Patents

Literature

295results about How to "Distribute" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ester slump retaining type polycarboxylate water reducer and preparation method thereof

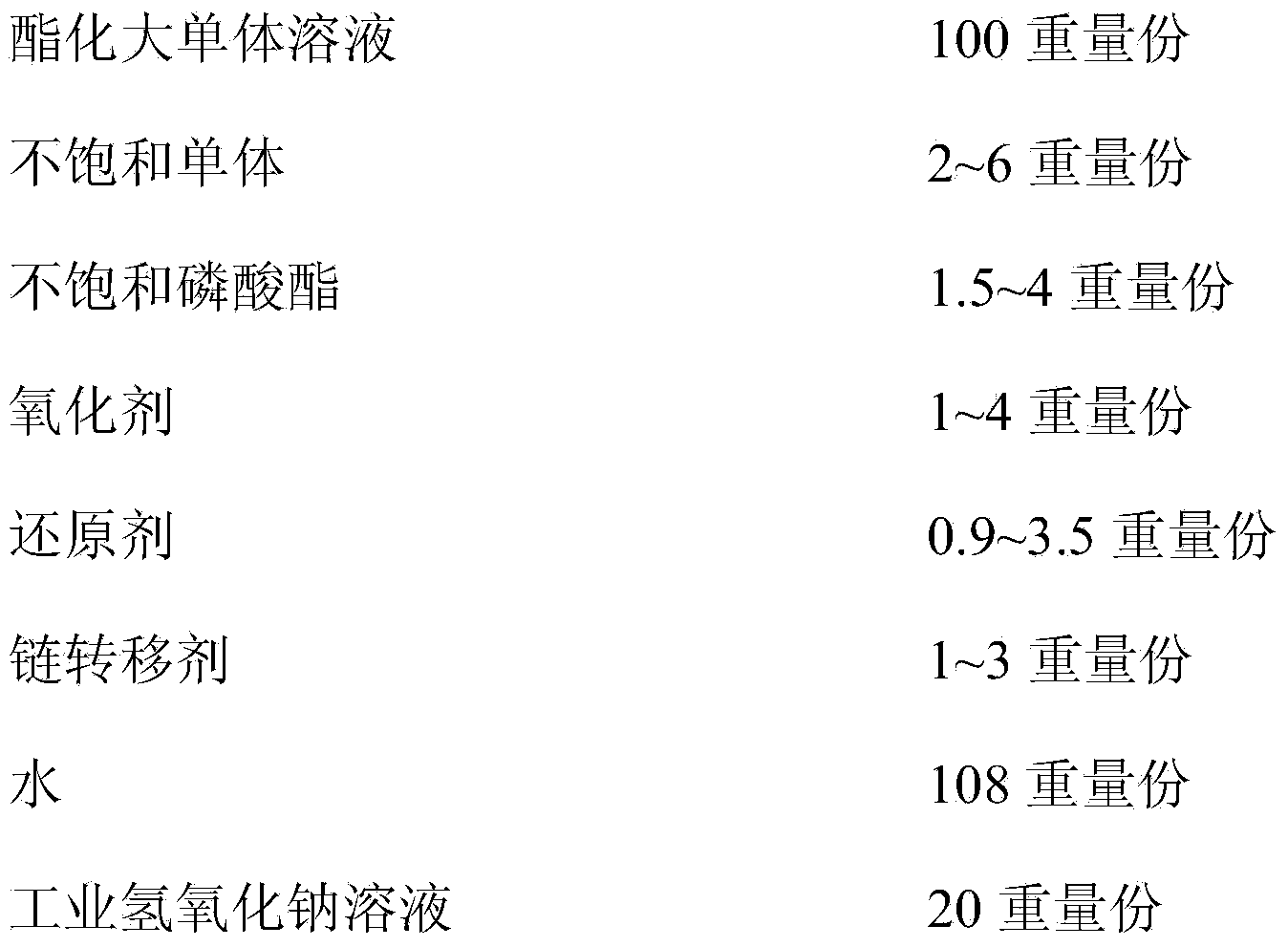

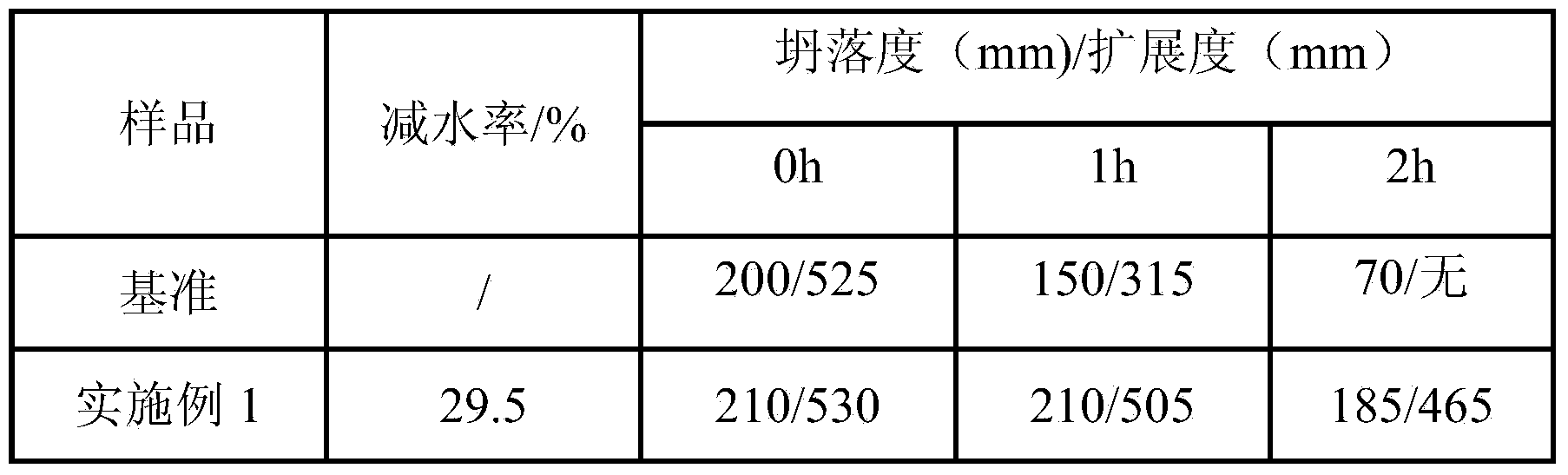

The invention discloses an ester slump retaining type polycarboxylate water reducer and a preparation method thereof. The ester slump retaining type polycarboxylate water reducer is made from raw materials comprising the following components in parts by weight: 100 parts of esterified macromer solution by weight, 2-6 parts of unsaturated monomer by weight, 1.5-4 parts of unsaturated phosphate by weight, 1-4 parts of an oxidizing agent by weight, 0.9-3.5 parts of a reducing agent by weight, 1-3 parts of a chain transfer agent by weight, 108 parts of water by weight, and 20 parts of industrial sodium hydroxide solution by weight, wherein the concentration of the esterified macromer solution is 75-85%, and a solute thereof is the mixture of methoxy polyethylene glycol methacrylate, crosslinking monomers triethylene glycol dmethylacrglate and methyl methacrylate; the unsaturated monomer is methacrylic acid, acrylic acid, hydroxyethyl methylacrylate, hydroxyethyl acrylate, hydroxypropyl methacrylate or hydroxypropyl acrylate. The ester slump retaining type polycarboxylate water reducer provided by the invention has good slump retaining performance, good dispersibility, good adaptability and low cost.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

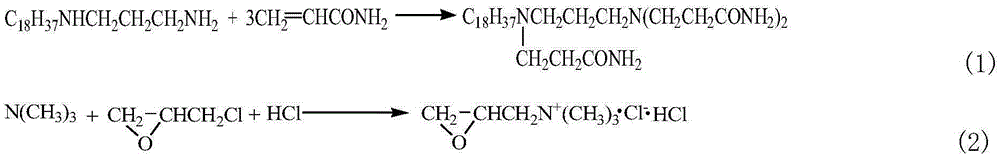

Multi-positive-ion amide-type asphalt emulsifier and preparation method thereof

InactiveCN105399645AGood emulsifying effectImprove hydrophilicityOrganic compound preparationCarboxylic acid amides preparationSolventHigh heat

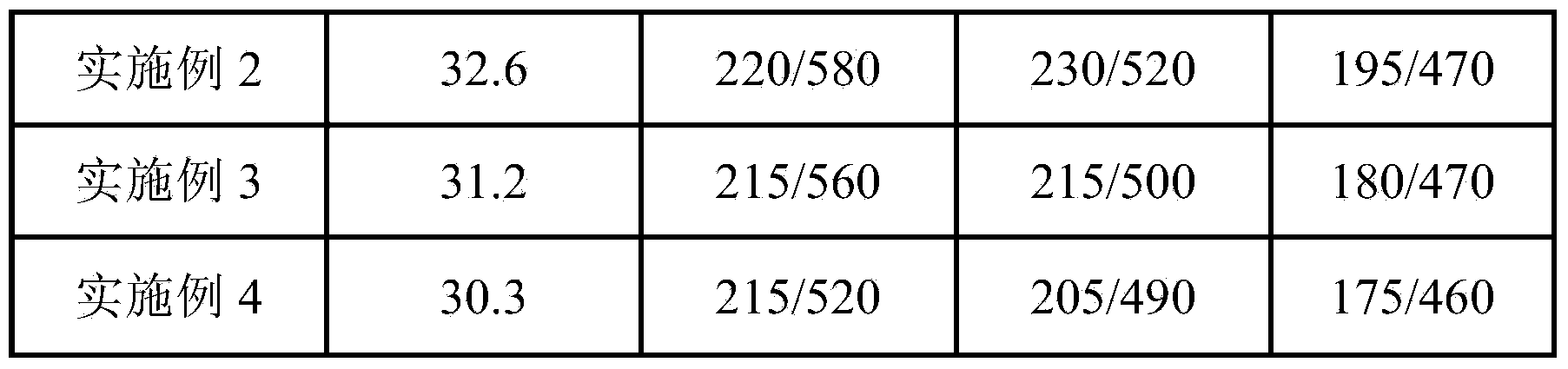

The present invention discloses a multi-positive-ion amide-type asphalt emulsifier and a preparation method thereof, and the asphalt emulsifier is prepared from raw materials of N-hydrogenated tallow-1,3-propylene diamine, an alcohol solvent, acrylamide, a low-carbon tertiary amine, industrial hydrochloride and epichlorohydrin in the molar ratio of N-hydrogenated tallow-1,3-propylene diamine to alcohol solvent to acrylamide to low-carbon tertiary amine to industrial hydrochloride to epichlorohydrin of 1mol: (5.00-11.00) mol: (3.00-3.10) mol: (2.02-2.10) mol: (2.02-2.10) mol: (2.02-2.08) mol. The alcohol solvent is ethanol, methanol or isopropanol. The low-carbon tertiary amine is a trimethylamine aqueous solution, triethylamine or triethanolamine. The asphalt emulsifier synthetic raw materials are readily available, production cost is low, a process is simple, and a high temperature reaction is not required. The asphalt emulsifier can emulsify a variety of different types of asphalt, the prepared emulsified asphalt is fine, uniform, and good in storage stability, and positive-ion-type emulsified asphalt can be prepared.

Owner:SHANDONG UNIV

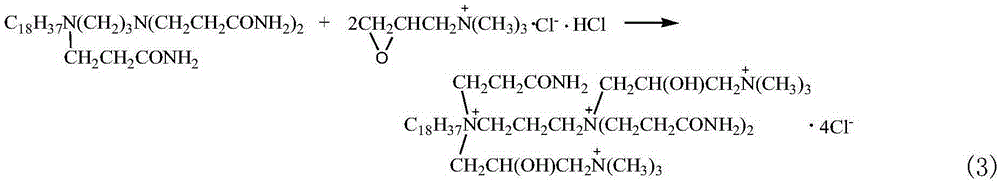

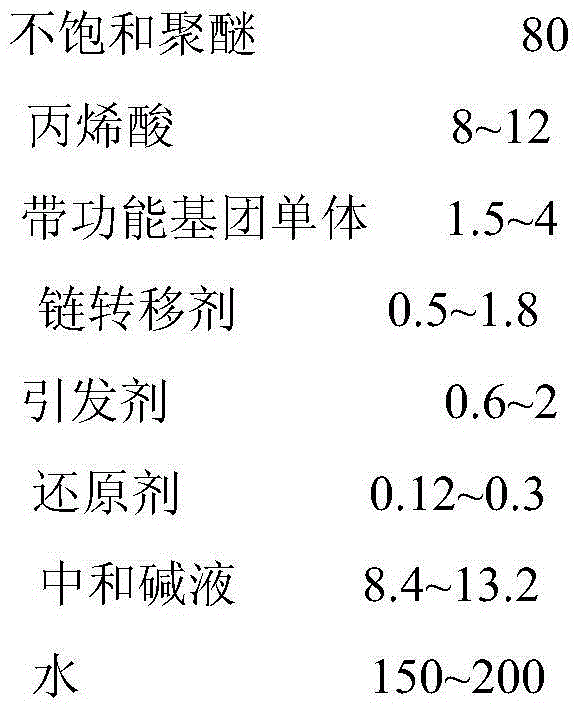

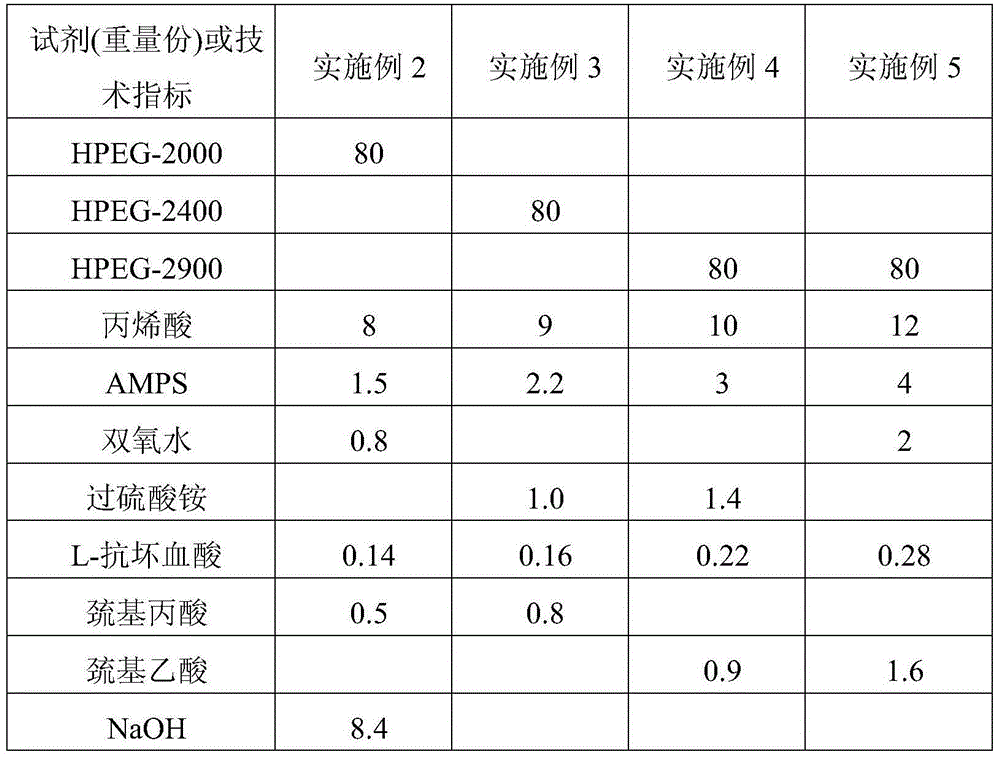

Multifunctional enhancement-type concrete admixture and preparation method thereof

