Patents

Literature

462results about How to "Reduce production steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

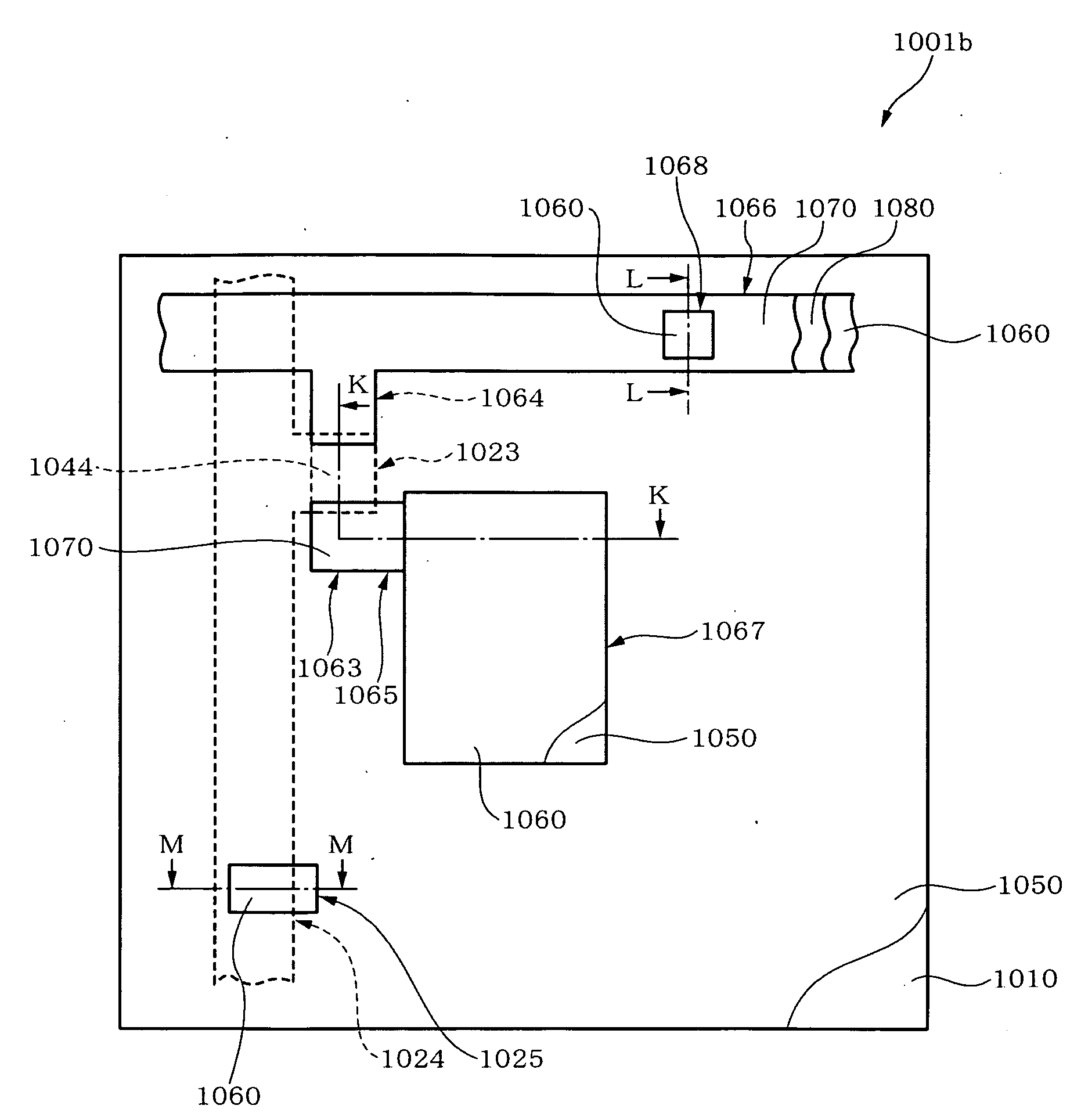

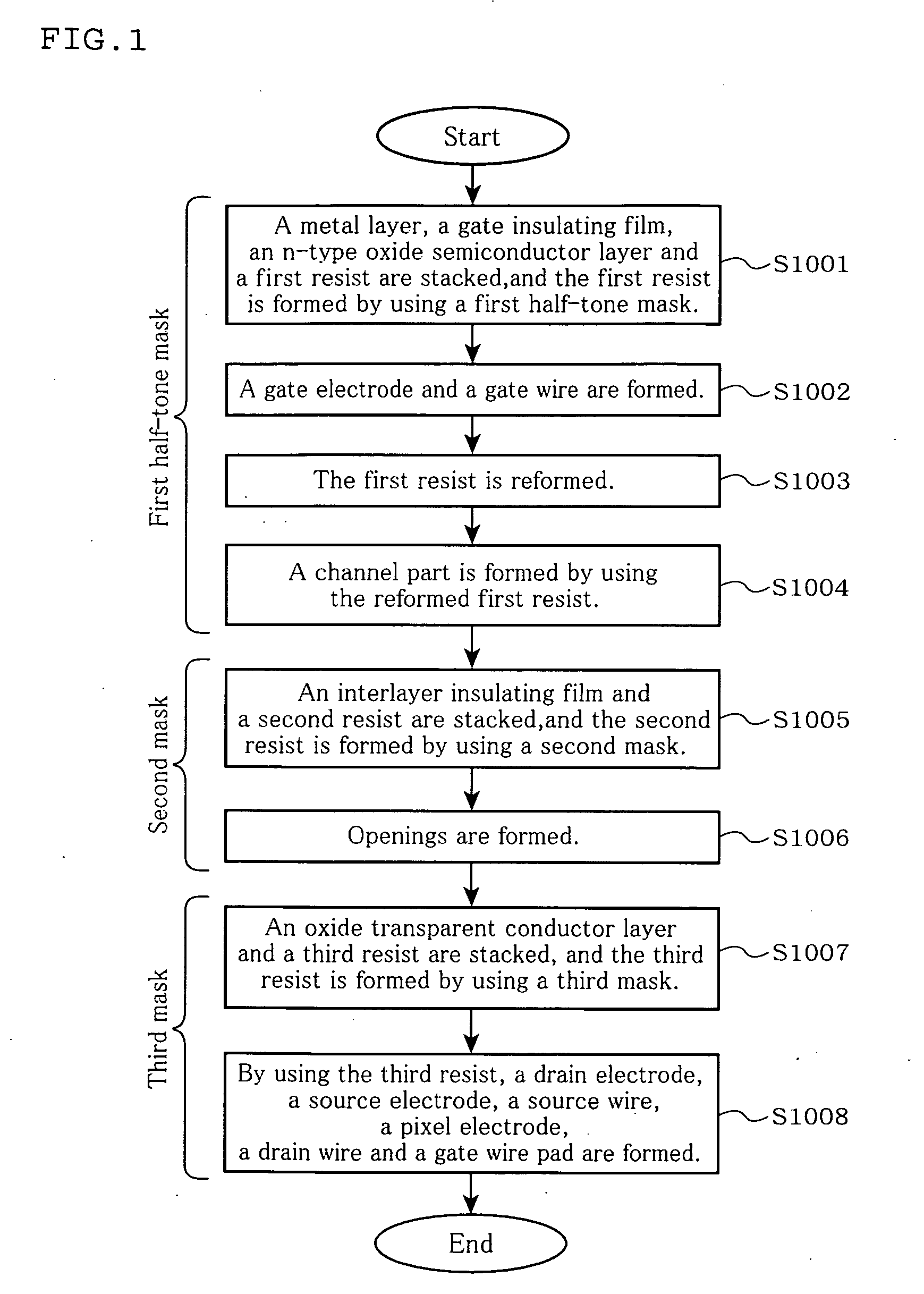

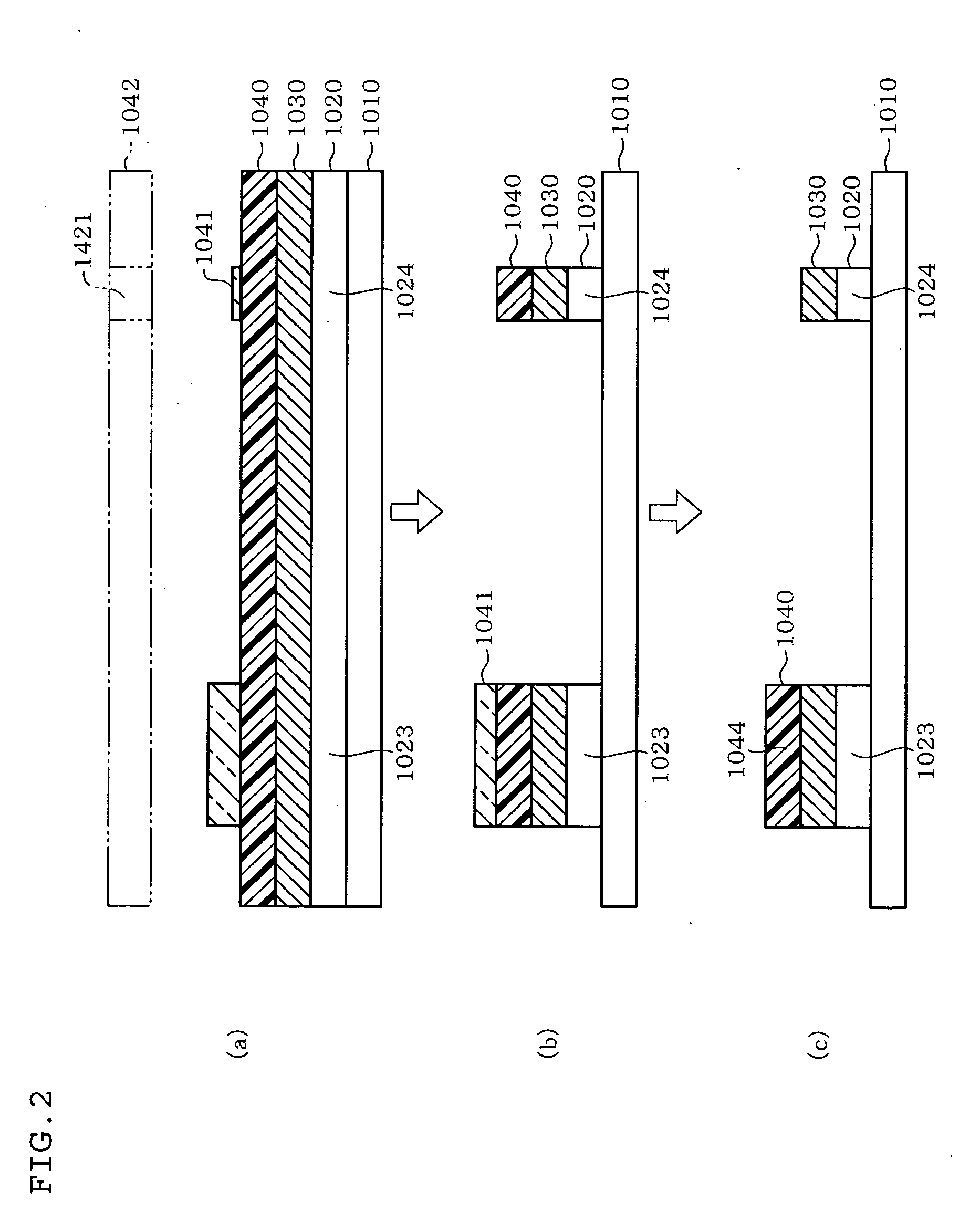

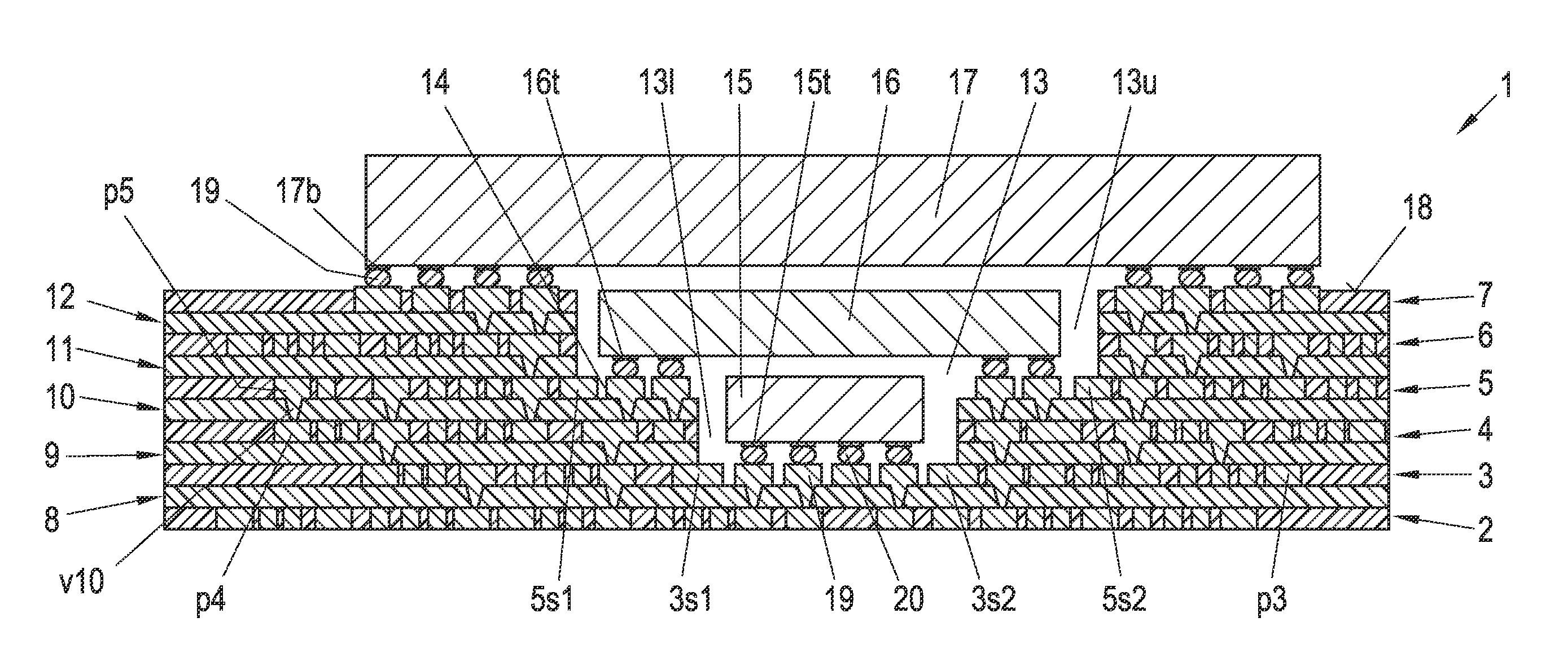

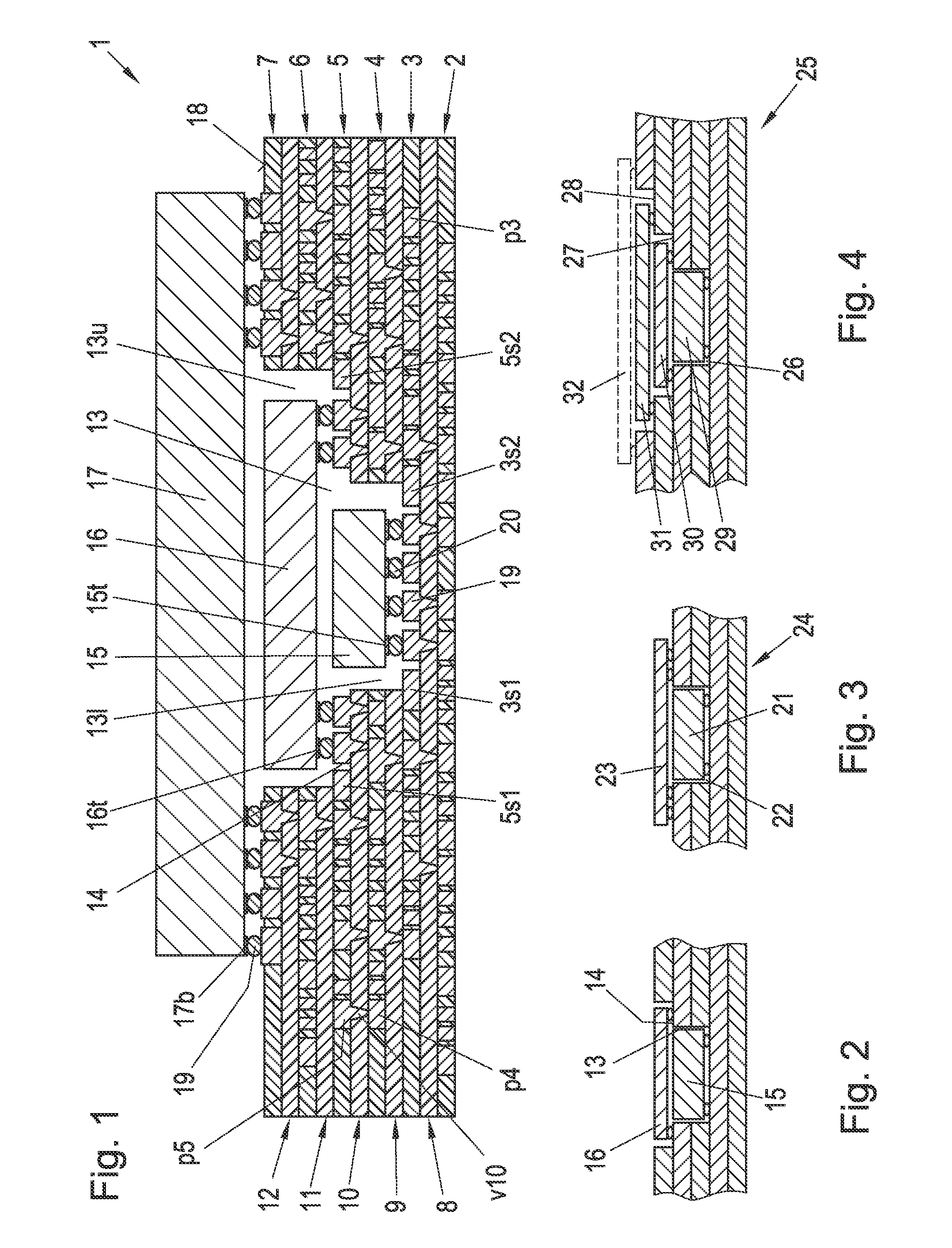

Tft Substrate, Reflective Tft Substrate and Method for Manufacturing These Substrates

InactiveUS20090001374A1Reduce production stepsReduce the number of masksTransistorSolid-state devicesManufacturing cost reductionElectrical conductor

An object of the invention is to propose a TFT substrate and a reflective TFT substrate which can be operated stably for a prolonged period of time, can be prevented from being suffering from crosstalk, and is capable of significantly reducing manufacturing cost by decreasing the number of production steps, as well as to propose the method for producing these substrates.A TFT substrate 1001 comprises: a glass substrate 1010; a gate electrode 1023 and a gate wire 1024 insulated by having their top surfaces covered with a gate insulating film 1030 and by having their side surfaces covered with an interlayer insulating film 1050; an n-type oxide semiconductor layer 1040 formed on the gate insulating film 1030 above the gate electrode 1023; an oxide transparent conductor layer 1060 formed on the n-type oxide semiconductor layer 1040 with a channel part 1044 interposed therebetween; and a channel guard 1500 for protecting the channel part 1044.

