Patents

Literature

31results about How to "Excellent high rate characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

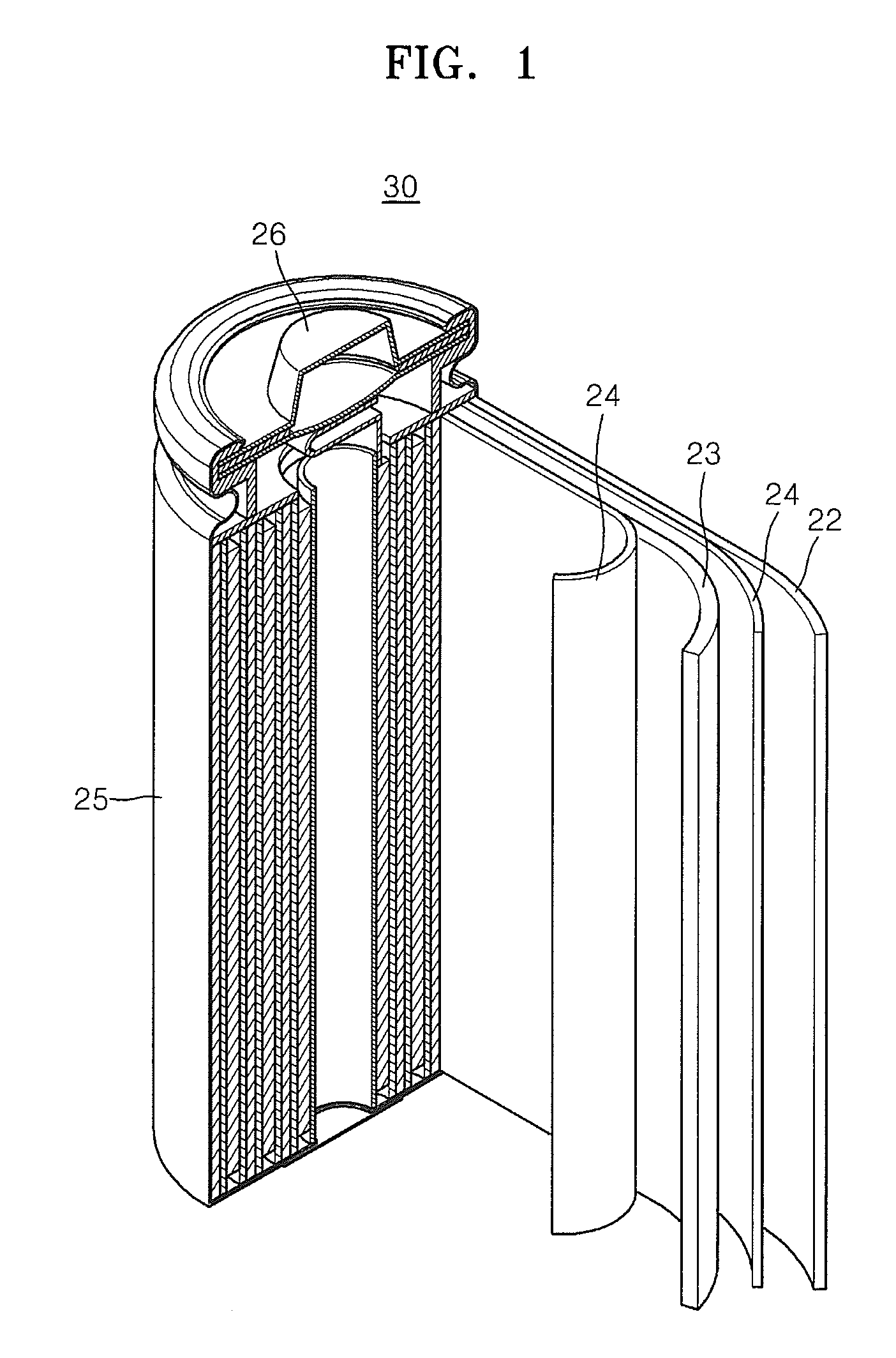

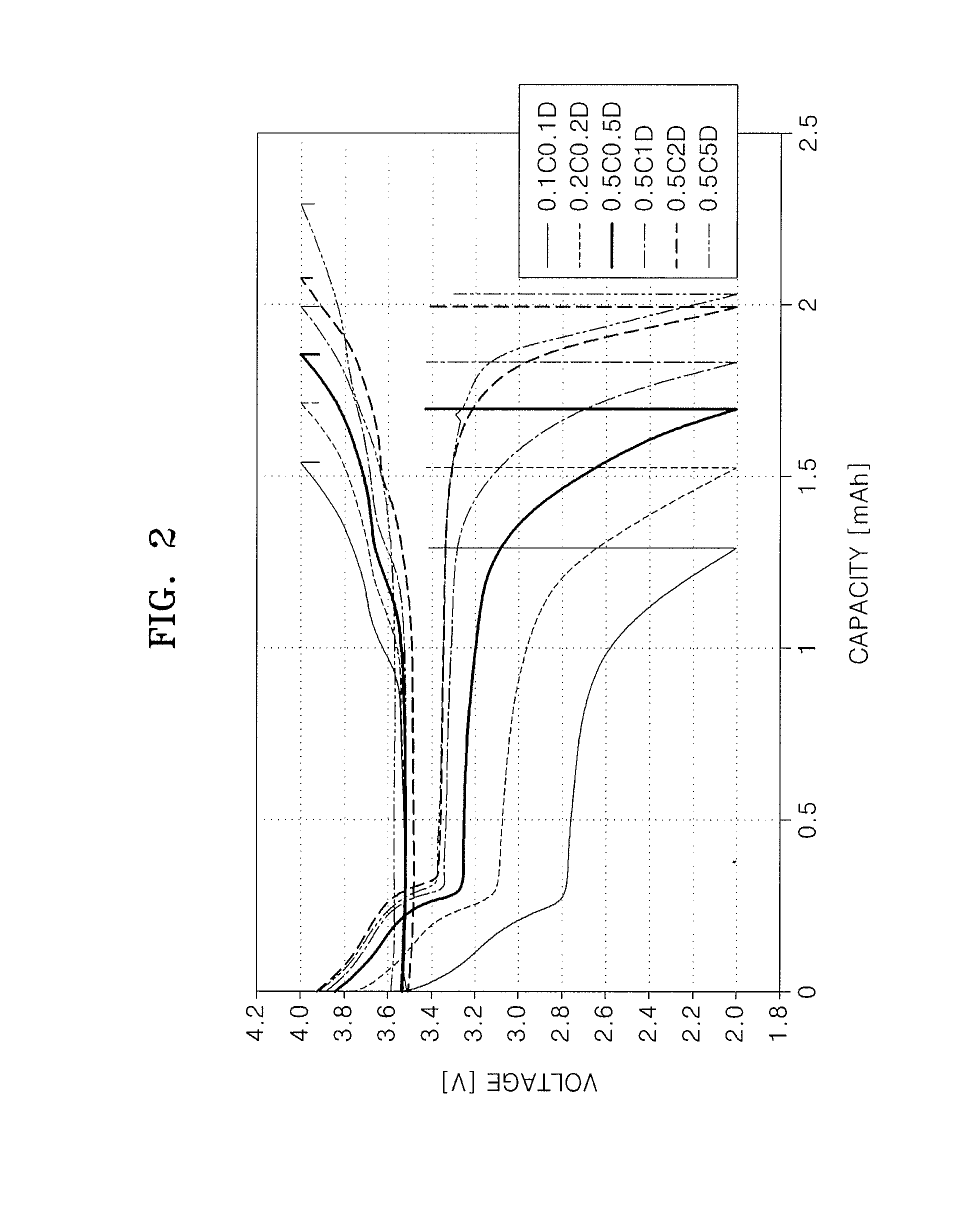

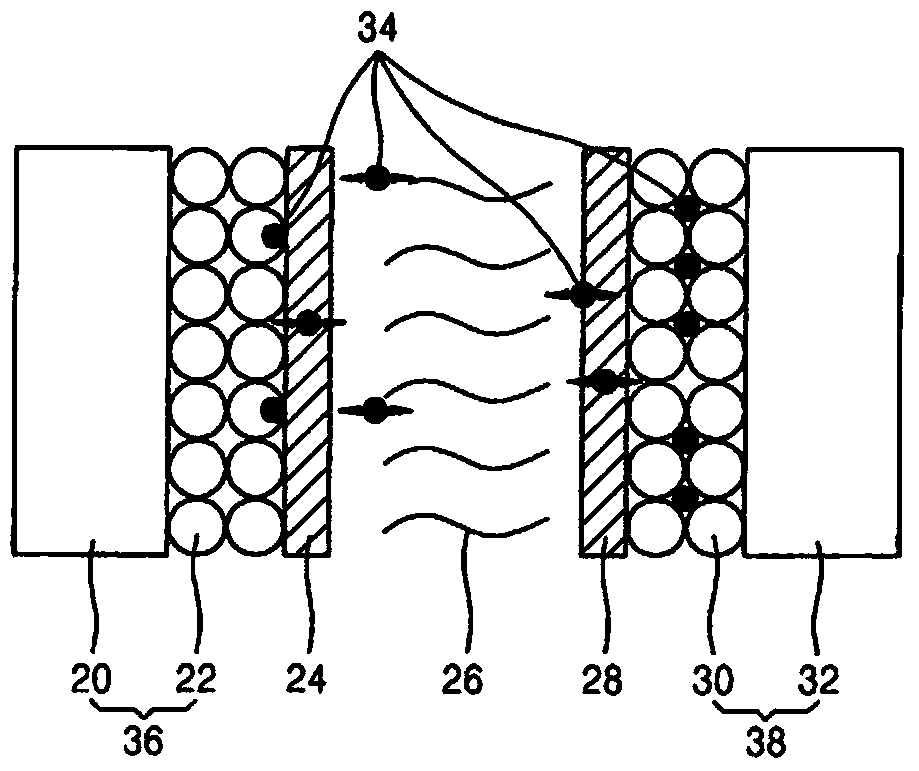

Nonaqueous electrolyte secondary battery

ActiveUS20050221187A1Excellent high rate characteristicsNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsEngineeringLi element

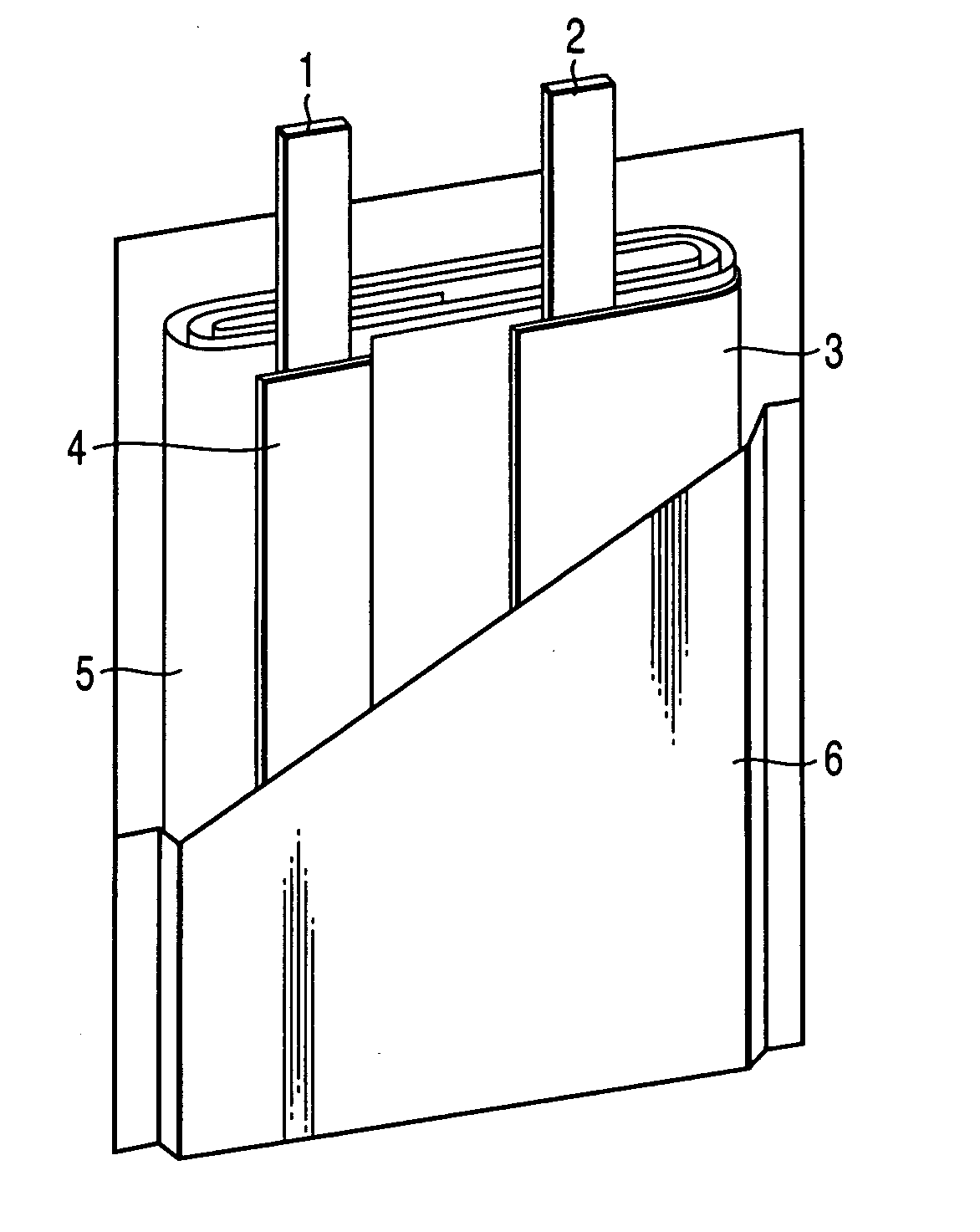

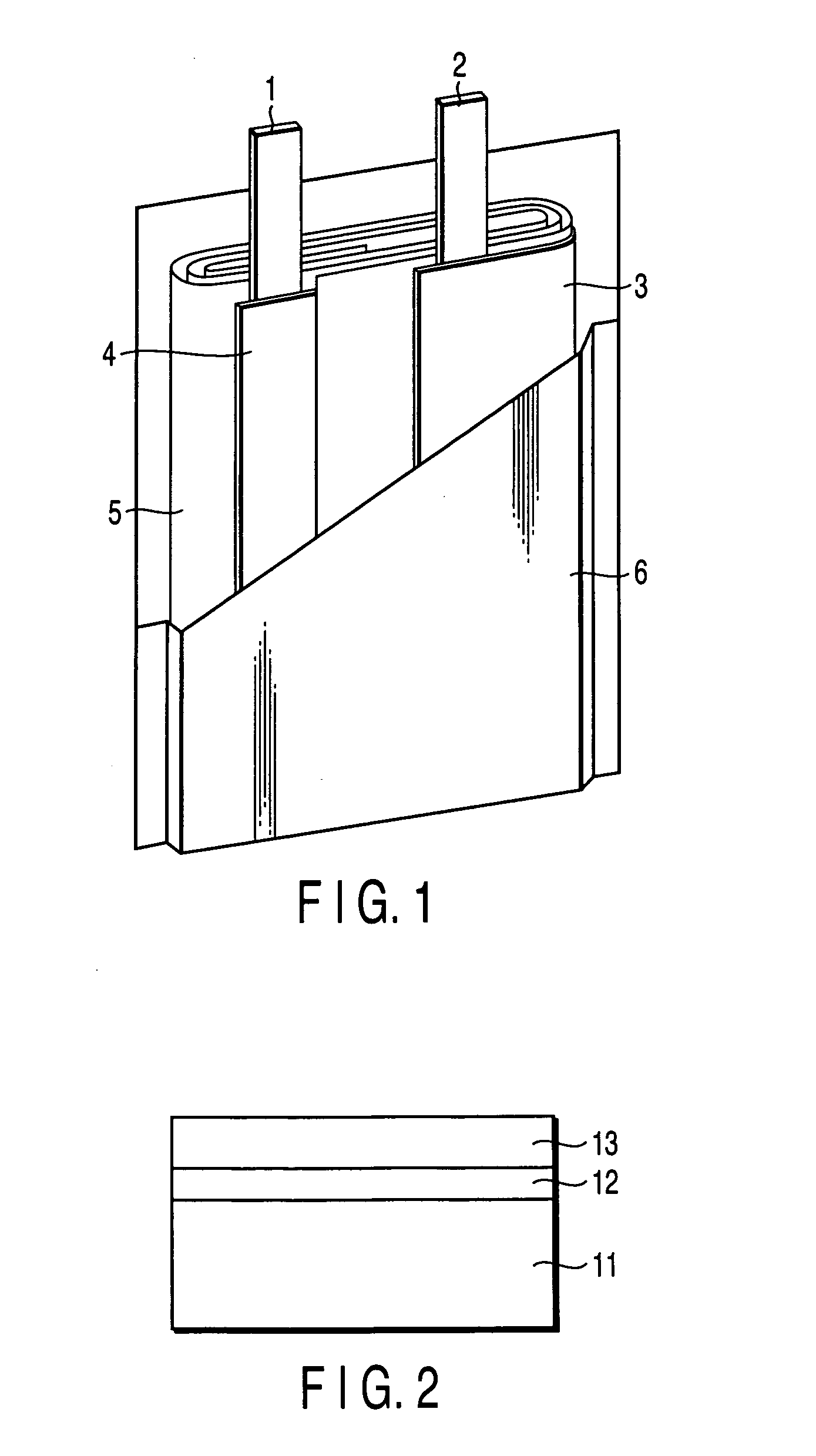

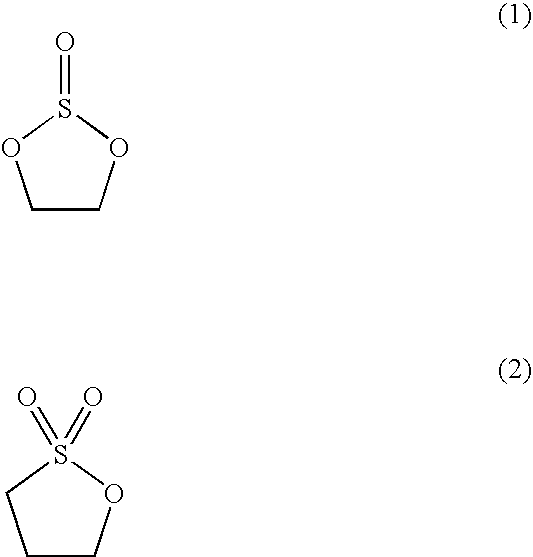

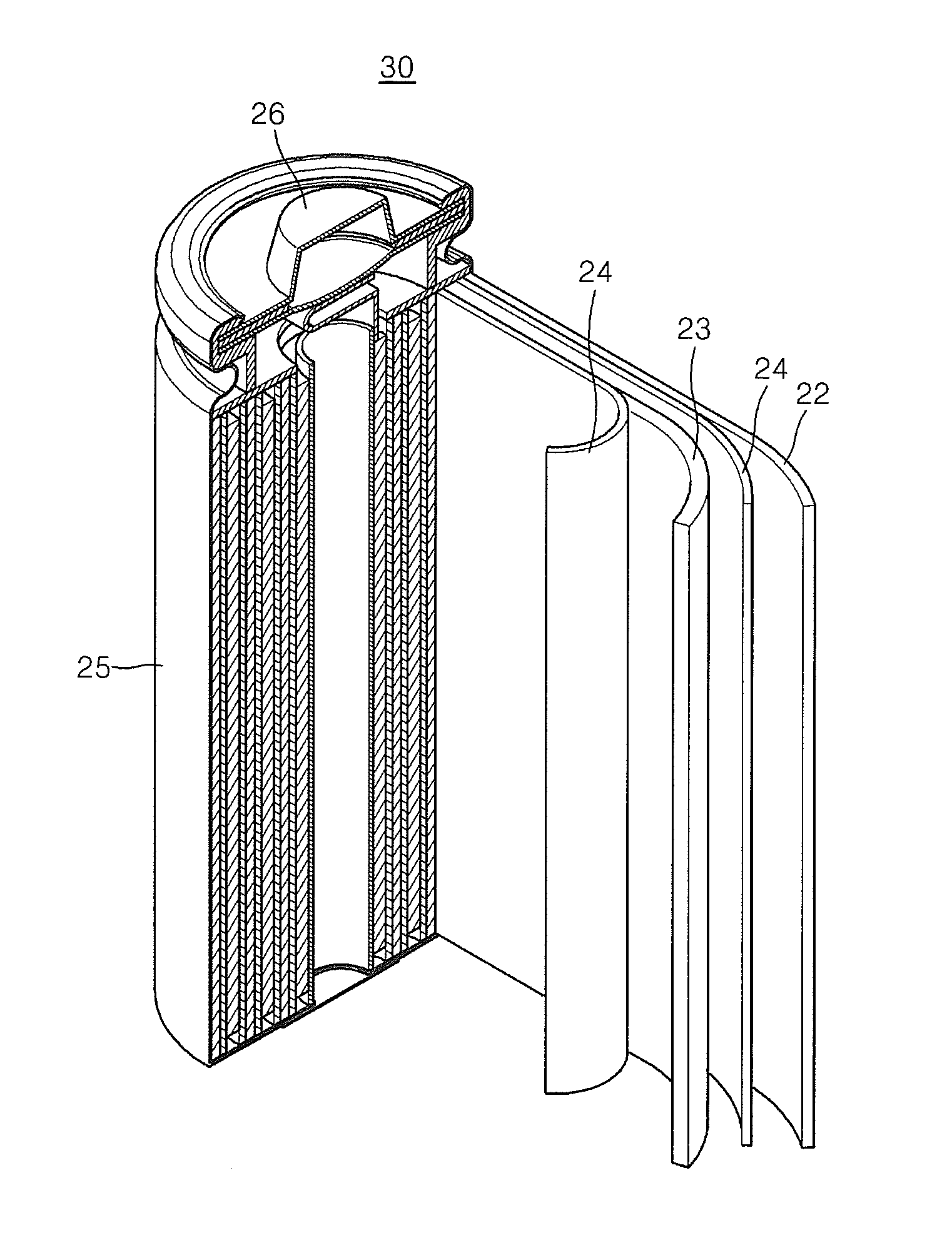

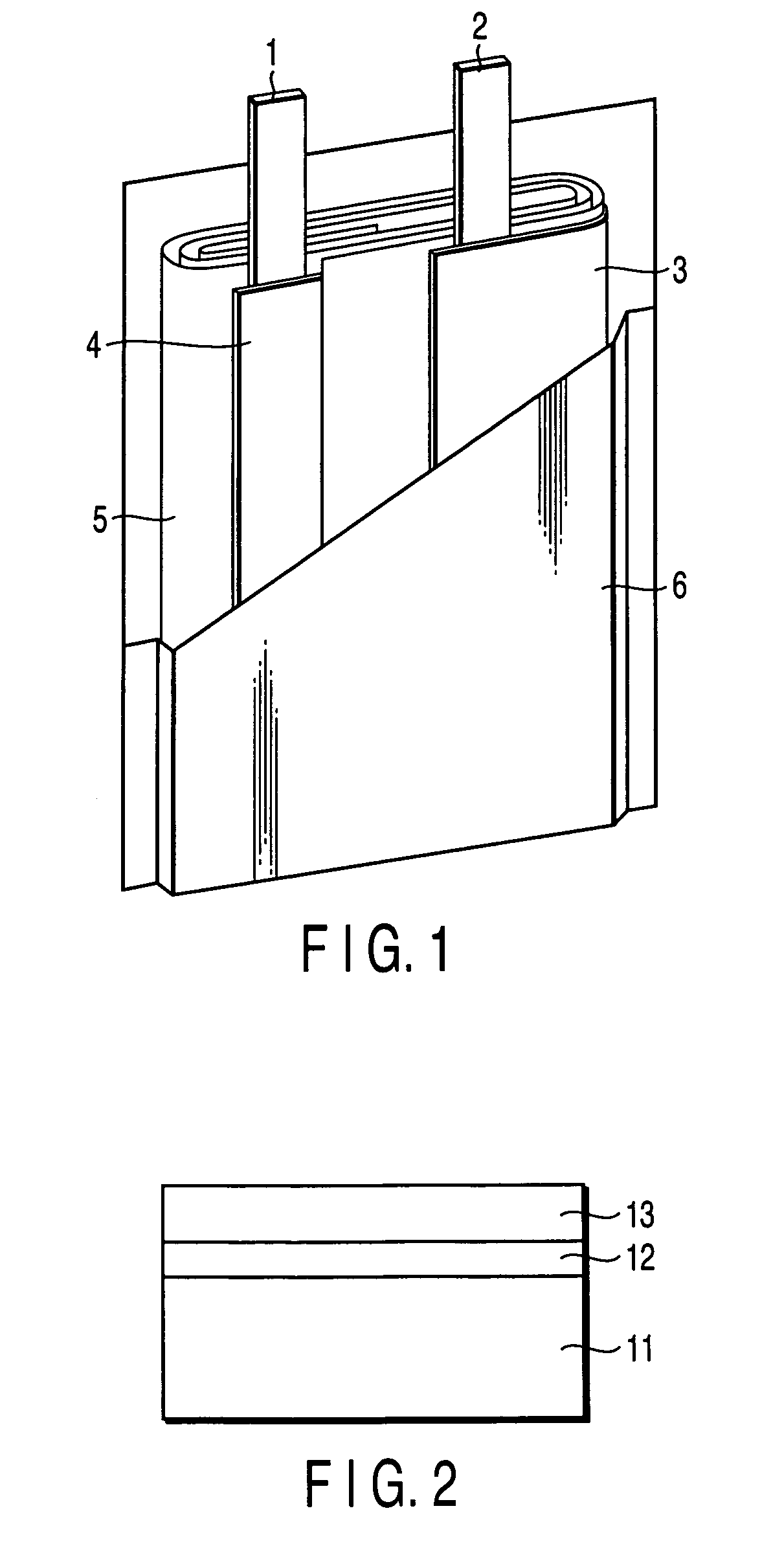

A nonaqueous electrolyte secondary battery includes a case, a nonaqueous electrolyte provided in the case and containing a linear sulfite, a positive electrode provided in the case and capable of absorbing-releasing Li element or Li ions, and a negative electrode provided in the case and containing a lithium titanium oxide and a conductive agent that includes a carbonaceous material.

