Preparation method of carbon/cobalt/graphene composite nanofiber anode material

A graphene composite and nanofiber technology, which is applied in the fields of nanomaterials and chemical power sources, can solve the problems of no relevant reports on the preparation method, reduced battery energy density, and no lithium storage capacity, and achieves broad development prospects and application prospects. The effect of improving energy density and excellent electrochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

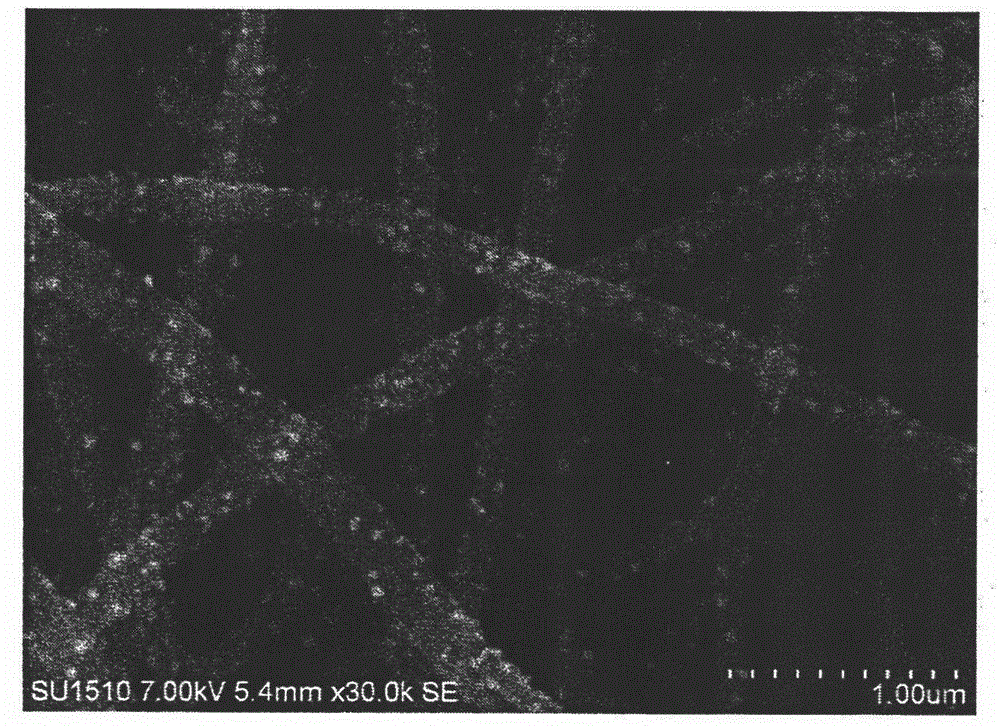

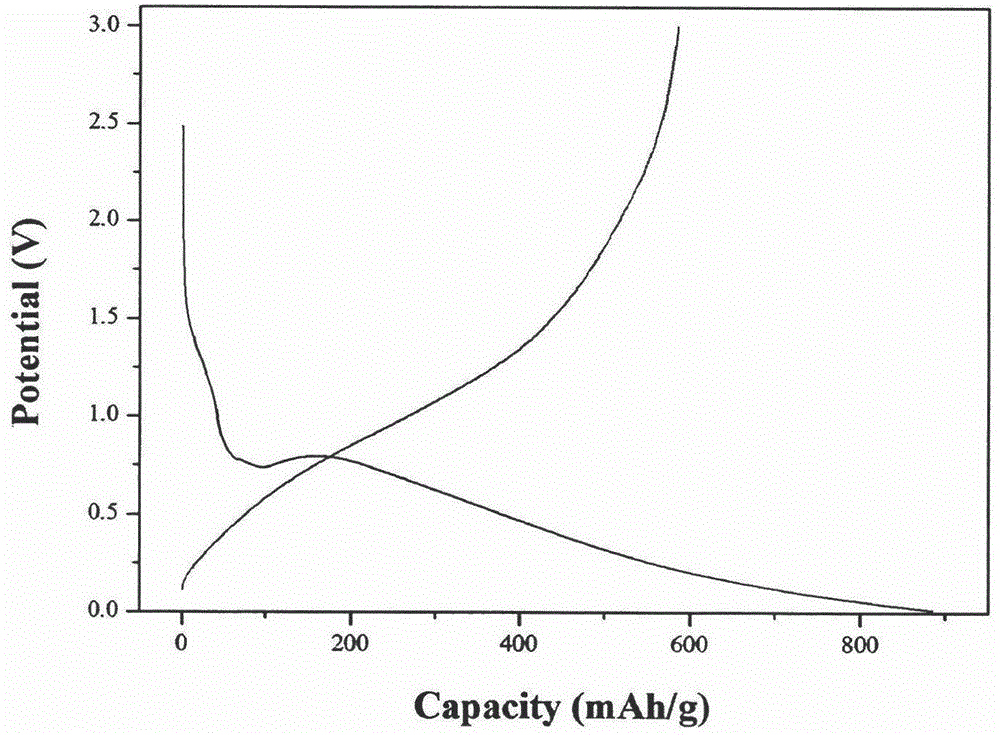

[0018] Weigh 3g of PAN and dissolve it in 27g of DMF, put it into a stirrer, adjust the appropriate speed, and stir at room temperature for 12-24 hours until uniform, and prepare a DMF solution with a mass fraction of PAN of 10%. Weigh 1.5g of cobalt chloride and 0.15g of graphene and add them into the above DMF solution, put them into a stirrer, adjust the appropriate speed, stir at room temperature for 8-10 hours, and ultrasonically oscillate for 1-3 hours to form a uniform solution. Spinning using an electrospinning device to obtain PAN / CoCl 2 / graphene composite nanofiber membrane, the spinning voltage is 20kV, the receiving distance is 20cm, and the spinning speed is 1mL / h. The obtained composite nanofiber membrane was put into a tube furnace, and the temperature was raised from room temperature to 250° C. at a heating rate of 2° C. / min in an air atmosphere, and the temperature was maintained for 2 h. Then, the temperature was raised to 800°C under nitrogen or argon prot...

Embodiment 2