Owner:IDEMITSU KOSAN CO LTD

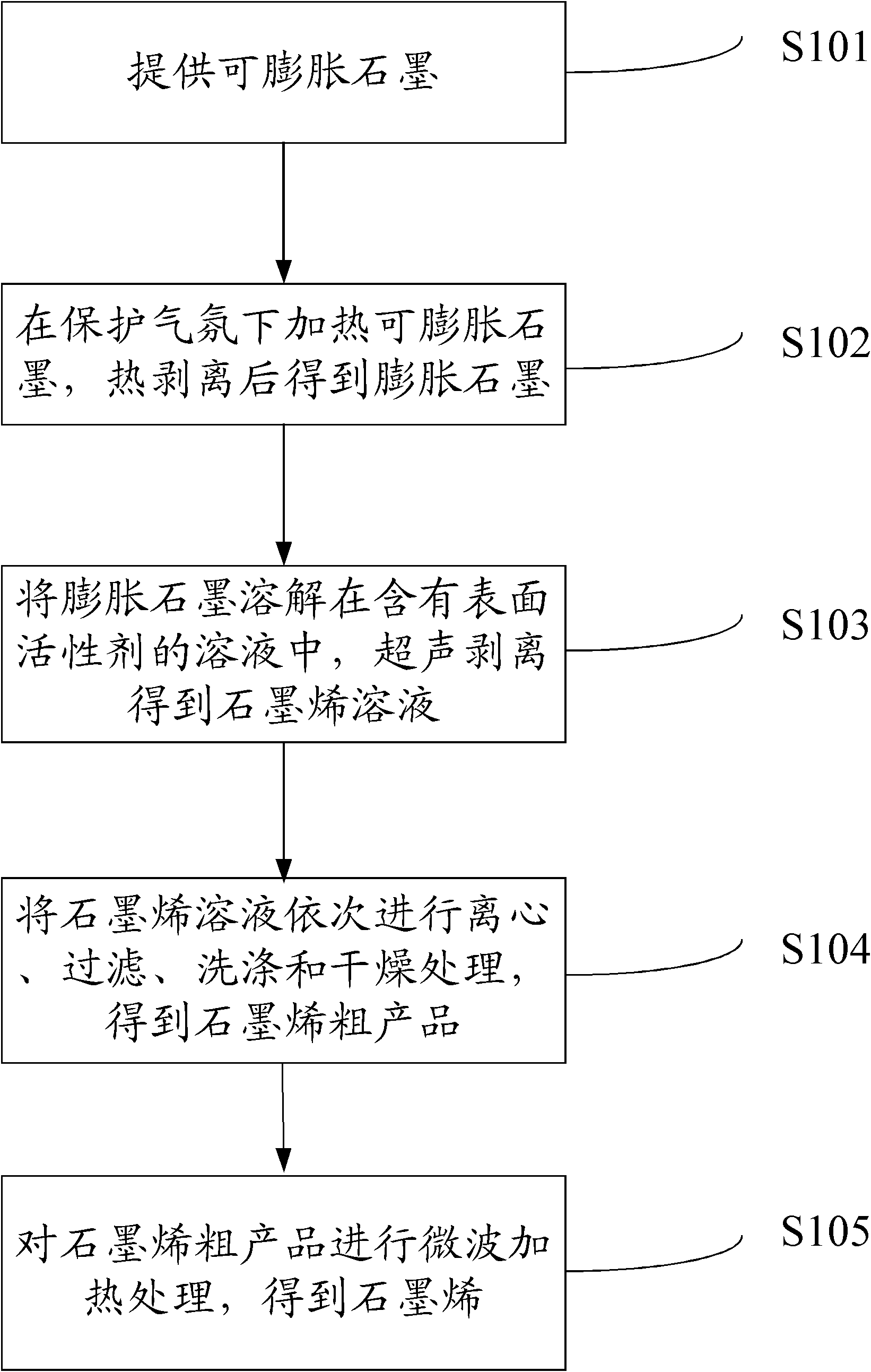

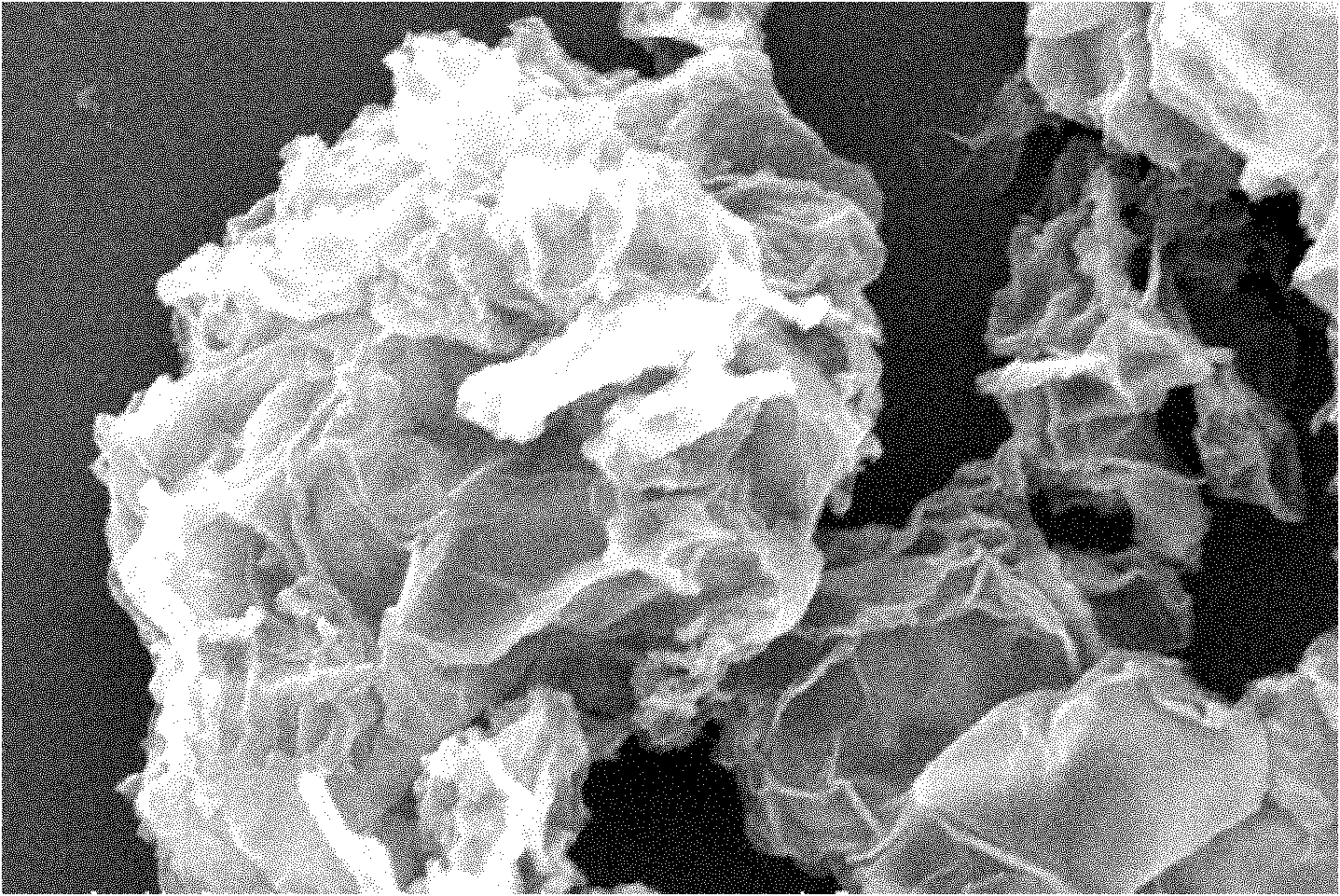

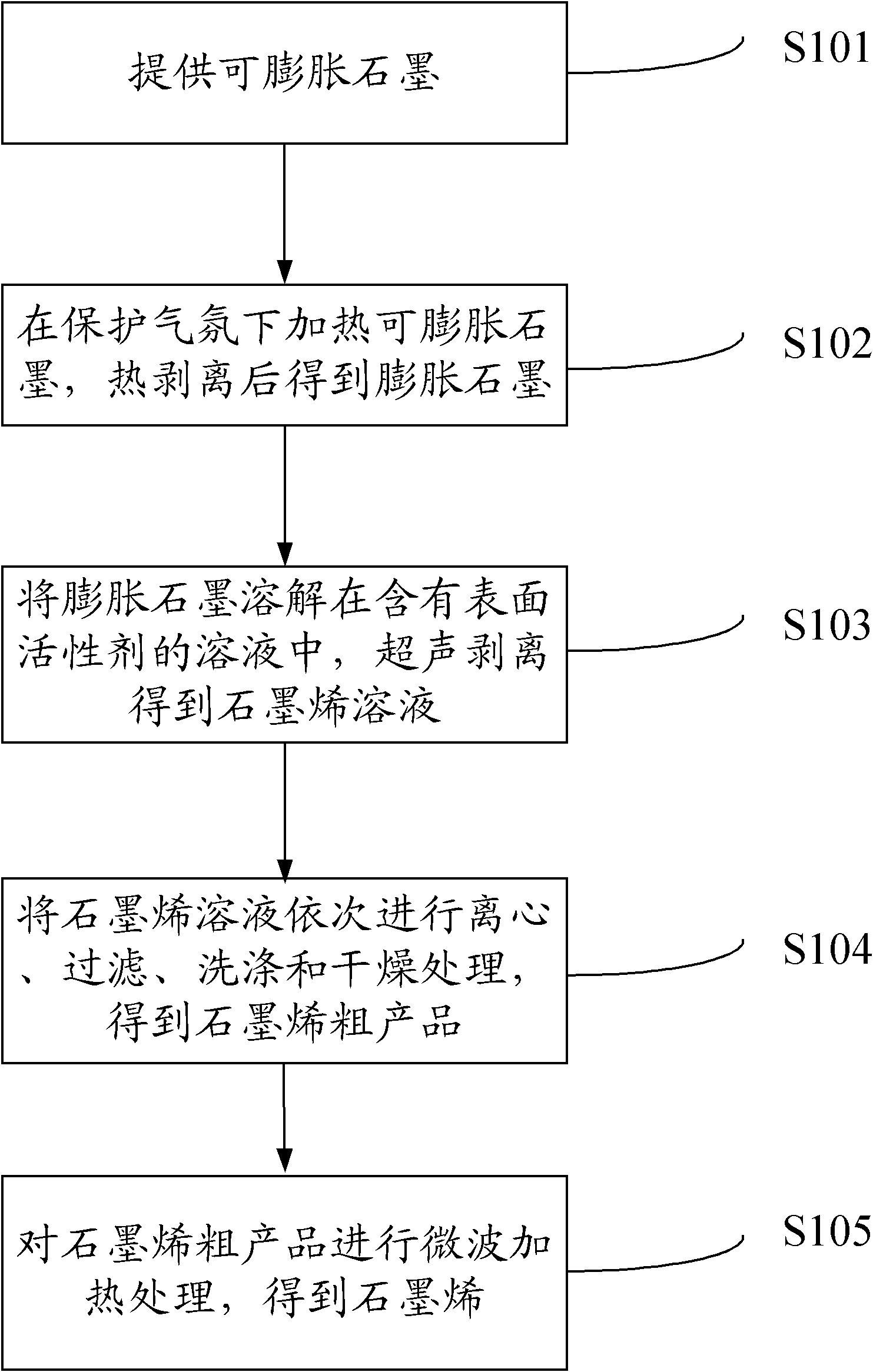

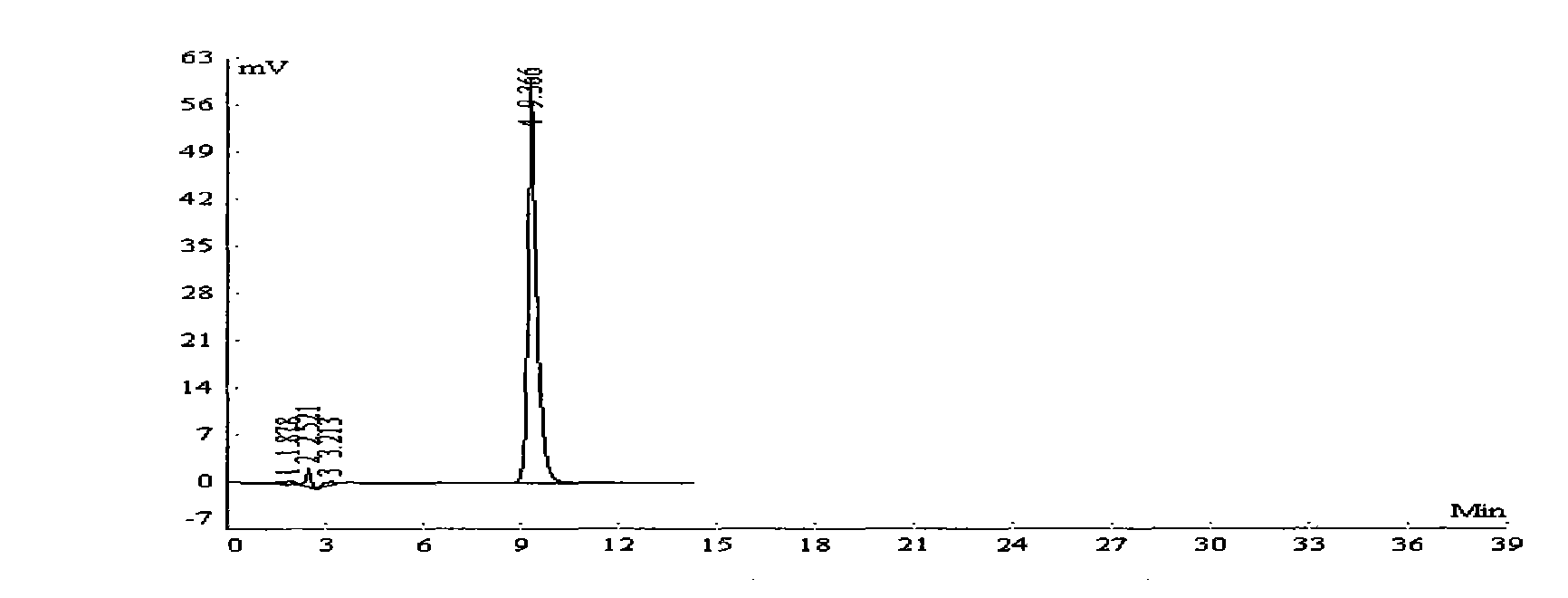

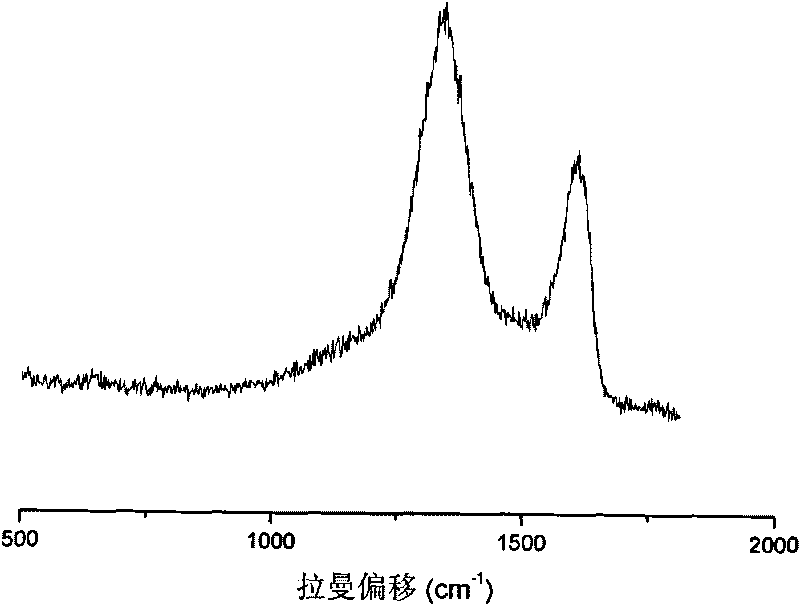

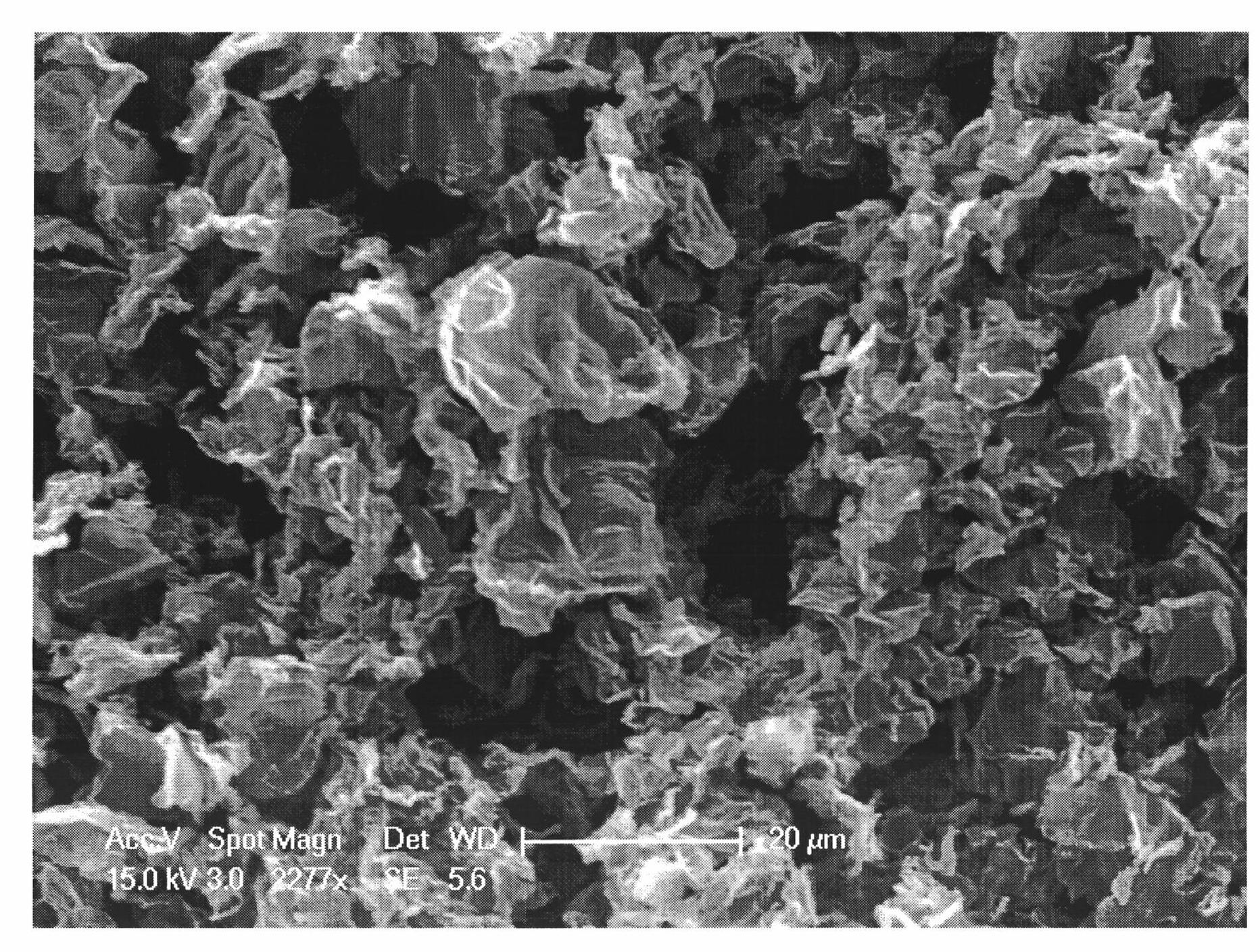

Preparation method of graphene

The invention relates to a preparation method of graphene, comprising the following steps of: heating expandable graphite in protective atmosphere, and thermally stripping to obtain expanded graphite; dissolving the expanded graphite into solution containing a surfactant, and ultrasonically stripping to obtain graphene solution; centrifuging, filtering, washing and drying the graphene solution in sequence so as to obtain a crude graphene product; and performing a microwave heating treatment to the crude graphene product to obtain the graphene. The preparation method of the graphene has the advantages of lower cost and higher purity.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

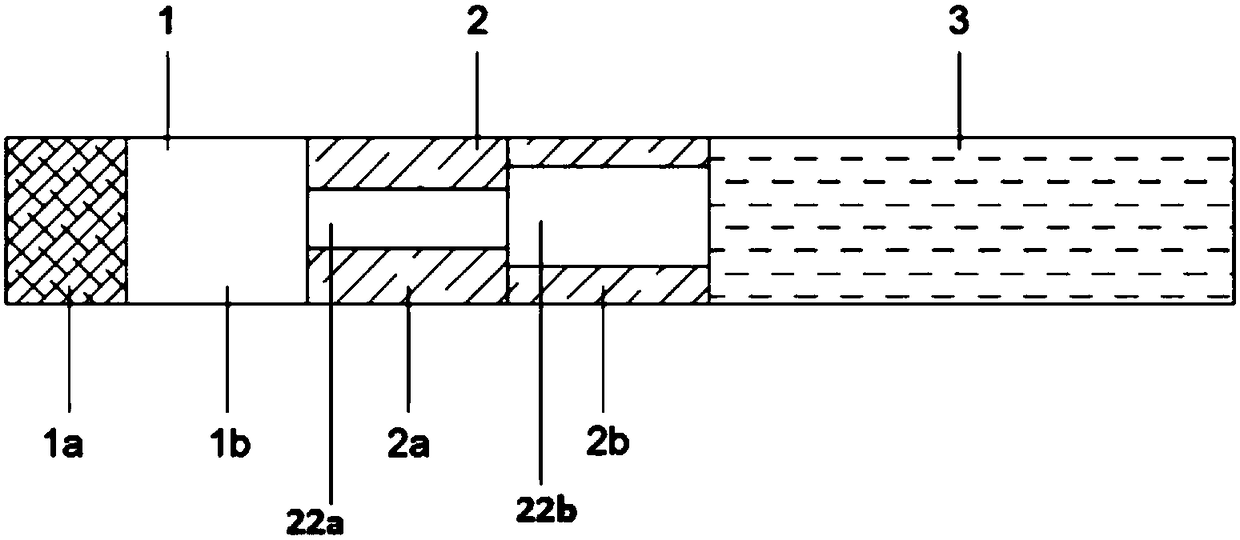

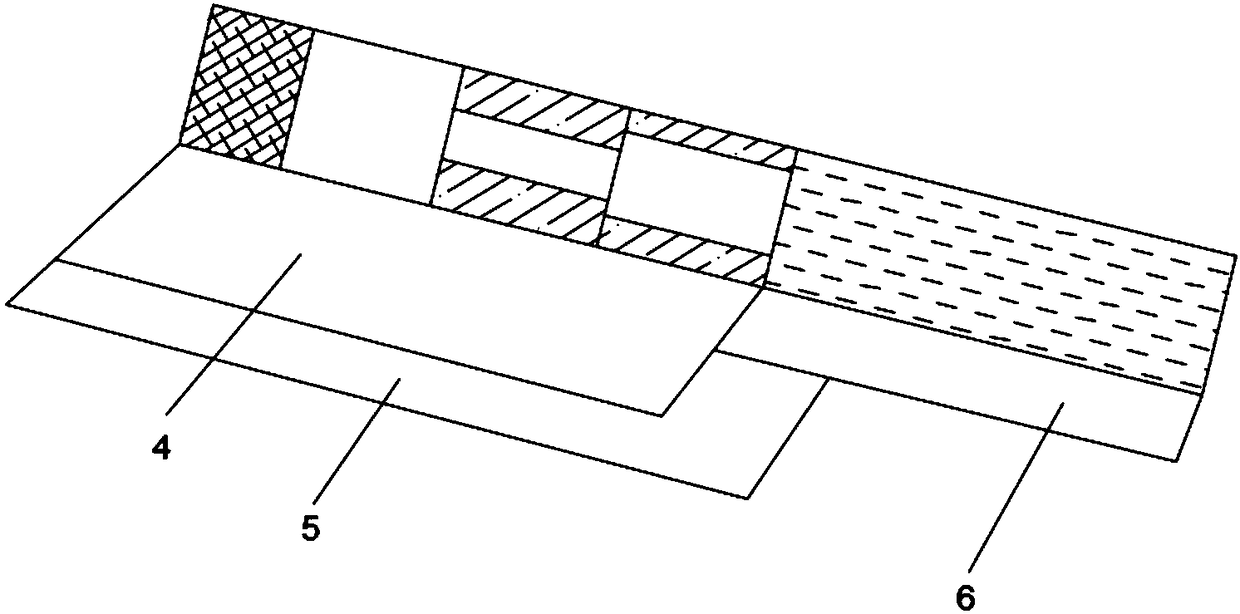

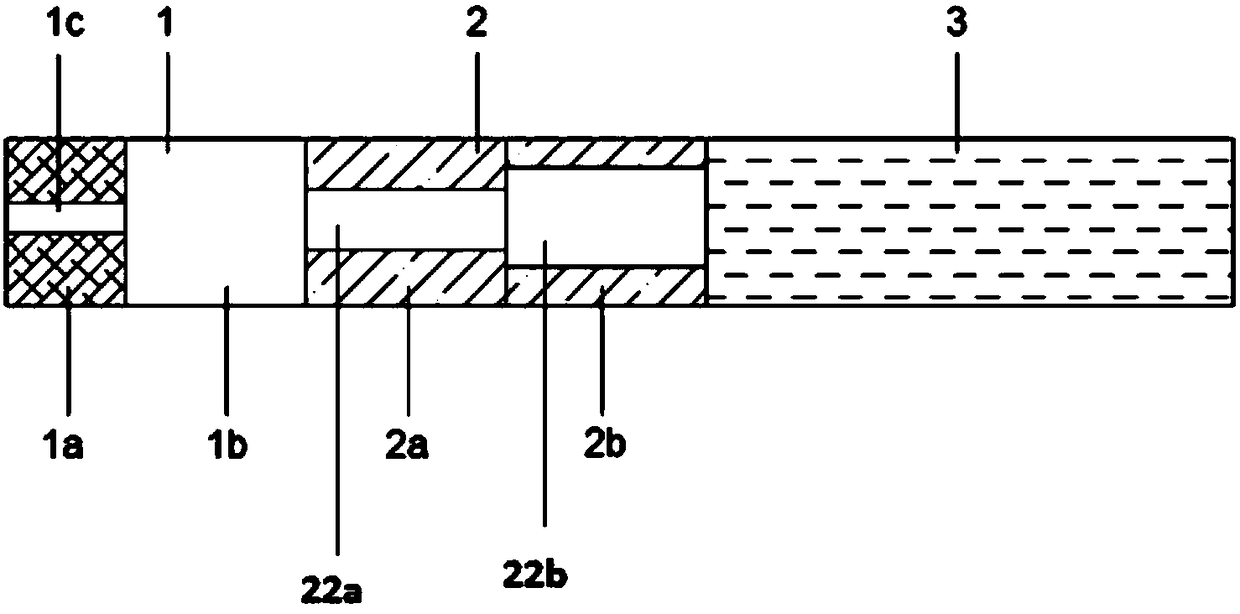

Novel cigarette for heating non-combustible tobacco

PendingCN108185517AReduce the temperatureReduce usageTobacco smoke filtersBiomedical engineeringVenturi effect