Owner:KK TOSHIBA

Positive active material, and electrode and lithium battery containing the positive active material

InactiveUS20120231341A1Improve conductivityExcellent high rate characteristicsMaterial nanotechnologyCobalt compoundsHigh rateOlivine

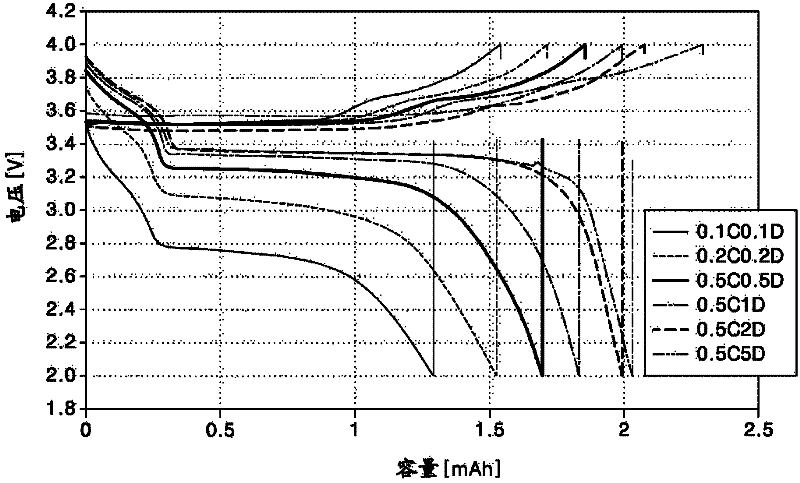

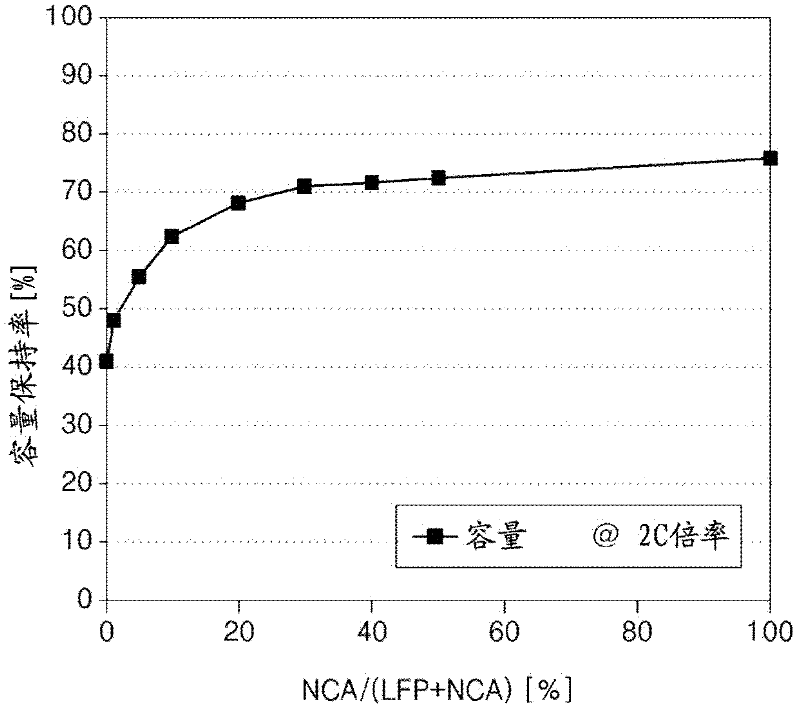

Embodiments of the present invention are directed to a positive active material, an electrode including the positive active material, and a lithium battery including the electrode. Due to the inclusion of a phosphate compound having an olivine structure and a lithium nickel composite oxide in the positive active material, the positive active material has high electric conductivity and high electrode density. A lithium battery manufactured using the positive active material has high capacity and good high-rate characteristics.

Owner:SAMSUNG SDI CO LTD

Nonaqueous electrolyte secondary battery

ActiveUS20140272534A1Excellent high rate characteristicsIncreased durabilityFinal product manufactureNon-aqueous electrolyte accumulator electrodesDiameter ratioLarge particle

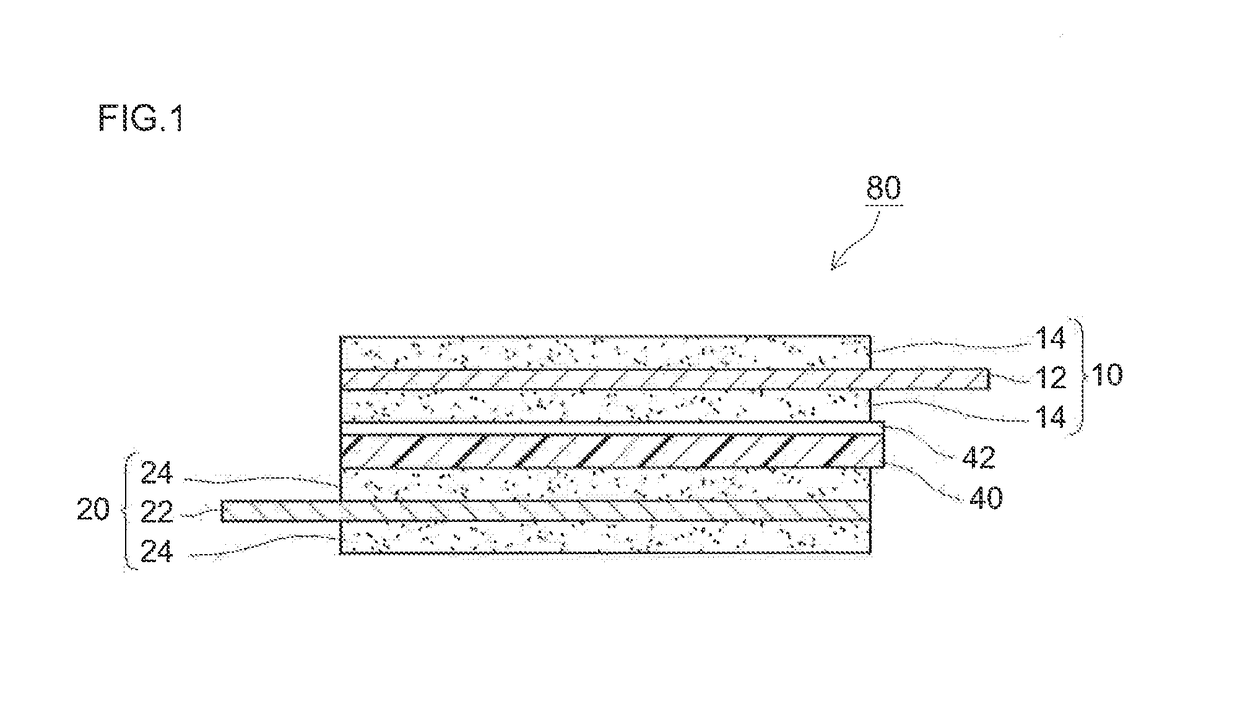

The nonaqueous electrolyte secondary battery of the present invention has a positive electrode, a negative electrode, a separator interposed between the positive electrode and the negative electrode, and a nonaqueous electrolyte solution. The battery further has a porous heat-resistant layer provided between the separator and at least one of the positive electrode and the negative electrode, wherein the porous heat-resistant layer includes an inorganic filler and a binder. The inorganic filler included in the porous heat-resistant layer has a particle size distribution with two peaks, which are a first peak (P1) at a relatively small particle diameter and a second peak (P2) at a relatively large particle diameter. When the particle diameter of the first peak (P1) is D1 be and the particle diameter of the second peak (P2) is D2 being, the peak particle diameter ratio D1 / D2 satisfies the condition 0.2≦D1 / D2≦0.7.

Owner:TOYOTA JIDOSHA KK

Nonaqueous electrolyte secondary battery

ActiveUS7629081B2Excellent high rate characteristicsNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsSulfiteEngineering

A nonaqueous electrolyte secondary battery includes a case, a nonaqueous electrolyte provided in the case and containing a linear sulfite, a positive electrode provided in the case and capable of absorbing-releasing Li element or Li ions, and a negative electrode provided in the case and containing a lithium titanium oxide and a conductive agent that includes a carbonaceous material.

Owner:KK TOSHIBA

Lithium-ion-battery multiwalled carbon nanotube/ molybdenum disulfide combination electrode and preparation method

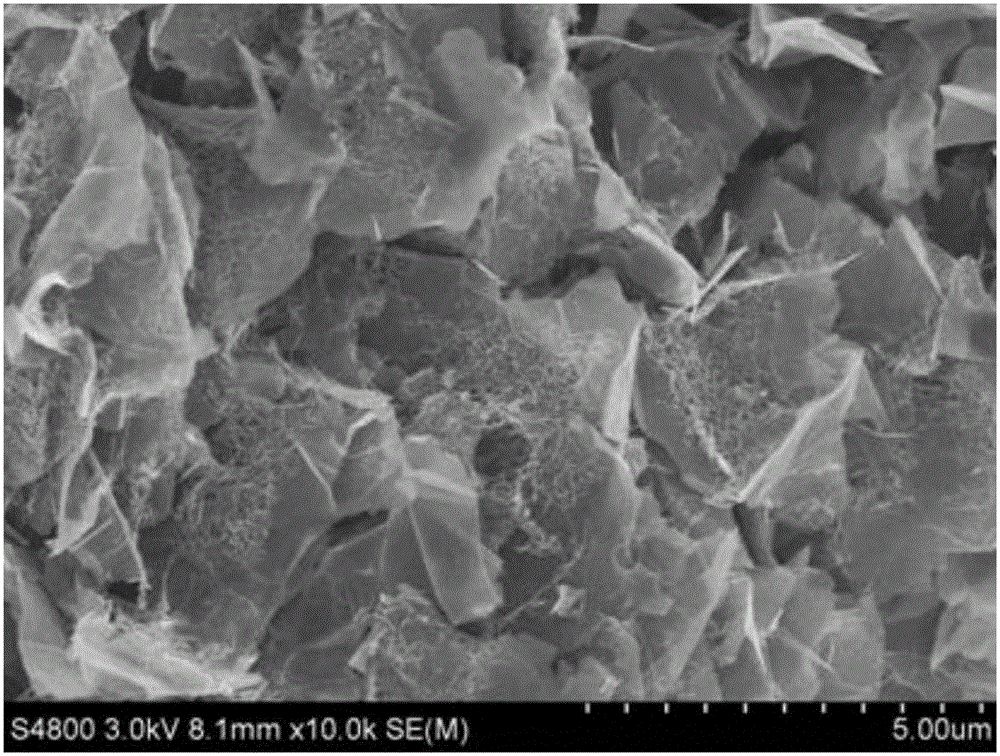

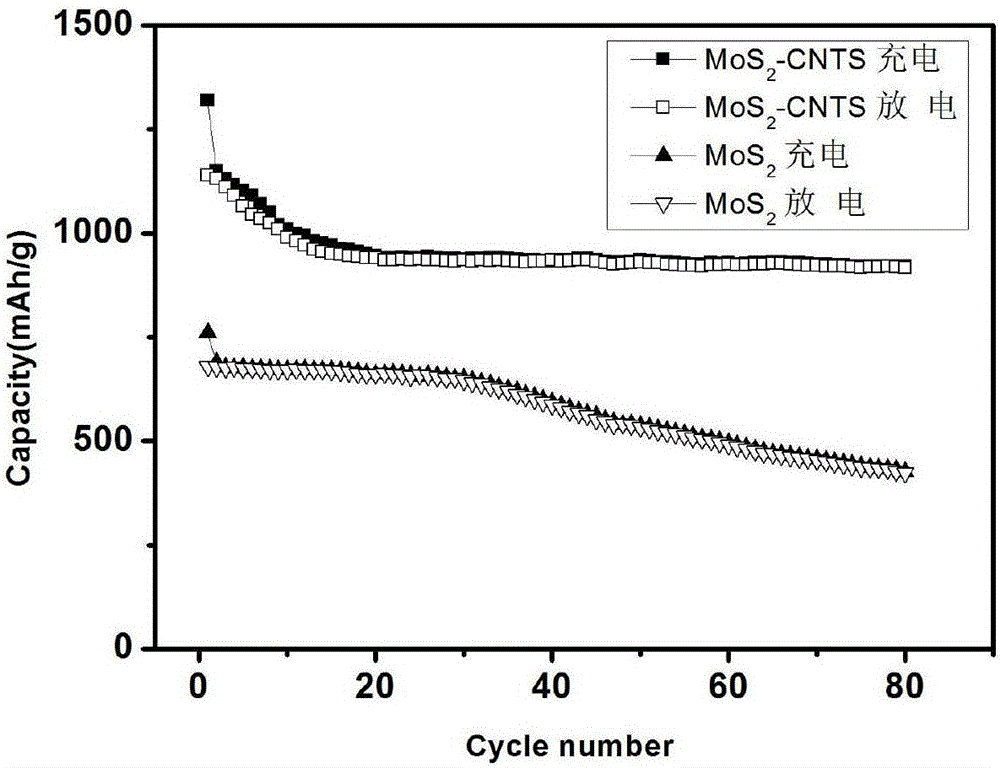

ActiveCN106711413AHigh electrochemical lithium storage specific capacityPromote circulationCell electrodesSecondary cellsHigh rateLithium-ion battery

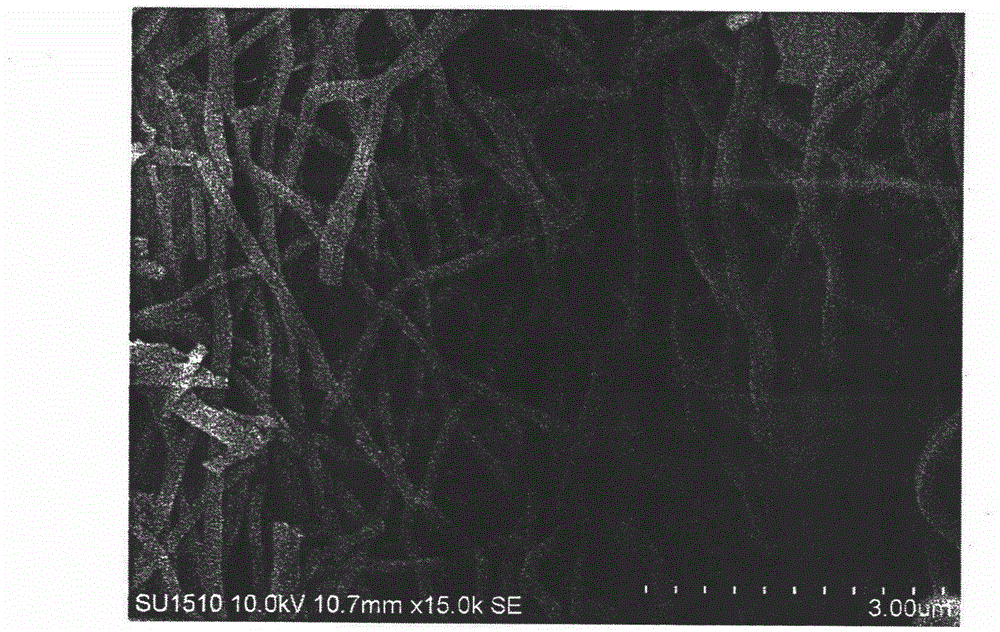

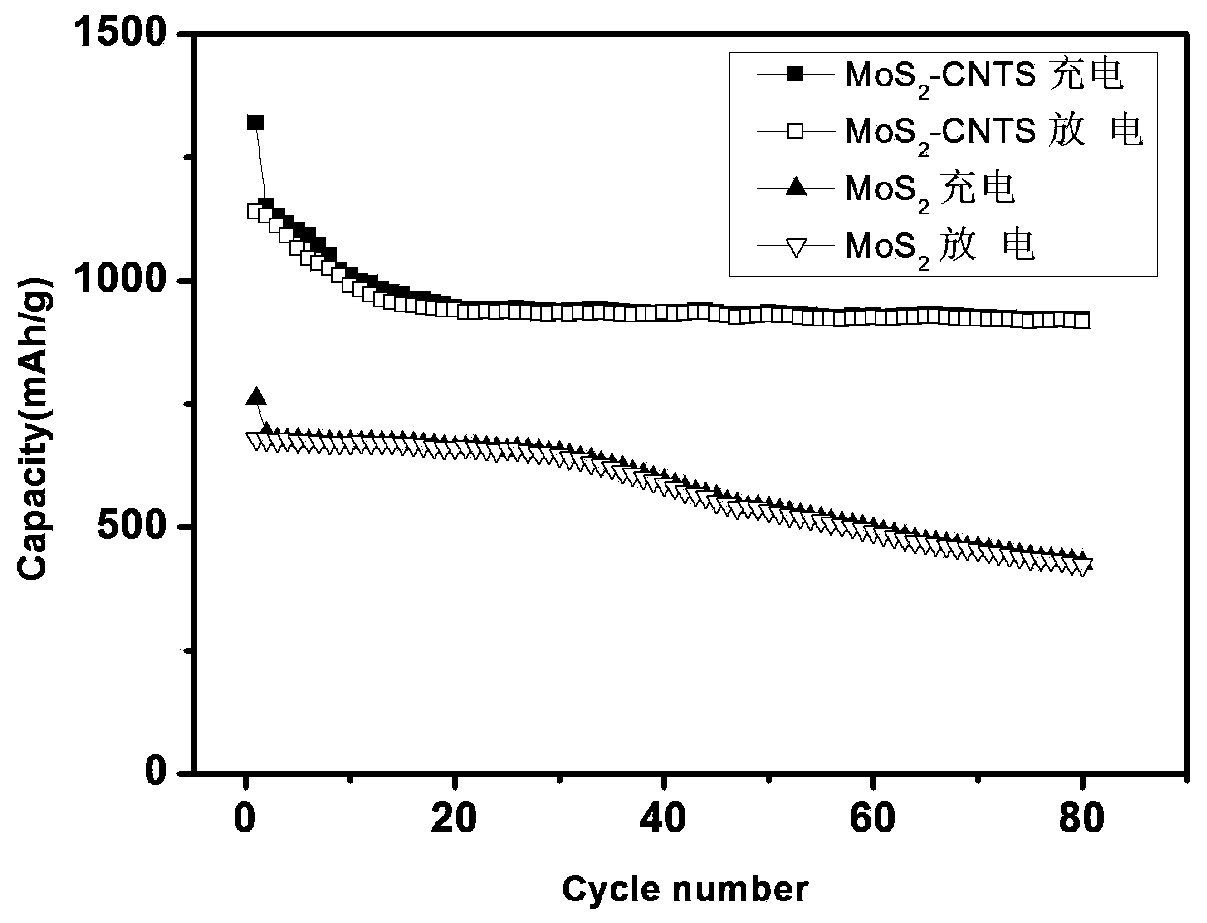

The invention provides a lithium-ion-battery multiwalled carbon nanotube / molybdenum disulfide combination electrode and a preparation method. According to the preparation method, multiwalled carbon nanotube, soluble molybdate and L-cysteine are adopted as materials, glucose and triton X-100 are used as additives, dispersion uniformity of MoS2 on the surface of the carbon nanotube is improved, and through an in-situ hydrothermal reduction method, a combination electrode material of MoS2 and the multiwalled carbon nanotube is synthesized. The material has high electrochemical storage lithium specific capacity, excellent cycle performance and a high-rate feature. Meanwhile, the synthetic method has the advantages of being moderate in reaction condition, simple in process, high in yield and good in repeatability.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Positive active material, positive electrode and rechargeable lithium battery

InactiveCN102683696AImprove conductivityHigh densityCobalt compoundsLi-accumulatorsHigh ratePhysical chemistry

A positive active material, an electrode including the positive active material, and a lithium battery including the electrode are provided. Due to the inclusion of a phosphate compound having the olivine structure and a lithium nickel composite oxide in the positive active material, the positive active material has high electric conductivity and high electrode density and thus, a lithium battery manufactured using the positive active material has high capacity and good high-rate characteristics.

Owner:SAMSUNG SDI CO LTD

Preparation method for carbon/tin/graphene composite nanofibers for lithium ion battery

InactiveCN106159210ASimple preparation processReduce manufacturing costCell electrodesNanotechnologyFiberHigh rate

The invention discloses a preparation method for carbon / tin / graphene composite nanofibers for a lithium ion battery, and belongs to the technical fields of nanomaterials and a chemical power supply. The preparation method comprises the steps of dissolving polyacrylonitrile, stannous chloride and graphene into N, N-dimethylformamide, and stirring uniformly to form a spinning solution; then preparing a polyacrylonitrile / stannous chloride / graphene composite nanofiber membrane through an electrospinning technique; and carrying out carbonization to obtain the carbon / tin / graphene composite nanofiber negative electrode material. The preparation process provided by the invention is simple, and the production cost is low; the composite nanofiber material prepared by the invention is used for the negative electrode material of the lithium ion battery, and the material has an excellent electrochemical property, a good cycling performance and high rate capability; the shortcoming of a poor cycling performance of a tin-based negative electrode material is overcome; and therefore, the carbon / tin / graphene composite nanofibers, which can used as the new generation of the negative electrode material of the lithium ion battery, can be widely applied in portable equipment.

Owner:JIANGNAN UNIV

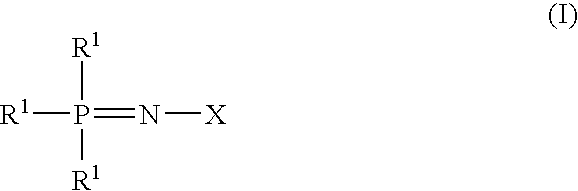

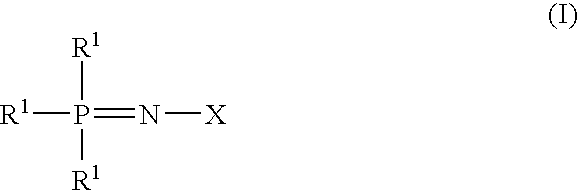

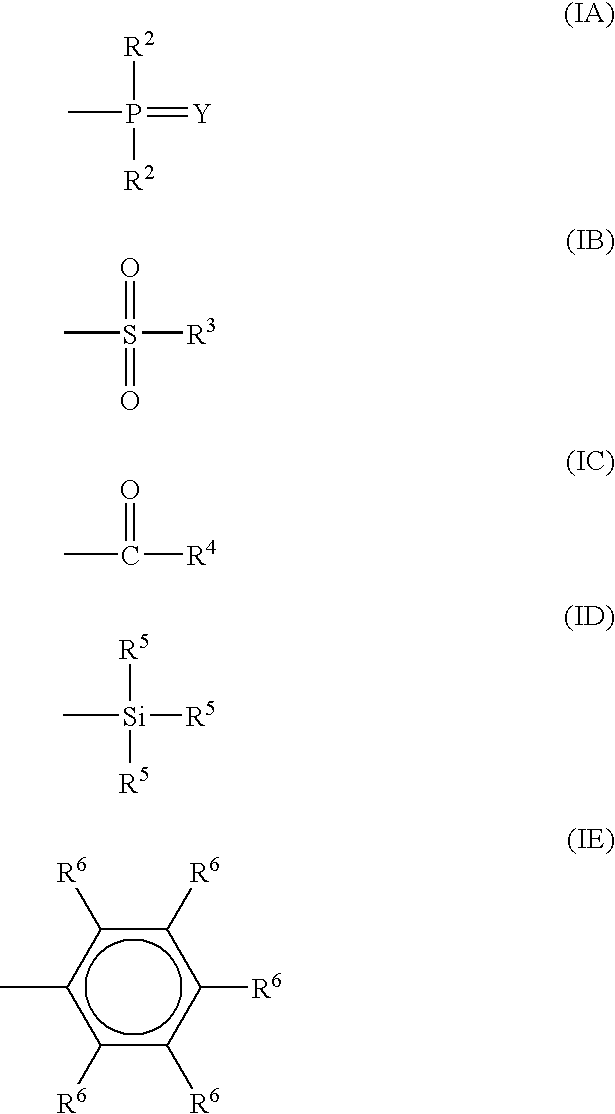

Additive for nonaqueous electrolytic solution of electric double layer capacitor and nonaqueous electrolyte electric double layer capacitor

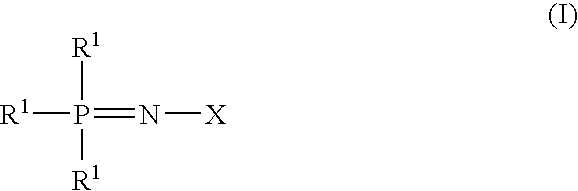

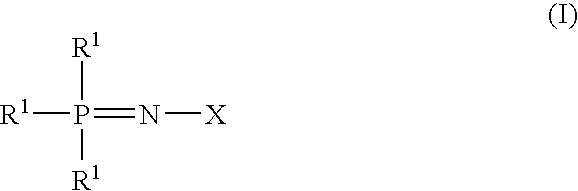

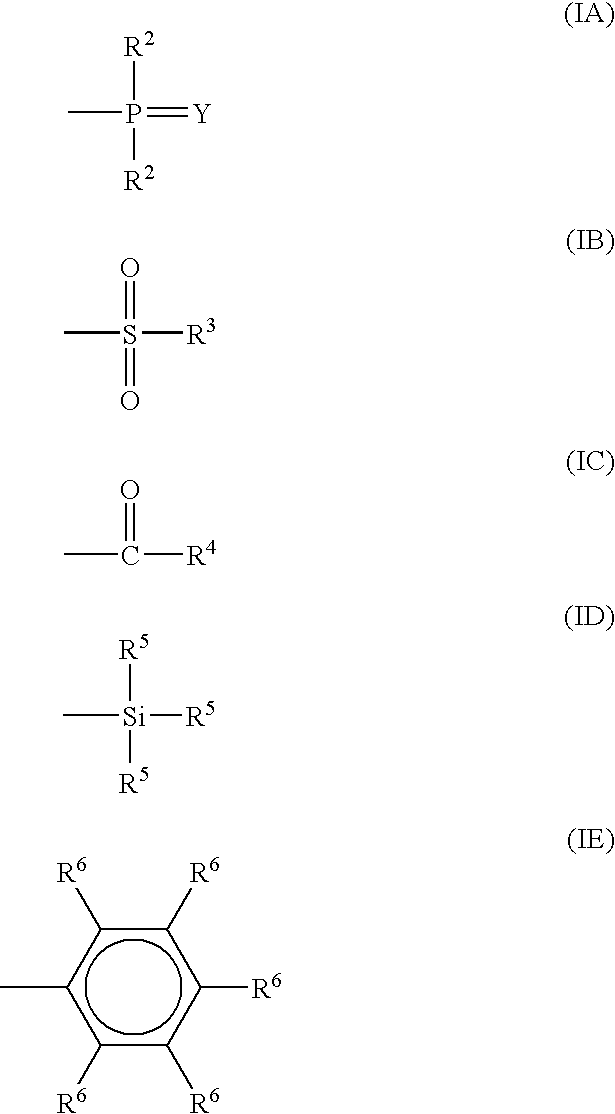

InactiveUS20060092596A1Excellent high rate characteristicLow viscosityHybrid capacitor electrolytesElectrolytic capacitorsChemistryNon aqueous electrolytes

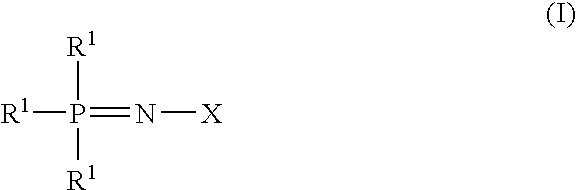

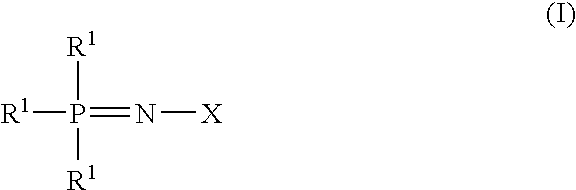

The invention is concerned with an additive for a non-aqueous electrolyte of an electric double layer capacitor having a high dissolving power of a support salt and a low viscosity and comprising a phosphazene derivative represented by the following formula (I): (wherein R1 is independently a halogen element or a monovalent substituent; and X is an organic group containing at least one element selected from the group consisting of carbon, silicon, nitrogen, phosphorus, oxygen and sulfur) as well as a non-aqueous electrolyte electric double layer capacitor comprising an electrolyte containing this additive and having excellent high-rate characteristics.

