Preparation method of cesium tungsten oxide ultrafine powder

A technology of cesium tungsten oxide and ultrafine powder, which is applied in the nano field, can solve problems such as being unfavorable to industrialized production, low efficiency, long reaction period, etc., and achieve the effects of short reaction preparation period, saving reaction raw materials, and saving preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of cesium tungsten oxide ultrafine powder, comprising the following steps:

[0028] (1) Take 5.07g of ammonium tungstate, 1.95g of cesium nitrate and 14.6g of EDTA, add 50ml of ethylene glycol, and react at 170°C for 3h;

[0029] (2) Put the mixed solution obtained in step (1) into a p-polystyrene pressure vessel for reaction, and react at 270°C for 5 hours;

[0030] (3) The reactant obtained in step (2) is washed with alcohol, centrifuged, and vacuum-dried at 80°C to obtain cesium tungsten powder with complete crystallinity.

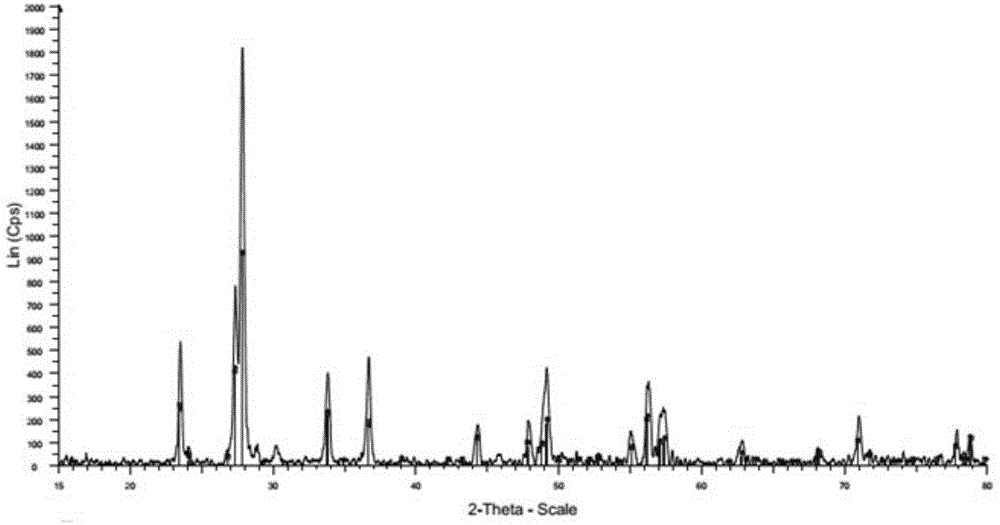

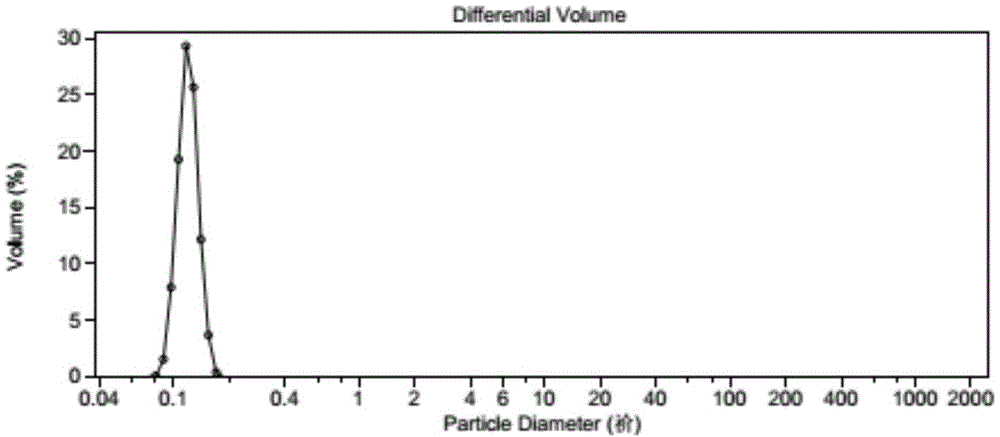

[0031] The cesium tungsten powder prepared in this embodiment is dark blue. from figure 1 , figure 2 It can be seen that the cesium tungsten powder prepared in this example has high crystallinity, and the crystal phase composition is Cs 0.3 WO 3 or Cs 0.32 WO 3 , the particle size is 119nm, the powder resistance is 1.2×10 4 Ω.

