Patents

Literature

53results about How to "Increase the gel content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cable sheath material for coal mine

ActiveCN101538380AImprove stabilityEasy to useInsulated cablesInsulated conductorsPolymer sciencePolyvinyl chloride

The invention discloses a cable sheath material for a coal mine, which is characterized by comprising the following raw materials for preparing effective constituents according to the parts by weight: 70-100 of butyronitrile-polyvinyl chloride compound, 10-30 of neoprene, 30-60 of white carbon black, 2-8 of magnesium oxide, 20-60 of aluminum hydroxide, 30-60 of chlorcosane, 2-6 of accelerant CZ, 3-8 of zinc oxide, 1-5 of stearic acid, 3-8 of age inhibitor, 4-15 of diantimony trioxide, 2-7 of titanium pigment and 3-9 of vulcanizing agent. The cable sheath material for the coal mine has better performance of stink resistance, cold resistance, flame resistance, oil resistance, ageing resistance, and the like and has good elasticity, high tensile strength, good tear resistance, good extrusion performance and low cost.

Owner:阳谷新太平洋电缆有限公司

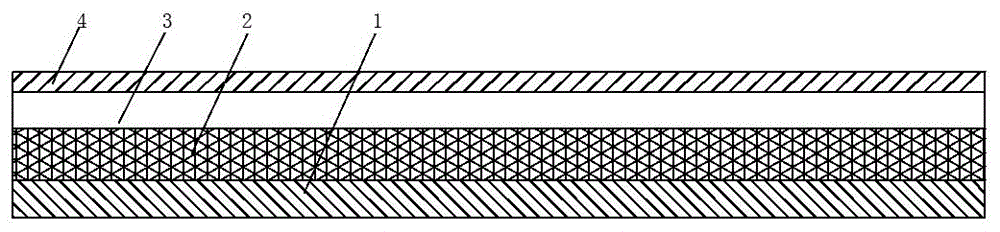

Inorganic high-pressure fireproof wear-resistant decorative plate and production method thereof

InactiveCN106379021AHigh tensile strengthWear-resistantDomestic upholsterySynthetic resin layered productsWear resistantDecomposition

The invention relates to a decoration sheet material, and concretely relate to an inorganic high-pressure fireproof wear-resistant decorative plate and a production method thereof. The decorative plate comprises a fireproof substrate, a buffer layer is arranged on the fireproof substrate, a decorative layer is arranged on the buffer layer, a wear-resistant protection layer is arranged on the decorative layer, the fireproof substrate is made by an inorganic non-combustible sheet material pressurized and impregnated by thermosetting alcohol-soluble phenolic resin; and the buffer layer is made by brown paper impregnated by thermosetting melamine resin adding a fire retardant and coated with alcohol-soluble phenolic resin on the back. The decorative plate has the advantages of water resistance, impact resistance, good size stability, high tensile strength and anti-folding intensity, pollution resistance on the surface, wear resistance, scratch resistance, no combustion encountered with fire, self extinguishing after away from the fire, good stability under high temperature, no decomposition of released asphyxiating toxic gasand smog, simple subsequent processing, sawing, no edge-breaking while boring, and no fragmentation.

Owner:HENAN YONGWEI SECURITY

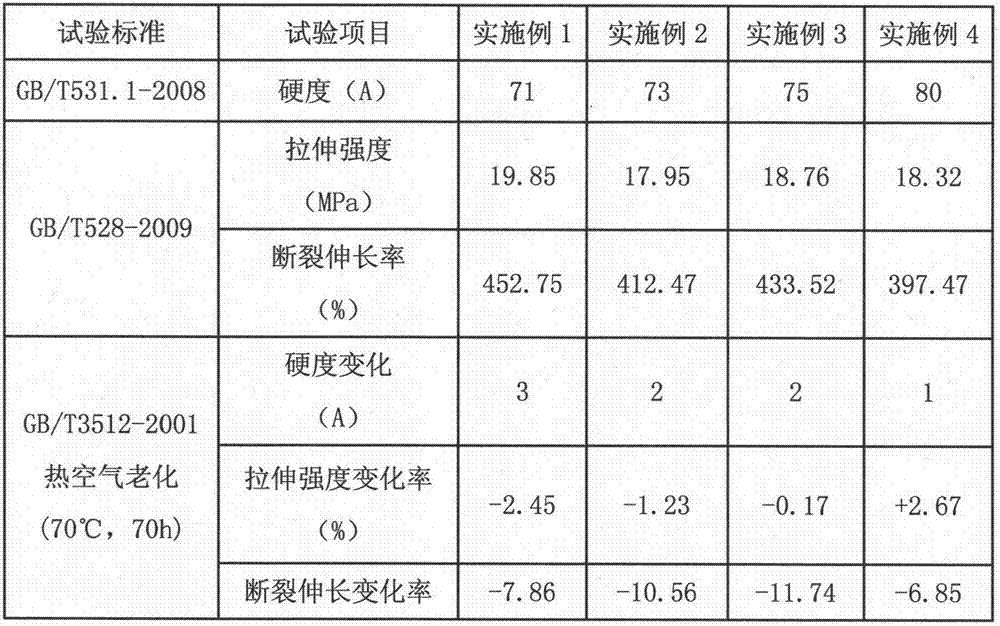

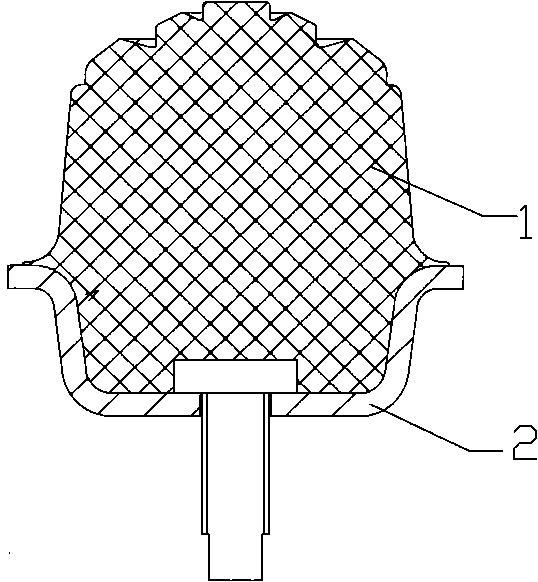

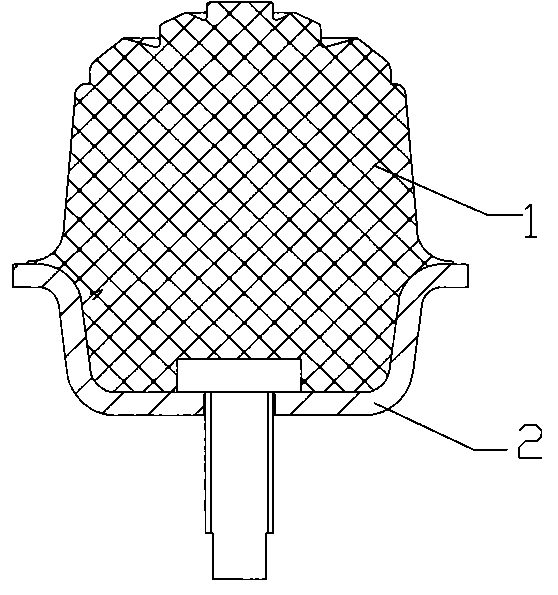

Buffer block rubber composition for automobile

The invention discloses a buffer block rubber composition for an automobile, which is characterized by being prepared by raw materials in parts by weight: 60-70 parts of nature rubber, 30-40 parts of butadiene rubber, 1.5-2.5 parts of p-phenylenediamine anti-aging agent, 1.5-2.5 parts of dihydro-quinoline anti-aging agent, 2-4 parts of physical anti-aging agent, 3-5 parts of dispersion homogenizing agent, 30-50 parts of reinforcing agent, 3-5 parts of plasticizer, 10-20 parts of zinc methacrylate, 1.5-2.5 parts of vulcanizing agent, 5-8 parts of active agent, 1-3 parts of stearic acid and 1.6-2.0 parts of accelerant. According to the buffer block rubber composition, the hardness of rubber is improved, and the rubber content of the rubber is effectively increased, so that the buffer block rubber composition is more excellent in elasticity, is not easily deformed and is very small in deformation.

Owner:SHANGHAI ZHONGLI AUTO PARTS

Transmission belt base rubber and preparation method thereof

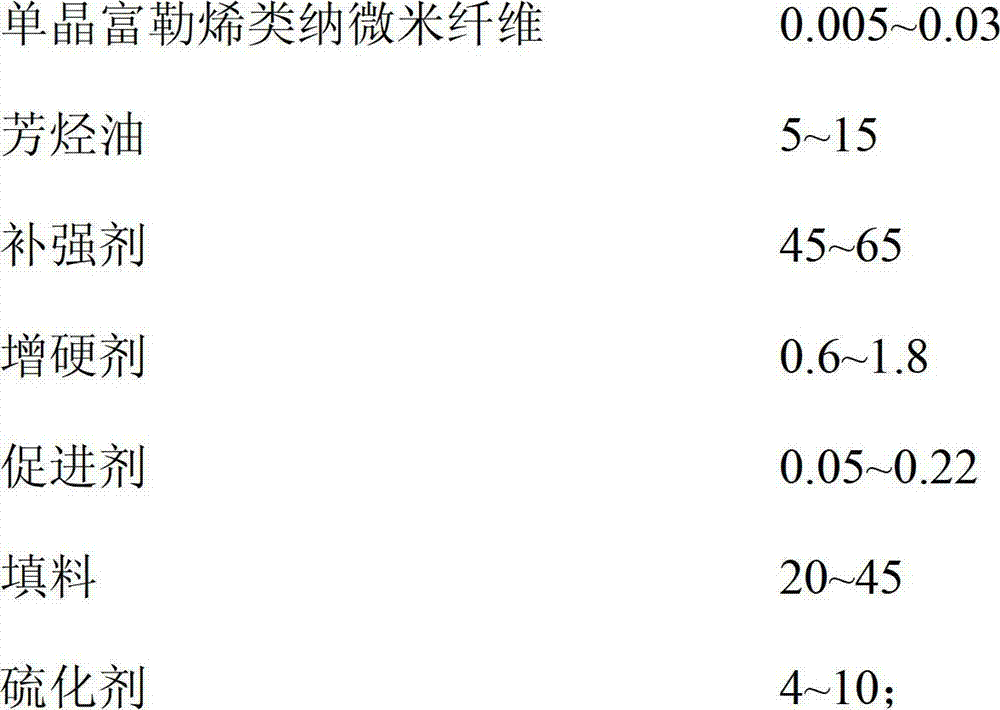

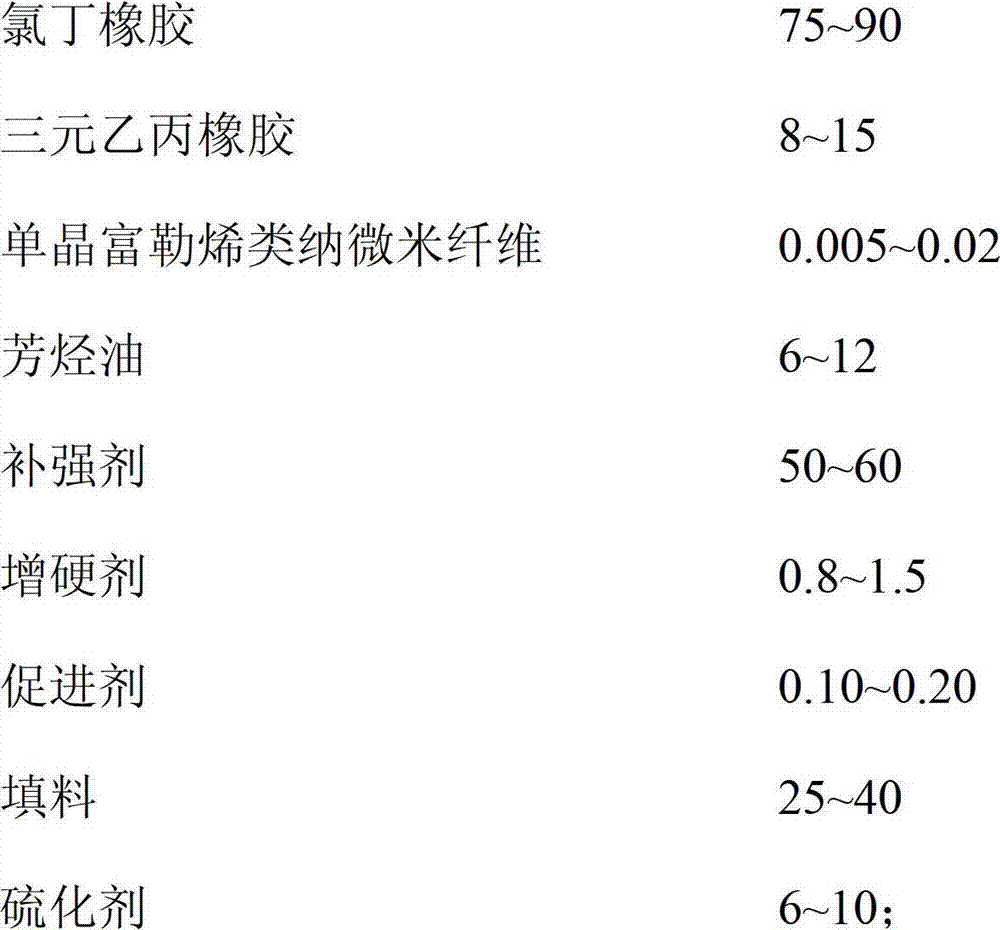

The invention relates to a transmission belt base rubber which comprises fullerene nano / micro fibers. The transmission belt base rubber comprises the following components in parts by mass: 70-100 parts of chloroprene rubber, 6-17 parts of ethylene propylene diene monomer rubber, 0.005-0.03 part of fullerene nano / micro fiber, 5-15 parts of aromatic oil, 45-65 parts of reinforcing agent, 0.6-1.8 parts of hardening agent, 0.05-0.22 part of accelerator, 20-45 parts of filler and 4-10 parts of vulcanizing agent. The invention also relates to a preparation method of the transmission belt base rubber. The chopped-fiber-reinforced CR (chloroprene rubber) is reinforced directionally by the transverse chopped fibers of the transmission belt, thereby achieving the excellent transverse side pressure and longitudinal flexibility of the transmission belt.