Owner:BRIDGESTONE CORP

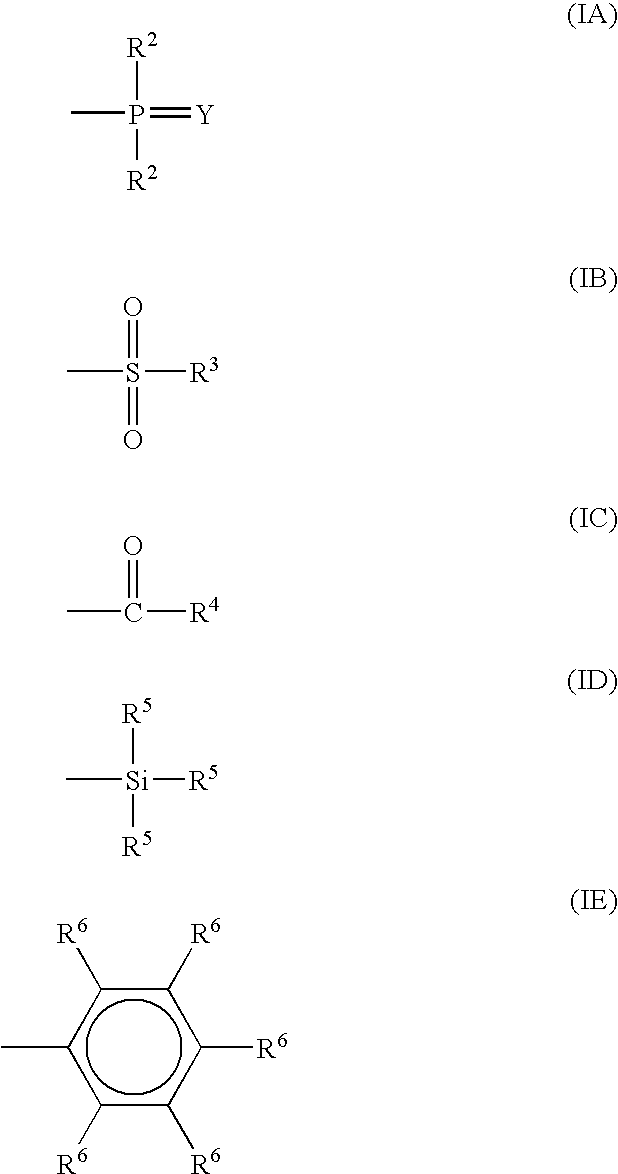

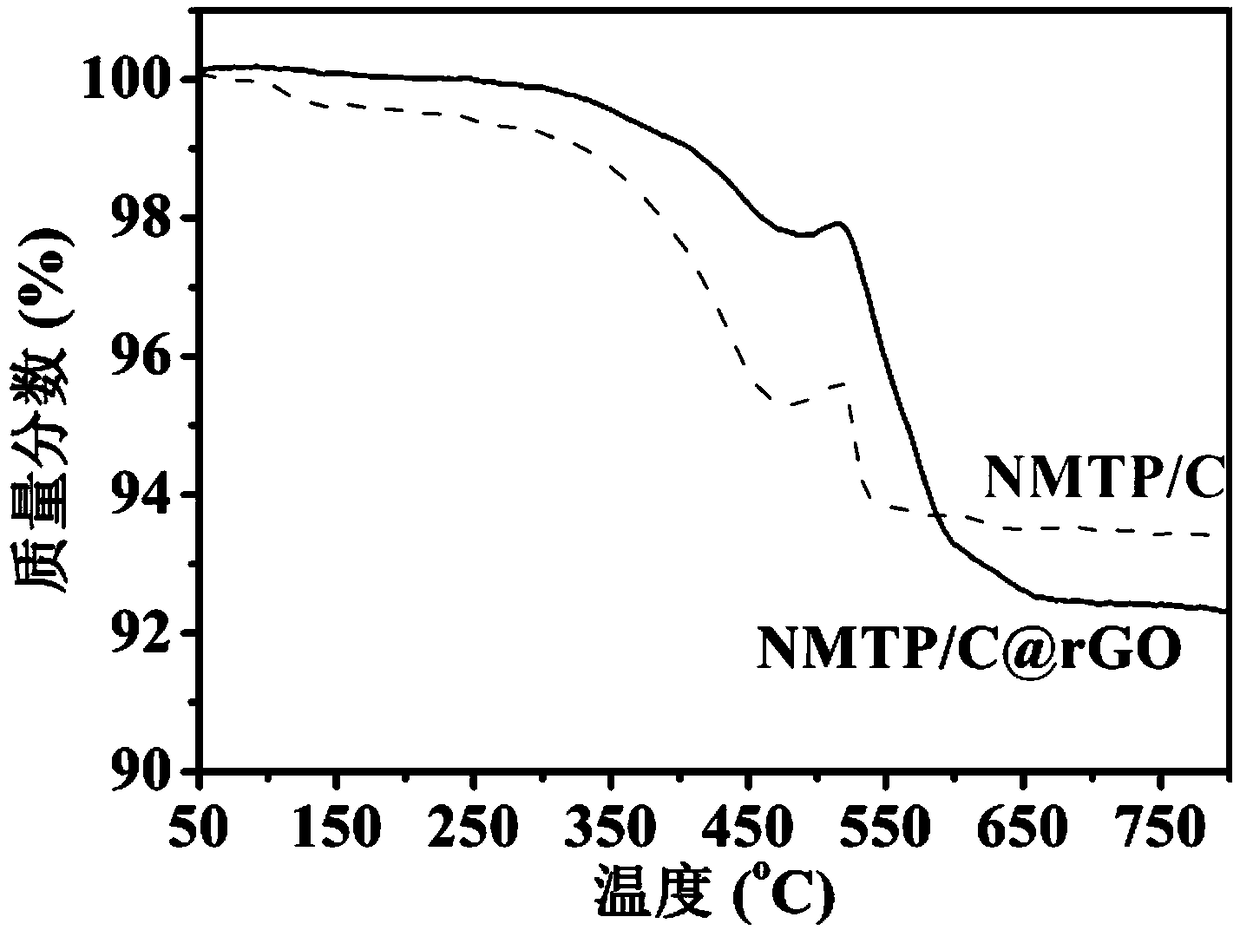

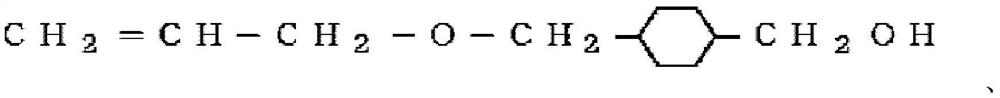

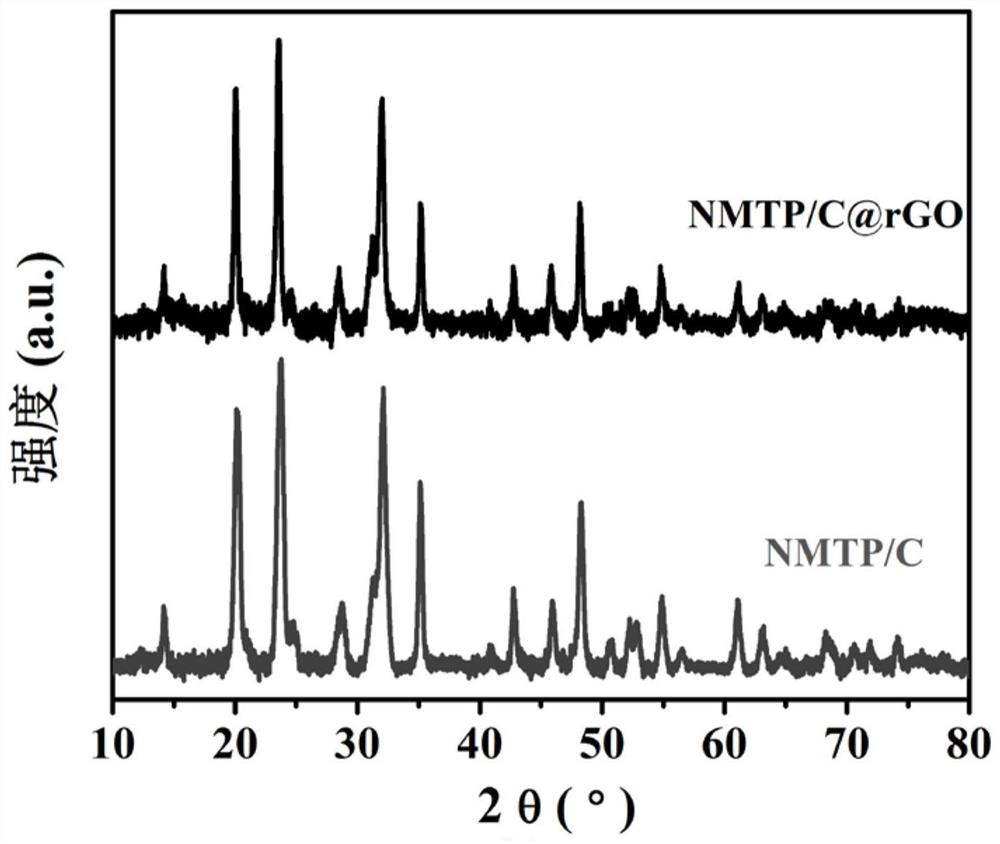

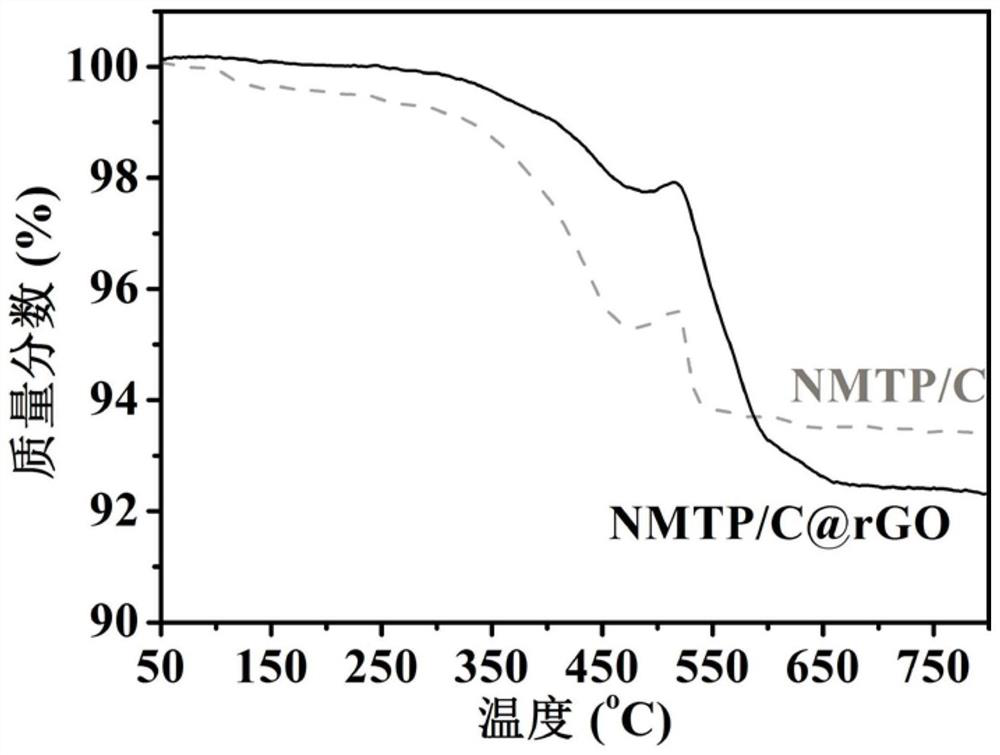

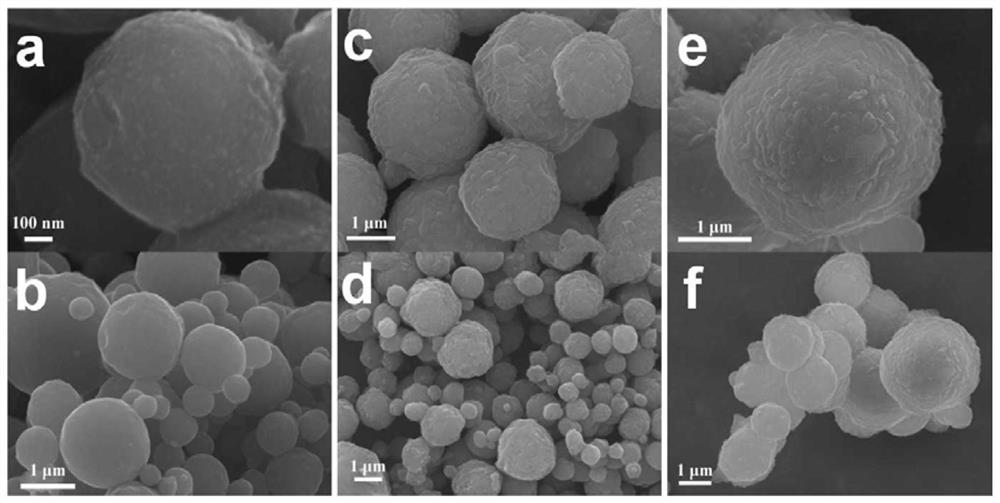

Graphene-reinforced carbon-coated sodium titanium manganese phosphate microsphere electrode material and preparation method and application thereof

ActiveCN108963235ALarge specific surface areaImprove electrochemical performanceSecondary cellsPositive electrodesMicrosphereSodium-ion battery

The invention relates to a graphene-reinforced carbon-coated sodium titanium manganese phosphate microsphere electrode material and a preparation method thereof, wherein the material can be used as apositive electrode active material of a sodium ion battery, the chemical formula is Na3MnTi (PO4) 3 / C @ rGO, and the diameter of the microsphere is 0.2-5. Mu. and the carbon content is 5%-10%. The invention has the advantages of: As a sodium ion cathode material, As that conductivity of the cathode material of the polyanion sodium ion battery is poor, Disadvantages of rapid capacity decay, At thesame time, the multiplier performance of the material is improved, so that the material possesses high reversible capacity, good cycle stability and high multiplier performance while possessing largecapacity, and the preparation process is simple, the yield is high, the material is suitable for industrialized mass production, is conducive to market promotion, and has wide application prospects inthe field of sodium ion batteries.

