Patents

Literature

92results about How to "Strong friction resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

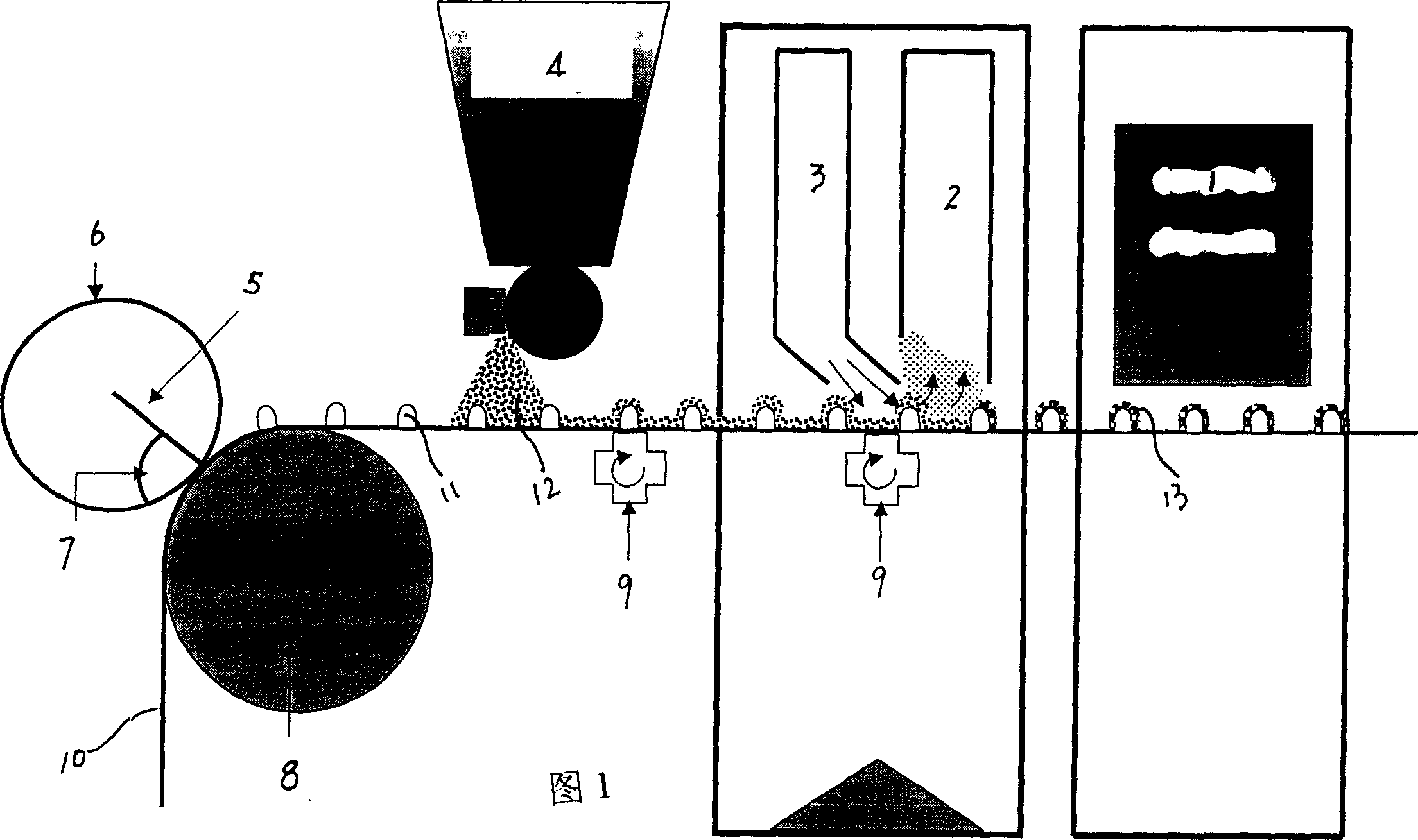

Printing adhesive liner cloth and its making process

InactiveCN101008155ARealistic patternStrong three-dimensional senseTransfer printing processTextile decorationSingle pointEngineering

The invention relates to a spinning adhesive liner and relative production, comprising that: preparing needed pattern on the treated base cloth via transfer or screen printing method; secondary treating and feeding it into special coating machine; to coat thermal-sensitive adhesive resin on the base cloth, with slurry point and single point, to obtain the target printed adhesive liner; using thermal rolling method to adhere the printed liner with face fabric to obtain clothes material.

Owner:NITTOBO CHINA CO LTD

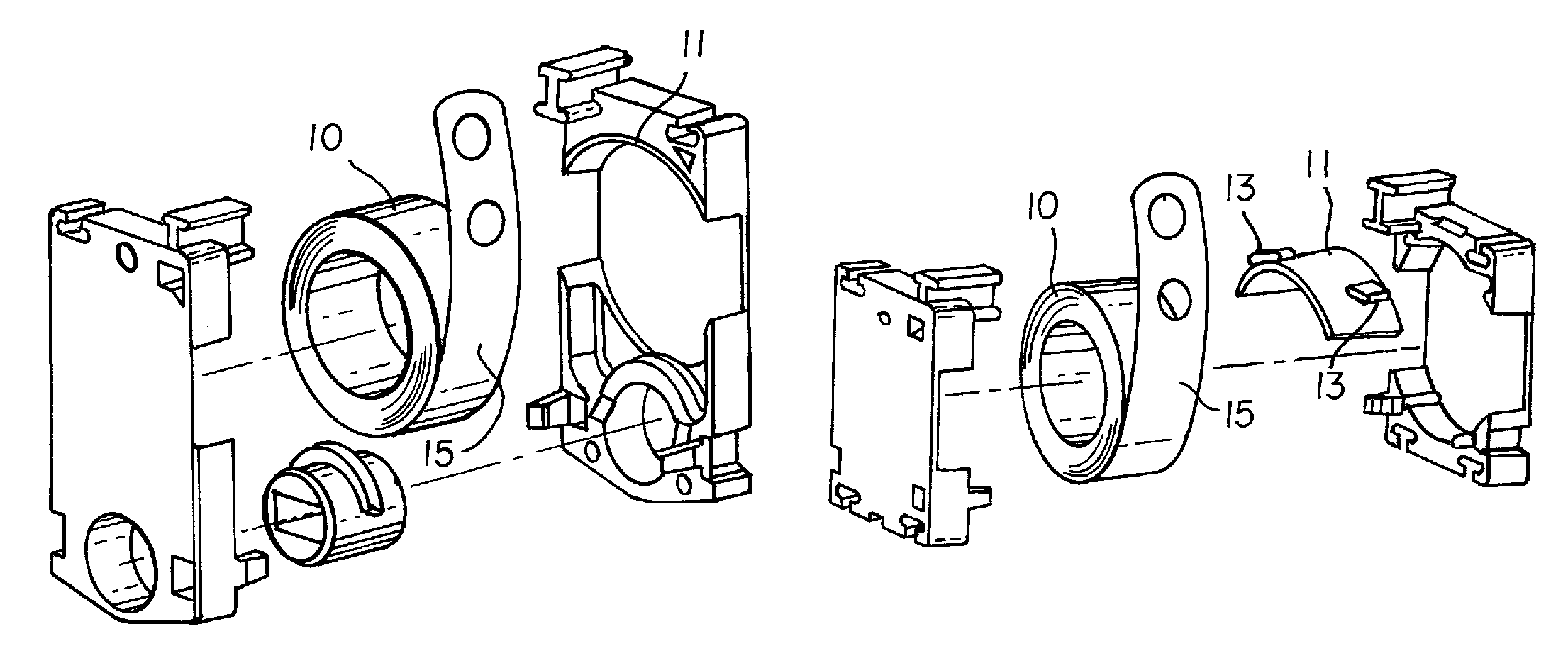

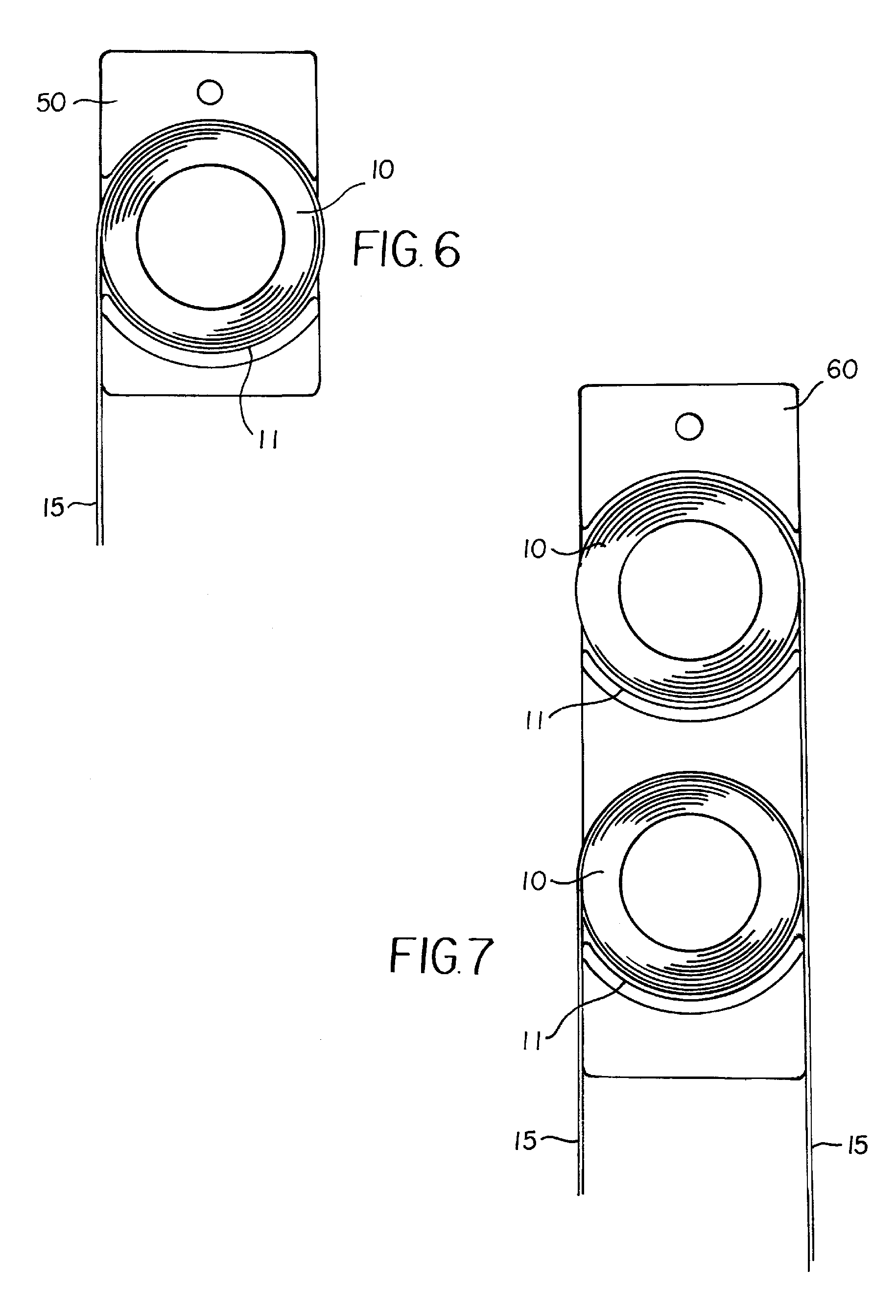

Frictional drop resistance for sash counterbalanced by curl springs

ActiveUS8074402B2Reduce in quantityLow costBuilding braking devicesWing openersSash windowEngineering

Window sash counterbalances using curl springs and holders can increase resistance to sash drop without causing sash hop by using a high coefficient of friction bearing surfaces against which curled up coils of curl springs slide when uncurling or re-curling. The higher friction bearing material produces more frictional resistance to spring uncurling than to spring re-curling and thus resists drop without causing hop. This allows a wider range of sash weights to be counterbalanced by a fewer number of counterbalance forces, saves manufacturing cost.

Owner:CALDWELL MFG NORTH AMERICA

Code-jetting ink and method for preparing same

The invention relates to jet coding printing oil and a preparation method thereof; the ink is prepared with the following raw materials and solvent by the weight percent: 15 to 35 of rosin modified resin, 3 to 15 of nitrocotton, 2 to 10 of pigment or dye, 20 to 50 of butanone, 5 to 20 of isopropanol and 10 to 30 of toluol. The steps are as follows: (1) mixed solvent which accounts for 40 percent of the total solvent is added into the pigment or dye while being stirred at 2000r / min to be fully dissolved with the temperature equal to or lower than 50 DEG C and the fineness after dissolution less than or equal to 5 Mu m, and the product is filtered for stand-by; (2) the rosin modified resin, the nitrocotton and the mixed solvent which accounts for 40 percent of the total solvent are dissolved while being stirred at high speed equal to or lower than 40 DEG C, and filtered for stand-by after being fully dissolved; (3) the dissolved pigment or dye liquid and resin liquid are mixed with the rest mixed solvent under the temperature equal to or lower than 40 DEG C, and then stirred evenly. All indexes are as follows: color: close to the label; fineness: equal to or less than 5 Mu m; viscosity: 10-15s / layer 4# cup.25 DEG C. The printing ink has stable ink performance, is not easy to block printing nozzles; the printing ink mark is clear; the ink can be firmly adhered to the substrate, is friction resistant and becomes dry quickly.

Owner:TIANJIN ANGEL CHEM GRP

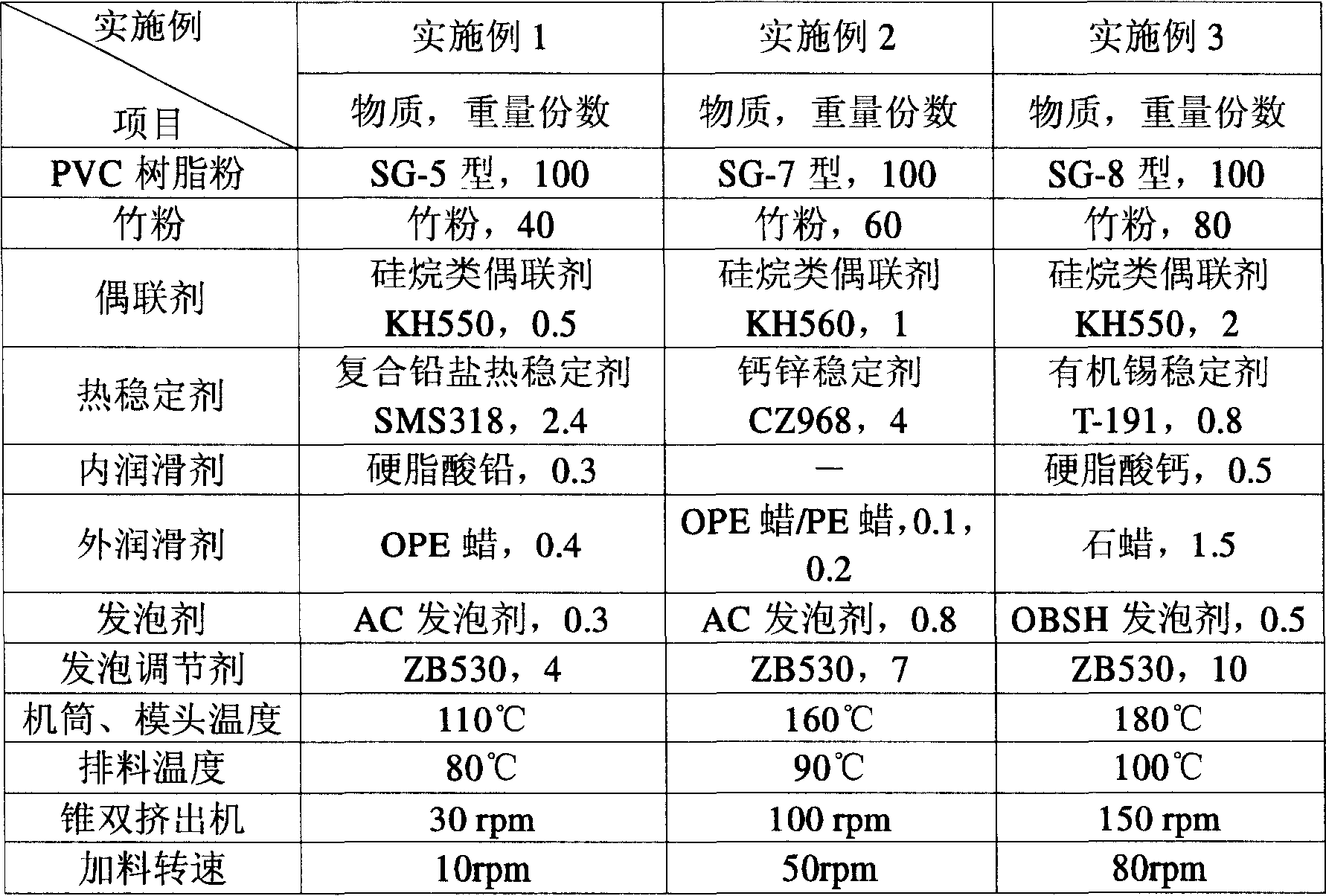

Bamboo/plastic surface crusting composite material and its preparation method

The invention discloses a bamboo-plastic composite material and its preparing process, wherein the composite material comprises the following constituents (by weight portions): PVC 100, bamboo powder 30-80, coupling agent 0.5-2%, heat stabilizer 0.5-4, lubricating agent 0.2-2%, foaming agent 0.2-0.8, and foaming regulation agent 3-12.

