Patents

Literature

33results about How to "Good water vapor resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fume denitration composite catalyst using titanium-base ceramics as carrier and preparation method thereof

ActiveCN101380543AGood chemical stabilityExtend your lifeCatalyst carriersDispersed particle separationCeriumChemical stability

The invention relates to a flue gas denitration composite catalyst and the preparation method thereof and pertains to the technical field of environment-friendly catalytic material and air pollution treatment. The invention is characterized in that aluminum-based or silicon-based ceramics is taken as a first carrier, aluminum-silicon composite oxide is taken as a second carrier, and cerium-zirconium composite metal oxide is taken as the catalyst active component. The aluminum-based or silicon-based ceramics is infused in the aluminum-silicon composite sol, after preparing a carrier coating by drying and baking, then the carrier coating is infused in cerium-zirconium composite solution for preparing the coating of active catalyst components. Compared with the prior art, the invention not only improves the activity and the chemical stability of the catalyst and enlarges the catalysis activity temperature window, but also improves the mechanical performance and thermal stability of the catalyst carrier, is environment-friendly and cheap, has no secondary pollution and lowers the loading quantity of the active components.

Owner:NANJING UNIV OF TECH

Ethylene-propylene-diene rubber thermal shrinkable tube and preparation method thereof

ActiveCN102030950AExcellent ozone resistanceGood weather resistanceRubber insulatorsHigh resistancePolymer science

The invention provides an ethylene-propylene-diene rubber thermal shrinkable tube to solve the problem that the conventional thermal shrinkable tube has low performance in the aspects of high-temperature resistance, oil resistance and solvent resistance and cannot meet the performance requirements of the industries such as automobiles, high-speed trains, military projects and aerospace on high oil resistance and high solvent resistance. The ethylene-propylene-diene rubber thermal shrinkable tube is made from the following materials: ethylene-propylene-diene rubber, thermal shrinkable resin and a reinforcing agent. The zinc oxide, zinc stearate, a softener and an age resister can be added selectively. When chemical crosslinking is adopted, a crosslinker is required. Meanwhile, the invention provides three methods for producing the thermal shrinkable tubes from the materials, namely a two-step mixing electronic crosslinking method, a one-step mixing electronic crosslinking method and a chemical crosslinking method. The ethylene-propylene-diene rubber thermal shrinkable tube provided by the invention has high ozone resistance, weather-aging resistance, high heat resistance, high vapor resistance, high electric insulation and high chemical medium resistance and can be applied in the connector protection and sealing of power supply lines.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