Owner:WUHAN UNIV OF TECH

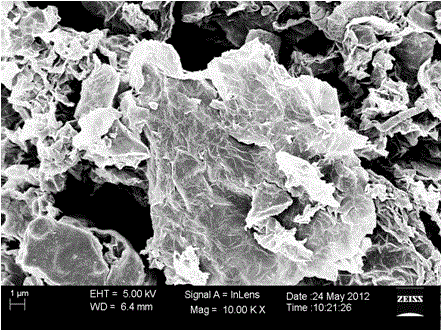

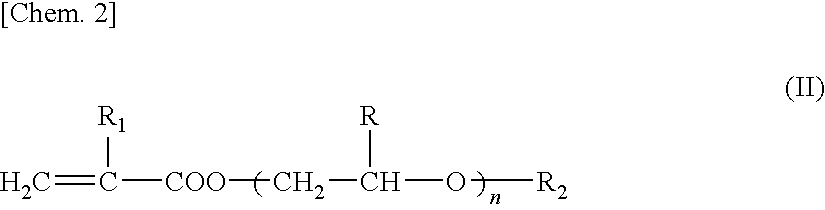

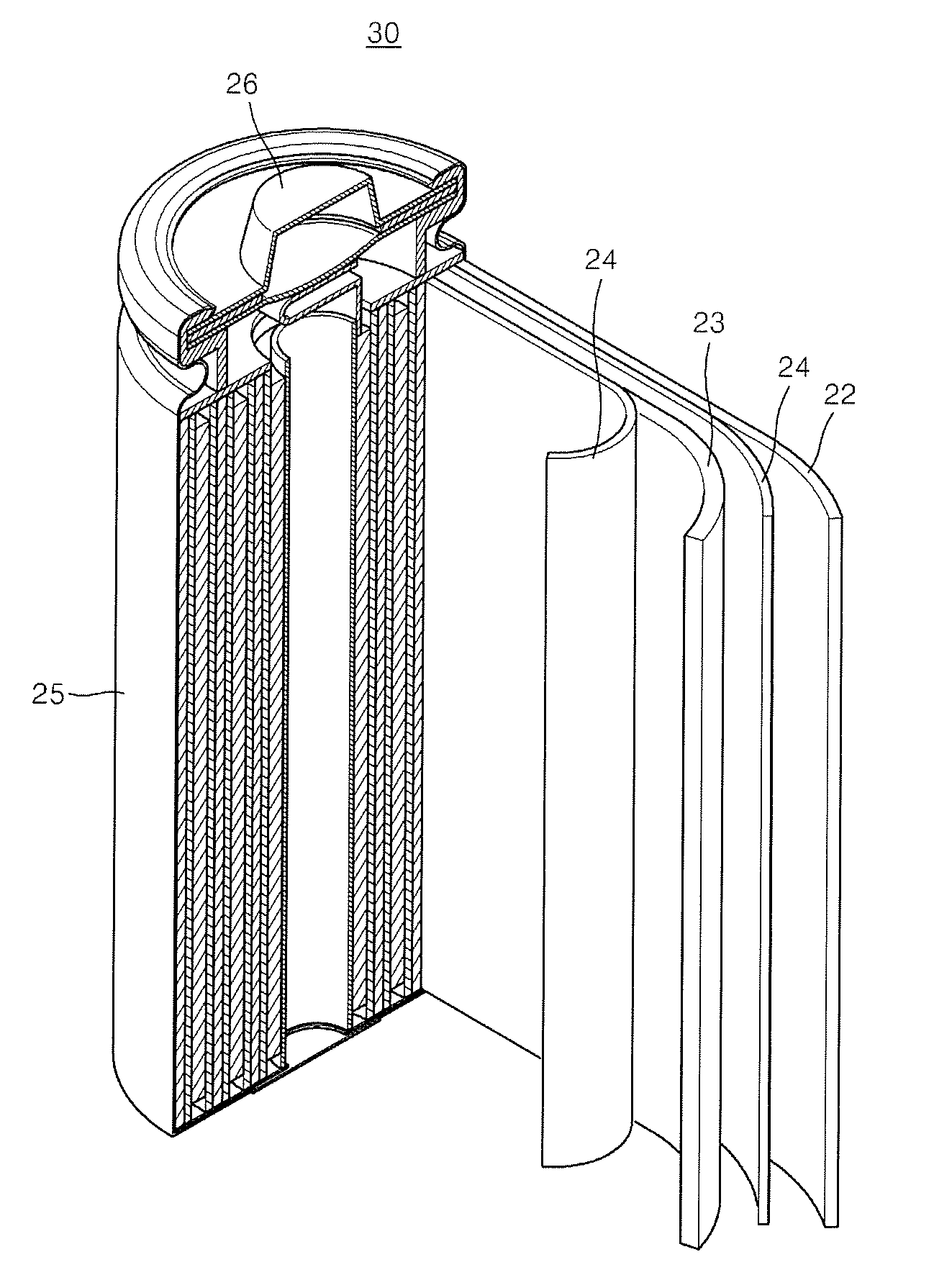

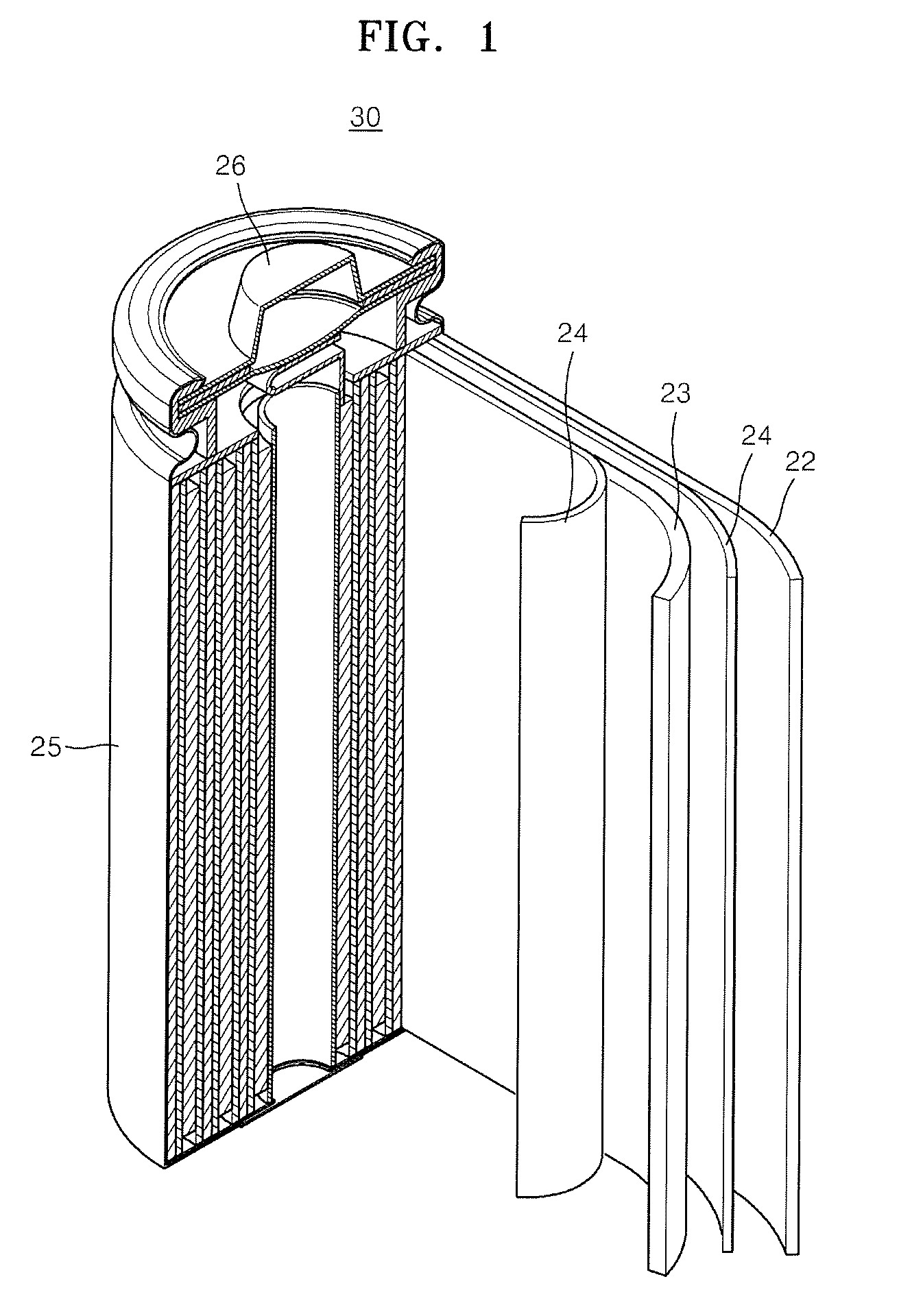

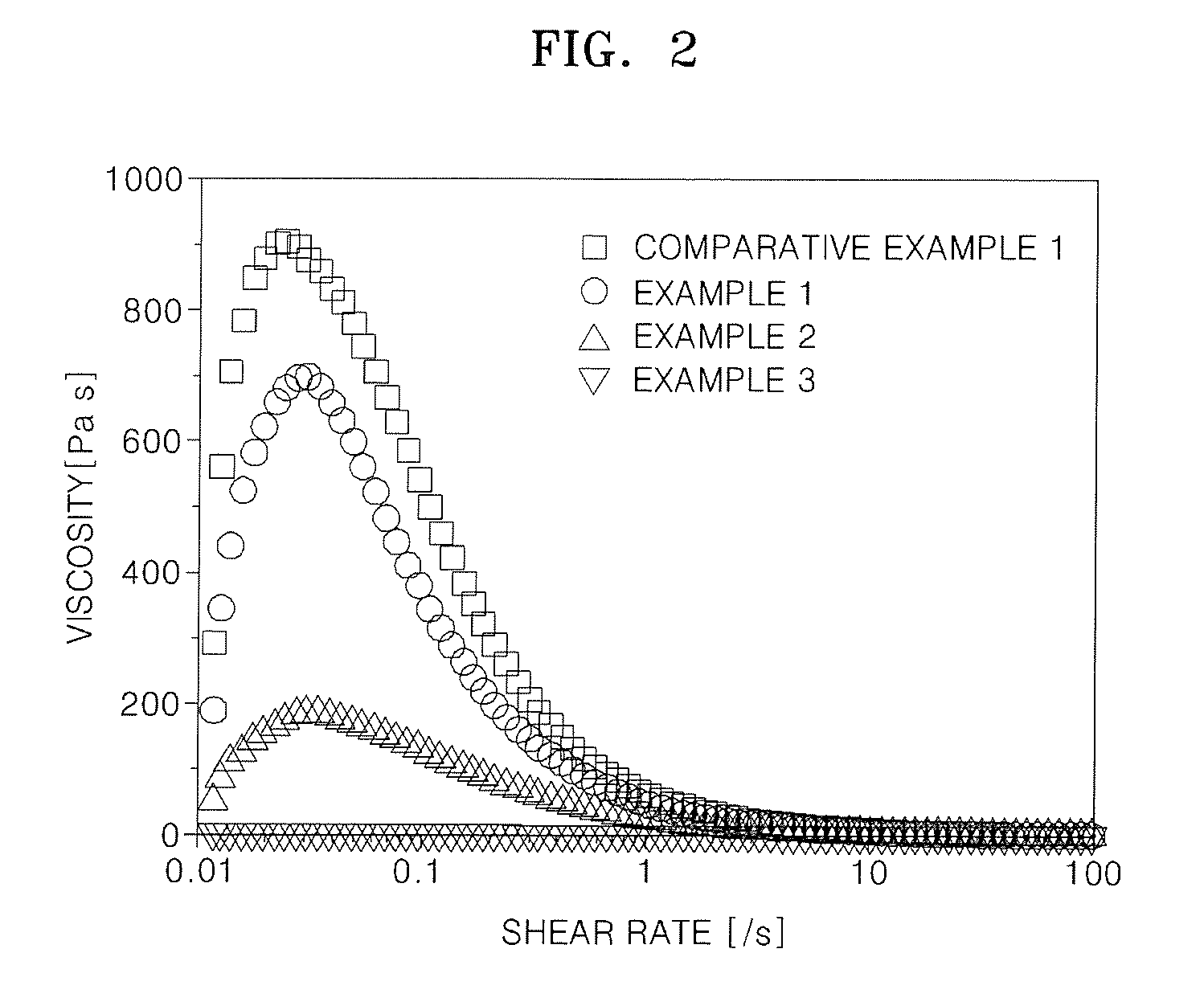

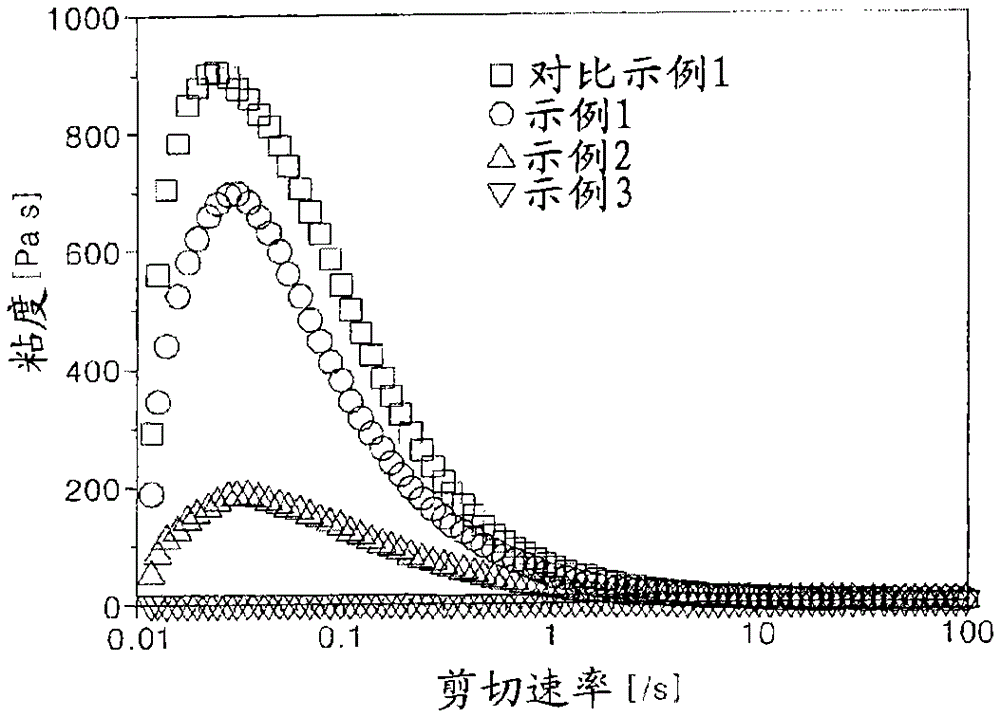

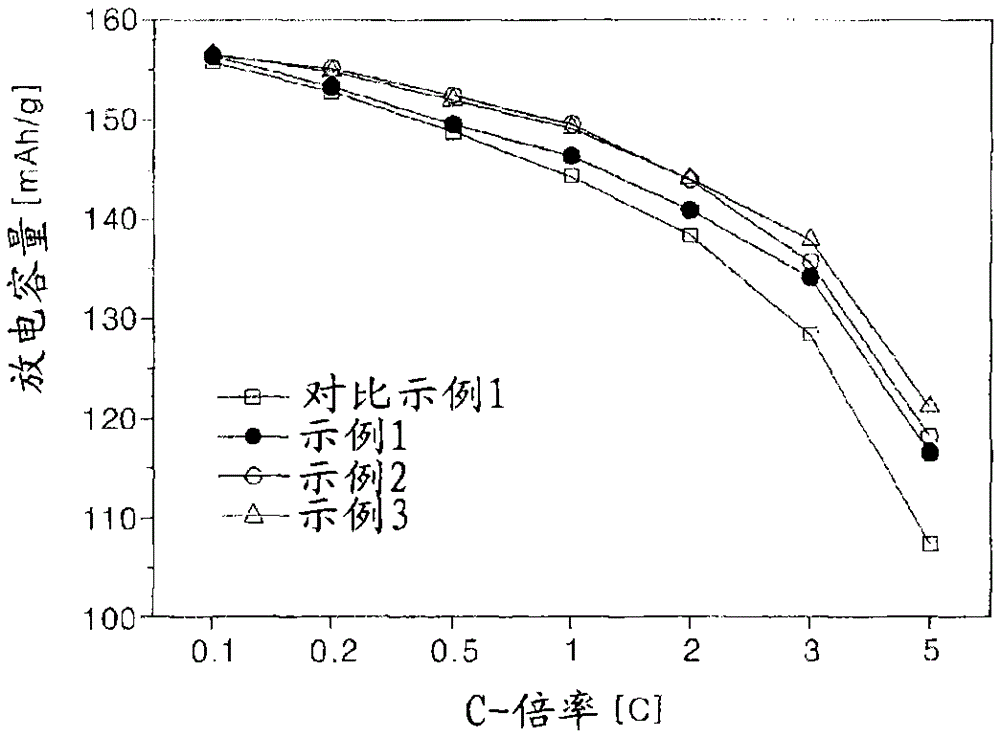

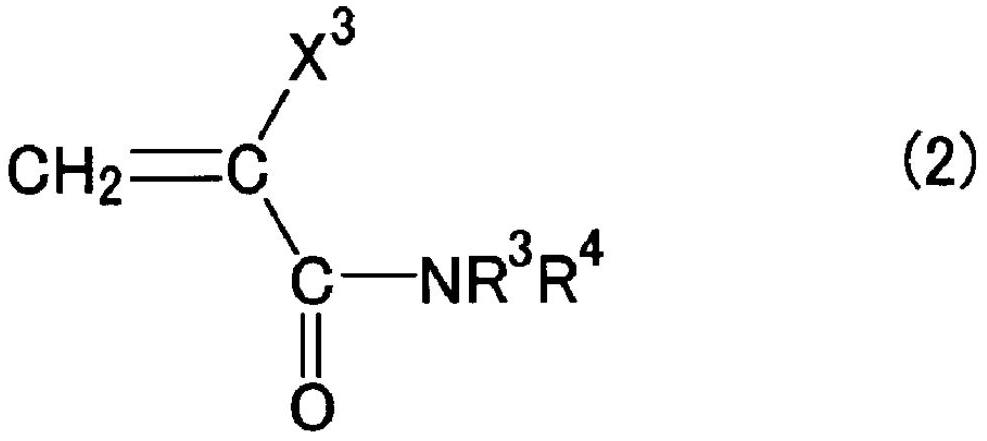

Binder for nonaqueous electrolyte secondary battery electrode, manufacturing method therefor and use therefor

ActiveUS20170352886A1Improve bending resistanceUniform layersSecondary cellsNon-aqueous electrolyte accumulator electrodesPolymer scienceCrosslinked polymers

Provided is a binder for a nonaqueous electrolyte secondary battery electrode. The binder contains a crosslinked polymer having a carboxyl group, or salt thereof, a use therefor, and a method for manufacturing a carboxyl group-containing crosslinked polymer or salt thereof for use in the binder. The crosslinked polymer contains a structural unit derived from an ethylenically unsaturated carboxylic acid monomer in the amount of 50 to 100 mass % of total structural units, and after the crosslinked polymer neutralized to a degree of a neutralization of 80 to 100 mol % has been subjected to water swelling in water and then dispersed in a 1 mass % NaCl aqueous solution, the particle diameter thereof is 0.1 to 7.0 μm in a volume-based median diameter.

Owner:TOAGOSEI CO LTD

Electrolyte for lithium secondary battery and lithium secondary battery including the same

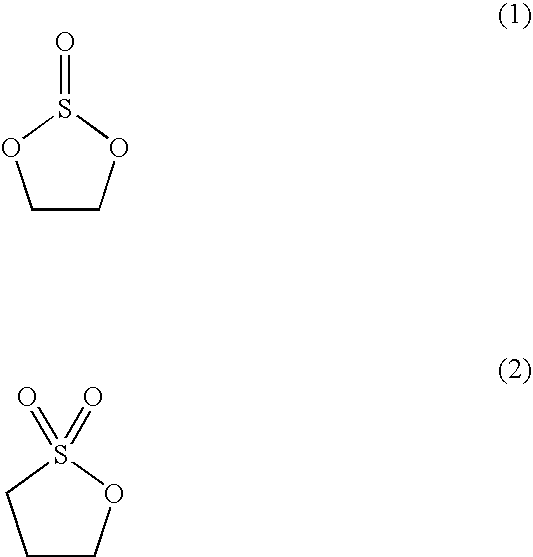

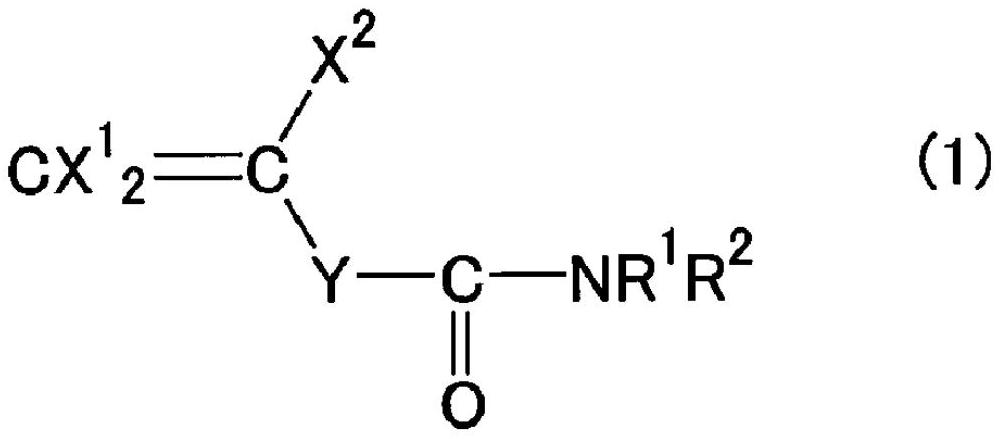

InactiveUS20140308562A1Excellent high rate characteristicsImprove featuresCell electrodesOrganic electrolyte cellsLithiumOrganic solvent

An electrolyte for lithium secondary batteries includes a lithium salt, a nonaqueous organic solvent, and a compound represented by Formula 1 below as an additive:where R1, R2, R3, R4, and R5 in Formula 1 are defined as those specified in the specification.

Owner:SAMSUNG SDI CO LTD

Additive for nonaqueous electrolyte solution of secondary battery and nonaqueous electrolyte secondary battery

InactiveUS20060046151A1Low viscosityExcellent high rate characteristicsElectrolytic capacitorsOrganic electrolyte cellsHigh rateOxygen

The invention is concerned with an additive for a non-aqueous electrolyte of a secondary battery having a high ability dissolving a support salt and a low viscosity and comprising a phosphazene derivative represented by the following formula (I): (wherein R1 is independently a halogen element or a monovalent substituent; and X is an organic group containing at least one element selected from the group consisting of carbon, silicon, nitrogen, phosphorus, oxygen and sulfur) as well as a non-aqueous electrolyte secondary battery comprising an electrolyte containing this additive and having excellent high-rate characteristics.