Owner:GUANGDONG LIANSU TECH INDAL

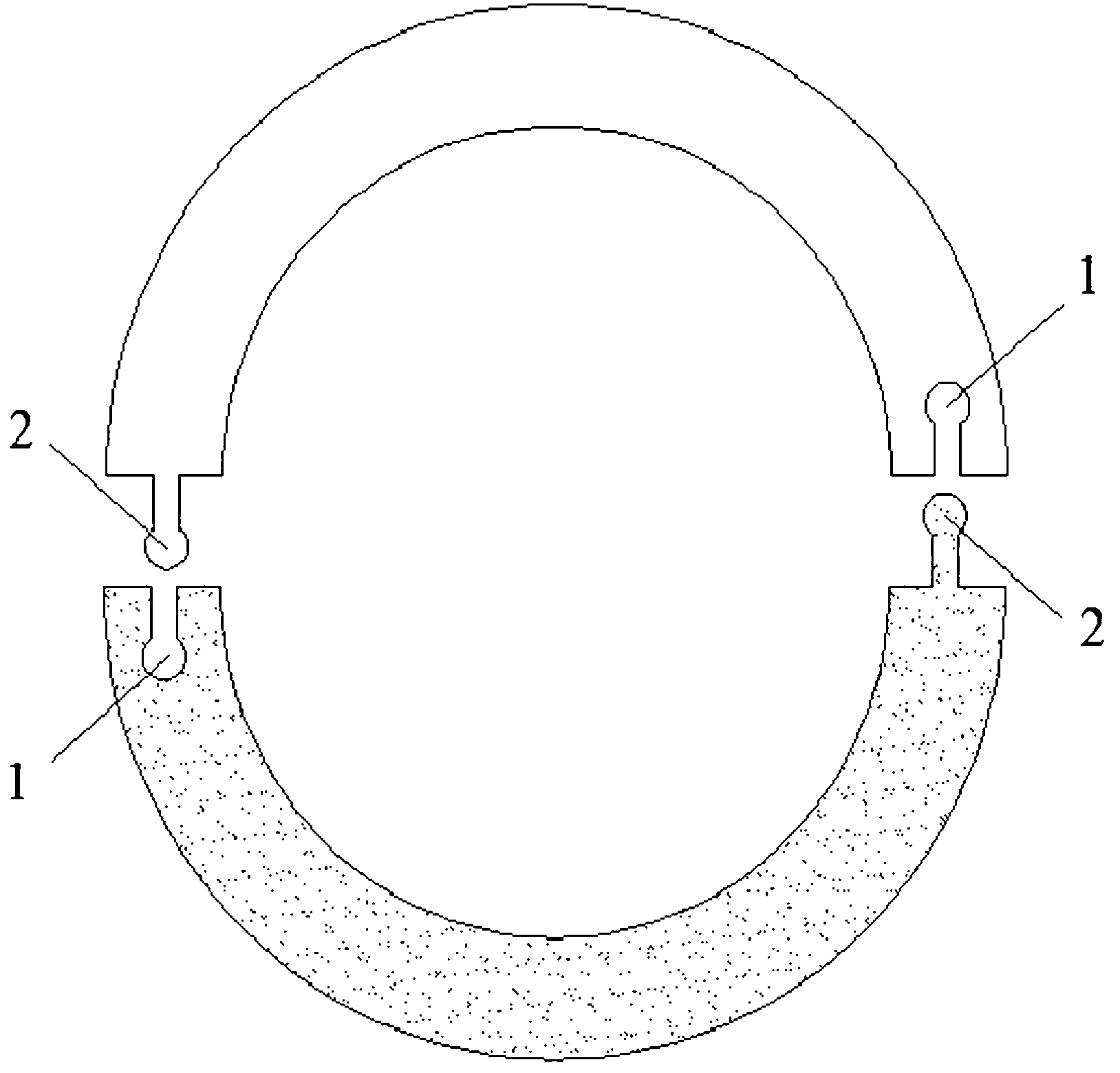

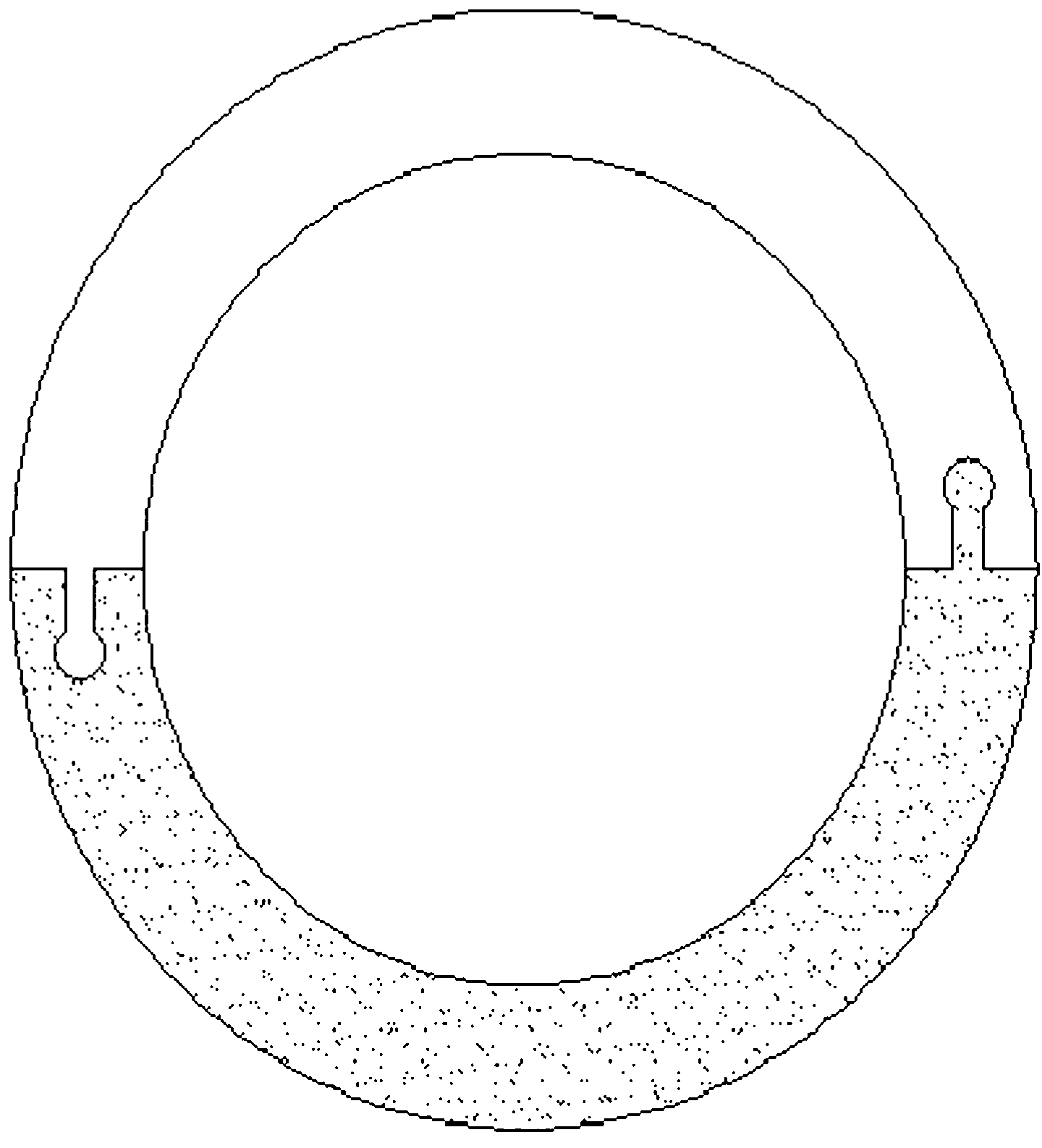

Split-type sealing ring

The invention discloses a split-type sealing ring. The sealing ring is characterized in that the sealing ring is formed by inserting combination of two separate halves, the two separate halves are assembled into the complete sealing ring through inserting grooves and limiting rods which are matched with inserting grooves, inserting grooves and limiting rods are formed on abut joint faces of the sealing ring, and the sealing ring is made of any combination of carbon tungsten alloys, silicon carbide and carbon graphite according to application requirements. The split-type sealing ring has the advantages that the structure is simple, the machining is simple, and the cost is low; the sealing ring is made of free combinations of carbon tungsten alloys, the silicon carbide and the carbon graphite according to application requirements and is high in corrosion resistance, capable of achieving different purposes, few in limitation, wide in application range and long in service life; and the split-type design is adopted, so that the sealing ring can be taken down from a long shaft or a thick shaft conveniently and quickly and is convenient to use, the workload is effectively reduced, and the production efficiency of an enterprise is improved.

Owner:张家港市三利密封合金材料有限公司

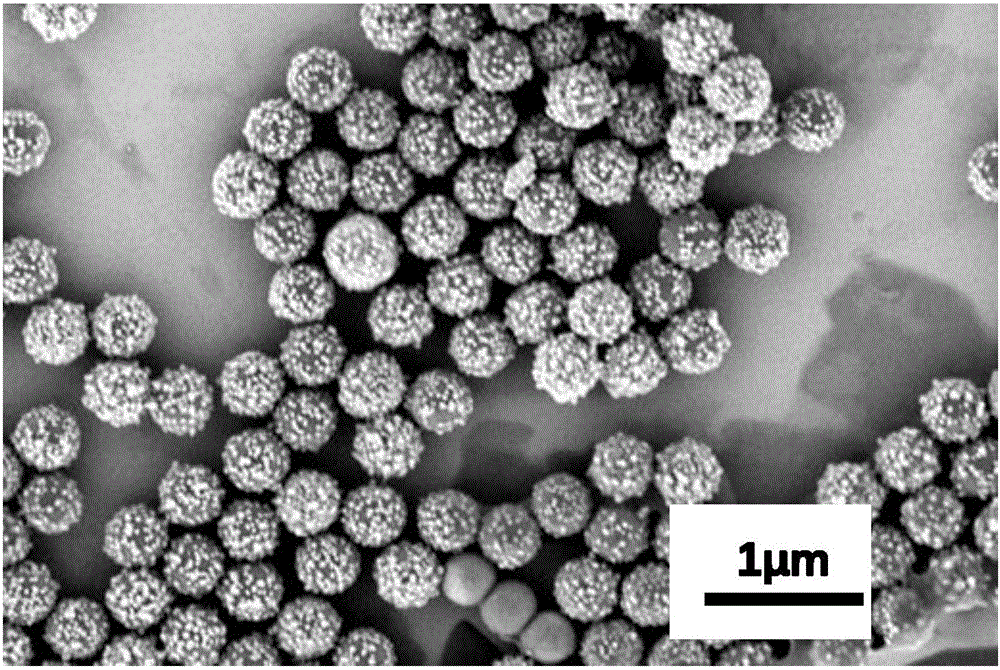

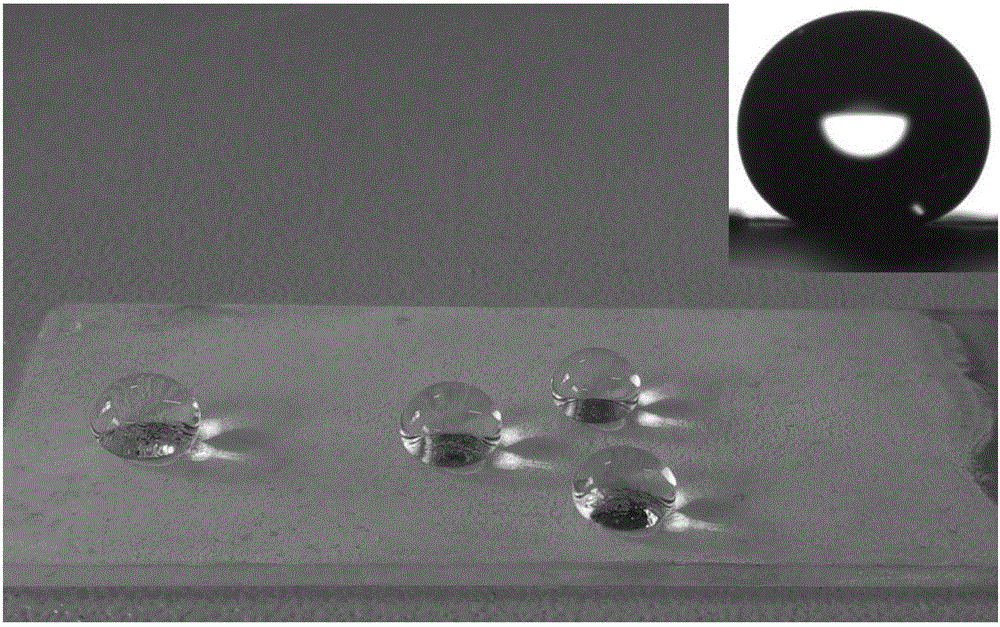

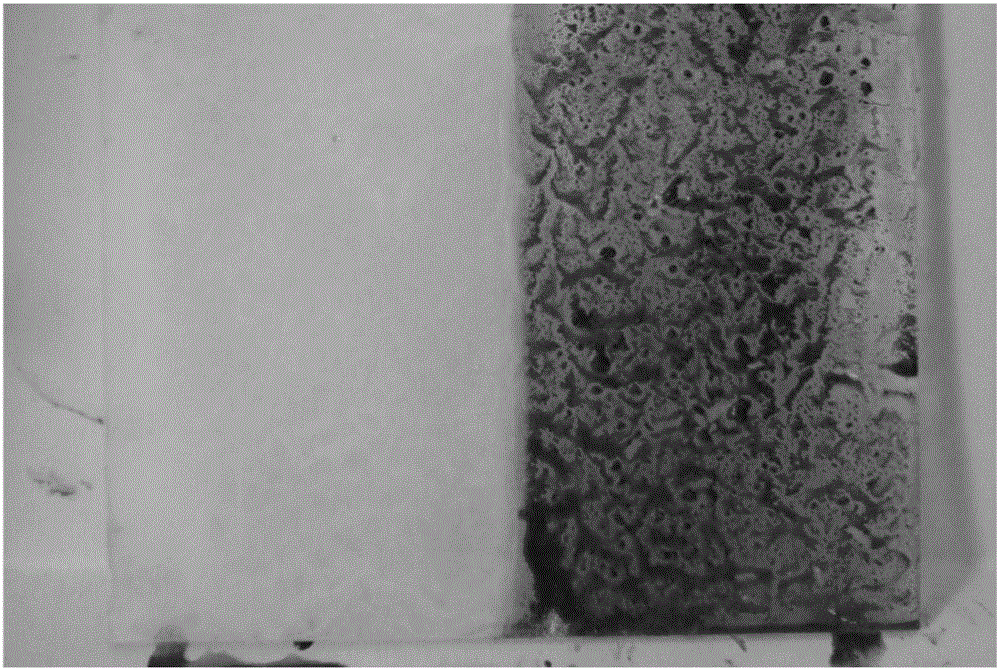

Strawberry-shaped super-hydrophobic composite microsphere and application thereof

InactiveCN106311103AGood durabilityWide range of applicationsMicroballoon preparationEpoxy resin coatingsSolventChemistry

The invention relates to a strawberry-shaped super-hydrophobic composite microsphere and application thereof. The microsphere is prepared through the following steps that (1) an amino polystyrene microsphere, ethyl alcohol, ethyl orthosilicate and distilled water are added into a reactor, and take a reaction for 24h at room temperature; the product is washed with ethyl alcohol; after vacuum drying is performed, a strawberry-shaped composite microsphere is obtained; (2) the strawberry-shaped composite microsphere, a solvent and a silane coupling agent are added into the reactor; the reaction is performed for 5 to 15h under the condition of 25 DEG C to 100 DEG C; the product is centrifuged to obtain the strawberry-shaped super-hydrophobic composite microsphere. The strawberry-shaped super-hydrophobic composite microsphere and epoxy resin are matched to be used as a super-hydrophobic coating; the excellent and stable super-hydrophobic performance is realized; muddy water is splashed on the prepared super-hydrophobic surface; the super-hydrophobic surface cannot be polluted by the muddy water, so that the self cleaning function of the surface is realized.