Owner:锐牛股份有限公司

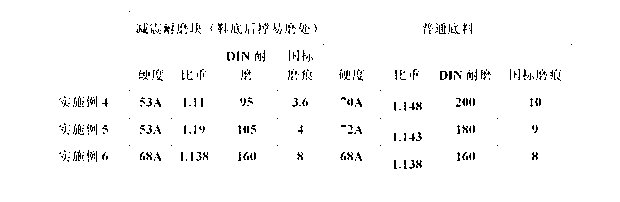

Double-hardness and double-physical-property rubber sole and preparation technology thereof

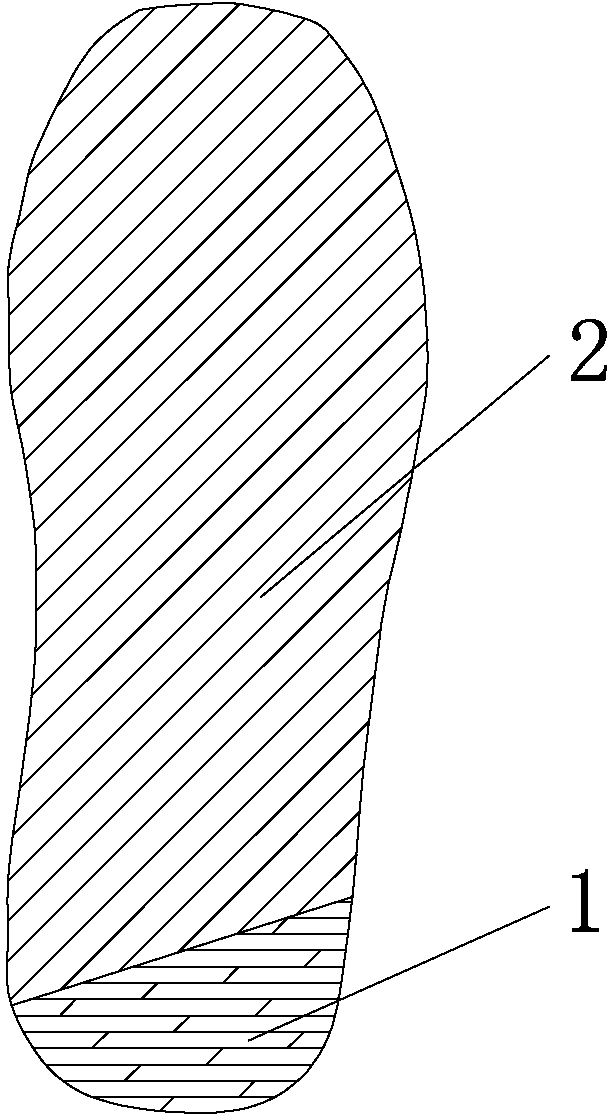

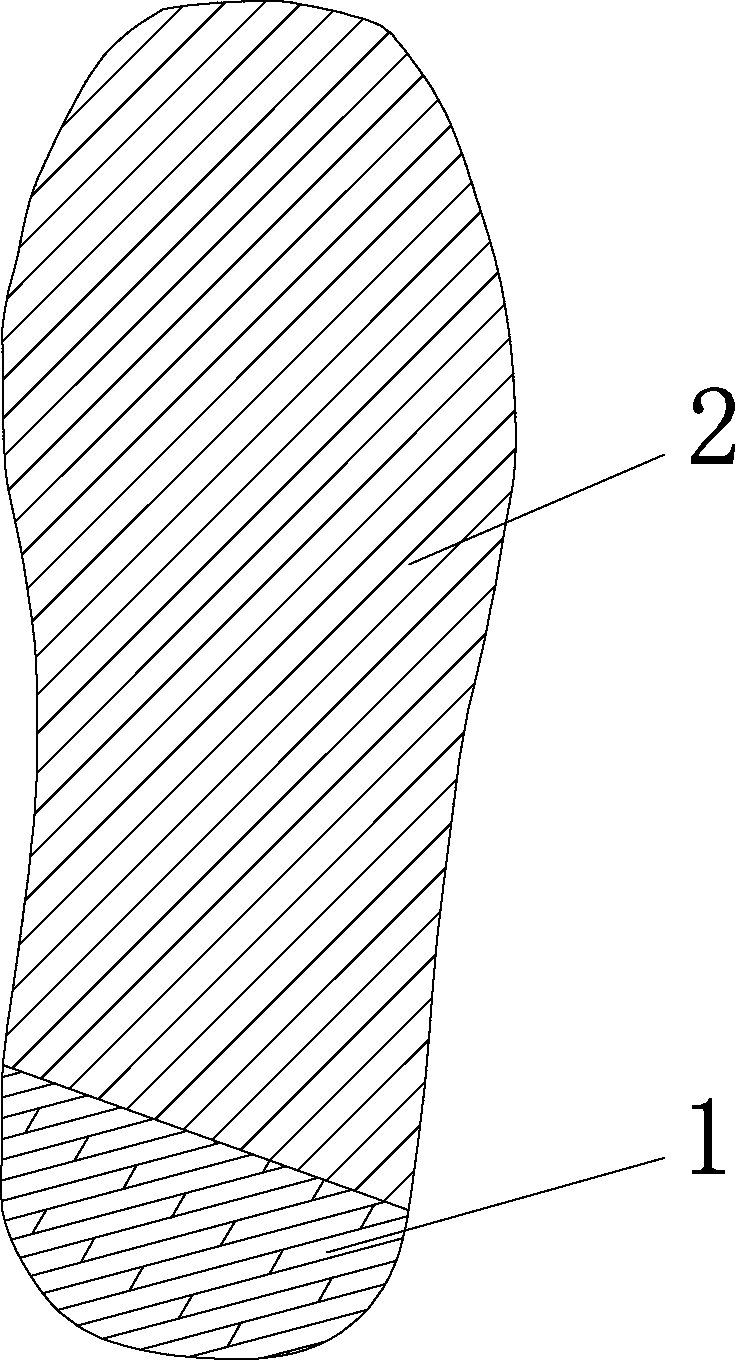

The invention provides wear-resistant rubber and a preparation method of the rubber, as well as a double-hardness and double-physical-property rubber sole and a preparation technology of the sole. The wear-resistant rubber can be obtained through the steps of: weighting required materials in proportion, then implementing closed milling, implementing opened milling, implementing vulcanization, and measuring a vulcanization curve. According to the double-hardness and double-physical-property rubber sole, a wearing-prone part of a heel is made from the wear-resistant rubber, while other parts are made from common rubber. The sole can be obtained through the steps of getting the wear-resistant rubber for later use, shaping a wear-resistant block by oil pressure, shaping a big sole, and post-treating. According to the sole produced by the formula and the production technology, the product cost is lowered and simultaneously the requirements of different people are met; and the produced finished product sole is improved in appearance grade and has the effects of good quality, comfort, wear resistance, shock absorbing, and the like.

Owner:DEZHOU XINHUARUN TECH CO LTD

High-hardness rubber composite for minitype automobile chassis buffer block

The invention relates to a high-hardness rubber composite for a minitype automobile chassis buffer block. The composite is characterized in that: the composite is prepared from the following raw materials in part by weight: 70 parts of natural rubber, 30 parts of synthetic rubber, 1.5 to 2.5 parts of p-phenylenediamine-kind age resister, 1.5 to 2.5 parts of dihyaroquinoline-kind age resister, 1 to 3 parts of physical age resister, 5 to 10 parts of plasticizer, 45 to 60 parts of reinforcing agent, 3 to 5 parts of dispersant, 10 to 15 parts of high styrene reinforced resin, 1.5 to 2.0 parts of vulcanizing agent, 5 to 8 parts of active agent, 1 to 2 parts of stearic acid, and 1.6 to 2.0 parts of accelerating agent. The high-hardness rubber composite for the minitype automobile chassis buffer block has the advantage of difficult deformation.

Owner:SHANGHAI ZHONGLI AUTO PARTS

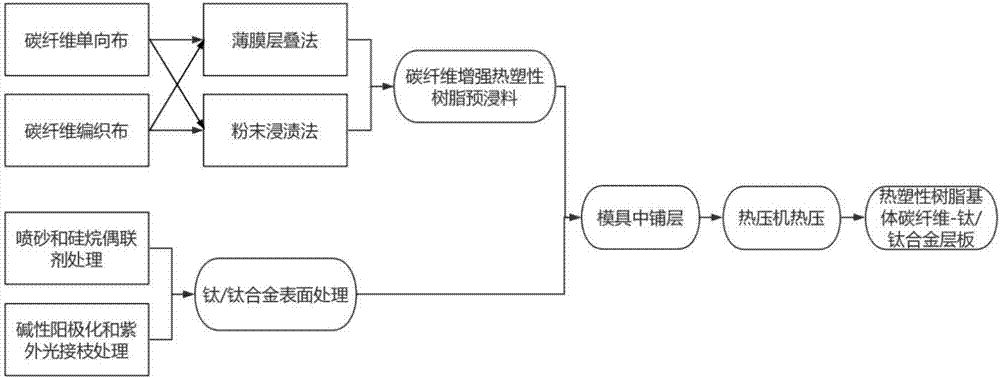

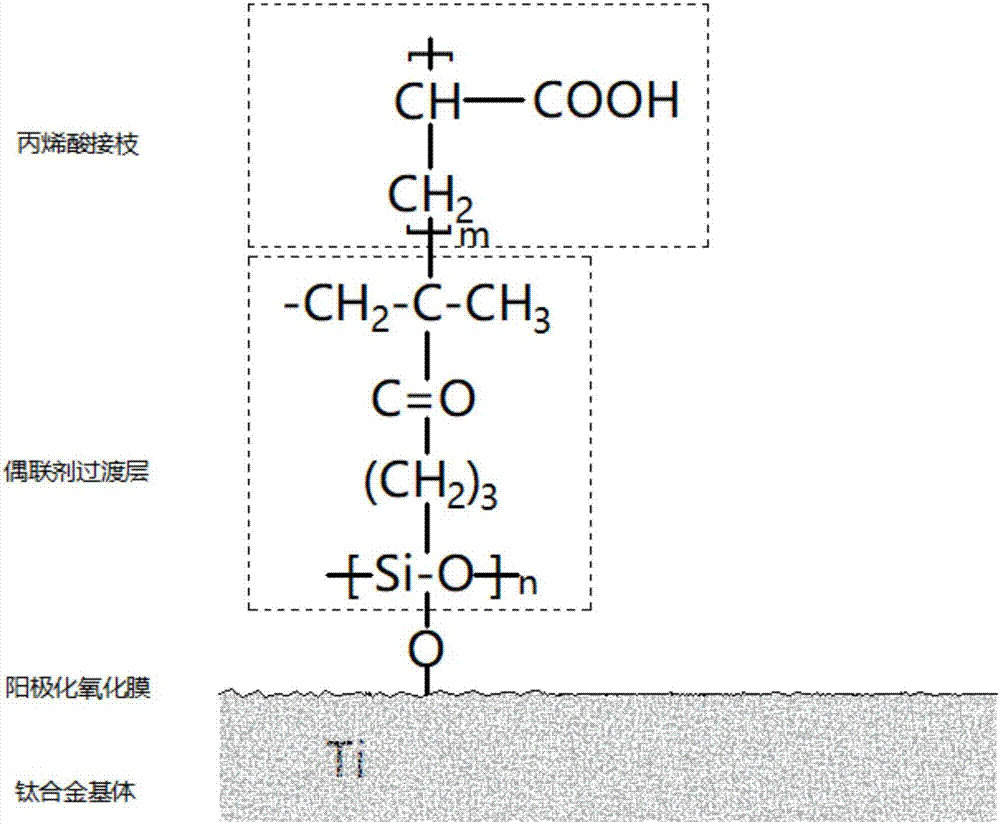

Preparing method of thermoplastic resin matrix carbon fiber-titanium/titanium alloy laminate plate

ActiveCN107283871AImprove impregnation effectHigh mechanical strengthCoatingsThermoplasticCarbon fibers

The invention discloses a preparing method of a thermoplastic resin matrix carbon fiber-titanium / titanium alloy laminate plate, and belongs to the field of light composite materials. The technical purpose is to solve the problem that currently the interface glue joint effect of titanium alloy of carbon fiber reinforcement titanium alloy laminate plate TiGr and a prepreg is poor. The thermoplastic resin comprises three kinds of high-performance thermoplastic resin including polyether-ether-ketone (PEEK), polyphenylene sulfide (PPS) and polyetherimid (PEI), with the coordination of a film laminating method and a powder impregnation method, the problem that the impregnation effect of the thermoplastic resin on carbon fiber is poor is solved.

Owner:HARBIN INST OF TECH

Composite insulating material for coal mine cable

InactiveCN105315562AGood heat resistanceGood water vapor resistanceRubber insulatorsPlastic/resin/waxes insulatorsWaxParaffin oils

The invention discloses a composite insulating material for a coal mine cable. The composite insulating material is characterized by being prepared from, by weight, 40-60 parts of EPDM rubber, 40-60 parts of polyolefin elastomer, 60-90 parts of calcined kaolin, 5-10 parts of zinc oxide, 1-3 parts of coupling agent A-172, 2-4 parts of paraffin, 3-10 parts of anti-aging agent, 6-12 parts of paraffin oil, 0.5-1 part of polyethylene wax, 0.5-1 part of stearic acid and 2-10 parts of vulcanizing agents. The composite insulating material for the coal mine cable has the advantages of being good in ozone aging resistant performance and thermal oxygen aging resistant performance, high in elasticity, small in permanent deformation, high in tensile strength, good in calendering performance, low in cost and the like.

