Lithium-ion-battery multiwalled carbon nanotube/ molybdenum disulfide combination electrode and preparation method

A multi-wall carbon nanotube, lithium-ion battery technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of uneven load, reduce the conductivity of carbon nanotubes, etc. High performance, high yield and reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Graphene-like MoS for lithium-ion batteries 2 A method for preparing a composite electrode with multi-walled carbon nanotubes, comprising the following steps:

[0038] (1) Ultrasonic co-oxidation treatment of multi-walled carbon nanotubes

[0039] Disperse 0.1g of multi-walled carbon nanotubes with a size of 30nm in 30ml of a mixed solution consisting of nitric acid and sulfuric acid at a volume ratio of 1:2.5, and perform ultrasonic oxidation treatment at 25°C, with the time controlled at 180min and the ultrasonic power at 60W , prepare the carbon nanotube suspension, then adjust the pH value to 8 with sodium carbonate, and then centrifuge to obtain the multi-walled carbon nanotube after oxidation treatment.

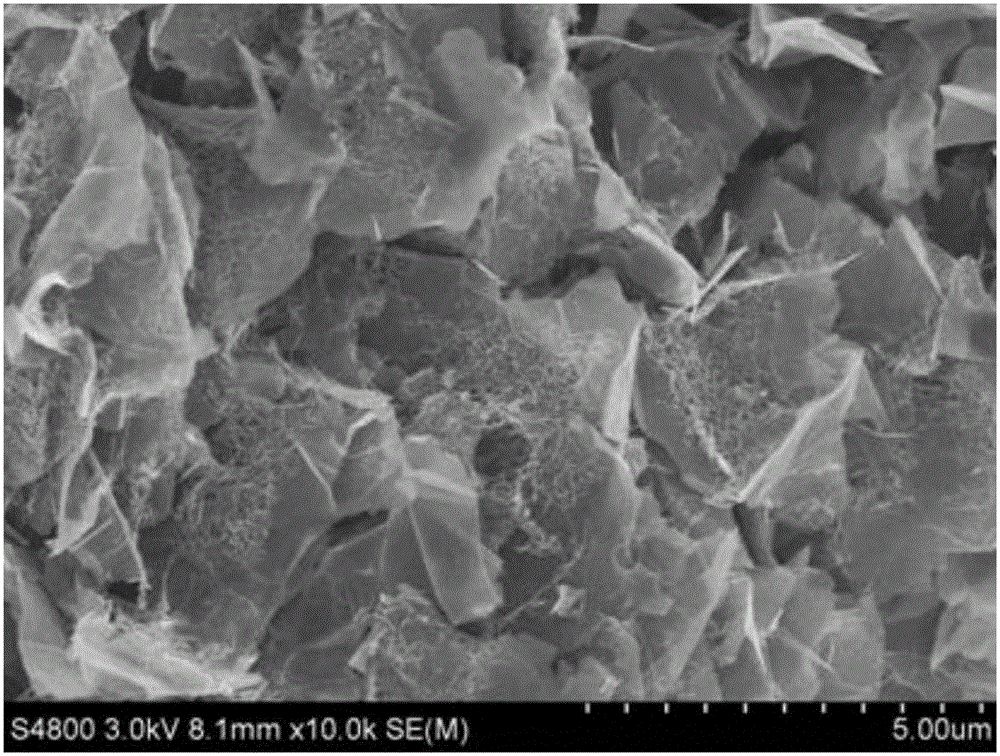

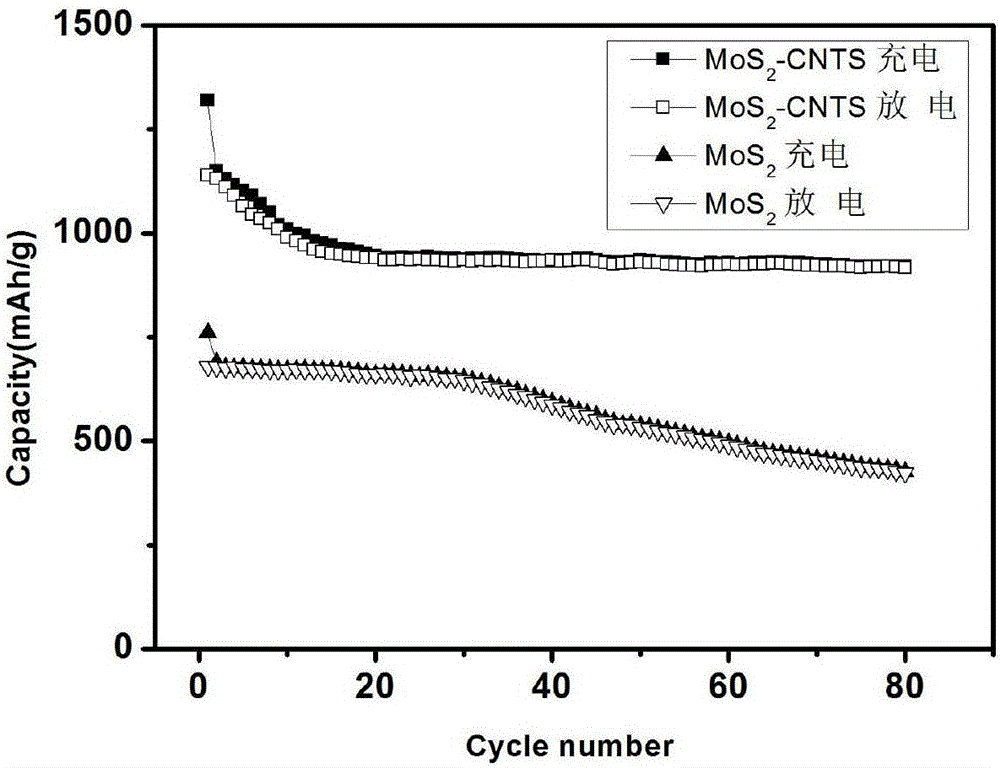

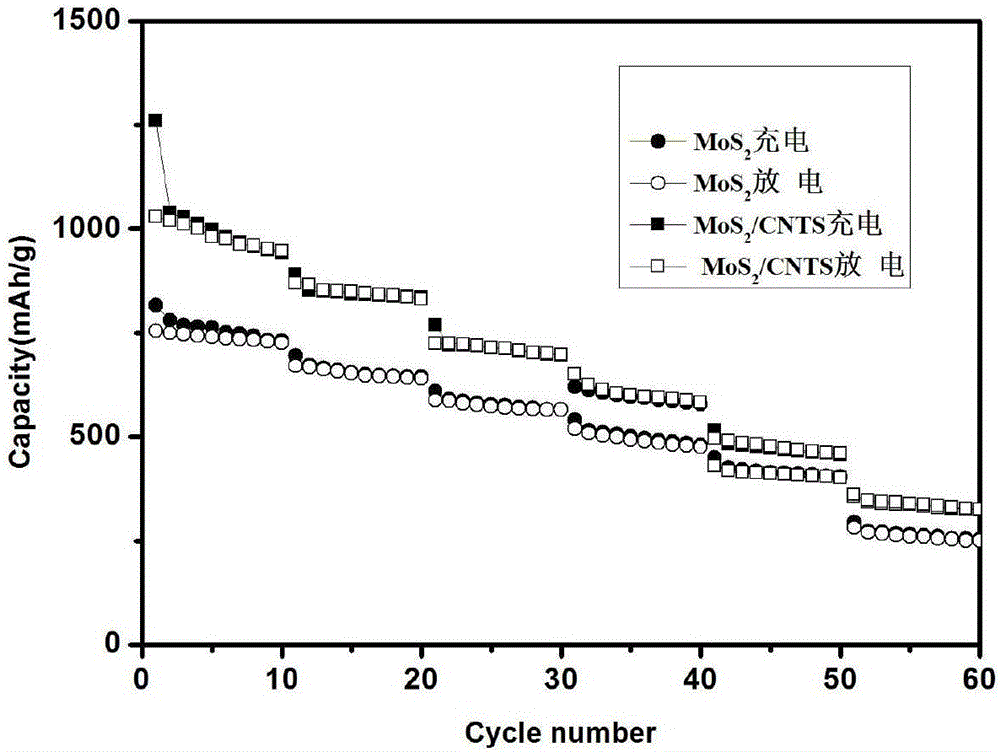

[0040] (2) Preparation of graphene-like MoS 2 Composite nanomaterials with multi-walled carbon nanotubes M O S 2 / CNTS

[0041] Dissolve sodium molybdate in a mixed solution of ethanol and water with a volume ratio of 1:1 to form a 0.02mol / L solution, add L-...

Embodiment 2

[0048] (1) Ultrasonic co-oxidation treatment of multi-walled carbon nanotubes