Owner:BRIDGESTONE CORP

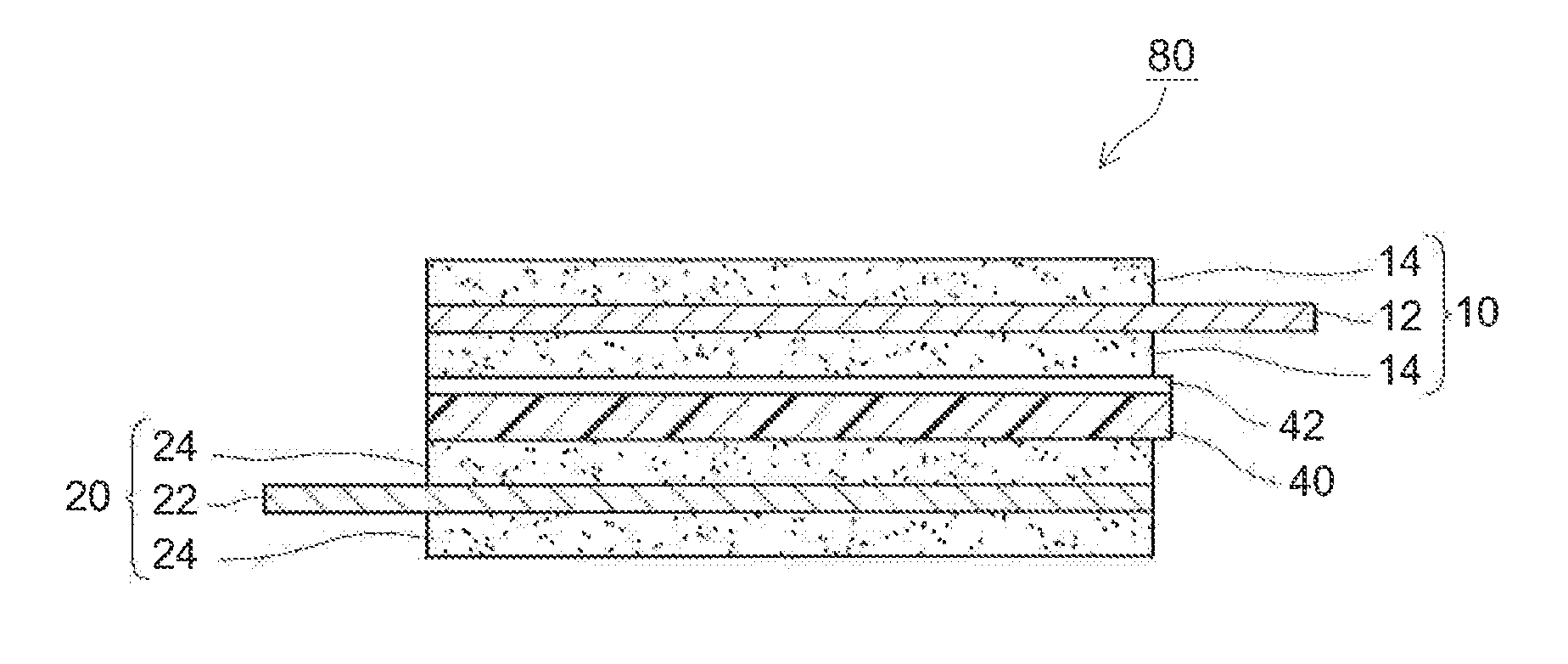

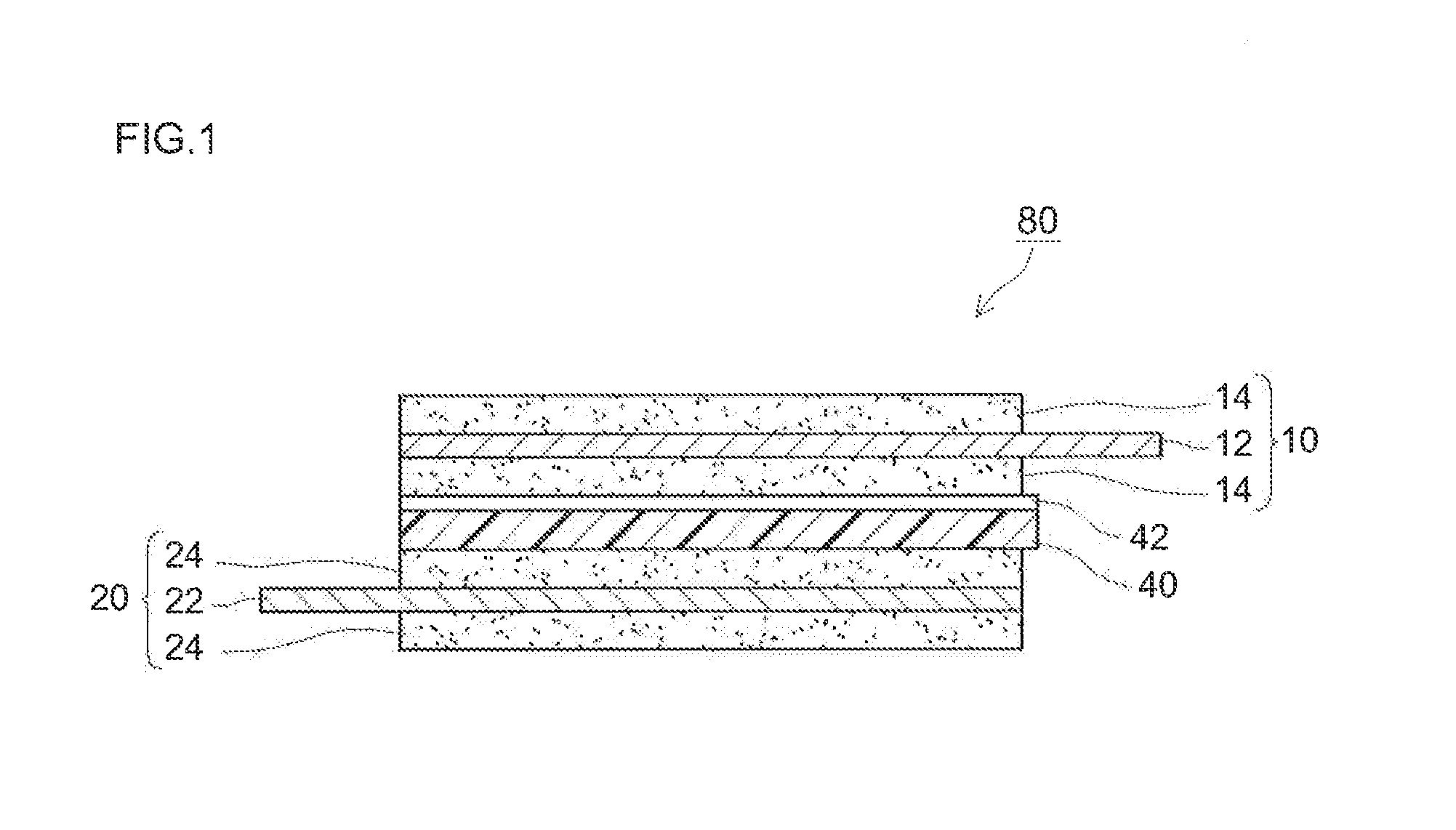

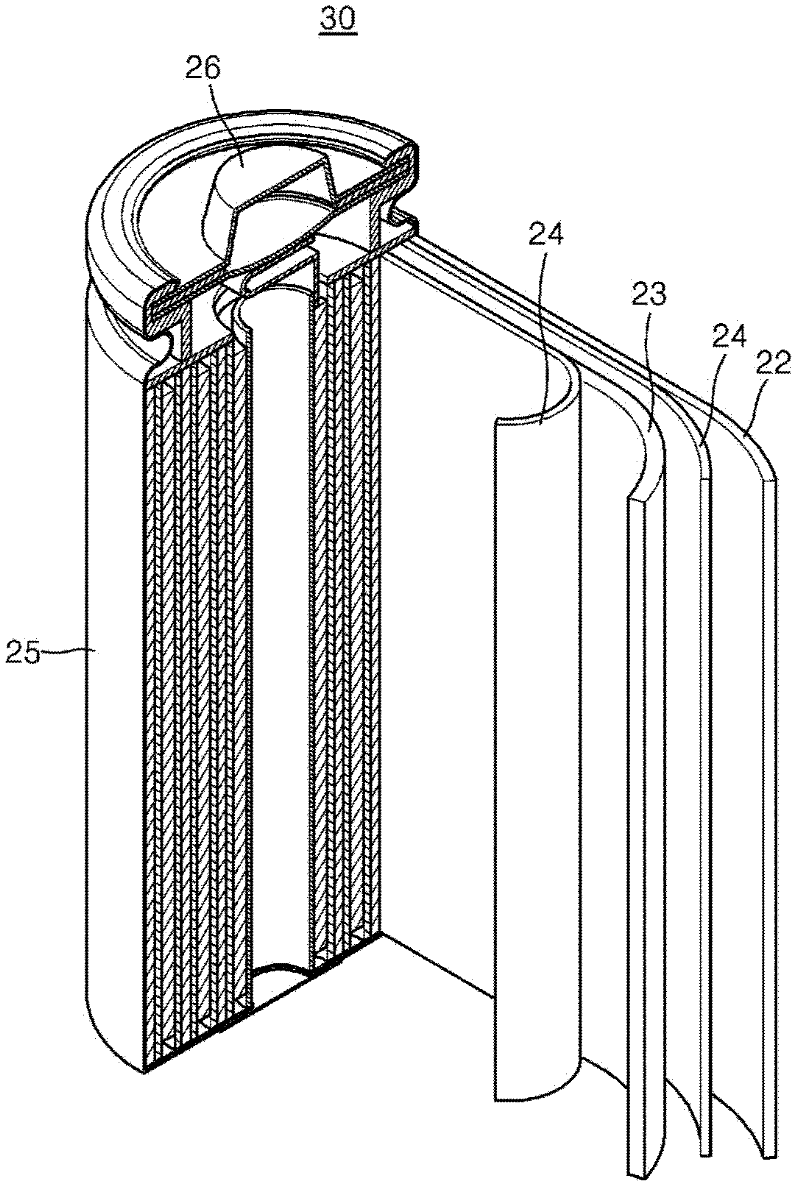

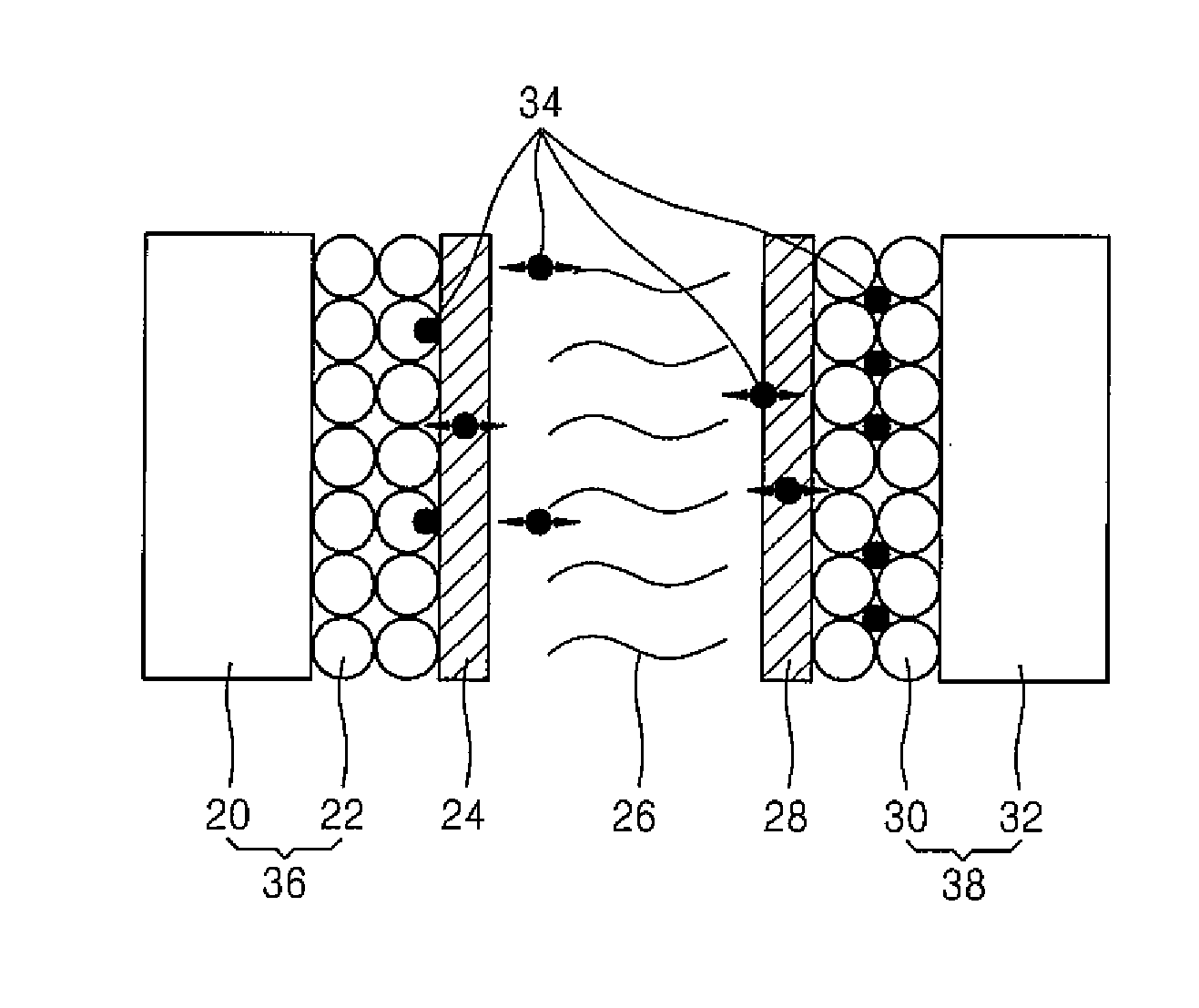

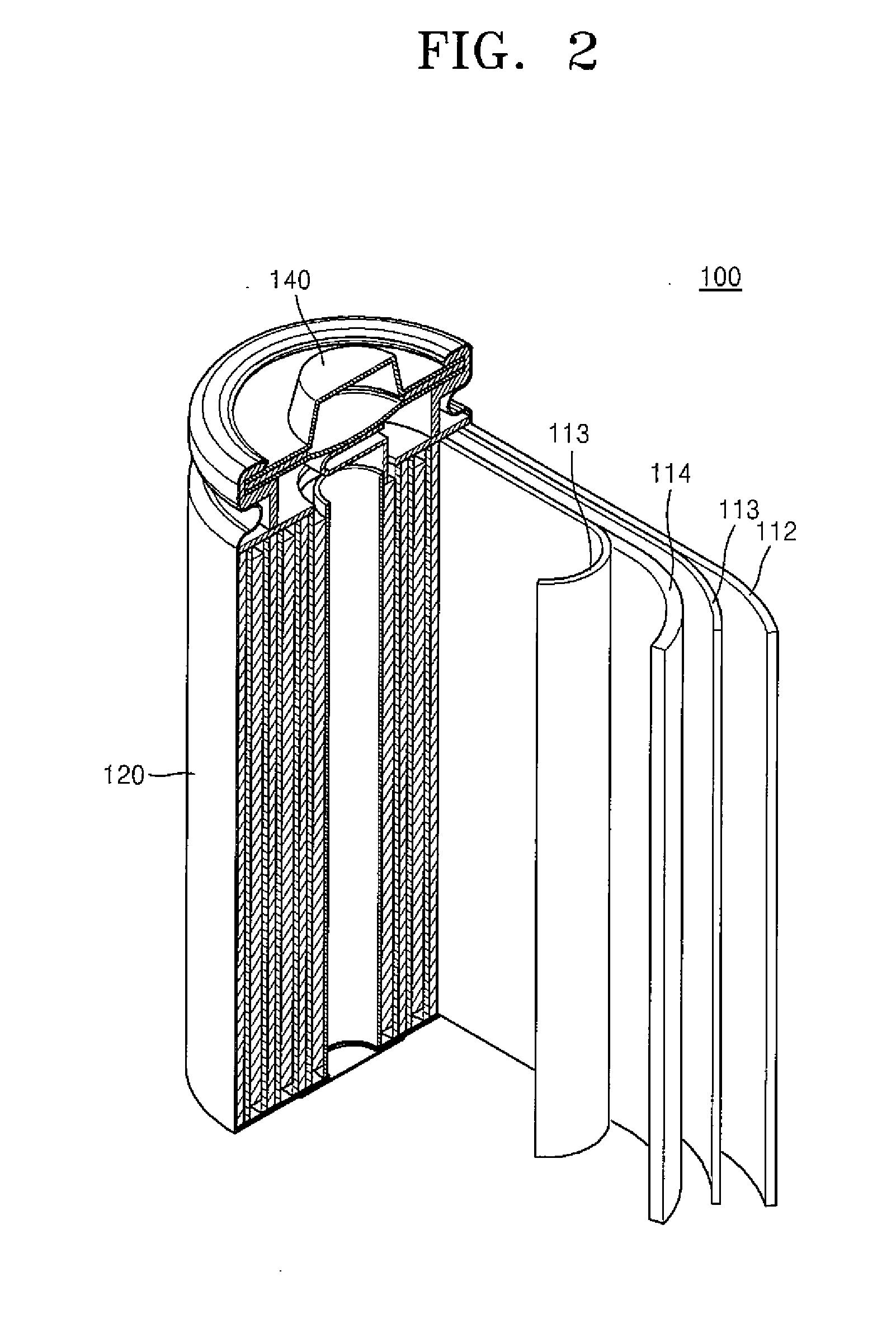

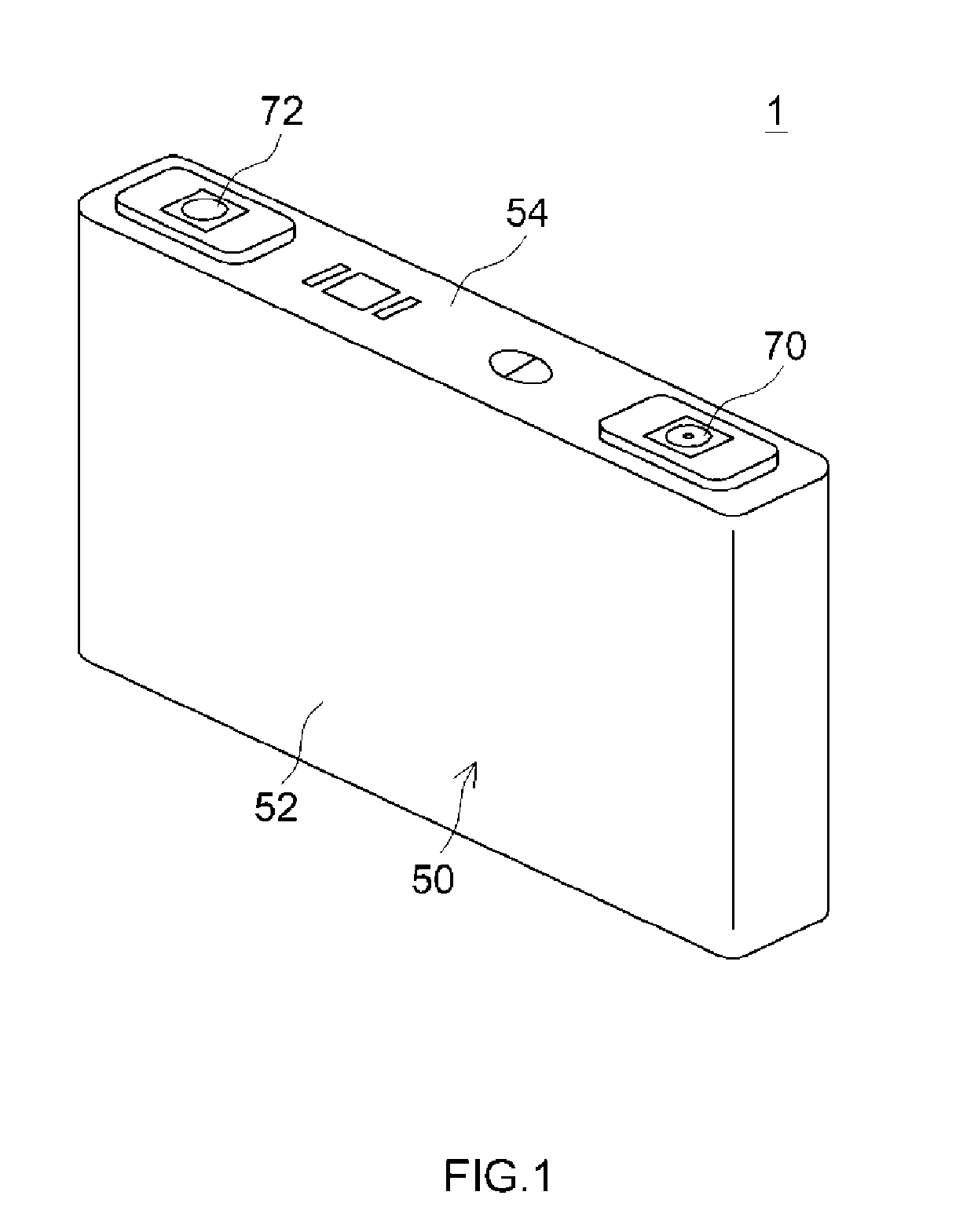

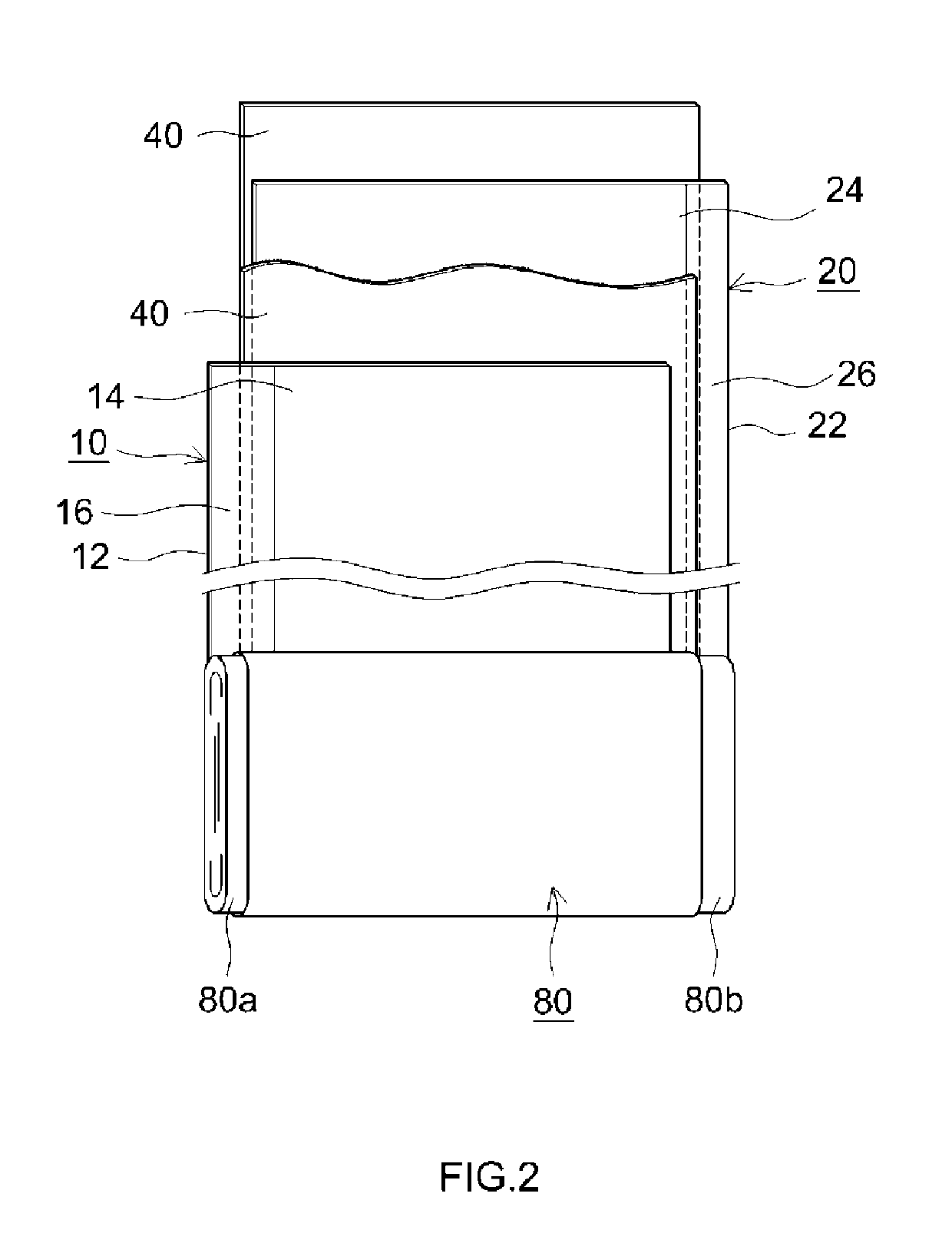

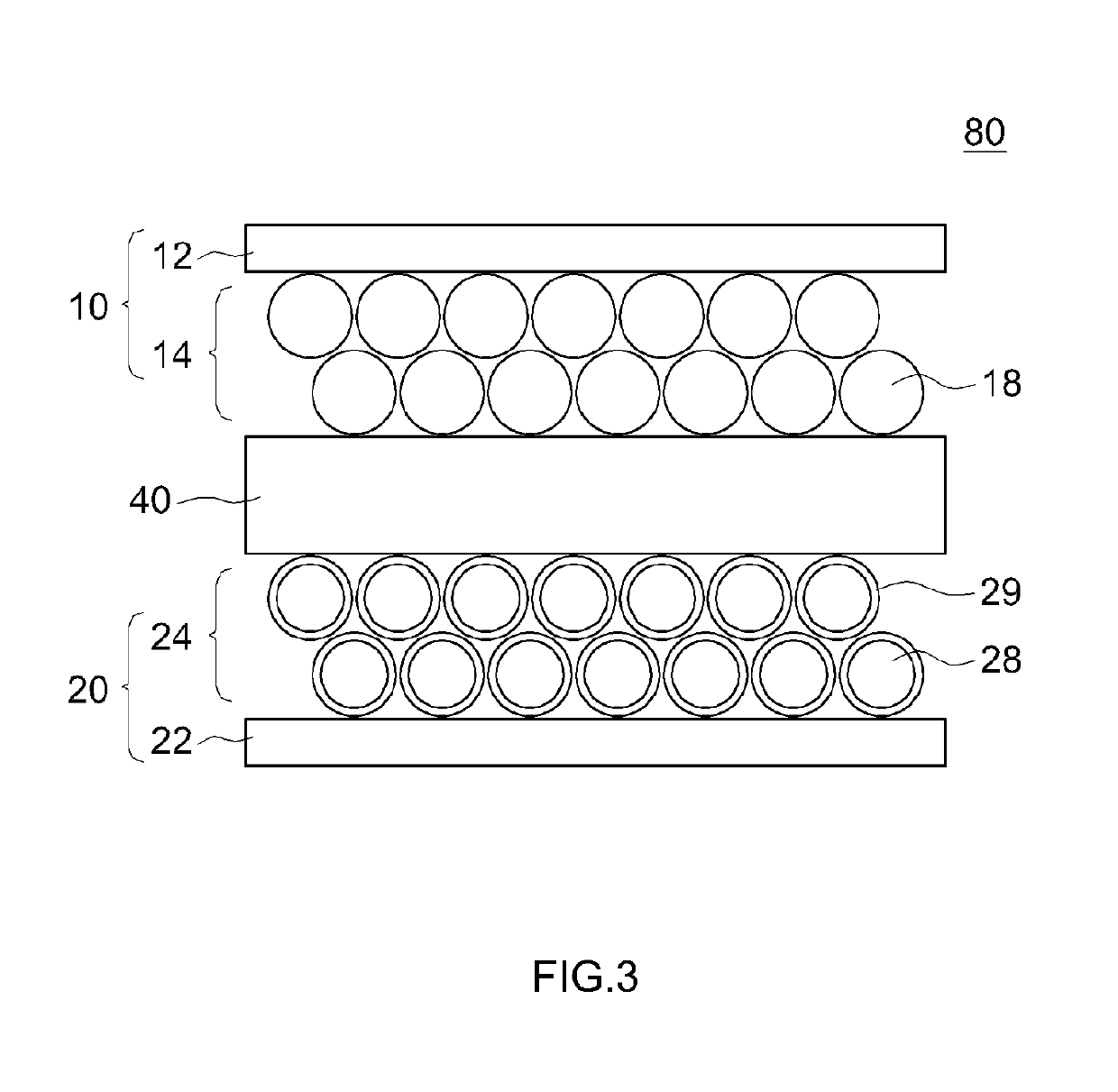

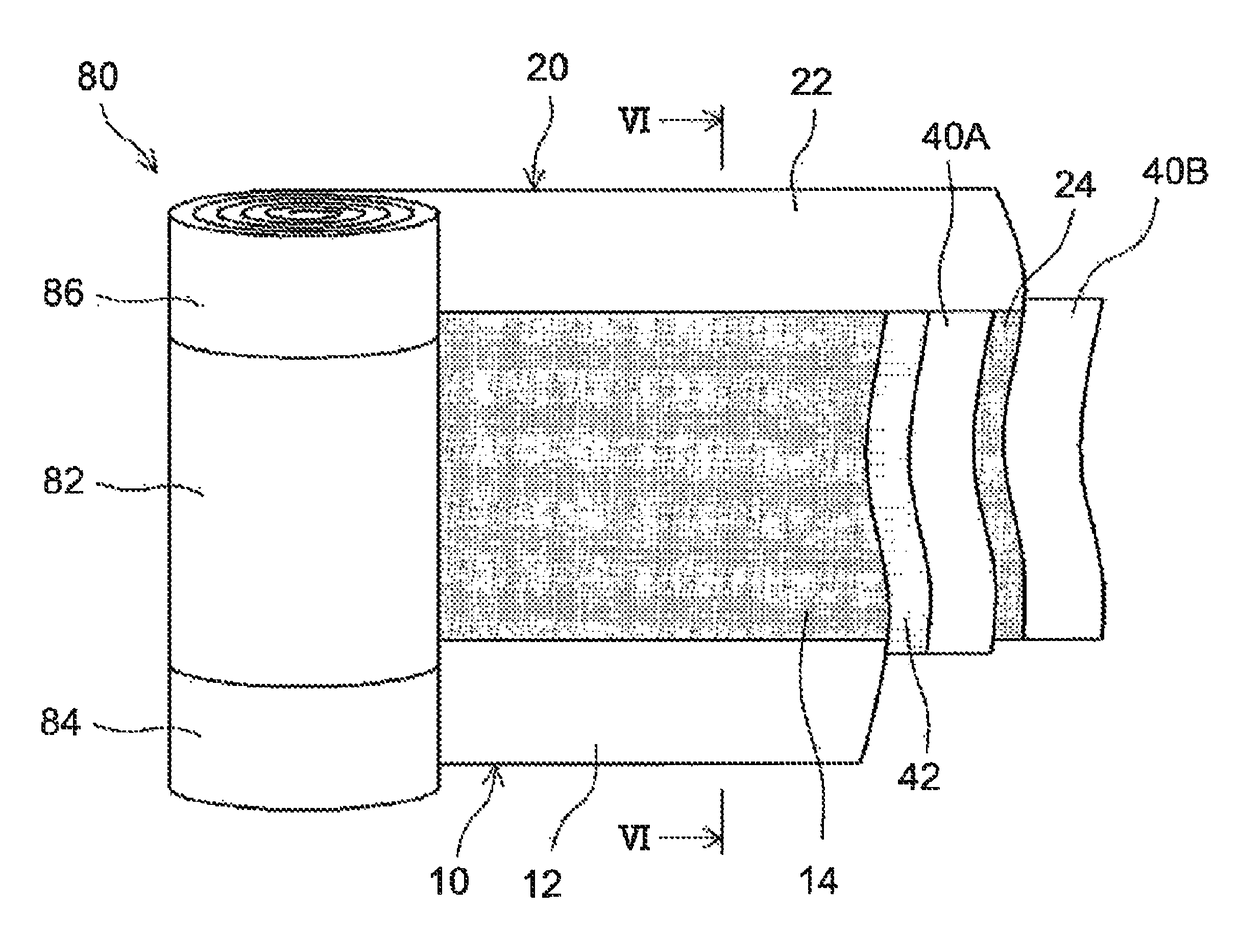

Nonaqueous electrolyte secondary battery

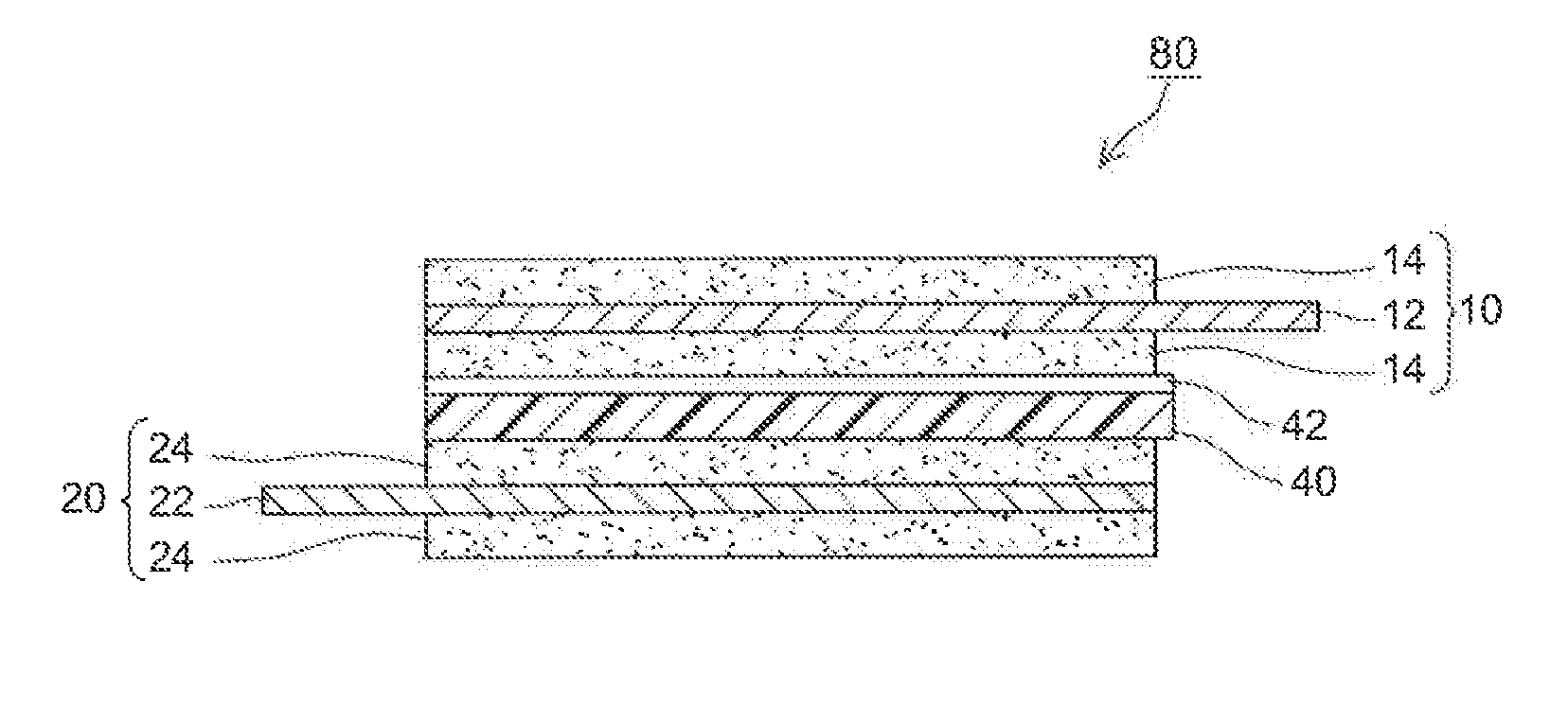

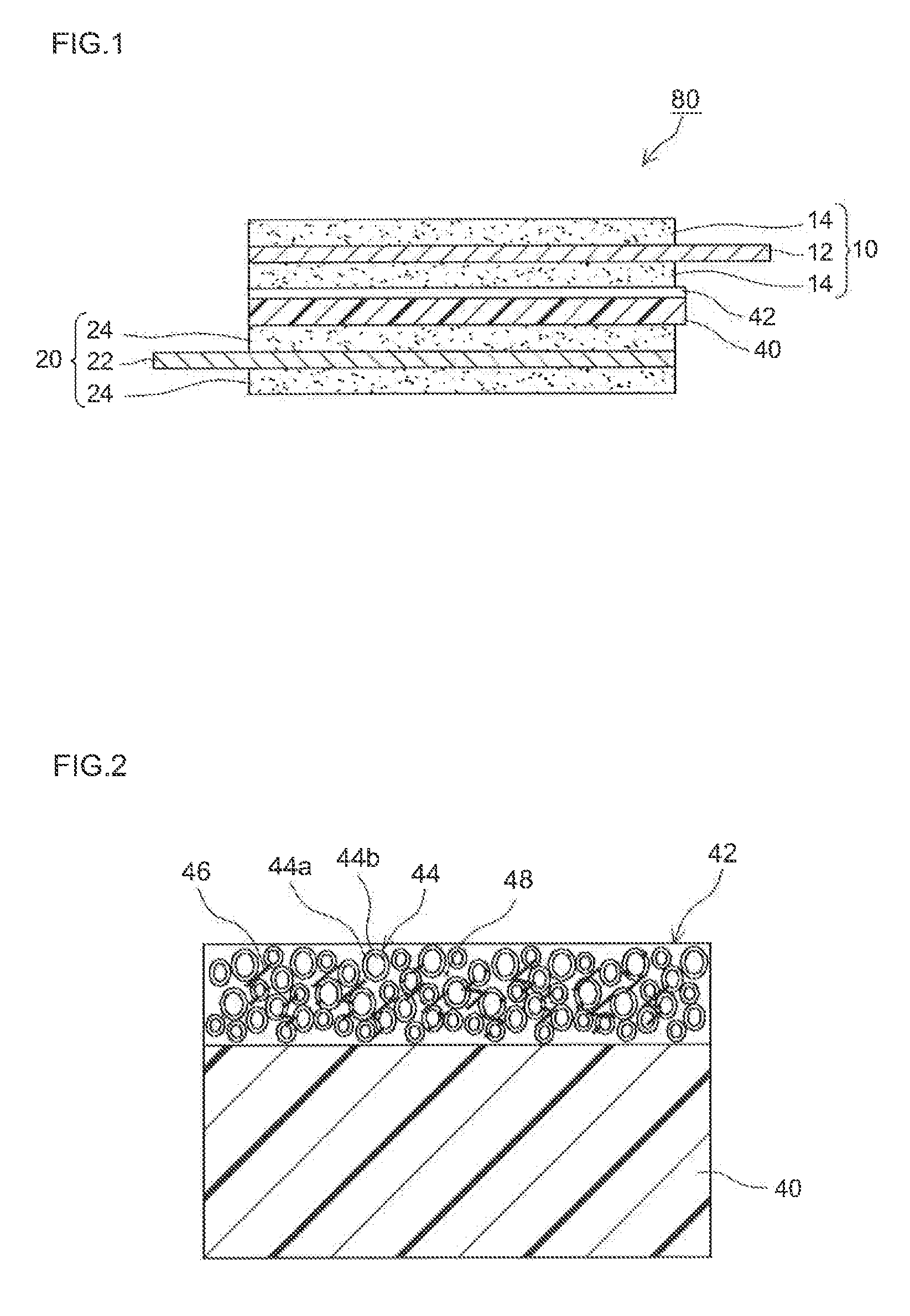

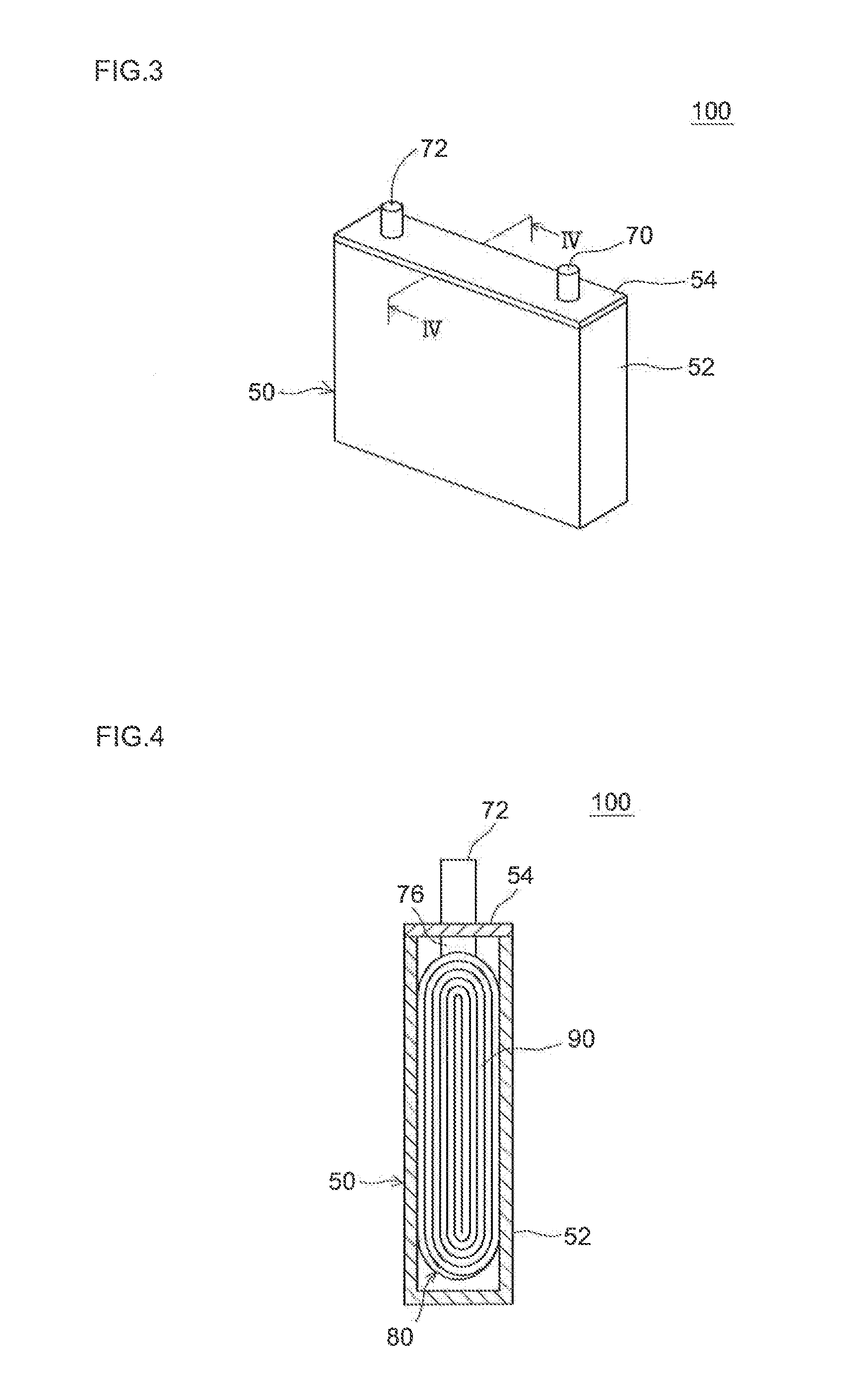

ActiveUS20140154583A1Excellent high rate characteristicsIncreased durabilityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsInorganic materialsElectrolyte

