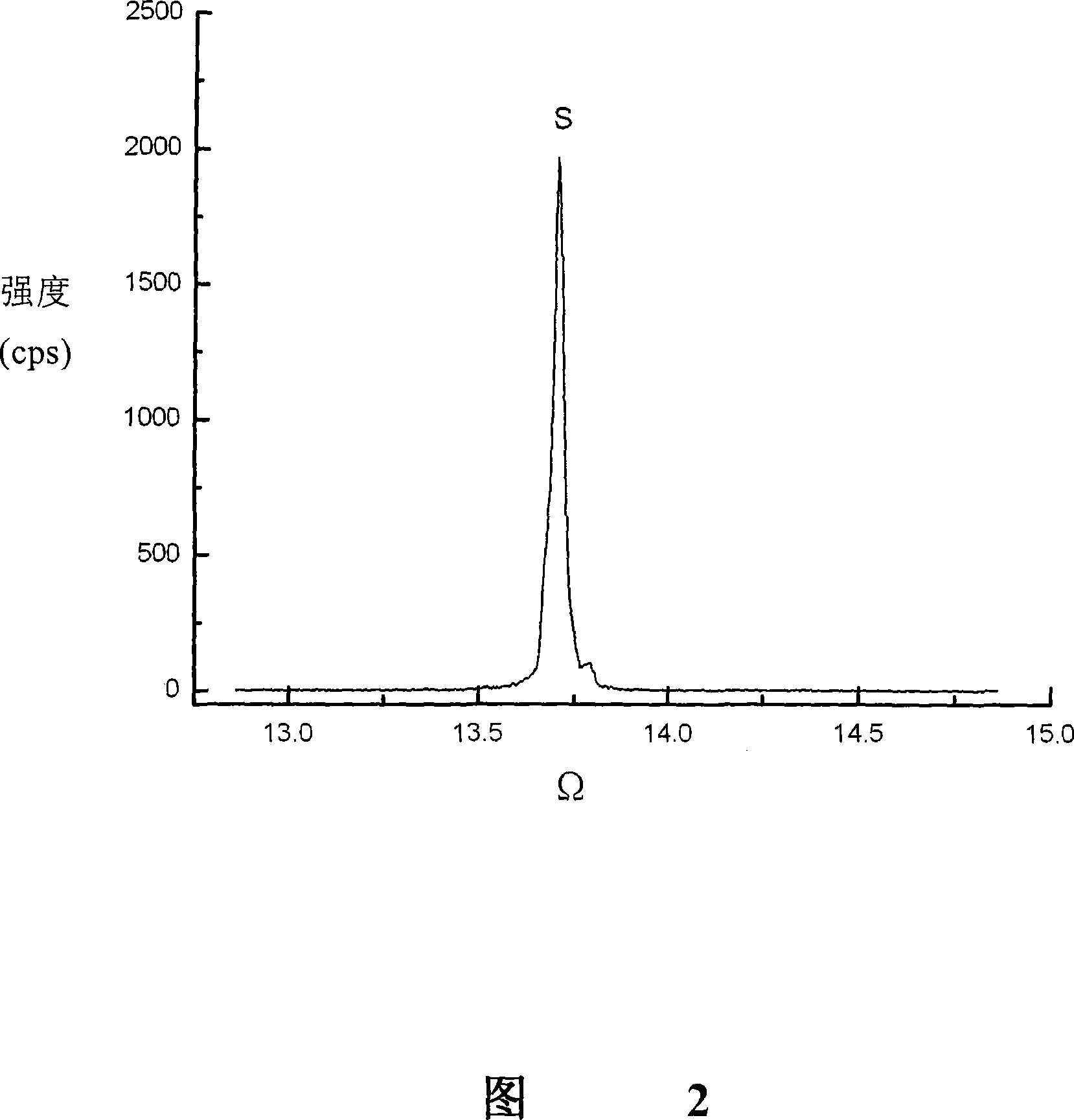

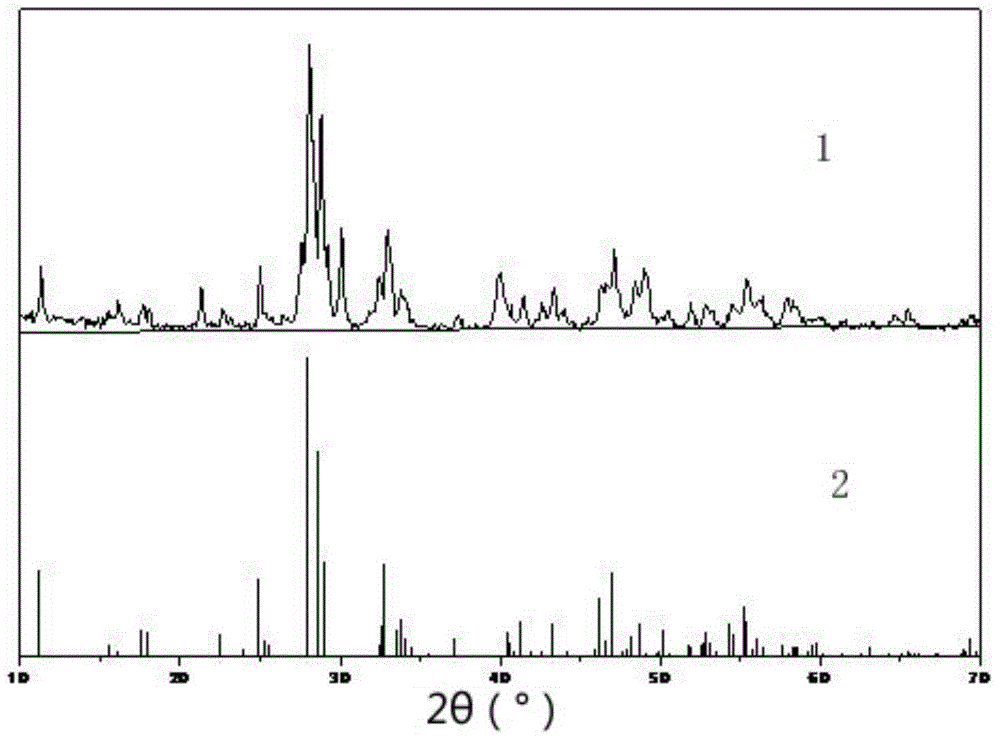

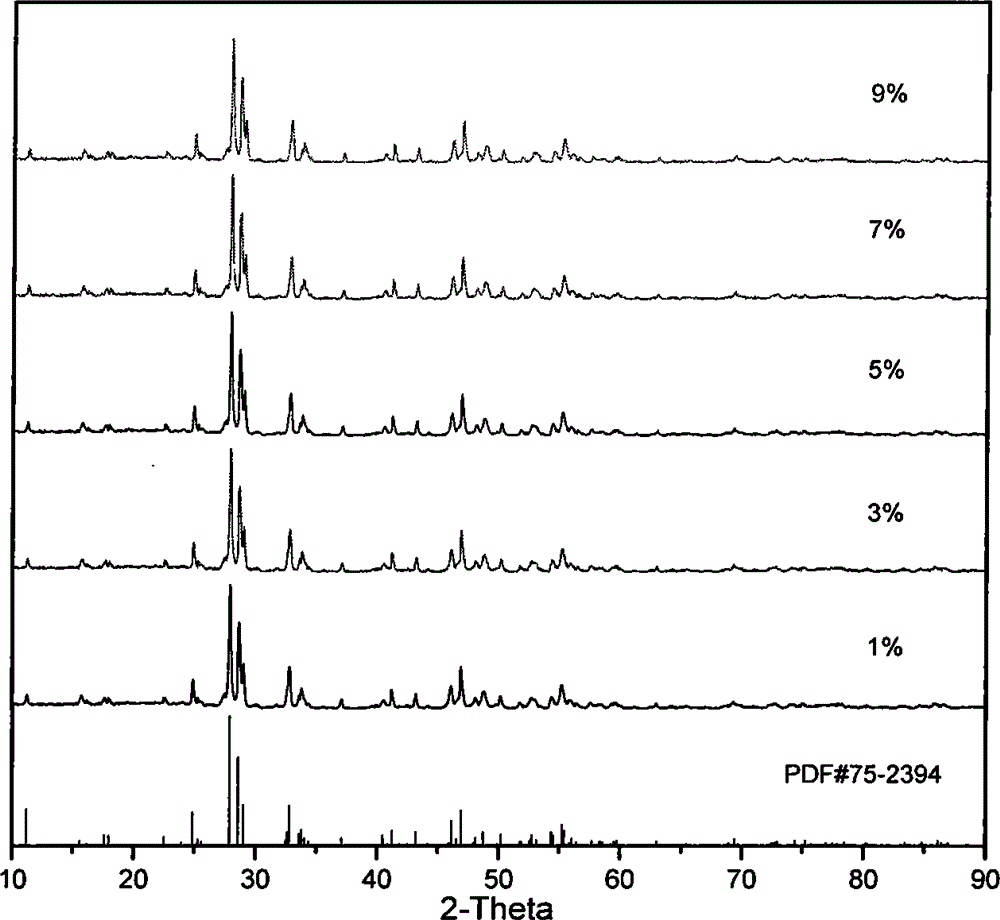

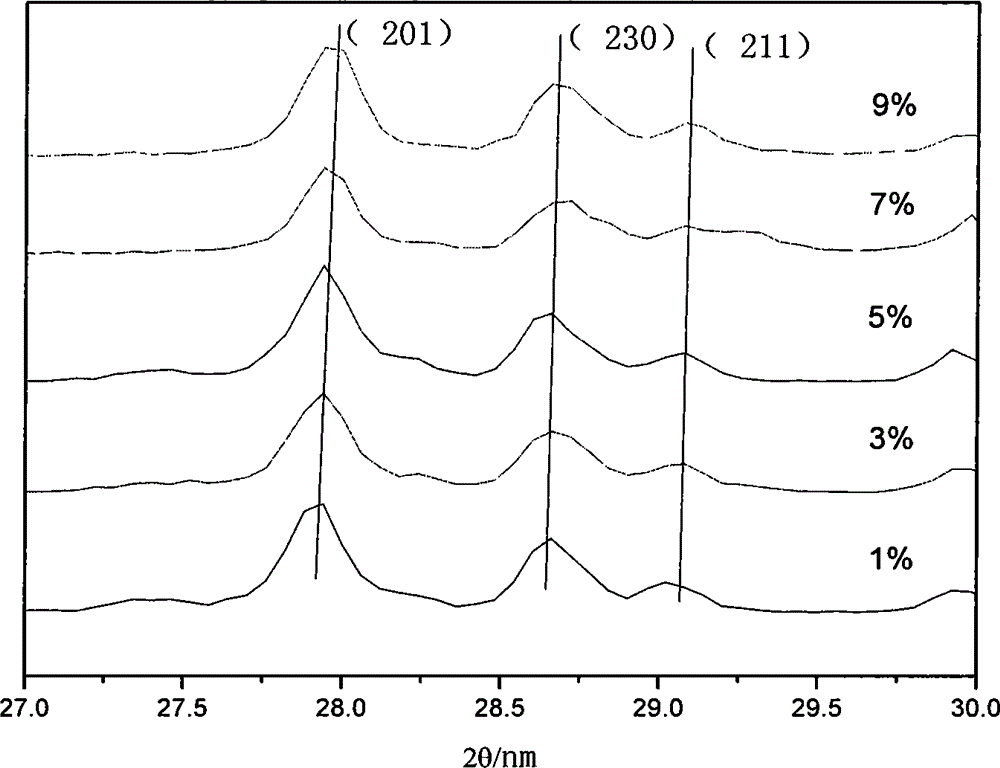

Lanthanum titanates single-crystal and upgrowth technology thereof

ActiveCN101063232AEasy to operateReduce manufacturing costPolycrystalline material growthBy pulling from meltLanthanumSeed crystal