[0049] Disperse 0.5g of multi-walled carbon nanotubes with a size of 50nm in 50ml of a mixed solution composed of nitric acid and sulfuric acid at a volume ratio of 1:2.5, and perform ultrasonic oxidation treatment at 60°C, with the time controlled at 120min and the ultrasonic power at 90W , preparing a suspension of carbon nanotubes, adjusting the pH value to 9 with ammonia water, and centrifuging to obtain multi-walled carbon nanotubes after oxidation treatment;

[0050] (2) Preparation of graphene-like MoS 2 Composite nanomaterial MoS with multi-walled carbon nanotubes 2 / CNTS

[0051] Dissolve sodium molybdate in a mixed solution of ethanol and water at a volume ratio of 1:5 to form a 0.07mol / L solution, add L-cysteine as a sulfur source and reducing agent, L-cysteine and molybdic acid The ratio of the amount of the substance of sodium is 8:1, then the multi-walled carbon nanotubes after...

Embodiment 3

[0055] (1) Ultrasonic co-oxidation treatment of multi-walled carbon nanotubes

[0056] Disperse 0.5g of multi-walled carbon nanotubes with a size of 50nm in 50ml of a mixed solution consisting of nitric acid and sulfuric acid at a volume ratio of 1:2.5, and perform ultrasonic oxidation treatment at 60°C, with the time controlled at 180min and the ultrasonic power at 90W , preparing a suspension of carbon nanotubes, adjusting the pH value to 9 with sodium hydroxide, and centrifuging to obtain multi-walled carbon nanotubes after oxidation treatment;

[0057] (2) Preparation of graphene-like MoS 2 Composite nanomaterial MoS with multi-walled carbon nanotubes 2 / CNTS

[0058] Dissolve sodium molybdate in a mixed solution of ethanol and water with a volume ratio of 1:5 to form a 0.05mol / L solution, add L-cysteine as a sulfur source and reducing agent, L-cysteine and molybdic acid The ratio of the amount of the substance of sodium is 10:1, then the multi-walled carbon nanotubes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com