A kind of light rubber sole and preparation method thereof

A rubber sole, lightweight technology, applied in the field of polymer chemistry, can solve the problems of inability to guarantee the physical properties of the sole, the quality of the sole is reduced, and the glossy and matte surface affects the overall effect of the sole, so as to achieve a beautiful overall appearance, solve the problem of loss of gloss, and improve The effect of appearance grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of lightweight rubber:

[0027] (1) Weighing: Weigh the following raw materials by weight: SBS-I5Kg with a hardness of 90A-, SBS-II12Kg with a hardness of 70A, 13Kg of styrene-butadiene rubber, 7Kg of white carbon black, bis-(3-triethoxysilane Propyl)-tetrasulfide 0.9Kg, stearic acid 0.23Kg, PEG40000.13Kg, zinc oxide 1.1Kg, dicumyl peroxide 0.62Kg;

[0028] (2) Internal mixing: Mix the accurately weighed raw materials except zinc oxide and dicumyl peroxide, start the internal mixer to mix the materials evenly, add 2 / 3 of the amount of white carbon black, and continue the internal mixing , Rubber and white carbon black are mixed and re-agglomerated. When the temperature reaches 97°C, add all the remaining raw materials and the remaining white carbon black until the temperature continues to rise to 100°C, and the mixture of all raw materials is re-agglomerated. Block, that is, the rubber compound that has been mixed;

[0029] (3) Smelting and vulcanization: ...

Embodiment 2

[0032] Preparation of lightweight rubber:

[0033] (1) Weighing: Weigh the following raw materials by weight: SBS-I8Kg with a hardness of 92A, SBS-II10Kg with a hardness of 68A, 18Kg of styrene-butadiene rubber, 5Kg of white carbon black, bis-(3-triethoxysilane propylene base)-tetrasulfide 1.5Kg, stearic acid 0.5Kg, PEG40000.48Kg, zinc oxide 1.45Kg, dicumyl peroxide 0.5Kg;

[0034] (2) Internal mixing: Mix the accurately weighed raw materials except zinc oxide and dicumyl peroxide, start the internal mixer to mix the materials evenly, add 2 / 3 of the amount of white carbon black, and continue the internal mixing , rubber and white carbon black are mixed, re-agglomerated, when the temperature reaches 103°C, add all the remaining raw materials and the remaining white carbon black, until the temperature continues to rise to 100°C, the mixture of all raw materials is re-agglomerated Block, that is, the rubber compound that has been mixed;

[0035] (3) Smelting and vulcanization: ...

Embodiment 3

[0038] Preparation of lightweight rubber soles:

[0039] (1) stocking: get the lightweight rubber prepared in Example 1, take out the sheet respectively by the difference of the sole shape, carry out the stocking in the mode of stripping, cutting with a knife;

[0040] (2) Vulcanization molding of shoe soles: adjust the vulcanization time of the hydraulic press according to the scorch time and positive vulcanization time of light rubber, cut the material into a preliminary shoe shape, put it in the mold on the hydraulic press after weighing it, and measure the time according to the measurement time of the rheometer Adjust the vulcanization time and corresponding vulcanization temperature for the production of soles, and obtain the rough product of light rubber soles;

[0041] (3) post-processing: take the crude light rubber sole product described in step 2 and carry out edge trimming, roughening, and carry out edge grinding, painting and other post-processing operations as req...

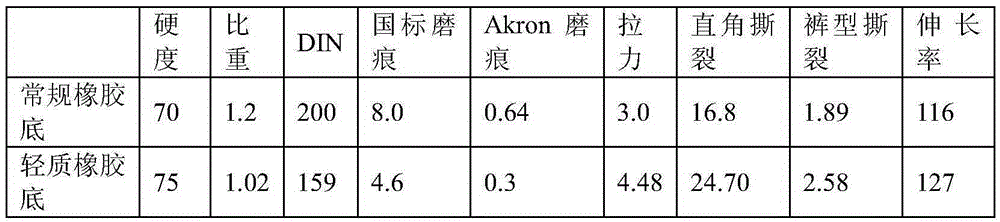

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com