Embodiment 2

[0033] A preparation method of cesium tungsten oxide ultrafine powder, comprising the following steps:

[0034] (1) Take 7.6g of ammonium paratungstate, 3.25g of cesium hydroxide and 17.5g of EDTA, add 50ml of ethylene glycol, and react at 170°C for 3h;

[0035] (2) Put the mixed solution obtained in step (1) into a p-polystyrene pressure vessel for reaction, and react at 270°C for 5 hours;

[0036] (3) The reactant obtained in step (2) is washed with alcohol, centrifuged, and vacuum-dried at 80°C to obtain cesium tungsten powder with complete crystallinity.

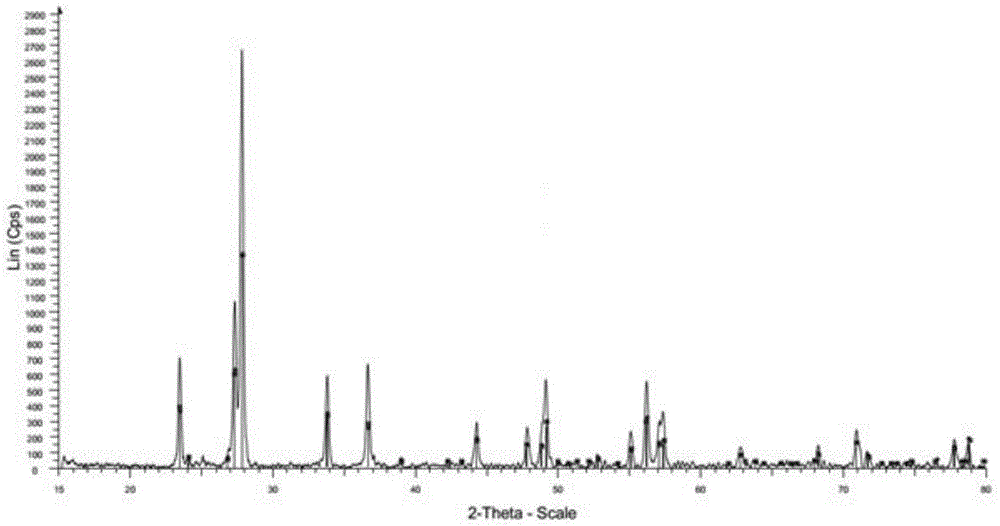

[0037] The cesium tungsten powder prepared in this embodiment is dark blue. from image 3 , Figure 4 It can be seen that the cesium tungsten powder prepared in this example has high crystallinity, and the crystal phase composition is Cs 0.3 WO 3 or Cs 0.32 WO 3 , the medium particle size is 119nm, and the powder resistance is 5.2×10 4 Ω.

Embodiment 3

[0039] A preparation method of cesium tungsten oxide ultrafine powder, comprising the following steps:

[0040] (1) Take 3.1g of ammonium metatungstate, 0.83g of cesium hydroxide and 5.1g of tartaric acid, add 50ml of propylene glycol, and react at 170°C for 3h;

[0041] (2) Put the mixed solution obtained in step (1) into a p-polystyrene pressure vessel for reaction, and react at 260°C for 8 hours;

[0042] (3) The reactant obtained in step (2) is washed with alcohol, centrifuged, and vacuum-dried at 80°C to obtain cesium tungsten powder with complete crystallinity.

[0043] The cesium tungsten powder prepared in this embodiment is dark blue. from Figure 5 , Image 6 It can be seen that the cesium tungsten powder prepared in this example has high crystallinity, and the crystal phase composition is Cs 0.3 WO 3 or Cs 0.32 WO 3 , the medium particle size is 119nm, and the powder resistance is 6.4×10 4 Ω.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com