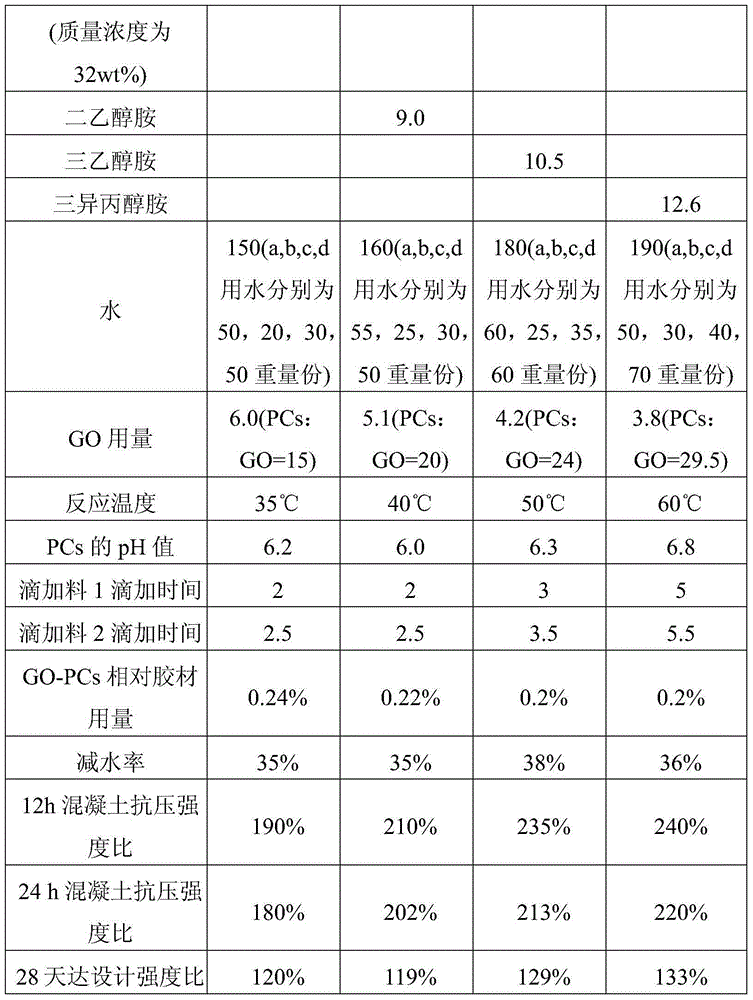

The invention relates to a multifunctional enhancement-type concrete admixture and a preparation method thereof. The concrete admixture is composed of an early-strength polycarboxylic acid water reducing agent (PCs) and nano graphene oxide (GO). The mass ratio of the solid to the GO in the early-strength water reducing agent (PCs) is (10-30):1. The early-strength polycarboxylic acid water reducing agent (PCs) is composed of the following components in parts by weight: 80 parts of unsaturated polyether, 8-12 parts of acrylic acid, 1.5-4 parts of monomer with functional groups, 0.5-1.8 parts of chain-transfer agent, 0.6-2 parts of initiator, 0.12-0.3 part of reducer, 8.4-13.2 parts of neutralizing alkali liquor and 150-200 parts of water. The admixture has an obvious enhancement action on concrete, implements high-strength long-service-life green concrete, and has important meanings in the field of application of high-strength high-performance concrete.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Composite curing agent for dredged silt in watercourse

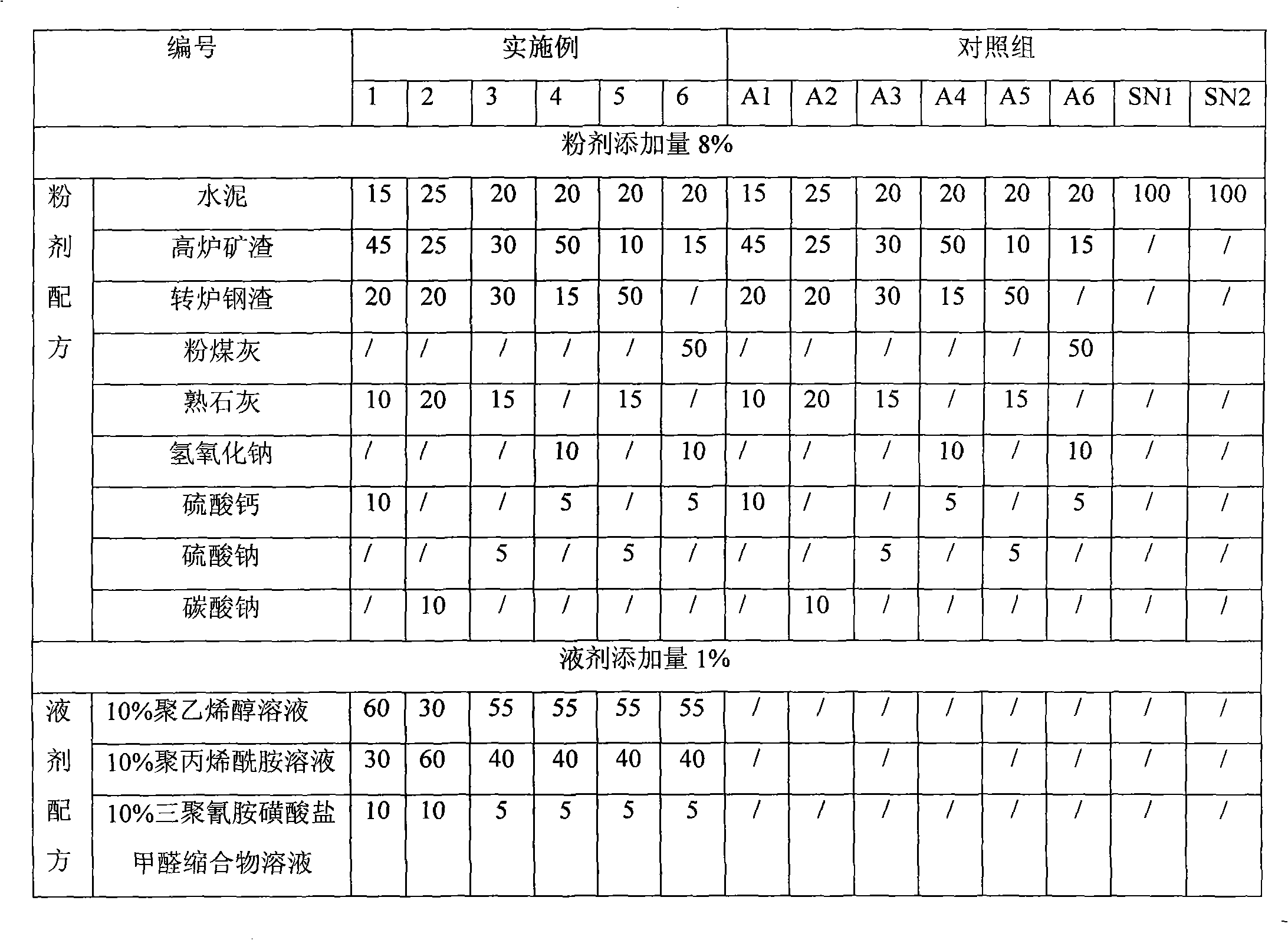

InactiveCN102060480AHigh strengthSpeed up the reaction processSludge treatmentSolid waste managementPolyvinyl alcoholCompressive strength

The invention discloses a composite curing agent for dredged silt in a watercourse, comprising a powdered agent and a liquid agent, wherein the powdered agent consists of the following components on the basis of 100 percent of the total mass fraction: 15-25 percent of cement, 45-65 percent of pozzolanic material, 10-20 percent of alkali activator and 5-10 percent of salt activator; and the liquid agent consists of the following components on the basis of 100 percent of the total mass fraction: 2-7 percent of polyvinyl alcohol, 2-7 percent of polyacrylamide, 0.5-1 percent of melamine sulfonate formaldehyde condensate and the balance of water. The dredged silt has high compressive strength after being solidified by the composite curing agent for the watercourse silt, and can meet the requirements of road construction.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI +1

Glass fiber reinforced and hydrolysis-resistant nylon PA (Polyethylene) 6/PA66 composite material and preparation method thereof

ActiveCN103113737AImprove bending strengthImprove the ability to withstand external forcesCoatingsGlass fiberAlkali free

The invention relates to a glass fiber reinforced and hydrolysis-resistant nylon PA (Polyethylene) 6 / PA66 composite material and a preparation method thereof. The composite material comprises the following components: PA6, PA66, hydrolysis-resistant alkali-free glass fibers, a compatilizer, a main hydrolysis resisting agent, an epoxide assistant hydrolysis resisting agent, a nucleating agent, an antioxidant that is the 1010 and 168 compounded antioxidant, a lubricant and simethicone. The preparation method comprises the following steps: placing the PA6, the PA66, the compatilizer and the simethicone into a high-speed mixer to mix according to the formula mass; adding each assistant mentioned above; mixing by the high-speed mixer; transferring into a twin-screen extruder; and molting, extruding, blanking and drying the materials, so as to obtain the composite material. The glass fiber reinforced and hydrolysis-resistant nylon PA6 / PA66 composite material has the advantages of being high in bending strength, excellent in toughness and hydrolysis resistance and wide in applicable scope, is mainly applicable to components of controllers of electric bicycle, and can meet the requirement of the performance of the materials.

Owner:天津万塑新材料科技有限公司

Reactive monomer modified nano calcium carbonate/polypropylene master batch and its preparing method

The present invention relates to a reactive monomer modified nano calcium carbonate / polypropylene mother material and its production method. Said mother material is formed from polypropylene base body, nano calcium carbonate filling material, reactive monomer (including maleic anhydride, acrylic acid and its esters and styrene) and universal stabilizing agent D of PP material. Its preparation method includes the steps of uniformly mixing by using high-speed mixing machine and extruding by means of twin screw extruder machine. Said invention can raise the mechanical property of nano calcium carbonate filled polypropylene material.

Owner:SUN YAT SEN UNIV

Preparation method of precipitated silicon dioxide

InactiveCN1669922AChange surface electrical propertiesPrevent rapid aggregationSilicaSaline solutionsUltra fine

The invention relates to a preparing method for depositing silica dioxide, which comprises the following steps: dissolving the silicate of alkali metal to saline solution a with water, dissolving the soluble salt of metallic ion with 2 valency or above 2 valency to saline solution b with water as a polymerization inhibitor, reacting with between saline solution a and saline solution b at a temperature of 10 -80 Deg. C to get the compound c, heating the compound c to 60-95 Deg. C, acidifying by adding acidating agent and adjust the PH in 1-5 to get the compound d1, then maturing 3-100 min with respect to heat to get the compound d2, filtering, washing and drying compound d2, to get the ultra-fine disposition silica dioxide.

Owner:SHANDONG HAIHUA GRP CO LTD

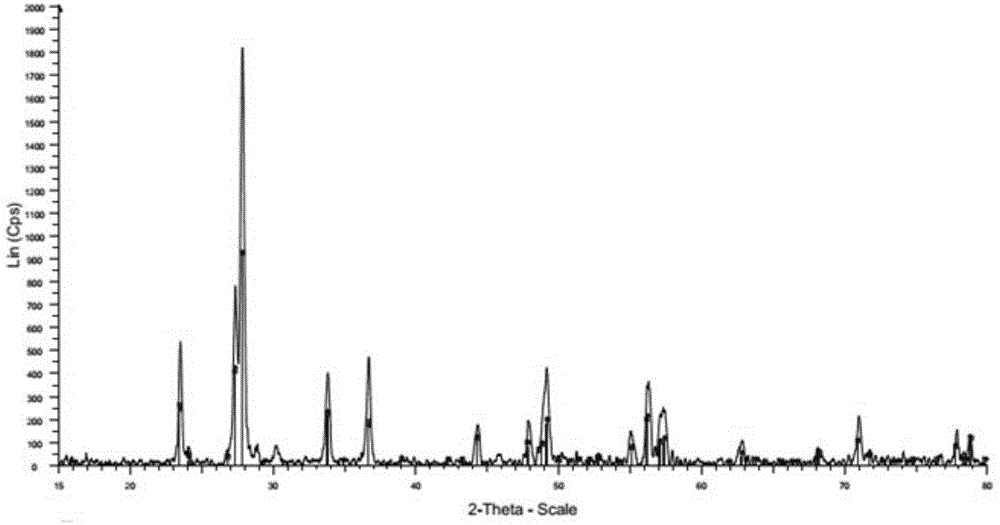

Preparation method of cesium tungsten oxide ultrafine powder

The invention belongs to the field of nanotechnology, and particularly relates to a preparation method of cesium tungsten oxide ultrafine powder. The preparation method of the cesium tungsten oxide ultrafine powder comprises the following steps: weighing cesium salt and tungsten salt according to Cs / W molar ratio of 1: (1.5-2.8), adding a chelating agent and an alcohol reagent, and reacting for 3 h at 170 DEG C; filling obtained mixed liquid into a pressure vessel, and reacting for 5-8 h at 260-270 DEG C; washing a reaction product with alcohol, centrifugating the reaction product, and performing vacuum drying at a temperature of 80 DEG C to obtain the cesium tungsten powder with complete crystallinity. Through the preparation method, reaction raw materials can be saved, so that the preparation cost; the preparation reaction period is short, so that industrial production is facilitated; the cesium tungsten oxide powder prepared through the preparation method is dark blue ultrafine powder with the particle size of 119 nm and the resistance of (1.2-6.4)*104 omega.