The invention discloses a lanthanum titanate crystal with chemical composition as La2Ti2O7 and growing technology, which comprises the following steps: (1) adopting TiO2 and La2O3 as initial raw material; choosing the usage ration in pursuance of chemical composition of La2Ti2O7; mixing evenly; briquetting; (2) transferring copple with briquette raw material of the step (1) into vacuum reduced furnace; heating the whole system; evacuating to 10-2-10-4Pa; charging into inert protective gas when temperature at 1500-1700 deg. c; heating to setting temperature continually; setting the setting temperature at 1850-1950 deg. c; (3) adjusting the position of copple in furnace tank; melting the raw material and seed crystal top; realizing seeding growth; controlling solid-liquid interface thermal gradient of crystal growth at 20-80 deg. c / cm; controlling dropped ratio at 0. 2-10mm / h; (4) finishing the crystal growth; decreasing the temperature to room temperature with 30-120 deg. c / h speed; annealing for crystal. This product possesses good crystallization property, big dielectric constant and high refracting power.

Owner:苏州晶生新材料有限公司

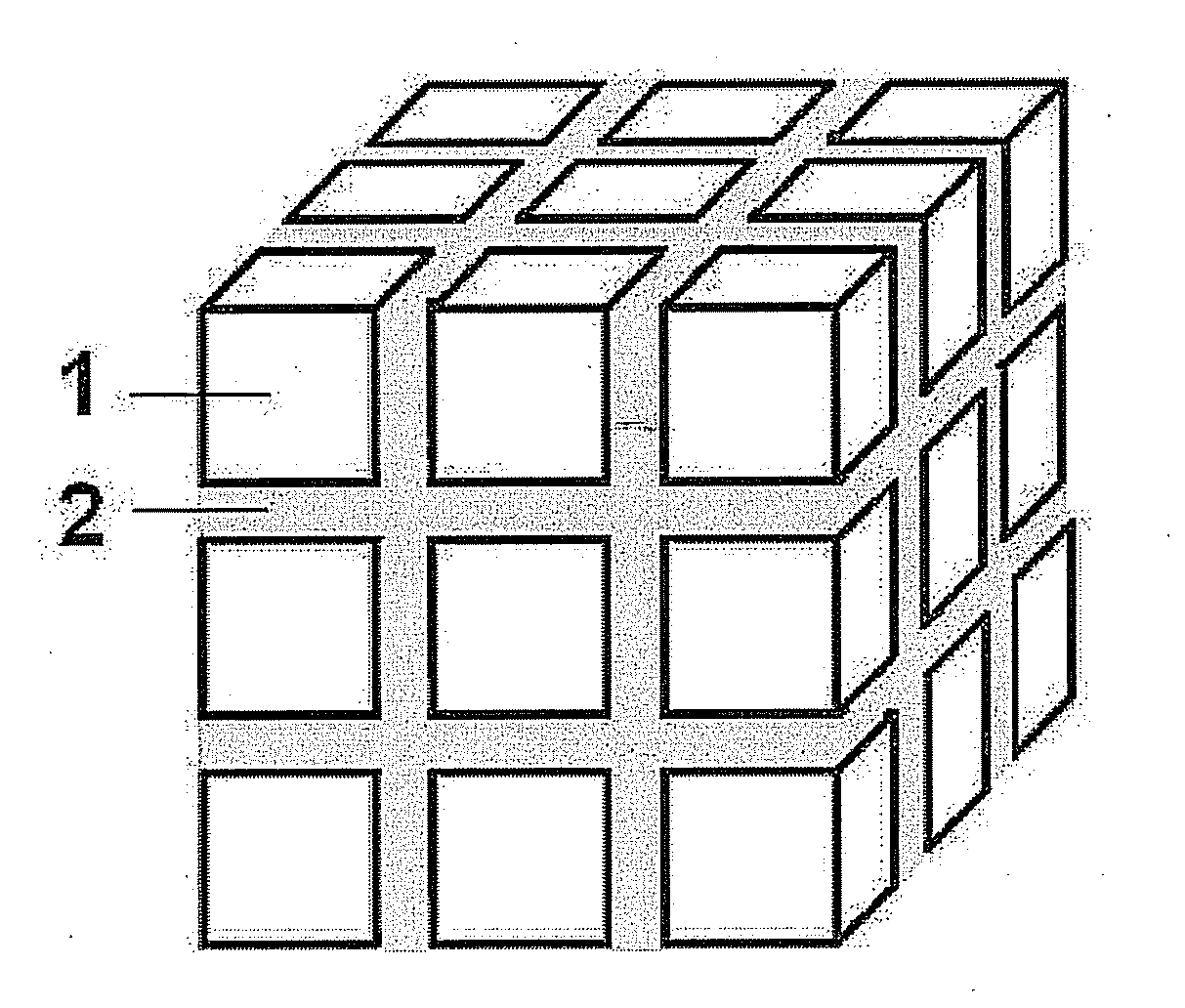

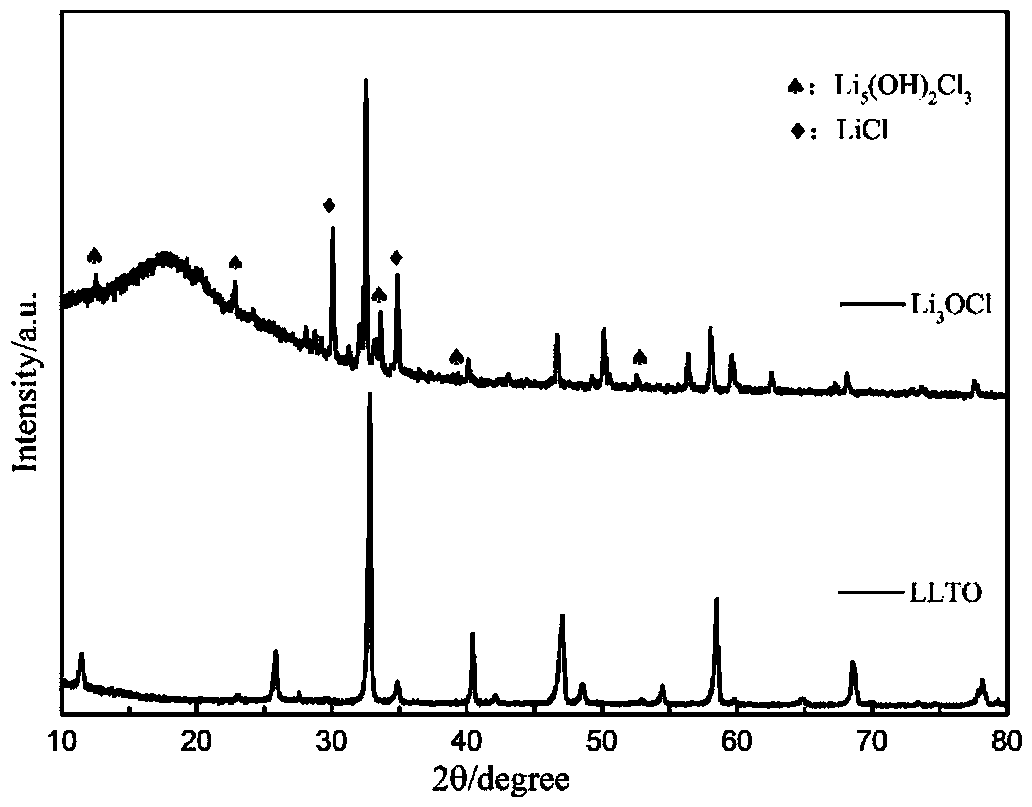

Lithium lanthanum titanate composite material and preparation method thereof, and lithium ion solid state battery

ActiveCN110556571AHigh densityIncreased total ionic conductanceFinal product manufactureElectrolytesCharge carrierSolid-state battery

The invention relates to a lithium lanthanum titanate composite material and a preparation method thereof and a lithium ion solid state battery. The lithium lanthanum titanate composite material is formed by compounding Li3OX with an anti-calcium ore structure and lithium lanthanum titanate with a calcium ore structure. The Li3OX is distributed at grain boundaries between lithium lanthanum titanate grains and partially diffuses into the grains of lithium lanthanum titanate. The chemical formula of the lithium lanthanum titanate is Li3xLa2 / 3-xTiO3, 0 <x<0.16, and X is halogen in the Li3OX. According to the lithium lanthanum titanate composite material, the Li3OX with rich lithium phase and low melting point is adopted to perform cationic supplement for LLTO so as to change the disorder degree of carriers or cation vacancies in the grains, improve the ionic conductivity in the grains, compensate the consumption of the carriers in the space charge layer at the grain boundaries and effectively improve the grain boundary and whole ionic conductivity.

