Printing ink with tough effect and surface finishing technology for paper packing boxes

A tactile effect, packaging box technology, applied in the directions of ink, application, printing device, etc., can solve the problems of single surface finishing effect, high rubbing force of metal parts, poor friction resistance, etc., to improve the appearance grade and avoid the surface The effect of scratch and friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

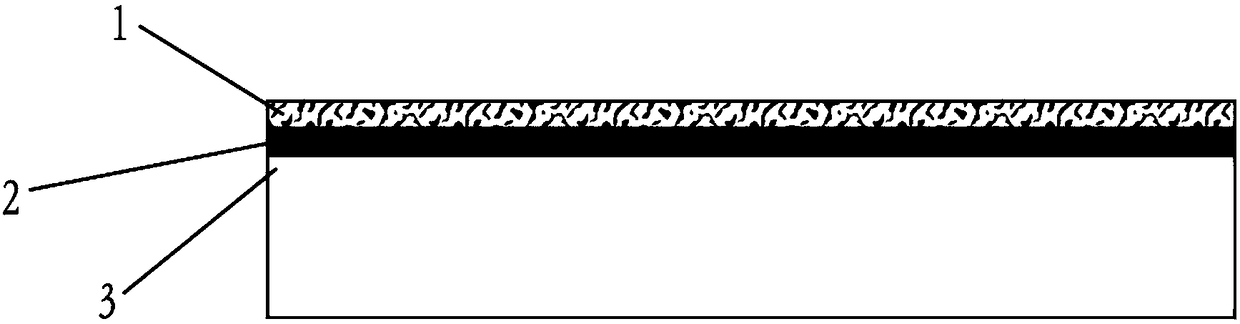

Image

Examples

Embodiment 1

[0040] Take a small paper cigarette packaging box as an example for illustration. The packaging box is a three-dimensional formed carton and is packaged by an automatic packaging machine assembly line. The paper of the carton is 240g / m 2 The PET silver cardboard first uses the sheet-fed gravure printing process to print the base color, and then uses a multi-color UV offset printing machine to coat the surface of the packaging box with tactile effect ink and print the pattern text simultaneously. Firstly, the tactile effect ink is coated on the first color group of the multi-color UV offset printing machine, and the coating position is at the corner after the three-dimensional molding of the packaging box. The printing plate of the tactile effect ink adopts CTP plate making, and the tactile effect finishing area on the printing plate is solid. The configuration of tactile effect ink is as follows (by weight): 48% polyurethane resin, 19% epoxy resin, 4% tripropylene glycol diac...

Embodiment 2

[0043] Take a paper cigarette packaging carton as an example for illustration. The packaging box is a folding carton and is packed in an automatic packaging machine assembly line. The paper used for the printing of this carton is 250g / m 2The aluminum-sprayed silver cardboard first adopts the sheet-fed gravure printing process to print the base color, and then uses a multi-color UV offset printing machine to coat the surface of the packaging box with tactile effect ink and print the pattern text simultaneously. First, apply the tactile effect ink on the first color group of the multi-color UV offset printing machine, and the coating position is on the side of the packaging box after three-dimensional molding. The printing plate of the tactile effect ink adopts CTP plate making, and the tactile effect finishing area on the printing plate is solid. The configuration of the tactile effect printing ink is as follows (by weight): 44% polyurethane resin, 25% epoxy resin, 3% tripropy...

Embodiment 3

[0046] Take a paper cosmetic packaging box as an example for illustration. The packaging box is a folding carton and is packaged by an automatic packaging machine assembly line. The paper used for the printing of this carton is 295g / m 2 The white cardboard is firstly printed with a sheet-fed gravure printing process, and then a multi-color UV offset printing machine is used to apply tactile effect ink on the surface of the printed sheet of the packaging box and simultaneously print the pattern text. First, apply the tactile effect ink on the first color group of the multi-color UV offset printing machine, and the coating position is on the side of the packaging box after three-dimensional molding. The printing plate of the tactile effect ink adopts CTP plate making, and the tactile effect finishing area on the printing plate is solid. The configuration of the tactile effect printing ink is as follows (by weight): 50% polyurethane resin, 15% epoxy resin, 6% tripropylene glycol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com