Skeleton medicine rubber stopper and its making process

A manufacturing method and skeleton technology, applied in the direction of using stopper closure, application, closing stopper, etc., can solve the problems of rubber stopper piercing into the bottle, decrease of airtight self-sealing performance of rubber stopper, difficult operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The following is a further description of the patent skeleton pharmaceutical rubber plug of the present invention according to the accompanying drawings.

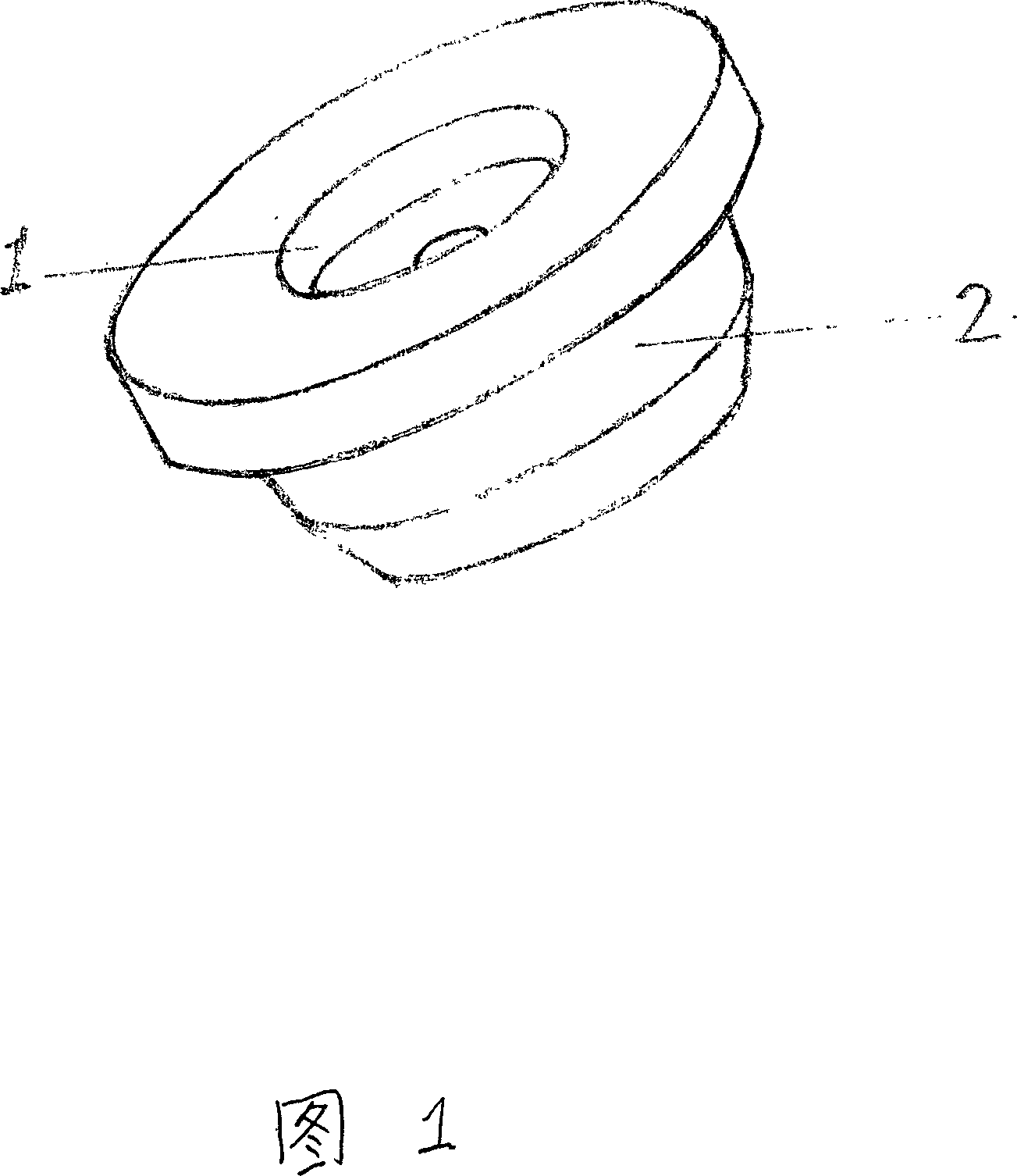

[0008] Referring to FIG. 1 , a schematic diagram of the patent skeleton medical rubber stopper covered with rubber of the present invention includes a skeleton stopper 1 and a medicinal elastomer material 2 .

