Si@SiC-Si3N4 electrode material based on catalytic nitridation method and preparation method thereof

An electrode material, nitriding technology, applied in chemical instruments and methods, nitrogen compounds, carbon compounds, etc., can solve the problems of limited porous materials, poor electrochemical performance, etc., and achieve low price, low cost, and excellent morphological characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A Si@SiC-Si Based on Catalytic Nitriding Method 3 N 4 Electrode material and its preparation method. The preparation method described in this embodiment is:

[0035] Step 1. Dissolve 5 parts by mass of catalyst in 1000 parts by mass of absolute ethanol, stir magnetically for 20 minutes, then add 100 parts by mass of silicon powder, stir magnetically for 15 minutes, then add 12.5 parts by mass of liquid phenolic resin, and stir magnetically 30 min, and finally dried at 90° C. for 30 h to obtain a catalyst-loaded precursor.

[0036] Step 2. Under nitrogen atmosphere conditions, first raise the temperature of the catalyst-loaded precursor to 1250°C at a rate of 4°C / min, and keep it for 3 hours; then raise the temperature to 1400°C at a rate of 2°C / min, keep it for 4 hours, cooling to prepare Si@SiC-Si based on catalytic nitridation method 3 N 4 electrode material.

[0037] The catalyst is iron nitrate nonahydrate.

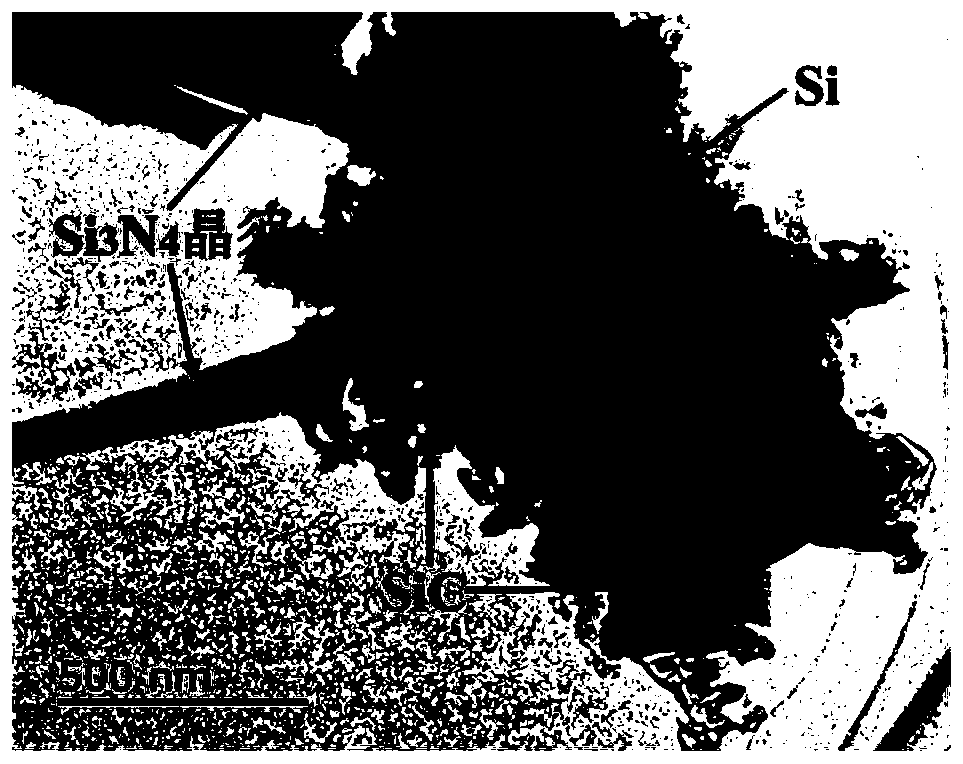

[0038] Si@SiC-Si based on catalytic nitridation me...

Embodiment 2

[0040] A Si@SiC-Si Based on Catalytic Nitriding Method 3 N 4 Electrode material and its preparation method. The preparation method described in this embodiment is:

[0041] Step 1. Dissolve 10 parts by mass of catalyst in 1000 parts by mass of absolute ethanol, stir magnetically for 18 minutes, then add 100 parts by mass of silicon powder, stir magnetically for 17 minutes, then add 14 parts by mass of liquid phenolic resin, and stir magnetically 29 minutes, and finally dried at 95° C. for 29 hours to obtain a catalyst-loaded precursor.

[0042] Step 2. Under the condition of nitrogen atmosphere, first raise the temperature of the catalyst-loaded precursor to 1280°C at a rate of 4°C / min, and keep it for 3 hours; cooling to prepare Si@SiC-Si based on catalytic nitridation method 3 N 4 electrode material.

[0043] The catalyst is nickel nitrate hexahydrate.