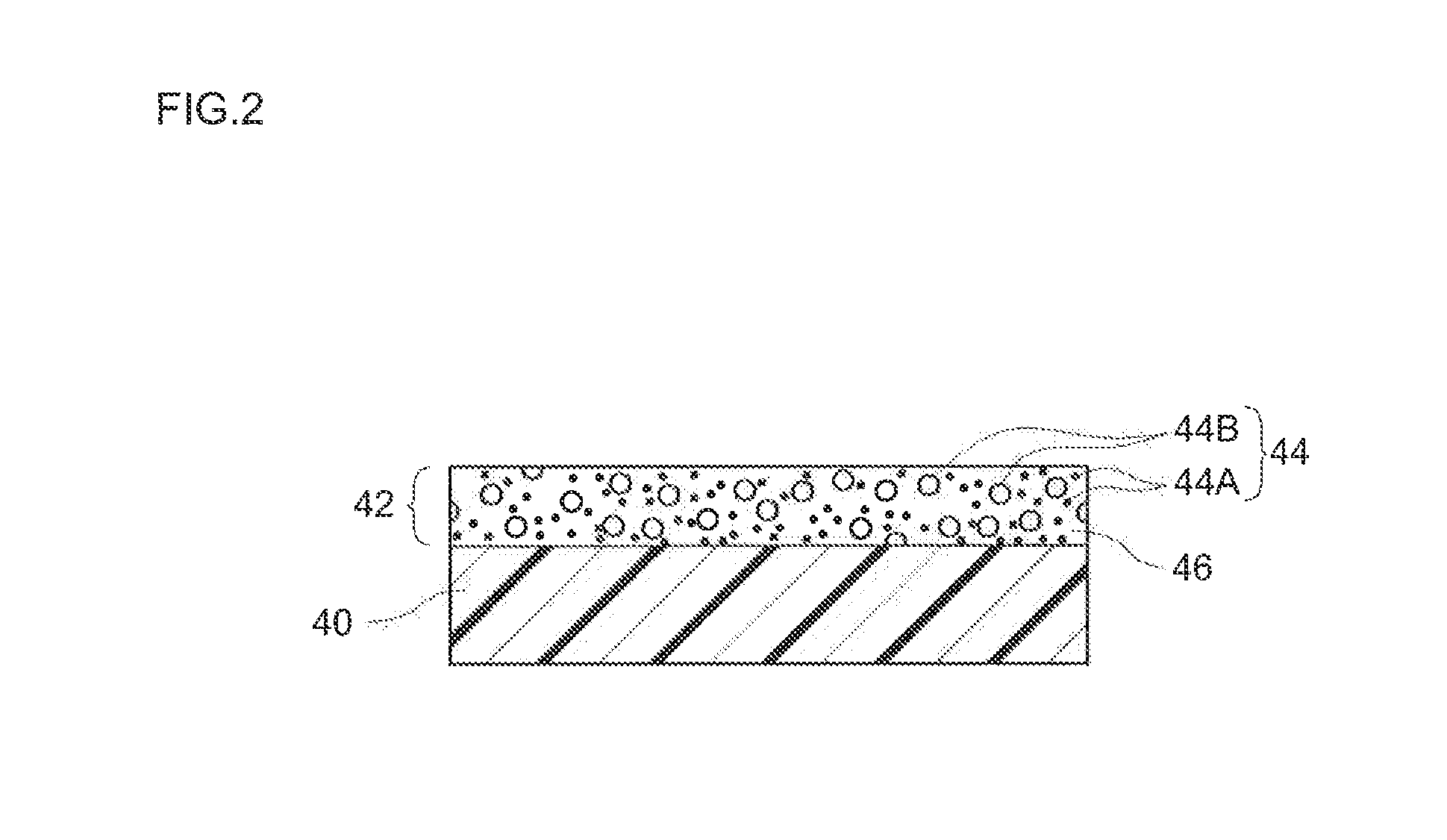

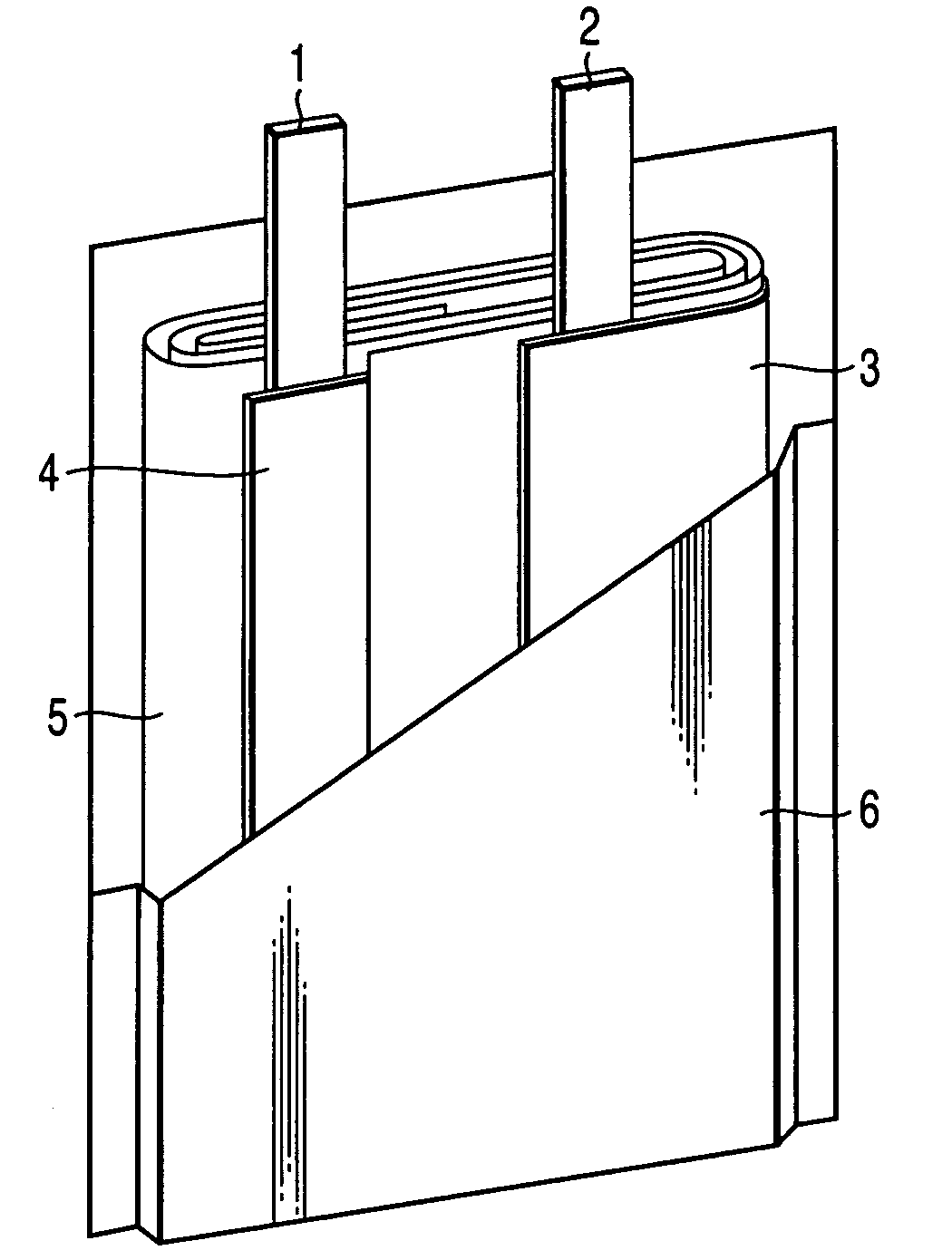

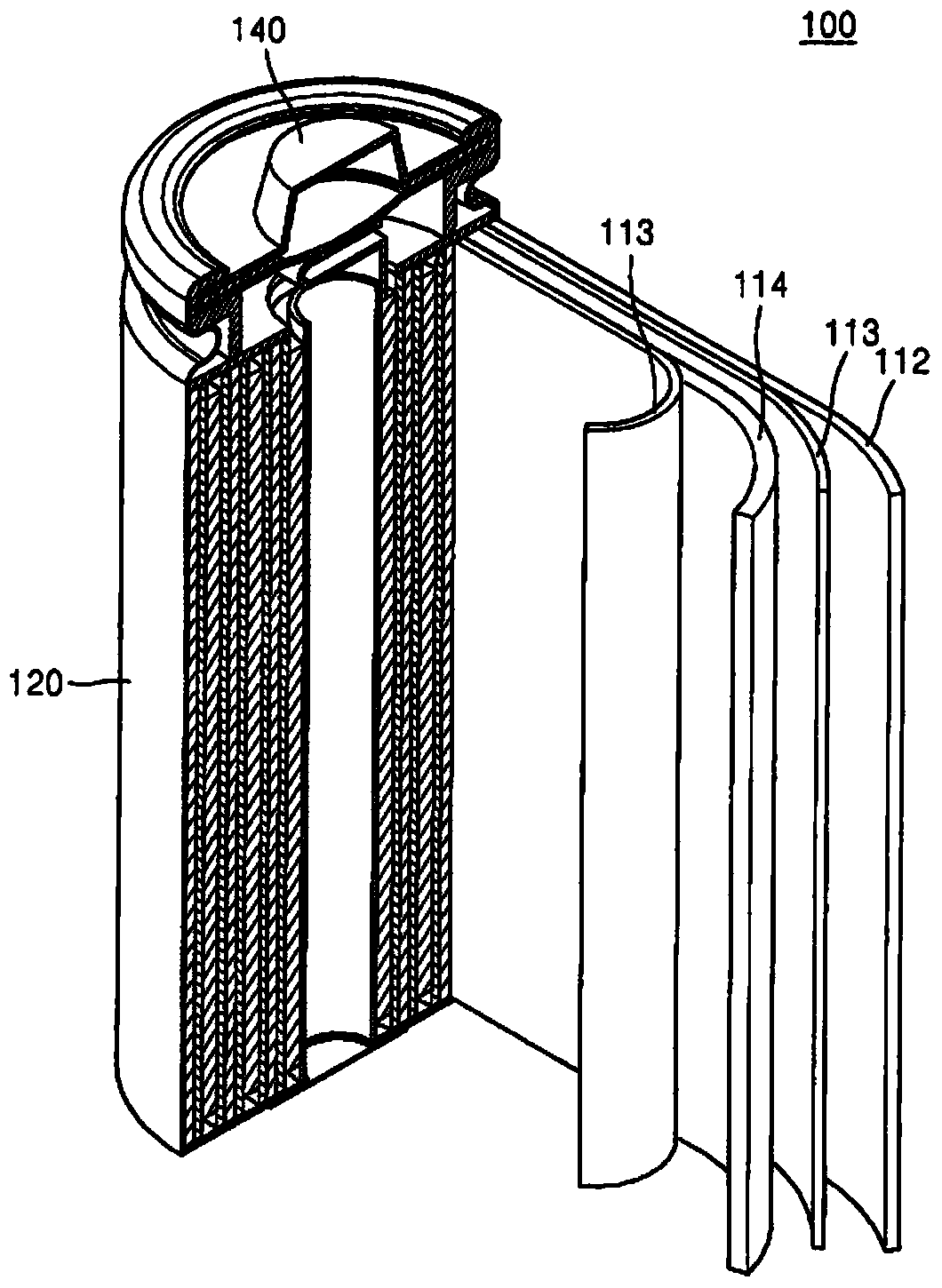

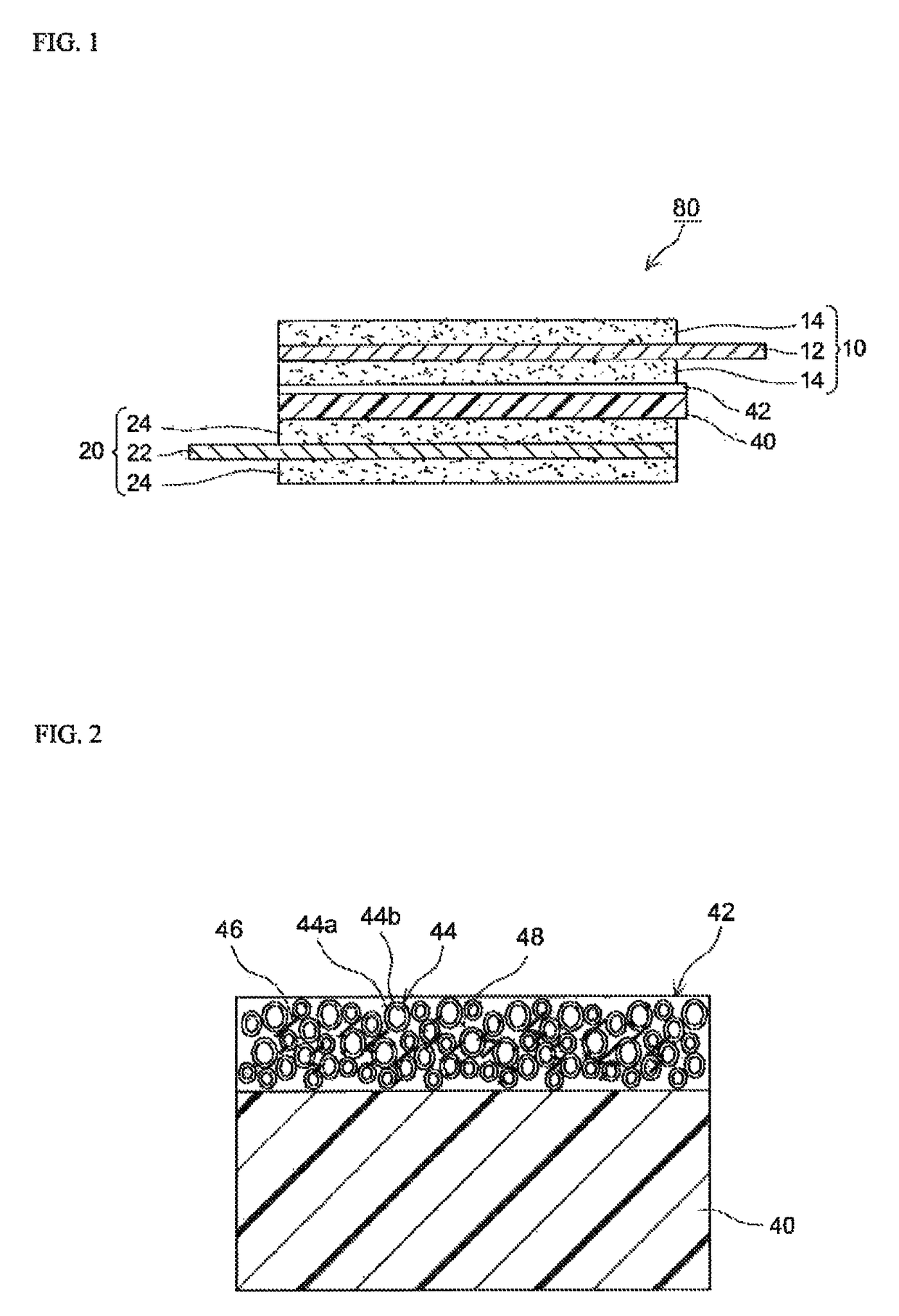

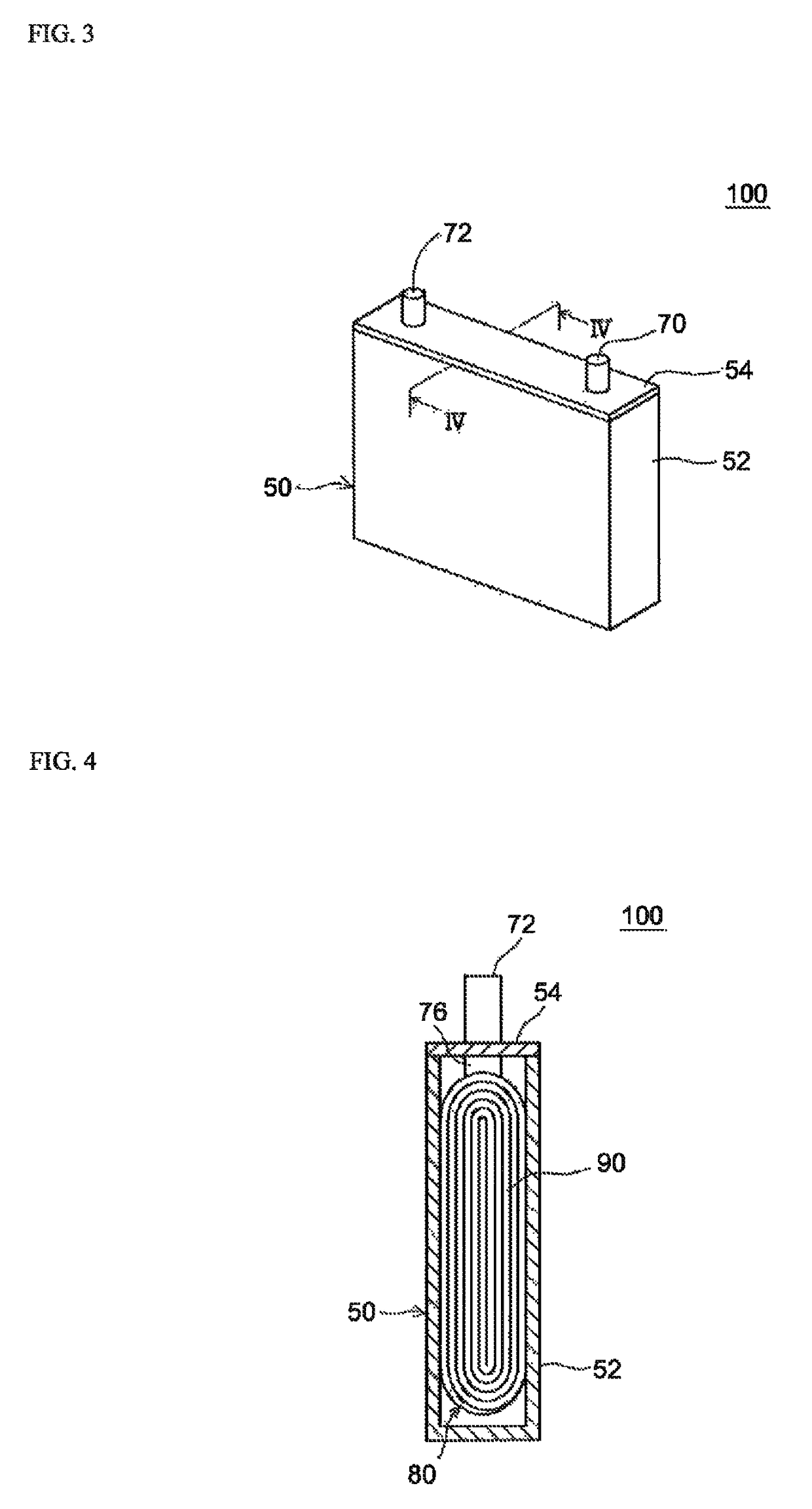

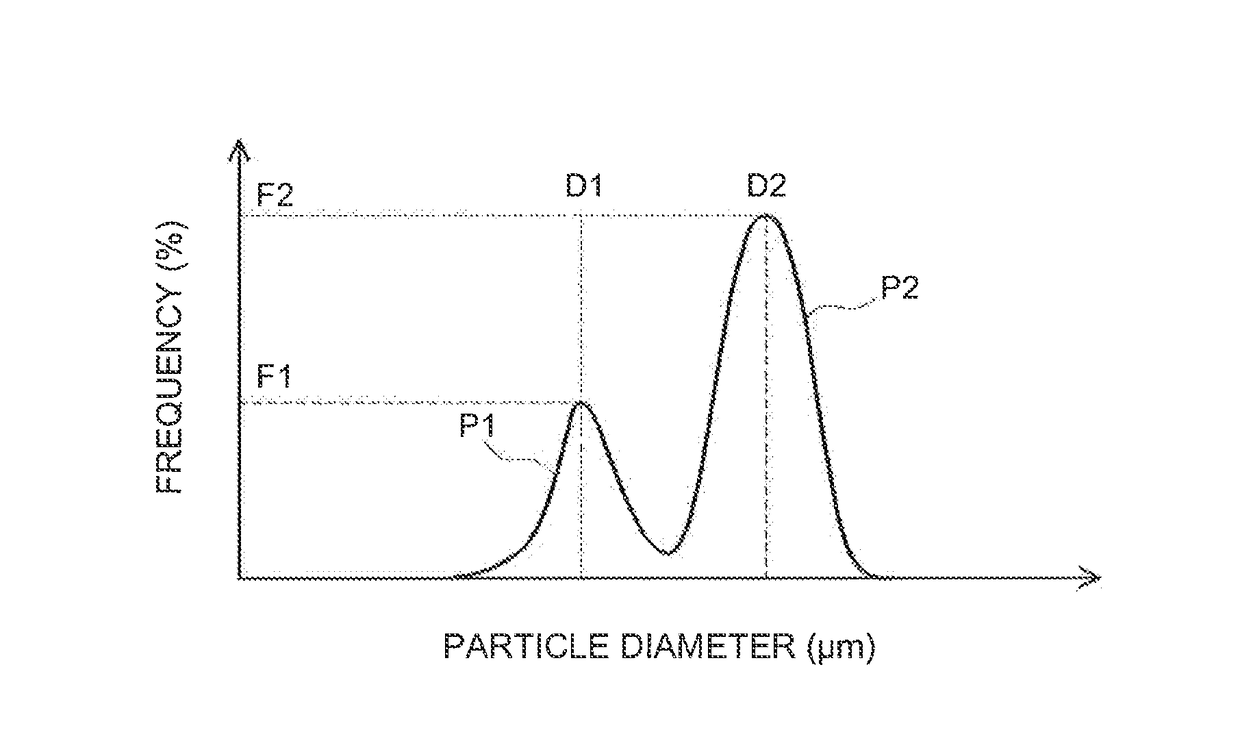

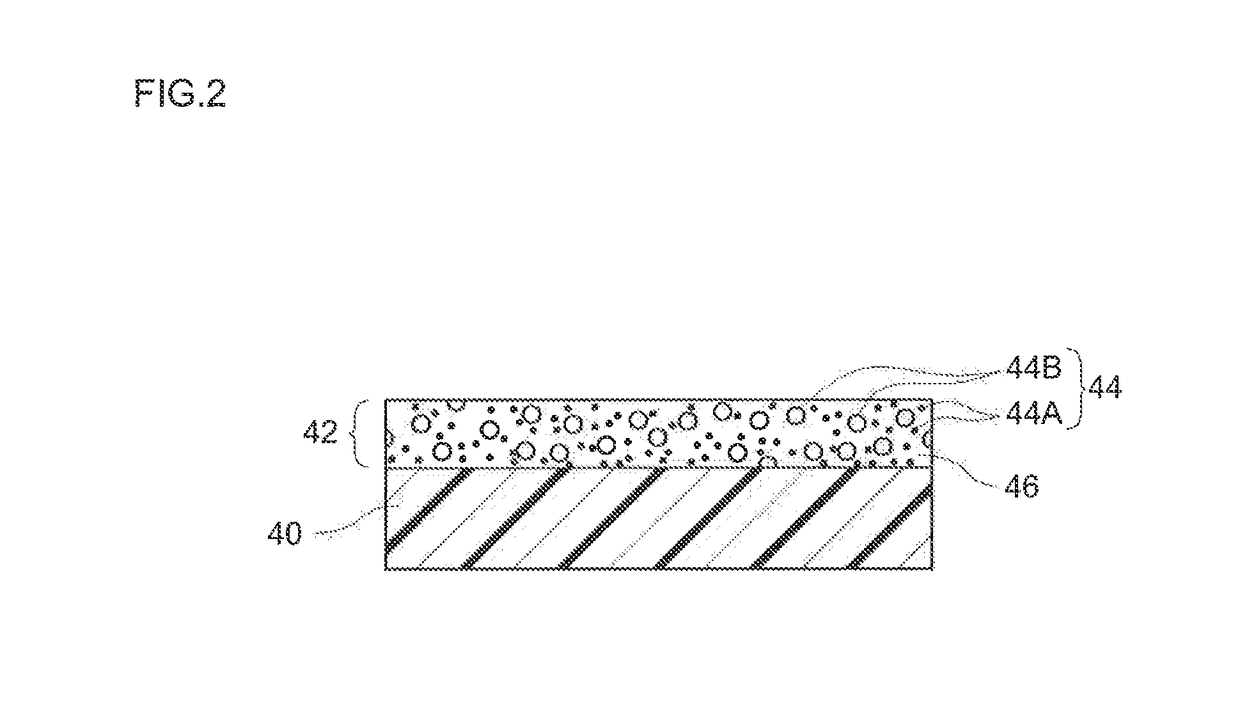

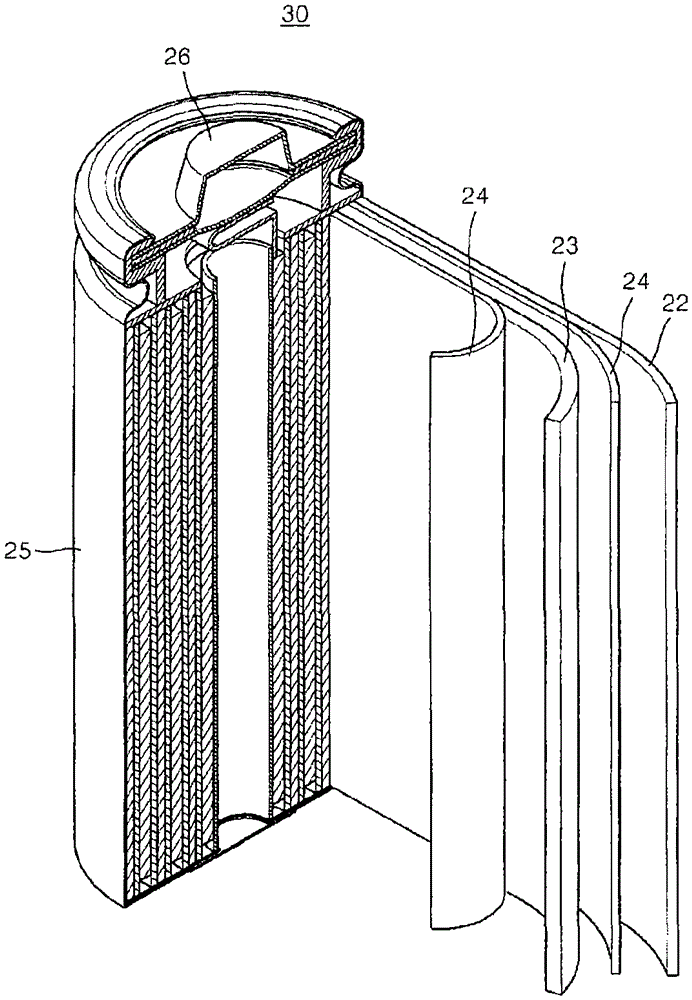

A nonaqueous electrolyte secondary battery 100 according to this invention includes a positive electrode 10, a negative electrode 20, a separator 40 interposed between the positive electrode 10 and the negative electrode 20, and a nonaqueous electrolyte solution. A porous heat-resistant layer 42 is additionally provided between the separator 40 and at least one electrode from among the positive electrode 10 and the negative electrode 20. The porous heat-resistant layer 42 includes hollow particles 44 made of an inorganic material, and a binder 46.