Owner:ZHENGZHOU NEW CENTURY MATERIALS GENOME INST CO LTD

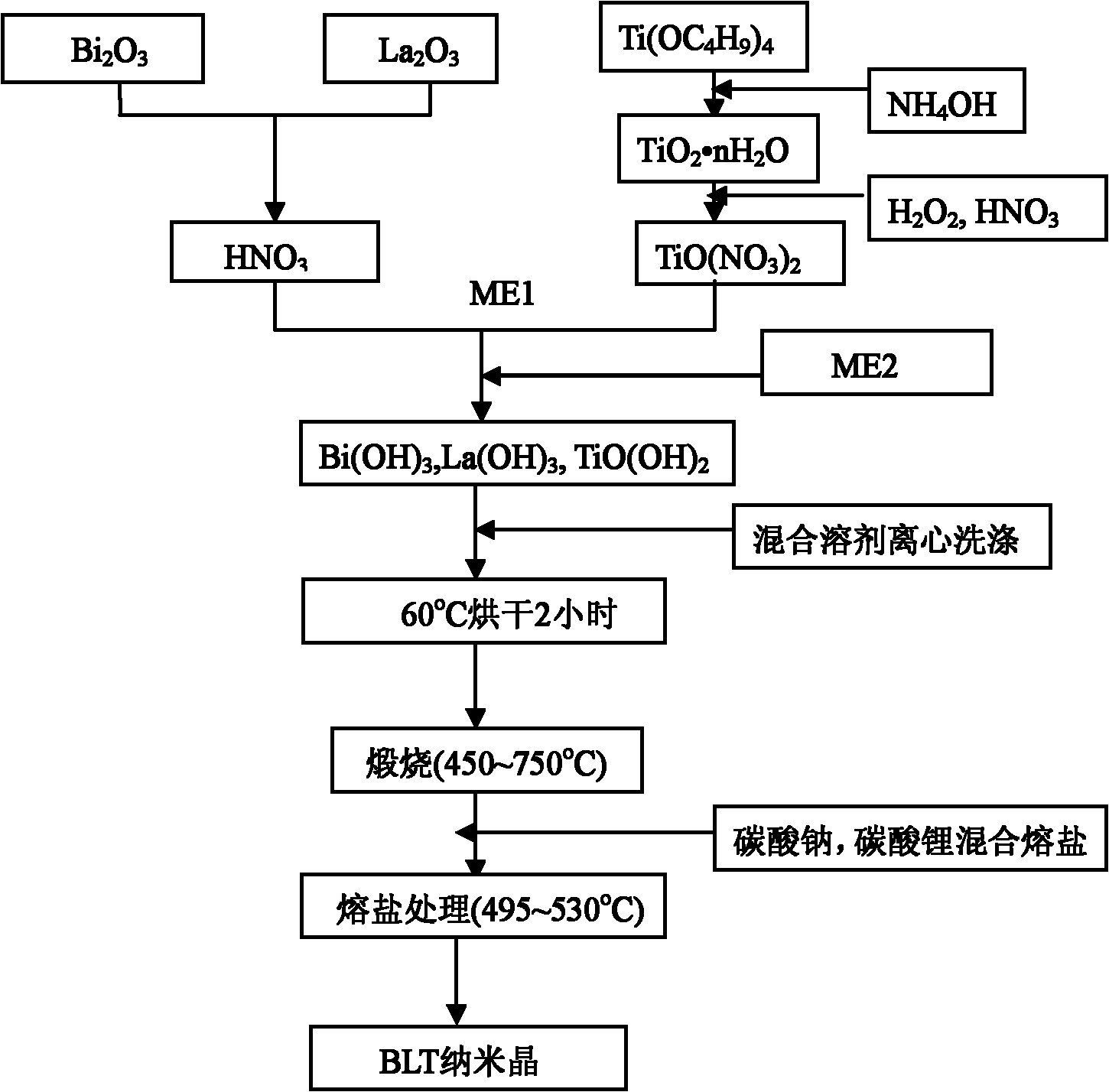

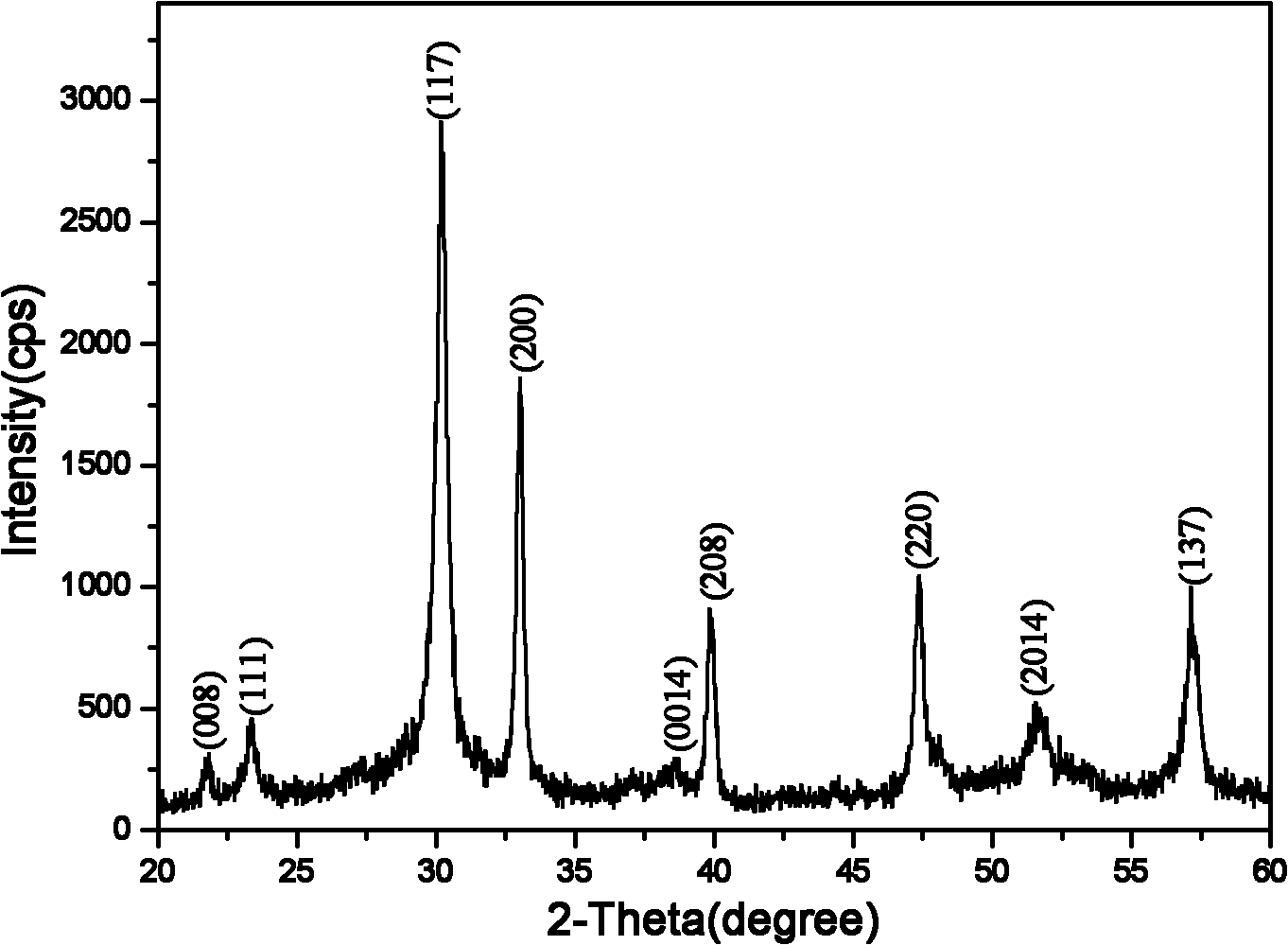

Quasi-cubic bismuth lanthanum titanate (BLT) nanoparticles and preparation method thereof

The invention discloses quasi-cubic bismuth lanthanum titanate (BLT) ferroelectric single crystal nanoparticles and a preparation method thereof. The nanoparticles and the preparation method have important application values for self-assembly of ferroelectric ordered nano-array structures. The technical scheme adopted by the invention is as follows: taking analytically pure Bi2O3, La2O3 and Cl6H36O4Ti as raw materials, cyclohexane as oil phase, Triton X-100 as a surfactant and n-butyl alcohol as a cosurfactant to form colloidal particles with chemical composition being Bi4-xLaxTi3O12 (x=0.5-1.0) through reverse microemulsion process, synthesizing BLT coarse nanocrystals through thermal treatment at the temperature of 450-750 DEG C, further putting the obtained BLT coarse nanocrystals intosodium carbonate / lithium carbonate mixed molten salt and obtaining the quasi-cubic BLT nanocrystals with uniform dimensions through melting-nucleation-growth. The microstructure characteristic of theBLT nanocrystals has not been publicly reported internationally so far.