Owner:烟台佳隆纳米产业有限公司

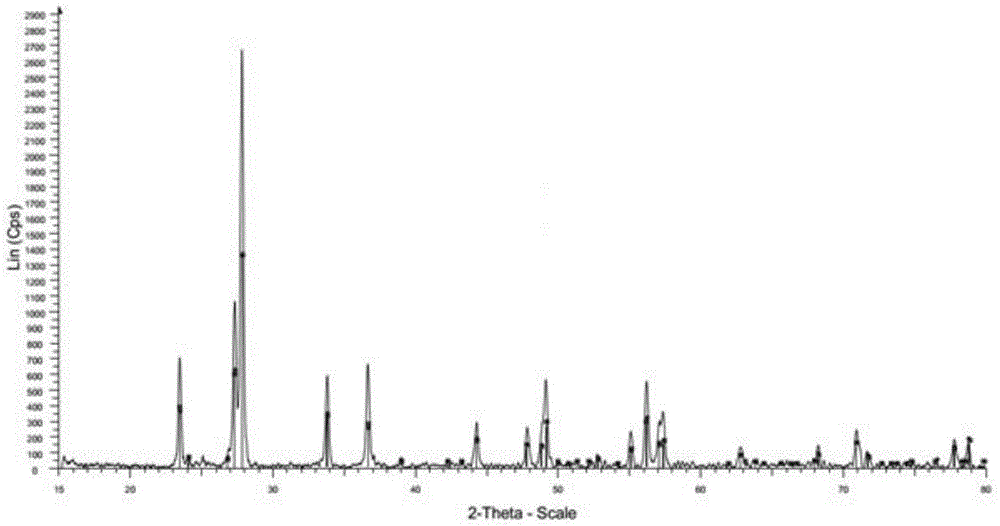

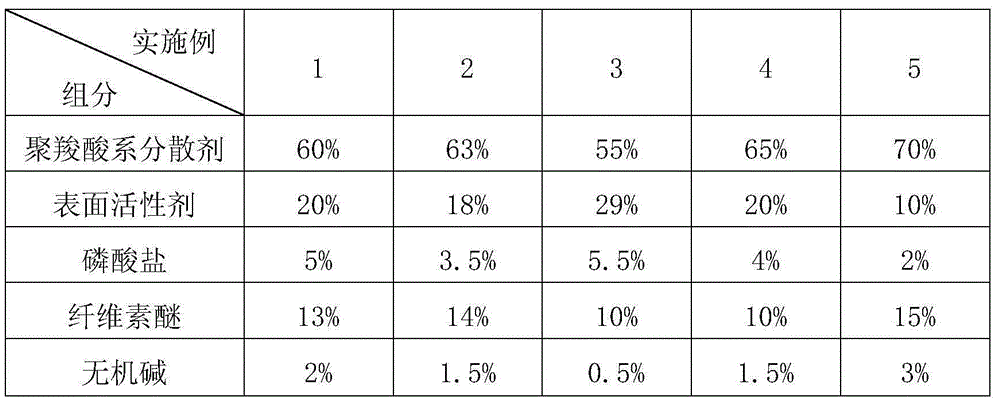

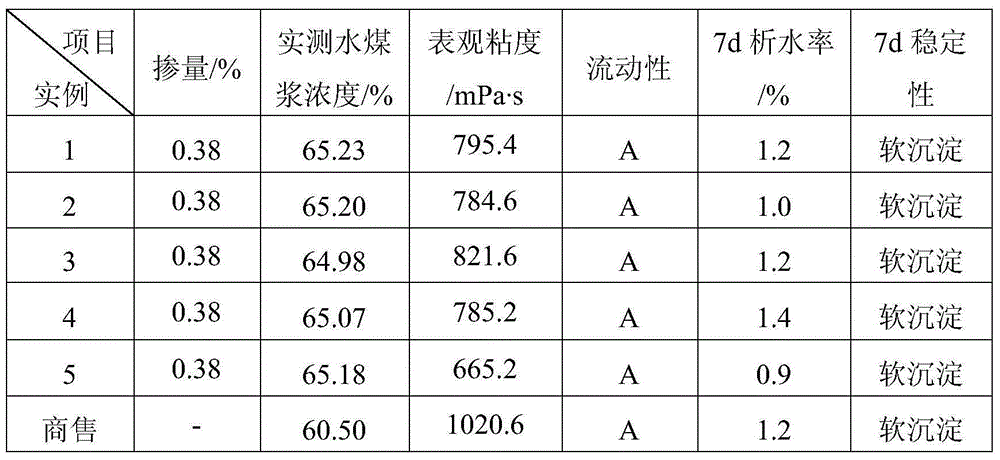

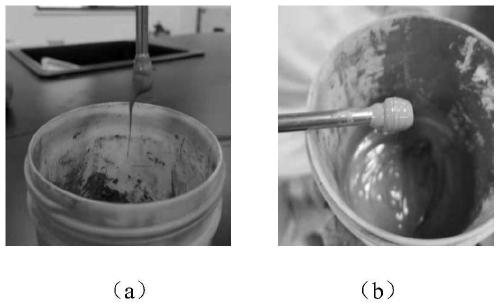

Multi-component coal water slurry additive and application thereof

The invention discloses a multi-component coal water slurry additive and application thereof. The multi-component coal water slurry additive comprises 50-80 parts of a polycarboxylate dispersing agent, 10-60 parts of a surfactant, 5-45 parts of cellulose ether, 1-15 parts of phosphate and 0-3 parts of inorganic base. The polycarboxylate dispersing agent is used for dispersing coal water slurry, can simultaneously take the effects of a dispersing agent and a stabilizer and is low in consumption, sulfur-free, little in pollution, efficient and environmentally friendly in the coal water slurry preparation process; the polycarboxylate dispersing agent, the surfactant and the phosphate are compounded, so that the interfacial tension and hydrophilicity / hydrophobicity of the surfaces of coal particles are changed, the dispersing agent is accelerated to be uniformly distributed on the pulverized coal particles, and the lubricating effect of a water film among the pulverized coal particles is improved; through a synergistic effect, the dispersing and stabilizing effects are achieved to the maximum extent; and due to the addition of the cellulose ether and the inorganic base, the storage stability of the coal water slurry can be improved. The coal water slurry disclosed by the invention has relatively high concentration and also has the characteristics of low viscosity, good stability and good flowability.

Owner:SICHUAN SEDAR CHEM

Silicon carbide ceramic paste for photocuring and preparation method thereof

InactiveCN110451985AImprove curing depthReduce clumpingAdditive manufacturing apparatusCeramic sinteringDispersity

The invention discloses silicon carbide ceramic paste for photocuring and a preparation method thereof. The paste is prepared by mixing SiC mixed powder, a dispersing agent, a monomer, a compatilizerand a photoinitiator, wherein the surface of the SiC mixed powder is coated with a SiO2 layer, so that the refractive index difference between the final paste and light-cured resin is reduced, and then printing efficiency is further improved. SiO2 can improve the solid phase content of the whole slurry, so that the sintering density of sintered ceramic and the mechanical property of finally formedceramic can be improved during subsequent ceramic sintering. Through addition of the dispersing agent into the slurry, the agglomeration phenomenon of the slurry can be reduced, the dispersity is improved, and the solid phase content of the whole slurry can be increased. Verification finds that the solid phase content in the paste can finally reach 40%-60%.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Method for synergistically improving arc ablation performance of CuW contact material

ActiveCN108950279AImproved arc ablation performanceImprove protectionContactsElectrolysisMaterials science

The invention discloses a method for synergistically improving the arc ablation performance of a CuW contact material. The method comprises the steps that firstly, spherical electrolytic copper powderis rolled into a sheet, then reduced tungsten powder is added for ball milling, even mixing is conducted, and tungsten-copper modified mixed powder is obtained; secondly, expanded graphite is sequentially subjected to low temperature intercalation oxidation, medium temperature intercalation oxidation and high temperature intercalation oxidation, and graphene oxide is obtained; thirdly, the tungsten-copper mixed powder and the graphene oxide are added into an ethanol-water mixed solution to be mixed evenly, drying is conducted, graphene oxide / tungsten-copper composite powder is obtained and then subjected to low-temperature thermal reduction, and reduced graphene oxide / tungsten-copper composite powder is obtained; and fourthly, the reduced graphene oxide / tungsten-copper composite powder issubjected to discharge plasma liquid phase sintering, and the CuW contact material is obtained. The graphene oxide is added into the tungsten-copper modified mixed powder, thermal reduction is conducted at first, the reduced graphene oxide is obtained, then discharge plasma liquid phase sintering is conducted, tungsten carbide nanoparticles are generated, and the arc ablation performance and mechanical performance of the CuW contact material are synergistically strengthened through the reduced graphene oxide and the tungsten carbide nanoparticles.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

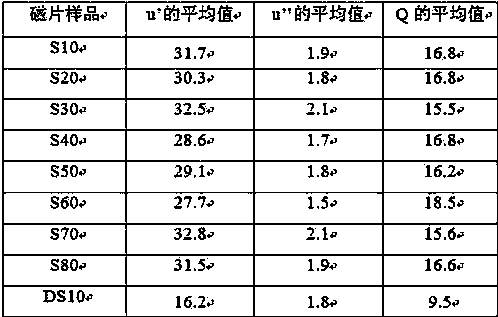

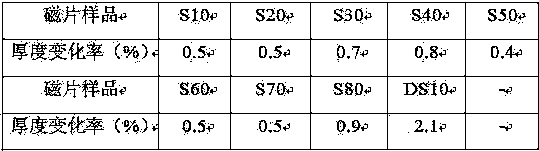

Sizing agent for near field communication (NFC) magnetic sheet, manufacturing method thereof and NFC magnetic sheet

ActiveCN103377787AShorten the production cycleImprove permeabilityMagnetsOrganic/organic-metallic materials magnetismState of artHigh humidity

The invention provides a sizing agent for a near field communication (NFC) magnetic sheet and a manufacturing method thereof. The sizing agent for the NFC magnetic sheet is composed of magnetic powder and organic carriers. The organic carriers contain 15-20wt% of adhesives, 75-83.8wt% of solvents, 0.1-1wt% of defoaming agents, 0.1-1wt% of dispersing agents and 1-5wt% of plasticizers. The adhesives are polyvinyl butyral and / or ethyecellulose. The invention further provides an NFC magnetic sheet manufactured by the sizing agent. The adhesives made of the powder polyvinyl butyral and / or ethyecellulose can replace resin and rubber in the prior art, so that production cycle of the NFC magnetic sheet can be shortened. Magnetic conductivity of the NFC magnetic sheet manufactured by the sizing agent is improved, magnetic powder is evenly distributed, and the magnetic sheet is small in thickness changing in a high-temperature high-humidity environment.