Owner:山东太平洋橡缆股份有限公司

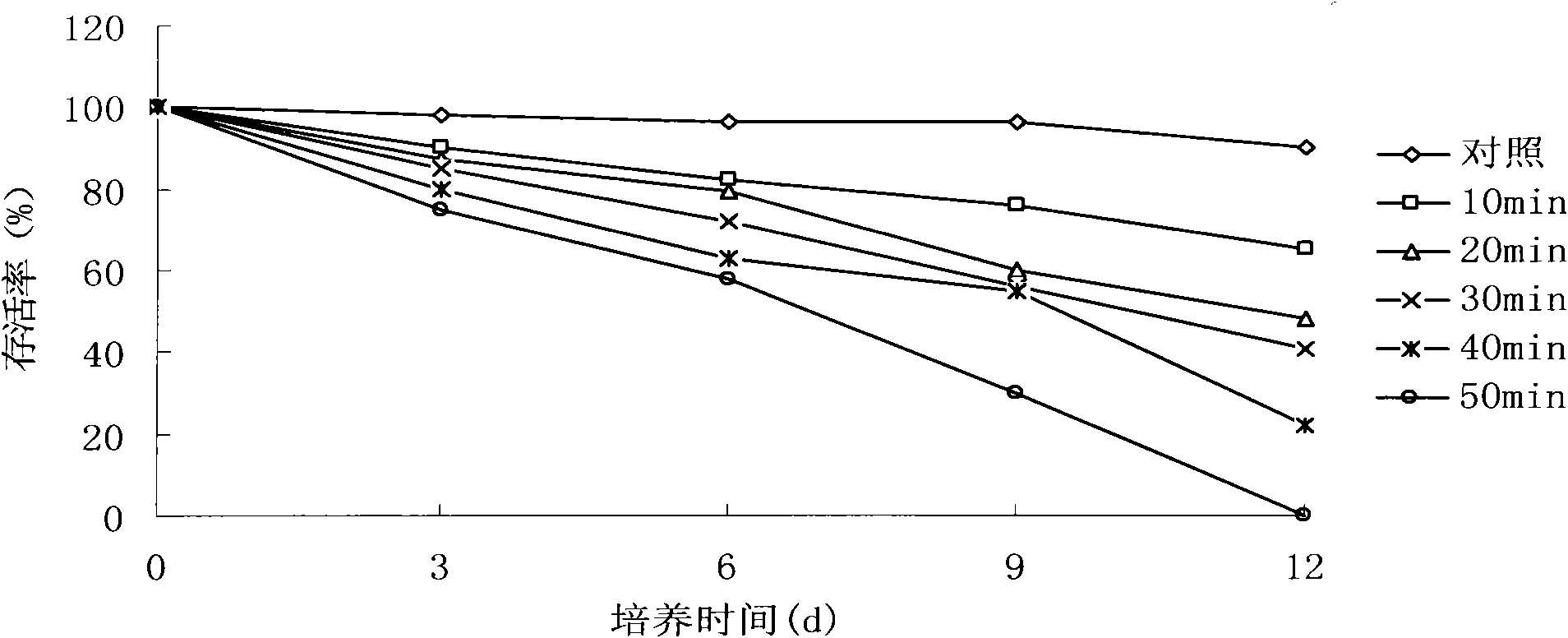

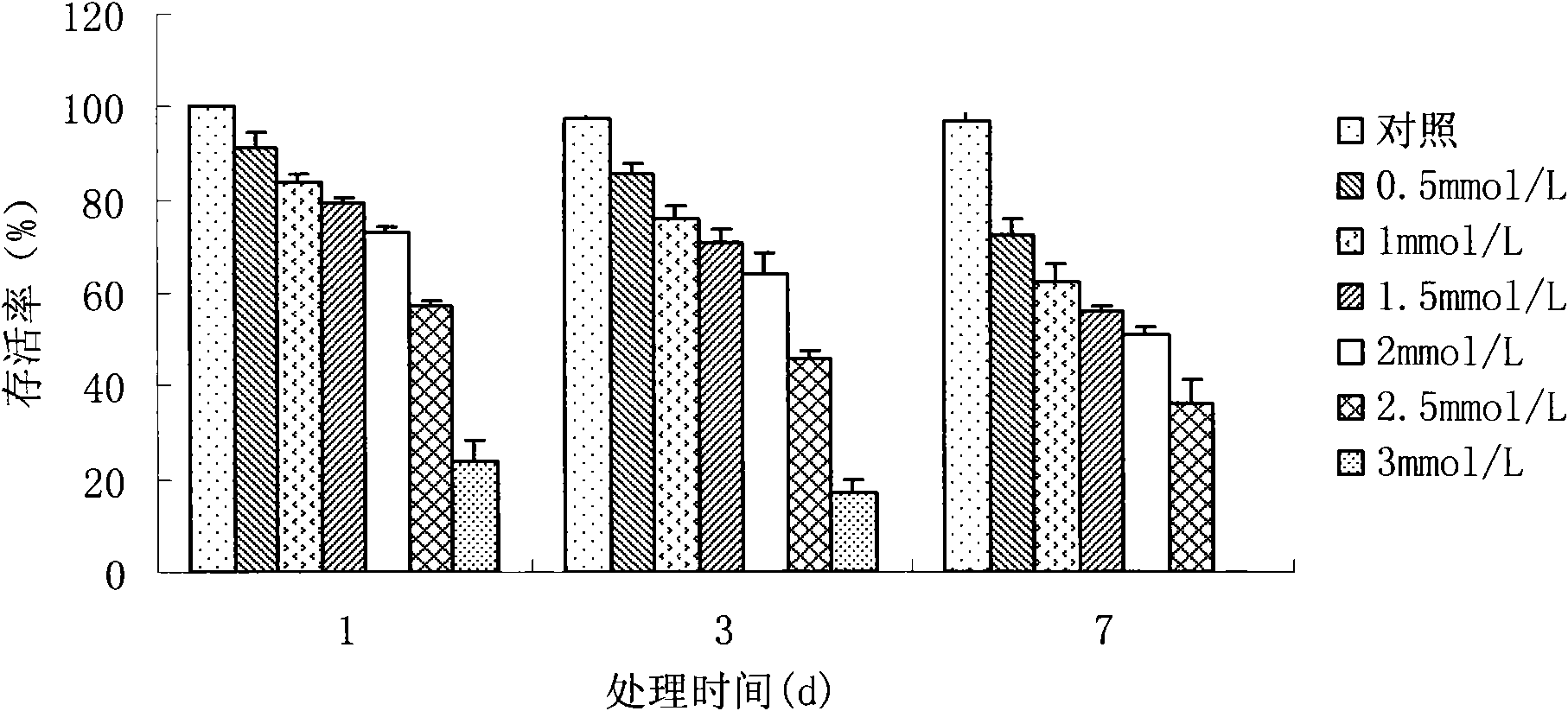

Method for mutagenesis breeding of high temperature resistant asparagus excellent variety series

InactiveCN101564004AImprove high temperature resistanceIncrease growth ratePlant genotype modificationWild typeResistant strain

The invention provides a method for mutagenesis breeding of a high temperature resistant asparagus excellent variety series, which can solve the problems that in the prior art a wild type asparagus has poor high temperature resistance, low growth rate and low gel content. The method for the mutagenesis breeding comprises the following steps: a, MNNG mutagenesis: soaking trichomes of the asparagus in an MNNG treating fluid to perform the mutagenesis; and b, HYP resistance series selection: putting the mutagenized trichomes of the asparagus into an f / 2 culture medium containing HYP to perform high-temperature cultivation, and screening out the required high temperature resistant strains. The asparagus variety obtained by the method not only is high temperature resistant, but also has high growth rate and higher gel content, thus the method provides a new variety series for cultivating the asparagus, and is significant for promoting the development of the agar manufacturing industry.

Owner:OCEAN UNIV OF CHINA

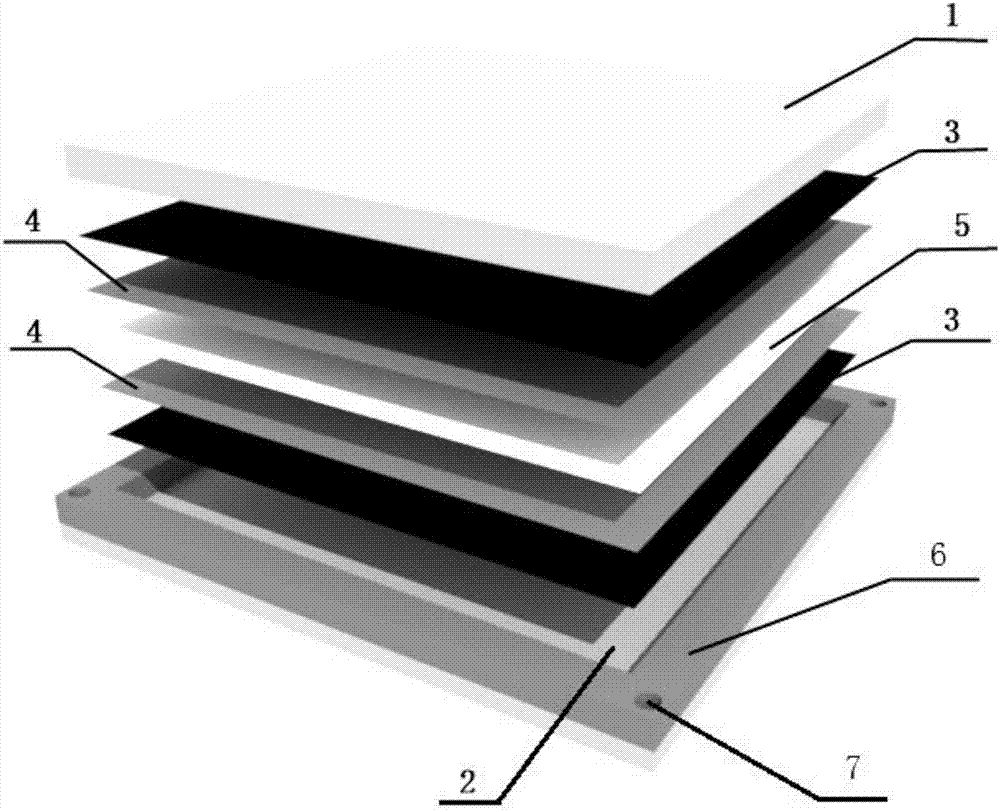

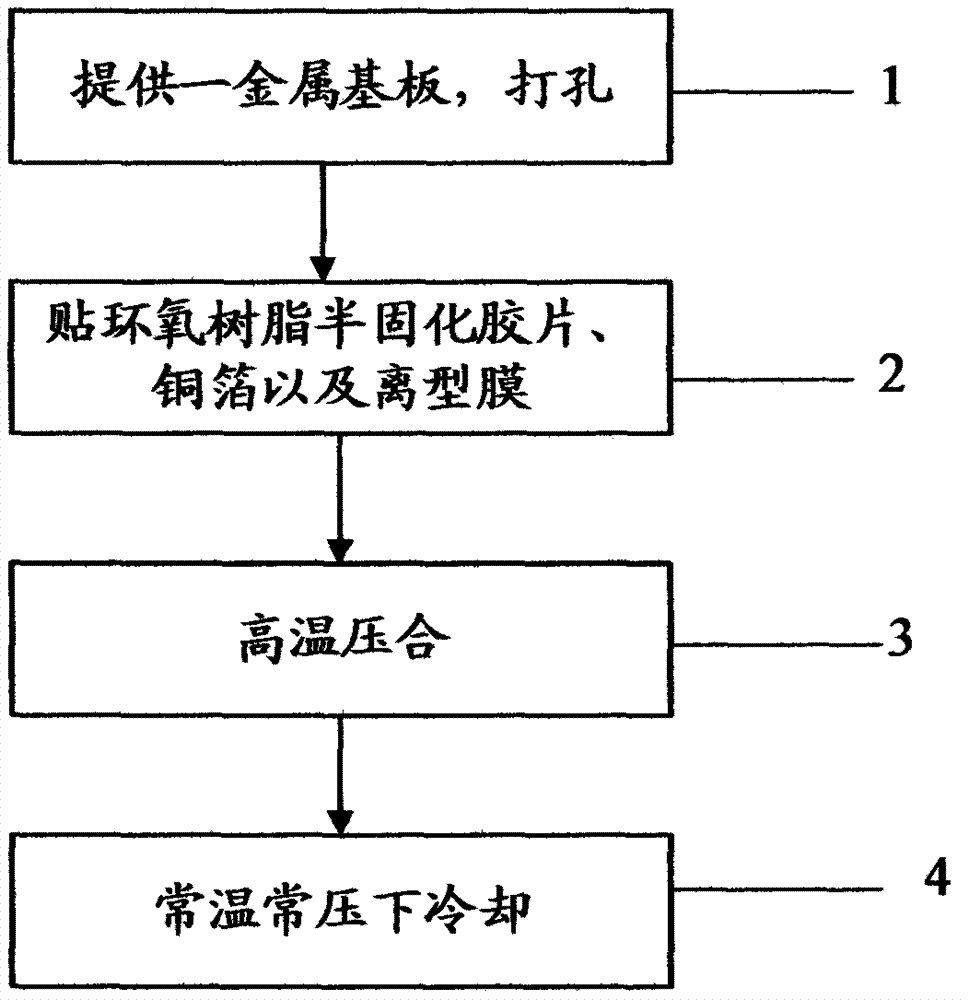

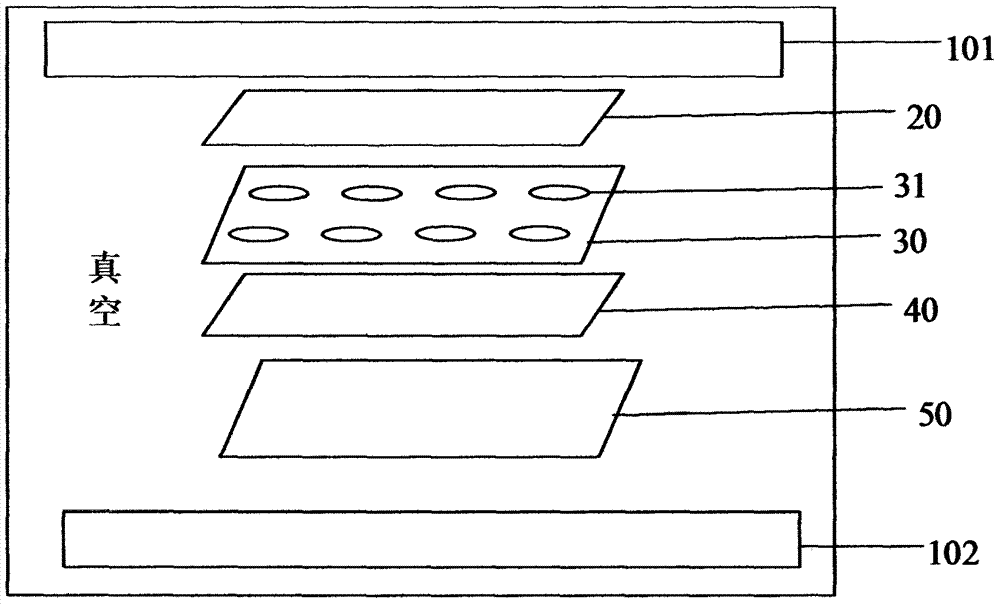

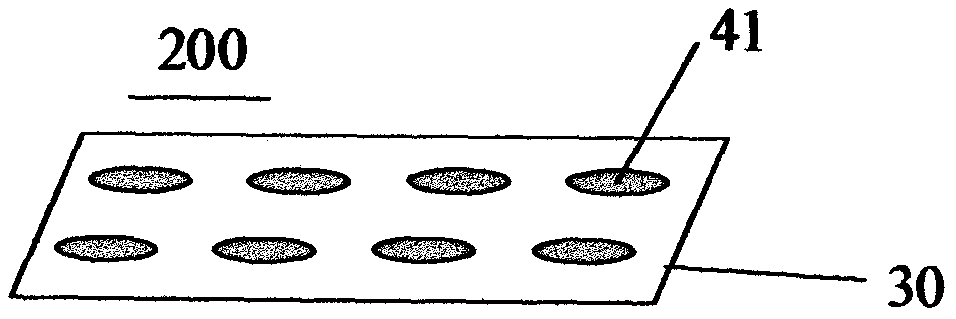

Light emitting diode (LED), printed circuit board (PCB), plug hole metal-based copper coating plate and fabrication method of plug hole metal-based copper coating plate

InactiveCN107072034AIncrease productivityIncrease the gel contentPrinted circuit aspectsElectrical connection printed elementsEpoxyCopper coating

The invention relates to a plug hole metal-based copper coating plate and a fabrication method thereof. The fabrication method of the plug hole metal-based copper coating plate comprises the steps of 1, providing a metal substrate, and punching the metal substrate; 2, pasting an epoxy resin semi-cured film, a copper foil and a release film; 3, performing high-temperature lamination; and 4, performing cooling under normal temperature and normal pressure to obtain the plug hole metal-based copper coating plate. A certain number of through holes are formed in the plug hole metal-based copper coating plate and the metal substrate thereof according to a certain layout, the through holes are filled with insulation voltage-resistant thermal conduction sheets, and the thicknesses of the insulation voltage-resistant thermal conduction sheets can approximate to the thickness of the metal substrate; due to high-temperature lamination formation in one time, the insulation voltage-resistant thermal conduction sheets and the metal substrate are firmly combined, the insulation voltage-resistant thermal conduction sheets have relatively large thicknesses, and an alternating current is prevented from being instantaneously broken down by high voltage; and the metal substrate also has favorable heat dissipation performance, thus, the plug hole metal-based copper coating plate is compatible with insulation performance and heat dissipation performance, and is particularly and suitably applied to an LED integrated circuit board.

Owner:广州市谷建杰电子有限公司

Method for preparing steel lining washing rollers

The invention provides a method for preparing steel lining washing rollers, which includes the following steps: firstly preparing a steel lining roller; then winding the steel lining roller with a carbon fiber layer, wherein during the winding process, frictioning is performed manually while winding to increase the content of carbon fiber; placing the steel lining roller wound with the carbon fiber layer in a curing box for heating and curing; performing the skim coating on the roller surface subjected to curing; finally preparing the finished steel lining composite carbon fiber washing roller. The finished steel lining composite carbon fiber washing roller prepared through adopting the method provided by the invention has the advantages of light weight, antifatigue, excellent rigidity, corrosion resistance and long service life.

Owner:JIANGSU YINGYOU TEXTILE MACHINERY

High-pressure glass fibre reinforced plastic pipe and producing technology thereof

ActiveCN1673595AGood physical and mechanical propertiesImprove anti-corrosion performanceRigid pipesTubular articlesWaxGlass fiber

The high pressure GRP pipe is prepared with the material including glass fiber yarn, epoxy resin and curing agent, and features that the epoxy resin is bisphenol A epoxy resin and the curing agent is modified imidazole or modified polyamine. The present invention also discloses the production process the GRP pipe. The high pressure GRP pipe has excellent mechanical and physical performance, high anticorrosive performance, excellent heat resistance, high pressure resistance up to 3.5-25 MPa, light weight, long service life, etc.