Owner:天津傲卓菲科技有限公司

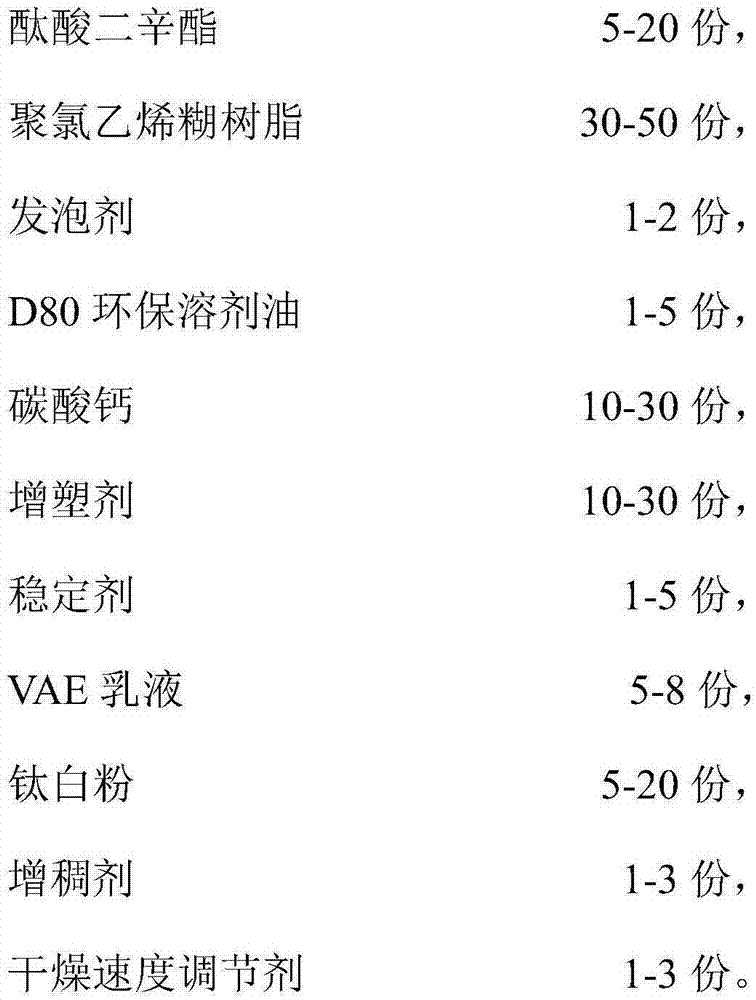

Special slurry for printing wallpaper having 3D stereo transparent streamer effect and preparation method for special slurry

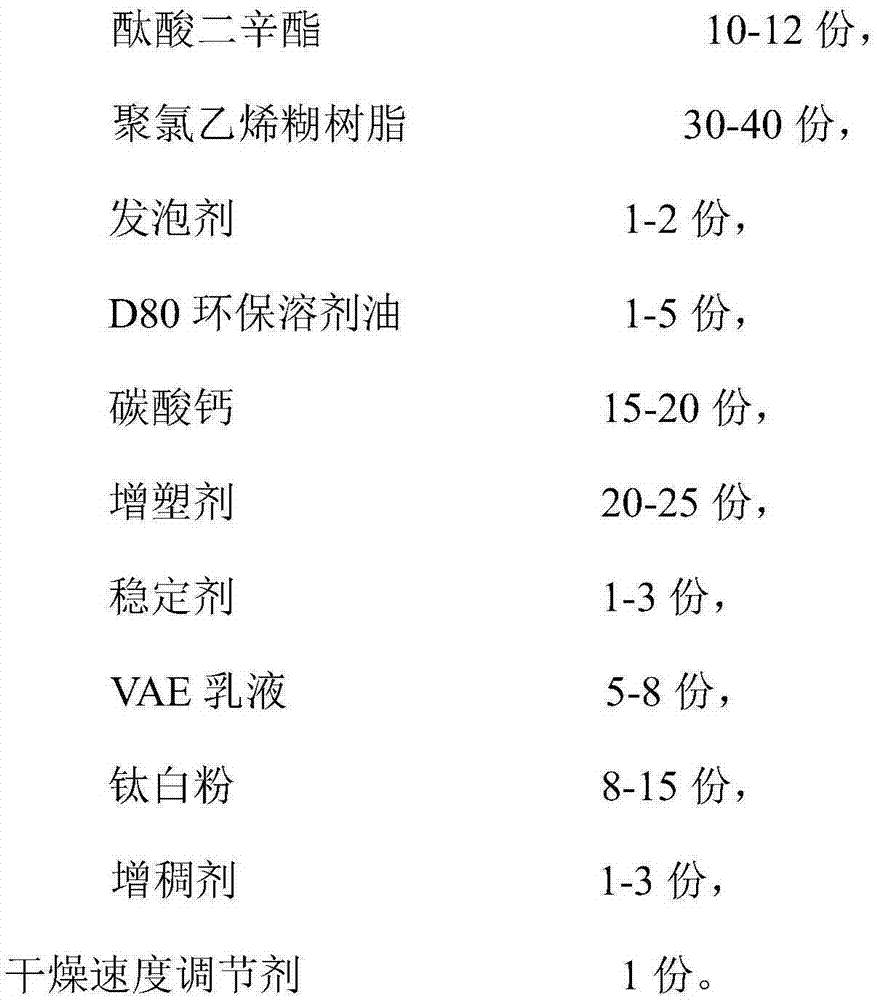

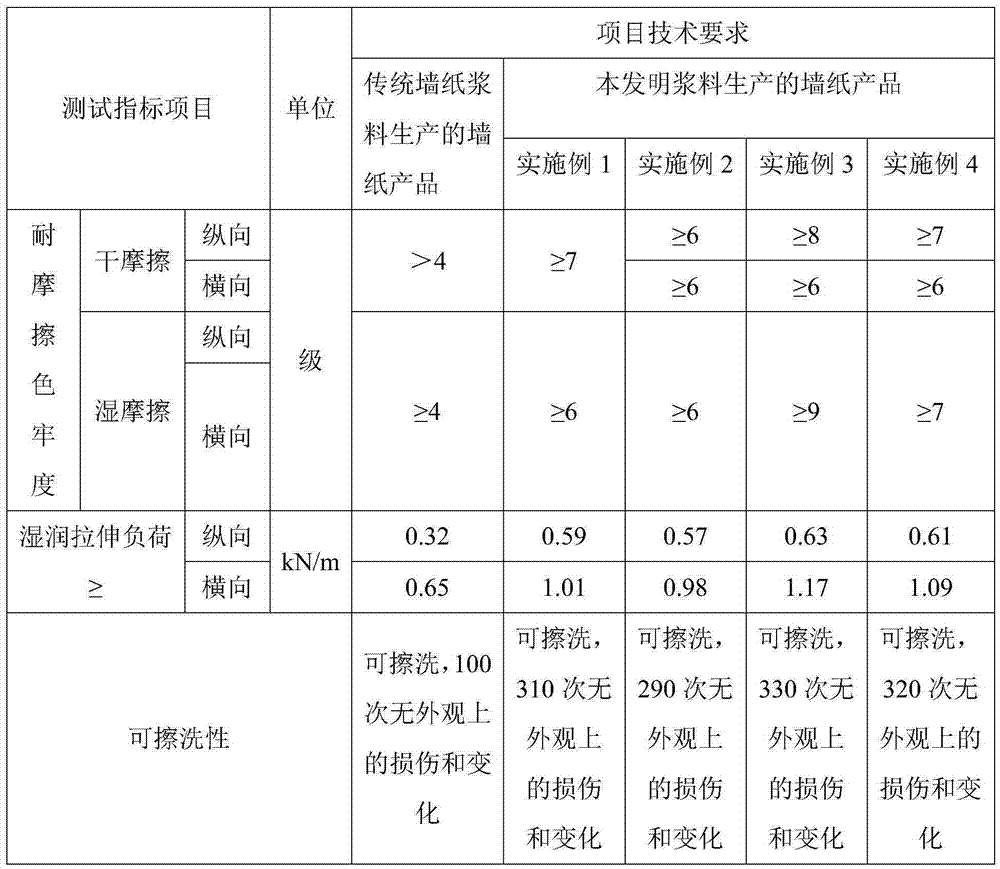

The present invention relates to slurry for printing wallpaper, and in particular to special slurry for printing wallpaper having a 3D stereo transparent streamer effect and a preparation method for the special slurry. The present invention provides special slurry for printing wallpaper having the 3D stereo transparent streamer effect. The slurry is mainly prepared by the following raw materials in parts by weight: 5-20 parts of dioctyl phthalate, 30-50 parts of polyvinyl chloride paste resins, 1-2 parts of a foaming agent, 1-5 parts of D80 environmental-friendly solvent oil, 10-30 parts of calcium carbonate, 10-30 parts of a plasticizer, 1-5 parts of a stabilizer, 5-8 parts of a VAE emulsion, 5-20 parts of titanium dioxide, 1-3 parts of a thickener and 1-3 parts of a drying speed regulator. The adhesive force of the slurry provided by the present invention is strong; meanwhile, the transparency effect can be displayed. The slurry is suitable for performing an embedding process on gold powder, silver powder and pearl powder in a gold spraying process, and can wrap up the gold powder, silver powder and pearl powder to promote the level of the wallpaper and prolong the service life of the wallpaper.

Owner:GAREFU TECH CO LTD

Light-storing long-afterglow light-emitting coating

InactiveCN105802475AStrong friction resistanceGood colorLuminescent paintsPolyurea/polyurethane coatingsEpoxyFluorescence

The invention belongs to the field of construction coating and particularly discloses light-storing long-afterglow light-emitting coating and a preparation method thereof. The light-storing long-afterglow light-emitting coating comprises a light emitting layer and a light reflecting layer. The light emitting layer comprises, by weight, 20-60 parts of organic resin, 15-25 parts of ethanol, 10-50 parts of light-storing powder, 0.3-1.7 parts of octadecanamide, 0.5-5 parts of powdered PED wax, 0.1-1.5 parts of coupling agent, 0.2-1.6 parts of stabilizing agent, 0.1-1.5 parts of antioxidant, 5-25 parts of fluorescent whitening agent, 1-5 parts of fumed silica and 1-5 parts of sodium tripolyphosphate. The light reflecting layer comprises, by weight, 10-30 parts of epoxy resin, 30-60 parts of filler, 0.2-2 parts of film-forming auxiliary, 0.5-4 parts of pigment, 5-20 parts of quartz material, 2-4 parts of organic bentonite and 5-15 parts of dimethyl benzene. The light-storing long-afterglow light-emitting coating is long in light emitting time, fast in drying and high in brightness.

Owner:WENZHOU CHUYING TECH CO LTD

Super weather-proof composite waterproof roll material

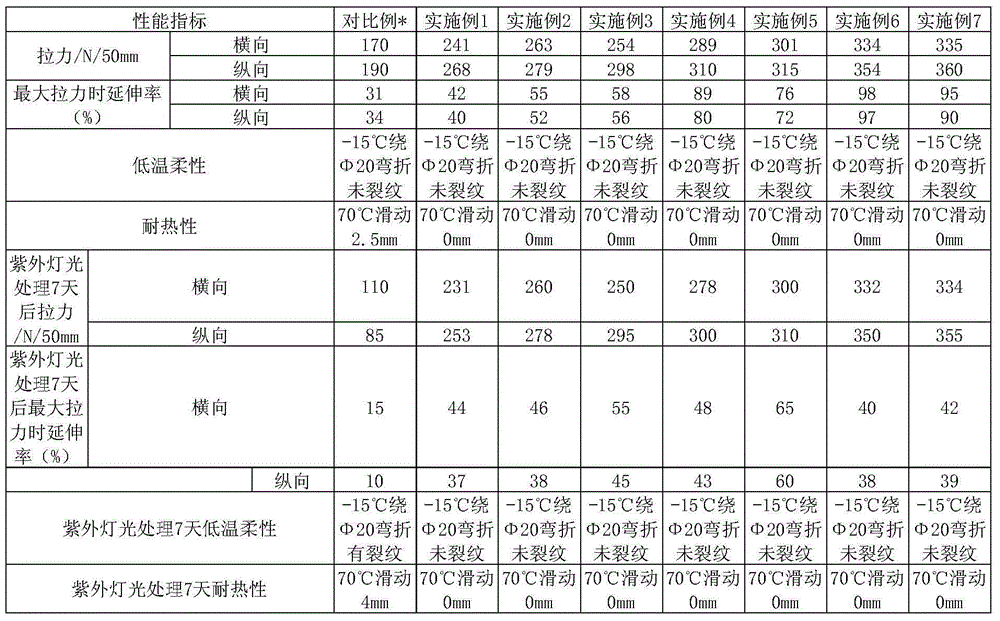

InactiveCN104553185AWith super weather resistanceResistant to UV radiationLamination ancillary operationsSynthetic resin layered productsHigh resistanceEnvironmental resistance

The invention relates to the field of waterproof roll materials, and particularly relates to a super weather-proof composite waterproof roll material. The super weather-proof composite waterproof roll material comprises a bonding and sealing adhesive layer and an isolating film protection layer, and also comprises a super weather-proof polymeric film layer, wherein the super weather-proof polymeric film layer, the bonding and sealing adhesive layer and the isolating film protection layer are sequentially arranged from top to bottom and are adhered into a whole in a hot pressing way. The hot pressing temperature is 30 to 220 DEG C, includes but is not limited to 30 to 220 DEG C, and can be adjusted according to factors such as specific production equipment and a hot pressing technology. The bonding and sealing adhesive layer is compounded with the a super weather-proof polymeric film structure, so that the structure has high environmental resistance, corrosion resistance, high strength and high toughness, good dimensional stability, and high impact resistance and puncture resistance, does not need to be protected by cement and mortar, and can be constructed in various environments.

Owner:HANGZHOU FUMO NEW MATERIAL TECH

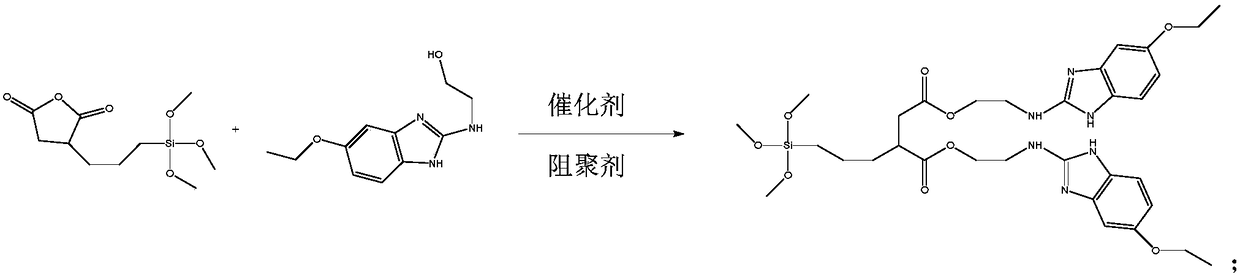

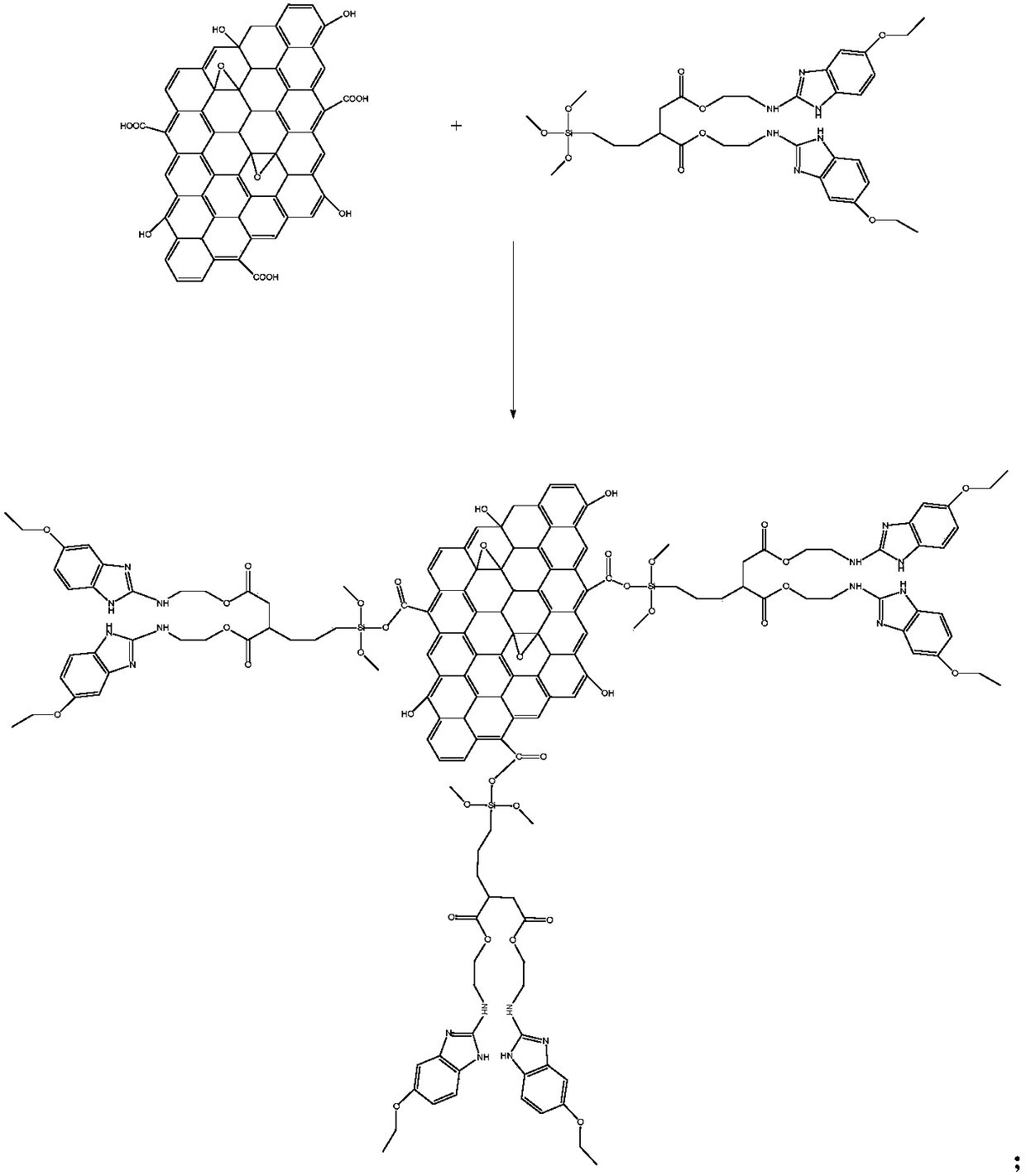

RE-Ni-Mo/GO nano composite deposition liquid as well as preparation method and application thereof

ActiveCN104911642AGood organizational performanceImprove coating crystal orientationRare-earth elementTrisodium citrate

The invention discloses an RE-Ni-Mo / GO nano composite deposition liquid. Each liter of the deposition liquid comprises 0.25-5g of graphene oxide, 45-55g of nickel sulfate, 4-10g of sodium molybdate, 55-65g of trisodium citrate, 0.2g of lauryl sodium sulfate, 0.1-5g of a rare earth element RE and the balance of distilled water. The invention further discloses a method for forming an RE-Ni-Mo / GO multifunctional nano composite deposition layer on the surface of low-carbon steel. By adopting the composite deposition liquid and with the combination of ultrasonic wave and electric deposition techniques, the RE-Ni-Mo / GO multifunctional nano composite deposition layer can be prepared on the surface of low-carbon steel. By adopting the composite deposition layer prepared by using the method disclosed by the invention, the corrosion resistance, the surface hardness, the wearing resistance, the breaking strength and the like of the low-carbon steel are effectively improved, and moreover, the difficulty that powder micro particles can be agglomerated in conventional composite electric deposition.