Owner:BYD CO LTD

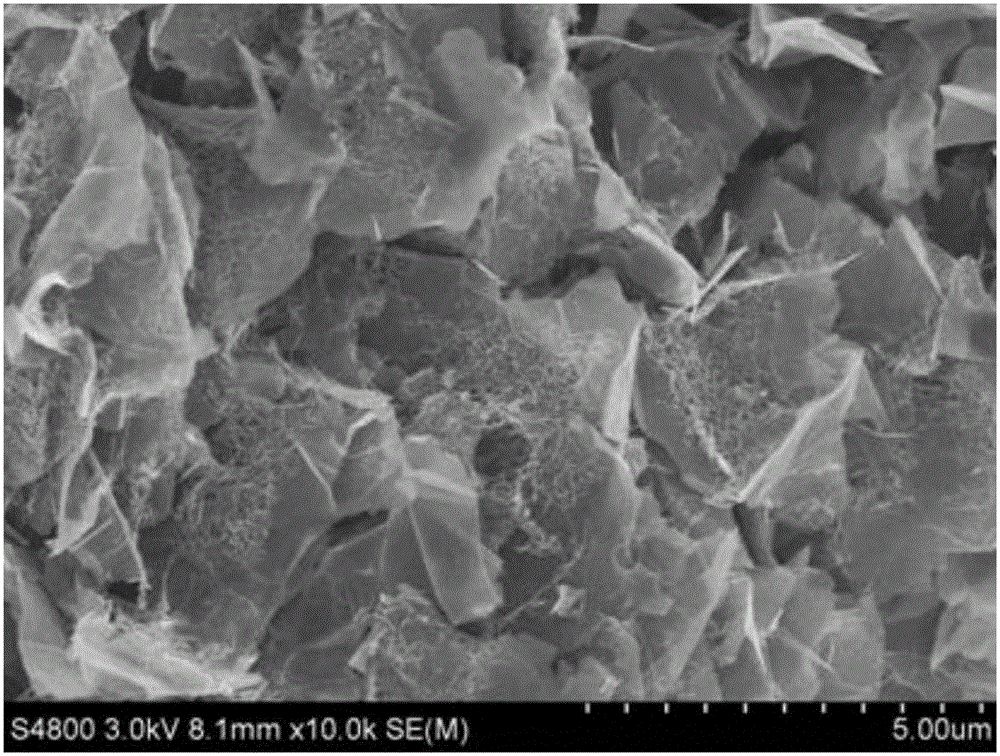

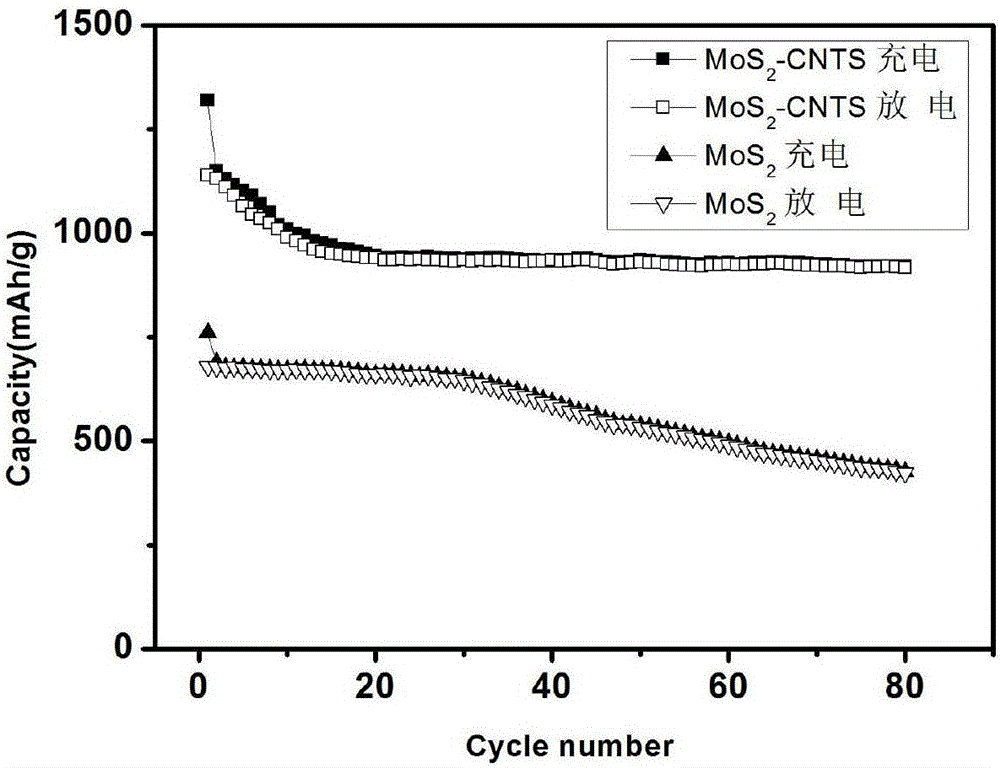

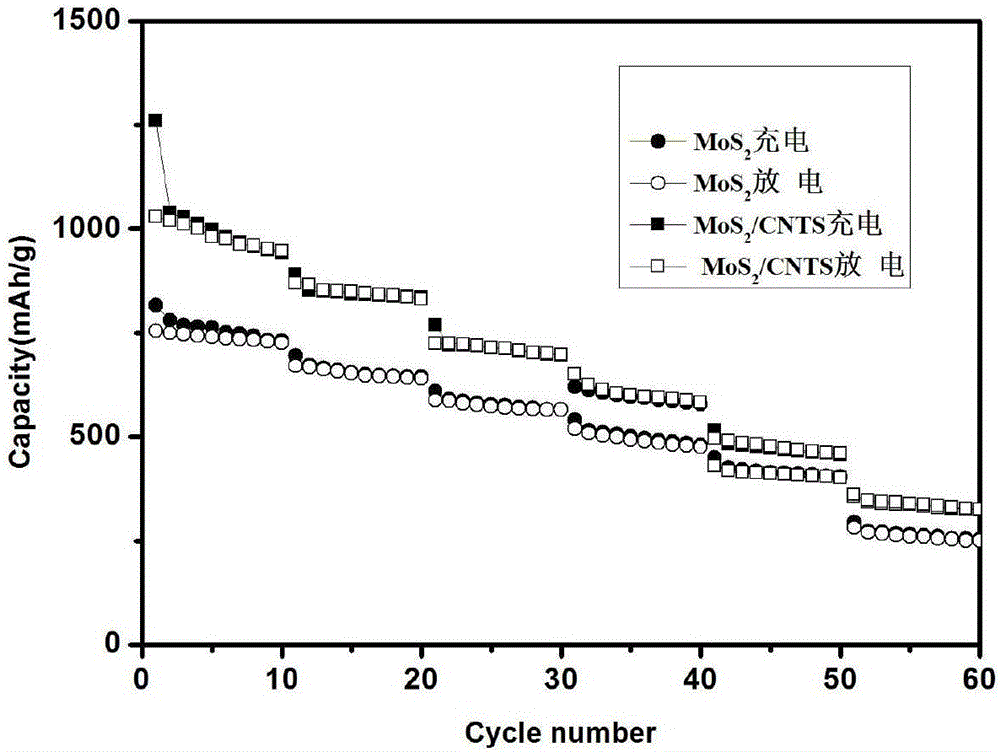

Lithium-ion-battery multiwalled carbon nanotube/ molybdenum disulfide combination electrode and preparation method

ActiveCN106711413AHigh electrochemical lithium storage specific capacityPromote circulationCell electrodesSecondary cellsHigh rateLithium-ion battery

The invention provides a lithium-ion-battery multiwalled carbon nanotube / molybdenum disulfide combination electrode and a preparation method. According to the preparation method, multiwalled carbon nanotube, soluble molybdate and L-cysteine are adopted as materials, glucose and triton X-100 are used as additives, dispersion uniformity of MoS2 on the surface of the carbon nanotube is improved, and through an in-situ hydrothermal reduction method, a combination electrode material of MoS2 and the multiwalled carbon nanotube is synthesized. The material has high electrochemical storage lithium specific capacity, excellent cycle performance and a high-rate feature. Meanwhile, the synthetic method has the advantages of being moderate in reaction condition, simple in process, high in yield and good in repeatability.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

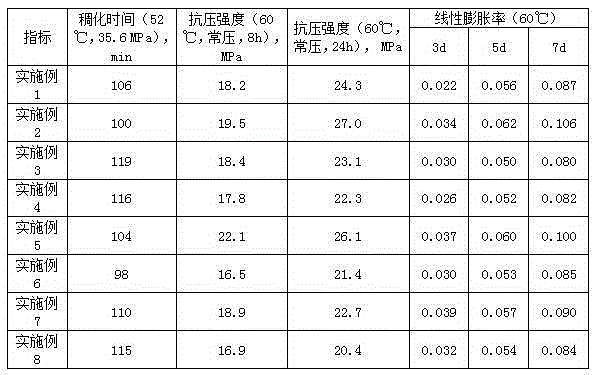

Slightly-expanded oil well cement

ActiveCN105295876AOvercome the defect of slow expansionPromote expansionDrilling compositionWell cementingUltimate tensile strength

The invention discloses slightly-expanded oil well cement, belonging to the technical field of well cementing and cementing for oil and gas wells. The well cementing cement comprises the following raw materials in parts by weight: 50 to 80 parts of gel material, 20 to 40 parts of active materials, 0.5 to 3 parts of magnesia expanding agent, 0.1 to 8 parts of alkaline activator, and 2 to 5 parts of stabilizing material; the magnesia expanding agent is light calcined magnesia powder. The slightly-expanded oil well cement disclosed by the invention is mainly used for solving the problem that the expansion effect of expanding cement is poor to influence the early strength in the prior art and has the advantages of good expansion properties in the early, medium and later stages of cement hydration.

Owner:JIAHUA SPECIAL CEMENT

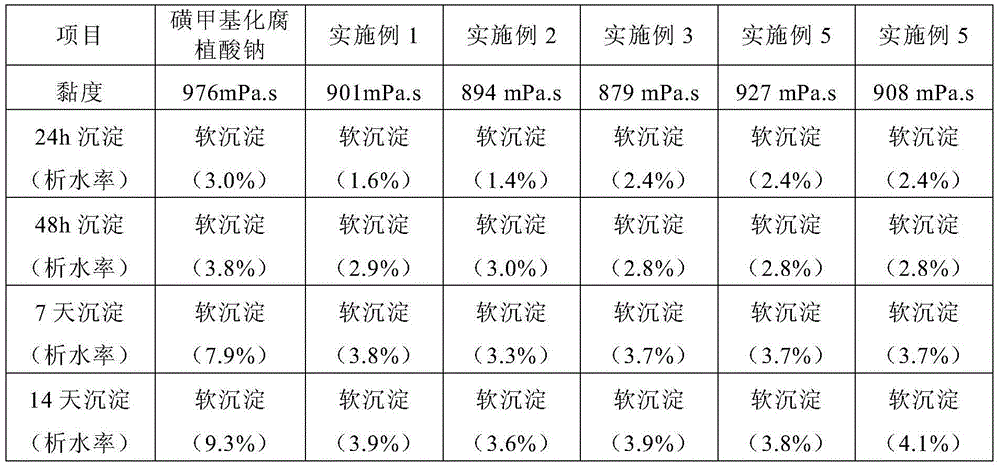

Amphoteric humate coal water slurry dispersant as well as preparation and application thereof

InactiveCN104152195APossesses both yin and yang characteristicsEvenly dispersedLiquid carbonaceous fuelsCoal waterCross linker

The invention discloses a preparation method of an amphoteric humate coal water slurry dispersant. The preparation method comprises the following steps: preparing sulfomethylated humic acid by reaction of humic acid, formaldehyde and a sulfonating agent; then further performing cationization reaction on sulfomethylated humic acid and a cationic etherifying agent and finally dropping a cross-linking agent to perform cross-linking reaction so as to obtain the novel amphoteric humate coal water slurry dispersant. The method for preparing the coal water slurry dispersant comprises three steps of sulfomethylation, cationization and cross-linking reaction, and anionic and cationic groups are introduced on a matrix of the humic acid, so that the relative molecular weight of the dispersant is also increased; by using the novel dispersant, the apparent viscosity of the coal water slurry can be effectively reduced and the stability of the coal water slurry can be also obviously improved.

Owner:SHAANXI UNIV OF SCI & TECH

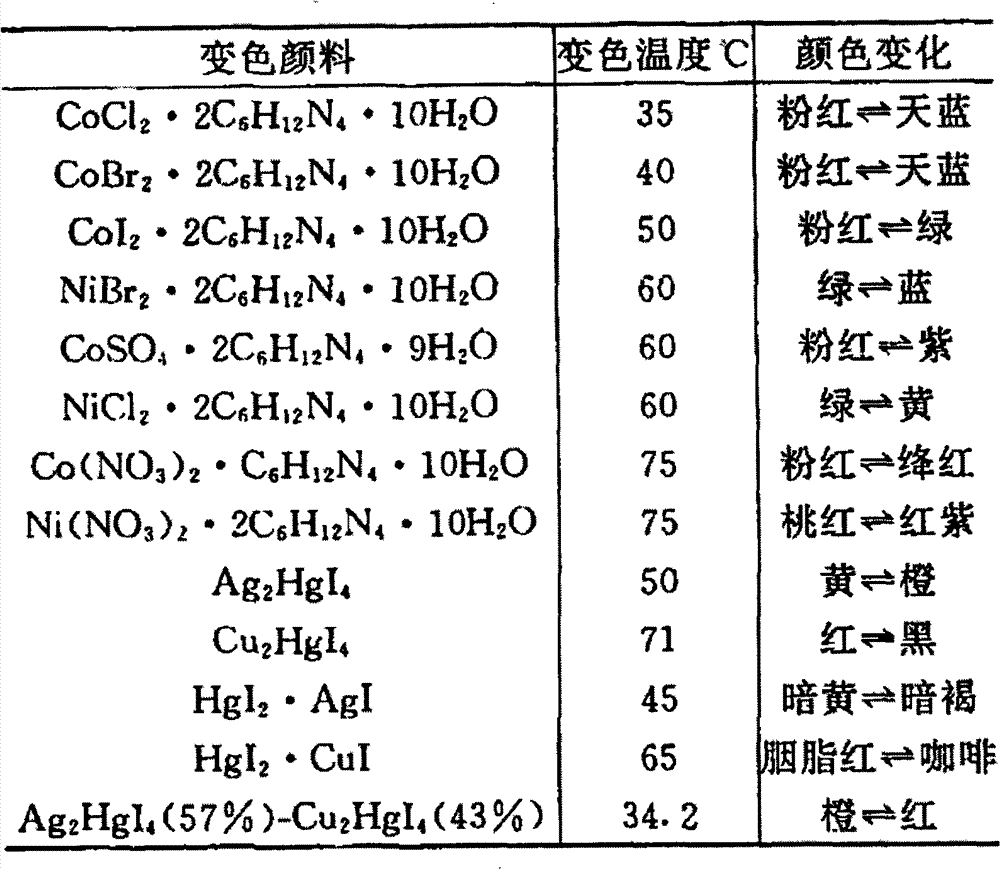

Fluorescent powder mixture and LED (Light-Emitting Diode) packaging device with color conversion function

The invention provides a fluorescent powder mixture and an LED (Light-Emitting Diode) packaging device with color conversion function and relates to an LED light source, for changing a color temperature, a tone or a color of light emitted by an LED device after being effected by the fluorescent powder mixture. According to the technical scheme, the LED packaging device comprises an LED chip and a colloidal fluorescent powder mixture for packaging the LED chip, wherein the fluorescent powder mixture comprises a reversible thermochromic material. The reversible thermochromic material provided by the invention is diffused in fluorescent powder, so as to prevent the fluorescent powder from depositing in a process of curing the fluorescent powder colloid and take the functions of a dispersing agent and an anti-precipitating agent. An LED lamp has no need of a lamp cover structure, so that the structure of a lamp can be simplified, and the cost is reduced. Furthermore, the front surface of the lamp is beneficial to ventilation and heat radiation of the front surface of the lamp. The fluorescent powder mixture and the LED packaging device have a wide application range in an indoor table lamp, a ceiling lamp, a tube lamp, a wall lamp, an LED lamp tube, a bulb lamp, a panel lamp and even backlight lamp and the like.

Owner:GUANGDONG SHENLAITE SCI & TECH

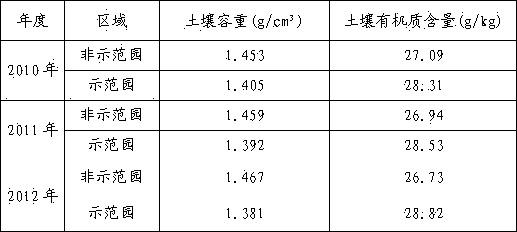

Water-retaining soil-loosening fertilizer

InactiveCN103601578AIncrease water solubilityPrevent invalidationFertilizer mixturesChemistrySolubility

The invention relates to the field of fertilizers, particularly a water-retaining soil-loosening fertilizer. The fertilizer is prepared from the following raw materials in parts by weight: 10-30 parts of carbamide, 10-20 parts of monoammonium phosphate, 10-35 parts of potassium dihydrogen phosphate, 0.01-5 parts of manganese sulfate, 0.01-1 part of copper sulfate, 0.1-5 parts of zinc sulfate, 0.01-2 parts of ammonium molybdate, 0.1-2 parts of ferrous sulfate, 0.05-5 parts of ethylenediamine tetraacetic acid, 10-43 parts of potassium nitrate, 5-15 parts of calcium biphosphate, 0.1-5 parts of boric acid, 0.05-5 parts of polyacrylamide and 0.1-5 parts of calcium lignosulphonate. The fertilizer loosens and activates the soil, and enhances the water solubility of the soil.