Owner:NANJING TECH UNIV

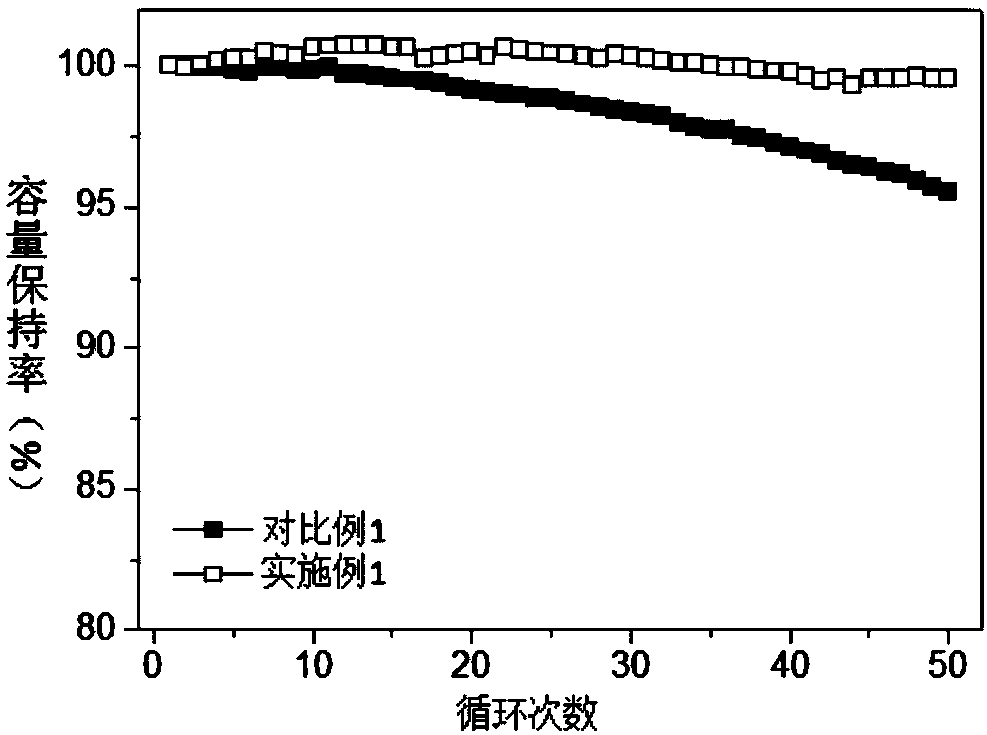

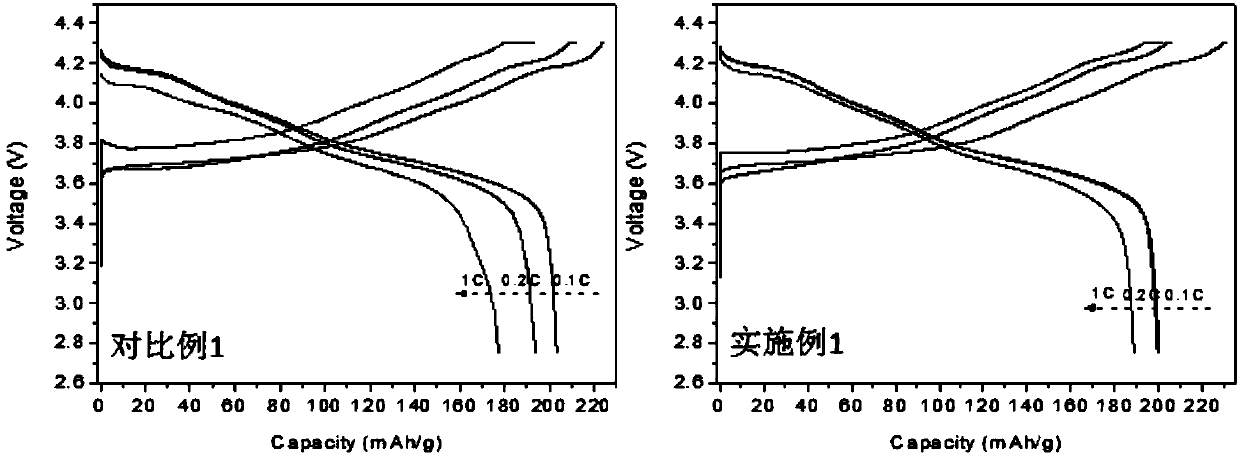

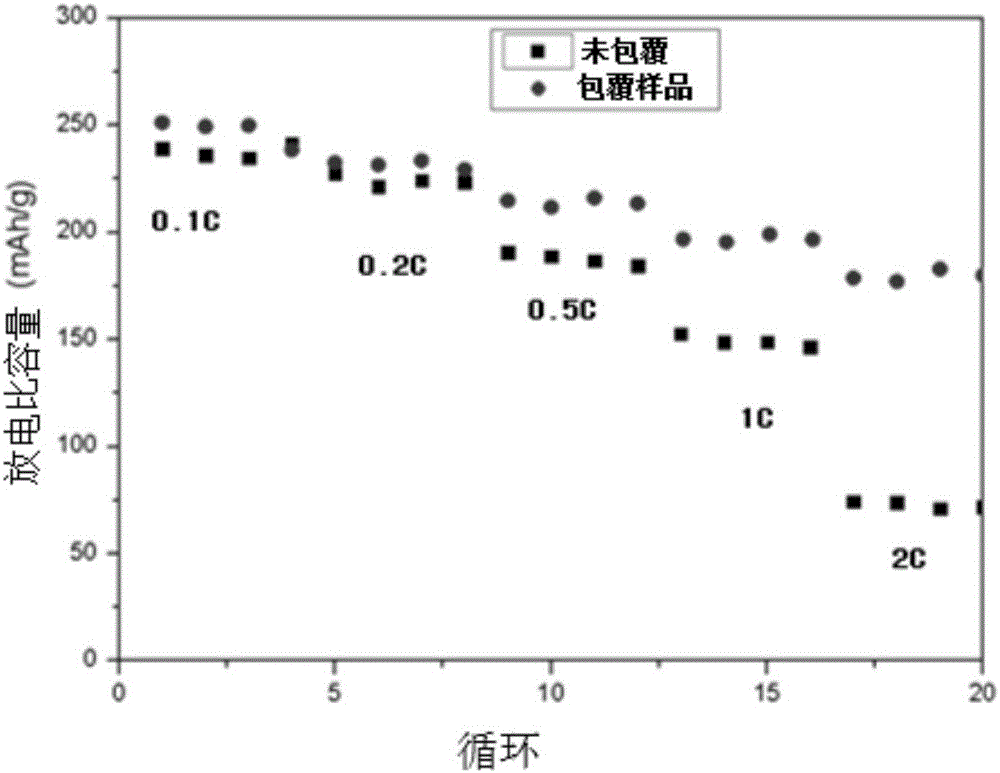

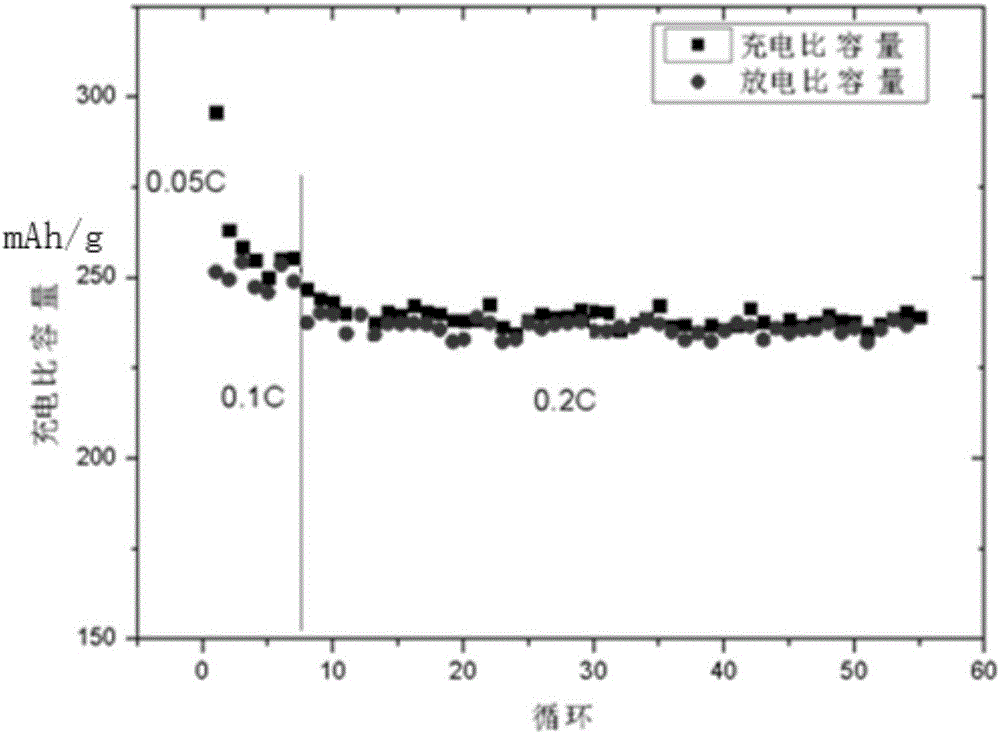

Lithium lanthanum titanate-lithium titanate coated lithium nickel cobalt aluminate cathode material and preparation method thereof

ActiveCN109119621AReduce alkalinityImprove ion conduction abilitySecondary cellsPositive electrodesOrganic solventTitanium

The invention relates to a lithium lanthanum titanate-lithium titanate coated lithium nickel cobalt aluminate cathode material and preparation method thereof. The preparation method comprises the following steps: S1, dissolving an organic titanium source and a lanthanum source in an organic solvent, and stirring to obtain a mixed solution; 2, adding lithium nickel cobalt aluminate and a surfactantinto the mixed solution, and stirring at 60-80 DEG C to obtain a suspension; 3, adding water drop by drop under the stirring condition, continuing stirring until the organic solvent volatilizes completely, and drying to obtain the coating material; S4, calcining the coating material at 450-650 DEG C for 5-10 hours to obtain the lanthanum lithium titanate-lithium titanate coated lithium nickel cobalt aluminate cathode material. The preparation method provided by the invention is simple in operation and easy to industrialize, and is suitable for popularizing and using in the field. The preparedlithium titanate-lithium lanthanum titanate coated lithium nickel cobalt aluminate cathode material has excellent electrochemical performance and cycle stability.