Owner:LIANYUNGANG ZHONGFU LIANZHONG COMPOSITES GRP

Formula of eccentric wear-resistant oil pipe and production process

InactiveCN101735572AGood physical and mechanical propertiesIncrease coefficient of frictionDrilling rodsDrilling casingsYarnGlass fiber

The invention provides a formula of an eccentric wear-resistant oil pipe and a production process. The preparation raw materials comprise glass fiber yarn, an epoxy resin, a curing agent, a flexibilizer and a flatting agent. The formula is characterized in that: the epoxy resin is a bisphenol A epoxy resin; the curing agent is acid anhydride or modified aromatic amine; the weight ratio of the bisphenol A epoxy resin to the acid anhydride is 100:80-100; the best weight ratio of the bisphenol A epoxy resin to the acid anhydride is 100:83; and the eccentric wear-resistant oil pipe has the advantages of good mechanical and physical performance, good corrosion resistance, high temperature resistance, long service life and good flow property of a medium, no scale, no wax deposition, difficult blockage and the like.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

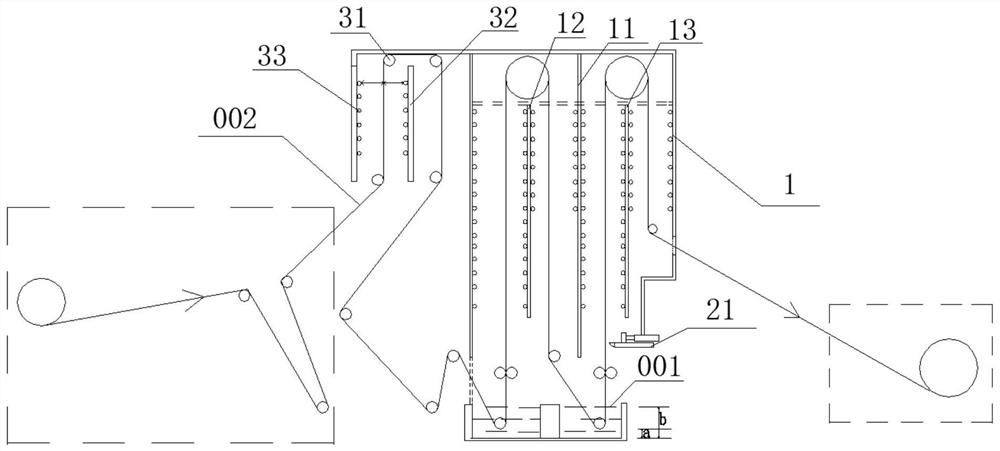

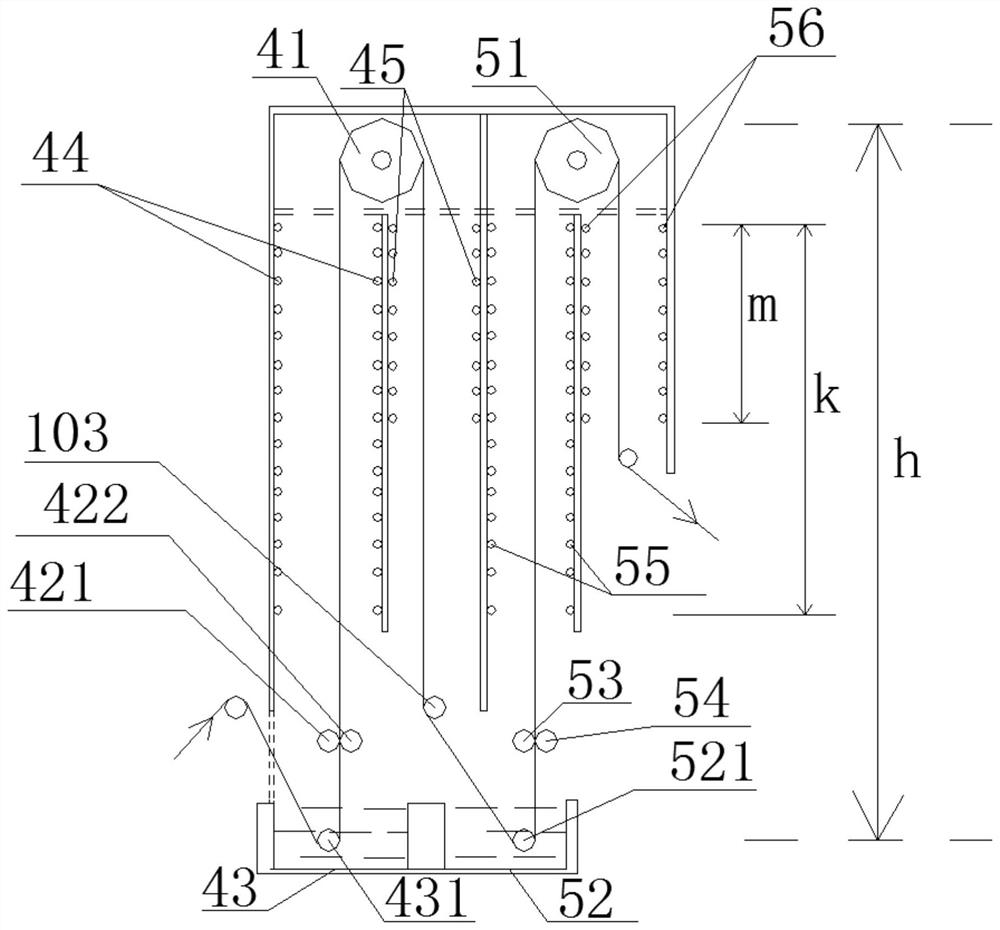

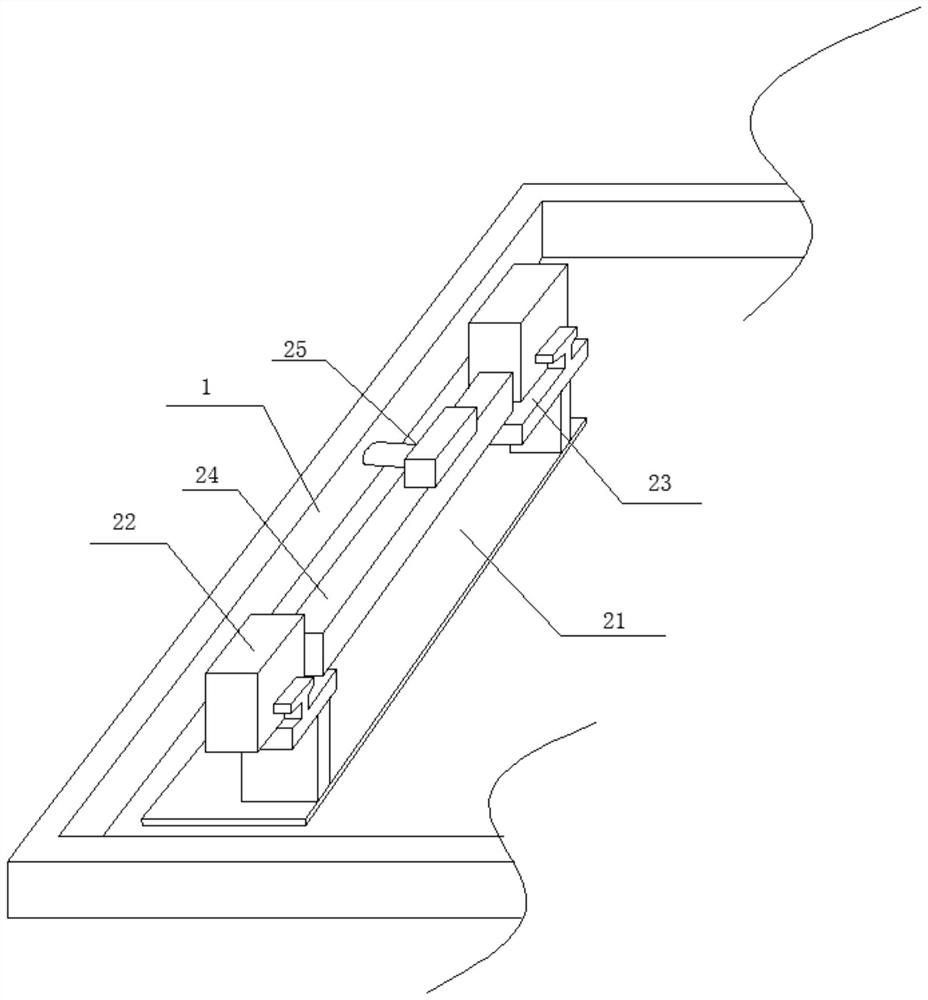

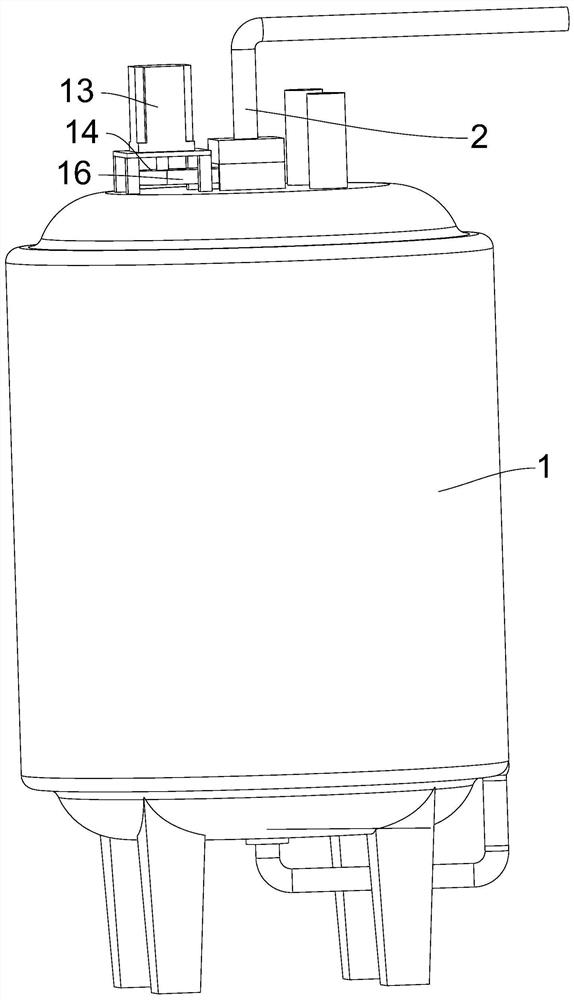

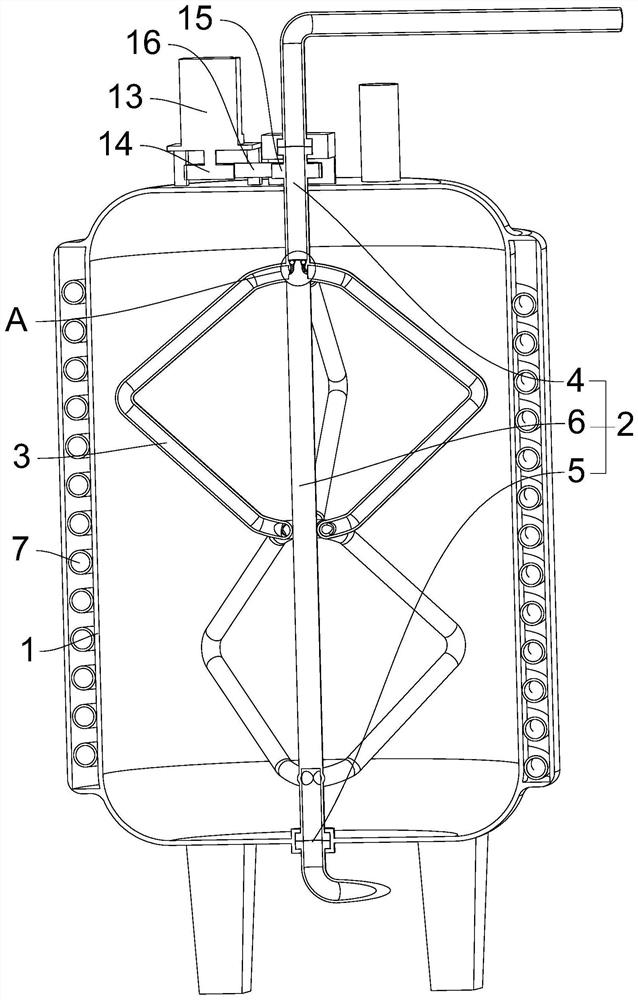

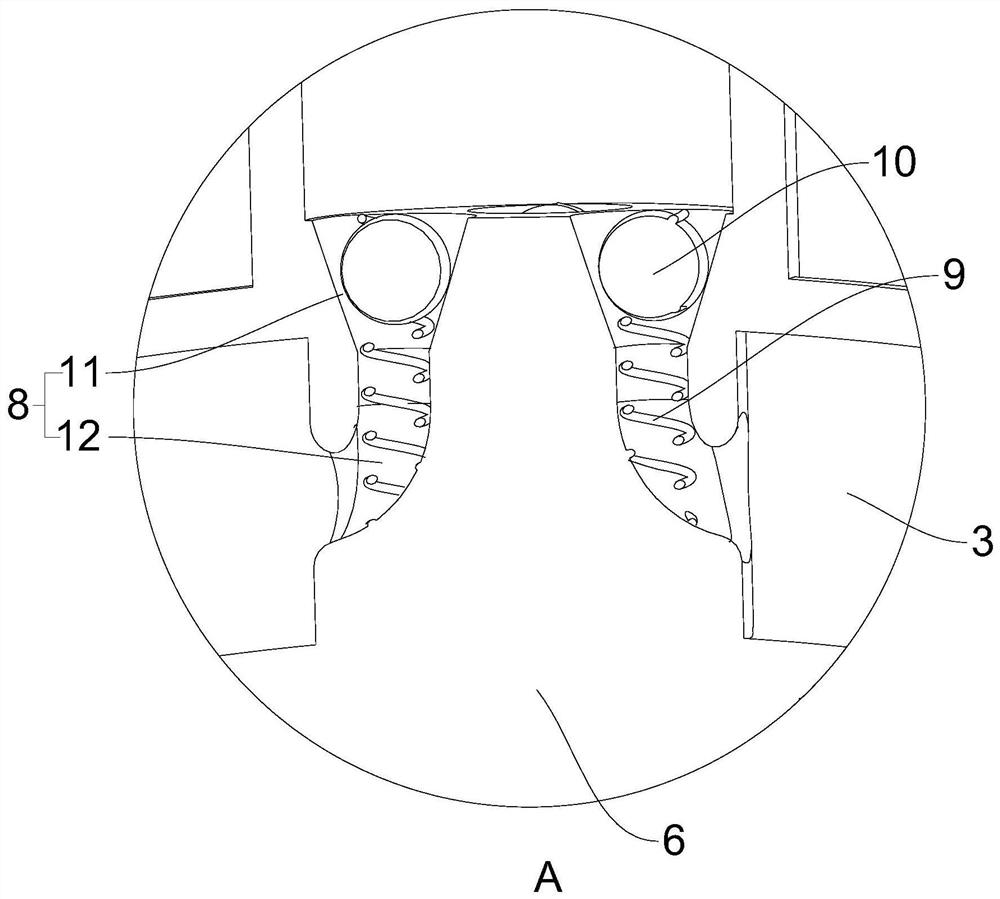

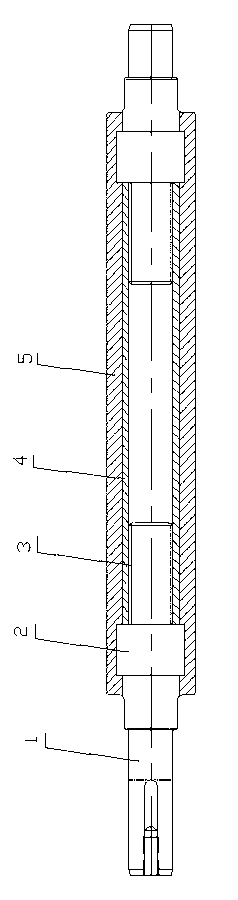

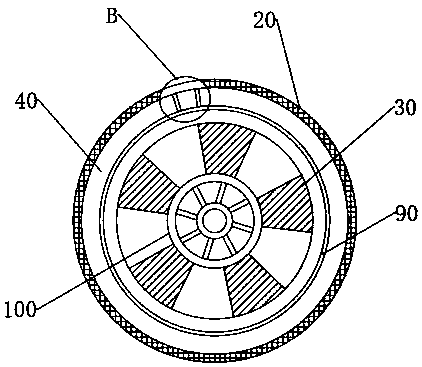

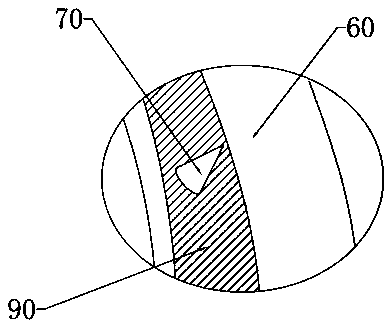

Vertical two-impregnation one-scraping polyester-mixed cotton cloth impregnator

PendingCN111790566AConvenient for advertisingImprove satisfactionLiquid surface applicatorsCoatingsPolyesterPolymer science