Owner:CHINA GATEWAY PHARMA DEV CO LTD

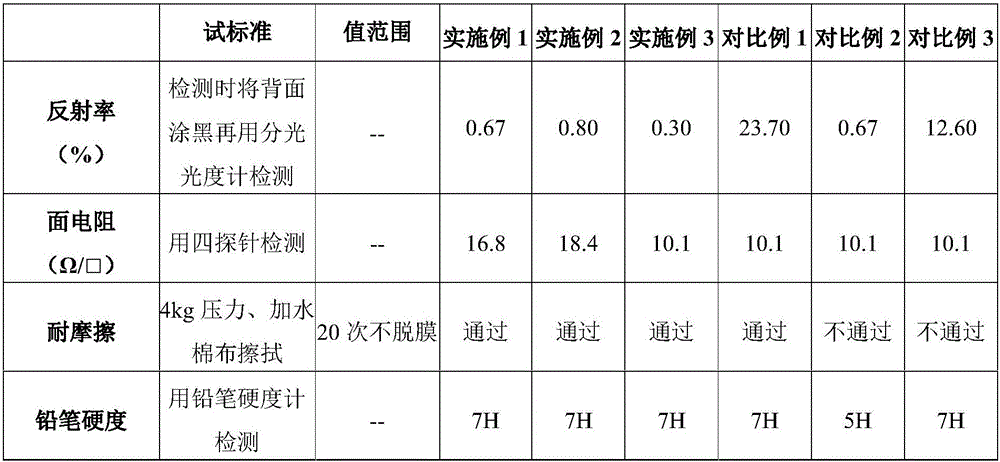

Reflecting film and manufacturing method thereof, and use of the reflecting film

InactiveCN101234544AWon't fall offImprove reflectivityLiquid surface applicatorsSolar heat devicesWeather resistanceGreenhouse

The invention relates to a reflecting film and a manufacturing method as well as application of the reflecting film. The reflecting film comprises a substrate and a bottom liner surface and is characterized in that the substrate adopts a PET plastic film with high transparency; aluminum films are plated on both sides of the substrate; one surface of the substrate which is plated with the aluminum film is bonded with the bottom liner surface by oiliness pressure sensitive adhesive; a layer of silicone glass resin coating is coated evenly on another surface of the substrate which is plated with the aluminum film. The invention has the advantages that both sides of the substrate are plated with aluminum, thus having a high reflecting rate; if the aluminum film in one surface is scarified, the aluminum film in another surface can still reflect and the reflecting rate can reach more than 85 percent; the oiliness pressure sensitive adhesive has high viscosity and strong bonding force and can be used for more than three years; a reflecting layer can not be dropped off from the bottom liner surface; the surface coating hardness of the reflecting layer is more than 4H and the reflecting layer has strong friction resistance and weather resistance; the reflecting film used in a solar cooker is a new generation product of the solar cooker made by glasses previously, which has light weight, simple bonding and durable use. The reflecting film of the invention can not only be used in the solar cooker, but also be suitable for reflecting in a plurality of fields such as solar energy cooking ranges, vegetable greenhouses and fruit trees.

Owner:孟庆国

Printing method for forming trademark or pattern on shell

The invention provides a printing method for forming a trademark or a pattern on a shell. The method comprises the following steps of: providing a metal shell; printing a first printing ink layer on the metal shell and drying the first printing ink layer for 15 to 25 minutes at the temperature of between 100 and 150 DEG C, wherein the first printing ink layer comprises an epoxy resin; printing a second printing ink layer on the first printing ink layer and drying the second printing ink layer for 15 to 25 minutes at the temperature of between 100 and 150 DEG C, wherein the second printing ink layer comprises an epoxy resin; and printing a third printing ink layer on the second printing ink layer and drying the third printing ink layer for 60 to 120 minutes at the temperature of between 100 and 150 DEG C, wherein the third printing ink layer comprises an epoxy resin.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Waterborne nano long-acting corrosion-resistant finishing coat and preparation method thereof

The invention belongs to the technical field of corrosion-resistant coatings, and particularly relates to waterborne nano long-acting corrosion-resistant finishing coat and a preparation method thereof. The finishing coat consists of a component A and a component B. The component A consists of the following raw materials in parts by weight: 30-40 parts of acrylic acid modified polyurethane emulsion, 10-20 parts of modified nano silicon dioxide sol, 0.5-1 part of a defoaming agent, 0.3-0.8 part of a leveling agent, 5-10 parts of a cosolvent, 0.5-1 part of a thickening agent, 1-3 parts of a wetting agent and the balance of deionized water. The component B is a waterborne curing agent. The waterborne nano long-acting corrosion-resistant finishing coat has the advantages of long-lasting and excellent corrosion resistance, high substrate adhesion, high hardness, excellent friction resistance, excellent salt fog resistance, high construction adaptability and the like. The preparation method is simple, the cost is low, operation is facilitated, the waterborne nano long-acting corrosion-resistant finishing coat is environmentally friendly and pollution-free, a coated film is dry quickly, and the construction period is short.

