Double-hardness and double-physical-property rubber sole and preparation technology thereof

A rubber sole and rubber technology, applied in the field of polymer chemistry, can solve the problems of poor vulcanization plasticity, inability to firmly bond, difficult to firmly bond, etc., and achieve the effects of improving appearance, firm bonding, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

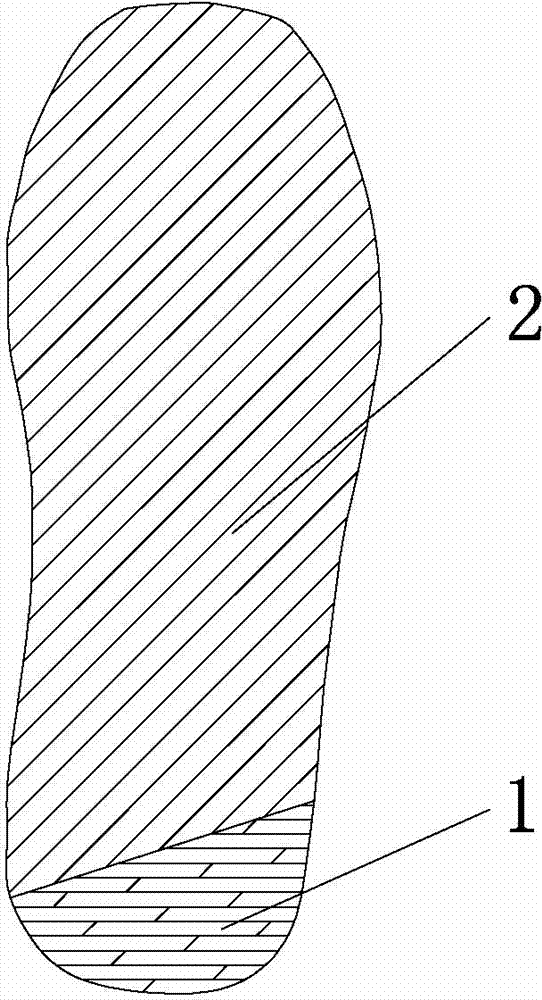

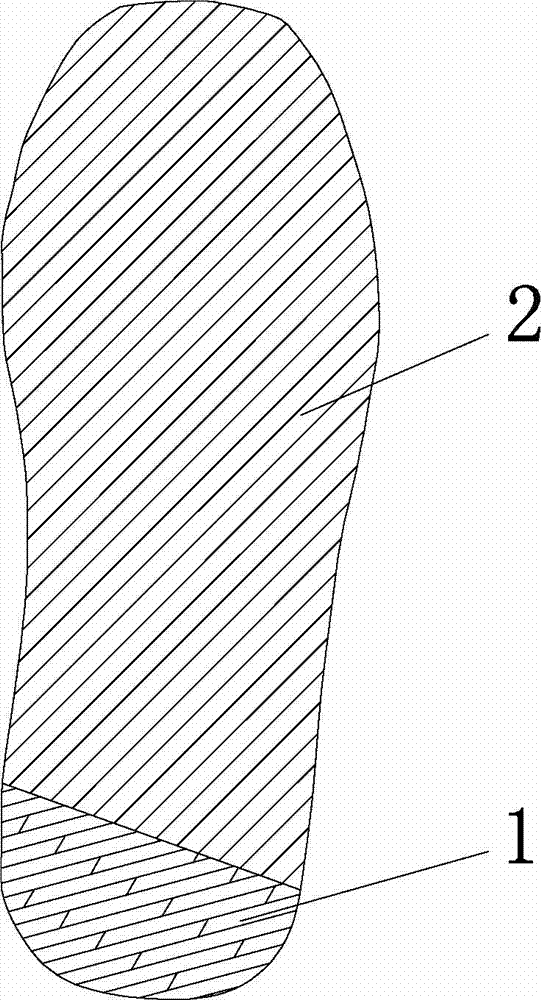

Image

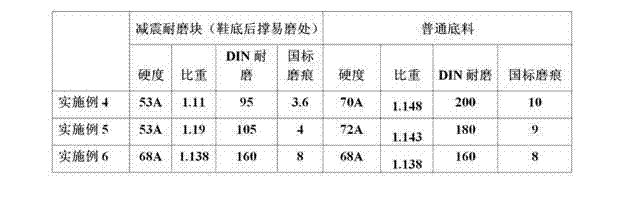

Examples

Embodiment 1

[0043] Wear-resistant rubber formula:

[0044] NO Name Mass (kg)

[0045] 1 2#natural rubber 14

[0046] 2 butadiene rubber 9000 28

[0047] 3 Silica 8

[0048] 4 tire powder 5

[0049] 5 naphthenic oil 8

[0050] 6 Accelerator D 0.1

[0051] 7 Accelerator M 0.3

[0052] 8 stearic acid ST 0.42

[0053] 9 Antiaging agent RD 0.6

[0054] 10 PEG4000 0.8

[0055] 11 Antifogging agent 0.32

[0056] 12 modifier 0.6

[0057] 13 Active zinc oxide 3.6

[0058] 14 Accelerator DM 0.3

[0059] Accelerator

[0060] 1. Insoluble sulfur 0.7

[0061] 2. TS-80 0.105

[0062] Preparation of wear-resistant rubber:

[0063] Step 1, Weighing: Weigh all the raw materials except the accelerant according to the above formula;

[0064] Step 2, internal mixing: Mix the accurately weighed rubber and tackifier raw materials, start the internal mixer to mix the materials evenly, add 2 / 3 of the amount of white carbon black, and continue the internal mixing, rubber and white carbon Mix black...

Embodiment 2

[0068] Wear-resistant rubber formula:

[0069] NO Name Mass (kg)

[0070] 1 2#natural rubber 10

[0071] 2 butadiene rubber 9000 35

[0072] 3 Silica 5

[0073] 4 tire powder 10

[0074] 5 naphthenic oil 5

[0075] 6 Accelerator D 0.3

[0076] 7 Accelerator M 0.5

[0077] 8 stearic acid ST 0.2

[0078] 9 Antiaging agent RD 0.8

[0079] 10 PEG4000 0.5

[0080] 11 Antifogging agent 0.5

[0081] 12 modifier 0.4

[0082] 13 Active Zinc Oxide 2

[0083] 14 Accelerator DM 0.2

[0084] Accelerator

[0085] 1. Insoluble sulfur 0.5

[0086] 2. TS-80 0.12

[0087] Preparation of wear-resistant rubber:

[0088] Step 1, Weighing: Weigh all the raw materials except the accelerant according to the above formula;

[0089] Step 2, internal mixing: Mix the accurately weighed rubber and tackifier raw materials, start the internal mixer to mix the materials evenly, add 2 / 3 of the amount of white carbon black, and continue the internal mixing, rubber and white carbon Mix black a...

Embodiment 3

[0093] Wear-resistant rubber formula:

[0094] NO Name Mass (kg)

[0095] 1 2#natural rubber 18

[0096] 2 butadiene rubber 9000 20

[0097] 3 Silica 10

[0098] 4 tire powder 5

[0099] 5 naphthenic oil 10

[0100] 6 Accelerator D 0.1

[0101] 7 Stearic acid ST 0.8

[0102] 8 Antiaging agent RD 0.3

[0103] 9 PEG4000 1.5

[0104] 10 Antifogging agent 0.2

[0105] 11 modifier 0.8

[0106] 12 Active Zinc Oxide 5

[0107] 13 Accelerator DM 0.1

[0108] Accelerator

[0109] 1. Insoluble sulfur 0.9

[0110] 2. TS-80 0.08

[0111] Preparation of wear-resistant rubber:

[0112] Step 1, Weighing: Weigh all the raw materials except the accelerant according to the above formula;

[0113] Step 2, internal mixing: Mix the accurately weighed rubber and tackifier raw materials, start the internal mixer to mix the materials evenly, add 2 / 3 of the amount of white carbon black, and continue the internal mixing, rubber and white carbon Mix black and re-agglomerate, when the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com