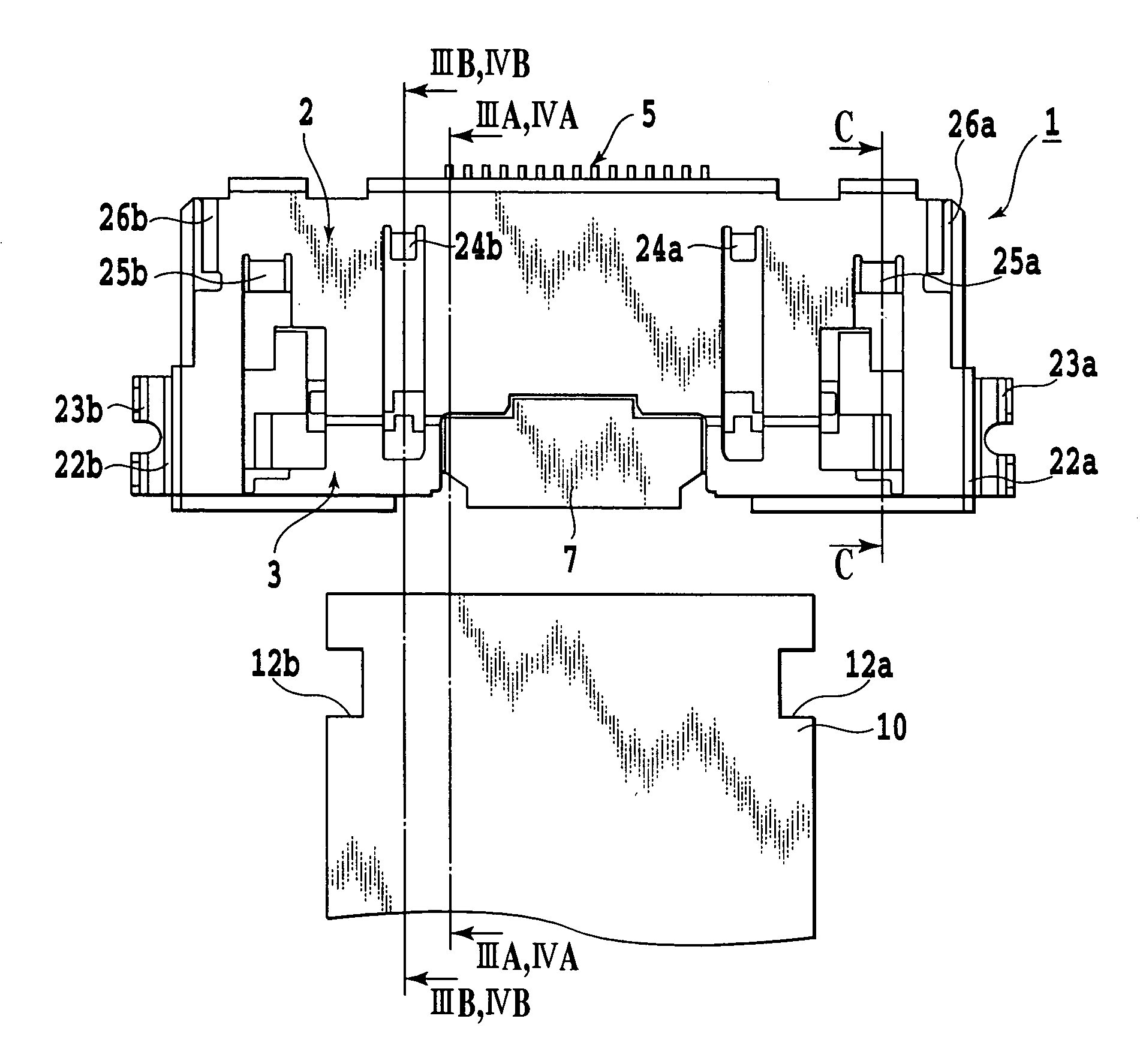

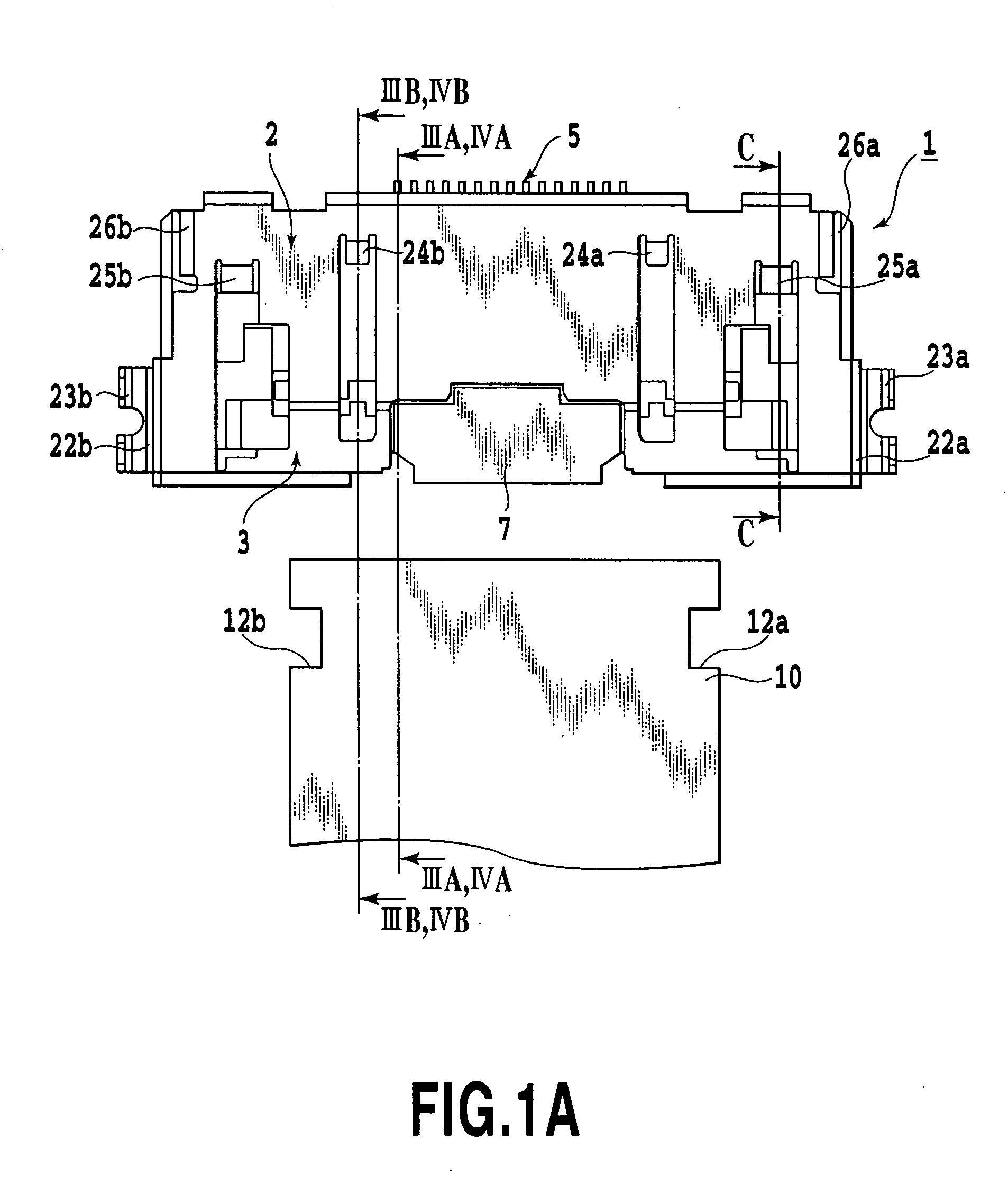

The invention discloses a novel cigarette for heating a non-combustible tobacco. The cigarette comprises a reversal counter-sunk filter stick (1), a first hollow filter stick (2a), a second hollow filter stick (2b) and a tobacco stick (3), wherein the reversal counter-sunk filter stick (1) comprises a filter section (1a) and a hollow section (1b); the first hollow filter stick (2a) is provided with a first axial cavity (22a); the second hollow filter stick (2b) is provided with a second axial cavity (22b); the equivalent diameter of the second axial cavity (22b) is greater than equivalent diameter of the first axial cavity (22a); and the equivalent diameter of the second axial cavity (22b) is less than the diameter of the hollow section (1b). The novel cigarette provided by the invention can be used for reducing smoke temperature on the basis of a Venturi effect; and the cigarette is sufficient in smodke amount, high in smoke release speed and high in smoking times.

Owner:CHINA TOBACCO YUNNAN IND

Copper-tungsten/copper-alloy integrated contact and preparation method thereof

The invention relates to a contact material for high-voltage switches and discloses a copper-tungsten / copper-alloy integrated contact and a preparation method thereof. The copper-tungsten / copper-alloy integrated contact comprises a contact part and a conducting rod part, wherein the tungsten content of the contact part gradually decreases from head to tail. The preparation method comprises the following steps: firstly, mechanically mixing powder by a wet method to prepare copper-tungsten particles with different tungsten contents; secondly, putting the tungsten in the die cavity of a compression mold according to the weight contents of tungsten in a descending order to carry out the press forming; thirdly, putting the pressed blank in a graphite boat, and sintering and infiltrating the pressed blank in a sintering furnace in the hydrogen atmosphere to obtain the copper-tungsten alloy of the contact part; and finally, sintering the low-tungsten-content end of the copper-tungsten alloy and the copper conducting rod part or the copper alloy conducting rod part to form an integral body by using a sintering method, an electro-beam welding method or a diffusion welding method, thereby obtaining the copper-tungsten / copper-alloy integrated contact.

Owner:XIAN FULAI ELECTRICAL ALLOY

Production of color filter by forming light-screening layer and irradiating resin layer to achieve ink-accepting property

InactiveUS6127072AReduce production stepsLow costOptical filtersOriginals for photomechanical treatmentIrradiationLight filter

Disclosed herein is a process for producing a color filter substrate, which comprises the steps of forming a resin layer for coloration, which develops an ink-accepting property by irradiation of light, on a base; forming a light-screening layer on the resin layer for coloration; exposing the resin layer for coloration through the light-screening layer as a mask; and applying color inks to the resin layer for coloration.

Owner:CANON KK

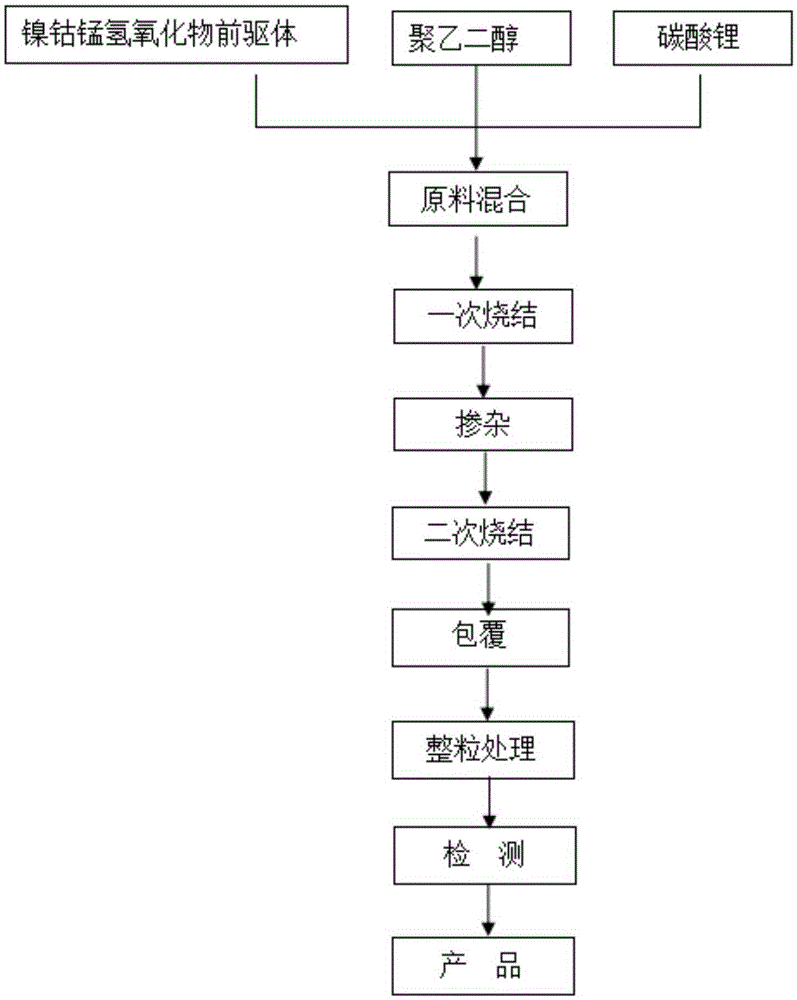

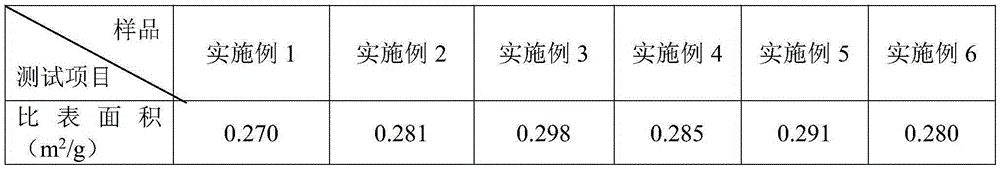

Preparation method of aluminum oxide coated lithium nickel manganese cobalt cathode material

ActiveCN105355911ASimple structureImprove electrochemical cycle performanceCell electrodesSecondary cellsManganesePolyethylene glycol

The invention belongs to the technical field of battery materials, and discloses a preparation method of an aluminum oxide coated lithium nickel manganese cobalt cathode material. The method comprises the steps of raw material mixing, primary sintering, doping, secondary sintering, coating and size stabilization treatment, wherein the step of raw material mixing comprises the steps that a three-dimensional efficient titled mixer is adopted, polyurethane balls serve as a mixing medium, dispersing, even mixing and smashing are conducted on lithium carbonate, a nanometer spherical nickel cobalt manganese hydroxide precursor and polyethylene glycol, and a uniform intermediate mixture is formed. The preparation method of the aluminum oxide coated lithium nickel manganese cobalt cathode material is low in primary sintering temperature, short in sintering time, simple in technology, large in specific capacity and good in cycling performance. The preparation method further has the advantages of being low in investment, reliable in technology, low in operating cost and the like, and the good economic benefit and market promotion value are achieved.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

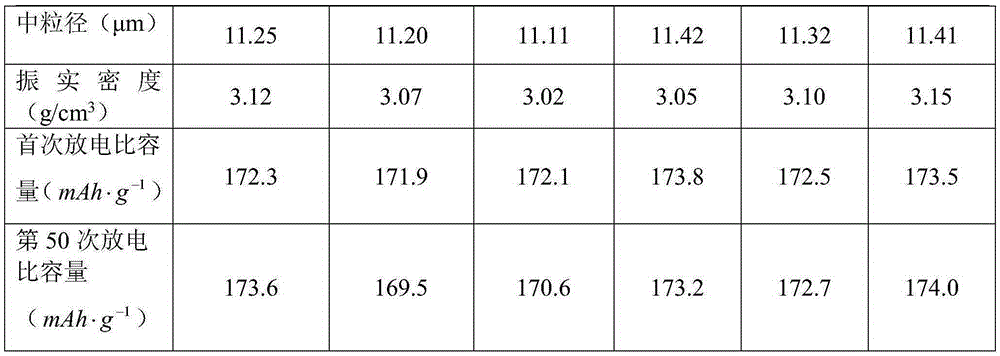

Samarium and cobalt sintered permanent magnet material and preparation method thereof

ActiveCN104637642ASpeed up coolingIntegrity guaranteedInorganic material magnetismCobaltCritical magnetic field

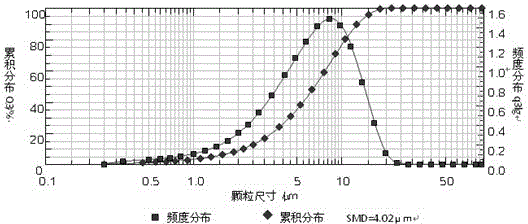

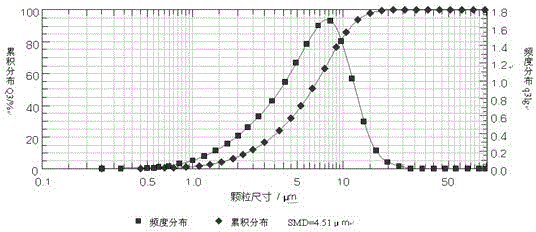

A samarium and cobalt sintered permanent magnet material comprises, in weight percent, 25-27%wt of samarium, 49-51%wt of cobalt, 5-6.5%wt of copper, 3-3.5%wt of zirconium and 15-18%wt of iron. A preparation method includes the steps: smelting; casting an ingot; absorbing hydrogen for the cast ingot; making powder; performing orientation forming and sintering. In the smelting process, the thickness of a casting mould cavity is decreased, cooling water is filled into the wall of the mould cavity, cooling of the cast ingot is accelerated, element composition segregation is decreased, the production process is stabilized, a dendrite crystal is restrained by adding a zirconium element, hydrogen absorbing is performed for the cast ingot in the smelting process, production steps are saved, and energy consumption is reduced. In the subsequent milling process, the cast ingot absorbed hydrogen is crystallized into particles, the particles fracture along crystal boundaries in the milling process of airflow, the integrality of crystal particles is ensured, the anisotropy of the crystal particles is improved, magnetic powder particles are obtained, particle size distribution is concentrated with the range of 3.5-4.5 micrometers, the sintering temperature needed by the magnetic powder particle of each point of a blank is the same in the later sintering process, the sizes of the sintered crystal particles are the same and uniform, and the performances, particularly, such as residual magnetism Br, maximum magnetic energy product (BH) max and critical magnetic field Hk of a sintered permanent magnet are improved.

Owner:NINGBO NINGGANG PERMANENT MAGNETIC MATERIALS

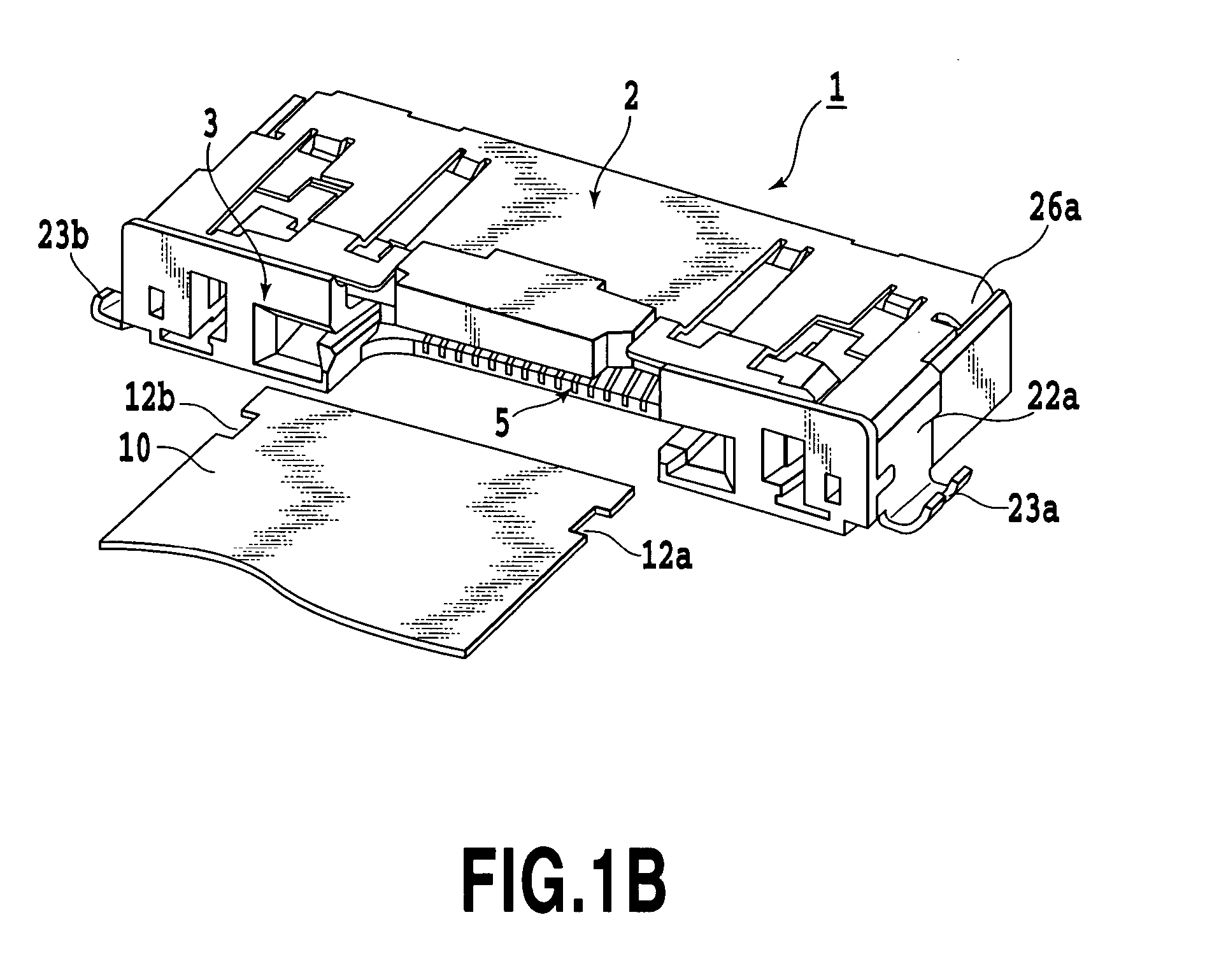

Connector for flexible printed circuit board

InactiveUS20050075004A1Reduce manufacturing errorAvoid noiseTwo-part coupling devicesCoupling protective earth/shielding arrangementsGround contactMetallic enclosure

An FPC connector having an electromagnetic wave shielding structure improved so that noises do not exceed an allowable value. The FPC connector includes at least a top plate, a metallic shell having left and right walls and a grounding terminal portion, a connector body covered with the metallic shell, a signal line contact, and a grounding contact for grounding the FPC, wherein the metallic shell has a grounding contact partially cut from the top plate and raised the cut portion.

Owner:YAMAICHI ELECTRONICS

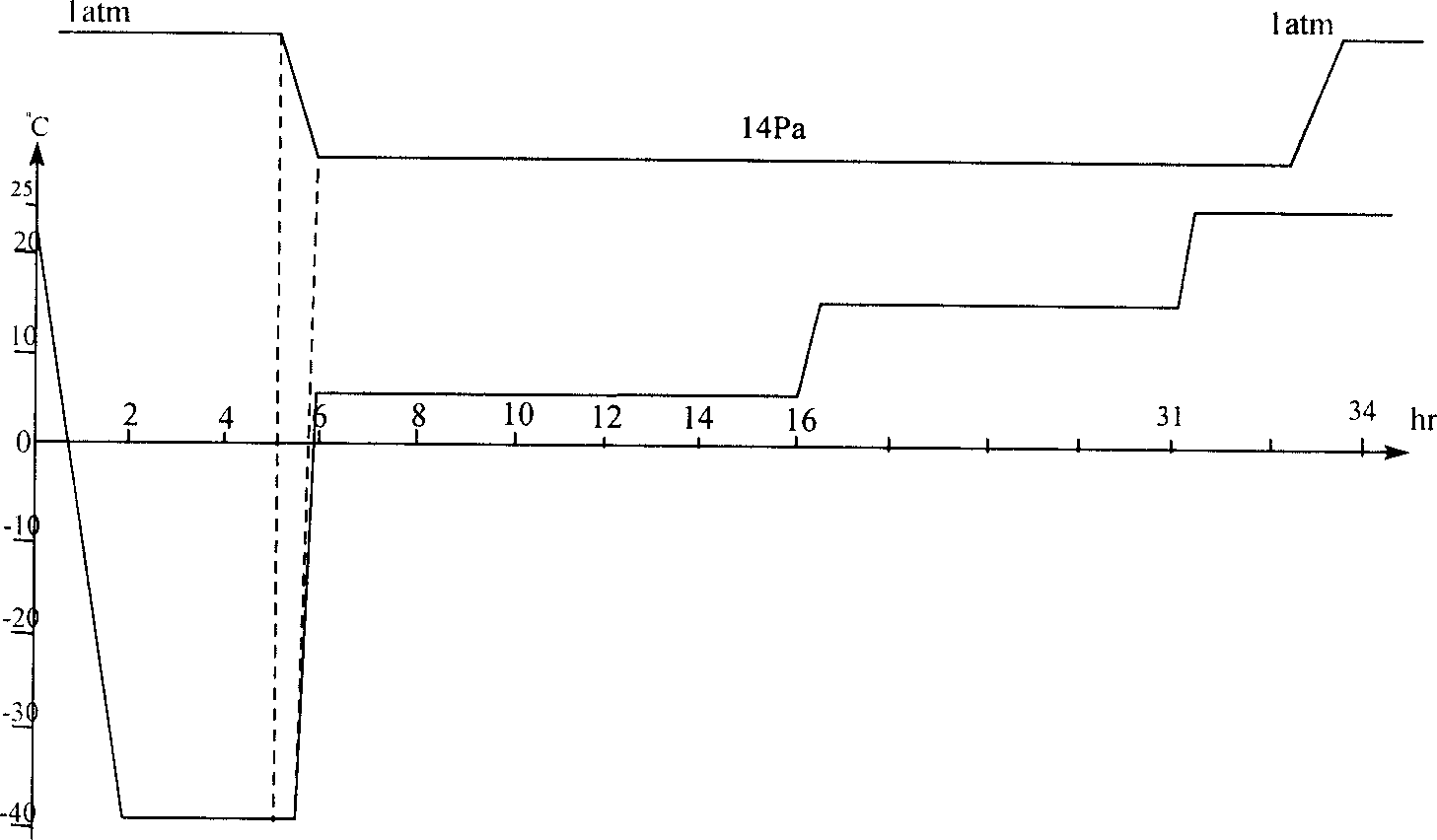

Brain protein hydrolysate and production process of its freeze dried preparation

InactiveCN1857711ANo pollution in the processReduce investmentPowder deliveryNervous disorderFreeze-dryingNitrogen

The present invention relates to a kind of brain protein hydrolysate and the production process of its freeze dried preparation. The brain protein hydrolysate for injection is prepared with pig brain and through the steps of homogenating in a colloid mill to collect slurry, hydrolyzing with pepsase and pancreatin to collect supernatant, filtering with filer paper to collect filtrate, separating and purifying the filtrate with hydroxyapetite column, regulating peptide map and collecting object, ultrafiltering with membrane of intercepting molecular weight 8 KD to collecting filtrate, nitrogen and amino acid analysis and adding amino acid in the required amount, and fine filtering with 0.22 micron filtering membrane. The brain protein hydrolysate for injection may be further freeze dried to obtain freeze dried brain protein hydrolysate preparation. The production process is environment friendly, high in yield and low in cost.