Owner:广东绿色大地化工有限公司

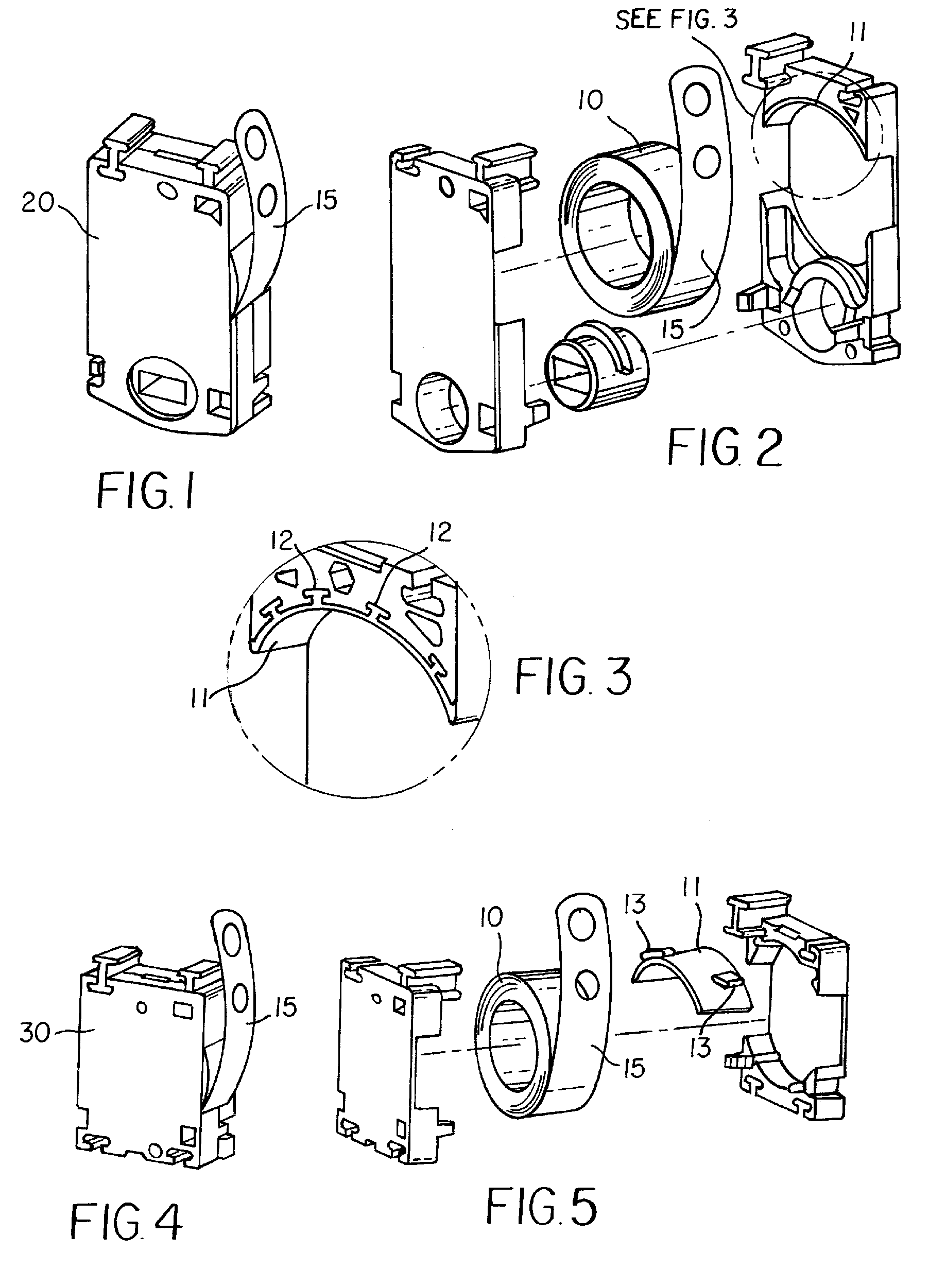

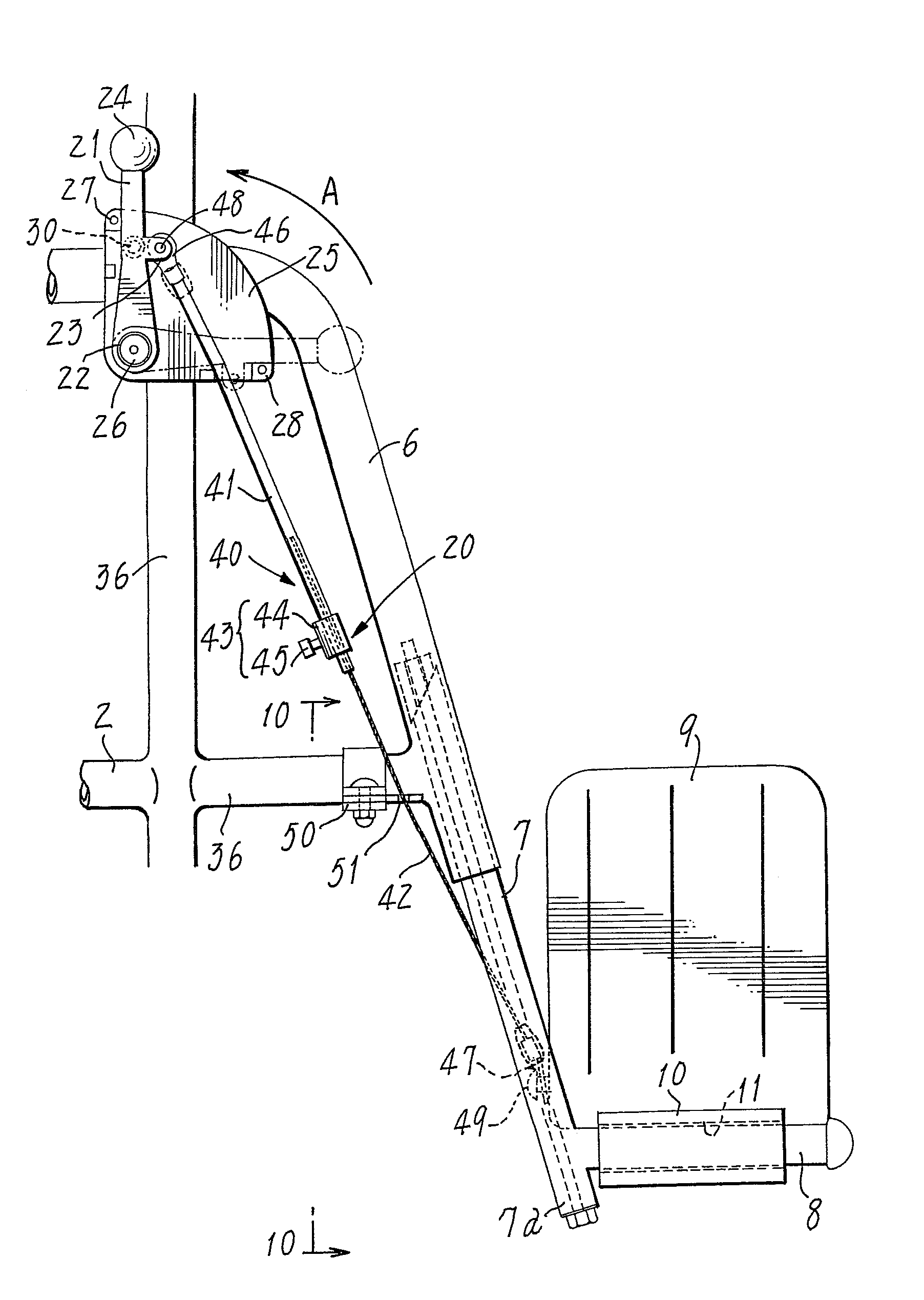

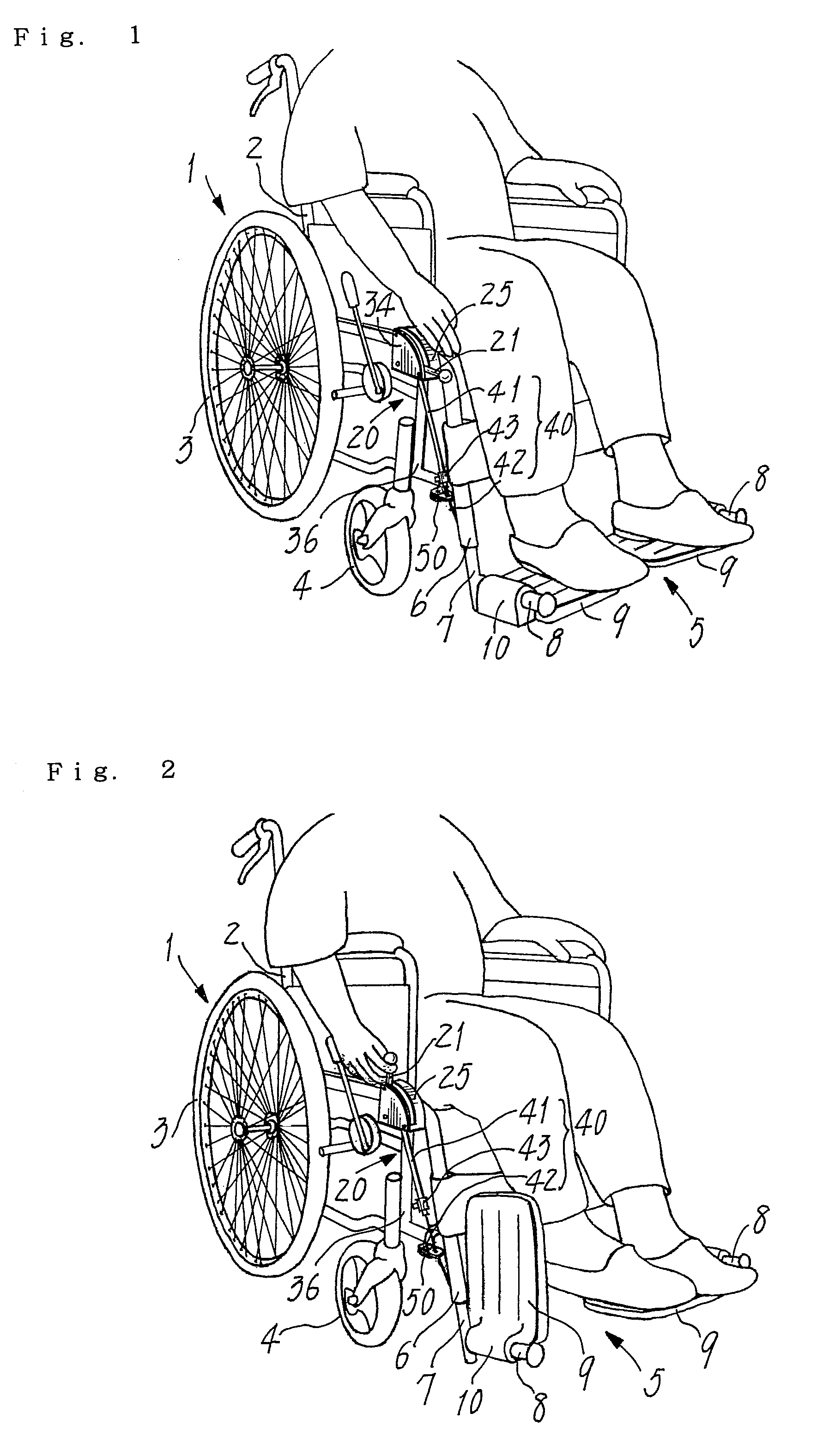

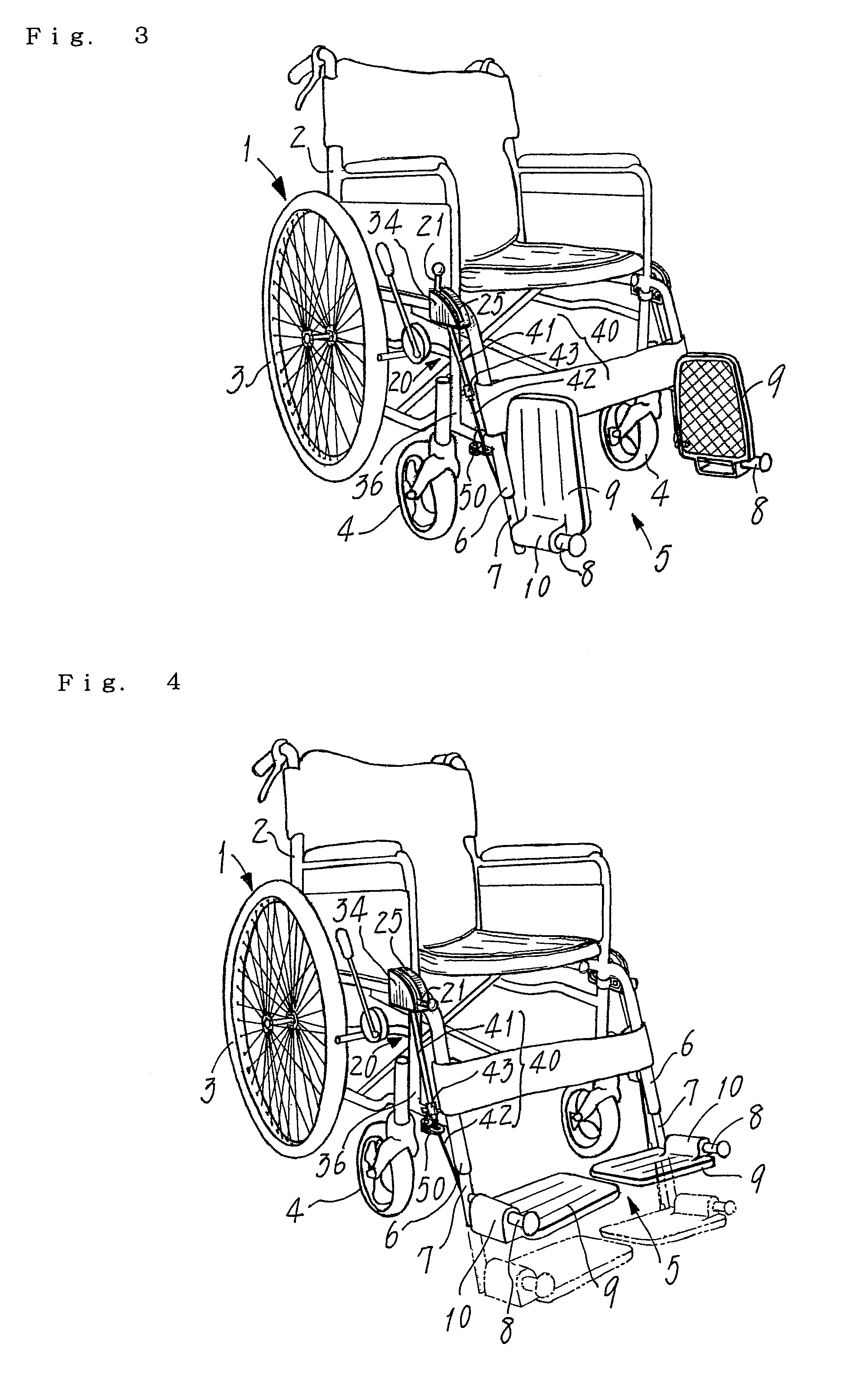

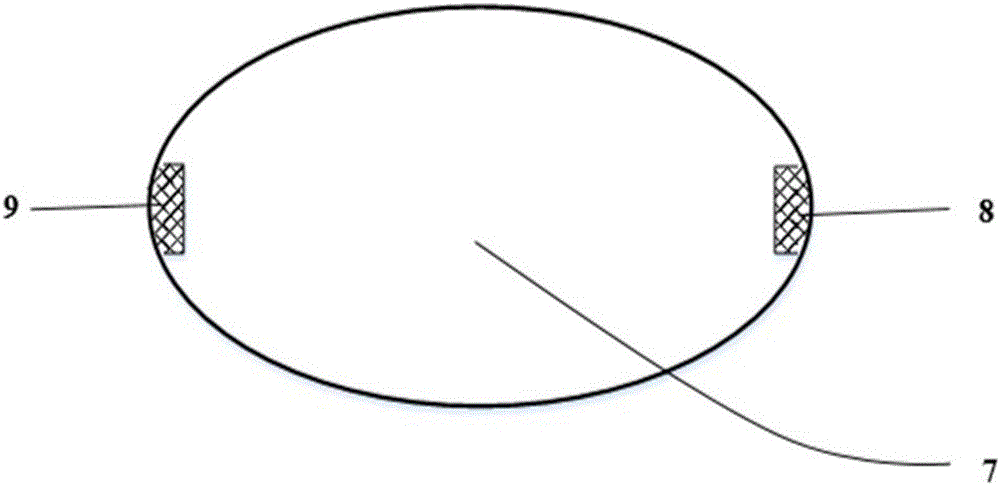

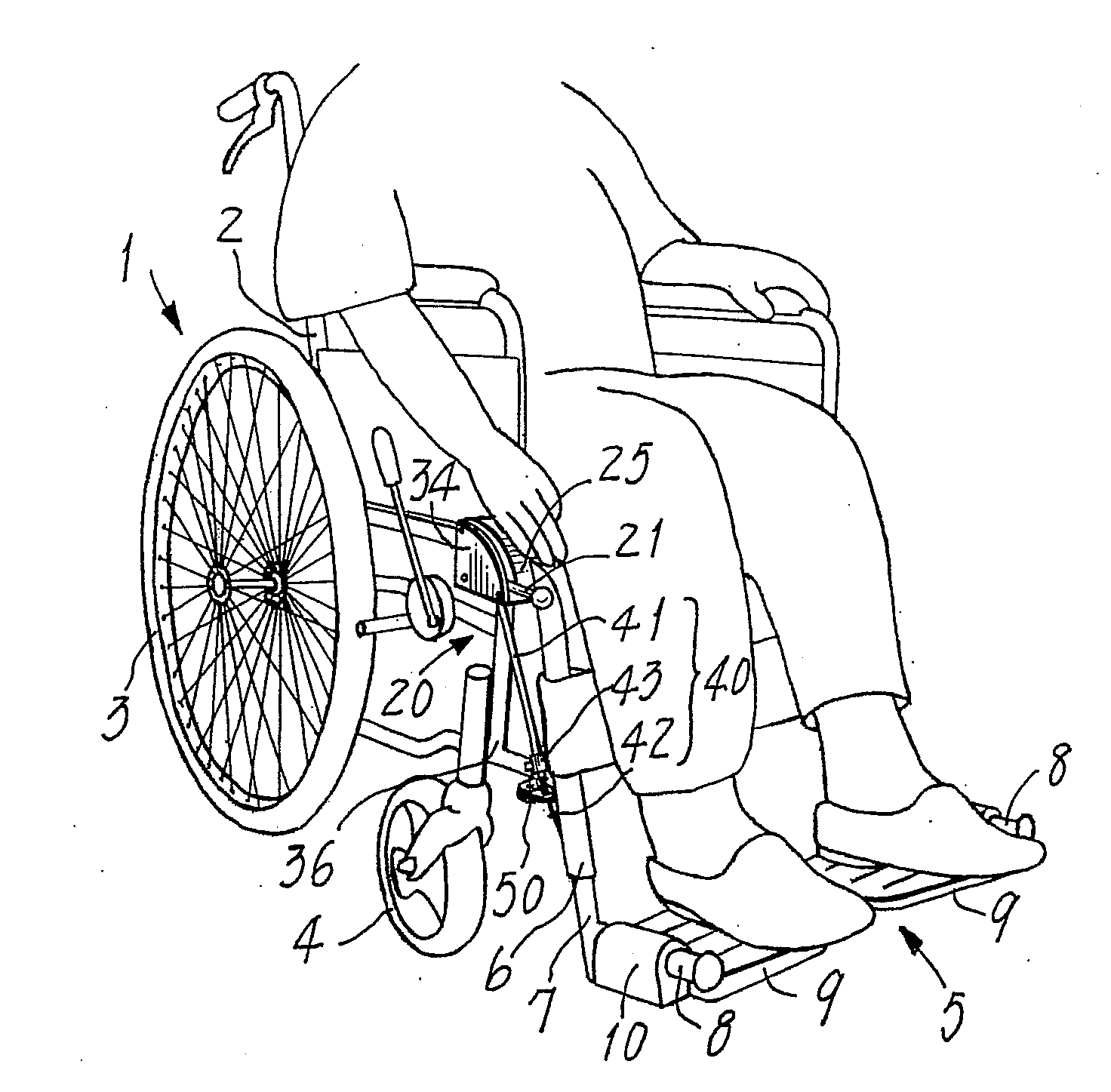

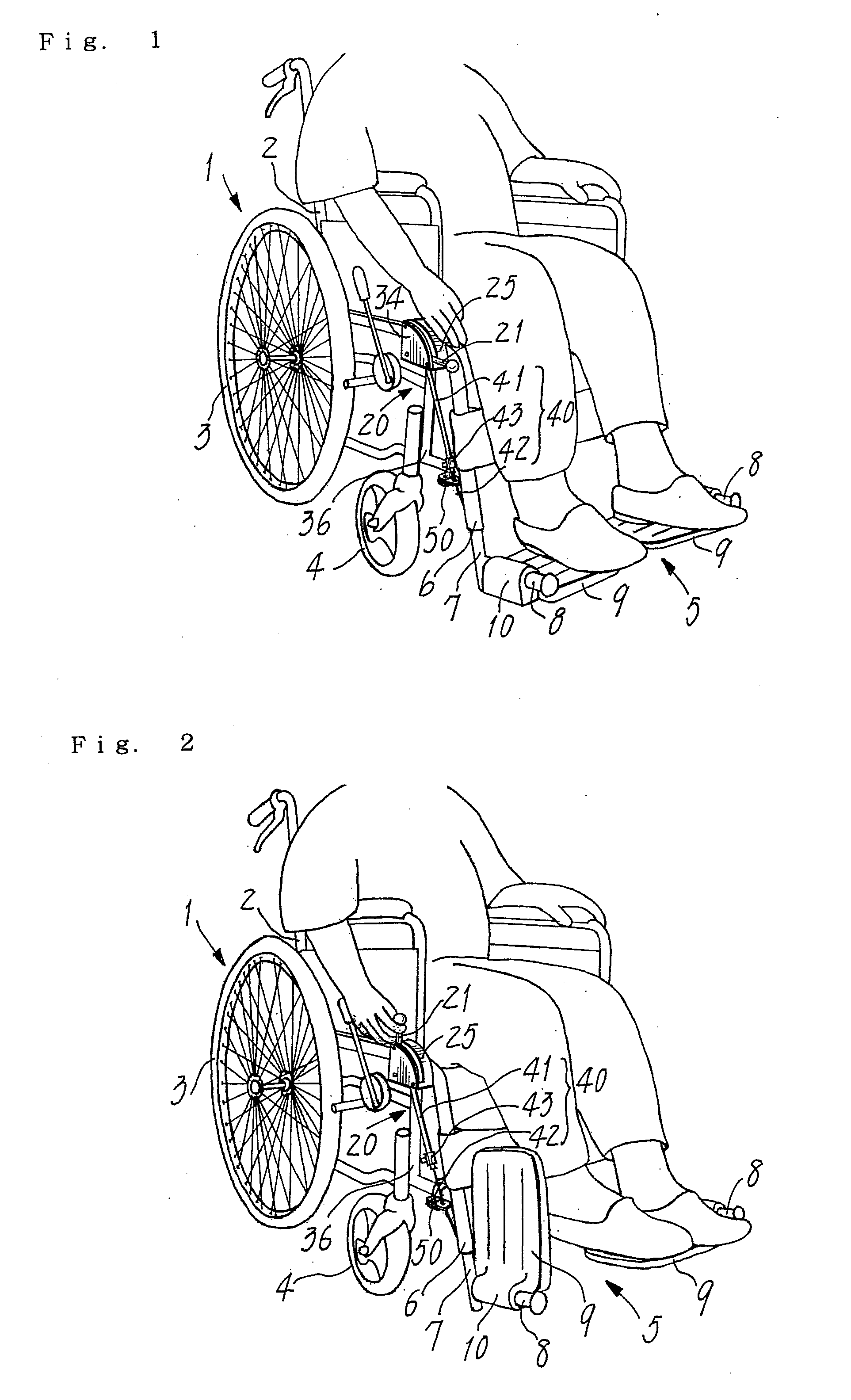

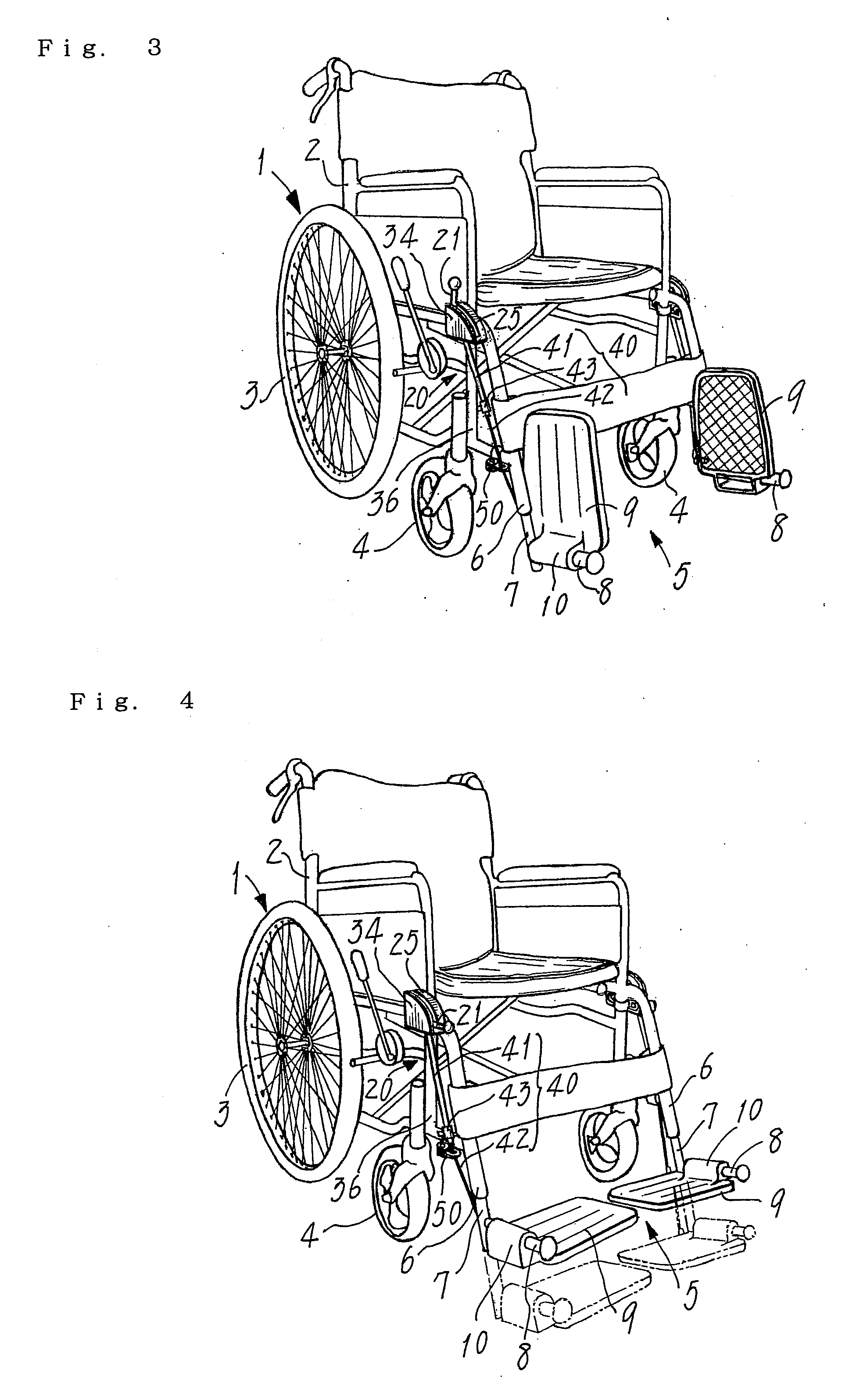

Manipulation device for wheelchair footrests

InactiveUS7347497B2Stress protectionStrong friction resistanceSofasWheelchairs/patient conveyanceEngineeringWheelchair footrest

A manipulation device is for wheelchair footrests that have a pair of shafts (8) extending forwards from opposite forward sides of the main frame (2) and a pair of foot plates (9) pivoted at lateral portions to the shafts. This device has manual levers (21) at the forward sides and actuating means (40) that connects the levers (21) to foot plates (9) and consists of a resilient tube (41), a metal wire (42) and a setting retainer (43) for securing the tube to the wire. The tube (41) can elongate in response to an extraordinary tension exceeding a normal stress imparted to said tube, and the wire (42) loosely inserted in the tube (41) can alter an exposed length. An end of each wire (42) is connected to the foot plate (9) at its rear portion located near the shaft (8) pivoting the foot plate. An end of each tube (41) is connected to the manual lever (21) operating to pull up the tube (41) with the wire (42) such that the foot plate (9) rotates and rises to the upright idle position.