Owner:烟台富迪康生物科技有限公司

Preparation method of ultrafine tungsten carbide powder

ActiveCN103408015AImprove uniformityAvoid uneven mixingTungsten/molybdenum carbideTungstenCarbon black

The invention relates to a preparation method of ultrafine tungsten carbide powder. A mixture of ultrafine tungsten powder, carbon black and ultrafine tungsten carbide powder used as an initial reactant is subjected to carbonization reaction in a non-oxidizing atmosphere to prepare the ultrafine tungsten carbide powder. The ultrafine tungsten carbide powder prepared by the method has the advantages of small particle size, uniform particle size distribution, favorable dispersity, no pellet and high combined carbon content; and the production technique can easily control the quality and can implement mass production.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

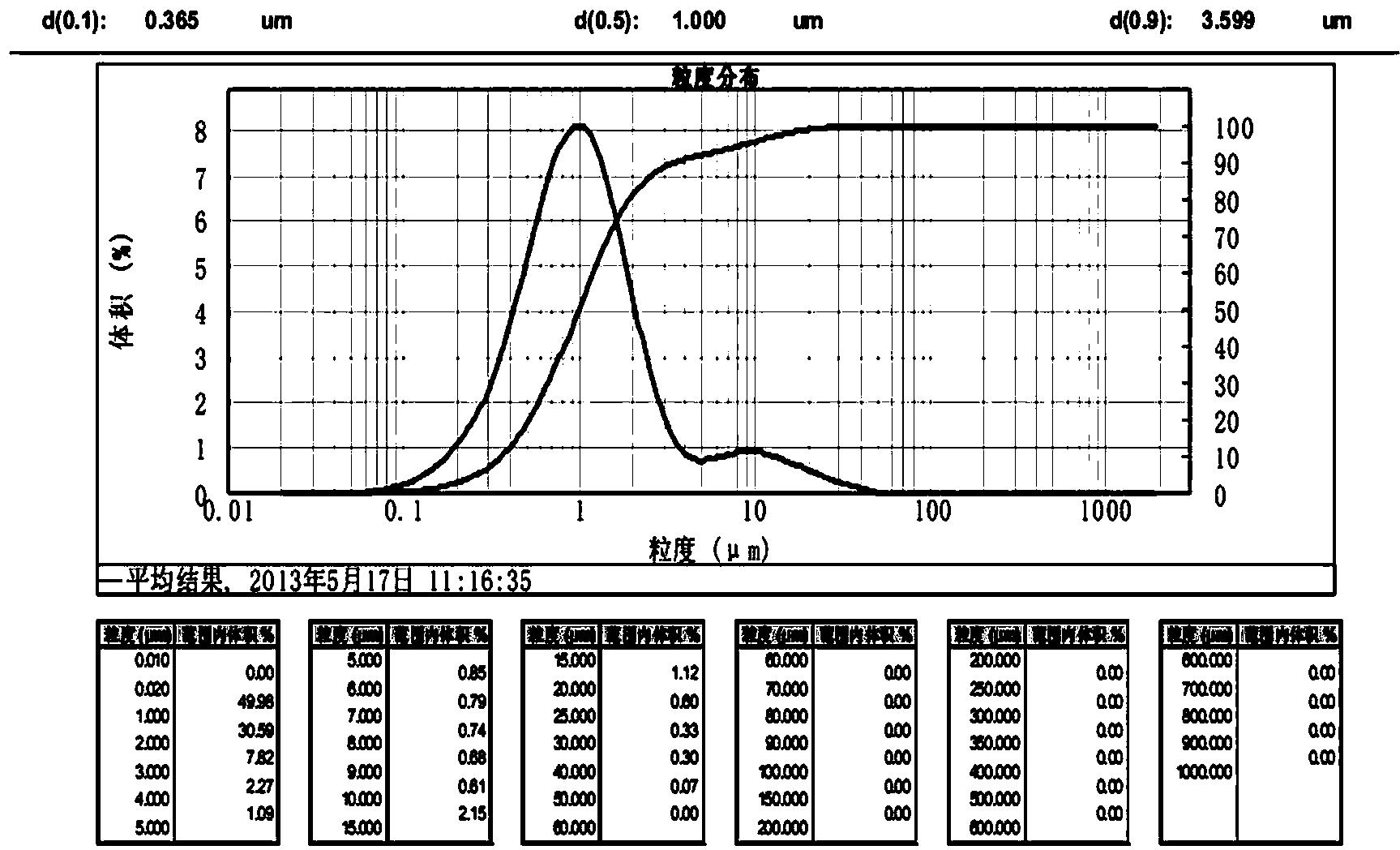

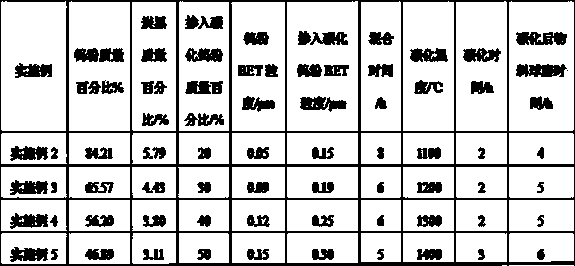

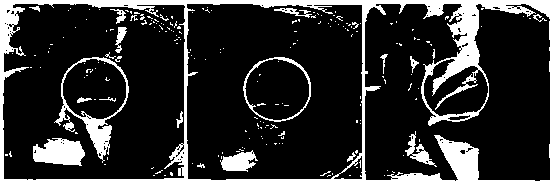

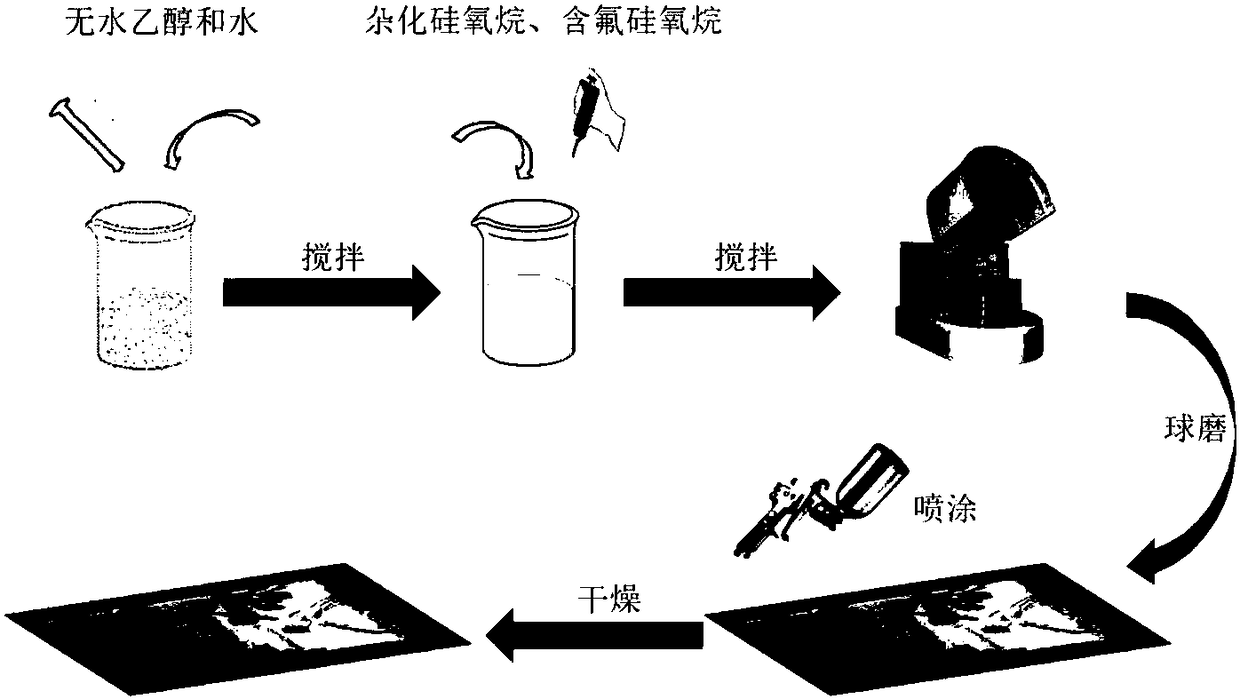

Transparent super-hydrophobic coating for preventing calligraphy and painting from being polluted as well as preparation method and application thereof

ActiveCN108178986ADoes not affect appearanceStrong resistance to beverages and even ink/ink contaminationFireproof paintsAntifouling/underwater paintsCoated surfaceRoom temperature

The invention discloses transparent super-hydrophobic coating for preventing calligraphy and painting from being polluted as well as a preparation method and application thereof. The method comprisesthe following steps: adding inorganic nanoparticles into a mixed solution of ethanol and water and uniformly mixing; then adding hybridized siloxane and fluorine-containing siloxane into the obtainedsolution; stirring at room temperature for 10 to 30min; then carrying out ball milling for 4 to 6h by utilizing a ball milling instrument to obtain the super-hydrophobic coating. The transparent super-hydrophobic coating for preventing the calligraphy and painting from being polluted, disclosed by the invention, is used as calligraphy or painting super-hydrophobic coating; the application is as follows: a substrate of the calligraphy or painting is coated with the super-hydrophobic coating and the super-hydrophobic coating is cured at 80 to 150 DEG C to obtain a super-hydrophobic pollution-preventing coating layer. The surface of the coating layer has a very strong beverage pollution, even Chinese ink / ink pollution prevention capability and has a certain high-temperature resisting capability. Meanwhile, the content of silicon dioxide is controlled in a certain range and a very food transparent effect can be realized; the appearance of the calligraphy and painting is not influenced.