Owner:HAINAN JINXING PHARMA

Method for producing bio-fungus fruit tree drop irrigation fertilizer

InactiveCN106495826AProduction Method AdvantagesRich in NPKSuperphosphatesBio-organic fraction processingPotassiumNutrient solution

The invention discloses a method for producing bio-fungus fruit tree drop irrigation fertilizer. The method comprises the following steps that 1, compound microorganism strain liquid is prepared; 2, water is added into protein waste and carbohydrate waste, a nutrient solution is prepared, and the nutrient solution is boiled for sterilization; 3, the nutrient solution is fermented with compound microorganisms to generate fermentation liquor rich in organic acid; 4, the fermentation liquor is filtered; 5, stirring is carried out, potassium and compound microelements are added and chelated with the organic acid to generate organic acid chelate, and the stable liquid fertilizer is prepared. The fertilizer is rich in nitrogen, phosphorus and potassium, complete in microelement and rich in organic acid and active microorganism, plant growth can be promoted, the disease resistance of plants can be improved, the yield of crops can be increased, the quality of the crops can be improved, and the organic content of soil can be increased; the liquid fertilizer is good in stability, not likely to generate sediment and suitable for a drop irrigation fertilization mode.

Owner:深圳市三盛环保科技有限公司

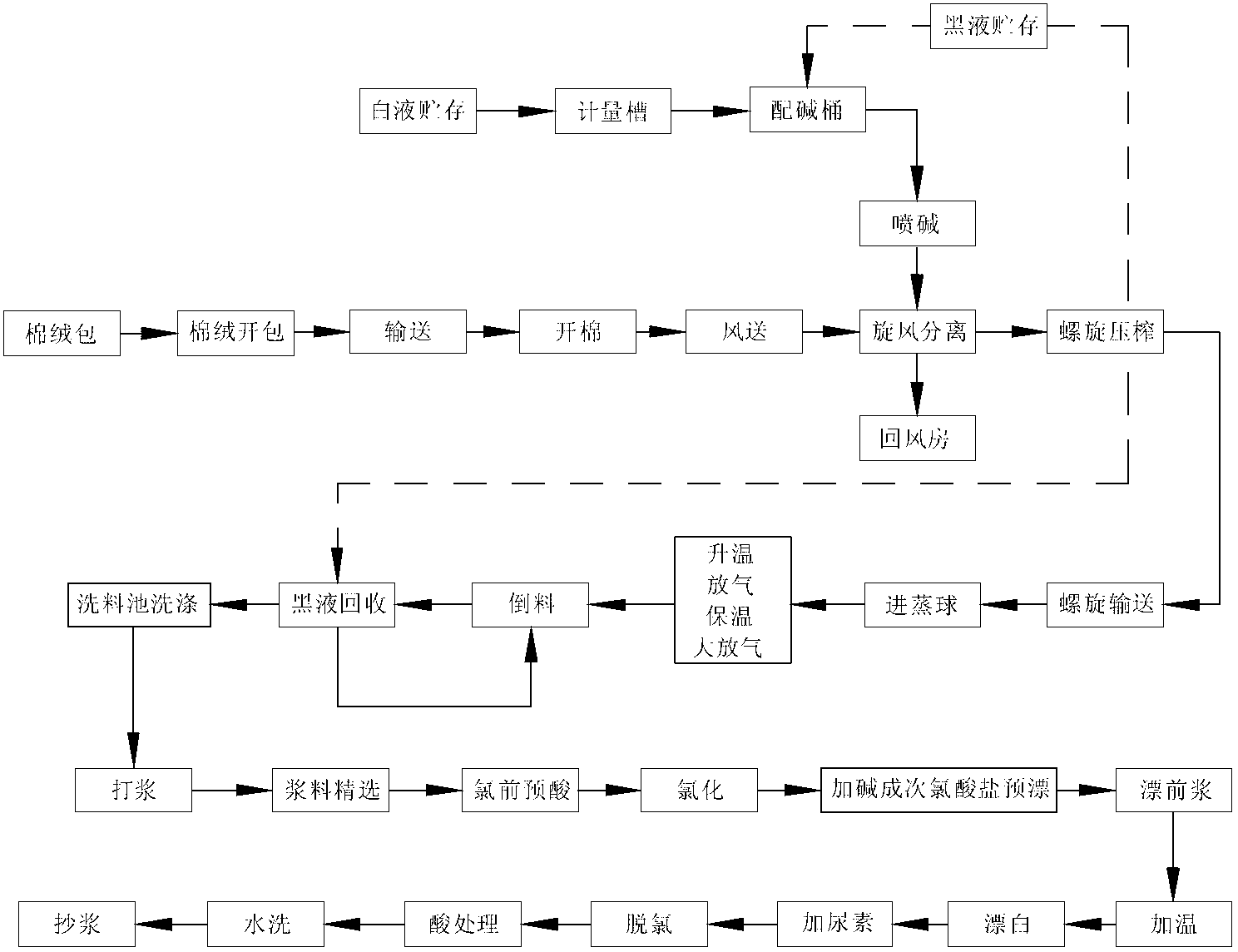

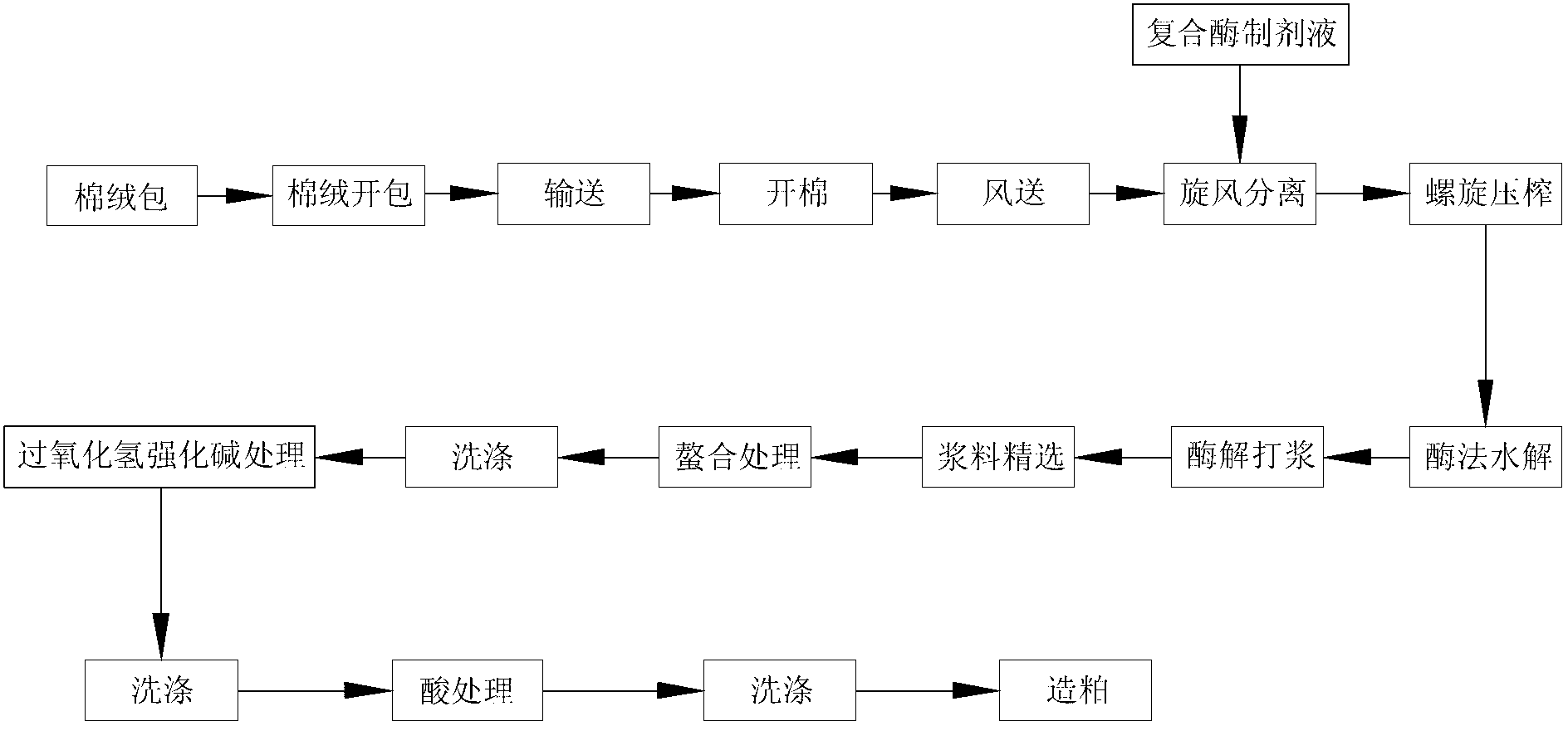

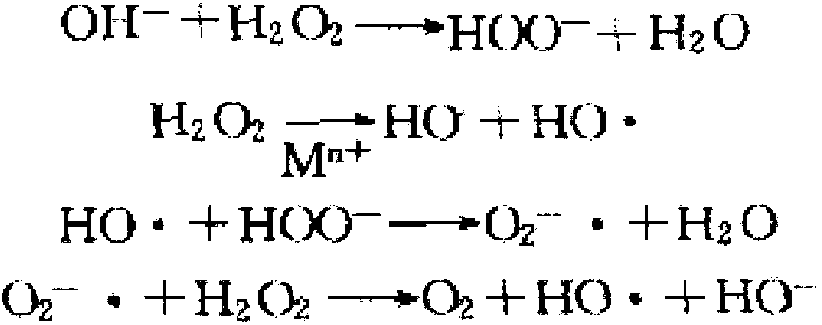

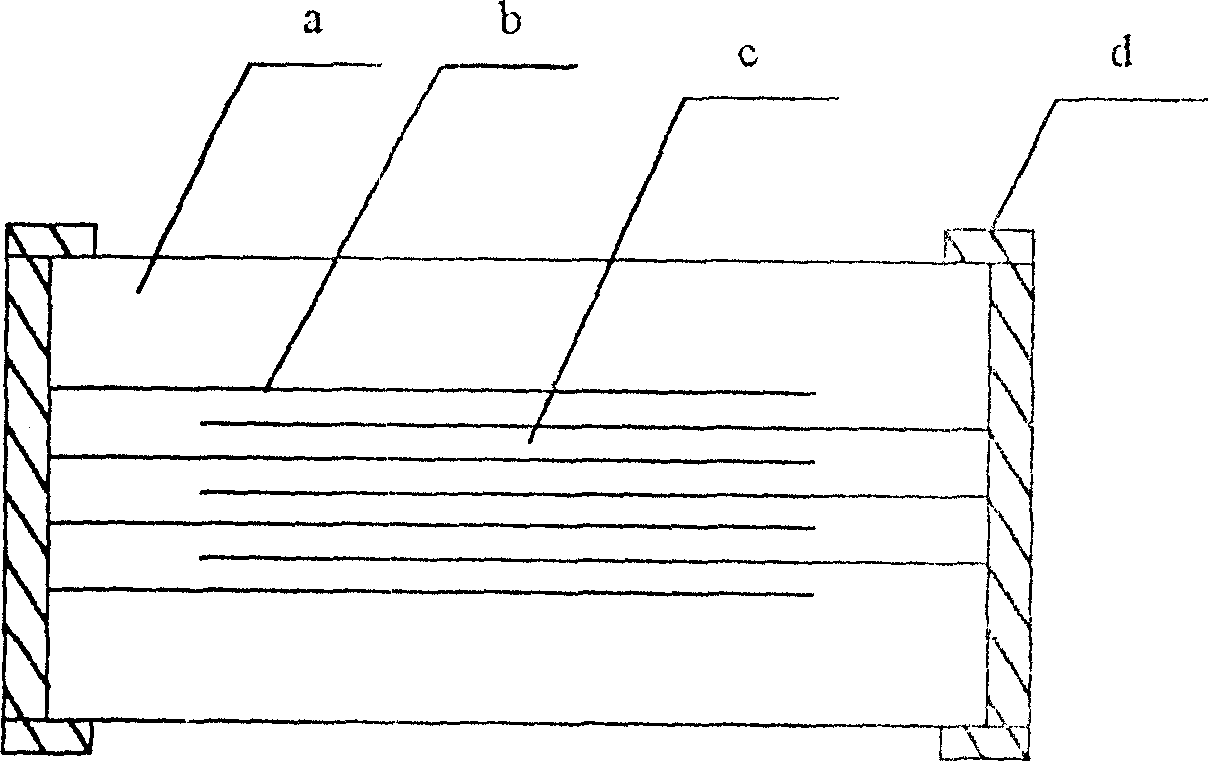

Complex enzyme preparation and technique for preparing dissolving pulp by using same

ActiveCN103061181ALoose structureEnhancement and effectPaper material treatmentChemical oxygen demandCellulose fiber

The invention relates to the technical field of production of regenerated cellulose fiber, in particular discloses a complex enzyme preparation applied in the preparation of dissolving pulp and a technique for preparing the dissolving pulp by using the enzyme preparation. The complex enzyme preparation is divided into a complex enzyme preparation I and a complex enzyme preparation II, wherein the complex enzyme preparation I mainly consists of feruloyl esterase, lipase and the like; and the complex enzyme preparation II mainly consists of xylanase, cellulase and the like. The complex enzyme preparation is applied in the technique for purifying alpha-cellulose and preparing the dissolving pulp; and the technique comprises the following steps of impurity removal for raw materials, enzyme method pretreatment, enzymolysis pulping, chelation treatment, alkali hydroxyl active oxygen cooking, acid treatment, washing, sand removal and pulp mixing. The method has the simple preparation technique, and adopts the complex enzyme preparation to treat the raw material pulp so as to effectively remove lignin, hemicellulose, pectin substance and waxiness and to reduce the degree of polymerization of the alpha-cellulose; the energy consumption is low under the normal pressure condition; the COD (Chemical Oxygen Demand) value of the pulping waste water is low; the yield of the dissolving pulp is high; the alpha-cellulose has high content and uniform degree of polymerization; and the production requirements of viscose can be satisfied.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

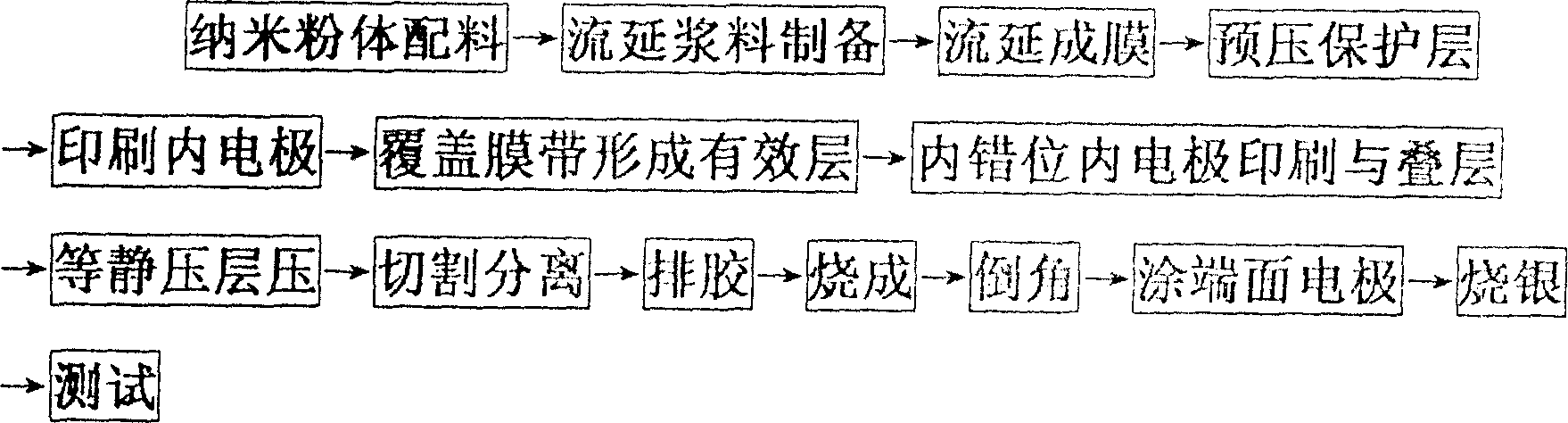

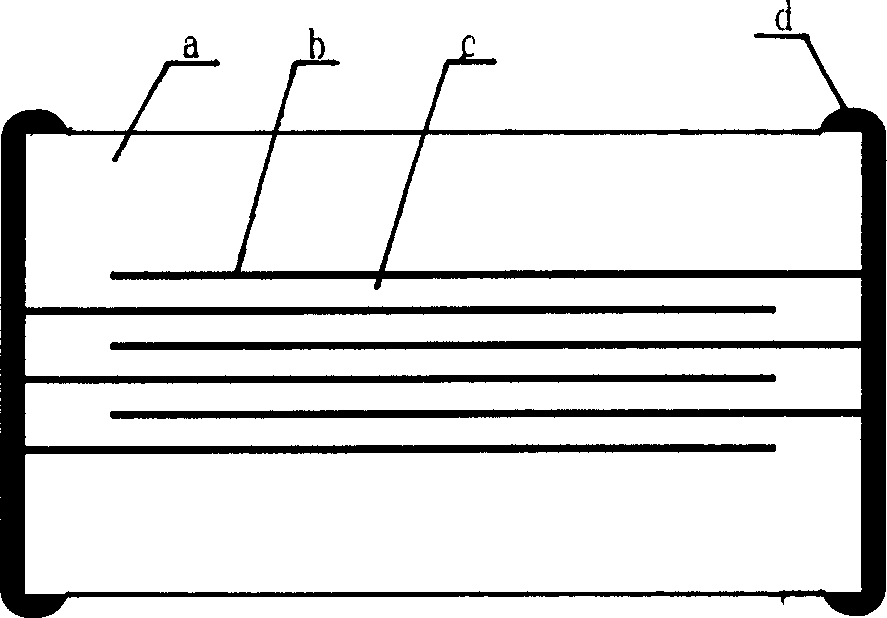

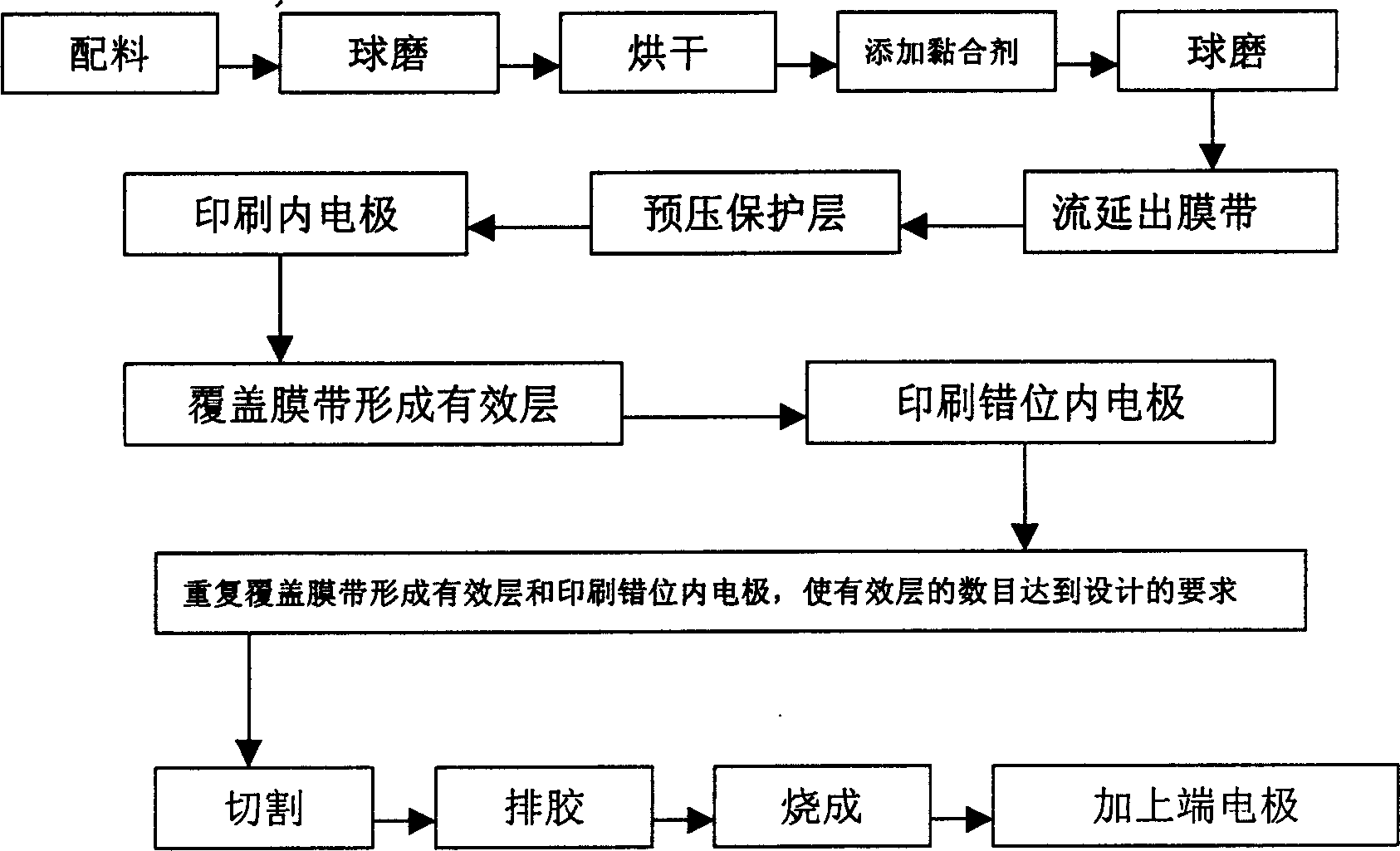

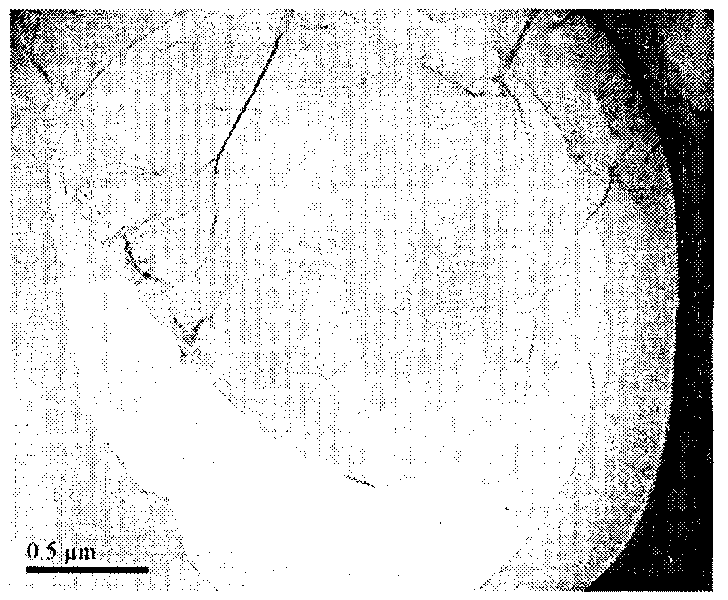

Multilayer chip ZnO varistor prepared by nano material and manufacturing method

InactiveCN1694187AImproved microstructural uniformityReduce production stepsResistor manufactureVaristor coresPressure sensitiveVaristor

The invention discloses a multi-layer chip style of ZnO pressure sensitive resistor made from nanometer materials. It is jointly sintered by the ZnO porcelain material made from nanometer materials and inner electrode layer crossways arranged. Its main characteristic are as follows. The granule shape of the main material of the ZnO porcelain material is orbicular or approximately orbicular. The ZnO nanometer power body of 1 - 99 nm average granule radius, add 3 - 8 % (mol percent) nanometer power body additive whose granule shape is orbicular or approximately orbicular. The said inner electrode layer is Pd / Ag inner electrode layer, in which the Pd proportion is 11 - 25 % of the weight of Pd / Ag inner electrode, and the Ag proportion is 75 - 89 % of the weight of Pd / Ag inner electrode. The ZnO porcelain material and the Pd / Ag inner electrode layer are crossways arranged, and are made by sintering in the temperature bound of 950 - 1100 Deg. C. The present invention also discloses a kind of manufacturing method of the said multi-layer piece style of ZnO pressure sensitive resistor made from nanometer materials. The non-linear coefficient alphaof the multi-layer piece style of ZnO pressure sensitive resistor of 1005 specification made by the present invention is over 20, leaking current IL is less than 2.0 mA.

