Low-gloss transparent glaze, ceramic tile using low-gloss transparent glaze and preparation method of ceramic tile

A low-gloss, ceramic tile technology, applied in the field of architectural ceramics, can solve problems such as high cost, inability to completely replace, and inability to achieve 3D concave-convex layering on the surface of the glaze layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the technical field of architectural ceramics, although the cost of the traditional ceramic glaze technology is low, the three-dimensional effect of the surface effect of the glaze layer after firing is relatively poor; although the existing digital glaze has a clear 3D layering, its There are also disadvantages of narrow color range and high cost. In the tide of increasingly stringent cost competition in the industry, digital glazes cannot completely replace traditional ceramic glazes for the preparation of ceramic glazes.

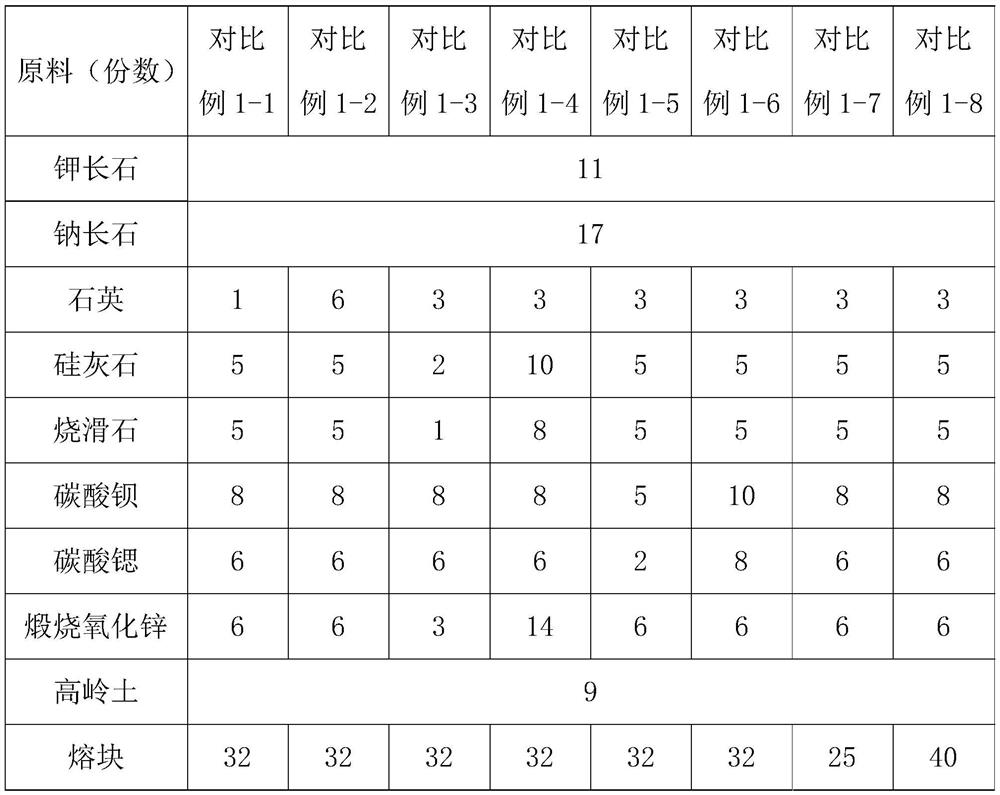

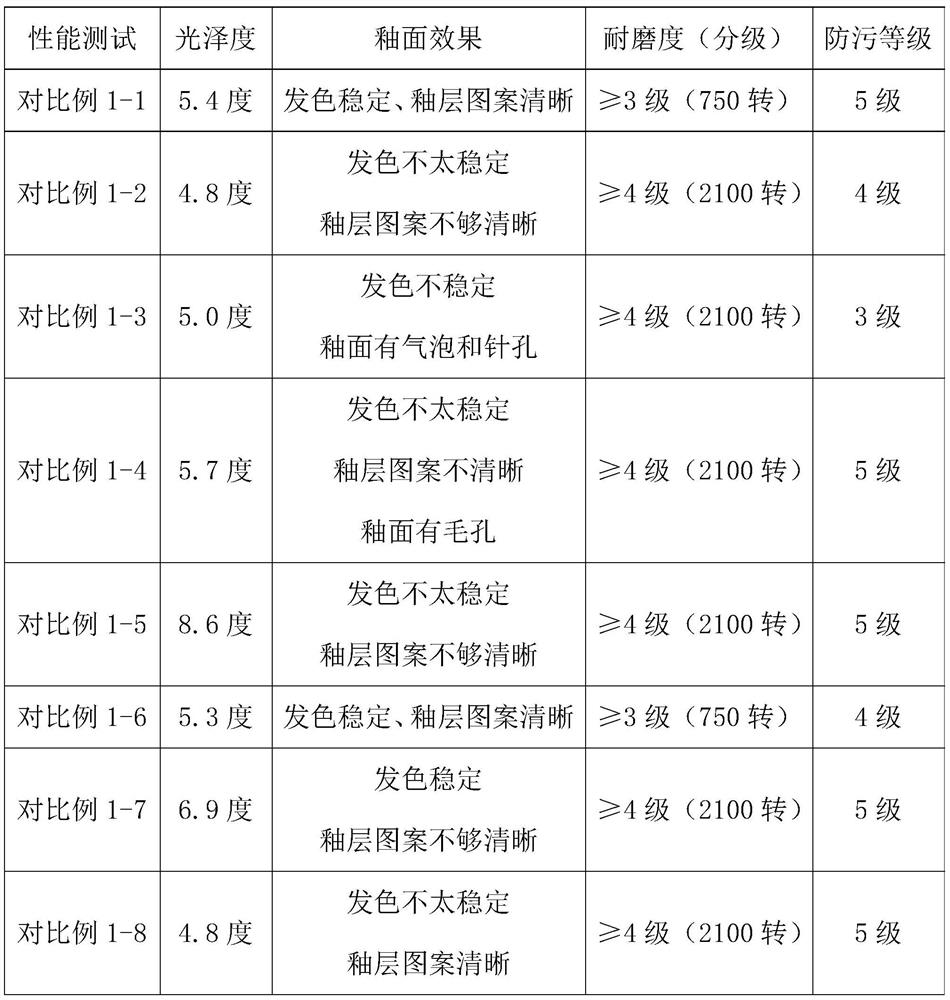

[0029] In order to solve the technical problems existing in traditional ceramic glazes and existing digital glazes, this technical solution proposes a low-gloss transparent glaze. By adjusting the glaze formula structure, the surface effect of the glaze layer after firing The 3D layering is clear, and the color of the glaze is stable, and the production cost is low. Specifically, calculated in parts by mass, the following raw materials are inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com