Owner:ZHEJIANG UNIV OF TECH

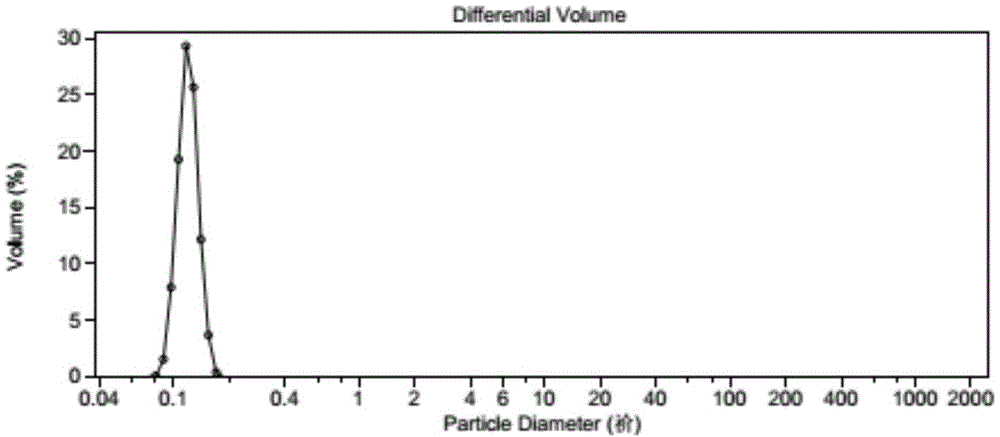

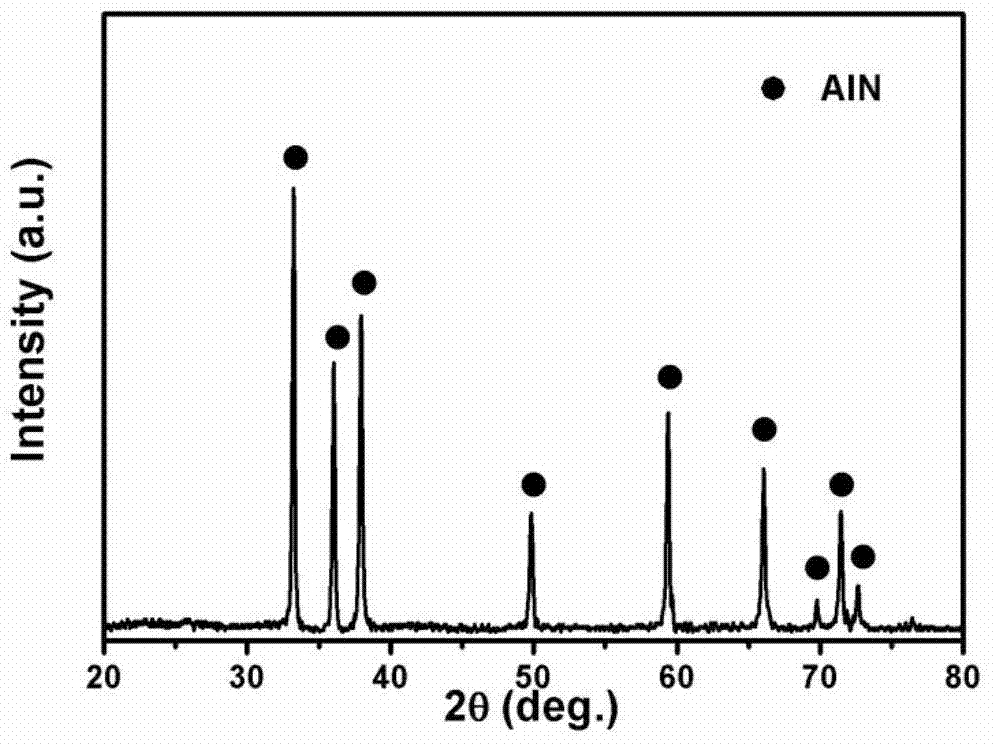

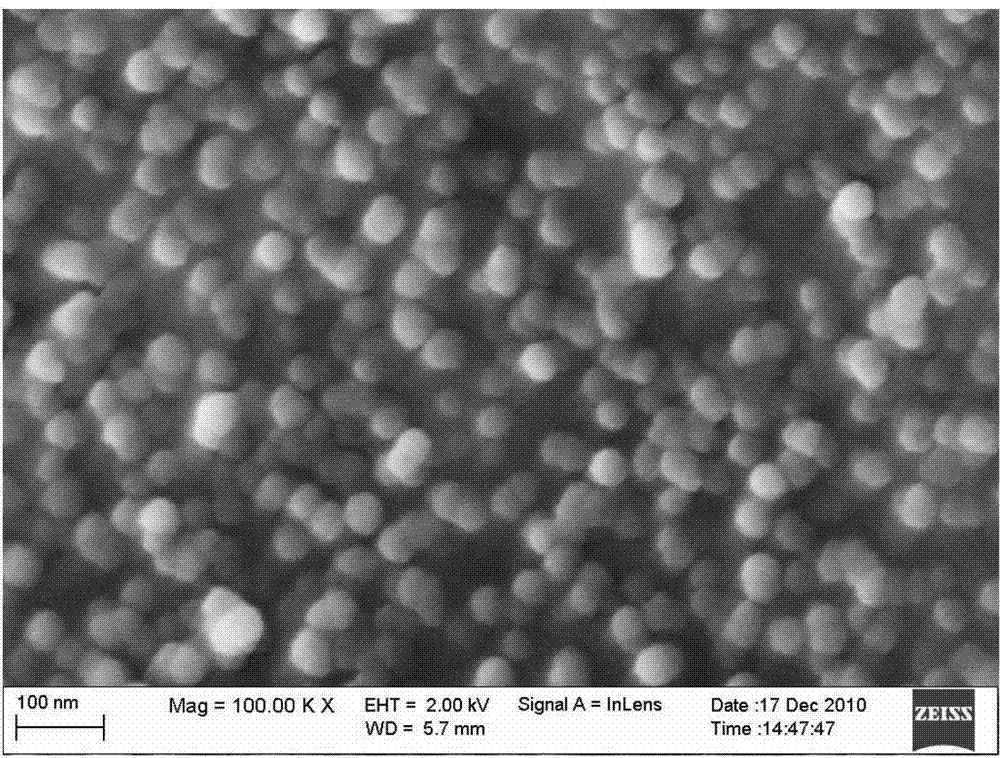

Preparation method of nano aluminium nitride powder

The invention discloses a preparation method of nano aluminium nitride powder, belonging to the technical field of nano material preparation. The preparation method comprises the following steps: preparing a solution according to a certain proportion by adopting aluminium sources, water-soluble carbon sources and assistant agents as raw materials; heating the solution, so that the solution is decomposed after being volatilized and concentrated, thus obtaining precursor powder; reacting the precursor powder in a certain atmosphere at 1200-1800 DEG C for 1-5 hours; treating the powder after reaction in the air at 500-800 DEG C for 1-3 hours, thus obtaining the nano aluminium nitride powder. The preparation method is simple in process and low in cost and can be used for obtaining the nano aluminium nitride powder which has good degree of sphericity and dispersibility and has a particle size smaller than 50nm.

Owner:UNIV OF SCI & TECH BEIJING

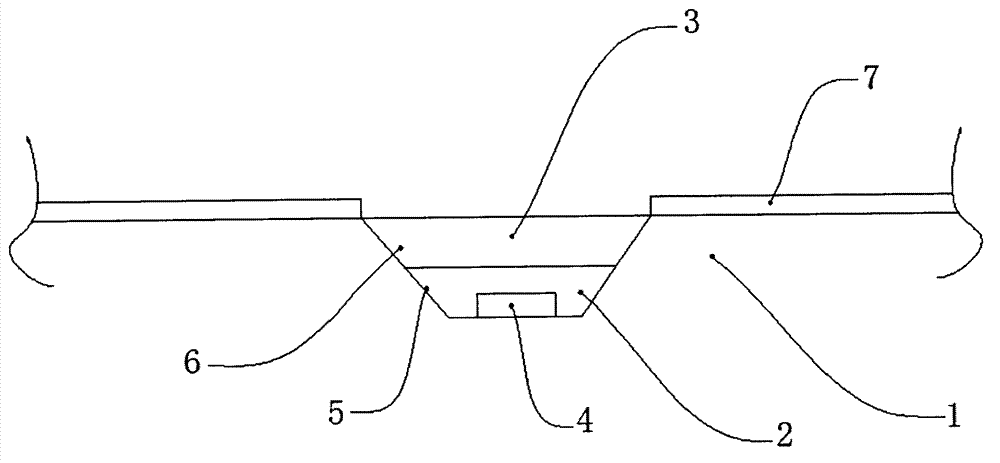

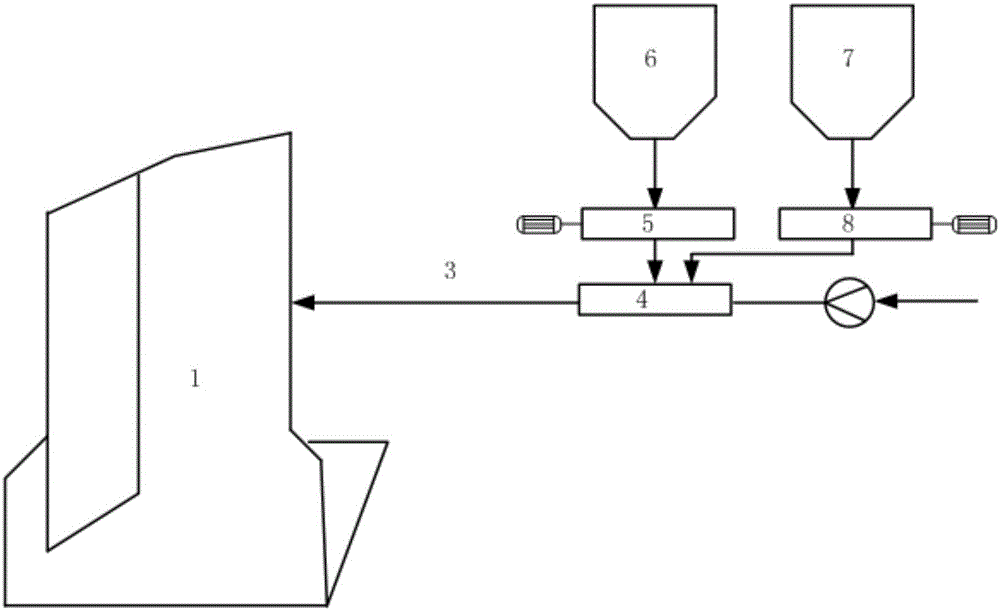

In-boiler desulfurization and denitration system and method for chain grate boiler

The invention discloses an in-boiler desulfurization and denitration system and method for a chain grate boiler. The system comprises the chain grate boiler, a feed bin and a smoke and powder mixer, wherein the feed bin is used for providing a space for containing a desulfurization agent and / or a denitration agent; the smoke and powder mixer is connected with the feed bin, a flue gas pipeline and the chain grate boiler respectively; flue gas is mixed with the desulfurization agent and the denitration agent in the smoke and powder mixer to provide power to deliver the desulfurization agent and the denitration agent to an injection pipeline component mounted in the chain grate boiler for injection; the desulfurization agent and the denitration agent are a calcium-based desulfurization agent and urea powder respectively. The desulfurization agent and the denitration agent are delivered into the chain grate boiler through the tail flue gas of the boiler, so that the urea powder can be effectively prevented from absorbing moisture for agglomeration; in addition, compared with that of hearth flue gas, the temperature and oxygen content of the tail flue gas are lower, so that an area of which the temperature is relatively proper and the oxygen concentration is relatively lower can be provided for denitration reaction in a higher-temperature area of a hearth, and the problems of instable hearth temperature, small reaction space and the like of the chain grate boiler can be solved.

Owner:SHANDONG SHENHUA SHANDA ENERGY ENVIRONMENTAL +1

Modified starch-based biodegradable plastic and preparation method thereof

InactiveCN110734633ADoes not affect usable mechanical propertiesIncreased degradation ratePlant protective coveringsPolymer sciencePolyvinyl alcohol

The invention discloses a modified starch-based degradable plastic and a preparation method thereof. The degradable plastic comprises the following preparation raw materials in parts by mass: 60-80 parts of polylactic acid, 20-30 parts of polyvinyl alcohol, 40-70 parts of modified starch, 3-15 parts of a cross-linking agent, 0-5 parts of a plasticizer and 0-3 parts of a dispersing agent, wherein the modified starch is alkenyl succinic acid esterified starch and / or peroxy acid esterified starch. According to the preparation method, double bonds are introduced into the polymer to increase the breaking probability of macromolecular chain, and a dioxygen bond is introduced into the polymer to provide a better living environment for aerobic microorganisms, so that the aerobic decomposition rateof the degradable plastic is fundamentally increased.

Owner:SHANDONG SI DA KE BIODEGRADABLE TECH CO LTD

Method for coating hollow microbeads with titanium-lanthanum oxides

InactiveCN102226042AImprove thermal insulation performanceImprove bindingReflecting/signal paintsPigment physical treatmentSurface oxidationRutile

The present invention discloses a method for coating hollow microbeads with titanium-lanthanum oxides. By the method, the surfaces of the hollow microbeads are evenly coated with rutile nano titanium oxide and have a good reflection effect, and the heat-insulation effect of the coating is improved. The method comprises: heating a mixed solution of titanium sulfate solution and lanthanum sulfate solution while stirring to 75-90 DEG C, maintaining the constant temperature and controlling the stirring speed at 500-800 rpm, and simultaneously adding soaked hollow microbeads to the mixed solution at a constant speed within 60-90 minutes; adjusting the pH value of the system to 8.0-9.5, then stirring the system at the stirring speed of 30-80 rpm for 40-90 minutes, and simultaneously ultrasonically vibrating the system; then filtering and washing until the material has a solid content of more than 40%; then carrying out microwave treatment for 15-25 minutes until the material has a solid content of more than 90% and fluffy oxidized surfaces; and heating the material in a roaster to 300 DEG C, maintaining for 1-3 hours, then heating to 900 DEG C and maintaining for 30-60 minutes so that titanium hydroxide coated on the surface of the hollow microbeads is transformed into rutile titanium dioxide.

Owner:TIANJIN HENGSHITONG ENG TECH DEV

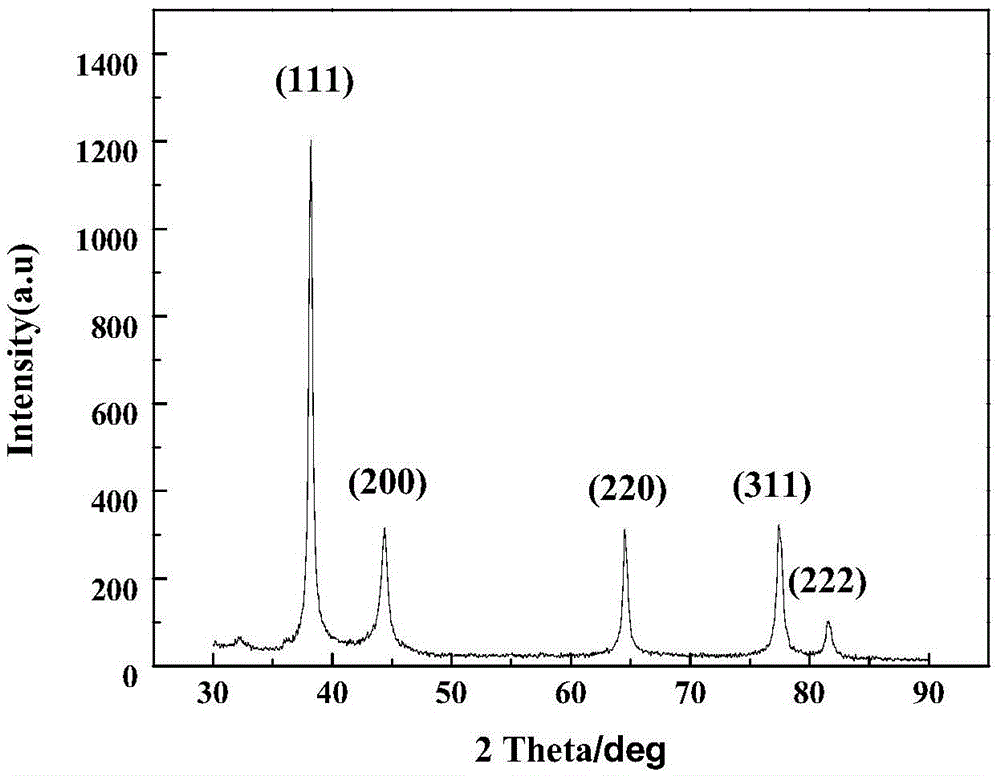

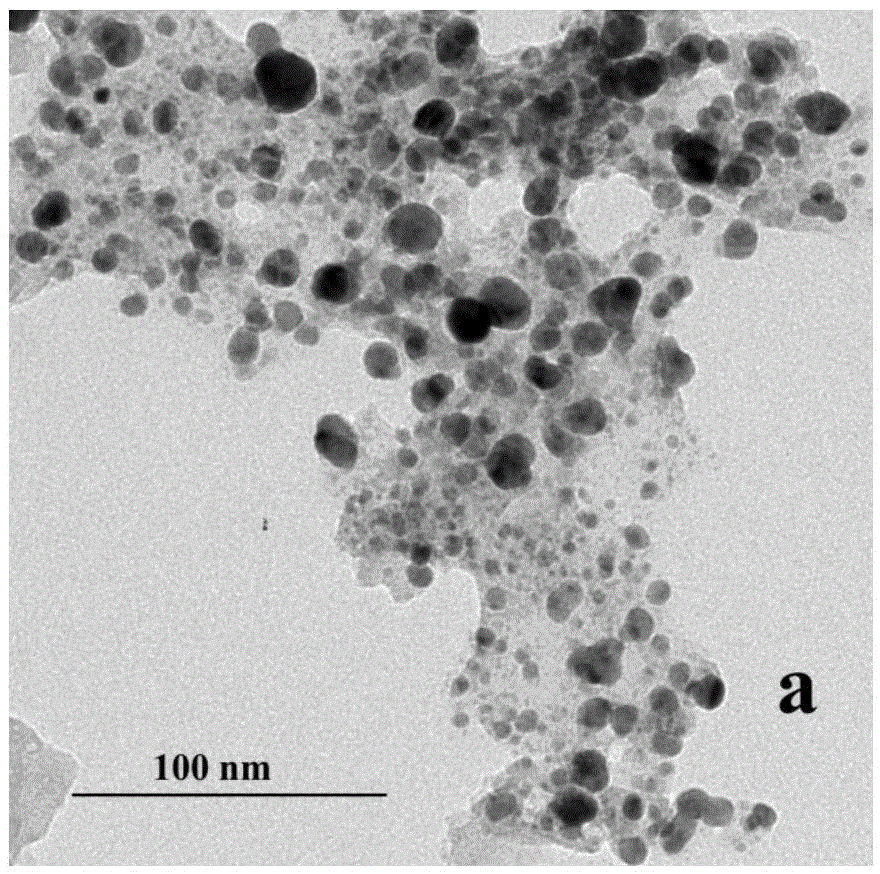

Biosynthesis method of nano Ag

InactiveCN105665737AUniform sizeGood dispersionMaterial nanotechnologyTransportation and packagingDispersityWater baths

A biosynthesis method of nano Ag comprises the following steps: adding green tea in ultra-pure water, heating in water bath and then filtering, and cooling to obtain a green tea extracting solution; adding AgNO3 crystals in the ultra-pure water to obtain an AgNO3 solution, mixing the green tea extracting solution and the AgNO3 solution, and magnetically stirring at room temperature to obtain a nano Ag colloidal solution; and washing precipitate obtained after centrifuging of the nano Ag colloidal solution by using the ultra-pure water, and then drying to obtain nano Ag particles with particle sizes of 5-20 nm. The green tea extracting solution is used as a reducing agent and a dispersing agent, the nano Ag particles are reduced and prepared from a silver nitrate (AgNO3) solution, in order to improve quality of products, the ultra-pure water is used as a solvent, any chemical reagents are not required, conditions are simple and mild, raw materials are easy to obtain, the method is easy and convenient to operate, sizes of the obtained products are uniform, and dispersity is good.