Owner:KOUJI FUJIHARA

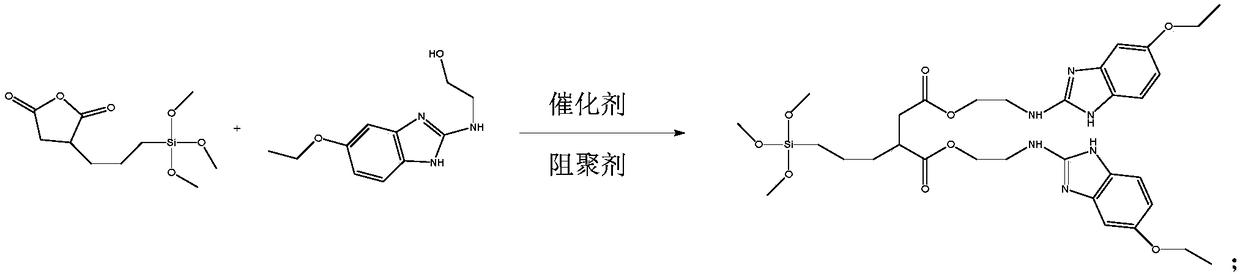

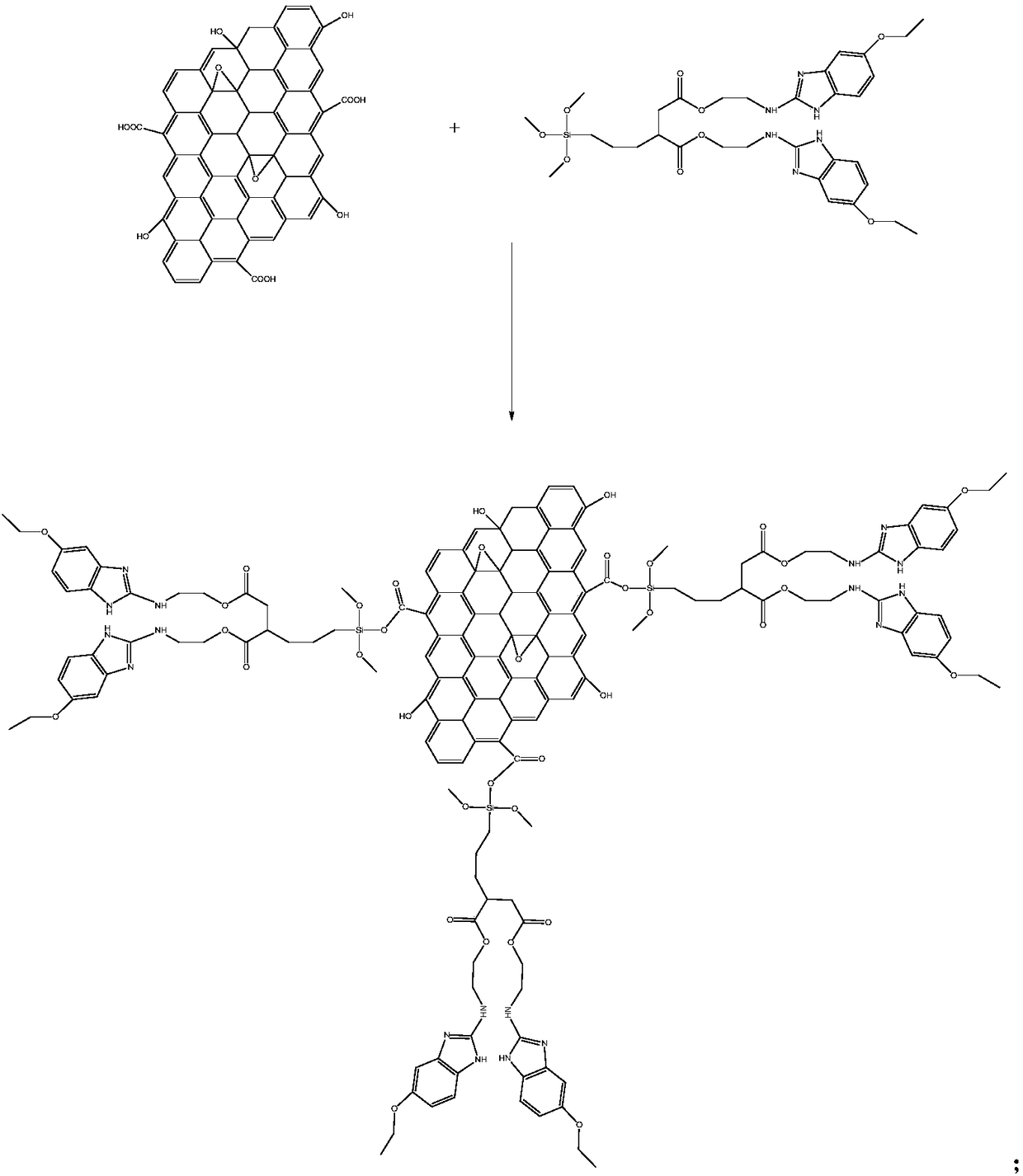

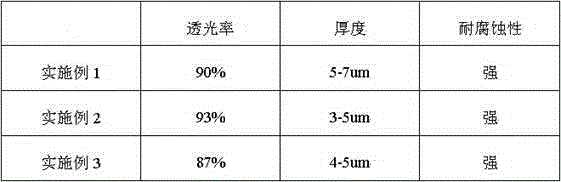

Metal substrate long-lasting anticorrosive inter-coat and preparation method thereof

ActiveCN108997916AHigh mechanical strengthImprove dispersion uniformityAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention belongs to the technical field of anticorrosive coating, and in particular, relates to a metal substrate long-lasting anticorrosive inter-coat and a preparation method thereof, wherein the inter-coat is composed of a component A and a component B, and the component A is composed of the following raw materials in parts by weight: 50-60 parts of an epoxy-organosilicone resin modified acrylic resin emulsion, 12-18 parts of functionalized modified graphene, 10-20 parts of a filler, 8-15 parts of a cosolvent, 0.1-0.5 part of a defoamer, 0.5-1 part of a leveling agent, 0.3-0.8 part ofa water-based drier, 0.3-0.8 part of a thickener, 0.5-1 part of a wetting agent, and 30-35 parts of deionized water; the component B is composed of the components in parts by weight: 40-50 parts of anisocyanate curing agent, and 10-20 parts of a cosolvent. The inter-coat has the advantages of long-term excellent anticorrosive performance, strong adhesion force of the substrate, high mechanical strength, excellent friction resistance, excellent salt spray resistance, good water resistance, chemical resistance, oil resistance and impact resistance, high construction adaptability and the like.

Owner:惠州市湾厦表面处理技术有限公司

Manufacturing process for heat transfer film

InactiveCN105479962AGood dimensional stabilityRich layersDuplicating/marking methodsPolymer sciencePolyethylene terephthalate glycol

The invention discloses a manufacturing process for a heat transfer film. The manufacturing process comprises the steps of preparing a raw material, unreeling, coating a mold releasing agent, coating printing ink and coating glue agent. Polyethylene terephthalate (PET) is selected for a raw material substrate thin film which has the characteristics of being good in dimensional stability, uniform in tension and good in heat-resisting effect and mold releasing property. The solid content of the mold releasing agent is controlled to be 20%-25%, so that the defect that the volatile speed of solvent in the mold releasing agent is high and the drawback that the transferring effect is not obvious are overcome. Hot melt glue is selected for the glue agent, after the glue agent is coated and dried to form a film, the film texture is transparent, the surface where the mold releasing agent and the printing ink are coated has the excellent composite fastness and the distinguished flexibility, and the capacity of resisting friction, water, acid, alkali and other mediums is high. According to the transfer film produced through the process, multi-color patterns can be mapped at a time, color registering is not needed, layers of printed patterns are rich, and the color difference is small.

Owner:丹阳市华兴纸箱有限公司

Lubricating wear-resisting cable outer sheath material

InactiveCN103804747AStrong friction resistanceImprove securityInsulated cablesInsulatorsAntioxidantPlasticizer

The invention relates to the technical field of cable production and processing, and in particular relates to a lubricating wear-resisting cable outer sheath material. According to the technical scheme, the lubricating wear-resisting cable outer sheath material is prepared from the following materials in parts by weight: 20-30 parts of high-density polyethylene, 10-15 parts of linear high-density polyethylene, 17-25 parts of medium-density polyethylene, 9-16 parts of linear medium-density polyethylene, 25-35 parts of low-density polyethylene, 13-18 parts of linear low-density polyethylene, 90-100 parts of polyvinyl chloride resin, 5-7 parts of carbon black, 40-50 parts of plasticizer, 3-8 parts of stabilizer, 20-26 parts of calcium carbonate or talcum powder, 2-4 parts of antioxidant and 1-3 parts of polyethylene wax. An outer sheath prepared from the material has excellent lubrication and wear-resisting properties, and therefore, the cable outer sheath is protected against damage due to friction in the mounting process.

Owner:浙江正导光电股份有限公司

Preparation method of multi-wall nanometer carbon tube conductive material for switch contact device

ActiveCN1699283AImprove conductivityHigh melting pointElectric switchesLiquid/solution decomposition chemical coatingAdhesiveModified carbon

The invention relates to the preparation method of multi-wall nanometer carbon tube conductive material for switch contact device which comprises the steps of, (1) subjecting the multiple wall carbon nano tube to modification treatment, mixing nitric acid and sulfuric acid by the weight ratio of 1:3, heating the prepared acid solution to 150 deg. C, backflowing and distilled water is used for scouring to neutrality, drying, high speed ball grinding 3 hours, obtaining modified nano carbon tube, (21) subjecting the modified carbon nano tube to silver-doping modification treatment, immersing into SnCl2 solution, loading into AgNO3 solution for ultrasonic oscillation, charging in ammonia and formaldehyde, finally pumping and washing to neutrality with distilled water, drying so as to obtain silver-doped modified nano carbon tube, (3) charging pnenolic aldehyde organic adhesive, thermally pressing into solid blocks, charring at 850 deg. C in retorts.

Owner:SHANGHAI UNIV

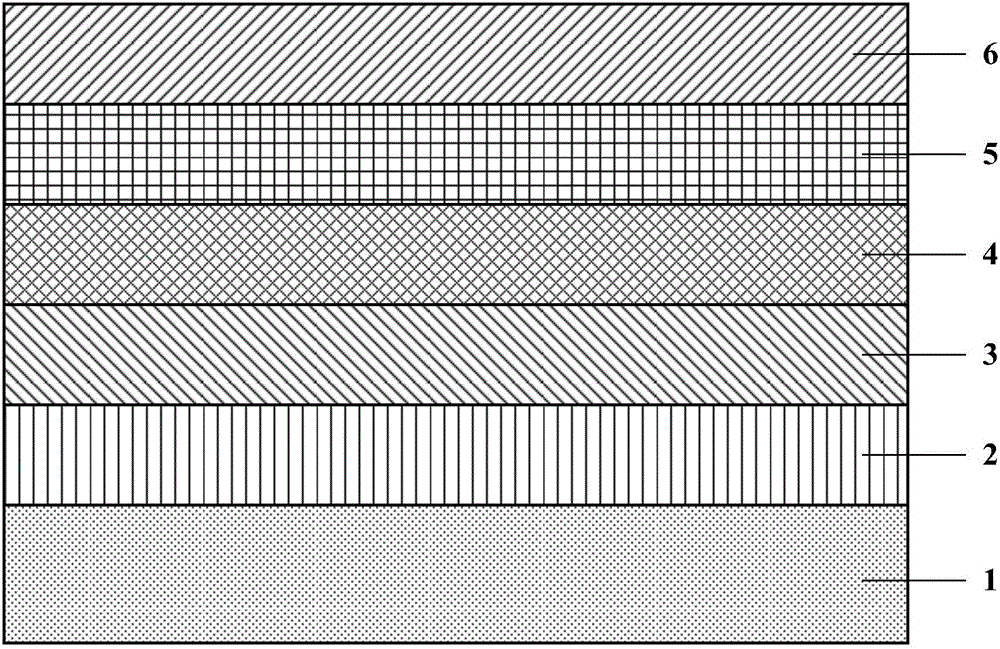

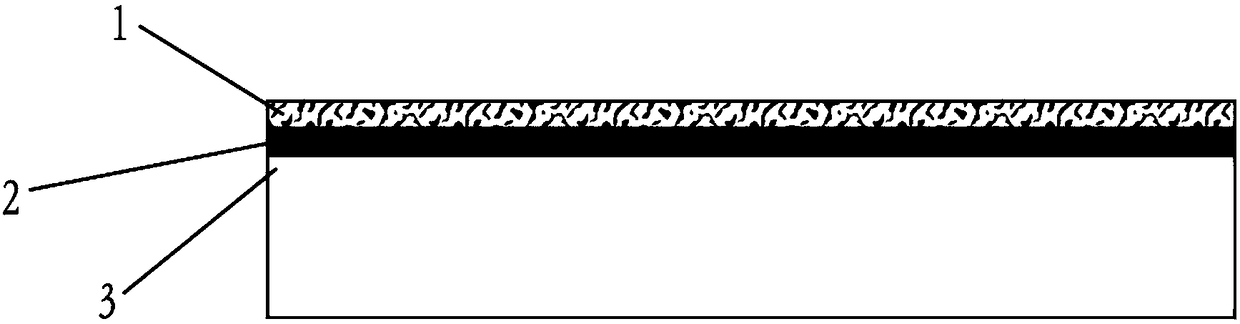

Resin eyeglass, lens anti-fog device, preparation method and applications thereof

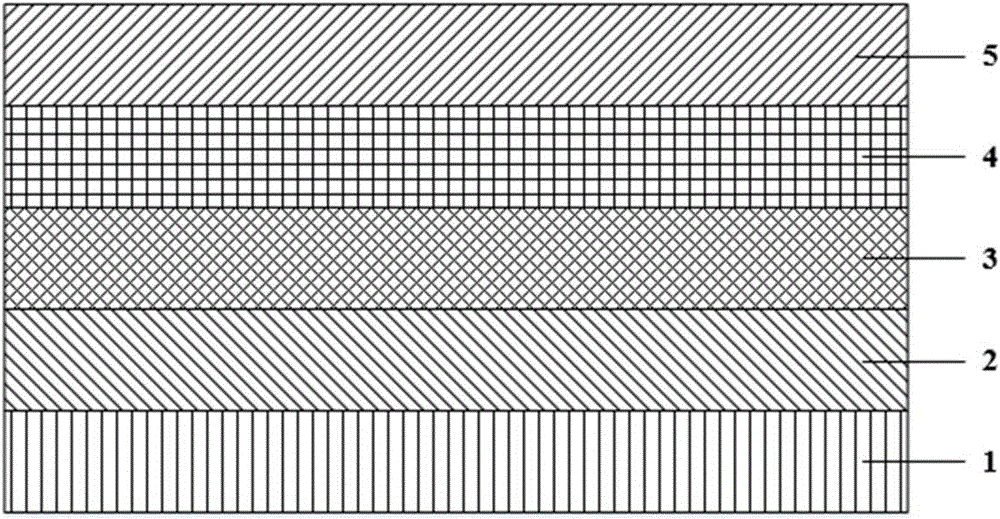

InactiveCN106054402ALower resistanceImprove conductivityCoatingsOptical partsCamera lensSilicon monoxide

The invention discloses a resin eyeglass, a lens anti-fog device, a preparation method and applications thereof. The resin eyeglass comprises a resin substrate, a priming layer, a bedding layer, a conductive layer, an anti-oxidation layer, and a protective layer, wherein the priming layer, the bedding layer, the conductive layer, the anti-oxidation layer, and the protective layer are adhered on the resin substrate in sequence, the priming layer is a silicon monoxide film with a thickness of 10 to 20 nm; the bedding layer is a zinc oxide film, a titanium film or a nickel-chromium alloy film; the conductive layer is a conductive metal film with a thickness of 5 to 15 nm; and the anti-oxidation layer is an anti-oxidation material film with a thickness of 1 to 5 nm. The lens anti-fog device comprises one provided resin eyeglass, a positive electrode, and a negative electrode, wherein the positive electrode and the negative electrode are arranged on two ends of the resin eyeglass respectively. The provided resin eyeglass has the advantages of good electro-conductive performance, anti-reflection effect, and anti-oxidation effect, moreover, the preparation method is simple, the production efficiency is high, and the yield of plating is high. The provided lens anti-fog device can be connected to a power supply to heat the film so as to prevent water steam from forming fog on the surface of lens.

Owner:SHANGHAI COPIOUS OPTICAL S & T CO LTD

Printing ink with tough effect and surface finishing technology for paper packing boxes

InactiveCN108059874AImprove appearance gradeStrong friction resistanceInksOther printing apparatusSurface finishingPOLYETHYLENE WAX

The invention relates to the field of packing and printing, and especially relates to a printing ink with a tough effect and a surface finishing technology for paper packing boxes. The printing ink comprises following raw materials in percentage by weight: 43 to 53% of polyurethane resin, 15 to 25% of epoxy resin, 3 to 6% of tri(propylene glycol) diacrylate, 3 to 6% of polyethylene wax, 1 to 3% ofphoto initiator TPO, 1 to 3% of photo initiator 369, 4 to 10% of silica, 4 to 8% of talcum powder, and 6 to 10% of bentonite. The printing ink is used to decorate the surface of a paper packing box by the provided surface finishing technology. The surface of the processed paper packing box has dark luster. People can feel flannelette touch when touching the surface of the paper packing box. The appearance of the paper packing box is upgraded, and the wear resistant performance of the surface of the paper packing box is strengthened.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