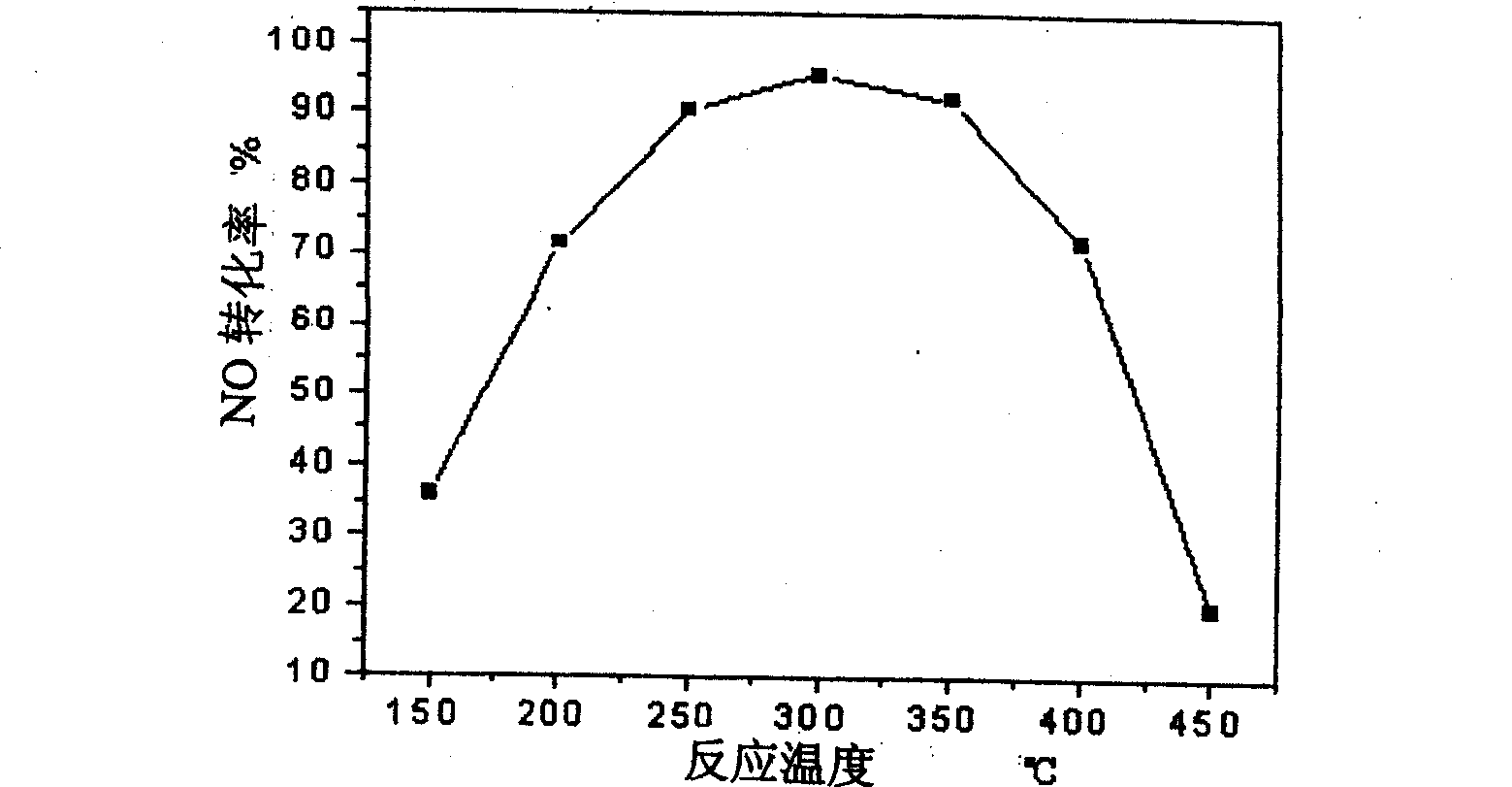

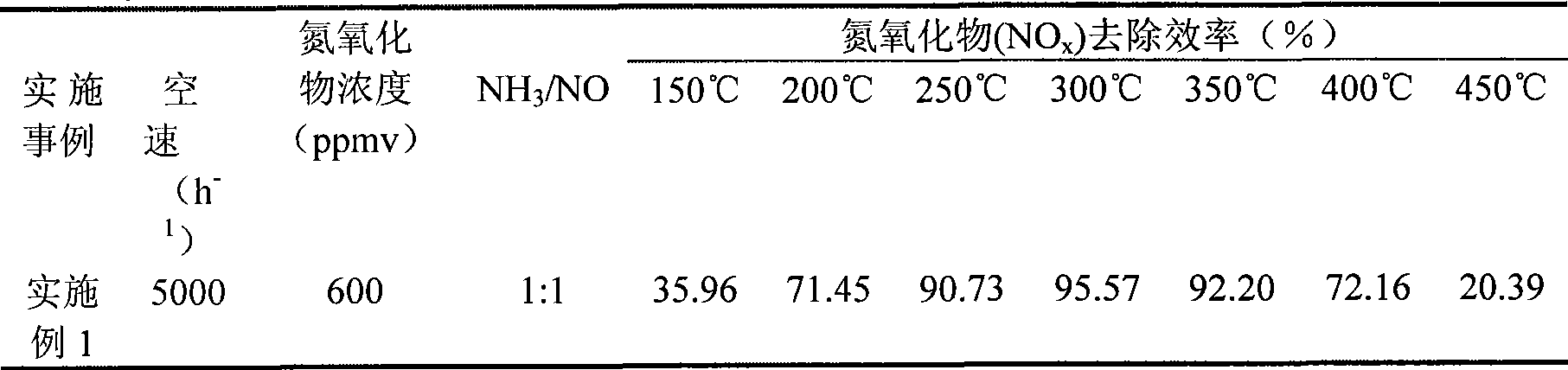