Owner:乳源东阳光新能源材料有限公司 +1

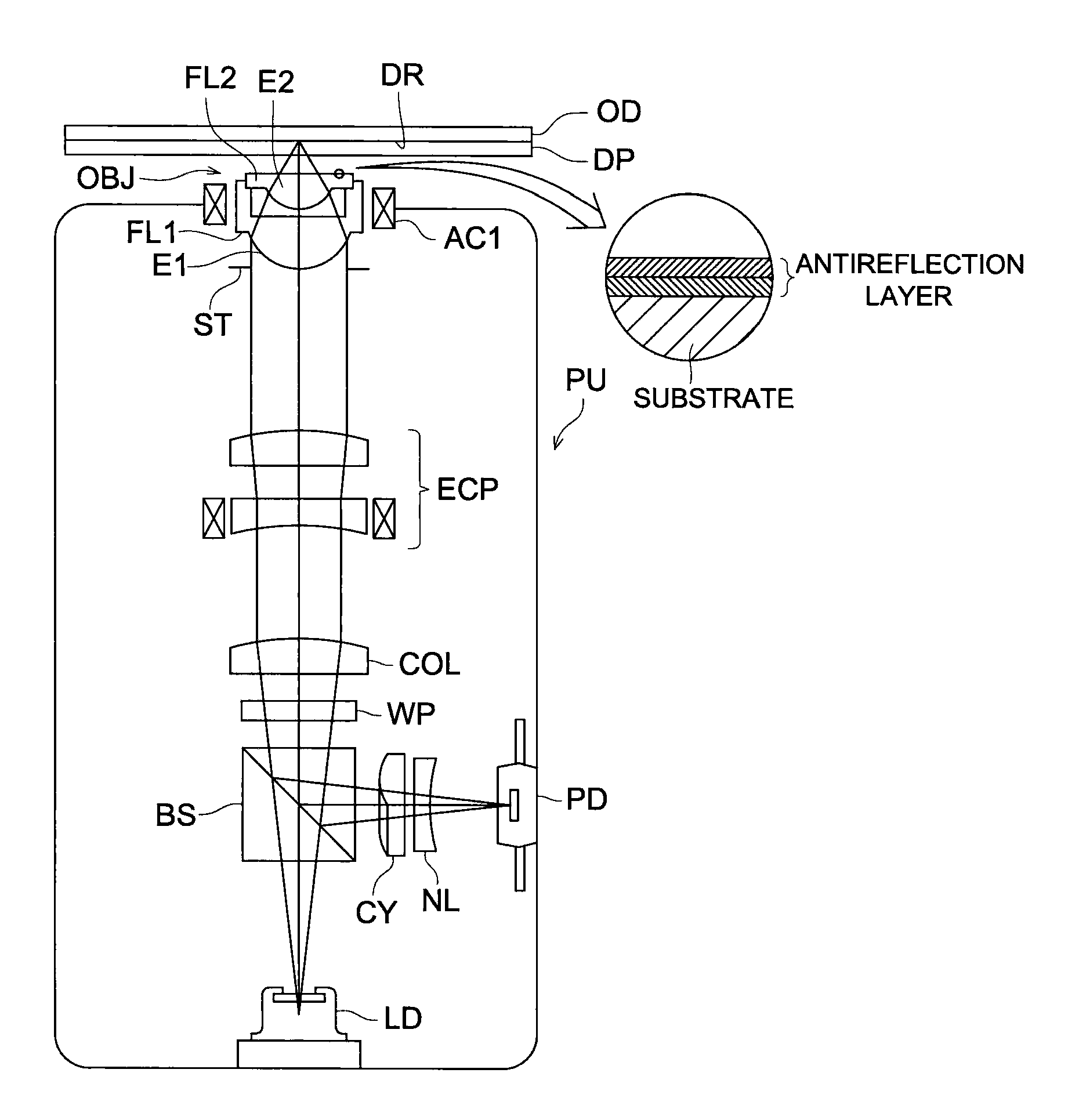

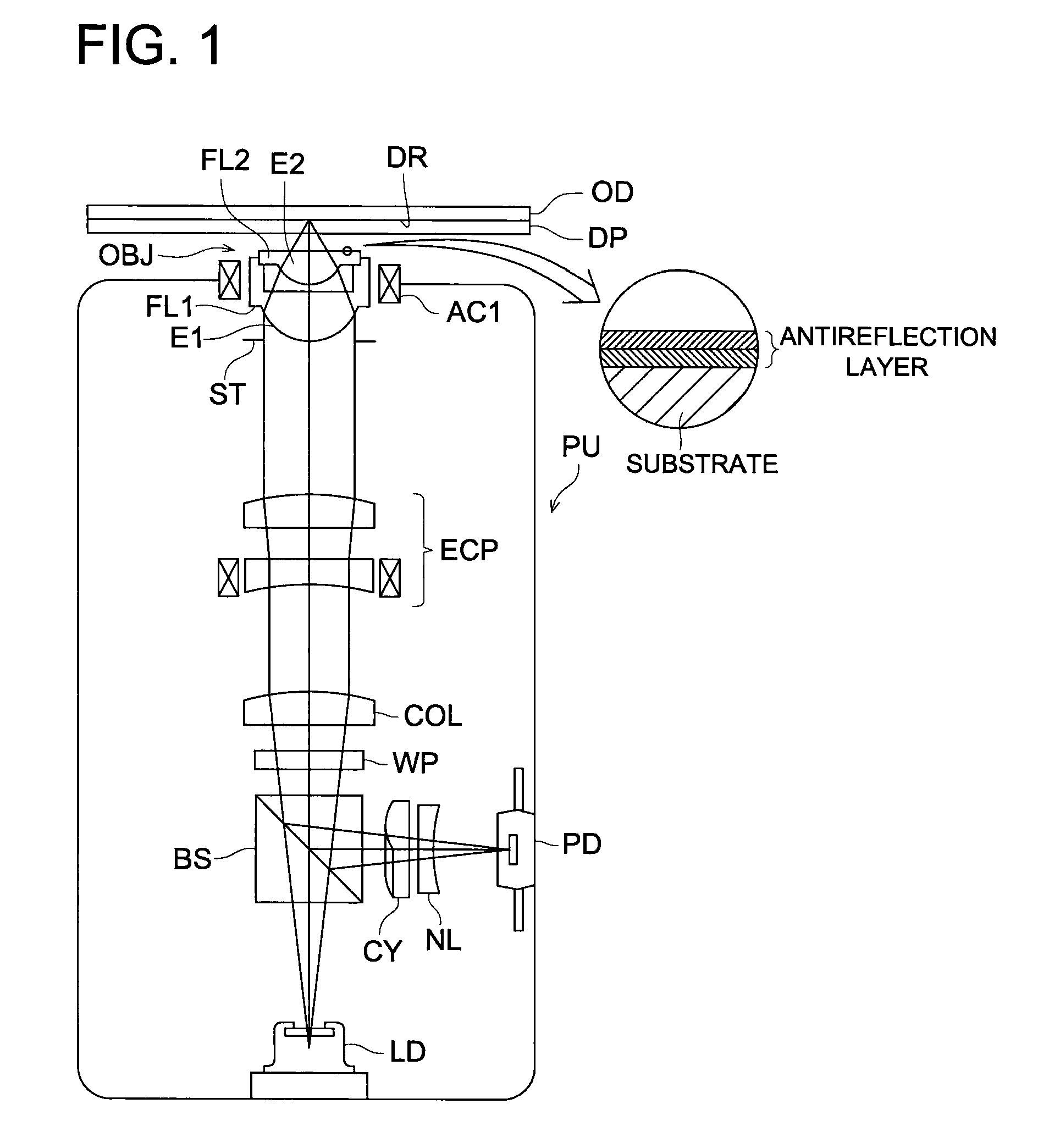

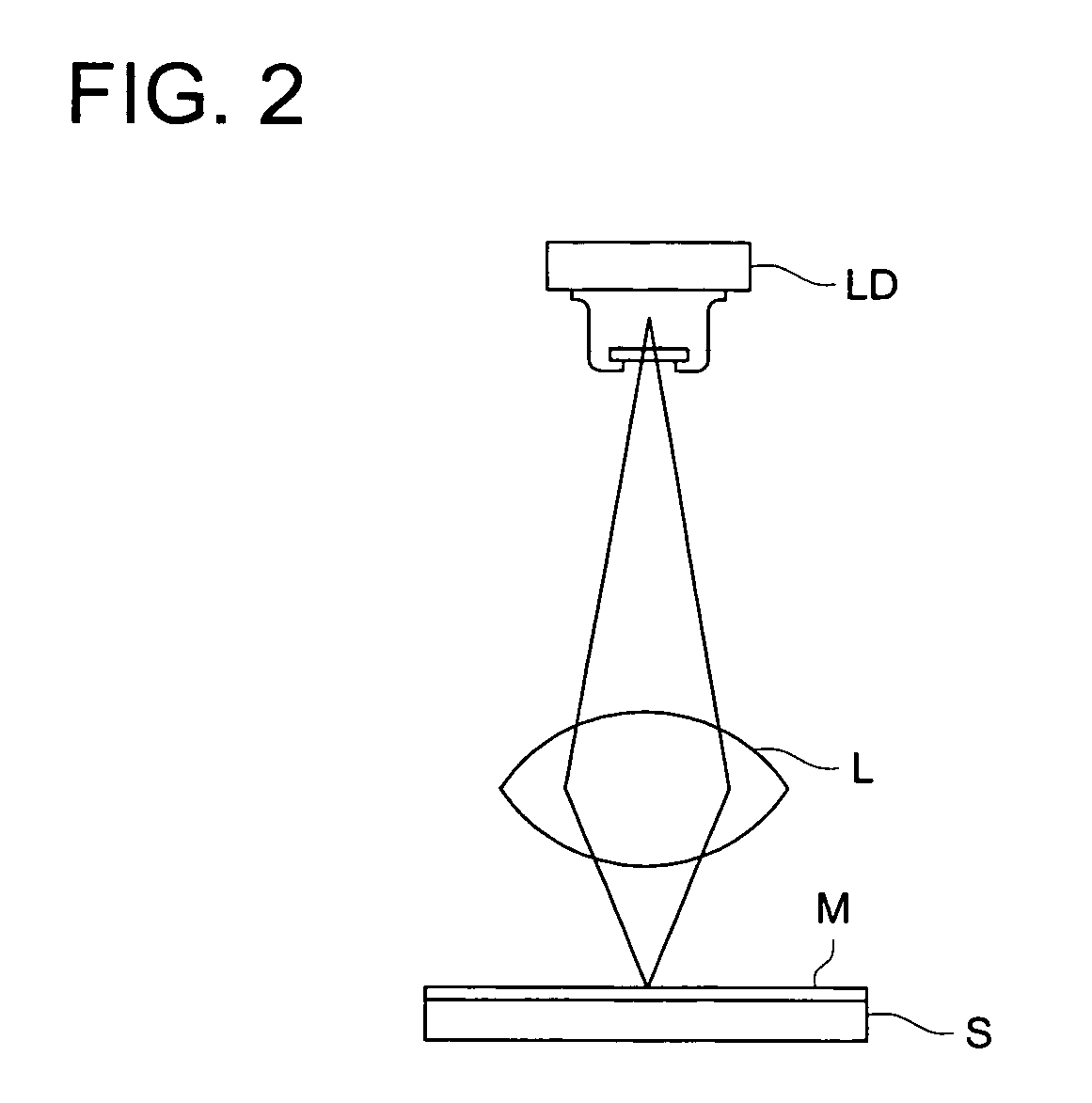

Optical element and optical pickup apparatus

InactiveUS7715302B2Avoid degradationImprove the heating effectLaser using scattering effectsSynthetic resin layered productsOptical pickupRefractive index

Owner:KONICA MINOLTA OPTO

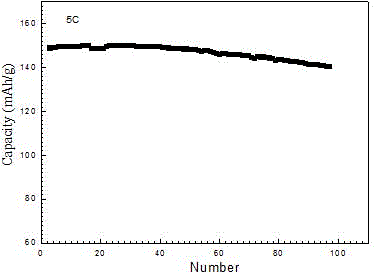

High-nickel ternary material of lithium ion battery and preparation method of high-nickel ternary material

ActiveCN107706373AReduced electrochemical performance varianceIncrease capacityMaterial nanotechnologyCell electrodesElectrical conductorNano al2o3

