Water-based UV light-cured polyurethane coating and preparation method thereof

A polyurethane coating and light-curing technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of wear resistance and poor adhesion, achieve good chemical corrosion resistance, and improve adhesion , Good acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

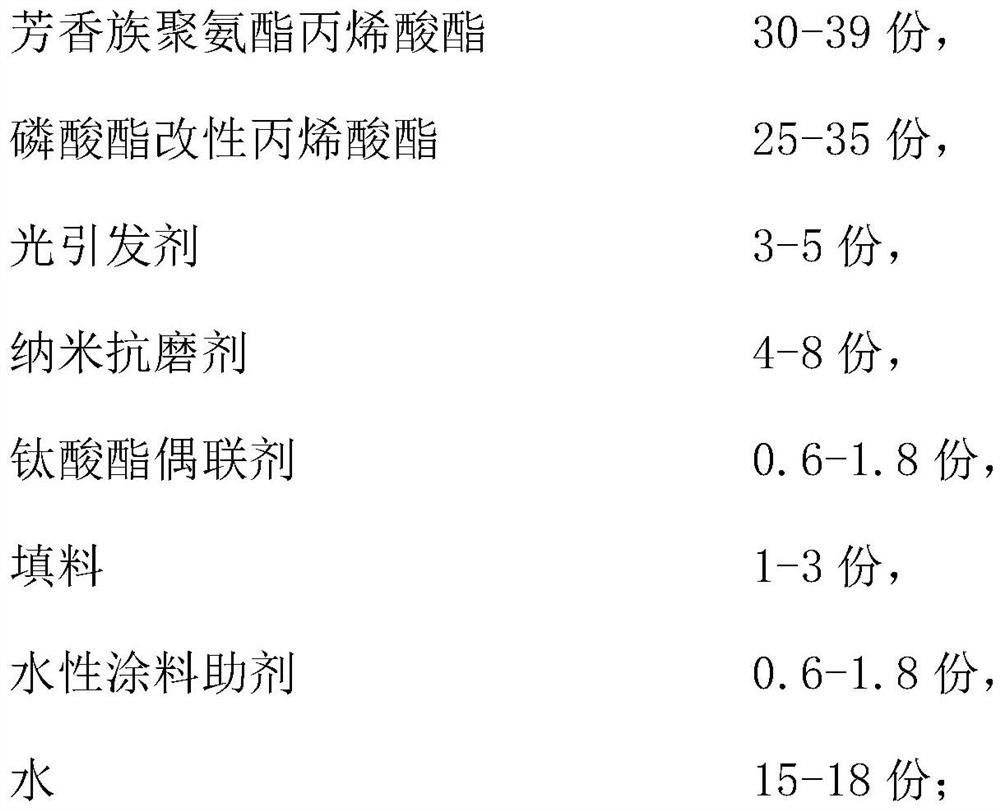

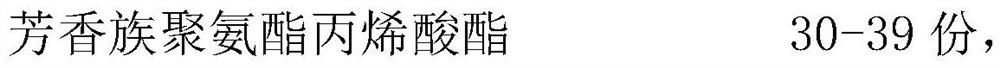

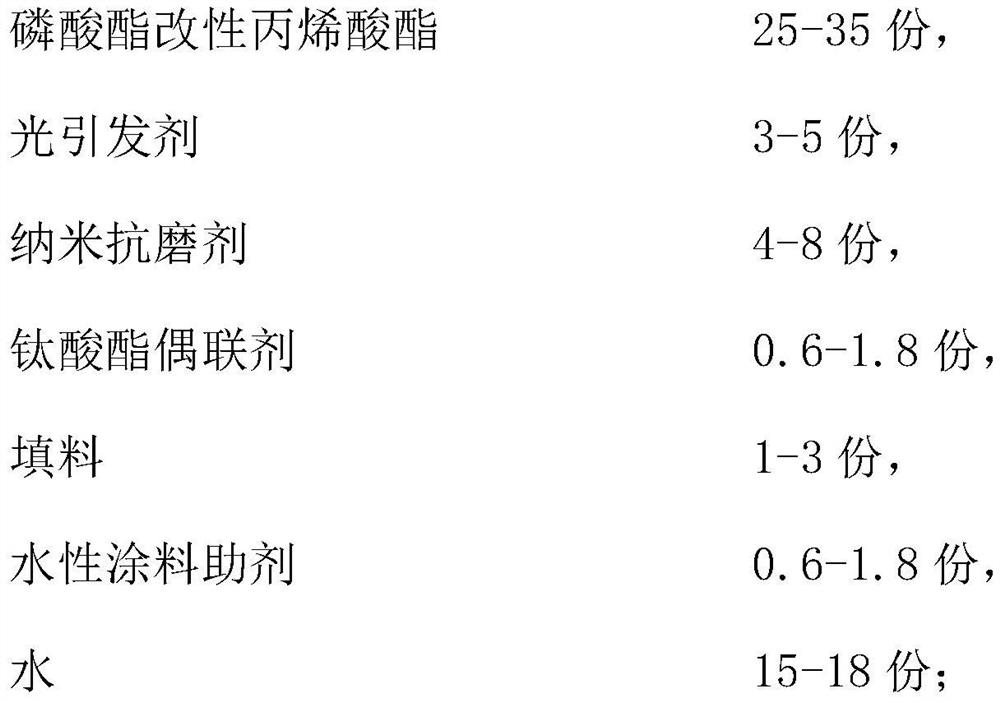

[0029] A kind of preparation method of above-mentioned waterborne UV photocurable polyurethane coating, comprises the following steps:

[0030] 1) Weigh each component according to the ratio in Table 1, mix aromatic urethane acrylate, phosphate-modified acrylate, filler, water-based paint additives and water, and stir at 400 rpm for 30 minutes to obtain the initial order mixture;

[0031] 2) Add nano anti-wear agent, titanate coupling agent and photoinitiator to the above primary mixture, stir at 250 rpm for 30 minutes, remove impurities through filtering equipment, and obtain the product.

Embodiment 2

[0033] A kind of preparation method of above-mentioned waterborne UV photocurable polyurethane coating, comprises the following steps:

[0034] 1) Weigh each component according to the ratio in Table 1, mix aromatic urethane acrylate, phosphate-modified acrylate, filler, water-based paint additives and water, and stir at 500 rpm for 20 minutes to obtain the initial order mixture;

[0035] 2) Add nano anti-wear agent, titanate coupling agent and photoinitiator to the above primary mixture, stir at 300 rpm for 20 minutes, remove impurities through filtering equipment, and obtain the product.

Embodiment 3

[0037] A kind of preparation method of above-mentioned waterborne UV photocurable polyurethane coating, comprises the following steps:

[0038]1) Weigh each component according to the ratio in Table 1, mix aromatic urethane acrylate, phosphate-modified acrylate, filler, water-based paint additives and water, and stir at 450 rpm for 30 minutes to obtain the initial order mixture;

[0039] 2) Add nano anti-wear agent, titanate coupling agent and photoinitiator to the above primary mixture, stir at 200 rpm for 30 minutes, remove impurities through filtering equipment, and obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com