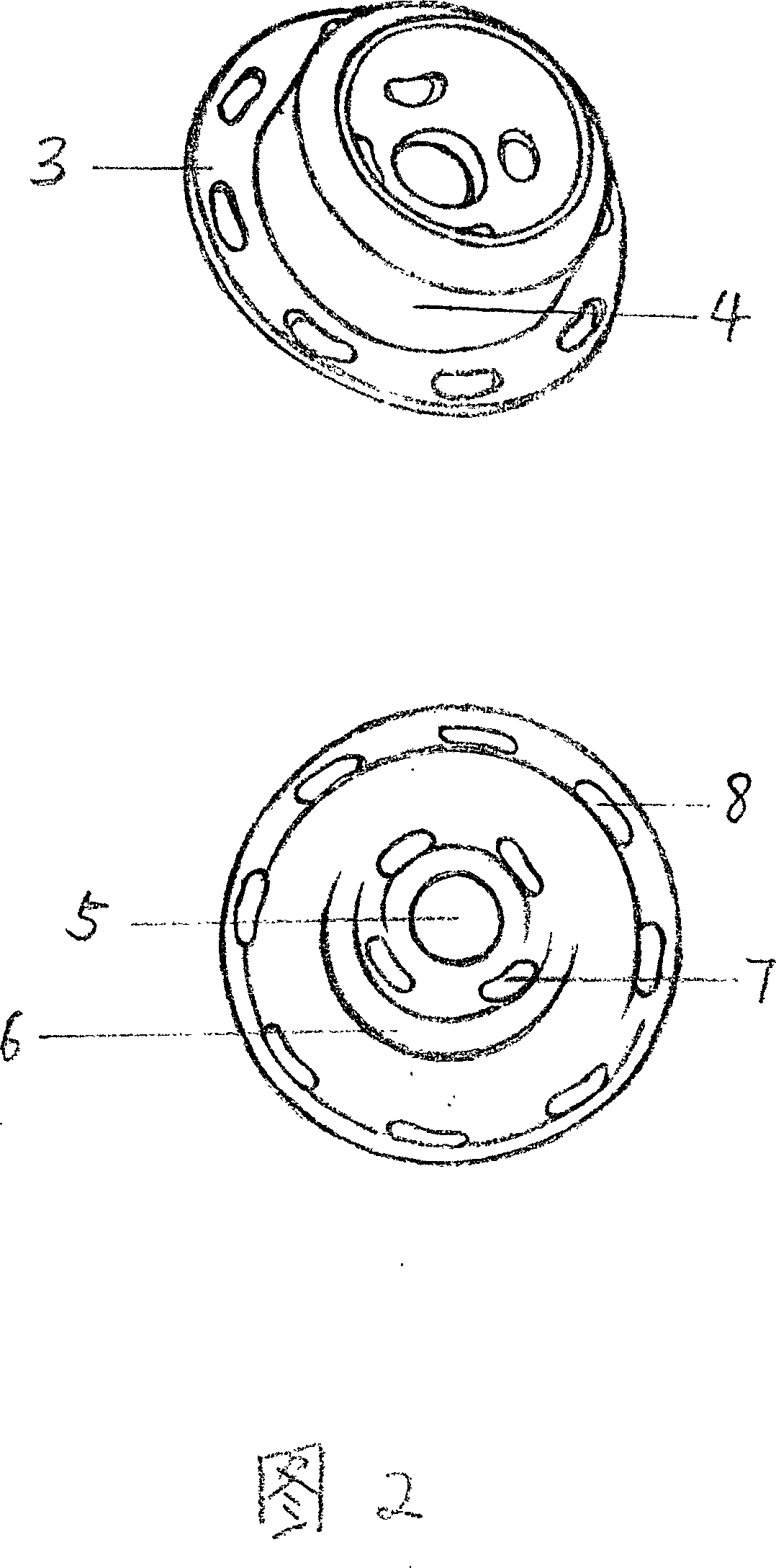

[0009] Referring to Fig. 2, it is a skeleton plug 1 in the patent of the present invention, which consists of a plug top 3 and a plug body 4. There is a puncture hole 5 in the middle of the plug top 3, a fixing groove 6 in the middle of the plug top 3, and an inner rubber hole in the middle of the plug top 3. 7. The plug top 3 is extended with an outer glue hole 8.

[0010] Its manufacturing method 1 is the flat-plate molding vulcanization method: firstly, the corresponding skeleton plug is manufactured, and after a certain treatment, the skeleton plug is put into and fixed in the lower mold of the steel mold,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com