[0020] Weigh 3g of PAN and dissolve it in 17g of DMF, put it into a stirrer, adjust the appropriate speed, and stir at room temperature for 12-24 hours until uniform, and prepare a DMF solution with a mass fraction of PAN of 15%. Weigh 1.5g of cobalt chloride and 0.15g of graphene and add them into the above DMF solution, put them into a stirrer, adjust the appropriate speed, stir at room temperature for 8-10 hours, and ultrasonically oscillate for 1-3 hours to form a uniform solution. Spinning using an electrospinning device to obtain PAN / CoCl 2 / graphene composite nanofiber membrane, the spinning voltage is 15kV, the receiving distance is 25cm, and the spinning speed is 0.5mL / h. The obtained composite nanofiber membrane was put into a tube furnace, and the temperature was raised from room temperature to 300° C. at a heating rate of 4° C. / min in an air atmosphere, and the temperature was maintained for 2 h. Afterwards, the temperature was raised to 600°C under nitrogen or ar...

Embodiment 3

[0022] Weigh 3g of PAN and dissolve it in 27g of DMF, put it into a stirrer, adjust the appropriate speed, and stir at room temperature for 12-24 hours until uniform, to prepare a DMF solution with a mass fraction of PAN of 10%. Weigh 1.5g of cobalt chloride and 0.1g of graphene and add them into the above DMF solution, put them into a stirrer, adjust the appropriate speed, stir at room temperature for 8-10 hours, and ultrasonically oscillate for 1-3 hours to form a uniform solution. Spinning using an electrospinning device to obtain PAN / CoCl 2 / graphene composite nanofiber membrane, the spinning voltage is 18kV, the receiving distance is 22cm, and the spinning speed is 0.8mL / h. The obtained composite nanofiber membrane was put into a tube furnace, and the temperature was raised from room temperature to 300° C. at a heating rate of 5° C. / min in an air atmosphere, and the temperature was maintained for 3 h. Then, the temperature was raised to 700°C under nitrogen or argon pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com