Conductive nitrile rubber and preparing method thereof

A technology of nitrile rubber and titanate coupling agent, which is applied in the field of conductive rubber to achieve excellent conductive effect, excellent aging resistance and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

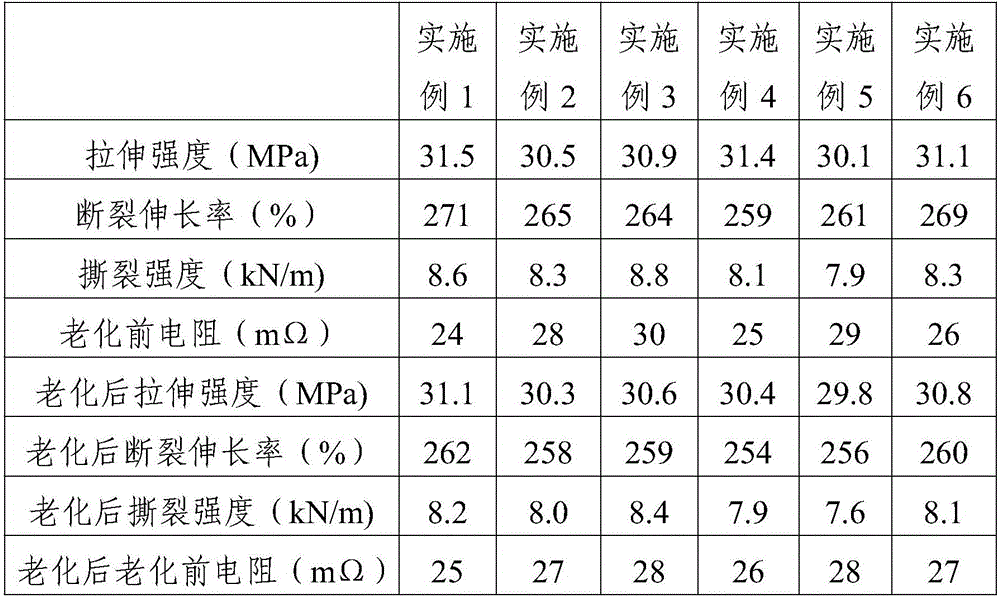

Examples

Embodiment 1

[0020] A kind of conductive nitrile rubber, is made up of the raw material of following weight part:

[0021] 95 parts of nitrile rubber, 25 parts of nano-rectorite, 12 parts of expanded graphite, 5 parts of carbon nanotubes, 20 parts of silver-plated copper powder, 5 parts of zinc oxide, 1 part of stearic acid, ligand-type titanate coupling 2 parts of dicumyl peroxide, 2 parts of magnesium dimethacrylate, 3 parts of tetramethylthiuram disulfide, 1 part of sulfur, CuSO 4 6 parts of powder, 3 parts of modified nano silicon nitride, nano SiO 2 0.8 parts, N, N'-di-sec-butyl-p-phenylenediamine 2.5 parts, magnesium hydroxide 2 parts.

[0022] The modified nano-silicon nitride is obtained by coating the surface of the nano-silicon nitride with an organic silicon coupling agent.

[0023] The preparation method of conductive nitrile rubber, comprises the following steps:

[0024] (1) take each raw material in proportion;

[0025] (2) Expanded graphite, carbon nanotubes, silver-pla...

Embodiment 2

[0030] A kind of conductive nitrile rubber, is made up of the raw material of following weight part:

[0031] 80 parts of nitrile rubber, 28 parts of nano-rectorite, 10 parts of expanded graphite, 6 parts of carbon nanotubes, 18 parts of silver-plated copper powder, 6 parts of zinc oxide, 0.5 parts of stearic acid, ligand-type titanate coupling 3 parts of agent, 2 parts of dicumyl peroxide, 3 parts of magnesium dimethacrylate, 2 parts of tetramethylthiuram disulfide, 1 part of sulfur, CuSO 4 5 parts of powder, 4 parts of modified nano silicon nitride, nano SiO 2 0.5 parts, N, N'-di-sec-butyl-p-phenylenediamine 3 parts, magnesium hydroxide 2 parts.

[0032] The modified nano-silicon nitride is obtained by coating the surface of the nano-silicon nitride with an organic silicon coupling agent.

[0033] The preparation method of conductive nitrile rubber, comprises the following steps:

[0034] (1) take each raw material in proportion;

[0035] (2) Expanded graphite, carbon na...

Embodiment 3

[0040] A kind of conductive nitrile rubber, is made up of the raw material of following weight part:

[0041] 110 parts of nitrile rubber, 22 parts of nano-rectorite, 15 parts of expanded graphite, 4 parts of carbon nanotubes, 22 parts of silver-plated copper powder, 4 parts of zinc oxide, 1.5 parts of stearic acid, ligand-type titanate coupling 1 part of agent, 3 parts of dicumyl peroxide, 2 parts of magnesium dimethacrylate, 3 parts of tetramethylthiuram disulfide, 0.5 parts of sulfur, CuSO 4 8 parts of powder, 2 parts of modified nano silicon nitride, nano SiO 2 1 part, N, N'-di-sec-butyl-p-phenylenediamine 1.5 parts, magnesium hydroxide 3 parts.

[0042]The modified nano-silicon nitride is obtained by coating the surface of the nano-silicon nitride with an organic silicon coupling agent.

[0043] The preparation method of conductive nitrile rubber, comprises the following steps:

[0044] (1) take each raw material in proportion;

[0045] (2) Expanded graphite, carbon n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com