Owner:HENAN JINGUAN WANGMA INFORMATION INDAL

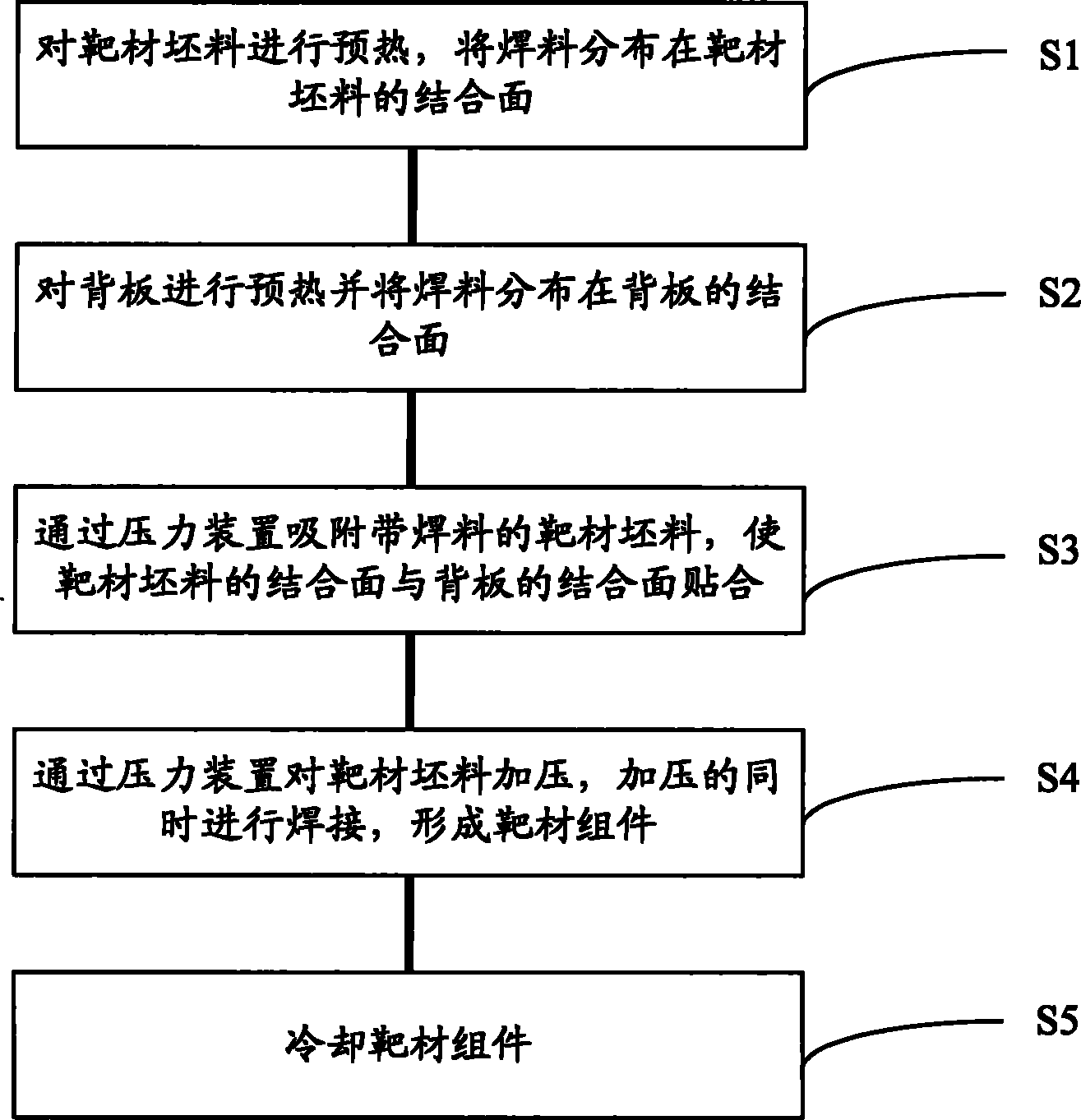

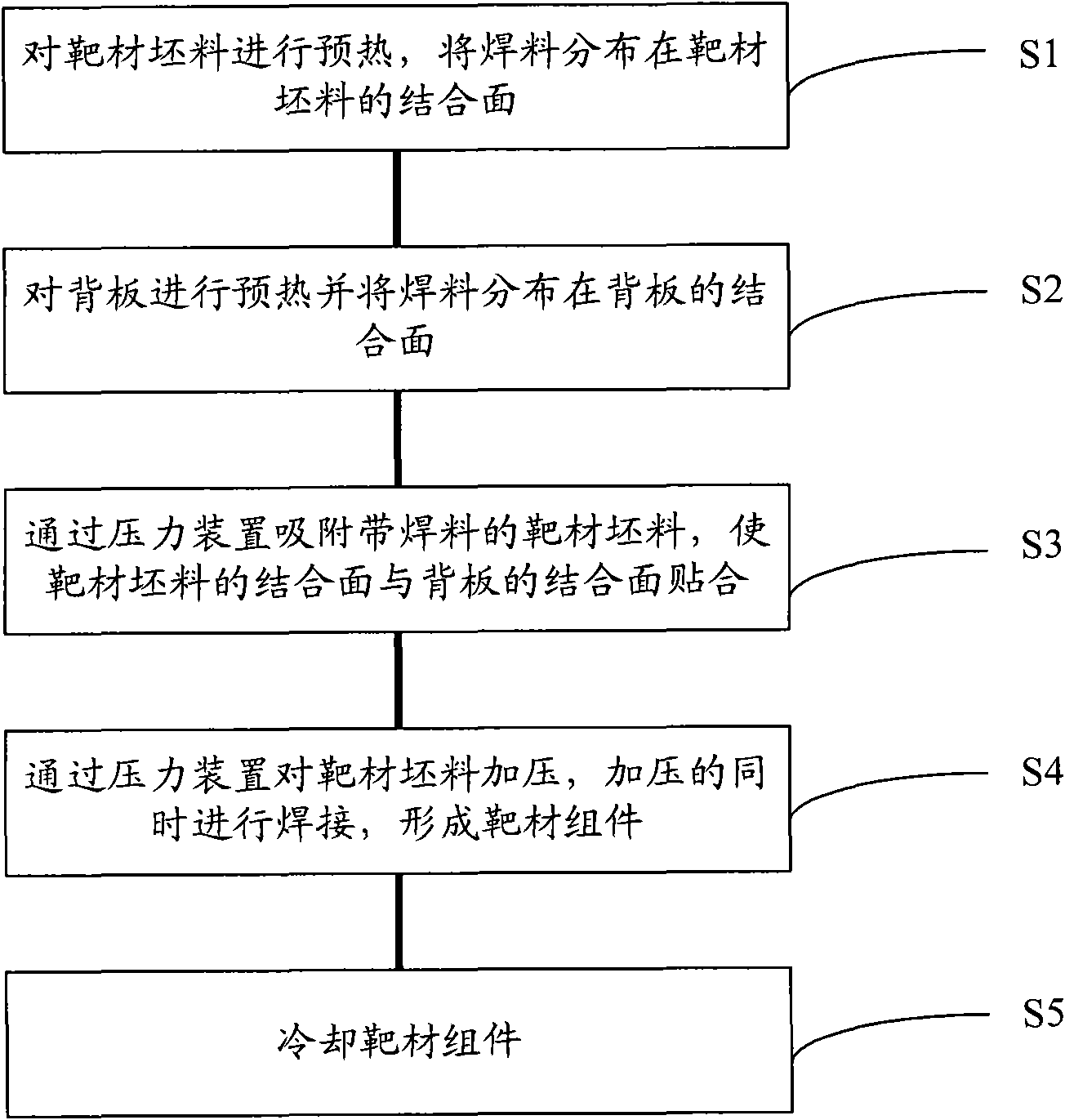

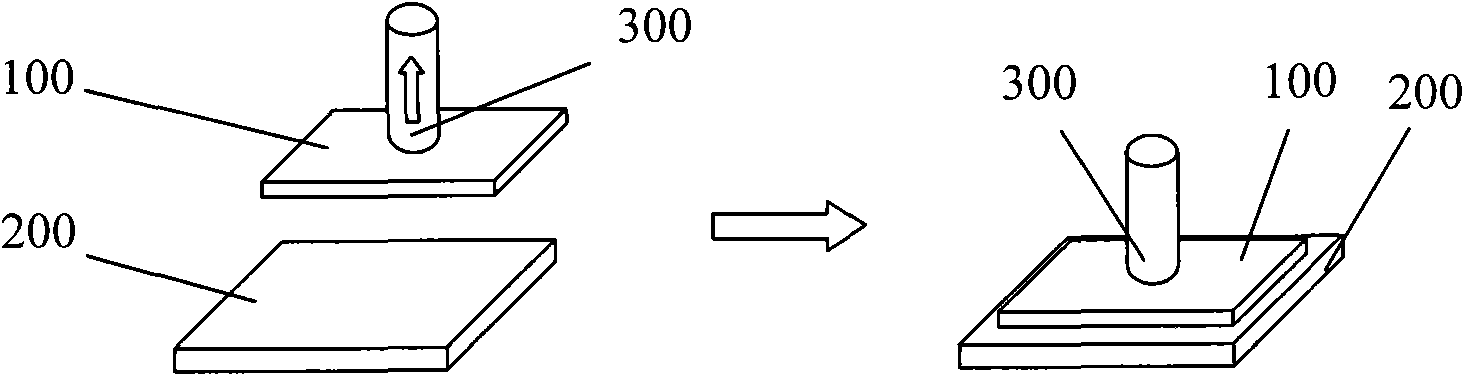

Welding method of target assembly

InactiveCN101811223AReduce production stepsShorten production timeNon-electric welding apparatusManufacturing efficiencyEngineering

The invention relates to a welding method of a target assembly. A pressure device having the functions of adsorption and pressurization is used by the method, and the pressure device comprises one or more working ends. The method comprises the following steps of: preheating a back plate and distributing solders on a bonding surface of the back plate; ensuring that the pressure device works under an adsorption state and adsorbing a target onto the back plate by using the working ends of the pressure device to ensure that a bonding surface of the target and the bonding surface of the back plate are jointed; ensuring that the pressure device works under a pressurization state, pressurizing the target by using the working ends of the pressurization device and welding while pressurizing; and cooling the target assembly. The invention can shorten the manufacture time, improve the manufacture efficiency, reduce the oxidation degree of the target and avoid the condition that the jointed target and the back plate have malpositions so as to obtain the target assembly with better quality. Moreover, the invention has small equipment using amount and smaller required space.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

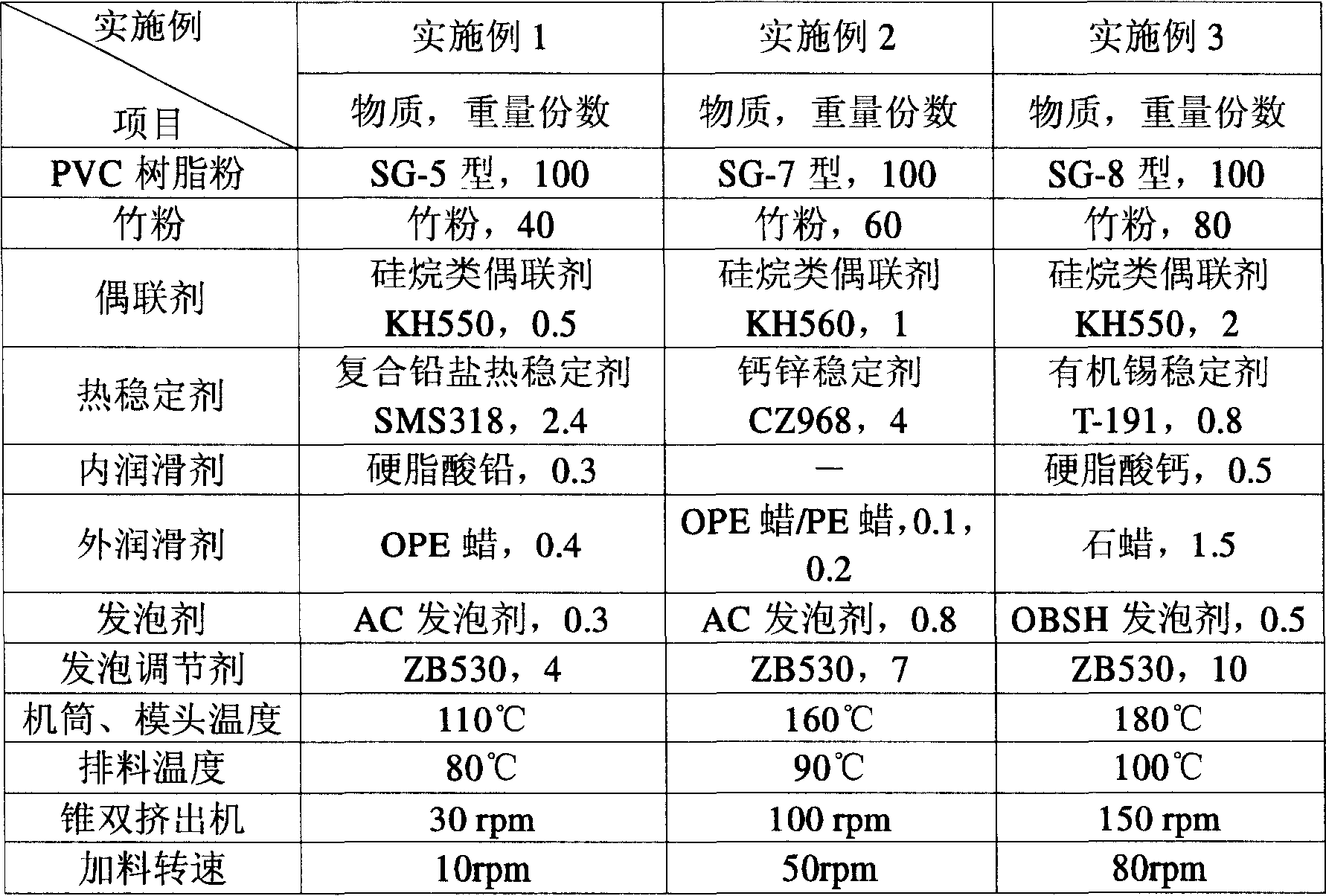

Bamboo/plastic surface crusting composite material and its preparation method

The invention discloses a bamboo-plastic composite material and its preparing process, wherein the composite material comprises the following constituents (by weight portions): PVC 100, bamboo powder 30-80, coupling agent 0.5-2%, heat stabilizer 0.5-4, lubricating agent 0.2-2%, foaming agent 0.2-0.8, and foaming regulation agent 3-12.

Owner:GUANGDONG LIANSU TECH INDAL

Low temp sintered ZnO multilyer pressure sensitive resister and its mfg. method

InactiveCN1564270AImprove flow capacityLow costResistor manufactureVaristor coresMetallurgyPalladium

The piezoresistor is fabricated by agglutinating interleaved ZnO porcelain and inner electrode. Main material of the ZnO porcelain is ZnO powder in sub micro of average particle diameter 0.10-0.99 micro. The inner electrode layer is made from palladium and argentine, and palladium is in 3-10% (Wt%) and argentine is in 990-97%. Agglutinating temp is 900-980 deg.C. The invention also discloses method for manufacturing the piezoresistor.

Owner:广州新日电子有限公司

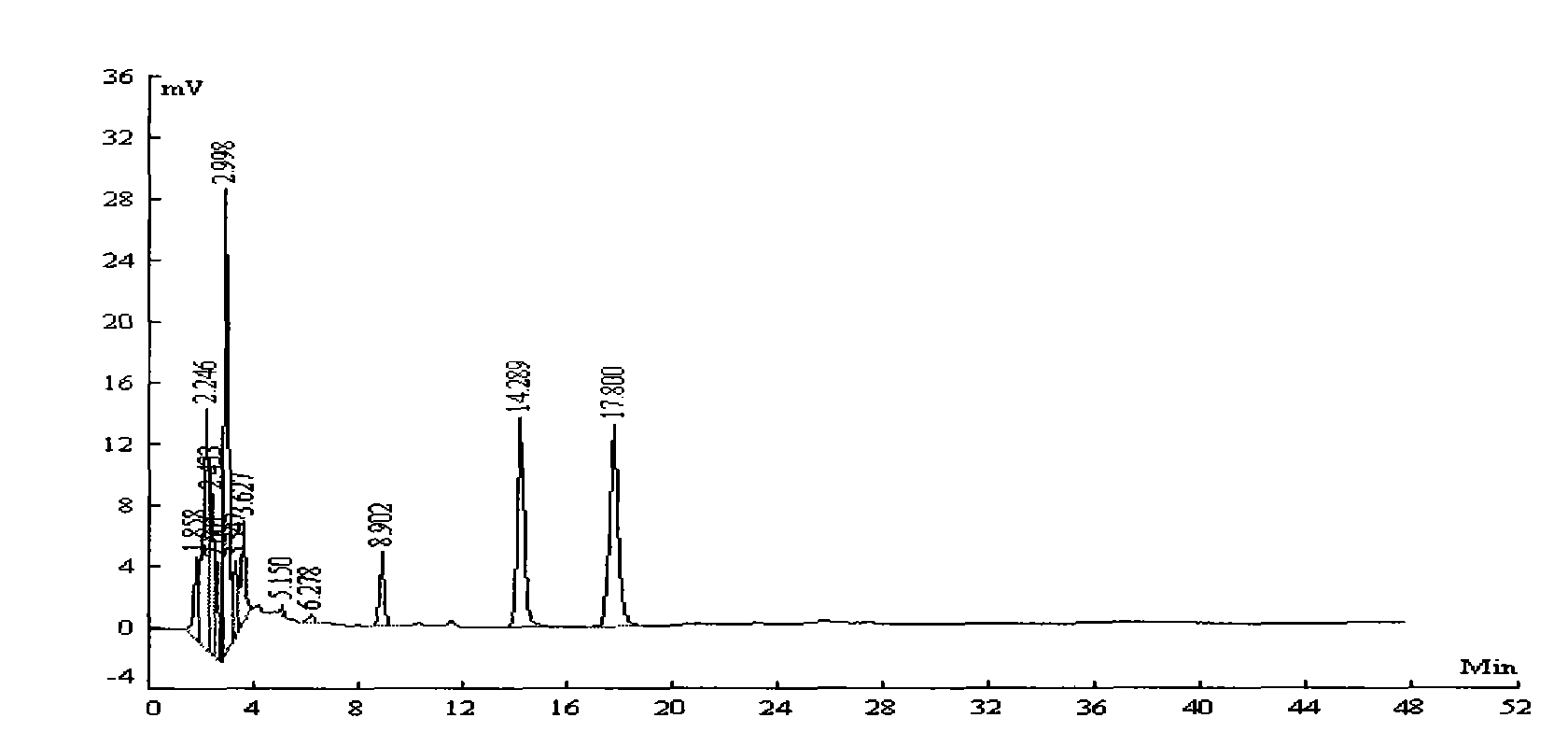

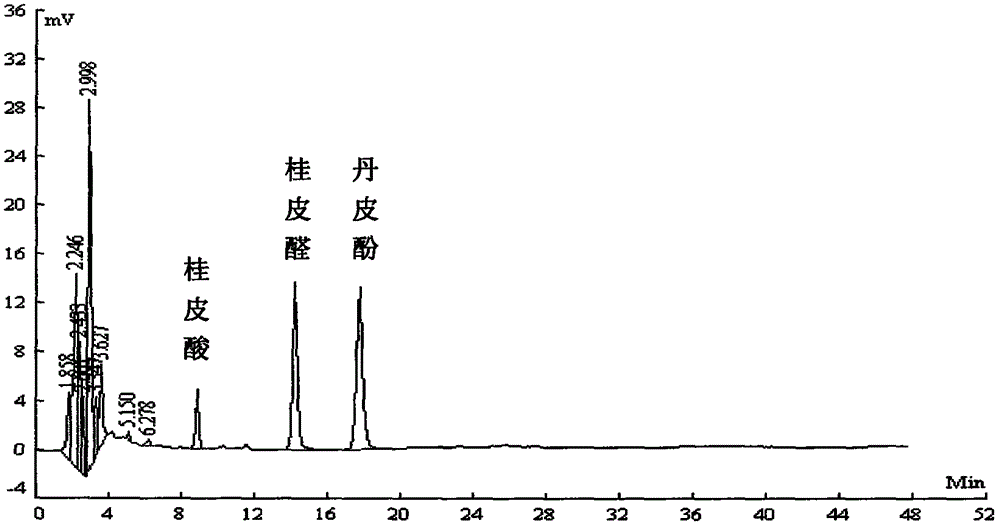

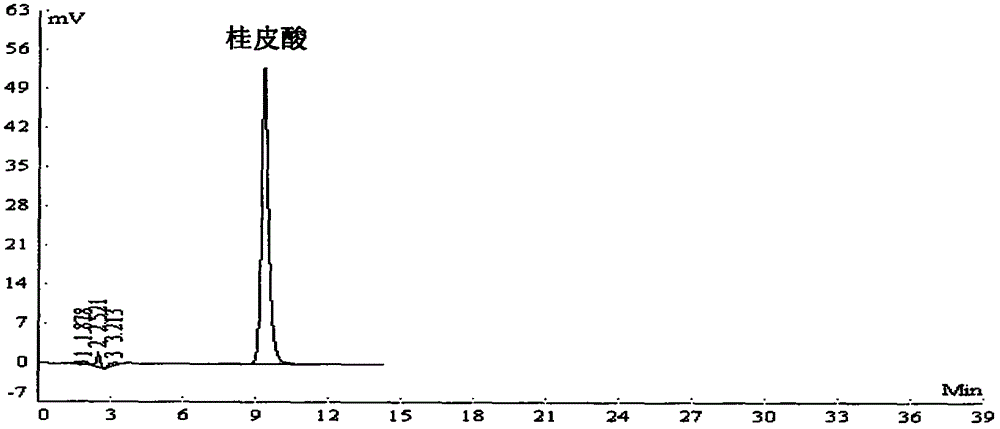

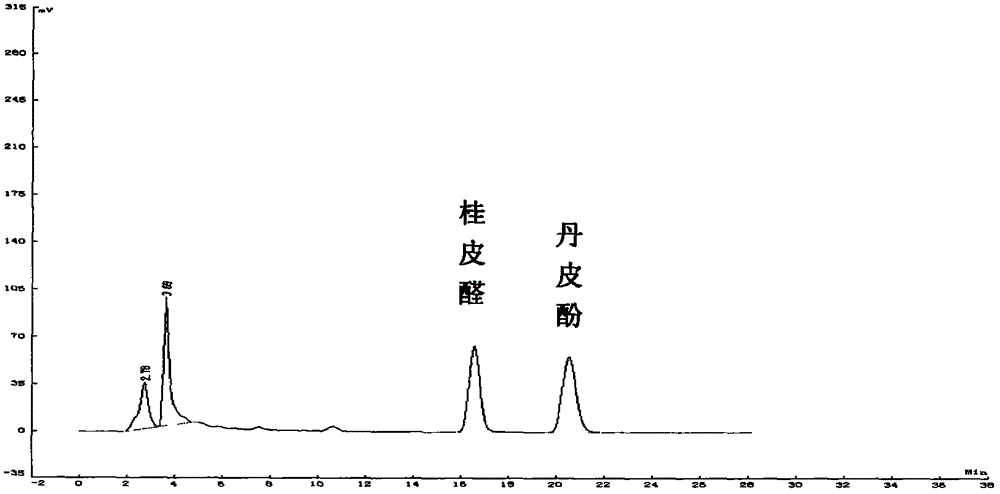

Preparation technology and quality control method of preparation containing cassia twig and tuckahoe

InactiveCN101653491AReduce production stepsShorten the production cycleComponent separationSexual disorderAdditive ingredientQuality control

The invention provides a new preparation method and a quality control method of a pill containing cassia twig and tuckahoe, The preparation method have the advantages of few production steps, short production cycle, high production mechanization, stable preparation quality, high content of effective ingredients, fast disintegration, high bioavailability, small dose, convenient administration and the like. The invention also provides the quality control method of cinnamyl aldehyde, cinnamic acid, paeonol, peoniflorin and amygdalin in the pill containing cassia twig and tuckahoe.

