Bamboo/plastic surface crusting composite material and its preparation method

A technology of crust foaming and composite materials, applied in the field of bamboo and plastic, to achieve the effect of low cost, high hardness and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

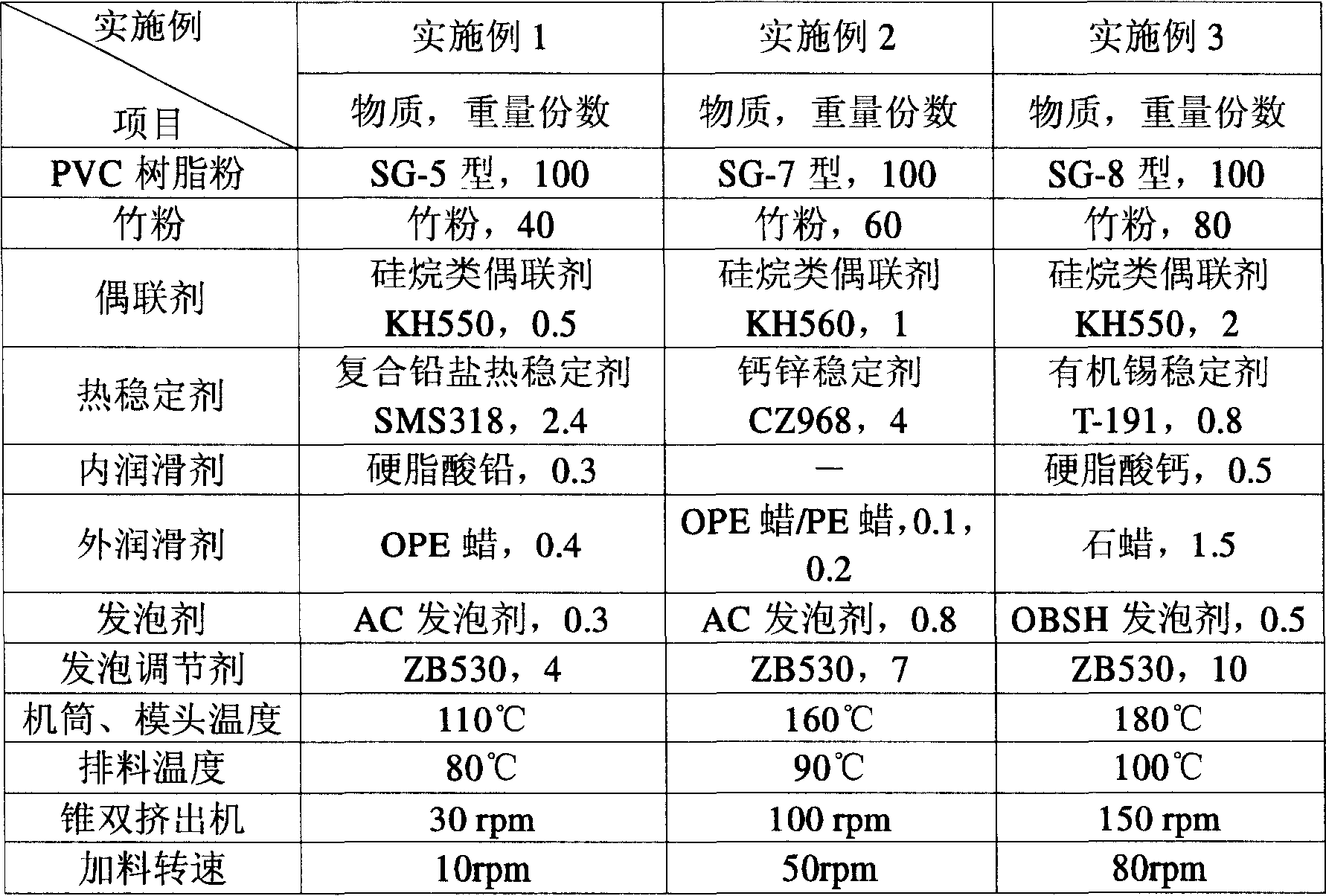

Examples

Embodiment Construction

[0029] First process the bamboo plant fiber into micropowder, then put the bamboo powder into the mixer, heat up and dry by external heating, remove a lot of water in the bamboo powder, then add coupling agent for surface treatment, and then add PVC resin powder , and then add heat stabilizer, lubricant, foaming regulator, and foaming agent in order, and mix evenly; add a cooling water jacket connected to the die die, and shorten the die core by 10cm; connect the extruder and The mold, cooling and shaping device, traction device, and cutting device are coordinated; set the temperature of the barrel and die head, turn on the cooling water jacket, cooling and shaping device, pulling device and cutting device, and put the mixed ingredients into the cone double extruder. Set the discharge temperature, the screw speed of the conical double extruder, and the feeding speed to produce bamboo-plastic foamed materials with a smooth surface without skinning and loose foaming inside. Acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com