The invention discloses a vertical two-impregnation one-scraping polyester-mixed cotton cloth impregnator, belongs to the technical field of impregnation, and particularly relates to the vertical two-impregnation one-scraping polyester-mixed cotton cloth impregnator. The impregnator comprises a machine base, wherein a first impregnation mechanism used for impregnating polyester-mixed cotton cloth,a second impregnation mechanism used for adding rubber to the polyester-mixed cotton cloth and a rubber scraping mechanism used for scraping rubber cement on one side of the polyester-mixed cotton cloth are arranged on the machine base, the impregnator further comprises a traction mechanism used for conveying the polyester-mixed cotton cloth to the first impregnation mechanism and a winding device used for collecting the polyester-mixed cotton cloth discharged from the second impregnation mechanism, and the rubber scraping mechanism comprises a scraper fixed to the machine base through a moving device. The impregnator is simple in structure and high in practicability.

Owner:台州捷豹橡胶有限公司

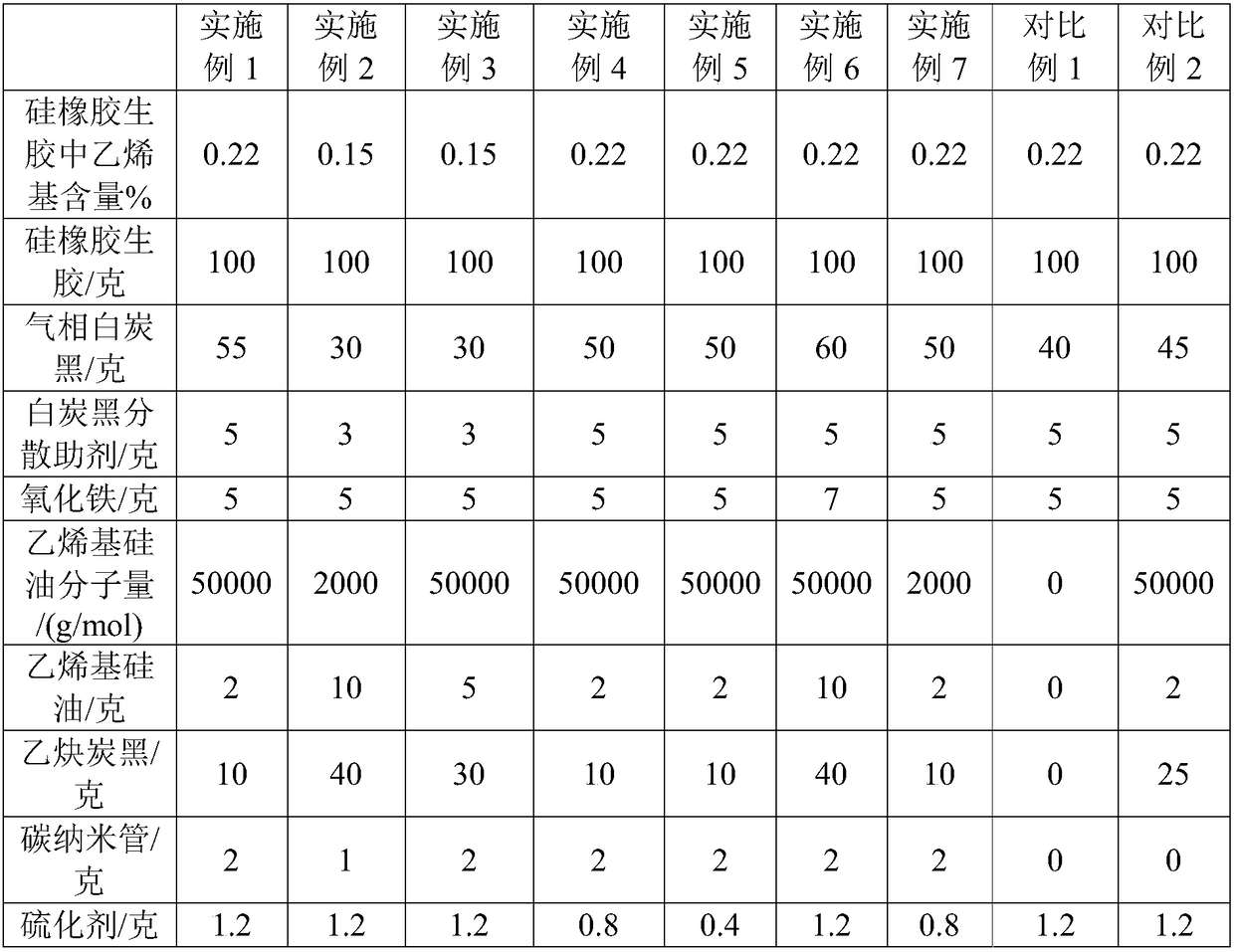

Solid silicon rubber and preparation method thereof

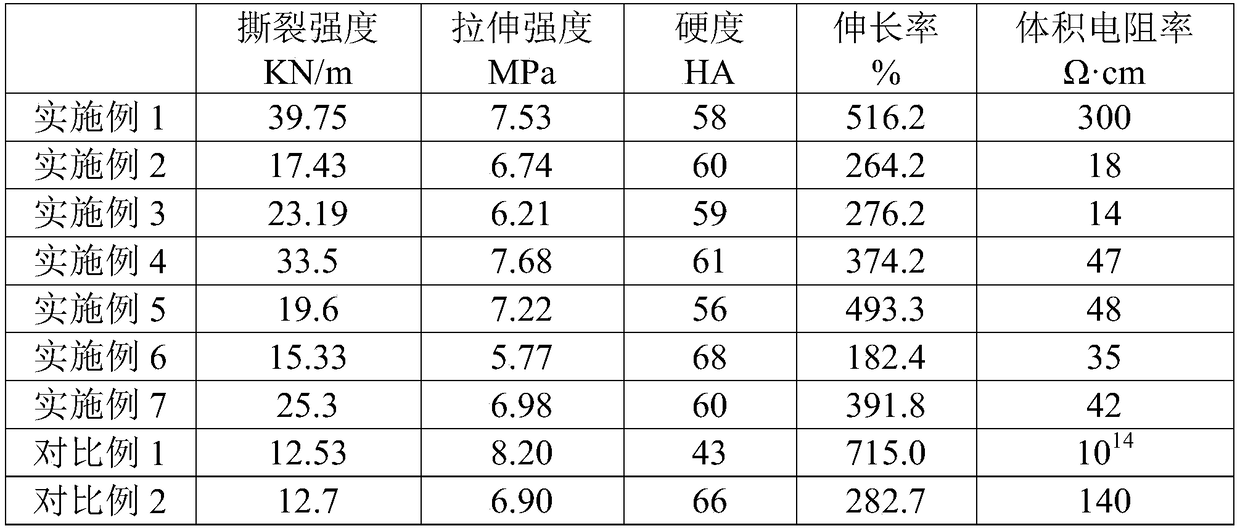

The invention provides solid silicon rubber and a preparation method thereof. The solid silicon rubber is prepared from the following components in parts by weight: 100 parts of raw silicon rubber, 30-60 parts of white carbon black, 2-10 parts of anti-tearing additive, 0.4-1.2 parts of vulcanizing agent, 1-2 parts of carbon nanotube, 10-40 parts of acetylene carbon black, 2-5 parts of white carbonblack dispersing additive and 2-7 parts of anti-thermooxidative-aging additive, wherein the anti-tearing additive is vinyl silicon oil. The solid silicon rubber and the preparation method provided bythe invention have the beneficial effects that due to addition of the vinyl silicon oil, the anti-tearing property of the solid silicon rubber can be well improved; meanwhile, by reuse of the carbonnanotubes and the acetylene carbon black, the volume resistivity of the solid silicon rubber can be greatly reduced, i.e., the conductivity of the solid silicon rubber can be improved; in addition, the solid silicon rubber prepared according to the proportion can meet the requirements of the solid silicon rubber for cable accessories in multiple respects of mechanical strength, anti-tearing strength and conductivity and the like in the power industry simultaneously.

Owner:ENN GRAPHENE TECH CO LTD

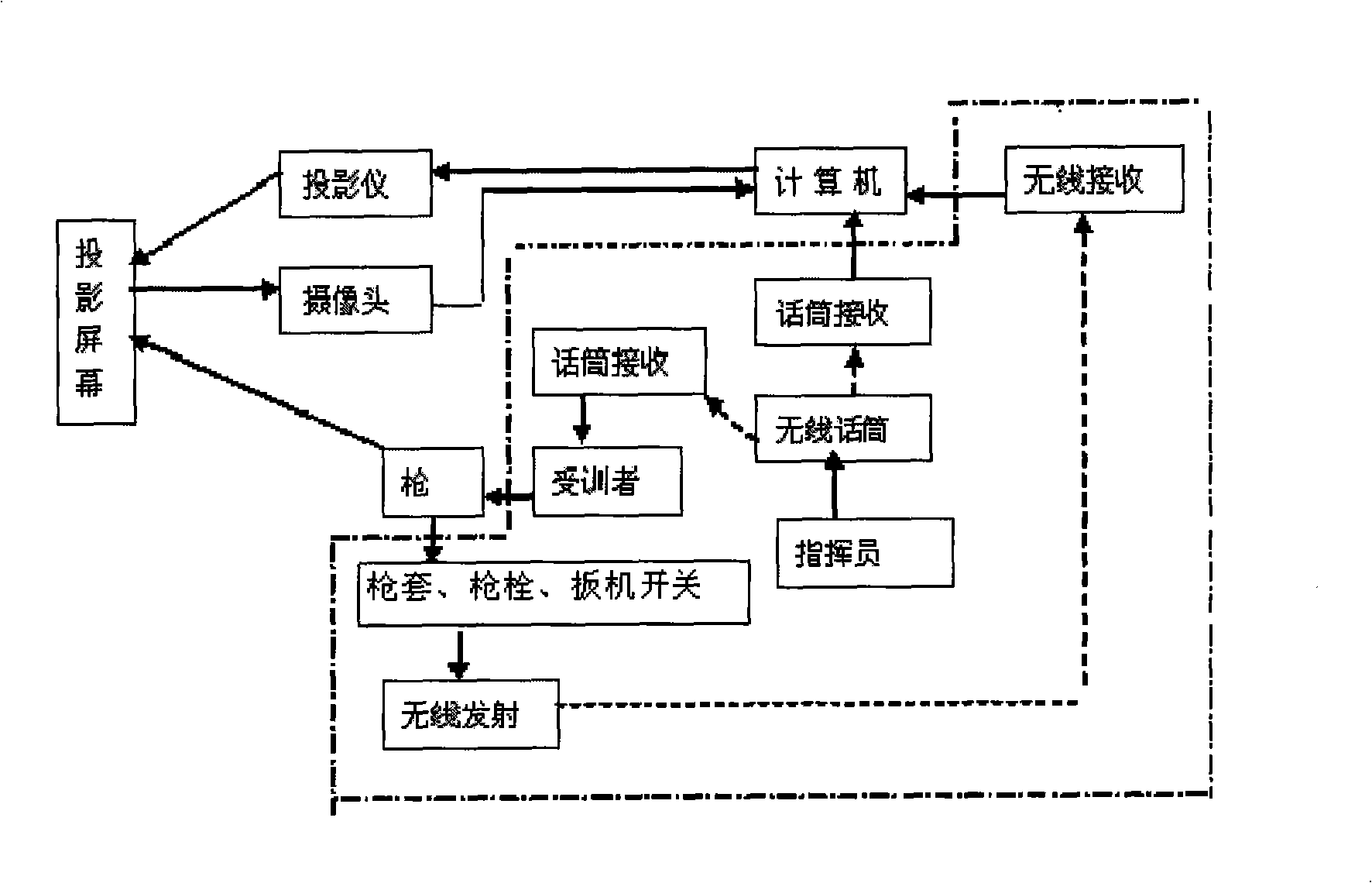

System and method for testing shooting speed for training

The invention discloses a shooting speed test system and a test method used for training. A wireless signal projector is arranged on a gun used for shooting and signal switches are respectively connected onto a holster, a gun bolt and a trigger; the signals are received by a wireless signal receiver connected with a computer; the command signal from the conductor is simultaneously sent to the computer and the trainees; as the command is sent by the conductor, the time from drawing gun, feeding, opening safety, pulling trigger to shooting the object are all recorded so as to overcome the defects of the existing system that only the complete time of the shooting can be recorded and the intermediate processes can not be accurately recorded. The invention can accurately measure the shooting speed of the trainees by recording the time of each action during the shooting process so as to help the trainees enhance the actual-combat adaptability and fully enhance the shooting level. The invention can be applied to the training sites with live shooting or laser simulated shooting.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Cable sheath material for coal mine

ActiveCN101538380BImprove stabilityEasy to useInsulated cablesInsulated conductorsPolyvinyl chlorideStearic acid

The invention discloses a cable sheath material for a coal mine, which is characterized by comprising the following raw materials for preparing effective constituents according to the parts by weight: 70-100 of butyronitrile-polyvinyl chloride compound, 10-30 of neoprene, 30-60 of white carbon black, 2-8 of magnesium oxide, 20-60 of aluminum hydroxide, 30-60 of chlorcosane, 2-6 of accelerant CZ, 3-8 of zinc oxide, 1-5 of stearic acid, 3-8 of age inhibitor, 4-15 of diantimony trioxide, 2-7 of titanium pigment and 3-9 of vulcanizing agent. The cable sheath material for the coal mine has better performance of stink resistance, cold resistance, flame resistance, oil resistance, ageing resistance, and the like and has good elasticity, high tensile strength, good tear resistance, good extrusionperformance and low cost.