Owner:陈世忠

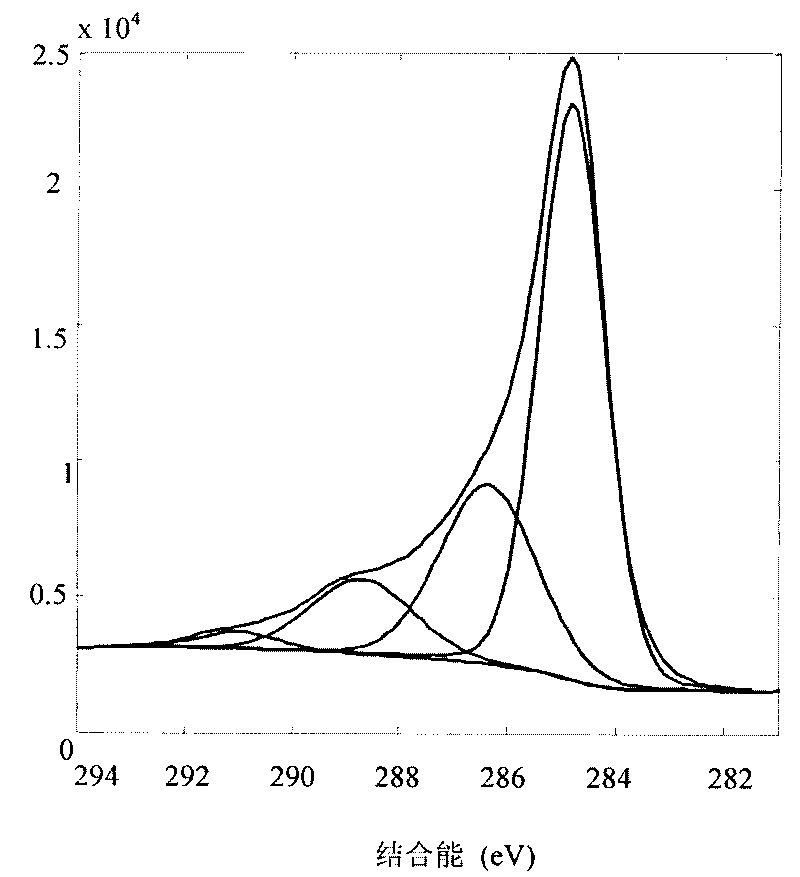

Preparation method of single-layer graphene

The invention relates to a preparation method of single-layer grapheme and belongs to the technical field of grapheme preparation. Single-layer graphene oxide is used as raw materials, and the invention comprises the following steps: dropwise adding concentrated sulfuric acid according to volume ratio in single-layer graphene oxide water dispersion liquid under the condition of an ice-water bath to prepare reaction liquid with sulfuric acid mass concentration of 70%-90%; reacting at 60 DEG C-100 DEG C, and then diluting with deionized water, cooling to room temperature and filtering; washing a filter cake with the deionized water, placing the filter cake in a vacuum dryer and drying at 65 DEG C-75 DEG C to obtain black grapheme. The invention has the advantages of low raw material cost, no poisons or damages and simple operation and is suitable for mass production. The prepared single-layer grapheme can be used in micro electronic elements, lithium ion batteries, fuel batteries, nano reinforced composites and other fields and has wide application prospects.

Owner:TIANJIN UNIV

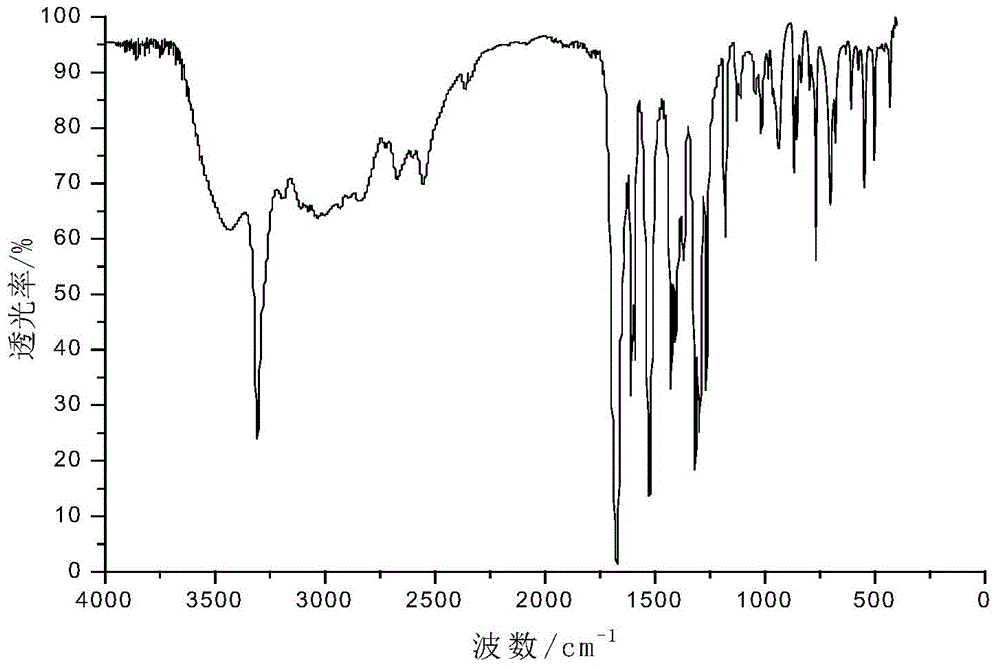

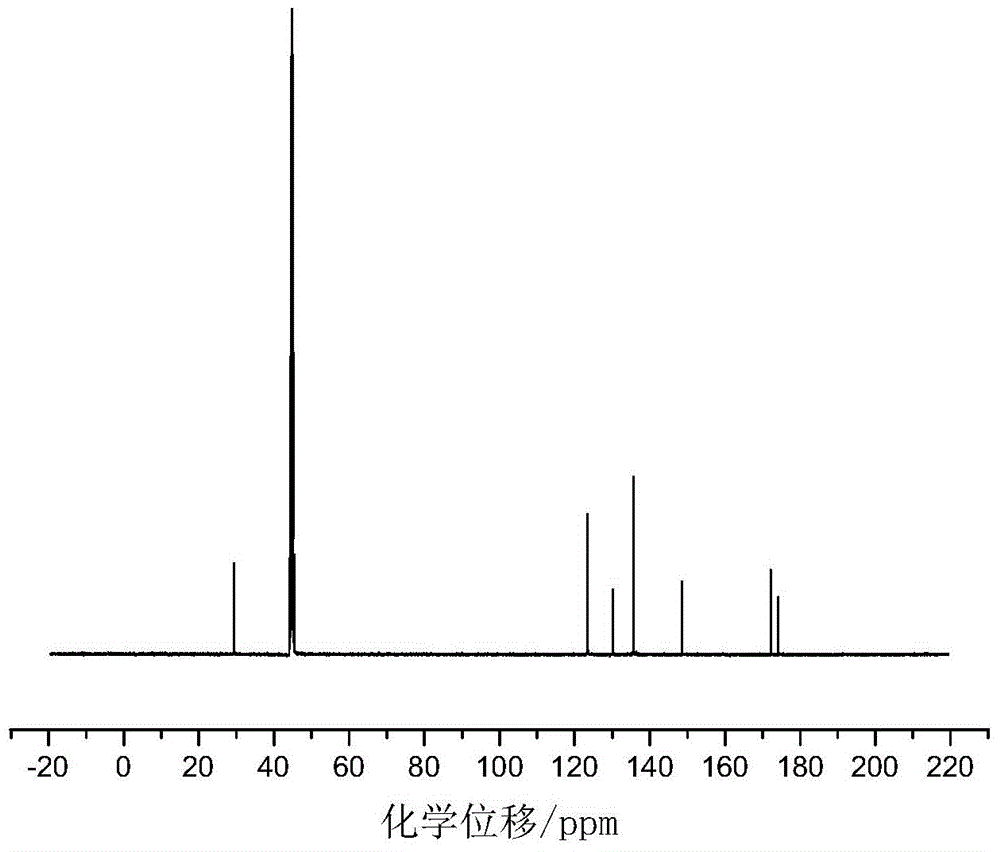

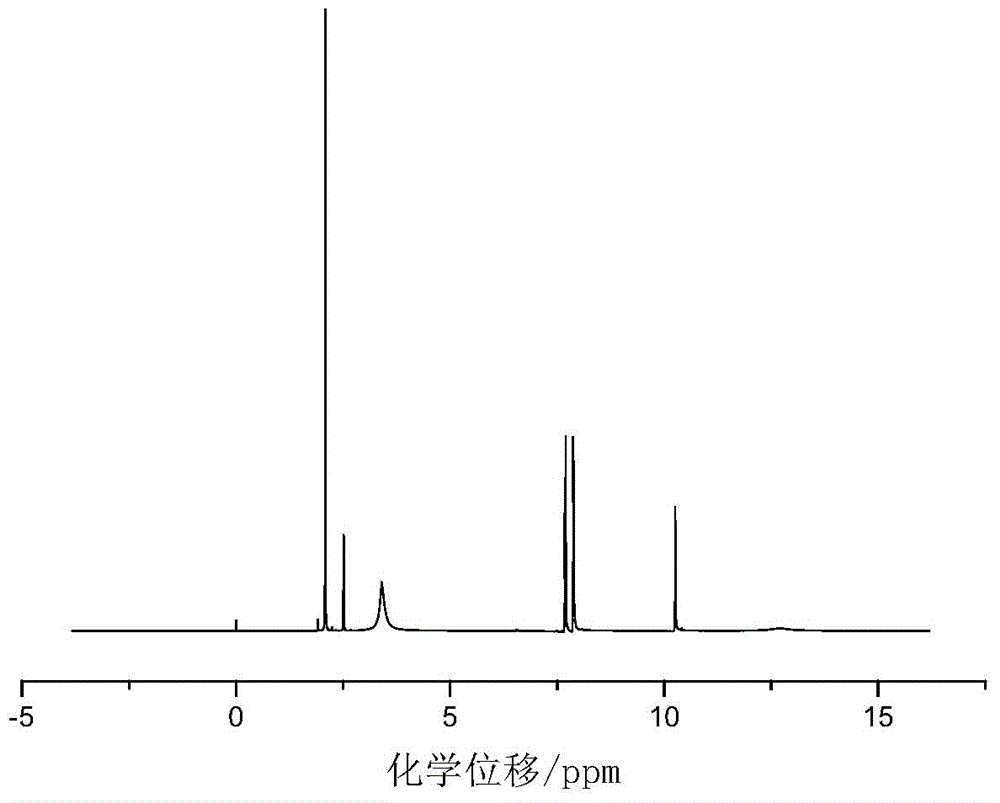

Reaction-type halogen-free flame retardant bis-(p-aminocarboxyphenyl)phenylphosphine oxide and synthetic method thereof

InactiveCN104945658APollution is notReduce production stepsGroup 5/15 element organic compoundsBenzoic acidDichlorophenylphosphine

The invention relates to reaction-type halogen-free flame retardant bis-(p-aminocarboxyphenyl)phenylphosphine oxide and its synthetic method and application and belongs to the field of preparation of a flame retardant. The synthetic method comprises the following steps: using glacial acetic acid as a solvent, adding para amino benzoic acid into glacial acetic acid, slowly dropwise adding dichlorophenylphosphine oxide into an acetic acid solution of para aminobenzoic acid, continuously stirring and reacting at 85-95 DEG C for 4-6 h, and absorbing hydrogen chloride discharged by the reaction by the use of aqueous alkali; and cooling a reaction product after the end of the reaction, carrying out suction filtration, washing and drying to obtain white powdery bis-(p-aminocarboxyphenyl)phenylphosphine oxide. The bis-(p-aminocarboxyphenyl)phenylphosphine oxide flame retardant has advantages of low toxicity, low smoke, innocuousness, high efficiency and the like, is a reactive flame retardant integrating a carbon source, an acid source and a gas source, and is applied in inherent flame retarding of nylon or thermoplastic polyester copolymer.

Owner:NANJING LIHAN CHEM CO LTD

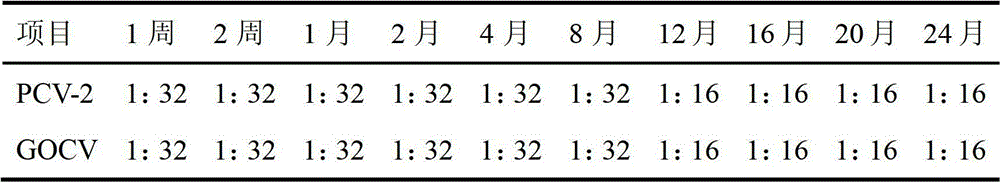

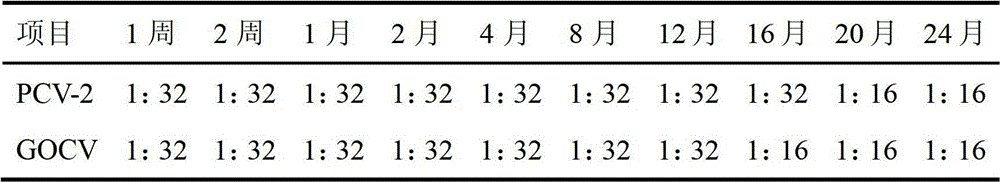

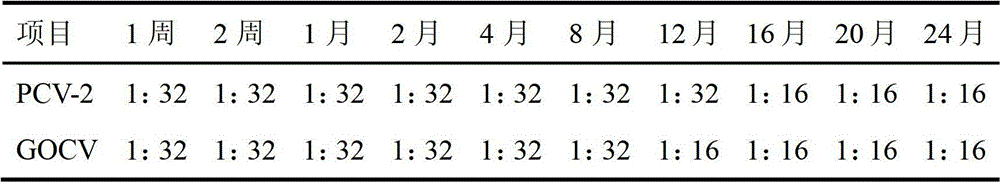

Cell inactivated vaccine, egg yolk antibody injection, and preparation method of cell inactivated vaccine

InactiveCN102716476AReduce lossesIncrease stimulationEgg immunoglobulinsViral antigen ingredientsDiseaseEpitope

The invention relates to a cell inactivated vaccine, an egg yolk antibody injection and a preparation method of the cell inactivated vaccine. The cell inactivated vaccine comprises a porcine circovirus antigenic epitope and a goose circovirus antigenic epitope. The preparation method of the cell inactivated vaccine comprises the following steps: firstly screening high-pathogenicity strains from the porcine circovirus, then selecting a plurality of virus epitopes having antibody immunocompetence from the strains, inserting the point of the porcine circovirus antigenic epitope into a goose circovirus genome by technologies such as purification and clone, and then carrying out viral multiplication in a large scale to obtain the cell inactivated vaccine. The invention also discloses the egg yolk antibody injection taking the cell inactivated vaccine as an antibody at the same time, the injection can be used for treating porcine circovirus diseases, takes effect quickly and has remarkable effects, meanwhile, a small dose can also be used for preventing the occurrence of the porcine circovirus diseases, so that the incidence rate is reduced and the economic benefit is improved. Meanwhile, the egg yolk antibody can also be used for treating the goose circovirus diseases. The preparation has lower stimulation on a human body, the working efficiency is further improved, and the feeding cost is lowered.