Owner:SHAANXI UNIV OF SCI & TECH

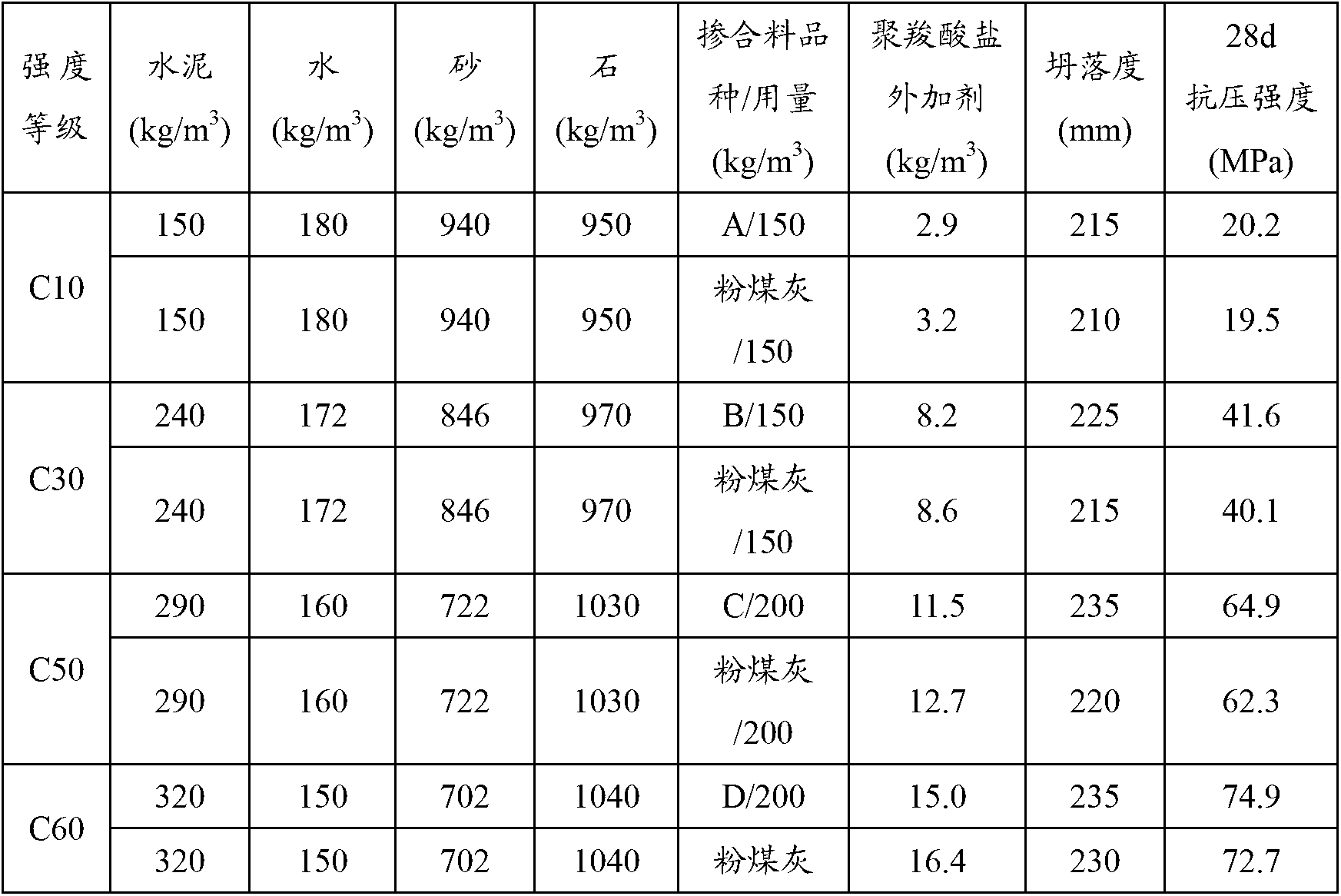

Modified active iron tailing admixture for concrete and preparation method thereof

The invention provides a modified active iron tailing admixture for concrete, which comprises the following elements: iron tailings and polycarboxylate, wherein the dosage of the polycarboxylate is 0.2-0.6wt% based on the mass of the iron tailings, and both the specific surface of the iron tailings and that of the polycarboxylate are 400-600m<2> / kg. Replacing slag powder and pulverized coal ash, the active iron tailing admixture provided by the invention is applied to the concrete and can prepare C10-C100 pump concrete, and the active iron tailing admixture can meet each performance index of build concrete and has a brilliant application prospect in the construction engineering.

Owner:北京东方建宇混凝土科学技术研究院有限公司

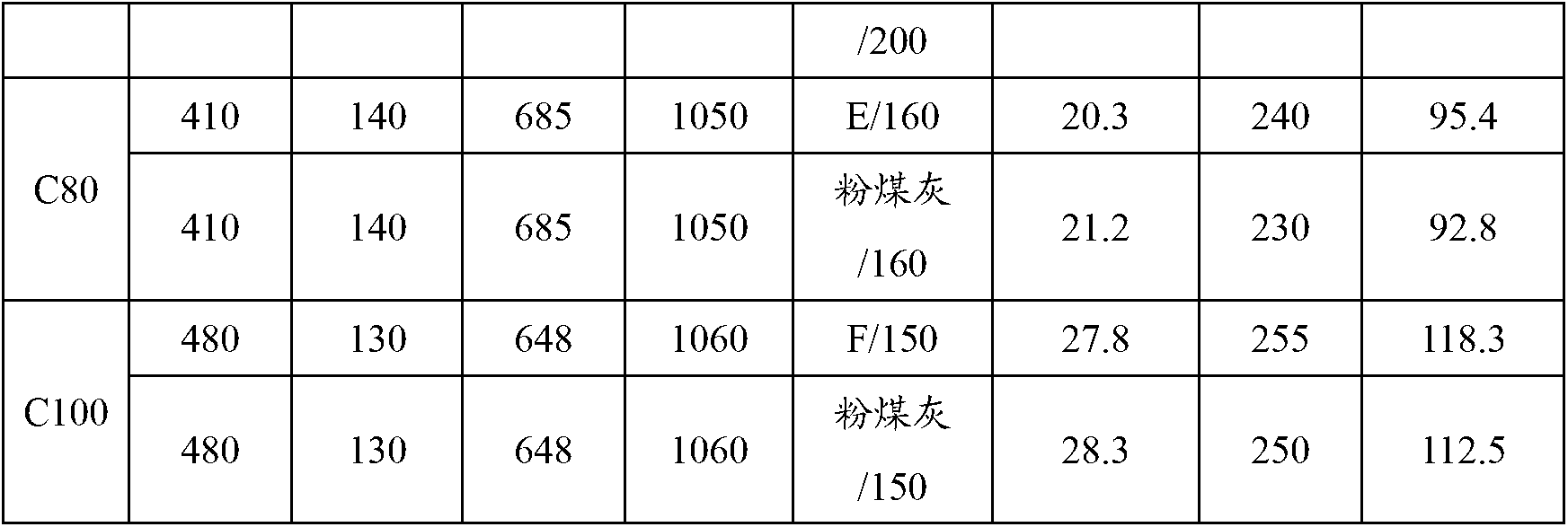

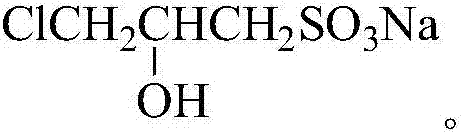

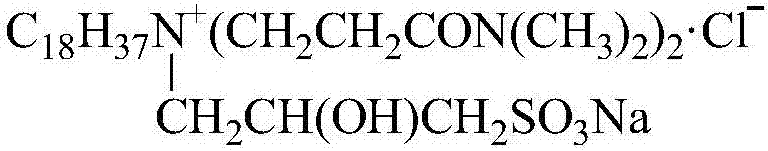

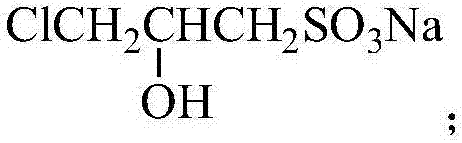

Tertiary amide quaternary ammonium salt type hydroxypropyl sodium sulfonate asphalt emulsifier and preparation method thereof

InactiveCN106977432AImprove hydrophilicityEnhanced charge strengthOrganic compound preparationTransportation and packagingEpoxySolvent

The invention discloses a tertiary amide quaternary ammonium salt type hydroxypropyl sodium sulfonate asphalt emulsifier and a preparation method thereof. The asphalt emulsifier is prepared from the following raw materials according to molar ratio: octadecylamine, an alcohol solvent, N,N-dimethylacrylamide, epoxy chloropropane and sodium hydrogen sulfite of which the molar ratio is 1mol to (4.00 to 9.00)mol to (2.00 to 2.10)mol to (1.00 to 1.15)mol to (1.05 to 1.25)mol. The alcohol solvent is ethanol, methanol or isopropyl alcohol. The asphalt emulsifier disclosed by the invention has the advantages of easily-obtained synthetic raw materials, low production cost, simple process and no need of a high temperature reaction; the asphalt emulsifier can be used for emulsifying multiple asphalts of different modes; prepared emulsified asphalt is fine, uniform and good in storage stability, and can be used for preparing cationic emulsified asphalt.

Owner:SHANDONG UNIV

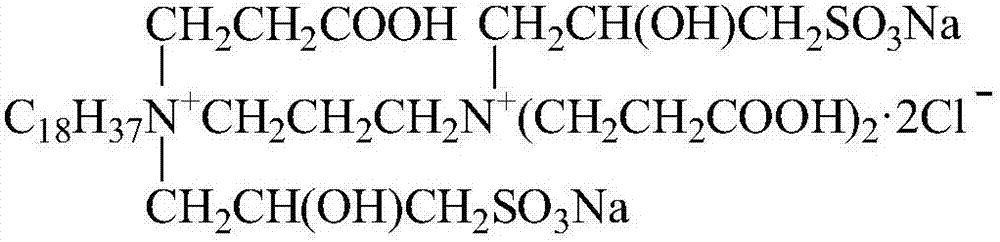

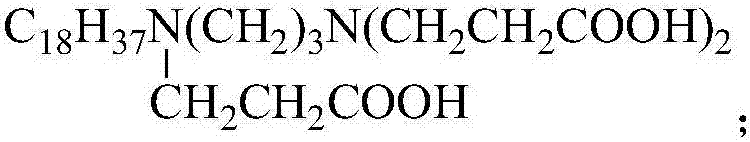

Carboxylic acid biquaternary ammonium salt type sodium hydroxypropyl sulfonate asphalt emulsifier and preparation method thereof

InactiveCN106946747AGood emulsifying effectImprove hydrophilicityOrganic compound preparationTransportation and packagingSulfonateCarboxylic acid

The invention discloses a carboxylic acid biquaternary ammonium salt type sodium hydroxypropyl sulfonate asphalt emulsifier, the molecular structure of which is as shown in the specification. The product is prepared from raw materials including N-hydrogenated tallow-1,3-trimethylenediamine, an alcohols solvent, acrylic acid, chloropropylene oxide and sodium bisulfate at the molar ratio of 1 mol: (5.00-11.00) mol: (3.00-3.10) mol: (2.00-2.30) mol: (2.10-2.50) mol. The asphalt emulsifier of the invention has advantages as follows: production cost is low; the process is simple; and high-temperature reaction is not required.