Owner:阳谷新太平洋电缆有限公司

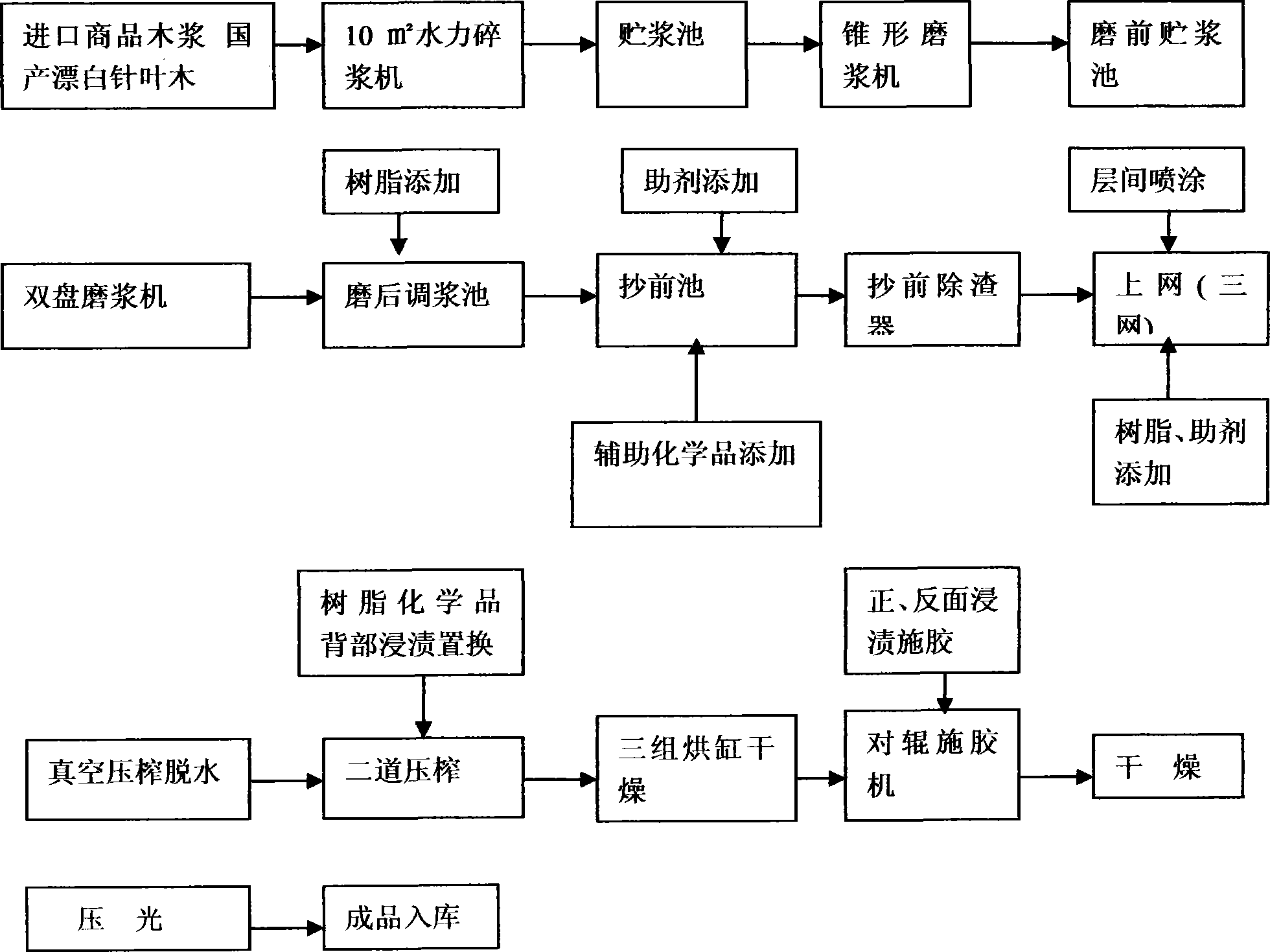

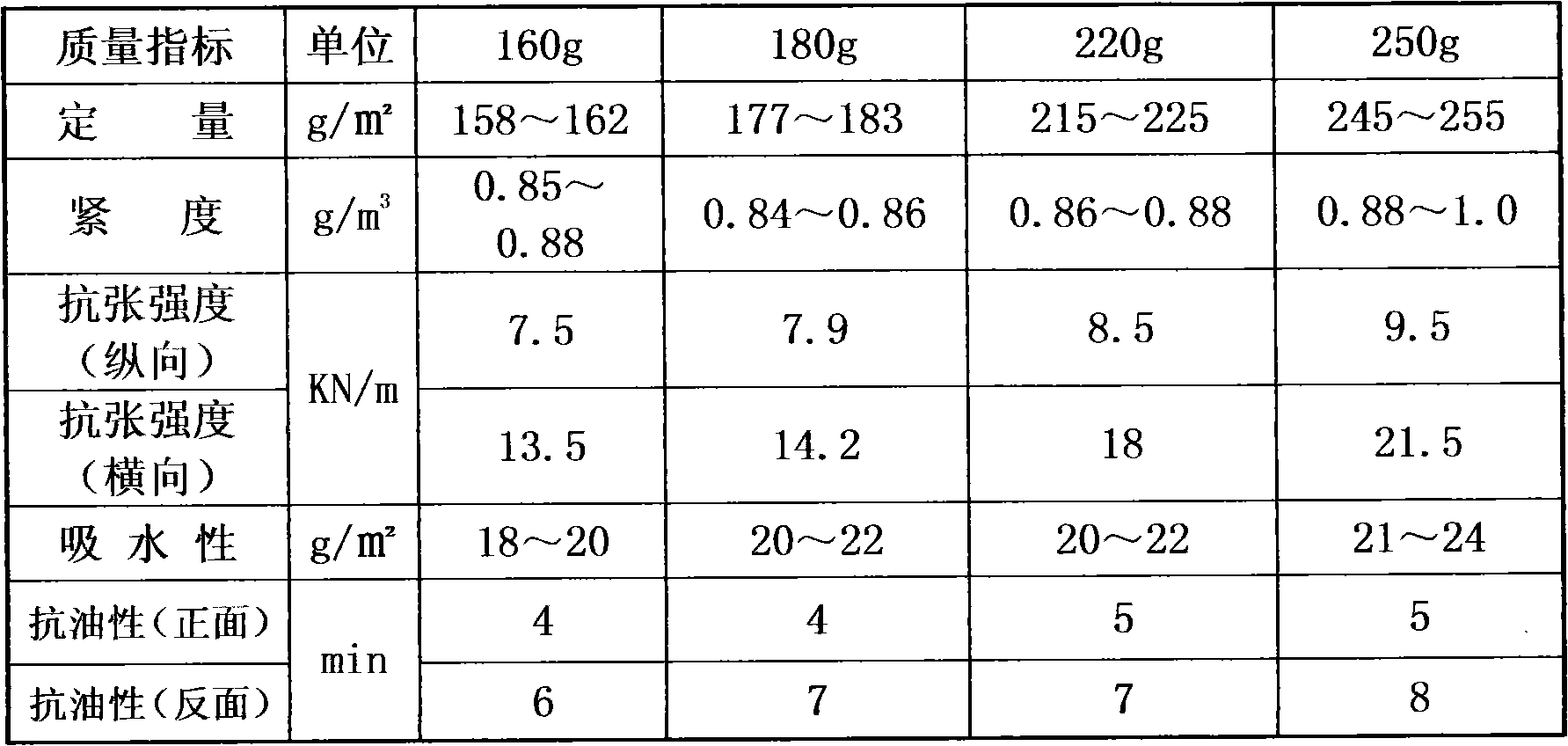

Strong abrasive belt base paper and preparation method

InactiveCN102441851BHigh peel strengthImprove matrix strengthNon-fibrous pulp additionSpecial paperProcess engineeringWet strength

The invention provides strong abrasive belt base paper and a preparation method. The strong abrasive belt base paper is high in strength and fine in flexibility and impermeability and is not layered. The preparation method for the base paper includes steps that 1, wood pulp is disintegrated, 2, the pulp is proportioned, materials are blended, and a pH (potential of hydrogen) value in blended materials is controlled to range from 6.5 to 7.0, 3, interlayer spraying of the paper on a screen is carried out, 4, a back is prestressed, replaced and dried, and 5, front and back impregnation, glue application and drying are carried out. Multiple times of glue application are realized in a paper making process, glue content in the paper is increased, the strength of a product is improved, and the product is not layered and is fine in flexibility and impermeability. The heavy base paper is high in interlayer peeling strength, dry and wet strengths of the heavy base paper meet indexes of like imported products, oil impermeability of the heavy base paper can completely meet the strong abrasive belt production requirement of the industry of coated abrasive tools, and performances, such as the strength, the flexibility and the like, of a base of a produced abrasive belt product are improved obviously.

Owner:湖北圣立纸业科技有限公司

Batching method and batching device for self-adhesive waterproof coiled material

PendingCN112898788AReduce process control pointsSimple processBuilding insulationsChemistryProcess engineering

The invention relates to the technical field of waterproof coiled material production, and discloses a self-adhesion waterproof coiled material batching method and a batching device.The self-adhesion waterproof coiled material batching method comprises the following steps: adding 30-35 parts of 90 # asphalt and 20-25 parts of 200 # asphalt into the batching device; adding 2 to 10 parts of SBS (styrene butadiene styrene) 1301 and 2 to 6 parts of granular SBR; raising the temperature to 155 to 165 DEG C, and dissolving the components for 0.5 to 1.5 hours; uniformly stirring and mixing the mixture for 0.5 to 1.5 hours, and grinding the mixture once, so as to obtain rubber master batch; and adding 1-3 parts of petroleum resin and 28-35 parts of talcum powder, stirring the components at 165 DEG C for 1 hour, and discharging a final product. The modifier SBR used in the batching method provided by the invention is granular, the granular SBR has no many limitations on temperature and blanking speed, and the granular SBR can be directly used for feeding, so that the batching method has the following advantages: a, the whole temperature rise process can be omitted, and thus a plurality of process control points are omitted; b, caking is avoided; c, mesh screening and oil immersion pretreatment are not needed, so that the feeding procedure can be simplified; therefore, by using the granular SBR, the overall feeding speed can be increased, and the production efficiency can be improved.