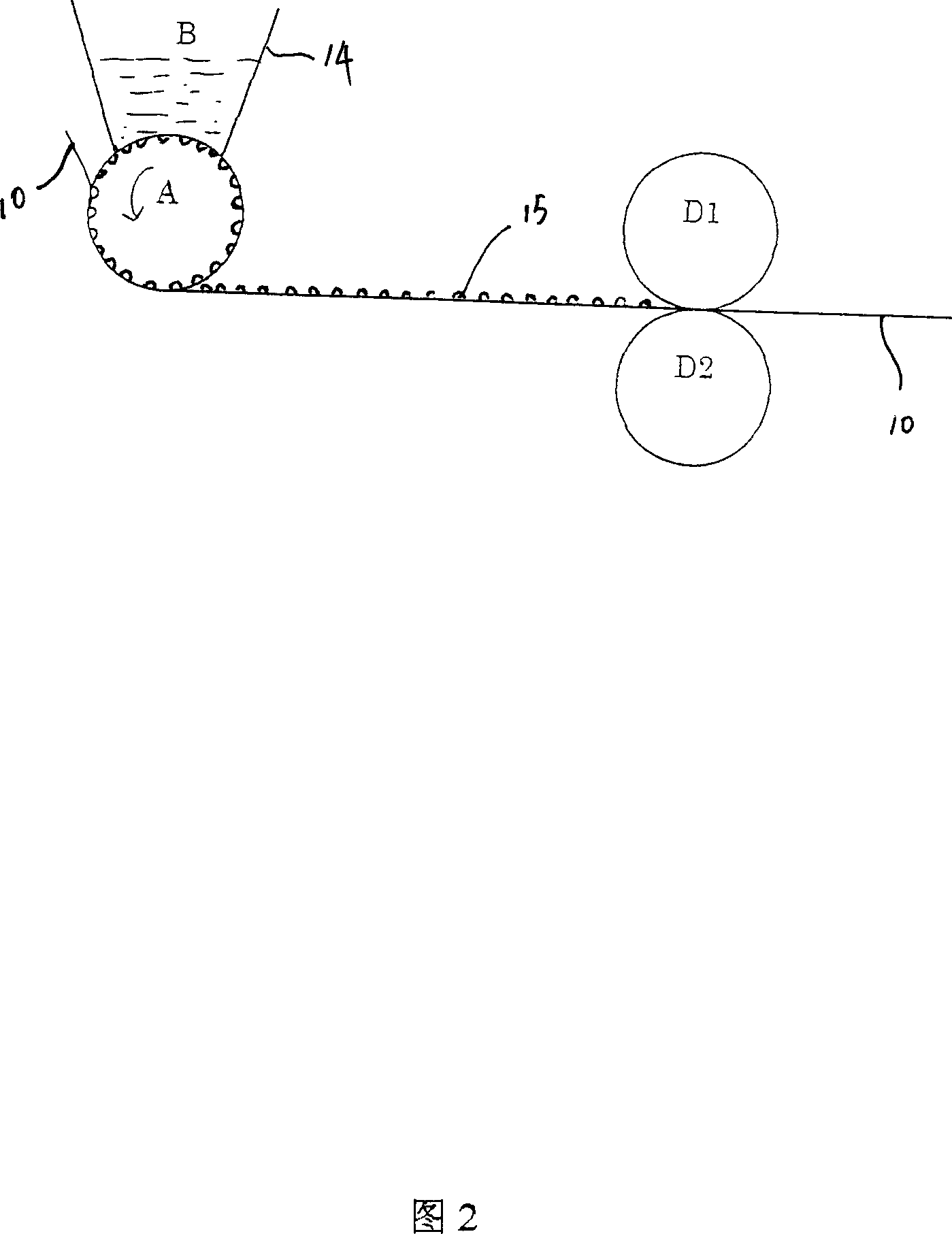

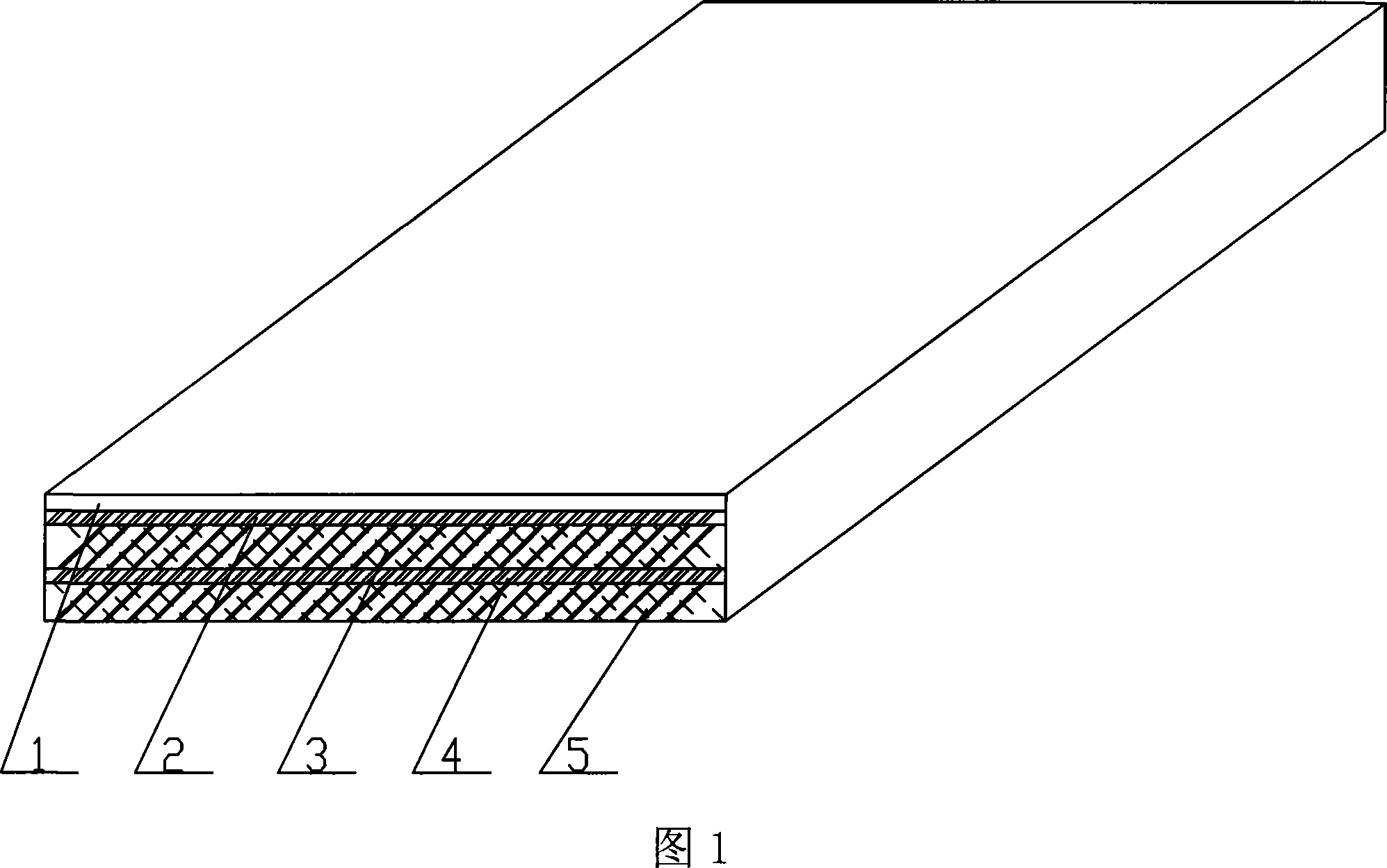

Printed adhesive interlining and preparation method thereof

InactiveCN105506998AEven by forceStrong water resistanceTransfer printing processGarmentsInterliningHot-melt adhesive

The invention discloses a printed adhesive interlining. The printed adhesive interlining comprises base cloth, one face of the base cloth is printed with printing patterns, the other face of the base cloth is coated with a hot melt adhesive, and the coating amount of the hot melt adhesive ranges from 8 g / m<2> to 15 g / m<2>. The invention further discloses a preparation method of the printed adhesive interlining. The prepared printed adhesive interlining can be directly bound with fabric into a whole without sewing, stress is even, and high washing resistance and friction resistance are achieved. Meanwhile, due to the fact that the stiffness of the adhesive interlining is high, the draping sense of clothes is higher. Due to the attractiveness of the printed adhesive interlining, the diversity of clothes wearing is increased.

Owner:GUANGZHOU SHENGHONG INTERLINING CO LTD

Long-lasting anticorrosive finishing paint for metal substrate and preparation method thereof

ActiveCN109337568AHigh mechanical strengthWeather resistantAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedSolvent

The invention belongs to the technical field of anticorrosive coating, and particularly relates to long-lasting anticorrosive finishing paint for a metal substrate and a preparation method thereof. The long-lasting anticorrosive finishing paint comprises a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 35-45 parts of an epoxy-organosilicone resin modified acrylate-polyurethane emulsion, 10-15 parts of functionalized modified graphene, 12-18 parts of fillers, 5-10 parts of a pigment, 8-12 parts of a cosolvent, 0.3-0.8 part of a defoaming agent, 0.5-1 part of a leveling agent, 0.5-1 part of a thickening agent, 0.5-1 part of a water-based drier, 0.8-1 part of a wetting agent and 20-30 parts of deionized water; the component B comprises the following raw materials in parts by weight: 55-65 parts of an isocyanate curing agent and 35-45 parts of a cosolvent. The long-lasting anticorrosive finishing paint for the metal substrate has the advantages of long-lasting excellent anticorrosive performance, strong substrate adhesion, high mechanical strength, excellent friction resistance, excellent salt spray resistance, strong construction adaptability and the like.

Owner:广东恒立信息科技有限公司

Manipulation device for wheelchair footrests

InactiveUS20080001461A1Simple structureEasy to operateSofasWheelchairs/patient conveyanceWheelchair footrestMetal

A manipulation device is for wheelchair footrests that have a pair of shafts (8) extending forwards from opposite forward sides of the main frame (2) and a pair of foot plates (9) pivoted at lateral portions to the shafts. This device has manual levers (21) at the forward sides and actuating means (40) that connects the levers (21) to foot plates (9) and consists of a resilient tube (41), a metal wire (42) and a setting retainer (43) for securing the tube to the wire. The tube (41) can elongate in response to an extraordinary tension exceeding a normal stress imparted to said tube, and the wire (42) loosely inserted in the tube (41) can alter an exposed length. An end of each wire (42) is connected to the foot plate (9) at its rear portion located near the shaft (8) pivoting the foot plate. An end of each tube (41) is connected to the manual lever (21) operating to pull up the tube (41) with the wire (42) such that the foot plate (9) rotates and rises to the upright idle position.

Owner:KOUJI FUJIHARA

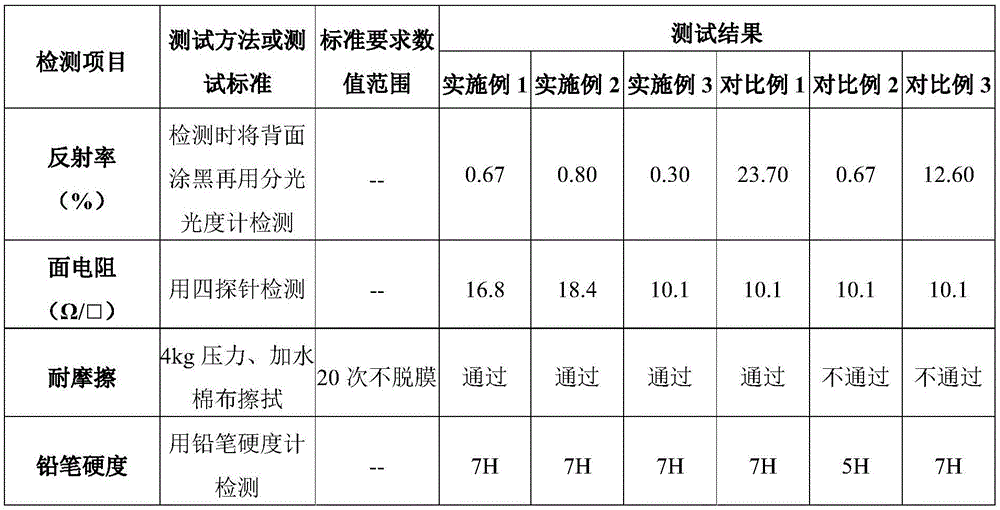

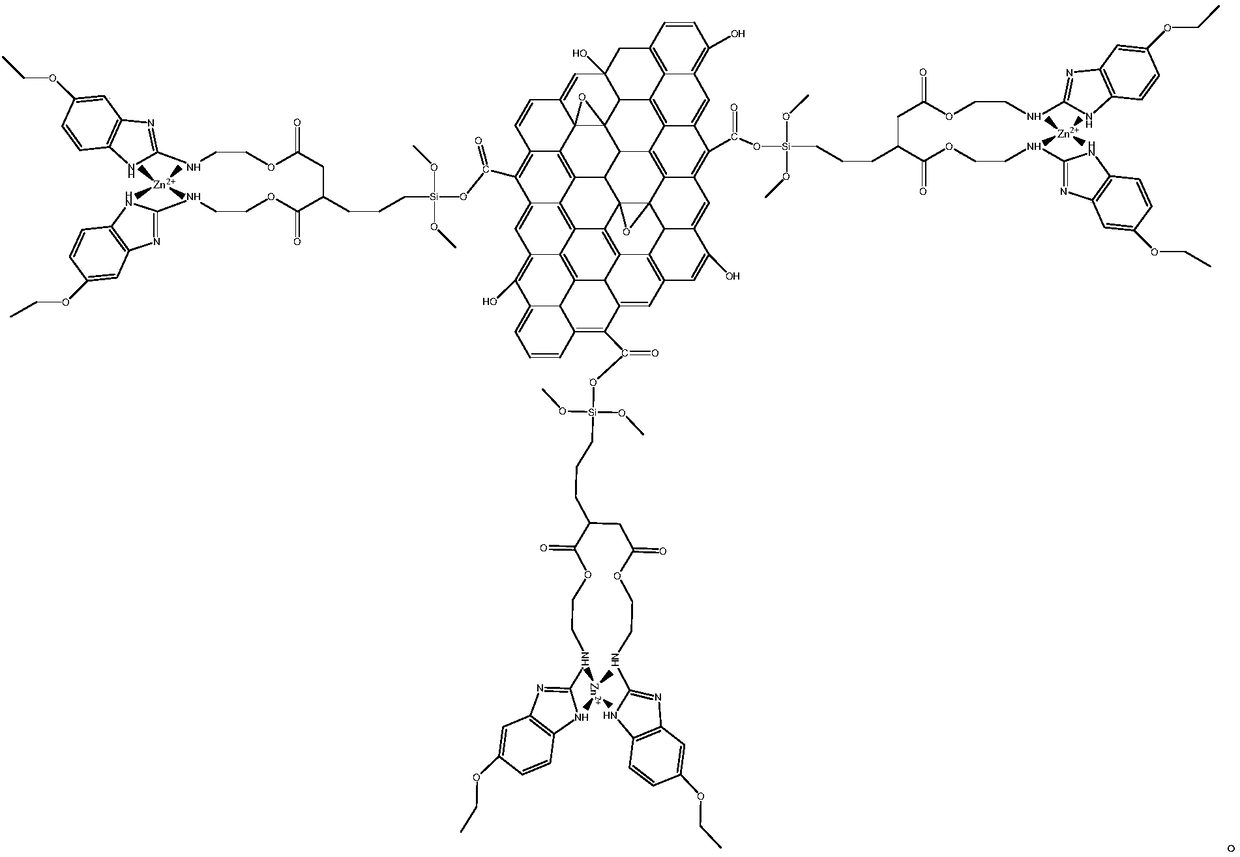

Composite conductive film and preparation method and application thereof

InactiveCN106028486ALower resistanceImprove conductivityTransparent/reflecting heating arrangementsSilicon monoxideChromium nickel

The invention discloses a composite conductive film and a preparation method and application thereof. The composite conductive film sequentially comprises a priming coating layer, an underlay layer, a conductive layer, an anti-oxidation layer, and a protection layer. The priming coating layer is a silicon monoxide film layer, and the thickness of the priming coating layer is from 10nm to 20nm. The underlay layer is a zinc oxide film layer, a titanium film layer or a nichrome alloy film layer. The conductive layer is a conductive metal film layer, and the thickness of the conductive layer is from 5nm to 15nm. The anti-oxidation layer is an anti-oxidation material film layer, and the thickness of the anti-oxidation layer is from 1nm to 5nm. The composite conductive film can be prepared through a conventional plating method, and is applied to a video glasses display screen. The composite conductive film achieves good conductivity, a good anti-reflection effect and a good anti-oxidation effect through the specified selection of the film layer materials and the thicknesses of all film layers. Moreover, the method is simple, is high in production efficiency, and is high in film plating yield.