Owner:TOYOTA JIDOSHA KK

Additive for non-aqueous electrolyte solution of secondary battery and non-aqueous electrolyte secondary battery

InactiveUS7695862B2Increase powerLow viscosityElectrolytic capacitorsOrganic electrolyte cellsHigh rateOxygen

The invention is concerned with an additive for a non-aqueous electrolyte of a secondary battery having a high ability dissolving a support salt and a low viscosity and comprising a phosphazene derivative represented by the following formula (I):(wherein R1 is independently a halogen element or a monovalent substituent; and X is an organic group containing at least one element selected from the group consisting of carbon, silicon, nitrogen, phosphorus, oxygen and sulfur) as well as a non-aqueous electrolyte secondary battery comprising an electrolyte containing this additive and having excellent high-rate characteristics.

Owner:BRIDGESTONE CORP

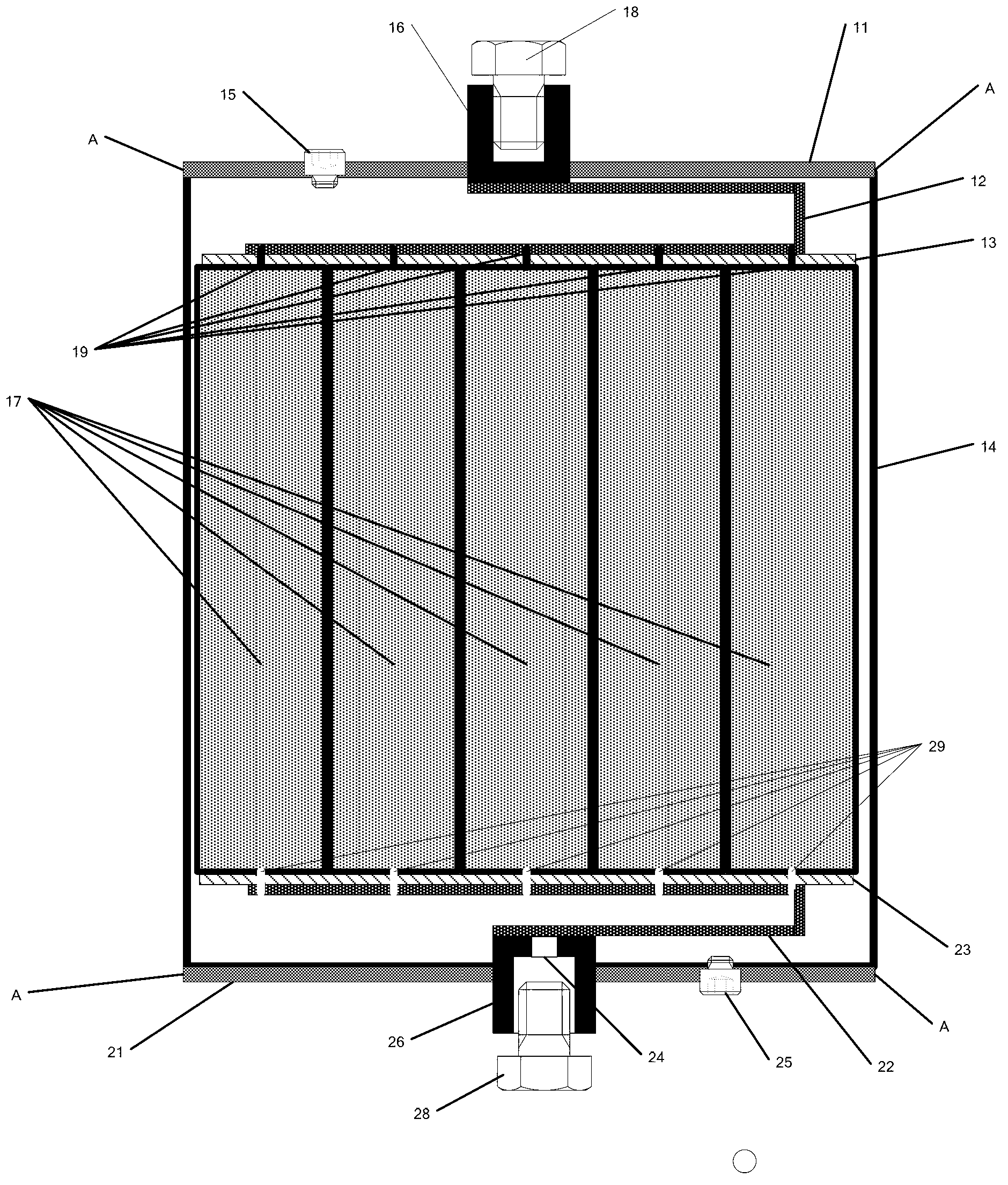

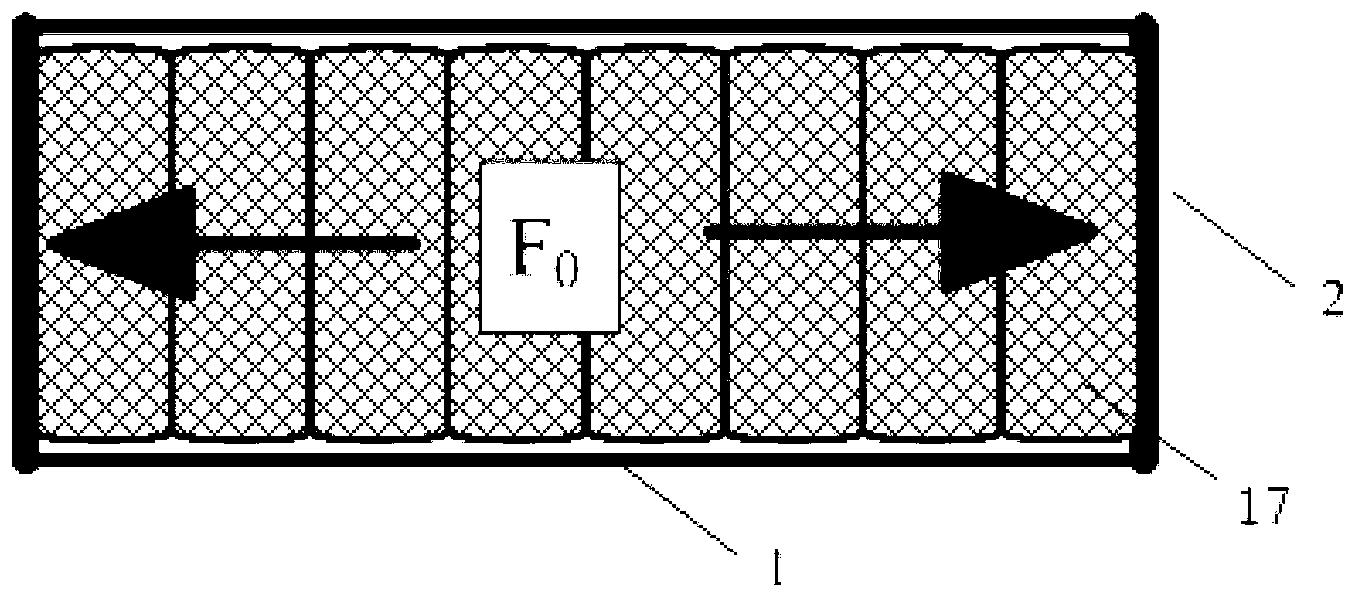

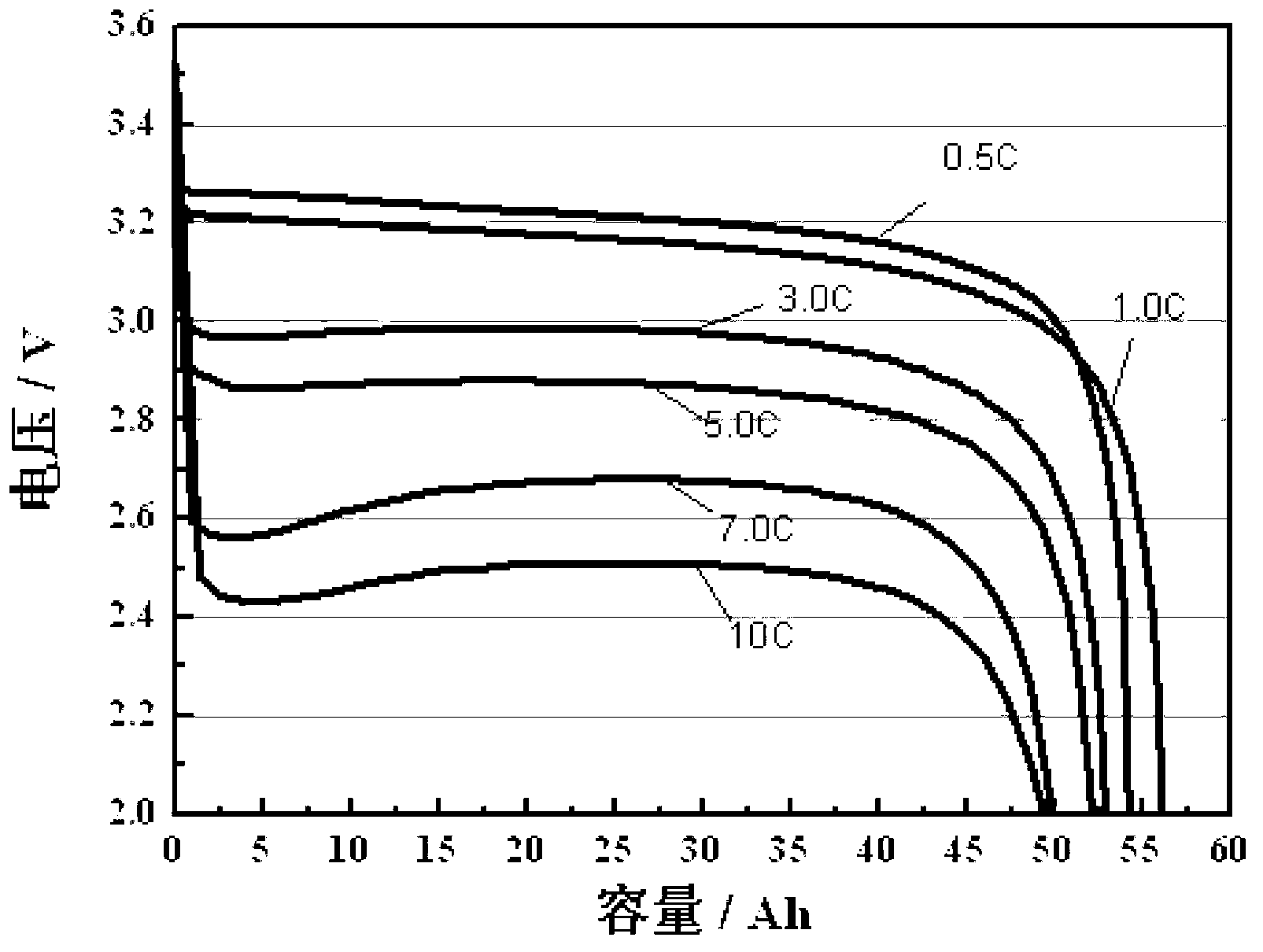

Square lithium ion battery with prestress structure

InactiveCN102800894AReduce bulge phenomenonIncrease stressFinal product manufactureSecondary cellsLithium-ion batteryBattery cell

The invention discloses a square lithium ion battery with a prestress structure. The square lithium ion battery comprises a battery cell, a battery shell used for packaging the battery cell, and an electrolyte, wherein the cross section of the battery shell is rectangular, the thicknesses on the battery shell are different, the thickness of the short edge of the battery shell is larger than that of the long edge of the battery shell; and the battery cell comprises a plurality of square coiling battery cells which are compressed in parallel, is installed in the battery shell and is matched with the battery shell tightly, and the distribution direction of the square coiling battery cell is parallel to the direction of the short edge of the battery shell. According to the square lithium ion battery with the prestress structure provided by the invention, the compression strength of the whole battery is improved, and the shell expansion in the charging and discharging processes of the battery is prevented.

Owner:ZHEJIANG GODSEND POWER TECH

Preparation method of carbon/cobalt/graphene composite nanofiber anode material

InactiveCN106159211AReduce production stepsIncrease energy densityCell electrodesNanotechnologyN dimethylformamideHigh magnification

The invention discloses a preparation method of a carbon / cobalt / graphene composite nanofiber anode material and belongs to the technical field of nanomaterials and chemical power sources. According to the method, polyacrylonitrile, cobalt chloride, graphene and N,N-dimethylformamide are used as raw materials. A precursor, namely, PNA / CoCl2 / graphene composite nanofiber membrane is prepared through electrostatic spinning firstly, then the obtained composite nanofiber membrane is placed in a high-temperature tube furnace to be carbonized, and the carbon / cobalt / graphene composite nanofiber anode material is obtained. The material prepared with the method can be directly applied to lithium ion batteries, no additive is required, production steps of the batteries are effectively reduced, and the energy density of the batteries is improved. The carbon / cobalt / graphene composite nanofiber anode material prepared with the method has excellent electrochemical properties, good cycle performance and the good high-magnification characteristic, so that the material used as a new-generation anode material for the lithium ion batteries has broad development and application prospect.

Owner:JIANGNAN UNIV

Phosphorus Compound And Preparation Method Thereof, Electrolyte For Lithium Secondary Battery And Lithium Secondary Battery Including The Same

InactiveCN104109172AExcellent high rate characteristicsImprove featuresCell electrodesGroup 5/15 element organic compoundsElectrical batteryPhysical chemistry

Owner:SAMSUNG SDI CO LTD

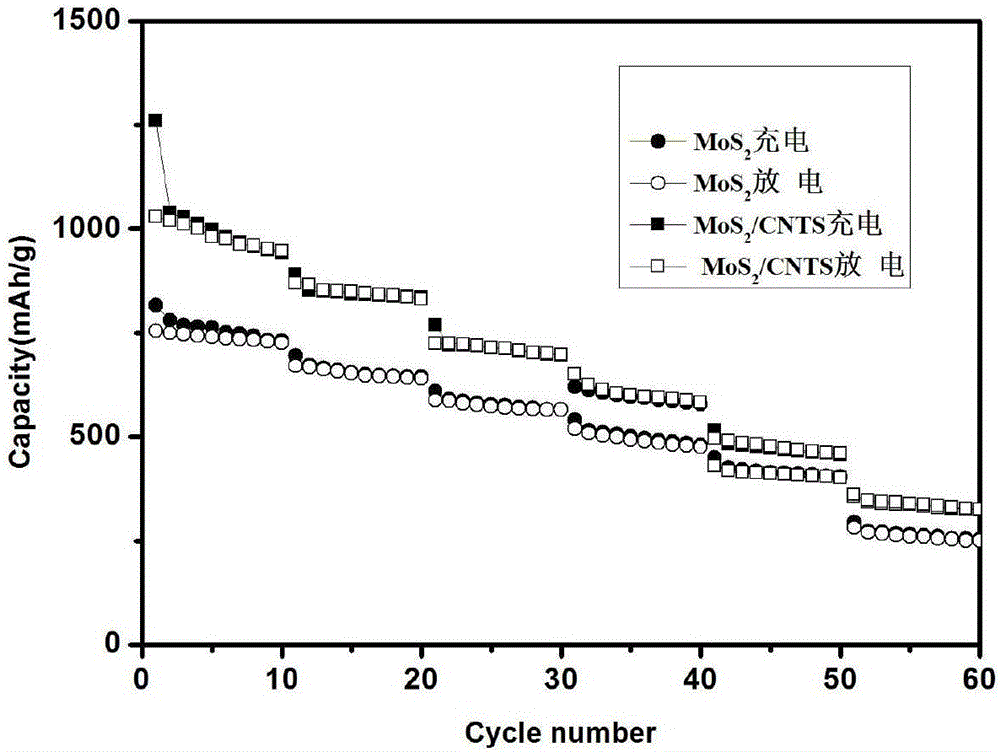

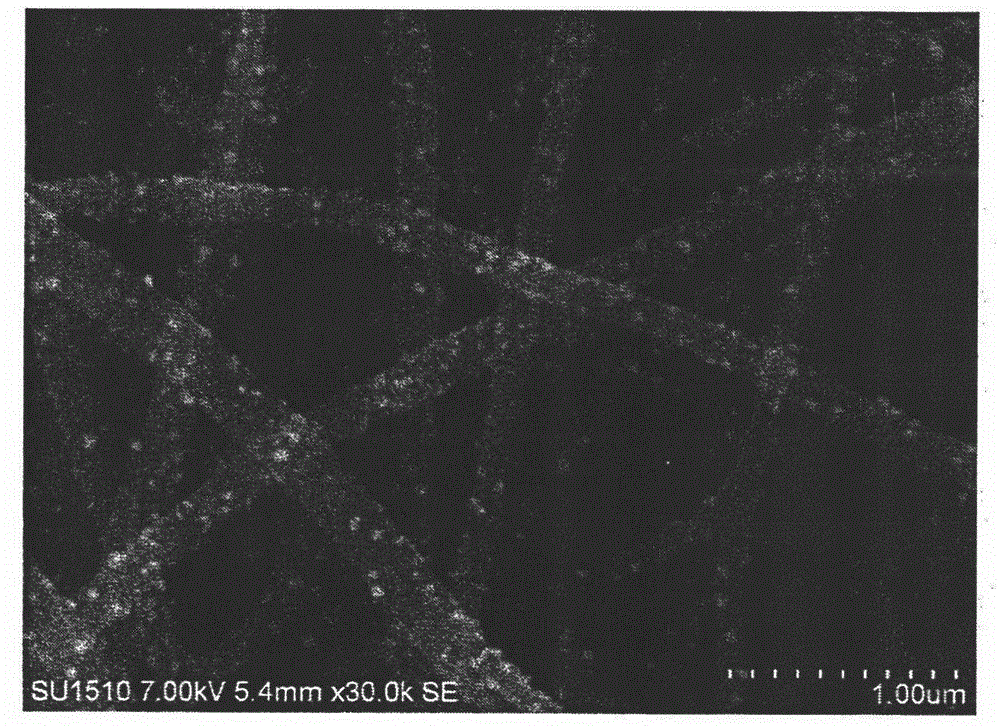

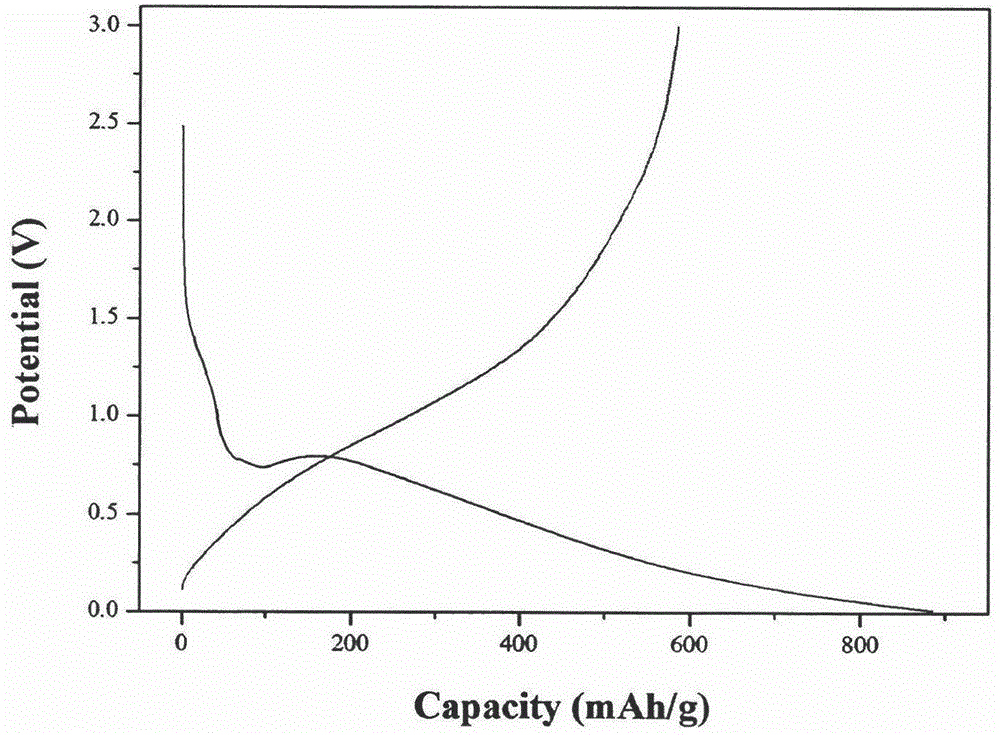

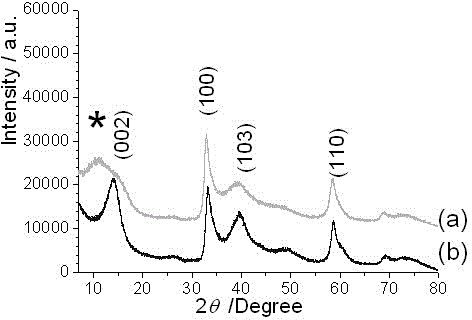

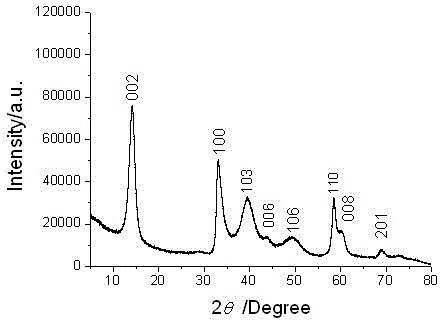

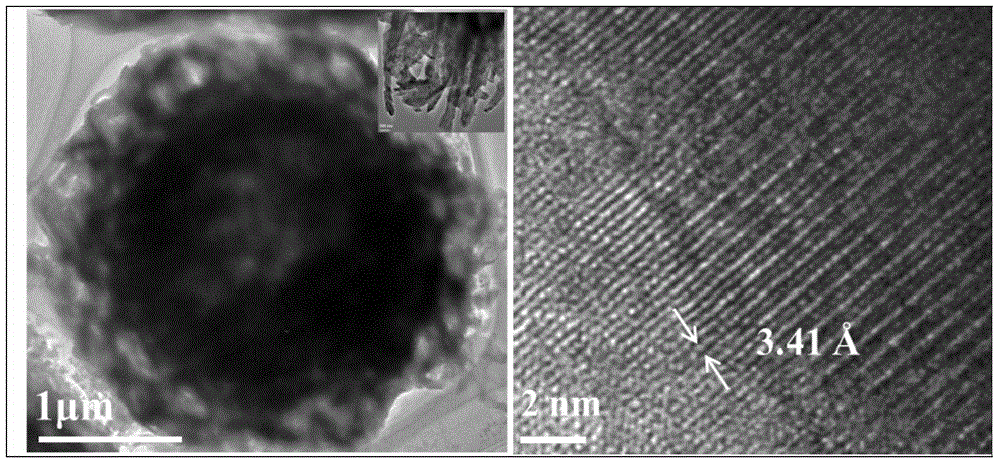

Preparation method of graphene-like MoS2/graphene combined electrode of lithium ion battery

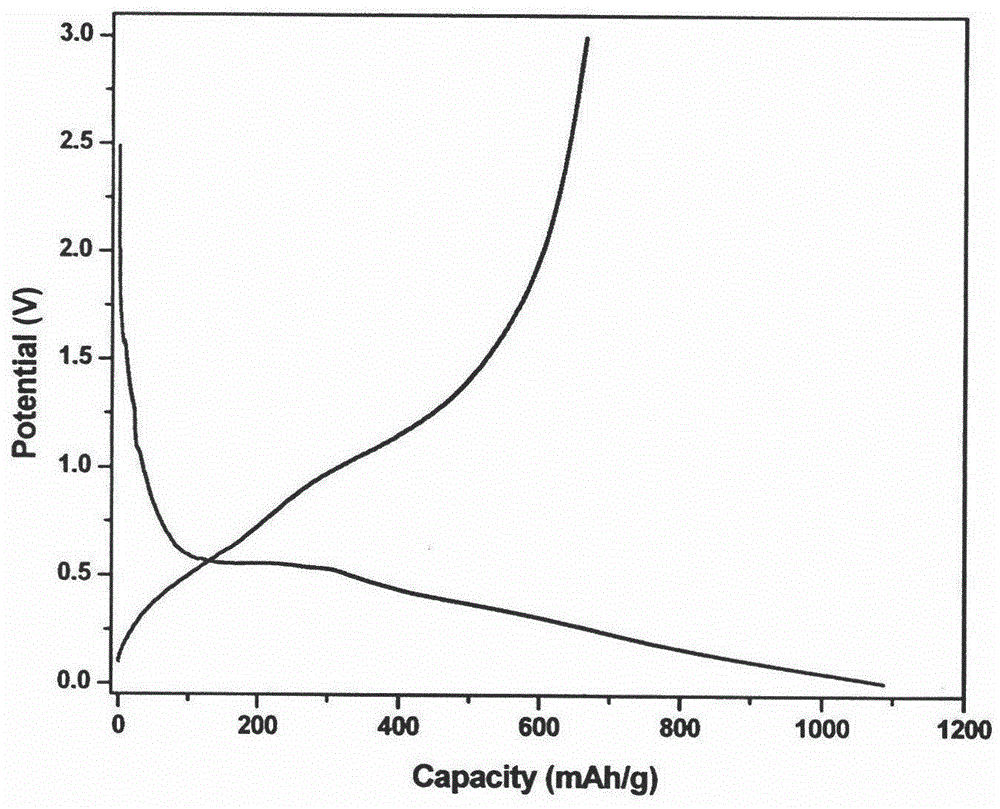

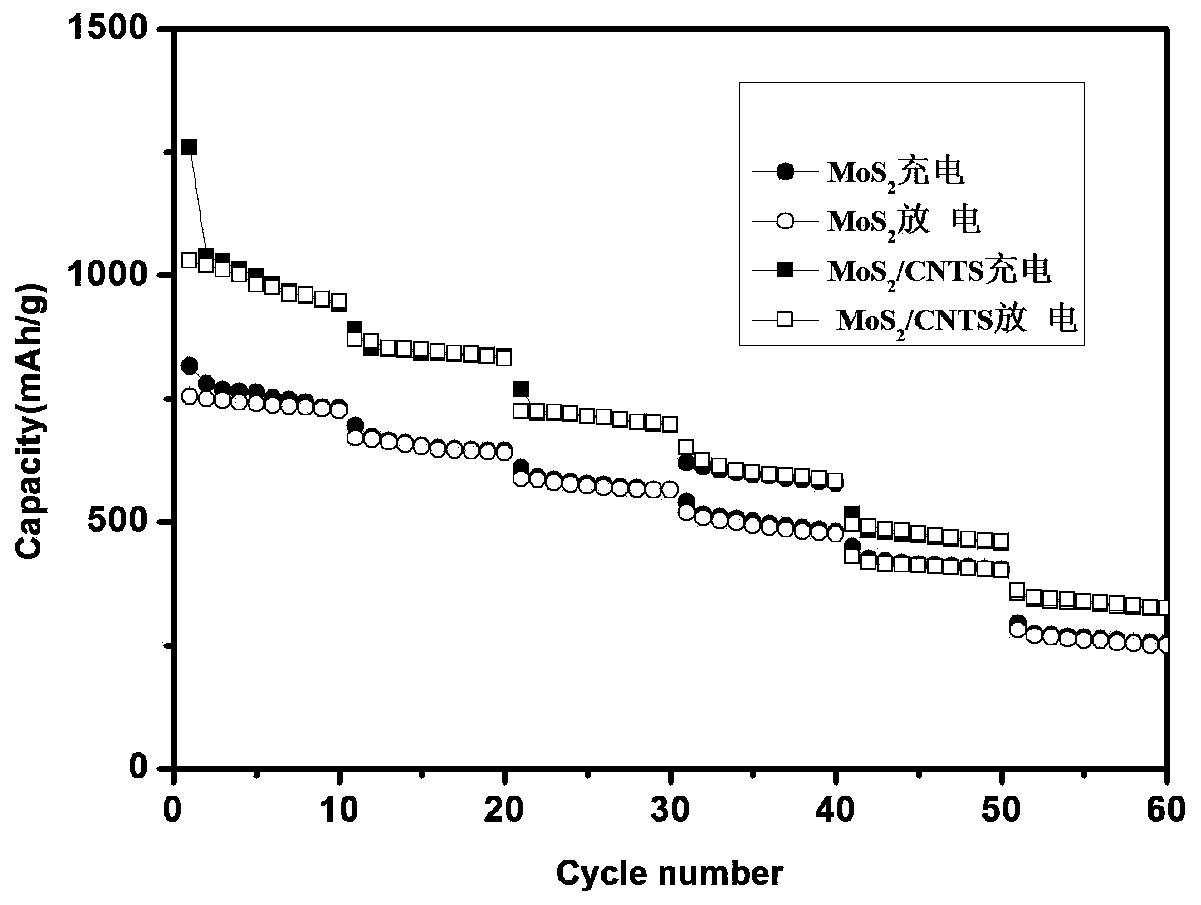

ActiveCN102683647BAdjust the average number of layersGood dispersionCell electrodesActive agentOrganosolv

The invention relates to a preparation method of a graphene-like MoS2 / graphene combined electrode of a lithium ion battery. The preparation method comprises the following steps of: dispersing oxidized graphene ultrasonically in deionized water, stirring, and firstly adding a cationic surfactant; then adding L-aminothiopropionic acid and sodium molybdate sequentially; transferring the obtained mixed dispersing system to a hydrothermal reaction kettle, and reacting at 220-250 DEG C for 24 hours, then cooling naturally, collecting solid products centrifugally, washing with the deionized water, drying, and carrying out heat treatment in a nitrogen / hydrogen mixed atmosphere, thereby obtaining a graphene-like MoS2 and graphene combined nano material of single layer or 2-4 layers on average; and mixing the graphene-like MoS2 and graphene combined nano material and acetylene black as well as polyvinylidene fluoride into paste, and coating the paste on a copper foil and rolling, thereby obtaining the electrode. The preparation method provided by the invention is simple in process, and organic solvents are not required to be consumed; the lithium ion battery combined electrode has the advantages of high electrochemistry lithium storage specific capacity, stable circulating performance, and good high-multiplying-power charging and discharging performance.