Owner:湖北卓宝科技有限公司

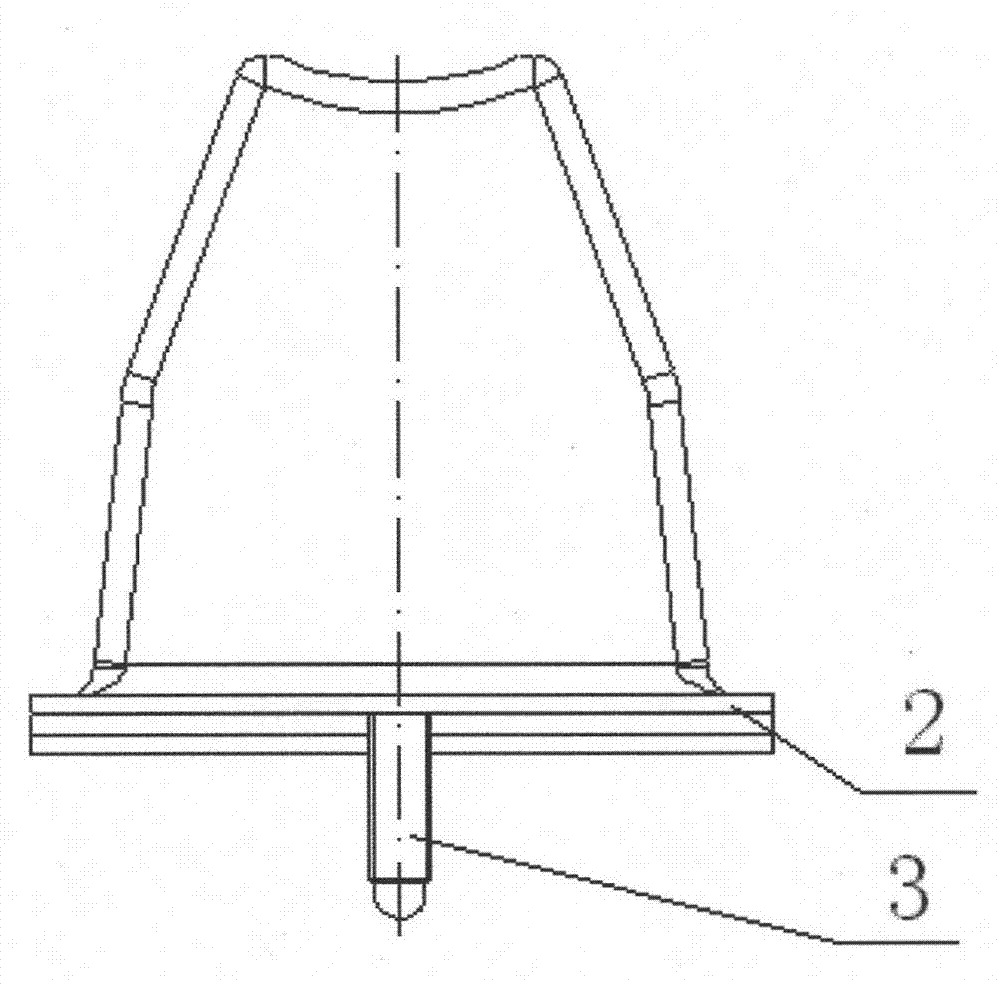

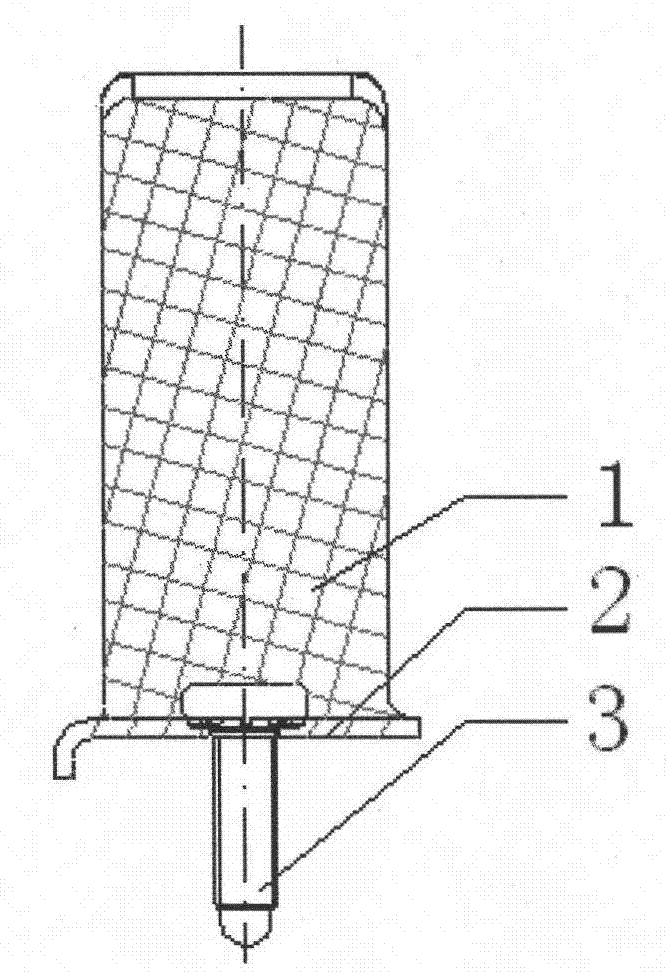

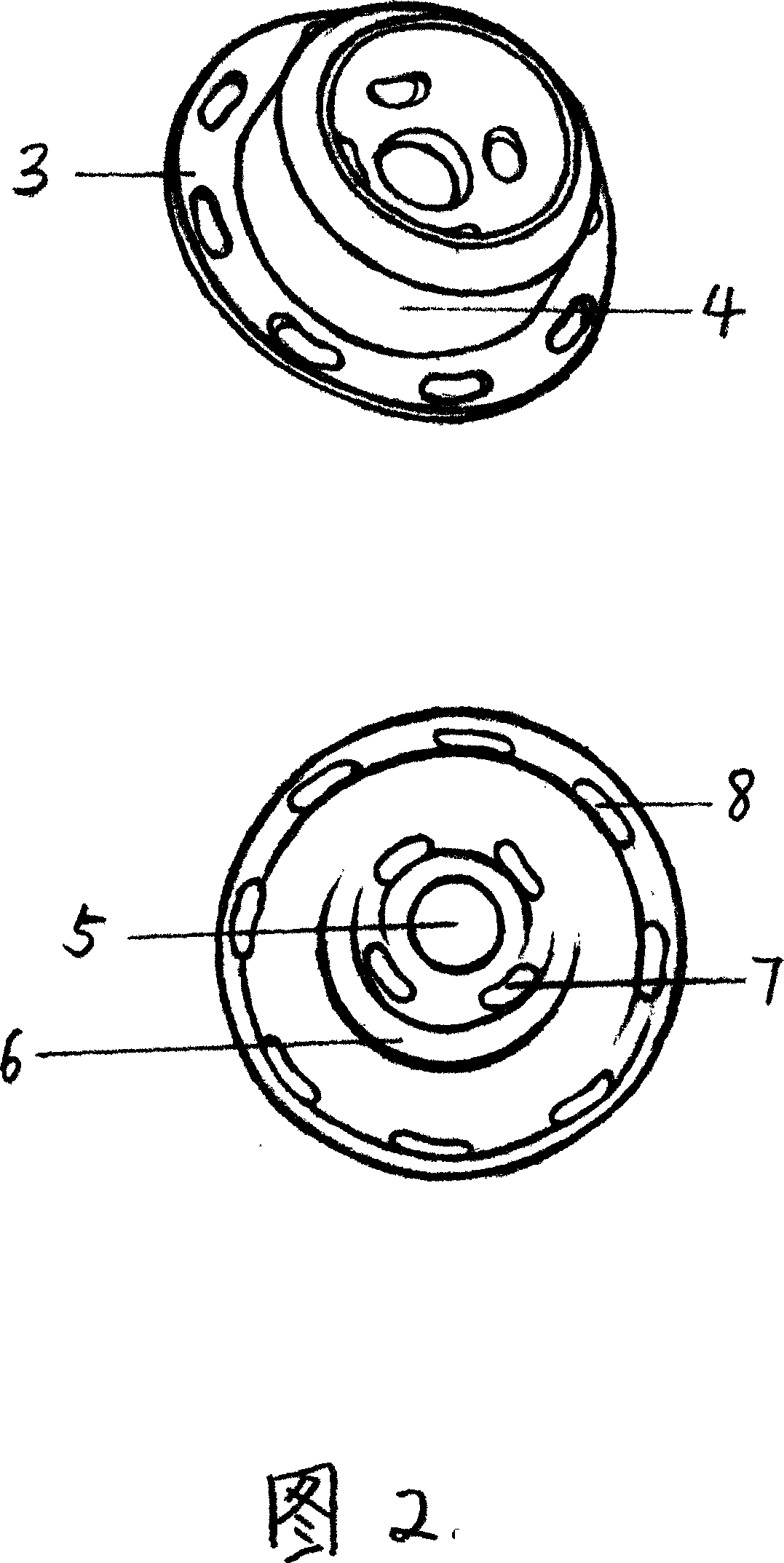

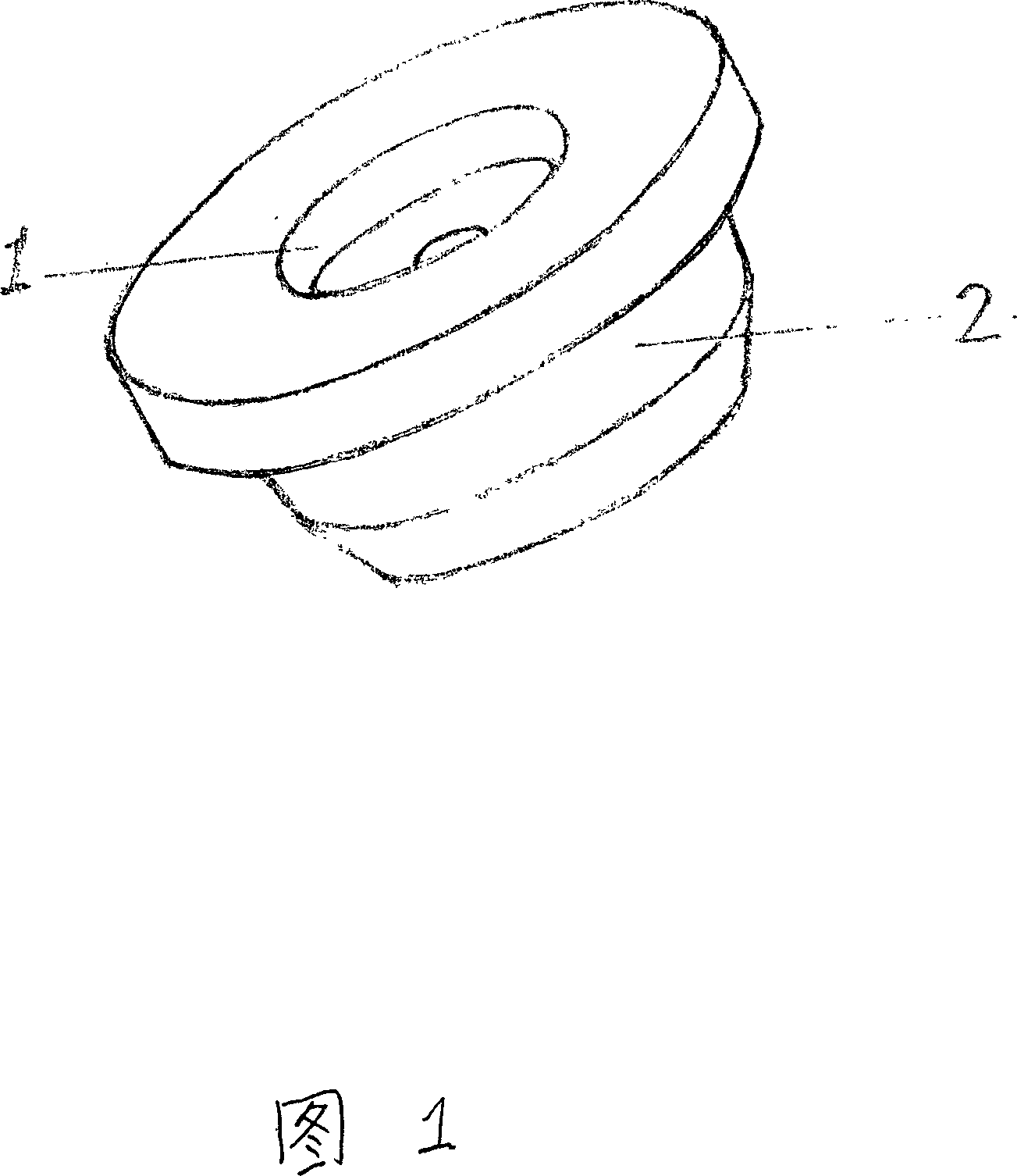

Medicinal butyl rubber stopper with plastic skeleton and its production

InactiveCN1981731AIncrease the gel contentHigh hardnessClosuresClosure using stoppersHardnessEngineering

A butyl rubber plug with plastic skeleton for medicine features that its plastic skeleton has a central through hole and two rings of holes for fixing the sulfurized butyl rubber on its surface. Its preparing process includes such steps as injection molding to obtain a plastic skeleton, pre-treating the plastic skeleton, putting it in lower die, covering it with the unsulfurized butyl rubber flakes, closing die set, heating to 150-165 deg.C while pressurizing to 7-12 MPa, sulfurizing for 10-15 min, cooling, demoulding, and removing excessive edge.

Owner:余东方

Fuzzing roller rolled by carbon fiber composite material in two-step method

The invention discloses a fuzzing roller rolled by a carbon fiber composite material in a two-step method. The fuzzing roller comprises a roller body of the fuzzing roller and shaft heads, wherein the shaft heads are arranged at the two ends of the roller body. A preparation method for the fuzzing roller comprises the following steps of: firstly, winding a carbon fiber preimpregnated cloth on a designed mould core rod to make a carbon fiber inner lining tube for later use; coating an adhesive in adhesion sections of the shaft heads; inserting the adhesion sections into the carbon fiber inner lining tube for adhering; and finally winding the carbon fiber preimpregnated cloth again by using the carbon fiber inner lining tube as a core rod and covering reinforcing shaft shoulders of the shaft heads into the carbon fiber inner lining tube at the same time to perform the steps of curing coarse processing, refine processing and coating to finally prepare the fuzzing roller serving as a finished product. The fuzzing roller is light in weight, and good in linearity degree, fatigue resistance and rigidity, so that the binding of the carbon fibers and resin is high, and the compactness is high; and because the binding strength of the fuzzing roller is greatly higher than that manufactured in a one-step method, and the service life of the fuzzing roller is prolonged. The carbon fiber composite material and the metal shaft heads are adhered by coating for twice, so that a contact surface of a carbon fiber tubular wall and the metal shaft heads is enhanced, the adhesion is firm, and the integral strength of the fuzzing roller of the carbon fiber composite material is greatly improved.

Owner:常州神鹰碳塑复合材料有限公司

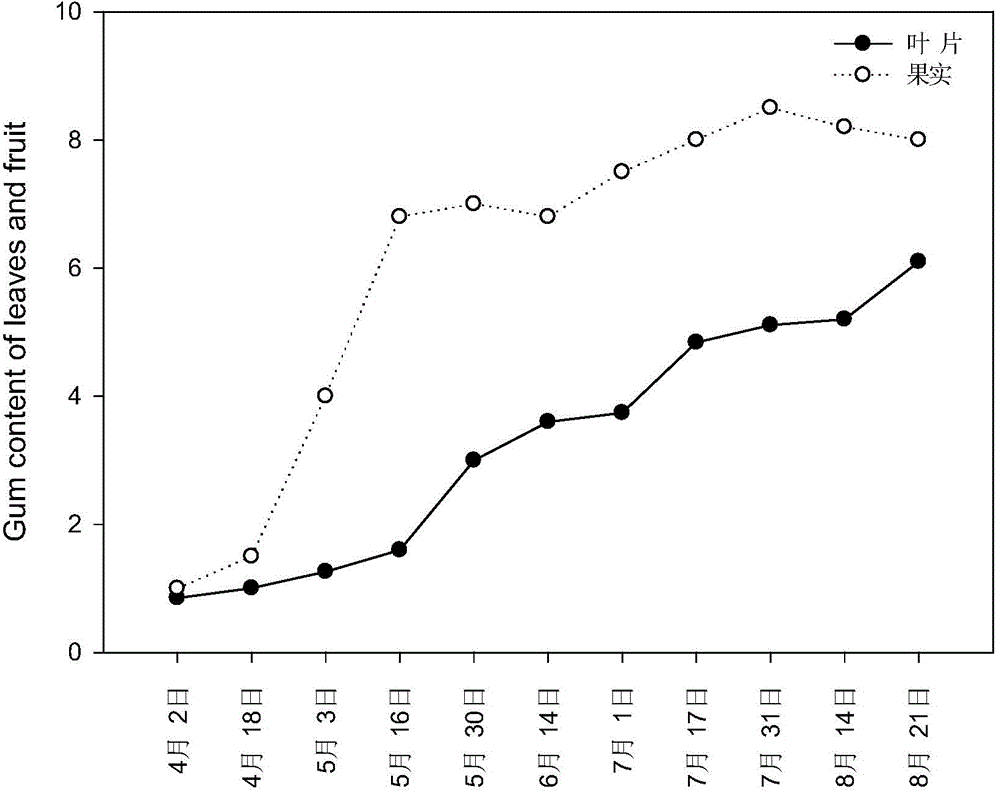

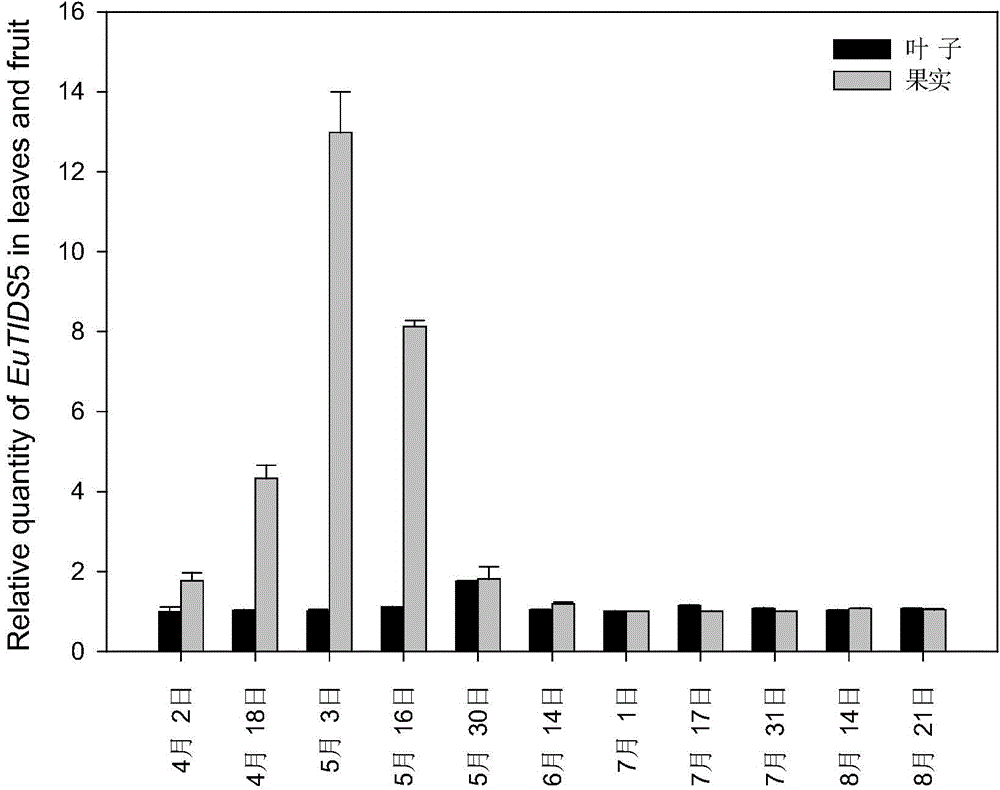

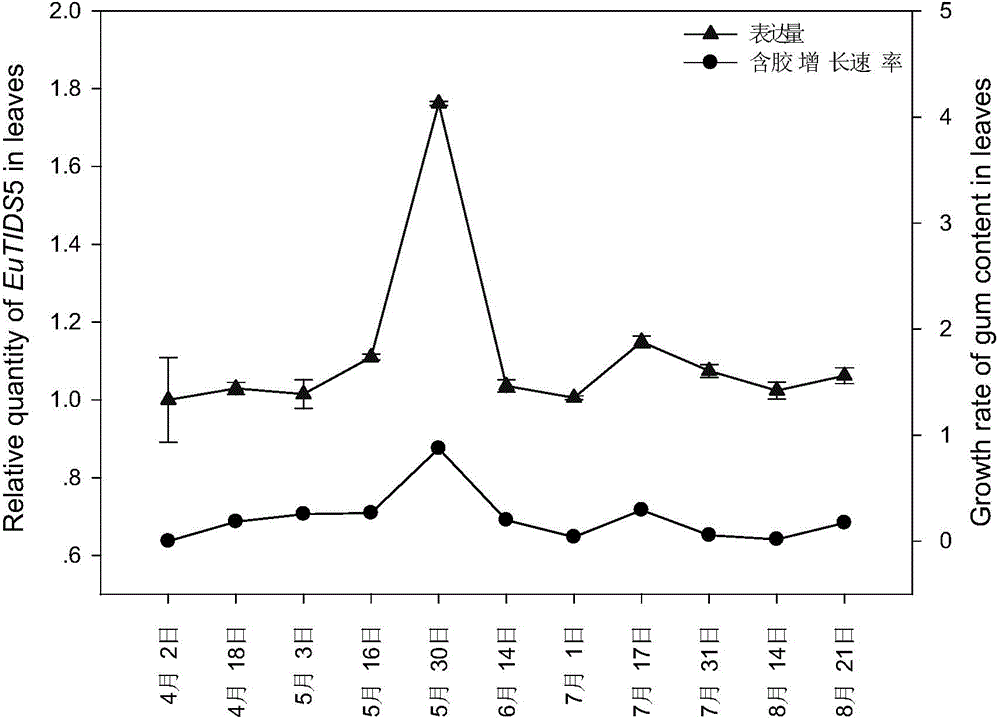

Method for increasing gel content of eucommia ulmoides

The invention relates to a method for increasing the gel content of eucommia ulmoides. The method includes the following steps: firstly, phloem of eucommia ulmoides bark is peeled off to form multiple cells, and cambium on the surface is exposed out in an interval cell shape; secondly, the dip dyeing operation is conducted, wherein bacterium liquid cultivated through single agrobacterium colonies containing EuTIDS5 recombinant expression vectors is picked to infect the cambium on the surface of peeled eucommia ulmoides; and thirdly, the peeled face is wrapped with a plastic film after peeling and infecting are conducted, and moisture preservation and sun protection growth is achieved. The infecting method is simple, feasible and excellent in gel content increasing effect.