Owner:河南后羿生物工程股份有限公司

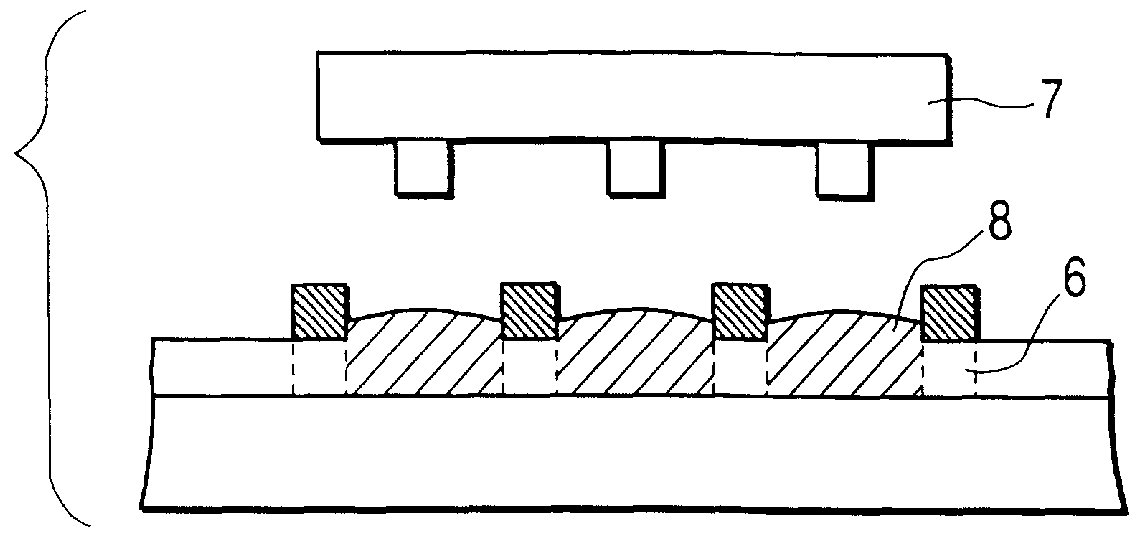

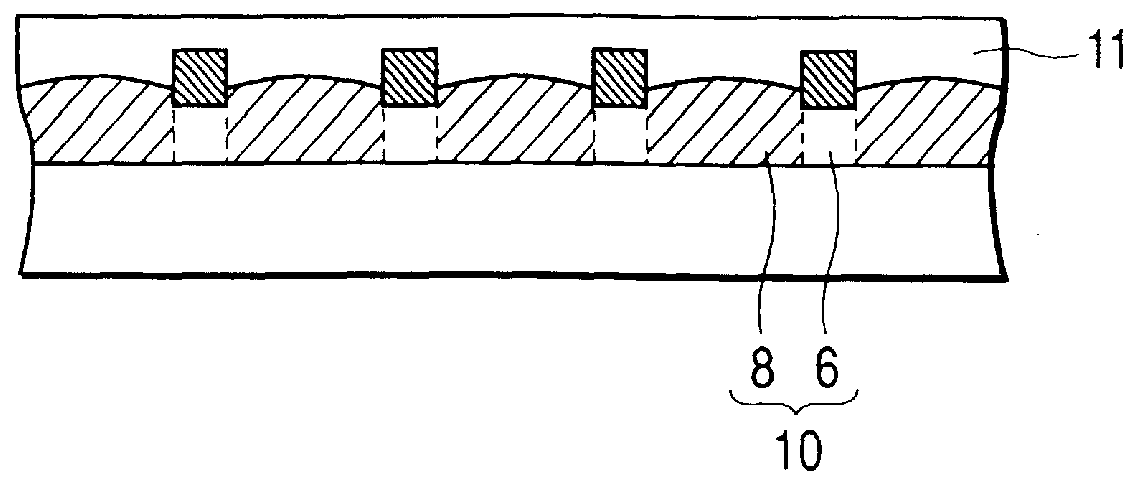

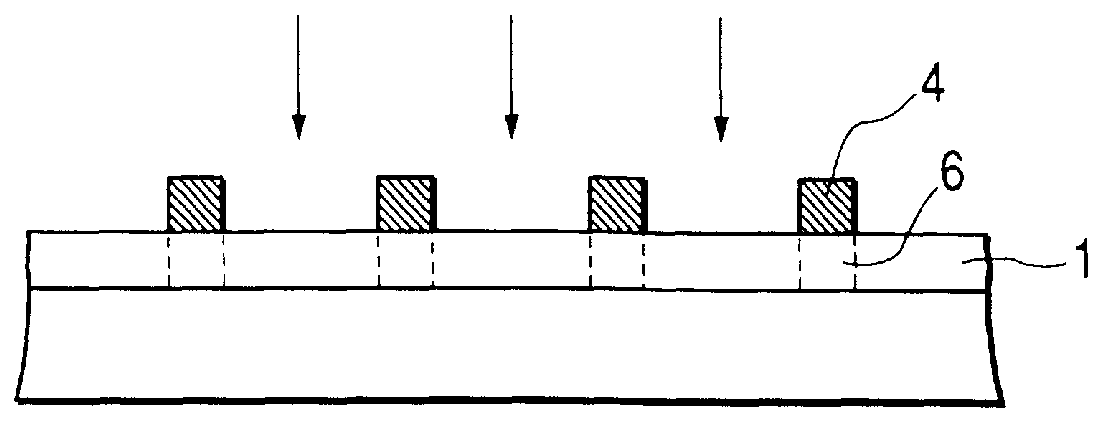

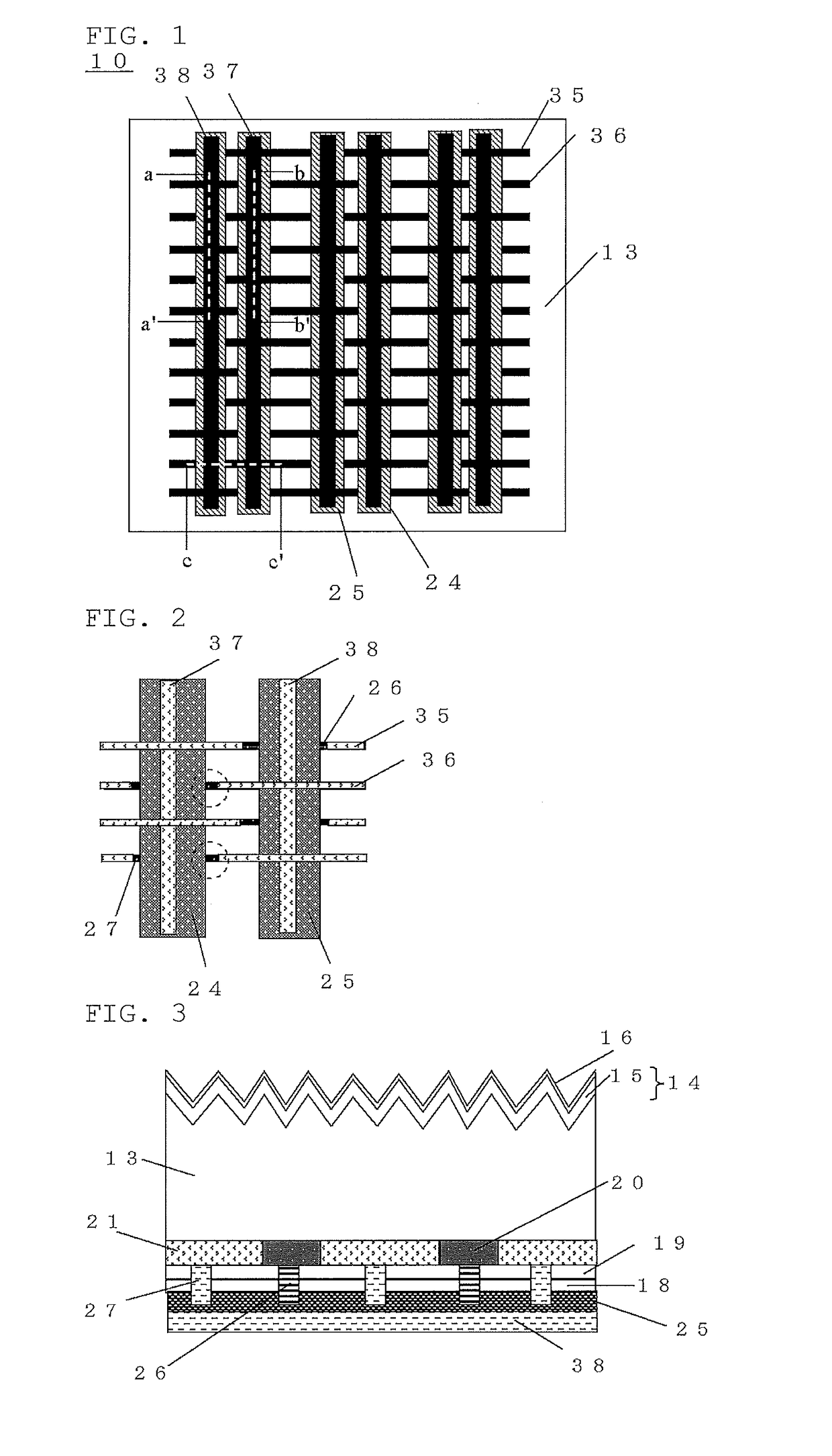

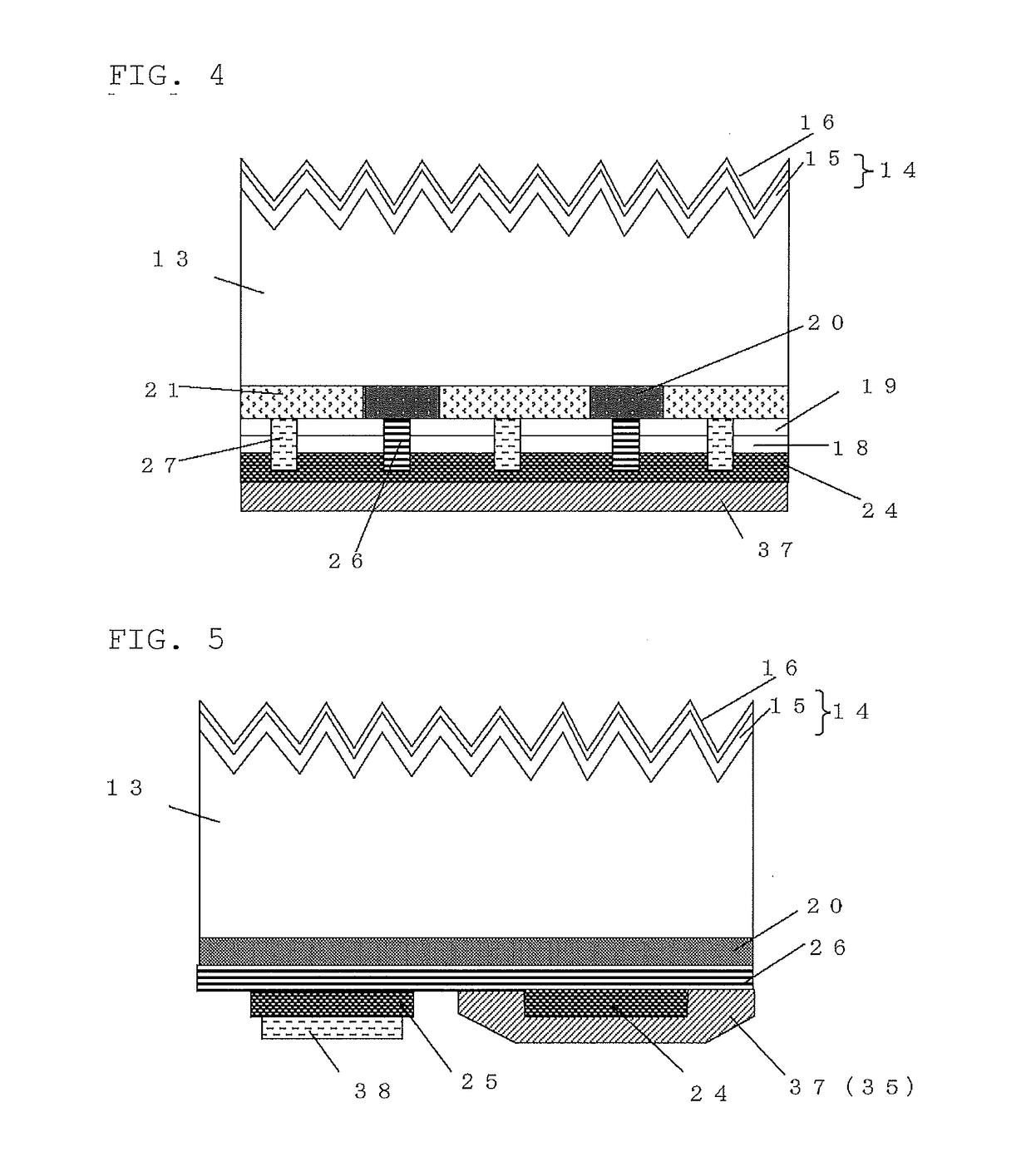

Solar cell and method for producing thereof

ActiveUS20170170338A1Increase the number ofShorten the lengthPhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

Solar cell including: a semiconductor substrate of a first conductivity type having a region of the first conductivity type and region of a second conductivity type on the back side; a first finger electrode composed of a first contact portion and first current collector, a second finger electrode composed of a second contact portion and second current collector, a first bus bar electrode, a second bus bar electrode on the backside; an insulator film disposed at least in the area just under the first bus bar electrode and second bus bar electrode; wherein the electrical contact between the first current collector and first bus bar electrode as well as electrical contact between the second current collector and the second bus bar electrode are made on the insulator film; and first contact portion and the second contact portion are in a continuous line shape at least just under the insulator film.

Owner:SHIN ETSU CHEM IND CO LTD

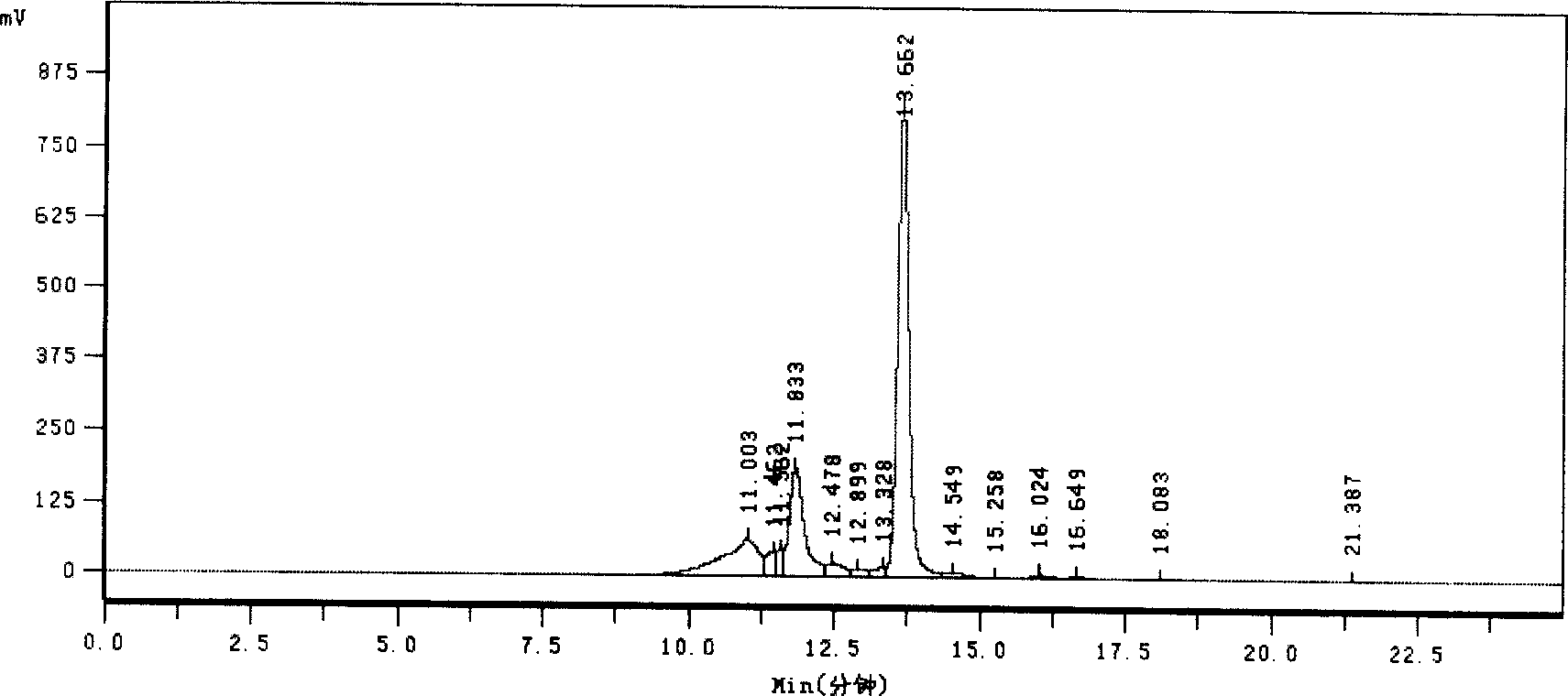

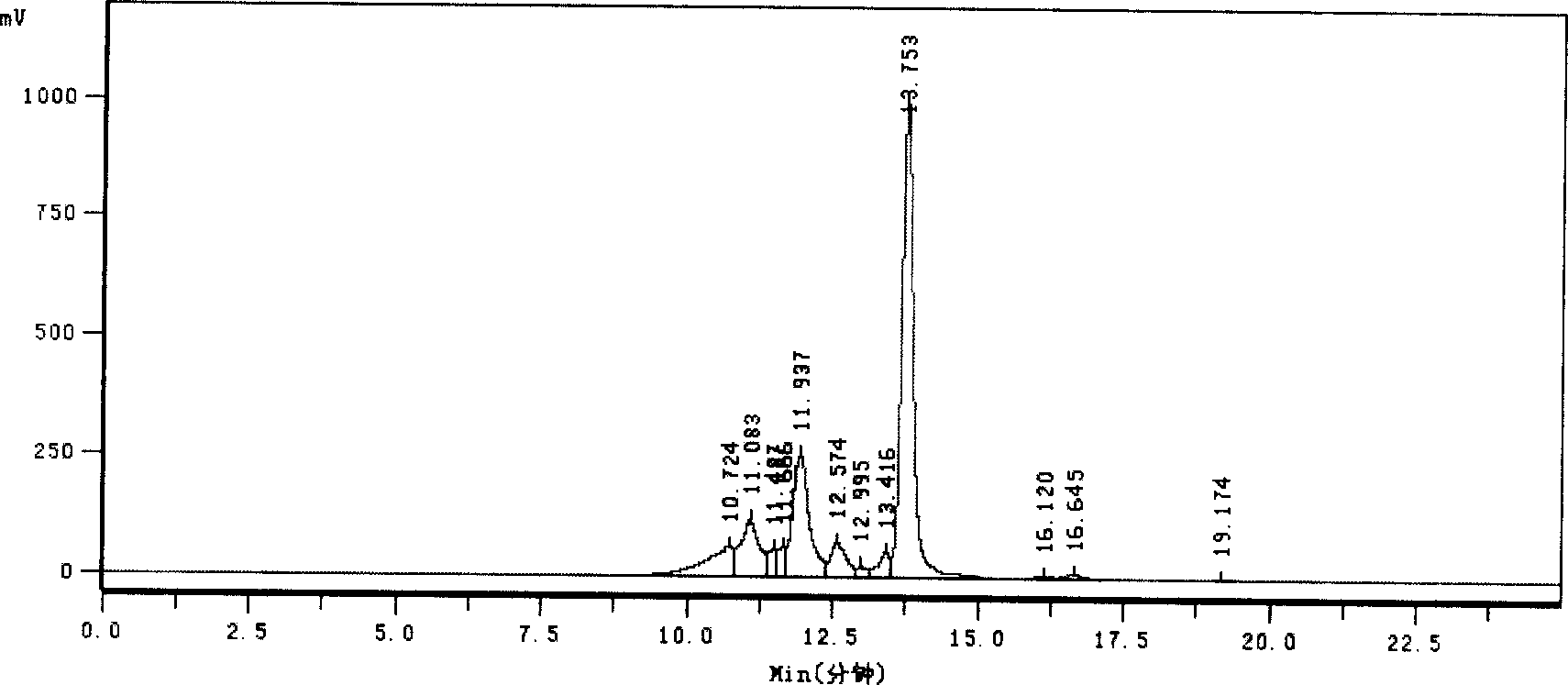

Novel multifunctional electrolyte

Provided is a novel multifunctional electrolyte which comprises lithium salts, a novel cosolvent and a functional compound. The novel cosolvent comprises line style carbonic ester and annular carbonic ester, wherein, line style carbonic ester with a low melting point and low viscosity accounts for the majority of the novel cosolvent, and the novel cosolvent is enabled to perform good charge and discharge performance at low temperature by compounding line style carbonic ester and annular carbonic ester according to an optimized ratio. The functional compound is obtained by mixing compounds A and compounds B, wherein, compounds A have a good film forming characteristic and maintain stable at high temperature, which enables cycle performance of a battery to be effectively improved, pneumatic swelling of the battery to be avoided and high temperature performance of the battery to be enhanced, and compounds B are phosphate ester compounds with a low melting point, which enables low temperature performance of the battery to be further enhanced on the one hand and safety performance of the battery to be substantially improved on the other hand thanks to the flame retardation characteristic of phosphate ester compounds. Through component and ratio optimization, the problems of low temperature performance, high temperature performance, safety performance, cycle performance and pneumatic swelling of the electrolyte are well solved simultaneously.

Owner:HUNAN UNIV

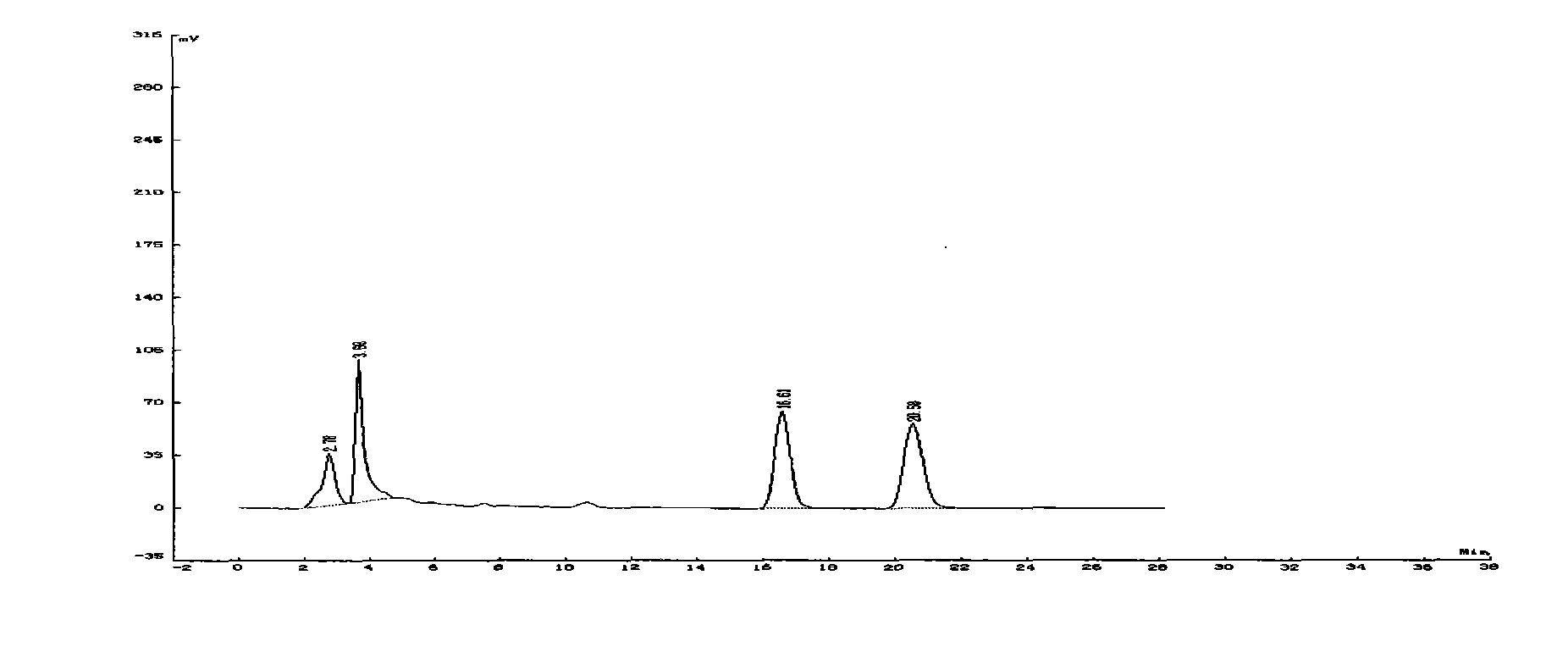

Preparation process and quality control method of cassia twig poria cocos preparation

InactiveCN104815025AReduce production stepsShorten the production cycleComponent separationAntineoplastic agentsBuccal administrationCinnamaldehyde

The invention provides a preparation process and a quality control method of a cassia twig poria cocos preparation. The preparation method has the advantages of less production steps, short production period, high production mechanical degree, stable quality of the preparation, high content of effective components, rapid disintegration, high bioavailability, small dose oral administration, convenience in oral administration and the like. The invention also provides a quality control method of cinnamaldehyde, cinnamic acid, paeonol, paeoniflorin and amygdalin in a cassia twig poria cocos pill.

Owner:陈世忠

Man-made lawn and preparation method therefor

ActiveCN105568498AIncrease binding forceImprove pullout forceGround pavingsGeotextilesEngineeringLawn

The invention relates to a preparation method for a man-made lawn. The preparation method comprises the following steps: arranging warp yarns on a warp beam of a braiding machine, arranging weft yarns on the braiding machine in a direction perpendicular to the warp yarns, arranging man-made grass silk yarns on a yarn creel at the back part of the braiding machine, enabling the man-made grass silk yarns to participate in braiding of bottom cloth in a direction parallel to the warp yarns, and performing grass jacquard weaving treatment on the man-made grass silk yarns by utilizing jacquard equipment of the braiding machine; bypassing the bottom cloth for 2-10 circles by each man-made grass silk yarn to form a cluster of grass silk, setting the height of the grass silk cluster to be 10-70mm, and arranging 6-12 warp yarns between any two adjacent grass silk clusters; and arranging 3-8 weft yarns between any two adjacent grass silk clusters in the grass silk clusters arranged vertically. The preparation method is simple, easy to operate and convenient for industrial production, and pullout force of the grass silk can be increased; and the man-made lawn prepared with the method has the advantages of environmental protection, wide application range and high stability.

Owner:GUANGZHOU AOSHENG ARTIFICIAL STRAW CO LTD

Preparation method of high performance halogen free environment-friendly extruded magnetic stripe made of rubber&plastic ferrite and magnetic stripe

InactiveCN102163496AReduce production stepsReduce energy consumptionMagnetsInductances/transformers/magnets manufactureAdhesiveFerrite powder

The invention discloses a preparation method of a high performance halogen free environment-friendly extruded magnetic stripe made of rubber&plastic ferrite. The method is characterized by comprising the following steps: (1) preparing raw material mixture, to be more specific, preparing uniform raw material mixture by mixing ferrite powder, the size of which is between 10 and 200 nanometers, cladding agent and adhesive; (2) extruding a sheet, to be more specific, setting a scope of extrusion thickness for an extruder, feeding the raw material mixture into the extruder, and successively extruding to obtain a plastic magnetic sheet; (3) cutting, to be more specific, cutting the plastic magnetic sheet into predetermined shape and dimension; (4) UV glazing, to be more specific, spraying UV oil polish on a surface of the magnetic sheet, thereby forming a protection film on the surface; (5) magnetizing, to be more specific, magnetizing by placing the magnetic sheet in a magnetic field to obtain a magnetic stripe. The invention also discloses an extruded magnetic stripe of high performance halogen free environment-friendly rubber&plastic ferrite prepared by the method. The invention can be widely applied to the manufacturing field of flexible rubber&plastic magnetic products.