Owner:SHANGHAI COPIOUS OPTICAL S & T CO LTD

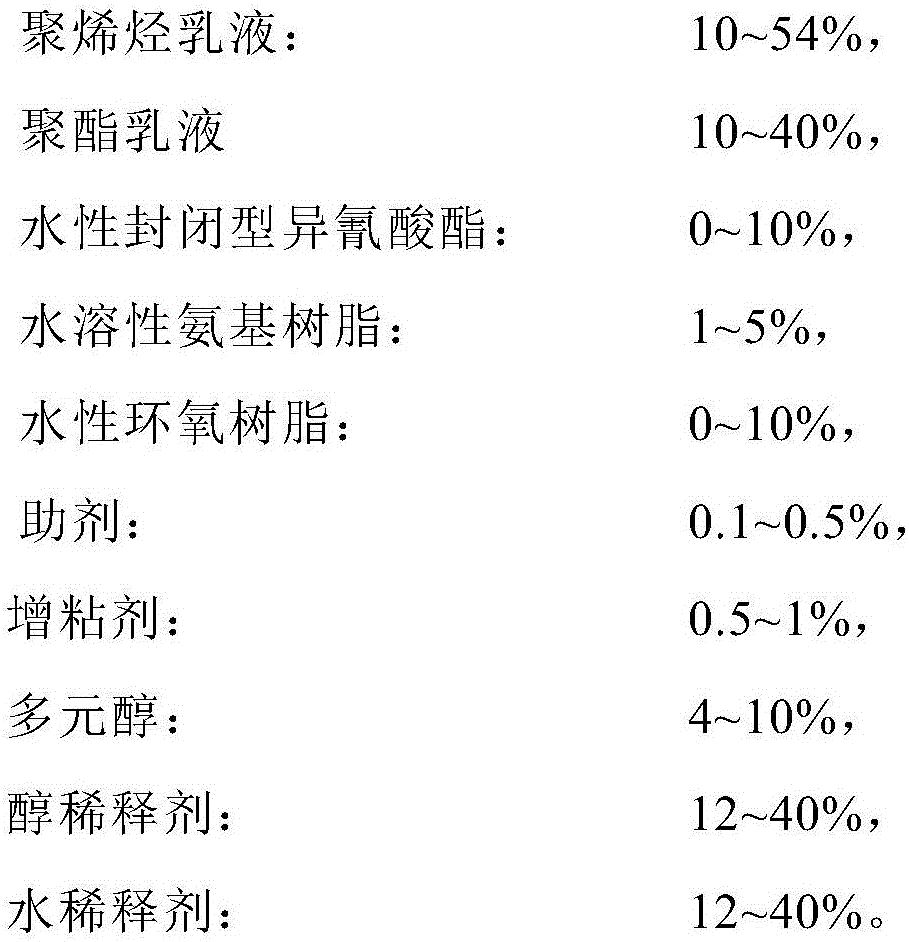

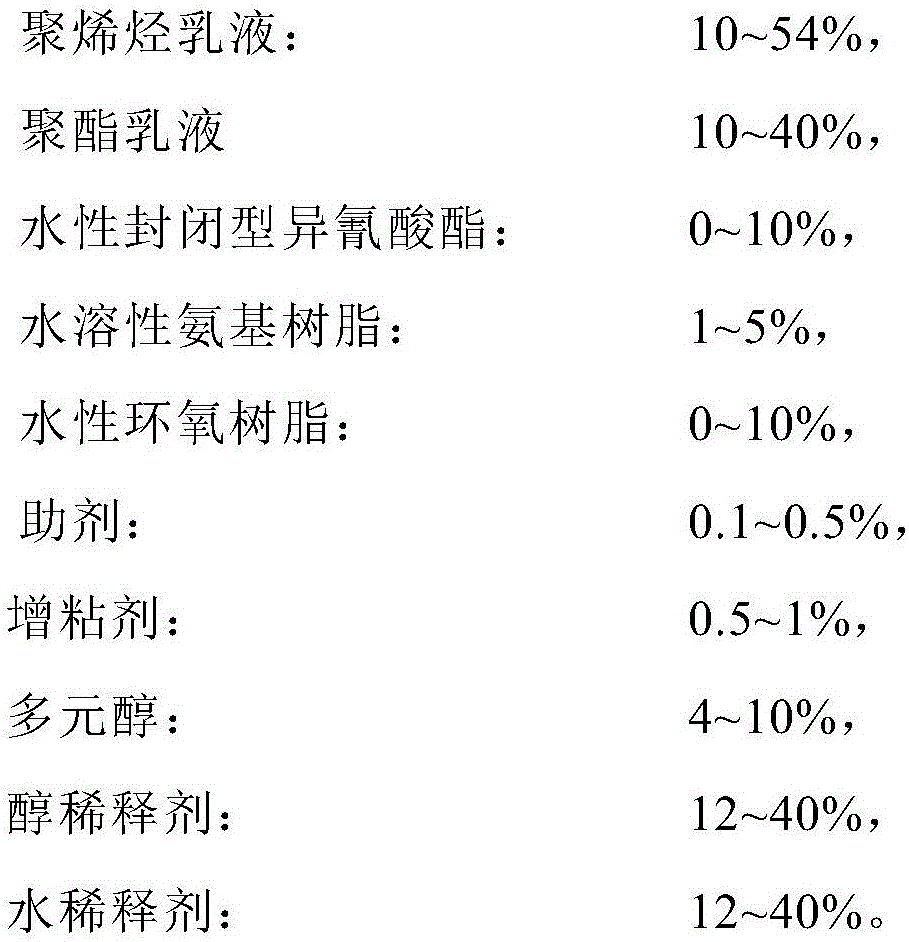

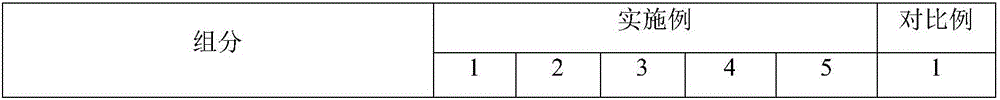

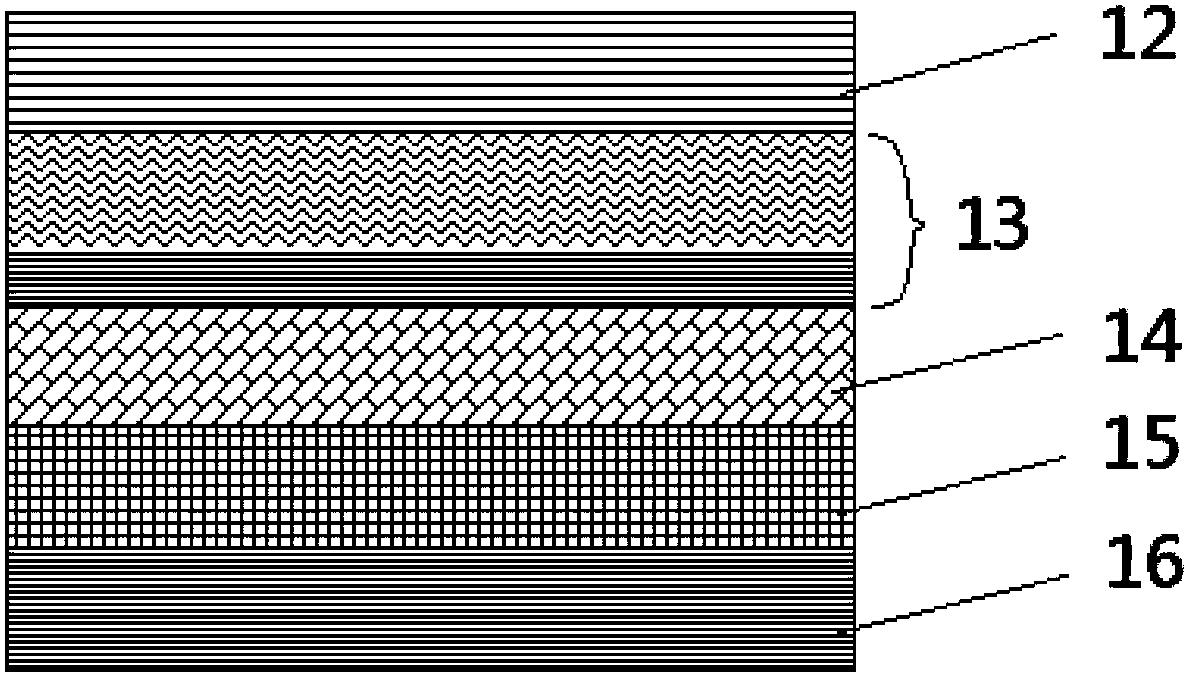

Water varnish for protection of printable aluminum foil for drug packing and preparation method of water varnish

InactiveCN106566400ALow VOC contentFast curingPolyurea/polyurethane coatingsPolyester coatingsPolyesterWater based

The invention discloses water varnish for protection of a printable aluminum foil for drug packing and a preparation method of the water varnish. The water varnish comprises the following components by weight percentage: 10-54% of polyolefin emulsion, 10-40% of polyester emulsion, 0-10% of water-based blocked isocyanates, 1-5% of water soluble amino resin, 0-10% of water-based epoxy resin, 0.1-0.5% of auxiliary, 0.5-1% of viscosifier, 4-10% of polyhydric alcohol, 12-40% of alcohol diluent and 12-40% of water. The curing speed of the water varnish is high, and the heat resistance is high when a bubble cap and the aluminum foil coated with a VC layer are subjected to heat sealing; the surface tension (smoothness) can be adjusted within a certain scope, so that different surface printing requirements can be met, and the surface printing adaptability is high; an adhesion force between the water varnish and the surface of the aluminum foil is high, the transparency is good, the friction resistance is high, and the solvent resistance is good.

Owner:SHANGHAI WEIKAI CHEM +1

High-strength steel sheet for rolling rack and heat treatment technology of high-strength steel sheet

The invention discloses a high-strength steel sheet for a rolling rack. The high-strength steel sheet comprises the following components in percentage by mass: 0.86%-0.88% of carbon, 3.52%-3.58% of manganese, 0.34%-0.36% of aluminum, 0.22%-0.24% of calcium, 0.51%-0.53% of silicon, 0.23%-0.25% of strontium, 2.36%-2.38% of vanadium, 0.43%-0.45% of titanium, 2.43%-2.45% of copper, 0.07%-0.09% of niobium, 4.13%-4.15% of chromium, 0.32%-0.35% of molybdenum, 6.71%-6.73% of nickel, 0.036%-0.038% of astatine, 0.42%-0.44% of magnesium, 0.55%-0.58% of bismuth, 0.52%-0.56% of lanthanum, 1.62%-1.64% of neodymium, 0.74%-0.76% of terbium, 0.21%-0.23% of erbium, 0.42%-0.45% of promethium and the balance of Fe.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

Preparation method for BOPET high-imitation metal wiredrawing VCM film

ActiveCN103692722ASave production costSave manufacturing costSynthetic resin layered productsMetal layered productsUltravioletBoPET

The invention discloses a preparation method for a BOPET (biaxially oriented polyester) high-imitation metal wiredrawing VCM film. The method includes: conducting surface wiredrawing treatment on one side of a transparent BOPET film; coating one surface without surface wiredrawing treatment by a polyurethane UV curable paint, carrying out UV photo-curing and heat curing, and performing natural cooling to obtain a surface hardened coating; coating the surface subjected to surface wiredrawing treatment with a model SC-400 pre-aluminizing prime coat to obtain a fastness enhanced coating; conducting vacuum aluminizing processing on the fastness enhanced coating to obtain a vacuum aluminized layer; and coating the aluminized surface of the vacuum aluminized layer with a model SC-500 topcoat, thus obtaining an antioxidant protective coating. Single-layer BOPET is adopted as a film main material, thus reducing the dosage of a raw material film, saving the production cost, prolonging the product life and improving the tolerance to various adverse conditions. The film obtained by the method has the visual effects of an imitated metal wire drawing board, thus realizing the purpose of high simulation of different material wiredrawing metal boards.

Owner:SHANGHAI RADIX VACUUM METALIZING

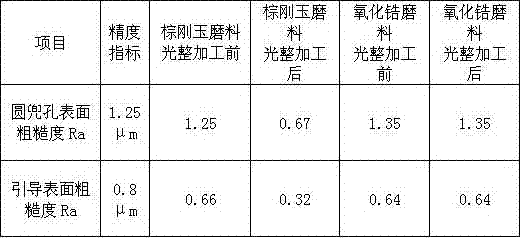

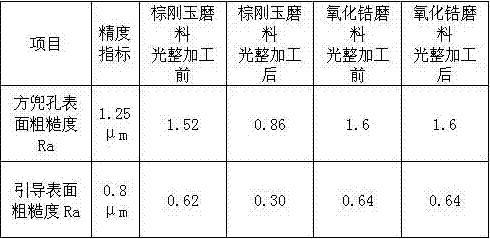

Finishing machining method for 40CrNiMoA steel retaining frame

InactiveCN107160286AHigh purityPromote crystallizationEdge grinding machinesPolishing machinesAluminum compositesMachining

The invention belongs to the technical field of bearing cage processing and provides a finishing method for a 40CrNiMoA steel cage. A proposed finishing method for 40CrNiMoA steel cage. The finishing method includes polishing and brightening; brown corundum is selected as the abrasive, and brown corundum includes brown corundum oblique cylinders, brown corundum oblique triangles and brown corundum balls; the abrasive and The workpieces are added to the polishing machine together; the polishing time is 4~5 hours, and it needs to be stopped after every 1.5~2 hours of polishing, the hot water in the container is drained, and cold water is poured in, and the abrasives and workpieces in the box are cooled before polishing; Select φ2.5-φ3.5mm zirconium-aluminum composite balls as bright abrasives, and put the abrasives and workpiece into the polishing machine for 30-40 minutes. The invention reduces the inner and outer surfaces and end surfaces of the cage, and improves the product quality of the cage.

Owner:LUOYANG LYC BEARING

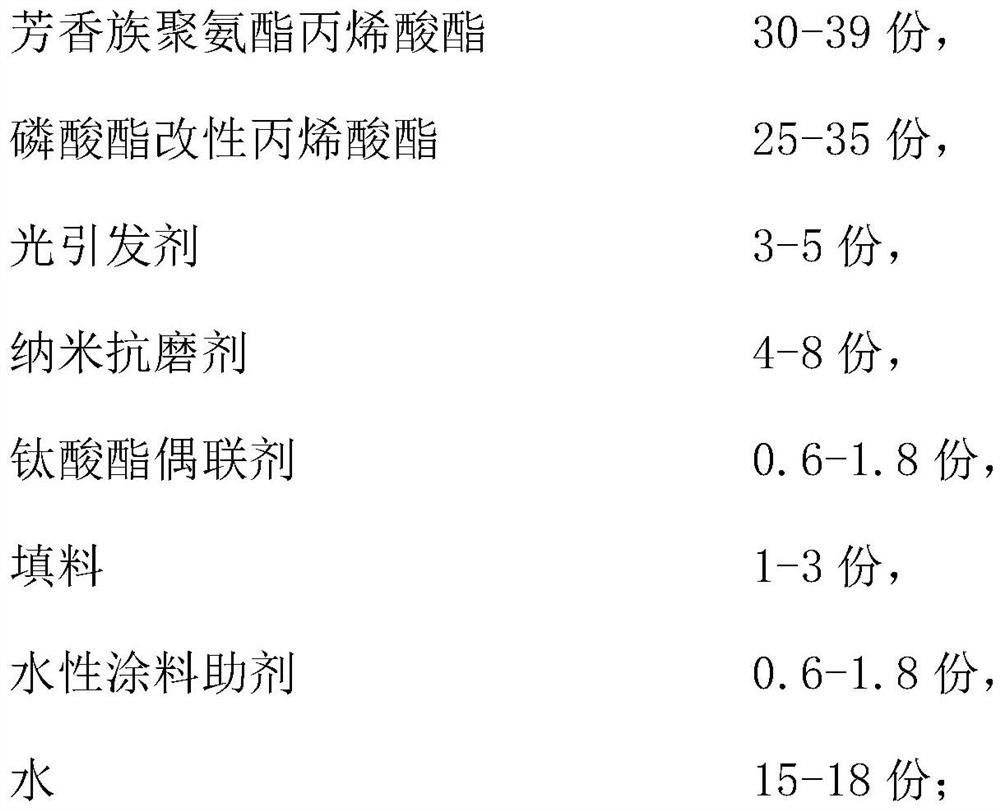

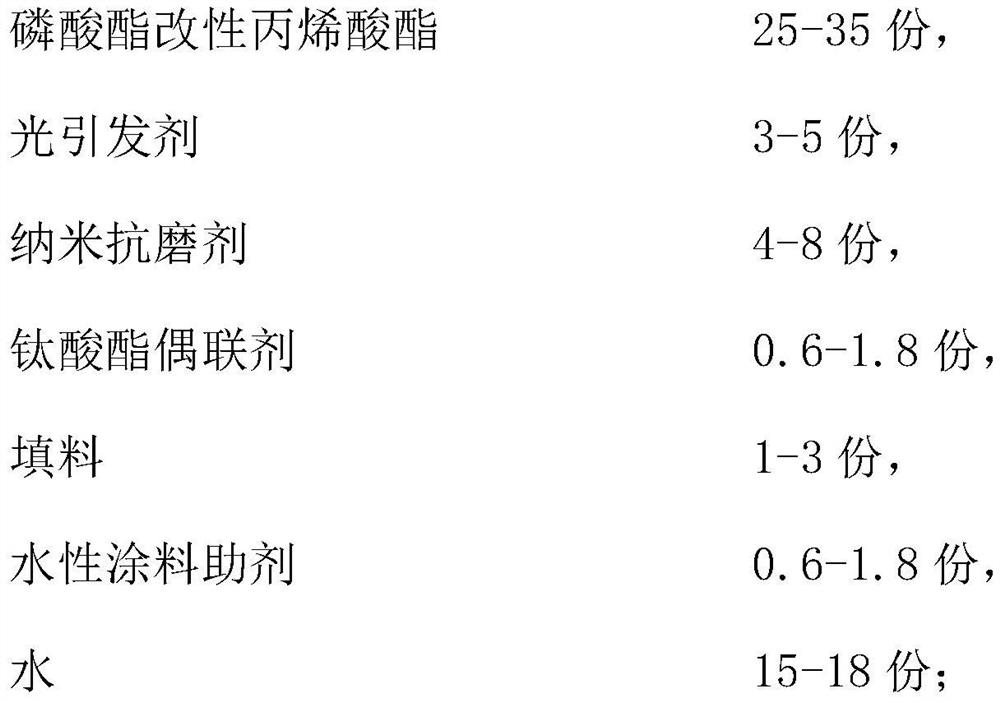

Water-based UV light-cured polyurethane coating and preparation method thereof

InactiveCN112480804AGood metal adhesionStrong chemical resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceCompatibilization

The invention discloses a water-based UV light-cured polyurethane coating and a preparation method thereof. The water-based UV light-cured polyurethane coating is prepared from the following components: 30-39 parts of aromatic polyurethane acrylate, 25-35 parts of phosphate modified acrylate, 3-5 parts of a photoinitiator, 4-8 parts of a nano anti-wear agent, 0.6-1.8 parts of a titanate coupling agent, 1-3 parts of filler, 0.6-1.8 parts of a water-based coating additive and 15-18 parts of water. Aromatic polyurethane acrylate is used as matrix resin and is subjected to polymerization reactionwith phosphate modified acrylate to form a hyperbranched oligomer with chemical bond connection acting force, then the nano anti-wear agent composed of a composite material is added, hydroxyl groups in molecules of a titanate coupling agent can form a bonding effect with a base material, and thus the adherence is greatly improved; and the water-based coating additive can improve the dispersity andcompatibility among the raw materials. Therefore, the water-based UV light-cured polyurethane coating has the characteristics of super wear resistance and high adhesive force, also has favorable acid / alkali resistance, and can be used for floors, furniture, wood fan blades, musical instruments and other wood products.

Owner:中山市鑫峰光固化材料有限公司

Coating containing trace photoinitiator and solidifying method thereof

InactiveCN102304318AShort curing timeImprove efficiencyPretreated surfacesPolyester coatingsAir atmospherePolyester

The invention relates to a coating containing trace photoinitiator. According to the invention, the main components of the coating are unsaturated polyester resin or acrylic acid type oligomer, acrylic acid monoester and polyester compounds as well as the photoinitiator, wherein the mass percentage of the photoinitiator is 0.1%-1%. The invention also provides a solidifying method of the coating. The solidifying method comprises the following steps: covering the coating on a substrate by using printing, spreading, roller painting and combination processes; irradiating the coating with ultraviolet light; and enabling the substrate to pass through a self-shielding electron accelerator which is located in the air atmosphere at the linear speed of 1-10 m / s, wherein the electron accelerator generates a low-energy electron beam to irradiate the coating so that the coating can be instantly solidified. The coating has the advantages that no odor emerges in the production process, trace residue of the photoinitiator in the coating can meet the requirement of food package, cost is low, and production efficiency is high; and the solidifying method is suitable for solidifying production of all-color coatings.

Owner:HUBEI ERAY NUCLEAR TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com