The invention discloses a high-nickel ternary material of a lithium ion battery. The high-nickel ternary material comprises quick ion conductor-coated particles and nanometer aluminum oxide-coated particles; the quick ion conductor-coated particle comprises a big-particle core and a quick ion conductor layer; the nanometer aluminum oxide-coated particle comprises a small-particle core and a nanometer aluminum oxide layer; the quick ion conductor-coated particles and nanometer aluminum oxide-coated particles are uniformly dispersed; the quick ion conductor layer coats the big-particle core; thenanometer aluminum oxide layer coats the small-particle core; the quick ion conductor layer is lithium lanthanum titanate; and the big-particle core and the small-particle core are the high-nickel ternary materials with the same chemical components. The invention also discloses a preparation method of the high-nickel ternary material of the lithium ion battery. By performing independent and targeted coating on the high-nickel ternary materials with the same chemical components and different dimensions, and by performing mixing based on a proper proportion, the rate capability and the cycle performance of the high-nickel ternary material can be improved on the basis of capacity maintaining.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Quartz sand supported lanthanum titanate photocatalyst and method for preparing same

InactiveCN105944710ADoes not affect basic physical and chemical propertiesDistributeMetal/metal-oxides/metal-hydroxide catalystsWater bathsLanthanum

The invention discloses a quartz sand supported lanthanum titanate photocatalyst. The quartz sand supported lanthanum titanate photocatalyst mainly comprises absolute ethyl alcohol, absolute methanol, acetone, titanium alkoxide, guiding agents, lanthanum acetate, ammonium acetate, glacial acetic acid, butylene glycol and quartz sand. A method for preparing the quartz sand supported lanthanum titanate photocatalyst includes preparing precursors, to be more specific, adding the titanium alkoxide and the guiding agents into the absolute ethyl alcohol, the absolute methanol and the acetone to obtain titanium alkoxide solution, forming lanthanum acetate solution from distilled water, the lanthanum acetate, the ammonium acetate and the glacial acetic acid, adding the titanium alkoxide solution into the lanthanum acetate solution drop by drop and adding the butylene glycol into the lanthanum acetate solution to obtain final transparent solution; carrying out support and heat treatment, to be more specific, adding the quartz sand into the final transparent solution, arranging beakers in magnetic stirring constant-temperature water bath kettles, stirring the final transparent solution under the condition of the temperature of 50-90 DEG C to obtain light yellow gel, drying the light yellow gel until the light yellow gel is dehydrated, grinding the light yellow gel to obtain powder, arranging the powder in a program-control chamber electric furnace, heating the program-control chamber electric furnace at the room temperature at the heating rate of 2-10 DEG C / min until the temperature of the program-control chamber electric furnace reaches a calcination temperature, keeping the calcination temperature unchanged for 1-10 h, cooling the powder and then grinding the powder to obtain materials. The quartz sand supported lanthanum titanate photocatalyst and the method have the advantage that the pollutant photocatalytic purification capacity of lanthanum titanate can be obviously improved.