Owner:CHINA PAULOWNIA RES CENT

Skeleton medicine rubber stopper and its making process

InactiveCN101066238AIncrease the gel contentImprove air tightnessClosuresClosure using stoppersInjection molding processEngineering

The present invention is one kind of medicinal rubber stopper with skeleton and its making process. The medicinal rubber stopper has a stopper skeleton coated with medicinal elastic material. It is made through one of three making processes, plate molding and vulcanizing process, one-step plate molding and vulcanizing process and injection molding process. The medicinal rubber stopper with skeleton has the advantages of high rubber content, high sealing performance, low cost, high hardness, high needle prick resistance, high heat resistance, etc.

Owner:余东方

Forming process of carbon fiber and phenolic resin composite material

The invention discloses a forming process of a carbon fiber and phenolic resin composite material. The forming process of the carbon fiber and phenolic resin composite material comprises the followingsteps of 1) preparing prepreg; 2) coating; 3) manufacturing a product mold cavity mold, and coating a mold release meter on the surface of the mold; 4) carbon fiber composite material enters a heating guide mechanism through a conveyor belt, and putting the carbon fiber composite material into the mold cavity mold after being heated; 5) pre-heating the mold cavity mold, and vacuumizing the mold at the same time; and 6) carrying out hot press molding in a vacuum environment, and demolding after cooling to obtain a molded product of the carbon fiber and the phenolic resin composite material. According to the forming process of the carbon fiber and phenolic resin composite material, the porosity can be effectively reduced, the operation is simple, and the cost is low.

Owner:YIXING YITAI CARBON FIBER WEAVING

Vamp rubber for rubber-vamp insulating boots

The invention discloses a shoe upper glue for rubber-faced insulating boots, which is characterized in that, calculated in parts by weight, it comprises: natural rubber 100, sulfur 0.7-0.9, accelerator M 0.4-0.6, accelerator D 0.3-0.5, accelerator Agent DM 0.2‑0.4, accelerator TMTD 0.7‑0.9, zinc oxide 1.9‑2.1, stearic acid 1.4‑1.6, antioxidant A 0.4‑0.6, antioxidant D 0.8‑1.2, talcum powder 87, montan wax 0.8‑1.2 , Paraffin 1.4-1.6, Zinc stearate 1.9-2.1, Oil-soluble black 1.2-1.4. Use natural rubber to improve the dielectric properties; reduce the amount of sulfur and use talcum powder with low water absorption; the upper rubber for insulating boots produced by this formula has better insulation performance and lower cost, and can adapt to the operating environment of electricians. Protection from electrical work.

Owner:黄思齐

Sheath material used for coal mine cable

The invention discloses a sheath material used for a coal mine cable. The sheath material used for the coal mine cable is characterized by being prepared from, by weight, the raw materials of 55-100 parts of elastomeric chlorinated polyethylene, 45-80 parts of resin type chlorinated polyethylene, 35-65 parts of white carbon black, 10-20 parts of magnesium oxide, 9-20 parts of magnesium hydroxide, 25-55 parts of chlorinated paraffin, 35-45 parts of cable powder, 1-3 parts of silane coupling agents A-172, 10-20 parts of dioctyl phthalate, 15-30 parts of flame retardant CM80AT, 10-20 parts of flame retardant TCEP, 1-3 parts of paraffin, 2-5 parts of polyethylene wax and 6-18 parts of vulcanizing agents. The sheath material has good thermo-oxidative ageing resistance and flame retardancy and has the advantages of being good in elasticity, high in tensile strength, good in tear resistance and calendaring performance, low in cost and the like.

Owner:山东太平洋橡缆股份有限公司

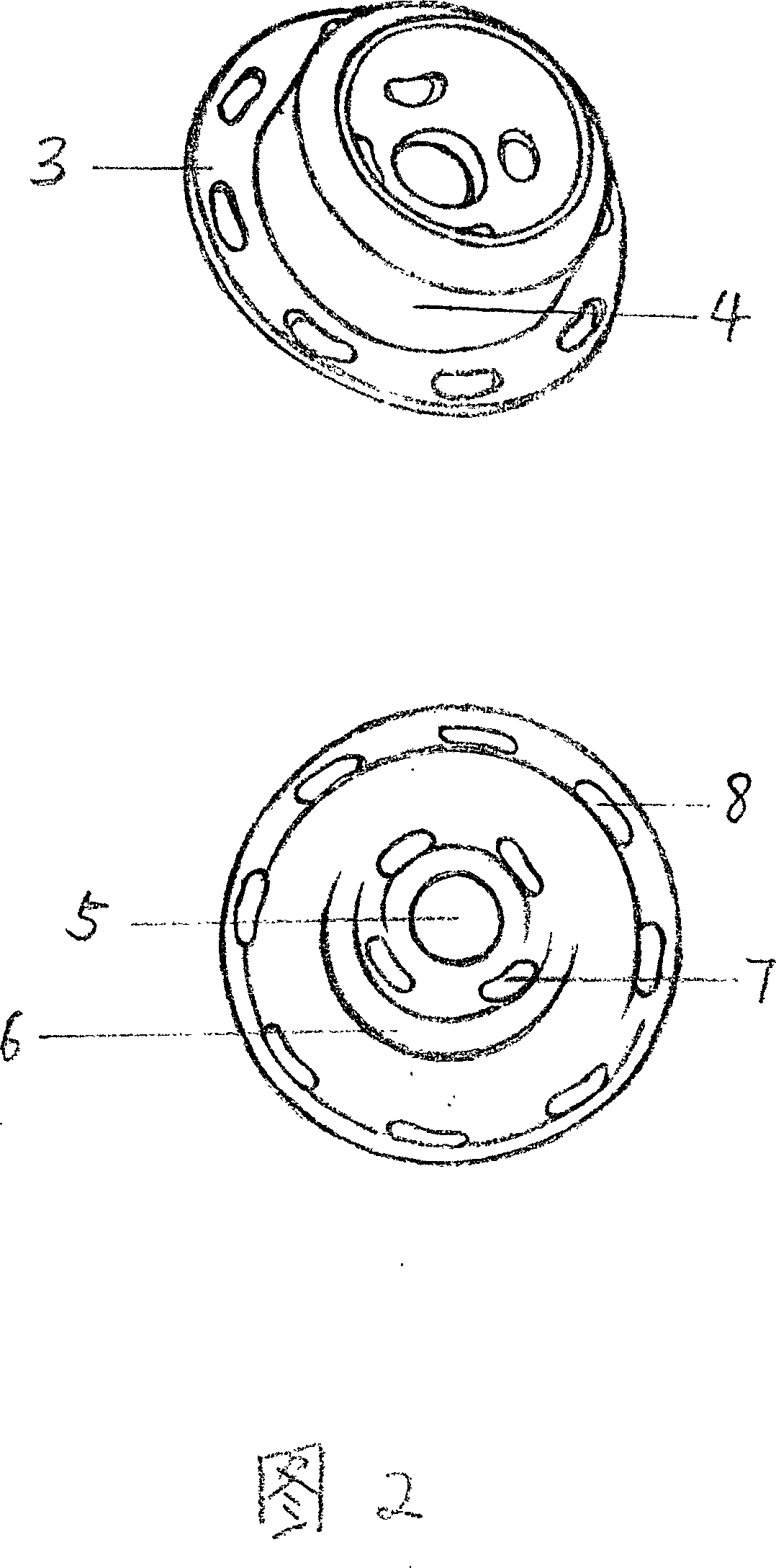

Rubber wheel for trolley and production process thereof

PendingCN110901292ANot easy to fall offNot easy to damageNon-metallic wheel bodyDomestic articlesStructural engineeringMechanical engineering

Owner:嘉兴智悦橡塑股份有限公司

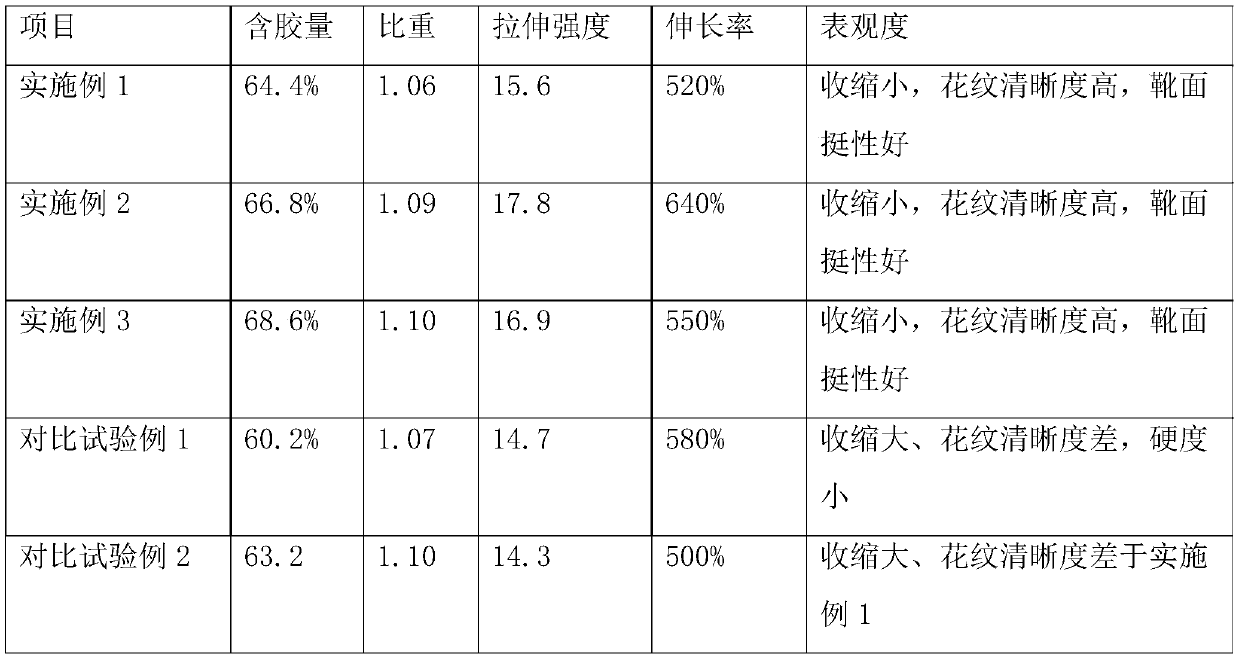

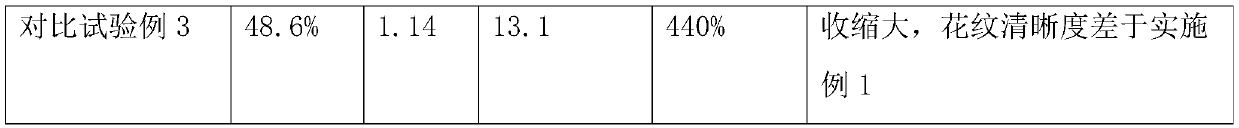

Light rubber boot vamp rubber compound

PendingCN111440361AIncrease the gel contentIncrease the proportionFootwearRubber materialPolymer science

The invention discloses a light rubber boot vamp rubber compound. Rubber materials comprise natural rubber, high styrene rubber, thermoplastic styrene butadiene rubber, sulfur, stearic acid, activatedzinc oxide, antiaging agent MB, antiaging agent 264, light white carbon black, hollow glass beads and phenolic resin, the specific gravity of the light white carbon black is 1.2 to 1.5, and the specific gravity of the hollow glass beads is 0.18 to 0.21; the light rubber boot vamp rubber compound has the characteristics of high adhesive content and light specific gravity, and the tensile strengthis greater than or equal to 14Ma, the extension is greater than or equal to 500%, the light rubber boot vamp rubber compound is used for special protective rubber boots (such as various industrial andmining boots); the weight up to 2.4 Kg-3. 4Kg of one pair of original protective rubber boots can be successfully reduced to about 2.2 Kg-3. 1Kg; for miners with very large daily walking amount and workload, the load is obviously reduced, and under the conditions of high glue content and small reinforcing agent dosage, the protective boots have small calendering shrinkage, clear patterns and goodvamp stiffness, and the problems of large calendering shrinkage, unclear patterns, poor vamp stiffness and the like caused by the high glue content, small reinforcing agent dosage and the like are solved.

Owner:JIHUA 3539 SHOE MAKING

Method for producing environment-friendly high-strength butyl-reclaimed rubber under high-temperature and normal-pressure condition

InactiveCN105328813AIncrease the gel contentReduce intensityPlastic recyclingPolycyclic aromatic hydrocarbonRubber material

The invention provides a method for producing environment-friendly high-strength butyl-reclaimed rubber under a high-temperature and normal-pressure condition. According to the method, a waste butyl rubber inner tube with the tensile strength being 8.5-10.0 MPa is selected, waste butyl rubber powder is added into a double-screw extruder connected with a vacuum device, no softener or regeneration activator is added, continuous high-temperature desulfuration is conducted, and in the continuous high-temperature desulfuration process of the double-screw extruder, toxic and harmful substances such as polycyclic aromatic hydrocarbon in rubber materials are collected, absorbed and treated through the vacuum device. In addition, no softener or regeneration activator is added in the regeneration process of the waste butyl rubber, and the pollution problem of reclaimed rubber preparation is well solved. The reclaimed rubber produced through the method is good in mechanical property and physical and chemical property.

Owner:河北茂祥橡胶制品有限公司

Scorch-preventing outsole adhesive for rubber-face insulating boots

The invention discloses an outsole rubber for insulating boots with a rubber surface that can prevent scorch, which is characterized in that, calculated in parts by weight, it comprises: natural rubber 100, sulfur 0.7-0.9, accelerator M 0.4-0.6, accelerator DM 1.0‑1.2, accelerator TMTD 0.7‑0.9, zinc oxide 4‑6, stearic acid 1.4‑1.6, antioxidant D 1.4‑1.6, calcium carbonate 60, clay 60, pine tar 9‑10, montan wax 0.8‑1.2 , Vaseline 1‑3, paraffin 0.8‑1.2, zinc stearate 0.9‑1.1, oil soluble black 3.8‑4.0, salicylic acid 0.2‑0.4, anti-scorch agent PVI 0.1‑0.5. The outsole glue for insulating boots produced with this formula has good insulation performance and low cost, can adapt to the operating environment of electricians, and is suitable for protection in electrical work; The compound has a recovery effect, which can further improve the processing safety of the compound.

Owner:黄思齐

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com