Owner:SHANDONG UNIV

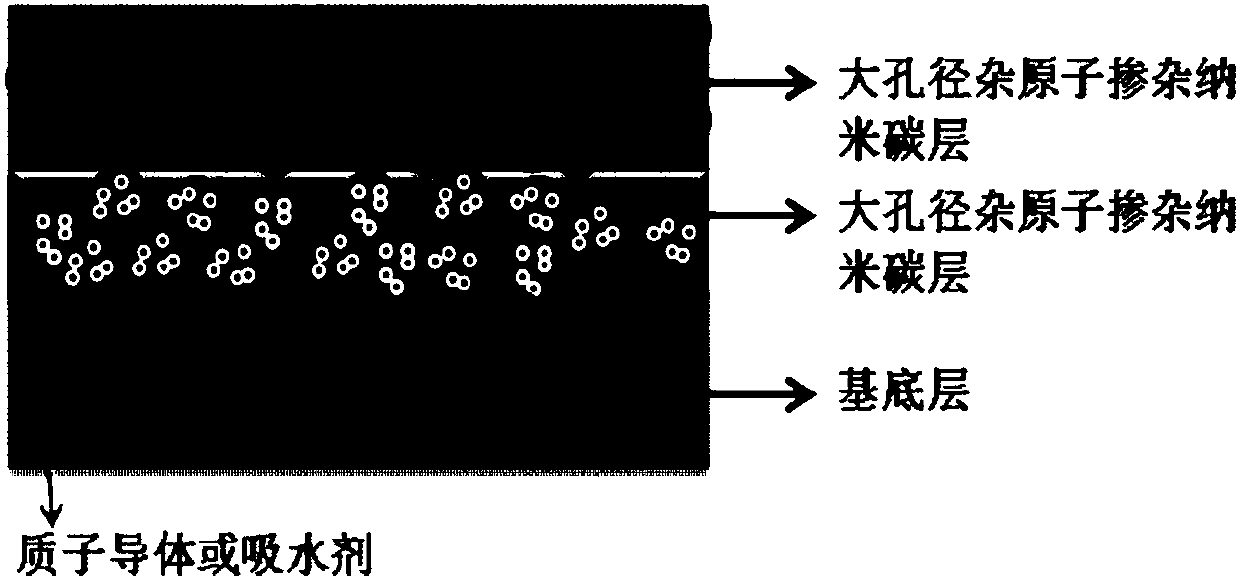

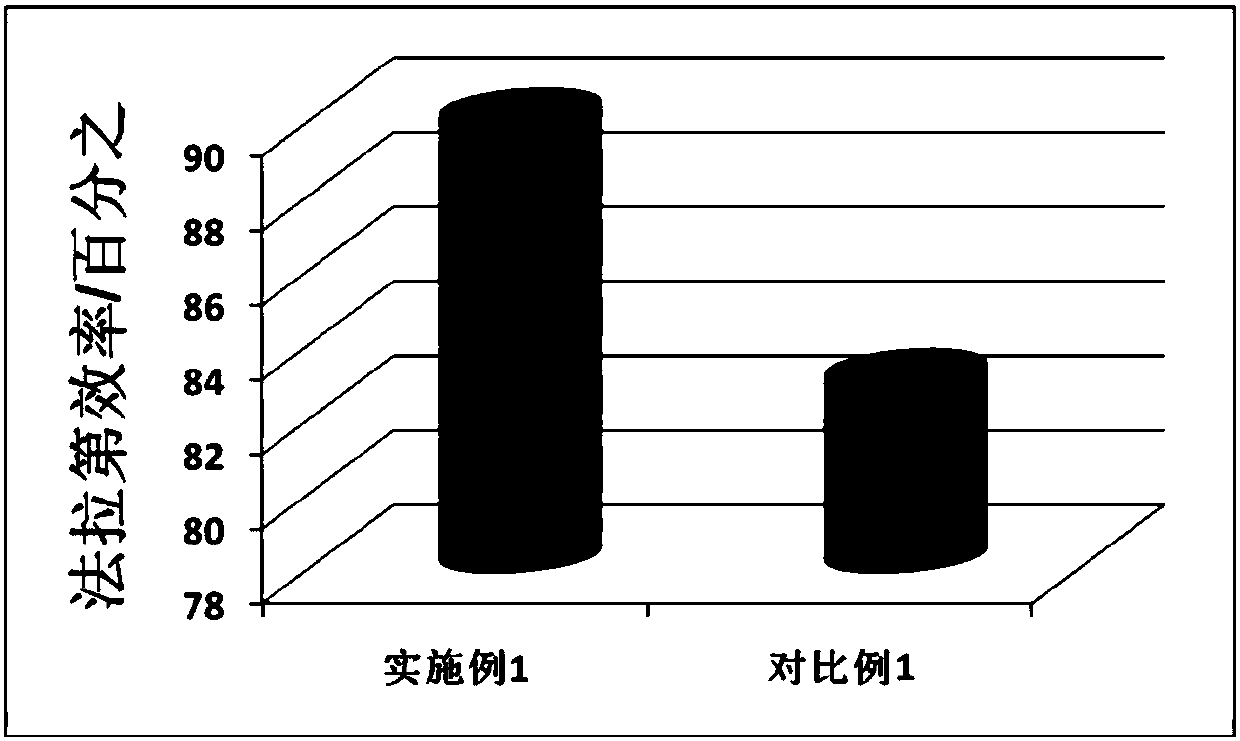

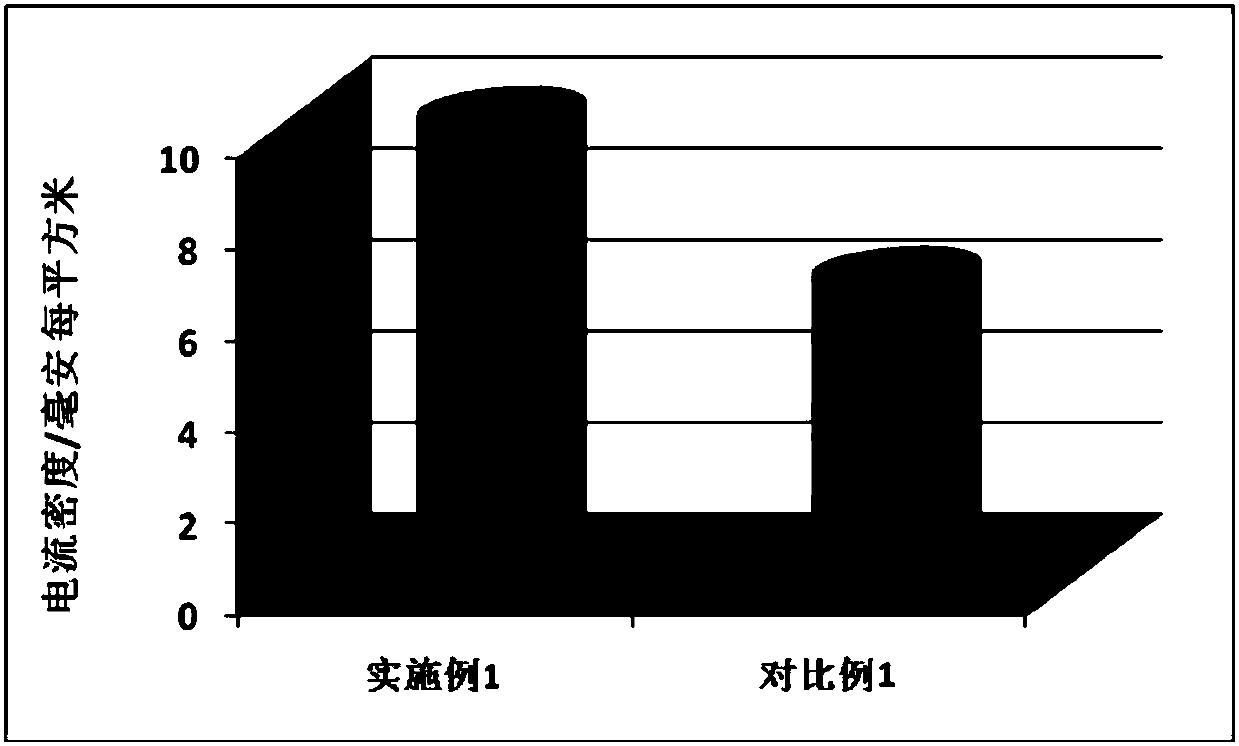

Negative electrode for electroreduction of carbon dioxide and preparation method thereof

ActiveCN107841764ALower mass transfer resistanceHigh specific surface areaElectrolytic organic productionElectrodesCarbon dioxideThree-phase

The invention relates to a negative electrode for electroreduction of carbon dioxide and a preparation method thereof. The negative electrode is such structured that carbon paper, carbon felt or carbon cloth is used as a substrate; one side surface of the substrate is successively bonded with two catalysis layers of different pore sizes; and the negative electrode is successively composed of the substrate, a large-size heteroatom-doped nanocarbon layer and a small-size metal-and-heteroatom-doped nanocarbon layer. The large-size catalysis layer is favorable for transmission of CO2 and productsand reduction of mass transfer resistance; and the small-size heteroatom-doped nanocarbon layer is beneficial for improving the reaction active specific surface area of a catalyst and enhancing the reaction activity of the catalyst. As the negative electrode with such a structure is applied to ERC, the area of a three-phase electrochemical reaction interface is greatly broadened, the utilization rate of the catalyst is increased, and mass transfer polarization of an electrolytic bath is reduced; and in virtue of adsorptivity or formation of chemical bonds between the negative electrode and products of electroreduction of carbon dioxide, the selectivity and conversion rate of an assigned reduction product can be improved, and high selectivity of the reduction product is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

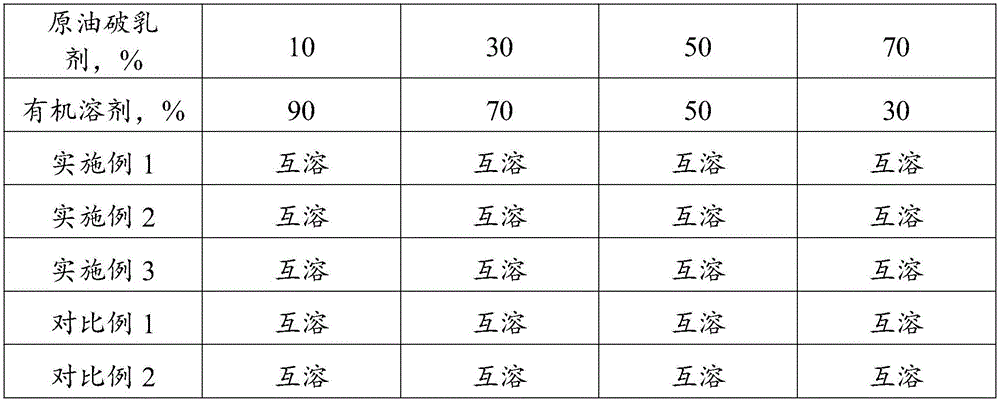

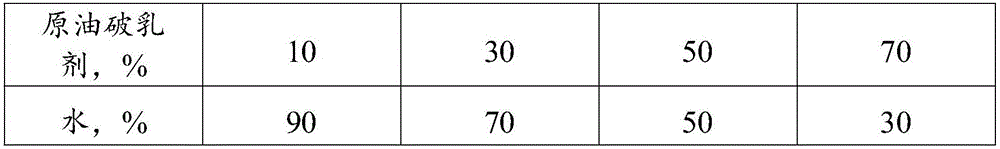

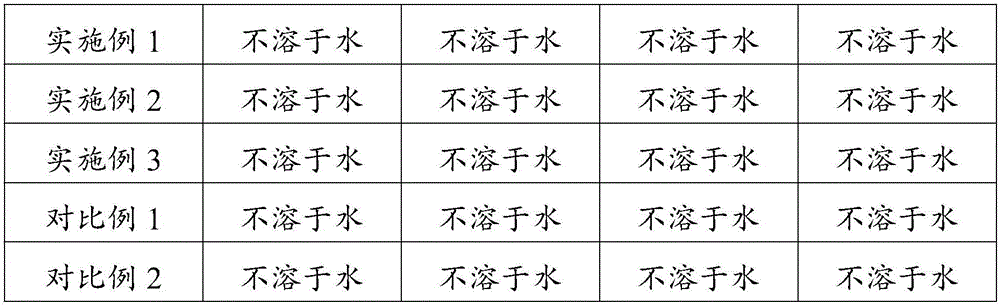

Crude oil demulsifier and preparation method thereof

ActiveCN106336892AGood demulsification effectImprove adaptabilityDewatering/demulsification with chemical meansHydrocarbon oils treatmentDemulsifierEthylene oxide

The invention relates to a crude oil demulsifier and a preparation method thereof. The crude oil demulsifier comprises macromolecular resin, bicyclo-oxide, sulfonic acids and solvent oil at a weight ratio of 100:(15-30):(2-5):(30-50), wherein the macromolecular resin is formed by polymerization of alkyl phenolic resin, ethylene oxide and propylene epoxide. The crude oil demulsifier is good in demulsification effect, wide in application range and good in adaptability and can be suitable for dewatering and desalting of a vast majority of crude oils.

Owner:广东粤首新科技有限公司

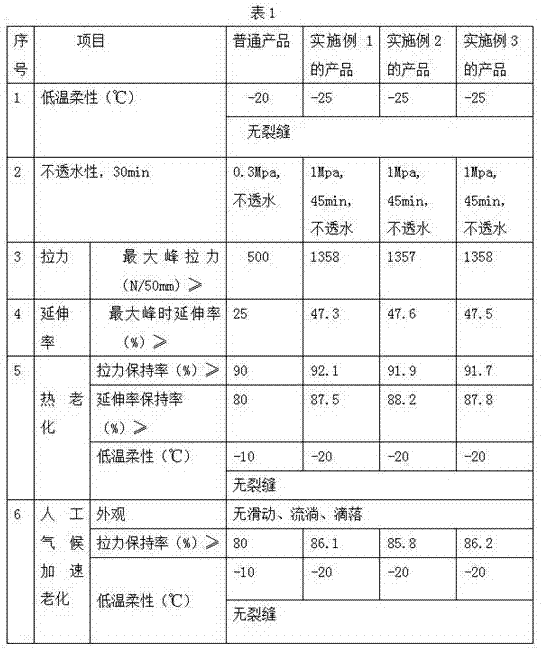

Self-sticky modified asphalt waterproof coil and production method thereof

InactiveCN107984823AGood resistance to mold reproductionImprove water resistanceLamination ancillary operationsRoof covering using flexible materialsDispersityBituminous waterproofing

The invention relates to a self-sticky modified asphalt waterproof coil. The waterproof coil has a five-layer type structure which comprises an upper surface isolation layer, an upper modified asphaltself-sticking layer, an tire-based layer, a lower modified asphalt self-sticking layer and a lower surface isolation layer from top to bottom; the upper modified asphalt self-sticking layer and the lower modified asphalt self-sticking layer are prepared from modified asphalt. After asphalt is modified through adopting materials such as butadiene styrene rubber, an SIS (styrene-isoprene-styrene) segmented copolymer and a trimethoxysilyl propyl diethylenetriamine tackifier, obtained modified asphalt has stable performance, added modified nano calcium carbonate has high dispersity, and the storage stability of a modified asphalt system is effectively improved; the modified asphalt is used for making the waterproof coil, the properties such as tearing strength, stickiness, water resistance and ageing resistance of the waterproof coil, which is obtained via production, are all improved, and the service life of the waterproof coil is prolonged.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com