Owner:SHENYANG LIGONG UNIV

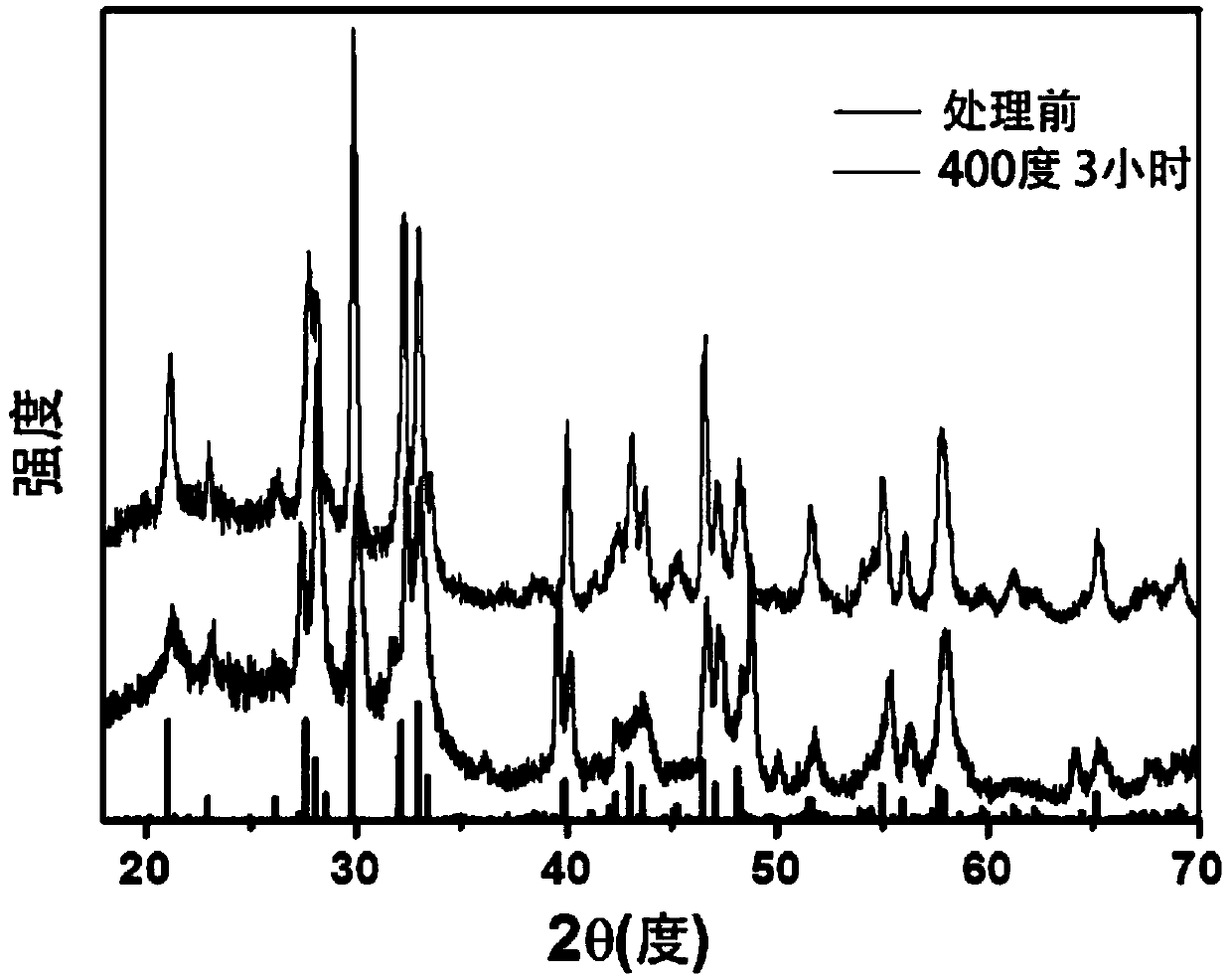

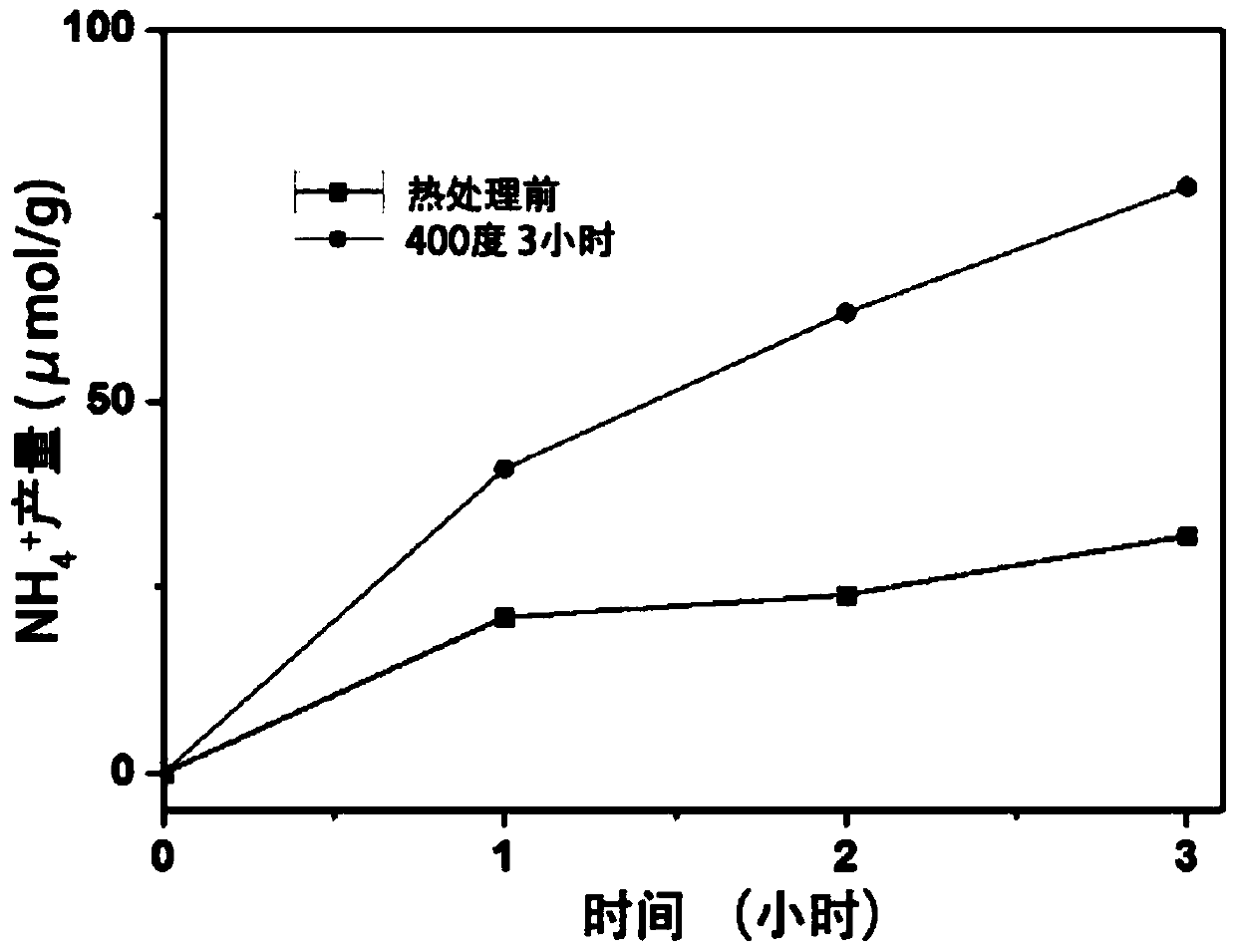

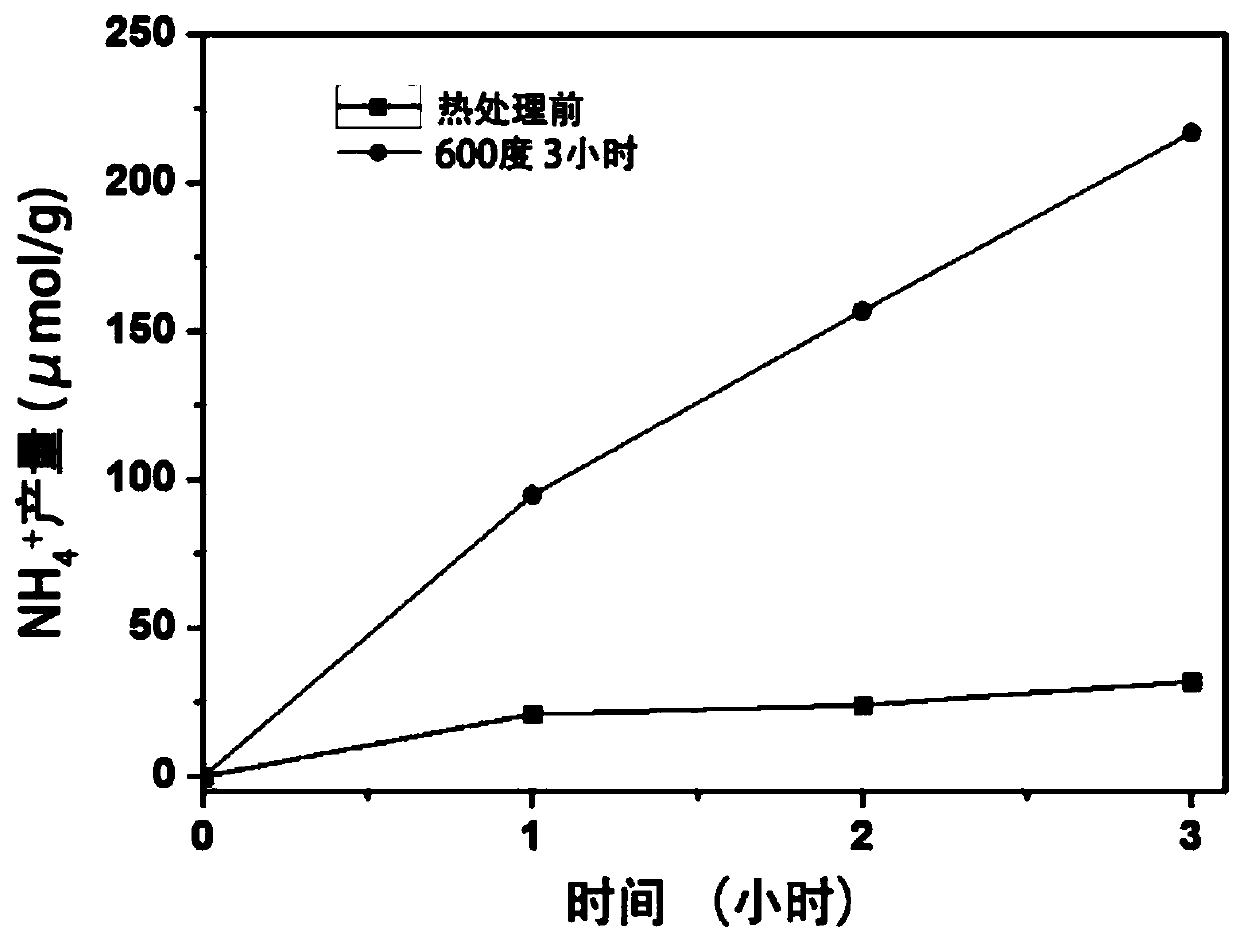

Application method of lanthanum titanate nano-sheet to photocatalysis nitrogen fixation

ActiveCN109534391ANon-toxicNo pollution in the processTitanatesMetal/metal-oxides/metal-hydroxide catalystsNon toxicityOxygen vacancy

The invention provides an application method of lanthanum titanate nano-sheet to photocatalysis nitrogen fixation, which comprises the following steps: step 1, preparation of La2Ti2O7 namely LTO nano-sheet; 2, adjusting oxygen vacancies in that LTO nano-sheet; 3, carrying out a typical test process. Through the above steps, the invention successfully synthesizes LTO nano-sheets containing oxygen vacancies, and applies the LTO nano-sheets to photocatalytic nitrogen fixation. Compared with the original LTO nanosheets, the LTO nanosheets containing oxygen vacancies have the characteristics of non-toxicity, non-pollution, stable performance and no need to add organic matter as sacrificial agent in the nitrogen fixation process; the photocatalytic nitrogen fixation performance has been significantly improved, and the conversion efficiency from solar energy to chemical energy has been greatly improved.

Owner:北京利特沃环境科技有限公司

Amorphous lithium lanthanum titanate thin films manufacturing method

An amorphous lithium lanthanum titanate (LLTO) thin film is produced by the sol-gel method wherein a polymer is mixed with a liquid alcohol to form a first solution. A second solution is then prepared by mixing a lanthanum alkoxide with an alcohol. The first solution is then mixed with the lanthanum based second solution. A lithium alkoxide and a titanium alkoxide are then also added to the lanthanum based second solution. This process produces a batch of LLTO precursor solution. The LLTO precursor solution is applied to a substrate to form a precursor layer which is then dried. The coating techniques that may be used include spin coating, spraying, casting, dripping, and the like, however, the spin coating technique is the preferred method recited herein.

Owner:JOHNSON IP HLDG LLC

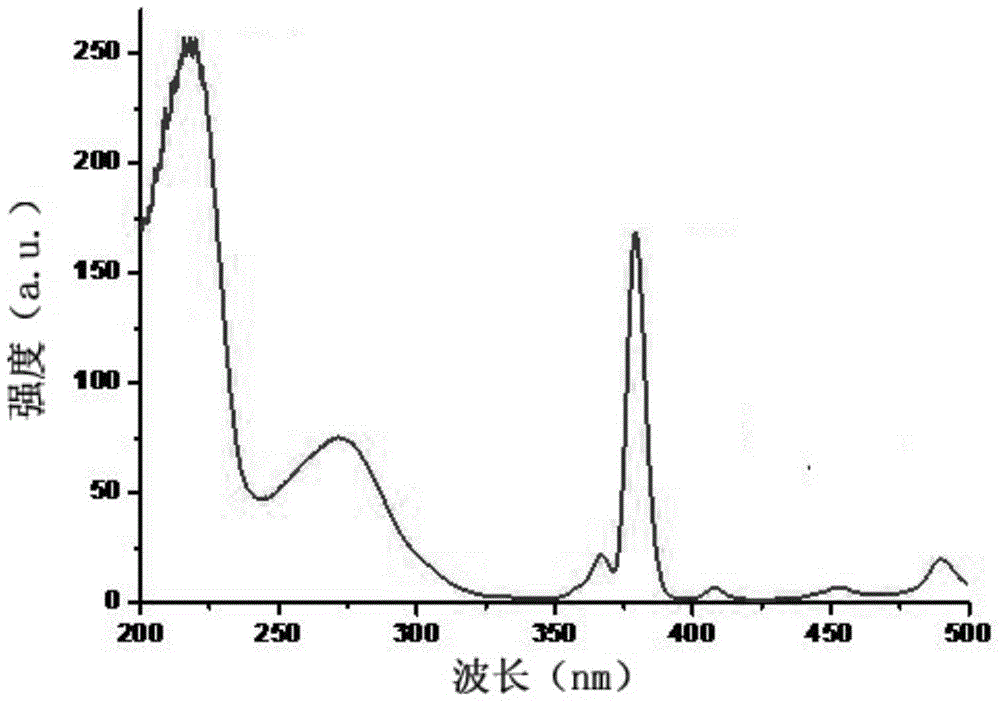

Erbium-doped lanthanum titanate fluorescent compound, and preparation method and application thereof

ActiveCN104910909AChemically stableImprove luminosityLuminescent compositionsAlcoholUltraviolet lights

The invention discloses an erbium-doped lanthanum titanate fluorescent compound of which the general formula is La2(1-x)Er2xTiO5, wherein 0.005<=x<=0.07. The preparation method comprises the following steps: dissolving a La soluble salt and an Er soluble salt in deionized water to obtain a solution A; mixing tetrabutyl titanate and alcohol to obtain a solution B; mixing the solution A and solution B, dropwisely adding acid, stirring to obtain a solution C, heating the solution C to 50-150 DEG C, and keeping the temperature to obtain a precursor gel; calcining the precursor gel; and pulverizing the calcined substance, grinding, washing and drying. The fluorescent compound can be an upconversion fluorescent compound or downconversion fluorescent compound, has stable chemical properties, can be excited by ultraviolet light or infrared light to obtain high luminescent intensity, and can be used as an upconversion fluorescent material or downconversion fluorescent material. The preparation method has the advantages of simple technique and low cost.

Owner:NORTHEASTERN UNIV

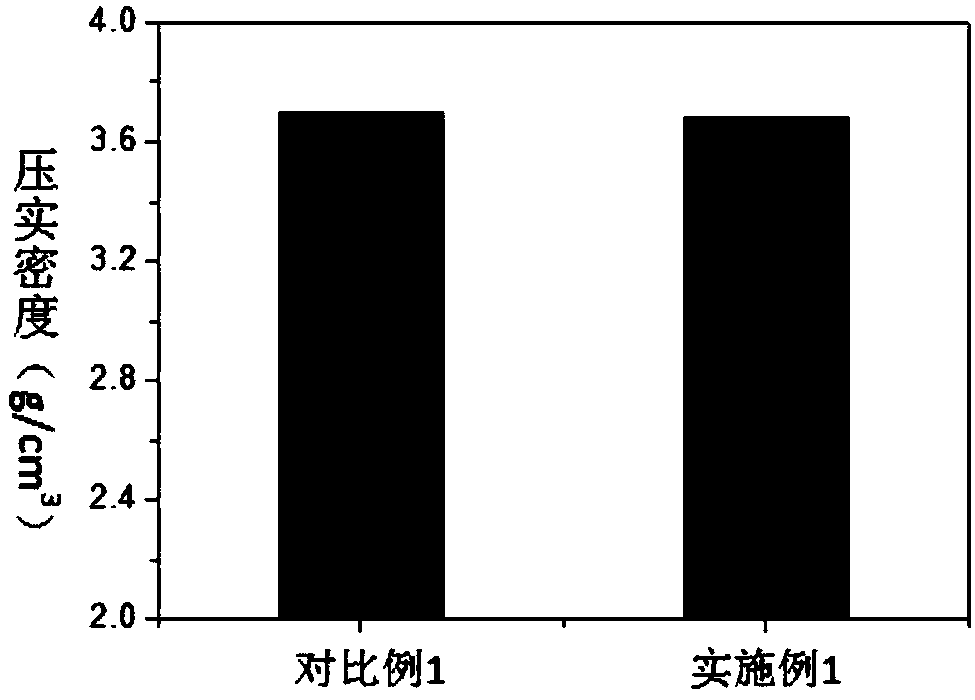

Preparation method of nanometer lithium lanthanum titanate coated 0.5Li2MnO3 0.5LiNi0.5Mn0.5O2 material