Owner:广州高馨能生物科技有限公司 +1

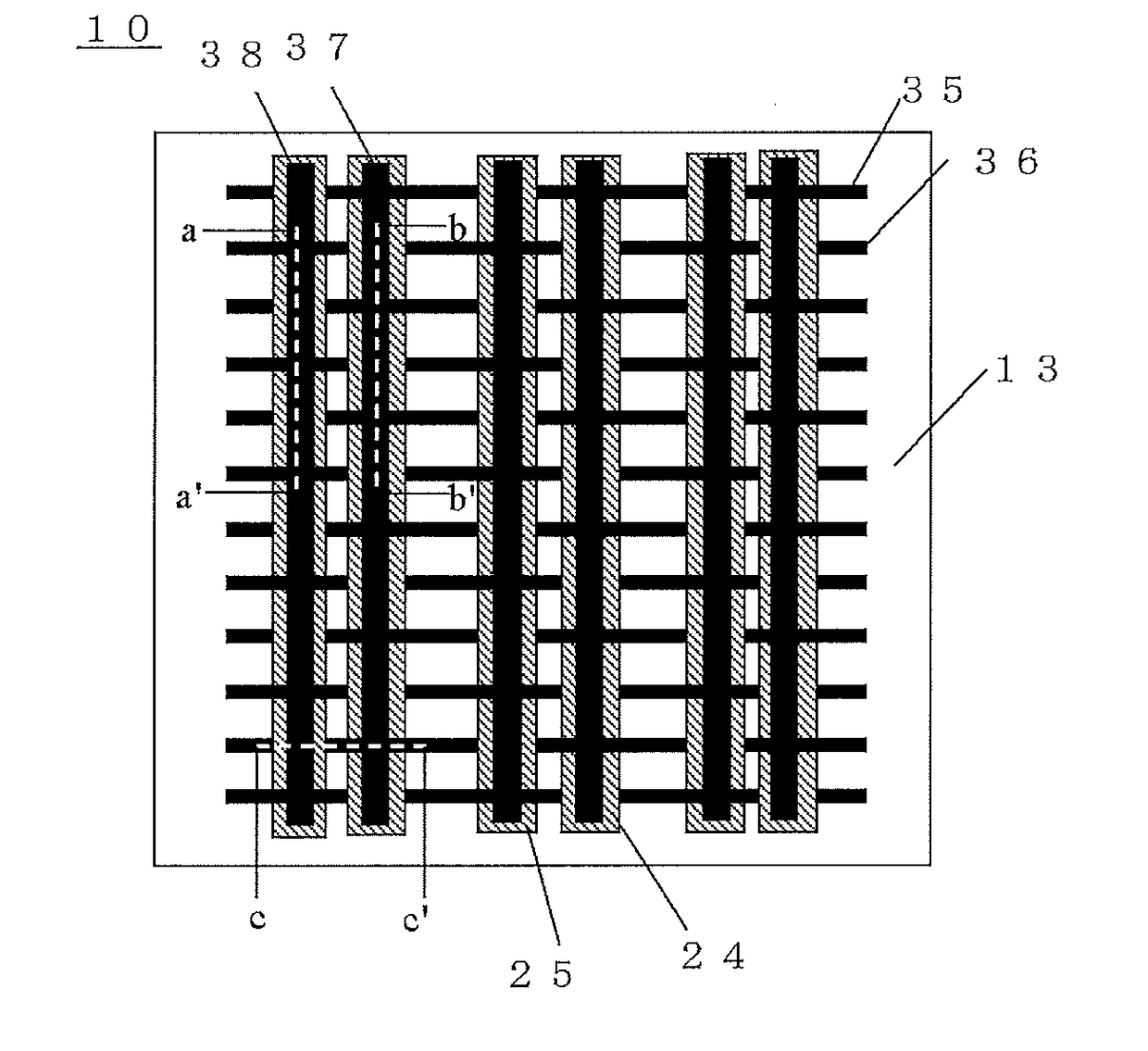

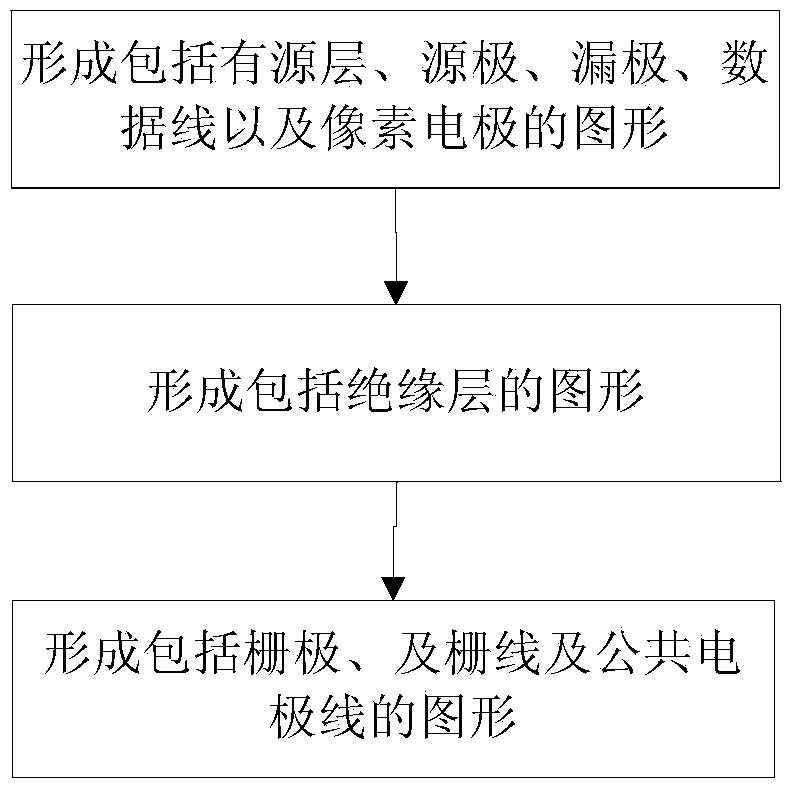

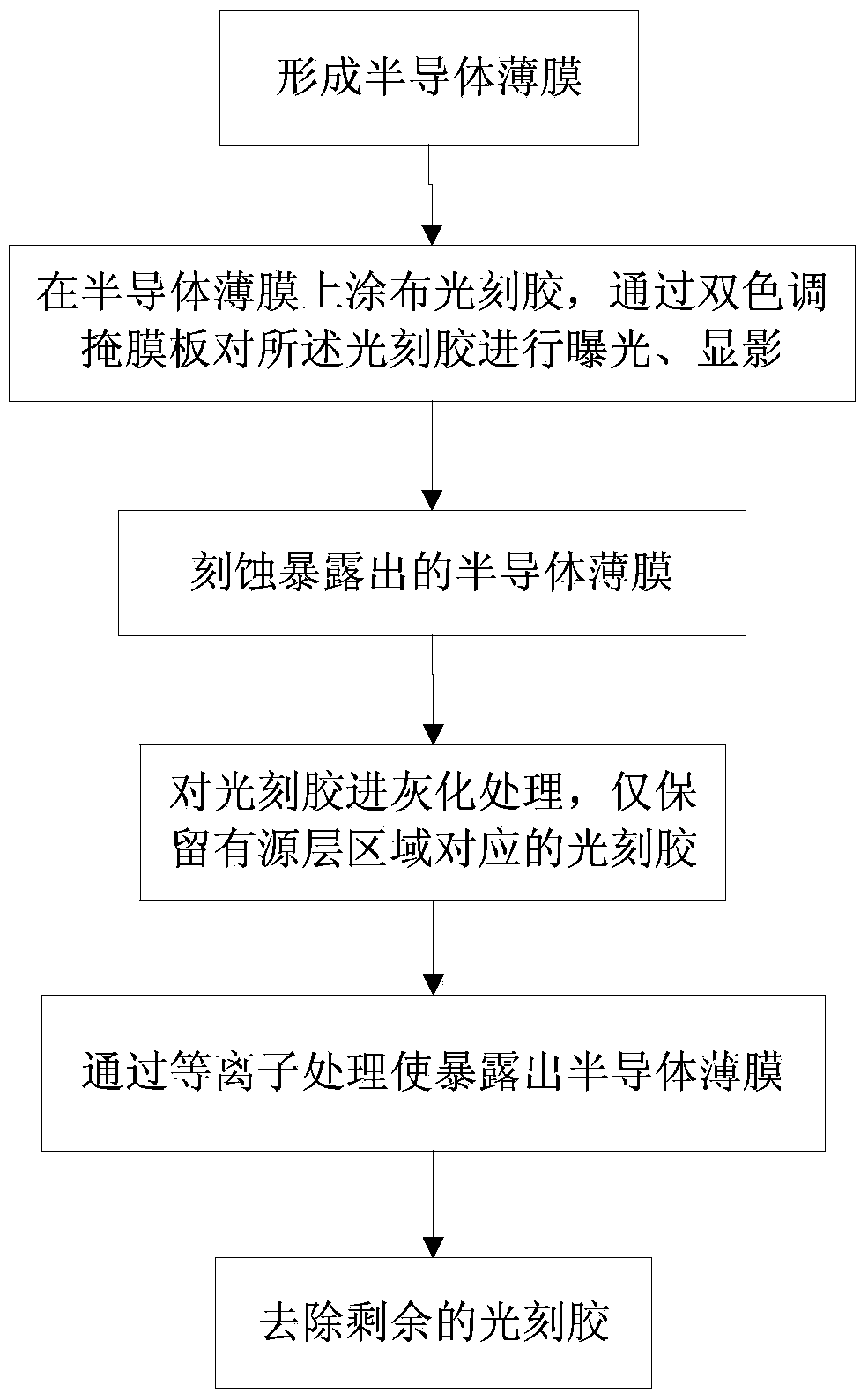

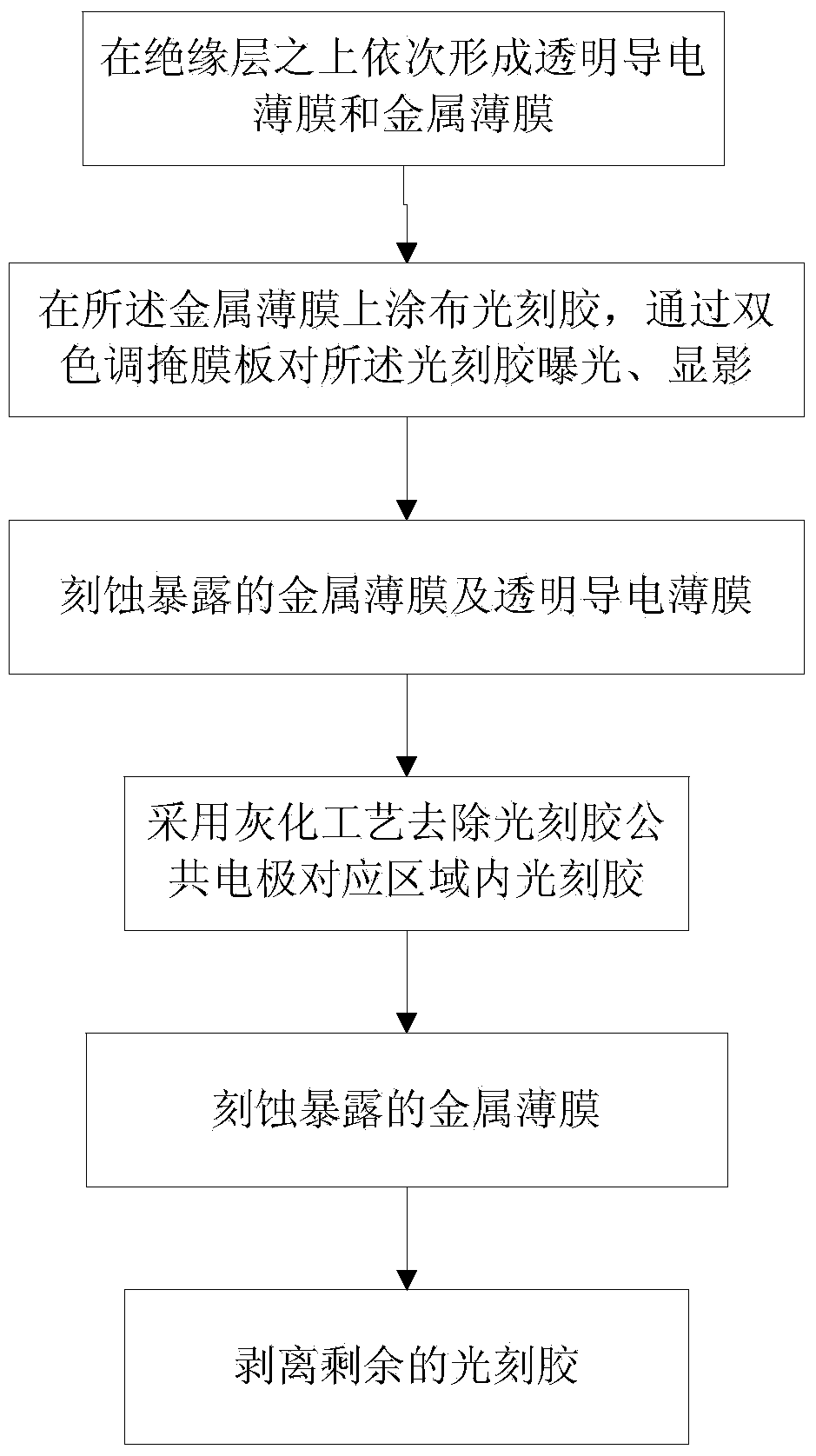

Manufacturing method of array substrate, array substrate and display device

ActiveCN103700628AReduce production stepsEasy to makeSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsData lines

The invention discloses a manufacturing method of an array substrate, the array substrate and a display device which are designed for solving the problems that an existing manufacturing technology of the array substrate is complicated, the economic benefit is low, and the like. The manufacturing method of the array device comprises the steps of forming a graph comprising an active layer, a source electrode, a drain electrode, a data line and a pixel electrode on a transparent substrate through one graph composition technology; forming a graph comprising an insulation layer; forming a graph comprising a grid electrode and a grid line through one graph composition technology. The manufacturing method of the array substrate, the array substrate and the display device, which are disclosed by the invention, have multiple advantages that the manufacturing technology is simple, the structure is simple and ingenious, the cost of a consumable device is low, the economic benefit is low, and the like.

Owner:BOE TECH GRP CO LTD

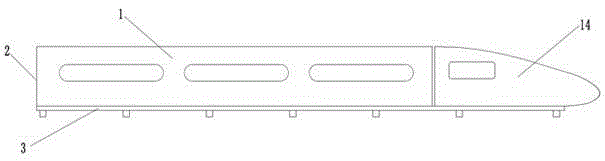

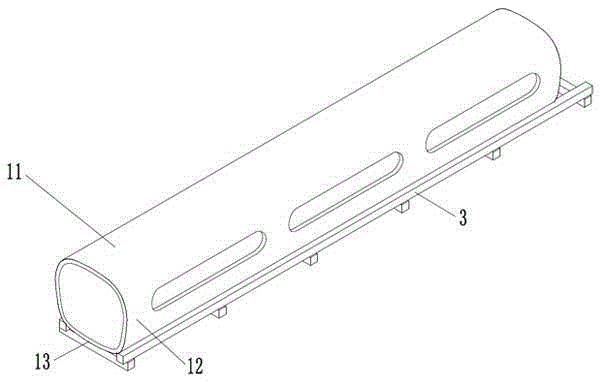

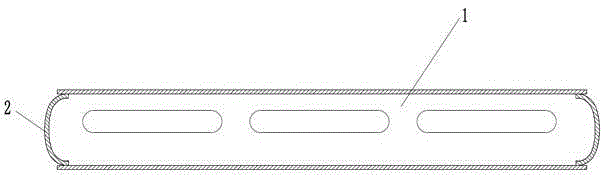

Rail vehicle body and preparation method thereof

ActiveCN105383506AImprove performanceHigh overall performance, good stiffnessRailway transportAxle-box lubricationEngineeringPre treatment

The invention discloses a rail vehicle body which is low in weight and renewable in resource, preserves heat and lowers noise. The rail vehicle body comprises a roof, end walls, a side wall and a bottom frame. The bottom frame comprises a bottom plate and a bearing structure. A vehicle main body is defined by the side wall, the roof and the bottom plate. The side wall and the roof are in fillet transition, the side wall and the bottom plate are in fillet transition, the vehicle main body is integrally formed by winding bamboo skin and resin, the end walls are fixed to the ends of the vehicle main body, and the vehicle main body is fixed to the bearing structure. The invention further discloses a preparation method of the rail vehicle body. The preparation method includes the steps of resin modification, wherein modifier and flame retardant are added to the resin; bamboo skin pretreatment, wherein the bamboo skin is subjected to water removal and antiseptic treatment, and then the bamboo skin is connected into a continuous bamboo skin belt; manufacturing of a mandrel; vehicle main body winding, wherein the bamboo skin belt winds around a mandrel in a transverse, longitudinal and spiral intersecting mode, and the modified resin is poured during winding; manufacturing of the end walls and the bearing structure; fixation of the end walls to the ends of the vehicle main body; fixation of the vehicle main body to the bearing structure.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

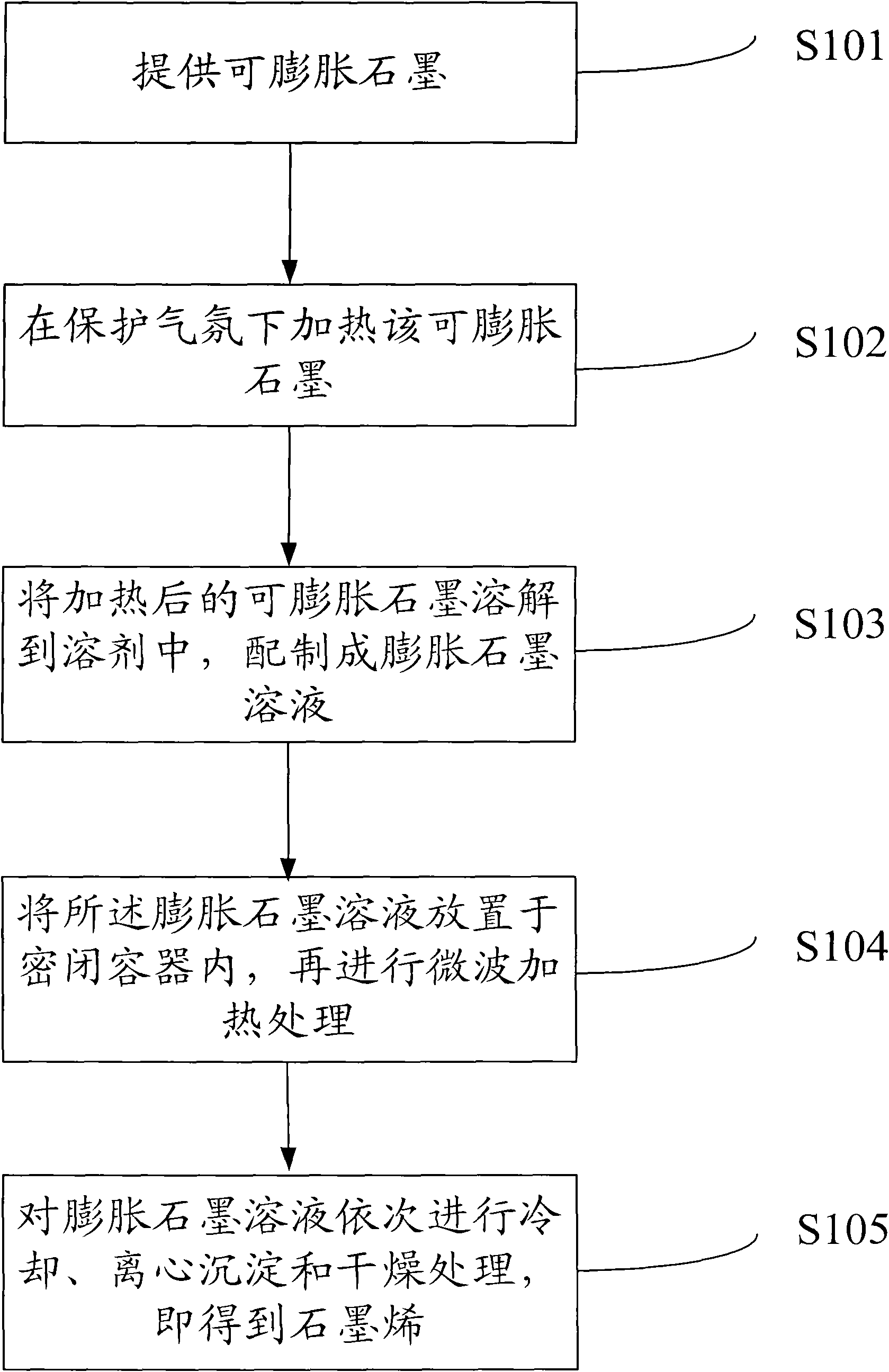

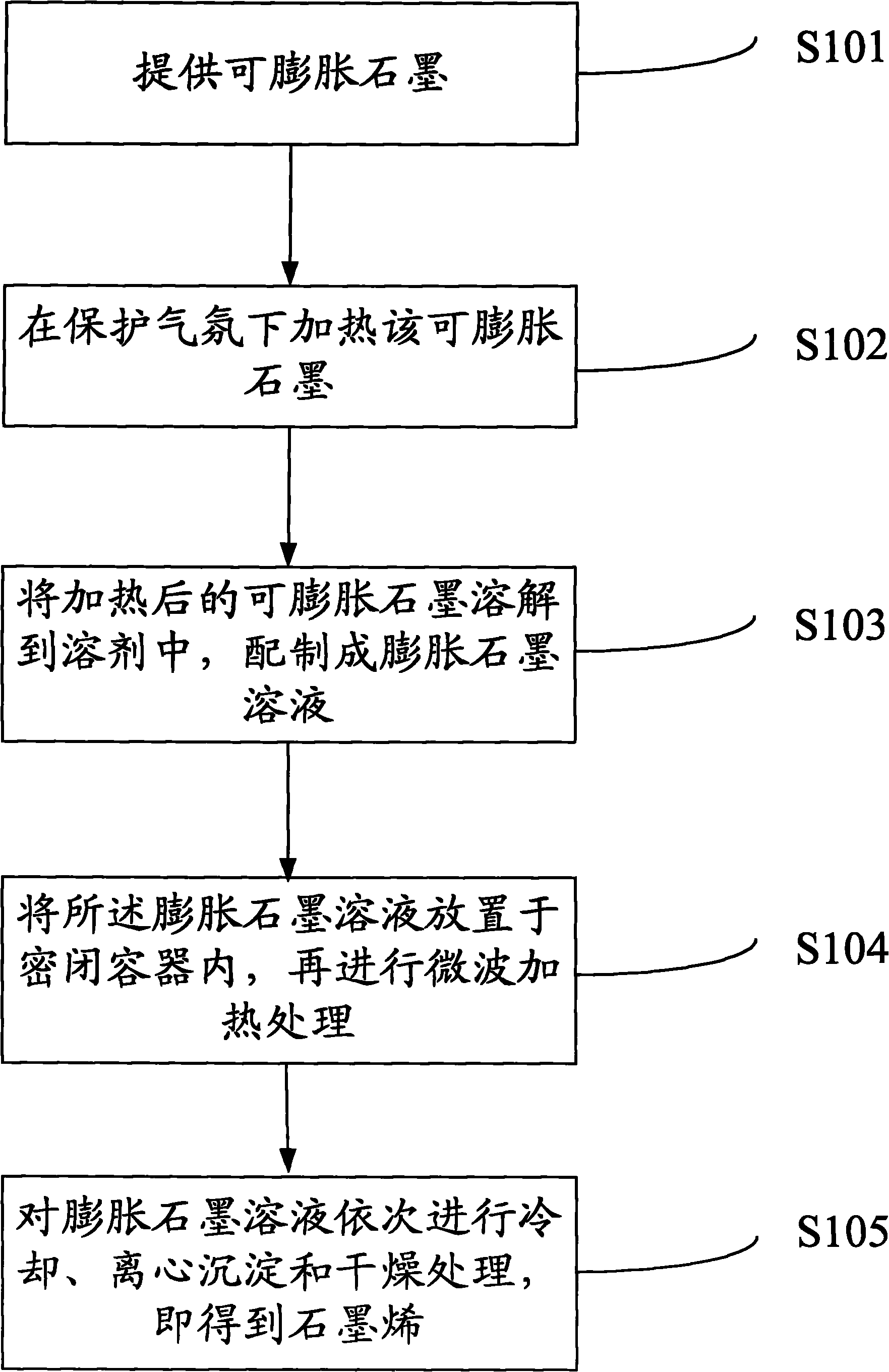

Preparation method of graphene

The invention discloses a preparation method of graphene. The preparation method comprises the following steps of heating expandable graphite in a protecting gas atmosphere, dissolving the heated expandable graphite in a solvent to obtain an expandable graphite solution, putting the expandable graphite solution into an enclosed container, carrying out microwave heating, and orderly carrying out cooling, centrifugation sedimentation and drying of the heated expandable graphite solution to obtain graphene. The preparation method of graphene has the advantages of low cost and high yield.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

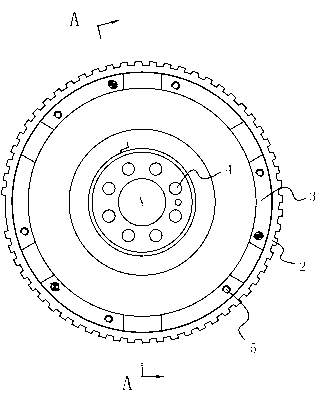

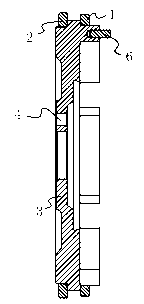

Production process of flywheel assembly for automobile engine

The invention discloses a production process of a flywheel assembly for an automobile engine. The production process of the flywheel assembly for the automobile engine comprises the following steps: (1) a signal disc is produced; (2) a gear ring is produced; (3) a flywheel body is produced; (4) assembling is conducted in a pressing mode, namely, the signal disc produced in the first step and the gear ring produced in the second step are assembled on the flywheel body produced in the third process, wherein the signal disc is riveted with a connecting disc at first, and then the gear ring is heated for 30-60 minutes under the environmental temperature of 200-300 degrees, is arranged on the flywheel body in a hot pressing mode through a pressing assembling machine after being taken out and is naturally cooled; (5) gravity balancing is adjusted; and (6) cleaning and packaging are conducted. Because the gear ring is heated for 30-60 minutes under the environmental temperature of 200-300 degrees, is arranged on the flywheel body in a hot pressing mode through the pressing assembling machine after being taken out and is naturally cooled, quality of the flywheel assembly is greatly improved, production steps are reduced, and production efficiency is improved.

Owner:QINGDAO JINHUAN AUTOPARTS MFR

Printed Circuit Board

InactiveUS20150334841A1Reduce production stepsPrinted circuit aspectsSolid-state devicesInsulation layerEngineering

A multilayer printed circuit board comprising conductive layers separated by dielectric insulation layers, at least one conductive layer being patterned and parts of conducting layers being interconnected by means of vias traversing insulation layers, and at least one component having terminals electrically connected with conducting layers is countersunk at least partly in a cavity having a floor and side walls, whereby a first component is completely countersunk in the cavity with its terminals connected face-down directly with contacts on the floor of the cavity and at least one further component is stacked above the first component, whereby an edge of the lower surface of the second component projecting over the upper surface area of the at least one further component is provided with terminals being connected directly face-down with contacts of the circuit board arranged on a level higher than the floor of the cavity.

Owner:AT & S AUSTRIA TECH & SYSTTECHN AG

Binder for 3D printed ceramic material and application of binder

The invention discloses a binder for a 3D printed ceramic material and an application of the binder. The binder can promote a curing agent, sol ions and a ceramic surface to form stable chemical bonds such as Si-O, Si-F, Al-O and the like under the conditions of ultraviolet irradiation, normal temperature and normal pressure, the binder and ceramic particles are connected into a whole, and a ceramic product is directly obtained. Popularization and application of the 3D printed ceramic material in life are greatly promoted, and the binder has wide market prospect.

Owner:湖南世纪特邦新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com