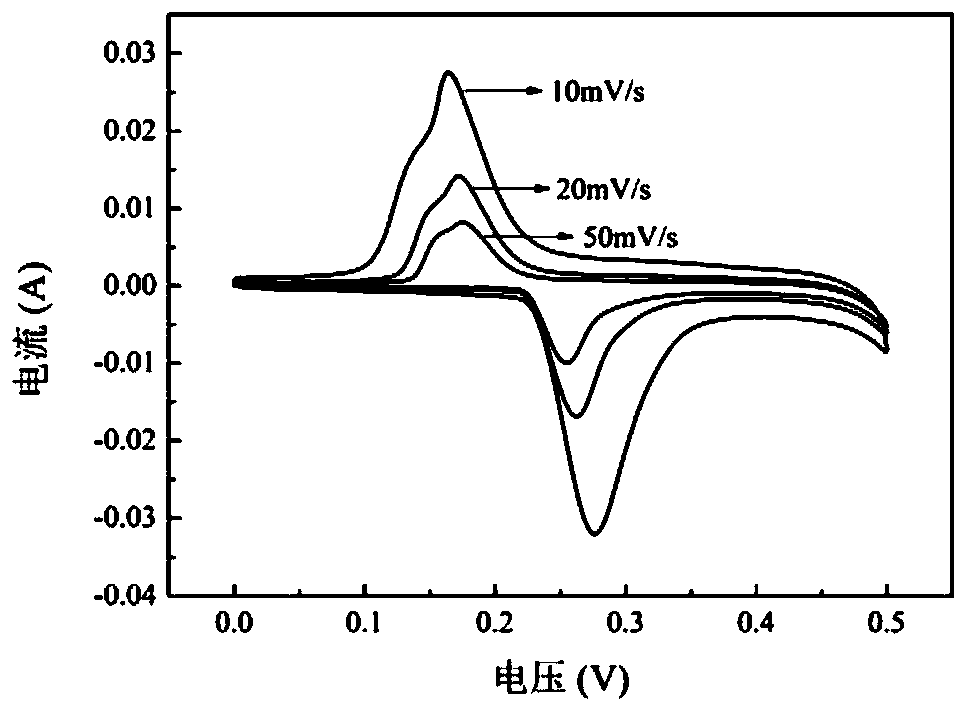

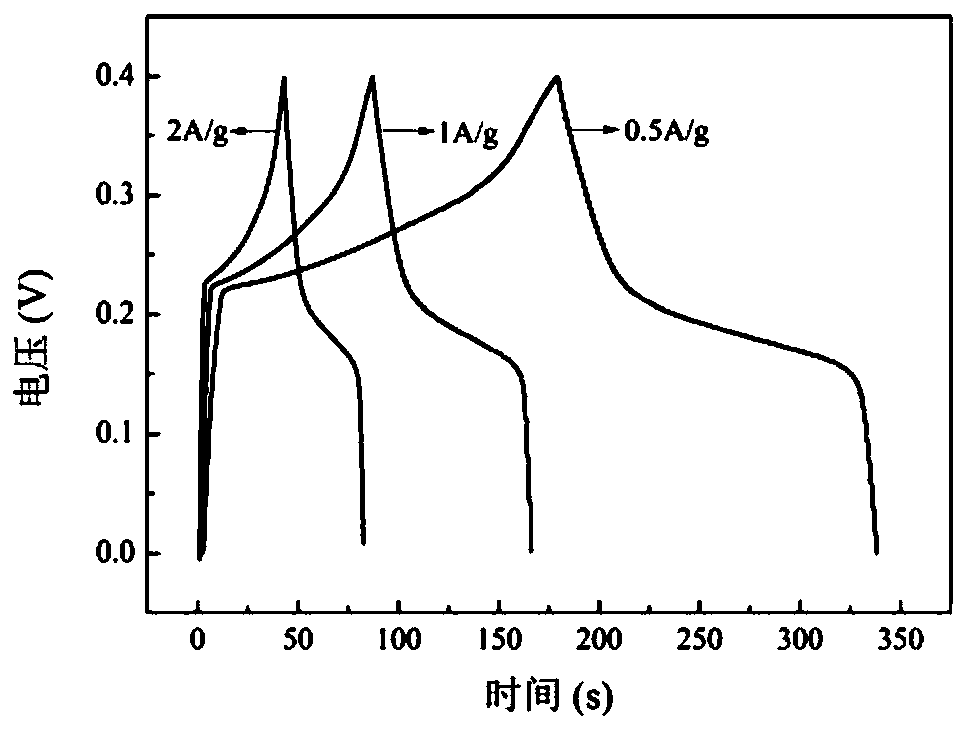

[0044] Si@SiC-Si based on catalytic nitridation method prepared in this example 3 N 4 The specific capacitance va...

Embodiment 3

[0046] A Si@SiC-Si Based on Catalytic Nitriding Method 3 N 4 Electrode material and its preparation method. The preparation method described in this embodiment is:

[0047] Step 1. Dissolve 15 parts by mass of catalyst in 1000 parts by mass of absolute ethanol, stir magnetically for 17 minutes, then add 100 parts by mass of silicon powder, stir magnetically for 18 minutes, then add 16 parts by mass of liquid phenolic resin, and stir magnetically 28min, and finally dried at 100°C for 28h to obtain a catalyst-loaded precursor.

[0048] Step 2. Under nitrogen atmosphere conditions, first raise the temperature of the catalyst-loaded precursor to 1300°C at a rate of 4.5°C / min and keep it warm for 2.5h; then raise the temperature to 1430°C at a rate of 2.5°C / min and keep it warm for 3.5h , natural cooling, prepared Si@SiC-Si based on catalytic nitridation method 3 N 4 electrode material.

[0049] The catalyst is cobalt nitrate hexahydrate.

[0050] Si@SiC-Si based on catalyti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com