InactiveCN106025199AImprove performanceImprove the first Coulombic efficiencyMaterial nanotechnologyCell electrodesManganeseDissolution

The invention provides a preparation method of a nanometer lithium lanthanum titanate coated 0.5Li2MnO3 0.5LiNi0.5Mn0.5O2 material. Compared with the prior art, the method has the advantages that the lithium lanthanum titanate is a very good lithium conductor, is applicable to fast migration of lithium ions, and achieves the effect of improving the material rate capability; meanwhile, due to the surface coating, the protection effect is achieved on the body material; the contact between the material and electrolyte can be reduced; the occurrence of side reaction can be reduced; the manganese ion dissolution separation due to corrosion of HF on the material per se is reduced; the coulombic efficiency and the circulation stability are improved. By controlling the preparation process parameters, the 0.5Li2MnO3 0.5LiNi0.5Mn0.5O2 material with good performance is obtained through preparation; then, the material is subjected to uniform nanometer lithium lanthanum titanate surface coating, so that the first-time coulombic efficiency, the rate capability and the circulation stability are improved.

Owner:CHERY AUTOMOBILE CO LTD

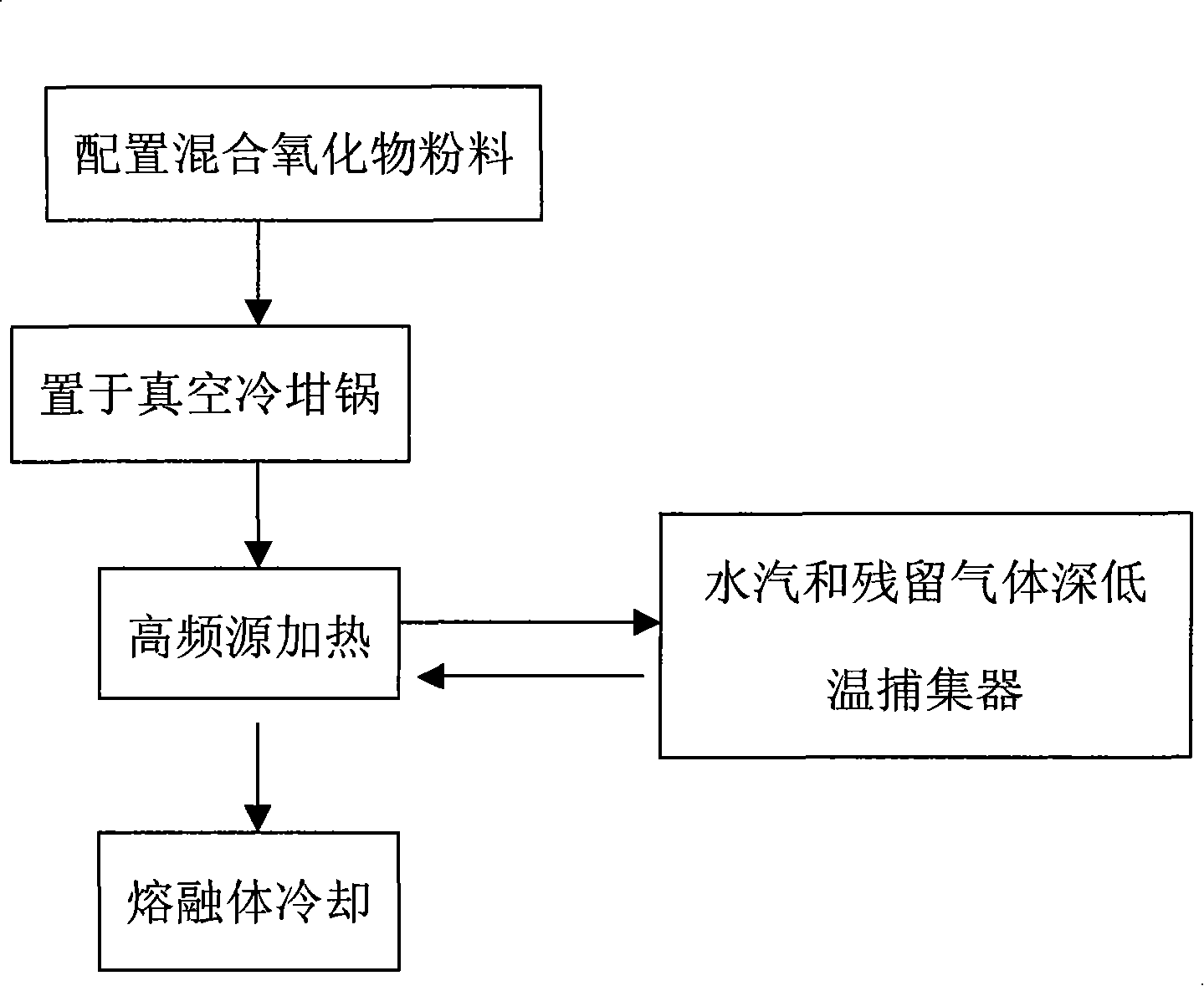

Method for preparing premelting lanthanum titanate crystalloid steam plating material

InactiveCN101200794AWon't escapeGood repeatabilityVacuum evaporation coatingSputtering coatingWater vaporVolumetric Mass Density

A pre-melted lanthanum titanate vapor plating material preparation method is provided. Firstly, lanthanum titanate mixed oxide powder is configured, which consists of 8 to 70 percent of La2O3 and 30 to 92 percent of TiO2 according to the weight percentage. The mixed oxide powder is arranged in a vacuum furnace cold crucible. Under the high vacuum (less than or equal to 1*10<-2>Pa), high frequency source is heated to 1800-2500 DEG C to form lanthanum titanate molten mass. The lanthanum titanate molten mass is cooled through slow settlement to form the pre-melted lanthanum titanate sparry vapor plating material. Water vapor and residue gas during the preparation process are trapped through a cold trap. The deep cold temperature is less than or equal to 100 DEG C below zero. The invention uses a high vacuum high frequency cold crucible slow settlement crystal growth method to prepare the pre-melted mixed oxide to be used as initial material with high purity and density used for vapor plating advanced optical films.

Owner:昆山光铭光电子元件有限公司

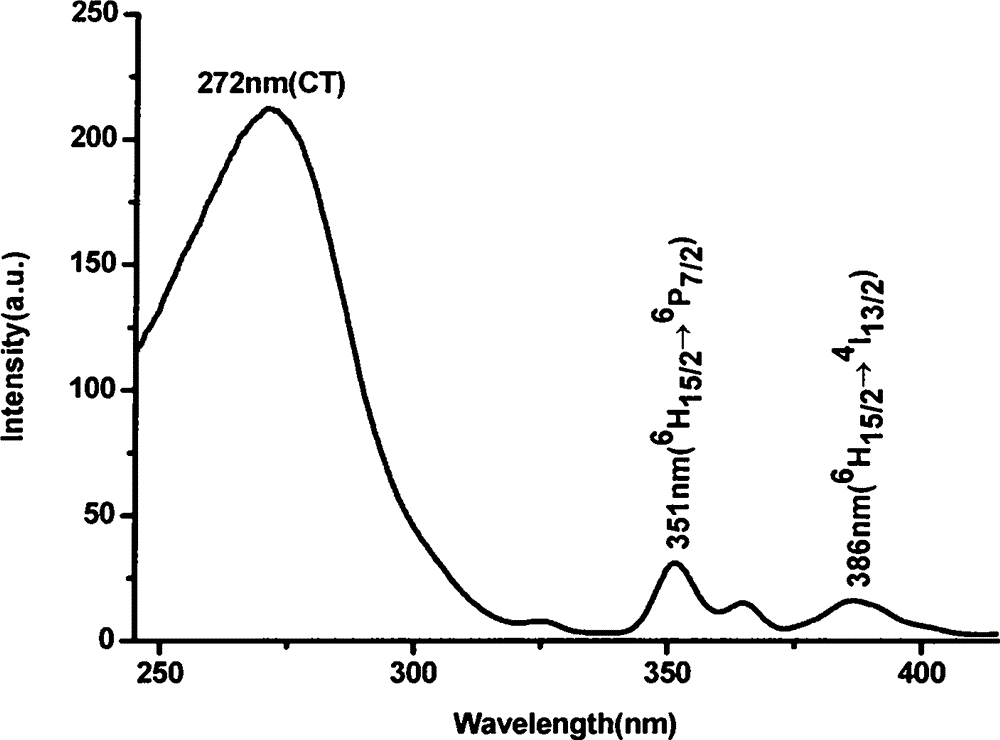

Preparation method and applications of dysprosium-doped blue phosphor

InactiveCN104830334AHigh purityHigh color puritySolid-state devicesSemiconductor/solid-state device manufacturingThermal insulationFluorescence

The present invention discloses a preparation method and applications of dysprosium-doped blue phosphor. The method comprises: weighing soluble salts of lanthanum and dysprosium according to the stoichiometric ratio of a chemical general formula (1-x)La2O3-TiO2-xDy2O3 (wherein x is 0.01-0.09), dissolving into an appropriate amount of deionized water, uniformly mixing to prepare a solution A, taking an appropriate amount of an alcohol solvent, adding an appropriate amount of tetrabutyl titanate in a dropwise manner to obtain a solution B, uniformly mixing the solution A and the solution B, adding an appropriate amount of a soluble acid, stirring, heating, carrying out thermal insulation to obtain a precursor gel C, placing the precursor gel C into a corundum crucible, calcining in a muffle furnace, and carrying out filtering and washing to obtain the blue phosphor. According to the present invention, the novel pyrochlore structure lanthanum titanate substrate is used and the single rare earth metal dysprosium is used to dope, such that the luminous efficiency is high, the obtained blue phosphor has characteristics of high purity and good color purity, and the method has characteristics of simple process and low preparing cost.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com