Owner:ZHEJIANG UNIV

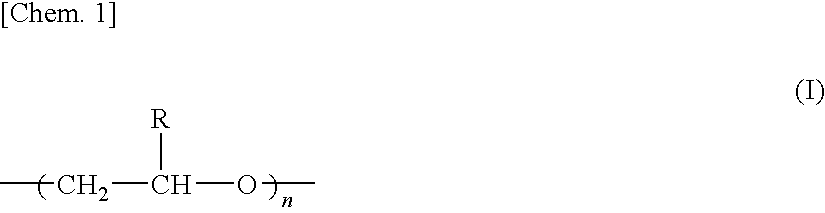

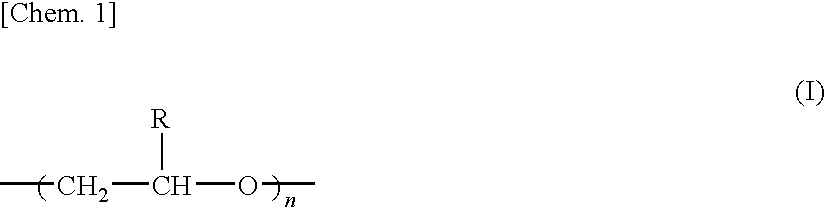

Crosslinking polymer-supported porous film for battery separator and use thereof

InactiveUS20100183908A1Improve ionic conductivityLow internal resistanceFinal product manufacturePrimary cellsPolymer supportedSide chain

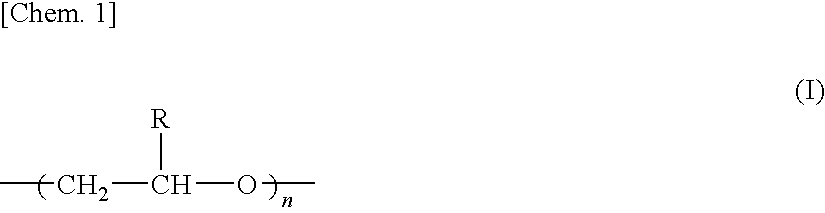

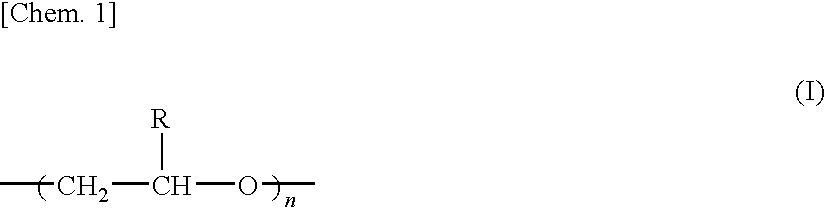

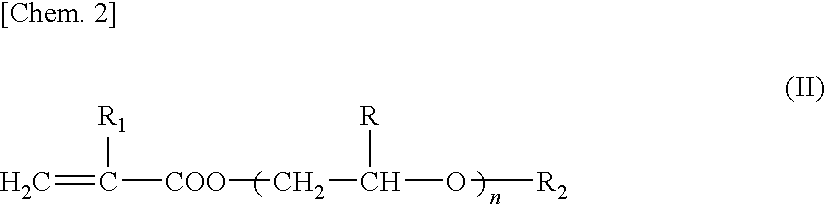

The present invention relates to a crosslinking polymer-supported porous film for battery separator, including: a porous film; and a crosslinking polymer supported on the porous film, the crosslinking polymer having a plurality of cation-polymerizable functional groups in the molecule thereof and having oxyalkylene groups represented by general formula (I):in which the Rs may be the same or different and each independently represent a hydrogen atom or a methyl group, and n represents an integer of 4 to 9, in a side chain thereof.

Owner:NITTO DENKO CORP +1

Electrode for lithium secondary battery and lithium secondary battery including the same

InactiveUS9287563B2Improved high-rate characteristic and lifetime characteristic and interior resistance characteristicExcellent high rate characteristicsFinal product manufactureSecondary cell gas removalEngineeringLithium-ion battery

An electrode for a lithium secondary battery includes an electrode active material, a conductive agent, and a polyurethane-based compound, and has pores having an average diameter of about 2 to about 20 nm. A lithium secondary battery includes the electrode.

Owner:SAMSUNG SDI CO LTD

A kind of lithium-ion battery multi-walled carbon nanotube/molybdenum disulfide composite electrode and preparation method

ActiveCN106711413BHigh electrochemical lithium storage specific capacityPromote circulationCell electrodesSecondary cellsHigh rateLithium-ion battery

The invention provides a lithium-ion-battery multiwalled carbon nanotube / molybdenum disulfide combination electrode and a preparation method. According to the preparation method, multiwalled carbon nanotube, soluble molybdate and L-cysteine are adopted as materials, glucose and triton X-100 are used as additives, dispersion uniformity of MoS2 on the surface of the carbon nanotube is improved, and through an in-situ hydrothermal reduction method, a combination electrode material of MoS2 and the multiwalled carbon nanotube is synthesized. The material has high electrochemical storage lithium specific capacity, excellent cycle performance and a high-rate feature. Meanwhile, the synthetic method has the advantages of being moderate in reaction condition, simple in process, high in yield and good in repeatability.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

V2O5 hollow micron wire ball with nano wire three-dimensional winding structure and preparation method and application thereof

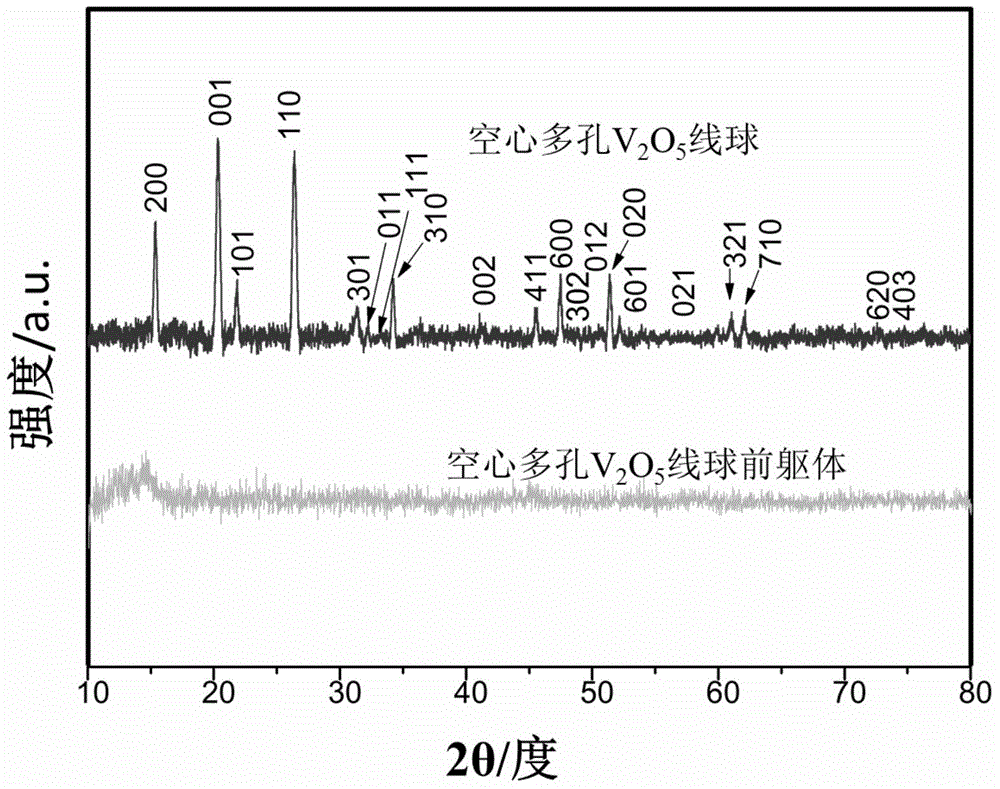

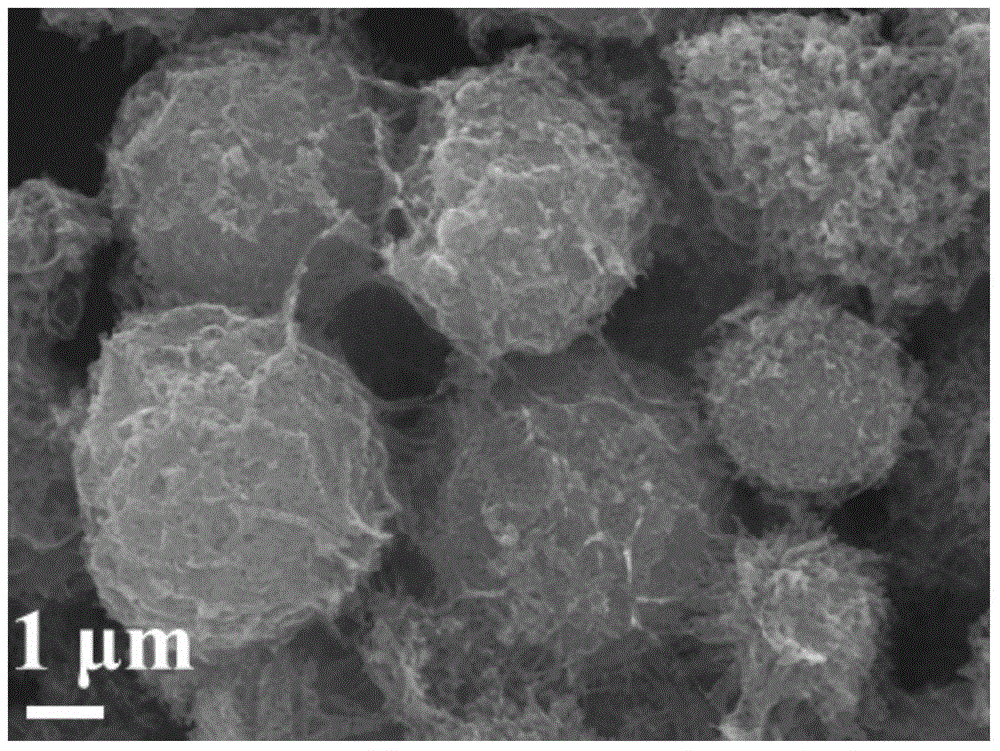

ActiveCN105118977AShorten the diffusion distanceImprove electrochemical performanceSecondary cellsPositive electrodesNanowireSolvent

The invention relates to a V2O5 hollow micron wire ball with a nano wire three-dimensional winding structure and a preparation method thereof. The method comprises the following steps: (1) measuring V2O5 gel, and diluting in deionized water to obtain a solution; (2) adding an organic solution into the solution obtain in the step (1) to obtain a solvent; (3) adding trihydroxymethyl aminomethane into the solution obtained in the step (2), and performing ultrasonic treatment for 0.5-2 hours; (4) transferring reactants obtained in the step (3) into a reaction kettle for hydrothermal reaction, taking out the reactants from the reaction kettle, and naturally cooling to room temperature; (5) centrifugally filtering the obtained products, washing by absolute ethyl alcohol, and drying in a drying box to obtain blue precursor powder; (6) putting the products obtained in the step (5) into a muffle furnace for calcining to obtain the V2O5 hollow micron wire ball. The V2O5 hollow micron wire ball has the beneficial effects of excellent circulating stability and good high-magnification characteristic, and is a potential application material for a lithium ion battery with high magnification and long life.

Owner:WUHAN UNIV OF TECH

Nonaqueous electrolyte secondary cell and cell assembly

ActiveUS20190252725A1Avoid depositionImprove battery performanceSecondary cellsNegative electrodesParticulatesLithium

Owner:TOYOTA JIDOSHA KK

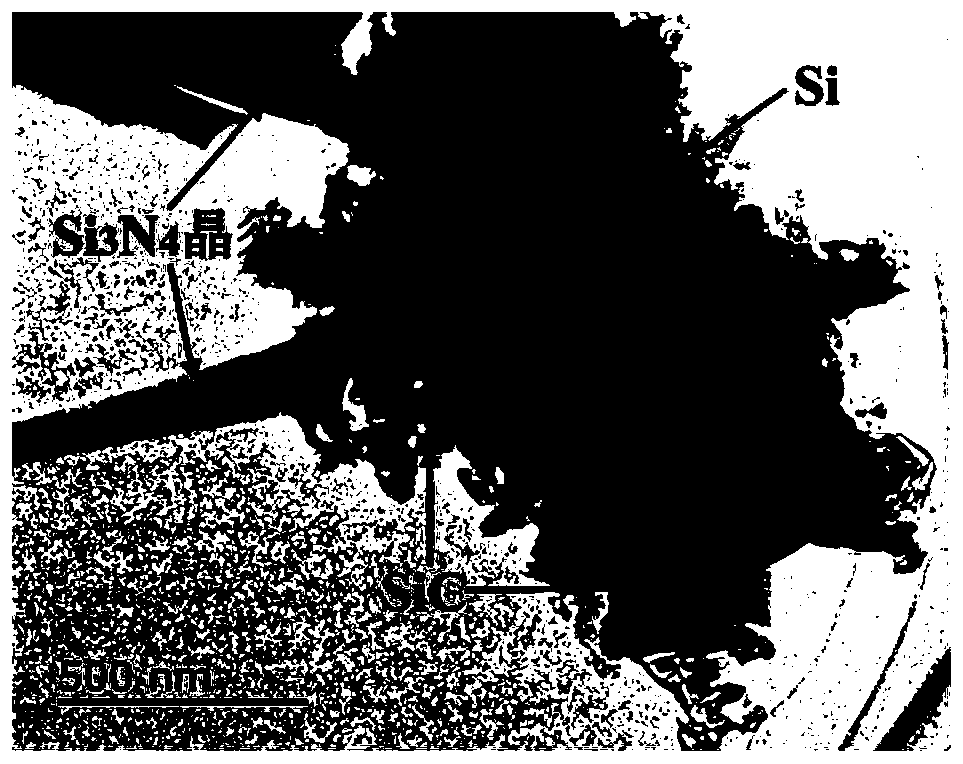

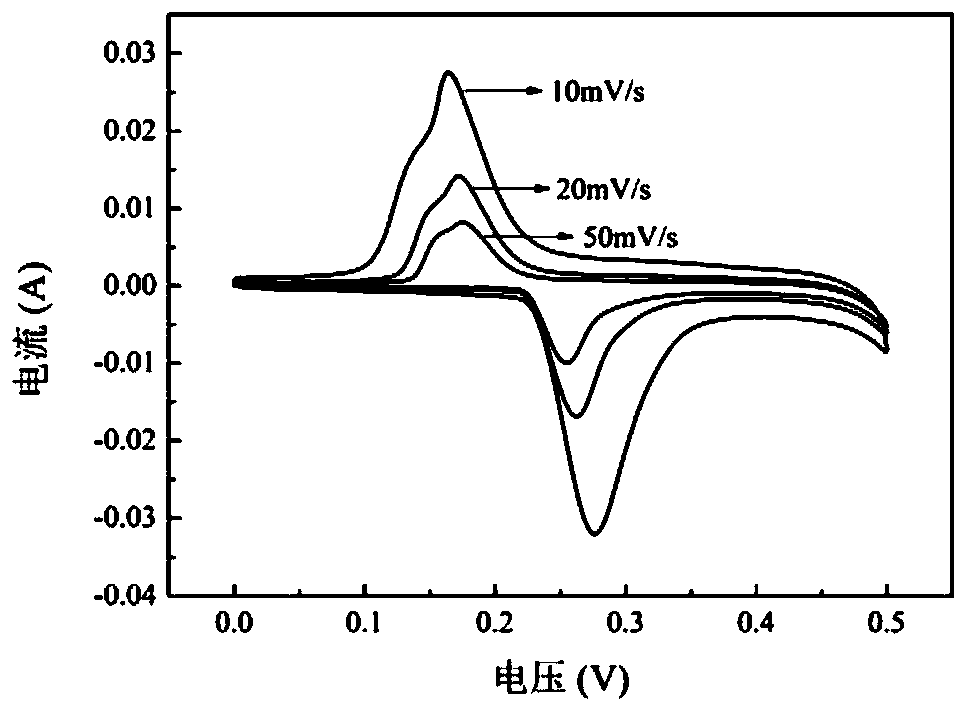

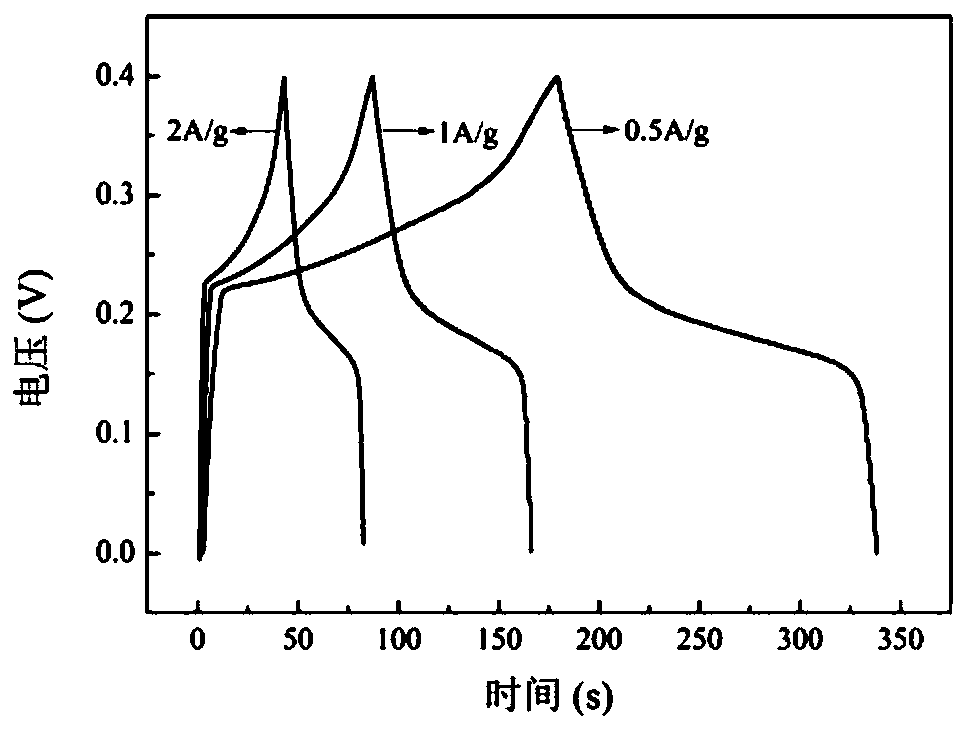

Si@SiC-Si3N4 electrode material based on catalytic nitridation method and preparation method thereof

ActiveCN110937604ASimple processSuitable for mass productionNitrogen compoundsSiliconPtru catalystAlcohol

The invention relates to a Si@SiC-Si3N4 electrode material based on a catalytic nitridation method and a preparation method thereof. The method comprises the following steps: dissolving 5-25 parts bymass of a catalyst in 1000 parts by mass of absolute ethyl alcohol, carrying out magnetic stirring for 15-20min, adding 100 parts by mass of silicon powder into the solution, carrying out magnetic stirring for 15-20min, adding 12.5-20 parts by mass of a liquid phenolic resin into the mixed solution, carrying out magnetic stirring for 25-30min, drying the solution at 90-110 DEG C for 24-30h to obtain a catalyst-loaded precursor, under the nitrogen atmosphere condition, heating the catalyst-loaded precursor to 1250-1350 DEG C at a rate of 4-5 DEG C / min, carrying out heat preservation for 2-3h, then heating the catalyst-loaded precursor to 1400-1450 DEG C at a rate of 2-3 DEG C / min, carrying out heat preservation for 3-4h, and carrying out natural cooling so as to obtain the Si@SiC-Si3N4 electrode material based on the catalytic nitridation method. According to the invention, the cost is low, the production process is simple, and the prepared product has excellent morphological characteristics, pseudocapacitance characteristics and excellent capacitance and high-rate performance.

Owner:WUHAN UNIV OF SCI & TECH

Nonaqueous electrolyte secondary battery

ActiveUS9595745B2Excellent high rate characteristicsIncreased durabilityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsInorganic materialsMaterials science

A nonaqueous electrolyte secondary battery 100 according to this invention includes a positive electrode 10, a negative electrode 20, a separator 40 interposed between the positive electrode 10 and the negative electrode 20, and a nonaqueous electrolyte solution. A porous heat-resistant layer 42 is additionally provided between the separator 40 and at least one electrode from among the positive electrode 10 and the negative electrode 20. The porous heat-resistant layer 42 includes hollow particles 44 made of an inorganic material, and a binder 46.

Owner:TOYOTA JIDOSHA KK

Nonaqueous electrolyte secondary battery

ActiveUS9673436B2Improve ion permeabilityExcellent high rate characteristicsFinal product manufactureLi-accumulatorsDiameter ratioLarge particle

The nonaqueous electrolyte secondary battery of the present invention has a positive electrode, a negative electrode, a separator interposed between the positive electrode and the negative electrode, and a nonaqueous electrolyte solution. The battery further has a porous heat-resistant layer provided between the separator and at least one of the positive electrode and the negative electrode, wherein the porous heat-resistant layer includes an inorganic filler and a binder. The inorganic filler included in the porous heat-resistant layer has a particle size distribution with two peaks, which are a first peak (P1) at a relatively small particle diameter and a second peak (P2) at a relatively large particle diameter. When the particle diameter of the first peak (P1) is D1 be and the particle diameter of the second peak (P2) is D2 being, the peak particle diameter ratio D1 / D2 satisfies the condition 0.2≦D1 / D2≦0.7.

Owner:TOYOTA JIDOSHA KK

Electrode for lithium rechargeable battery and lithium rechargeable battery comprising same

InactiveCN102610789BExcellent high rate characteristicsGood internal resistanceLi-accumulatorsNon-aqueous electrolyte accumulator electrodesEngineeringLithium-ion battery

An electrode for a lithium rechargeable battery including an electrode active material and a polyurethane-based compound, and having pores having an average diameter of 2 to 20 nm, and a lithium secondary battery including the electrode

Owner:SAMSUNG SDI CO LTD

Crosslinking polymer-supported porous film for battery separator and use thereof

InactiveUS8420247B2Lower internal resistanceExcellent high rate characteristicsFinal product manufactureLi-accumulatorsHydrogen atomPolymer science

The present invention relates to a crosslinking polymer-supported porous film for battery separator, including: a porous film; and a crosslinking polymer supported on the porous film, the crosslinking polymer having a plurality of cation-polymerizable functional groups in the molecule thereof and having oxyalkylene groups represented by general formula (I):in which the Rs may be the same or different and each independently represent a hydrogen atom or a methyl group, and n represents an integer of 4 to 9, in a side chain thereof.

Owner:NITTO DENKO CORP +1

Separation film for secondary battery and the secondary battery

PendingCN113067103AImprove heat resistanceHigh ion conductivitySecondary cellsCell component detailsElectrolytic agentPhysical chemistry

The present invention relates to a separation film for a secondary battery and the secondary battery. The secondary battery separator has excellent heat resistance and ion conductivity, has less heat-induced shrinkage, and is not easy to swell in the electrolyte at high temperatures. Moreover, a composite porous separation film containing binder polymers and inorganic particles (at least one selected from the group consisting of metal oxide particles and metal hydroxide particles) in the separation film is firmly bonded to a porous body .

Owner:DAIKIN IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com