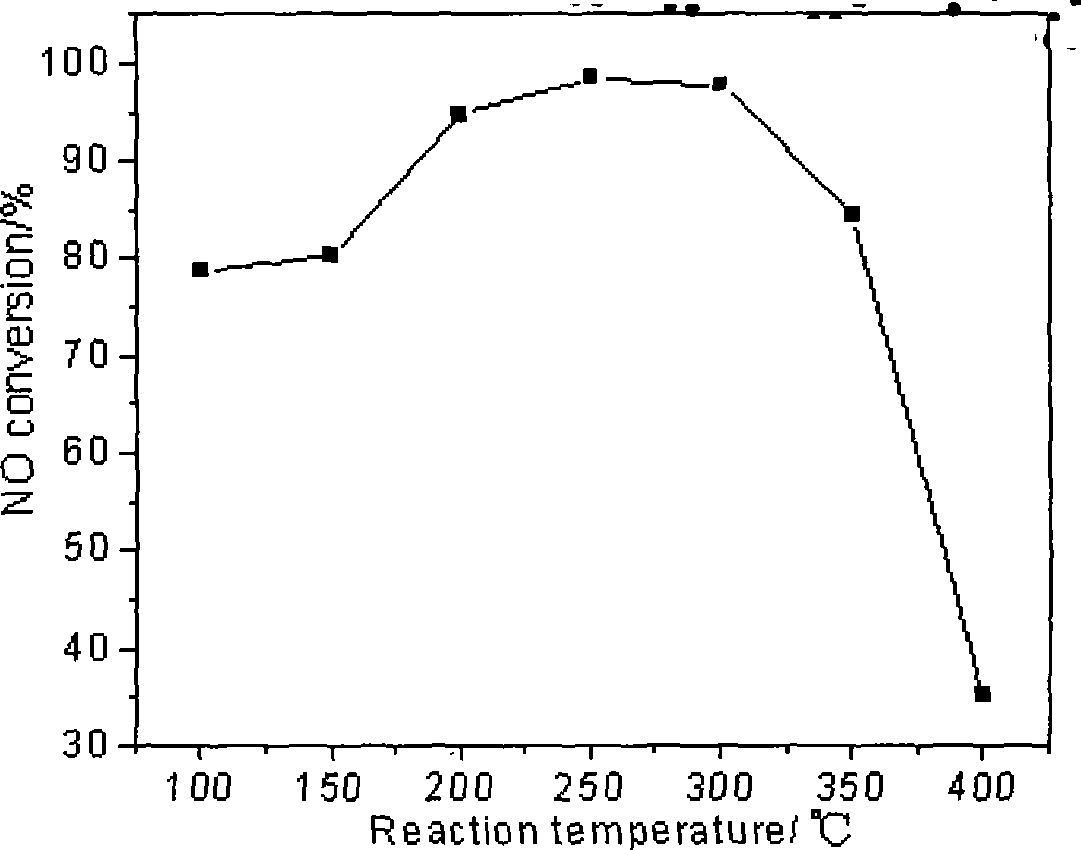

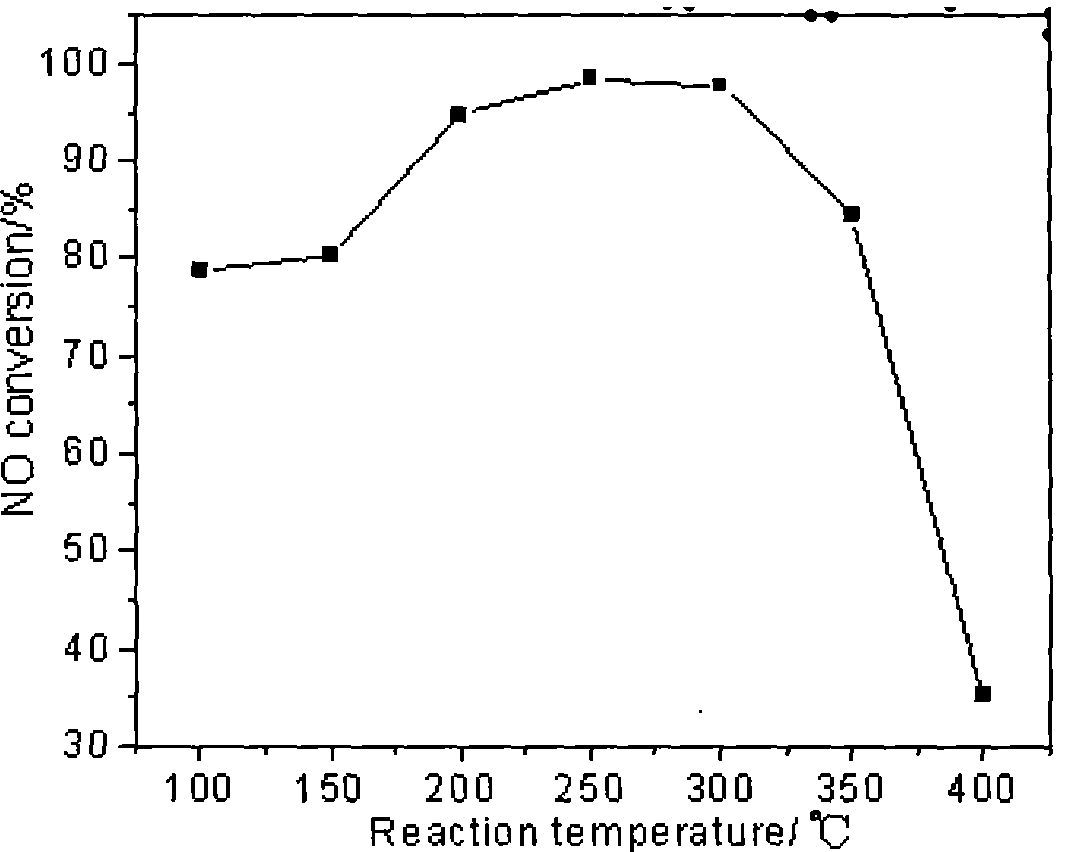

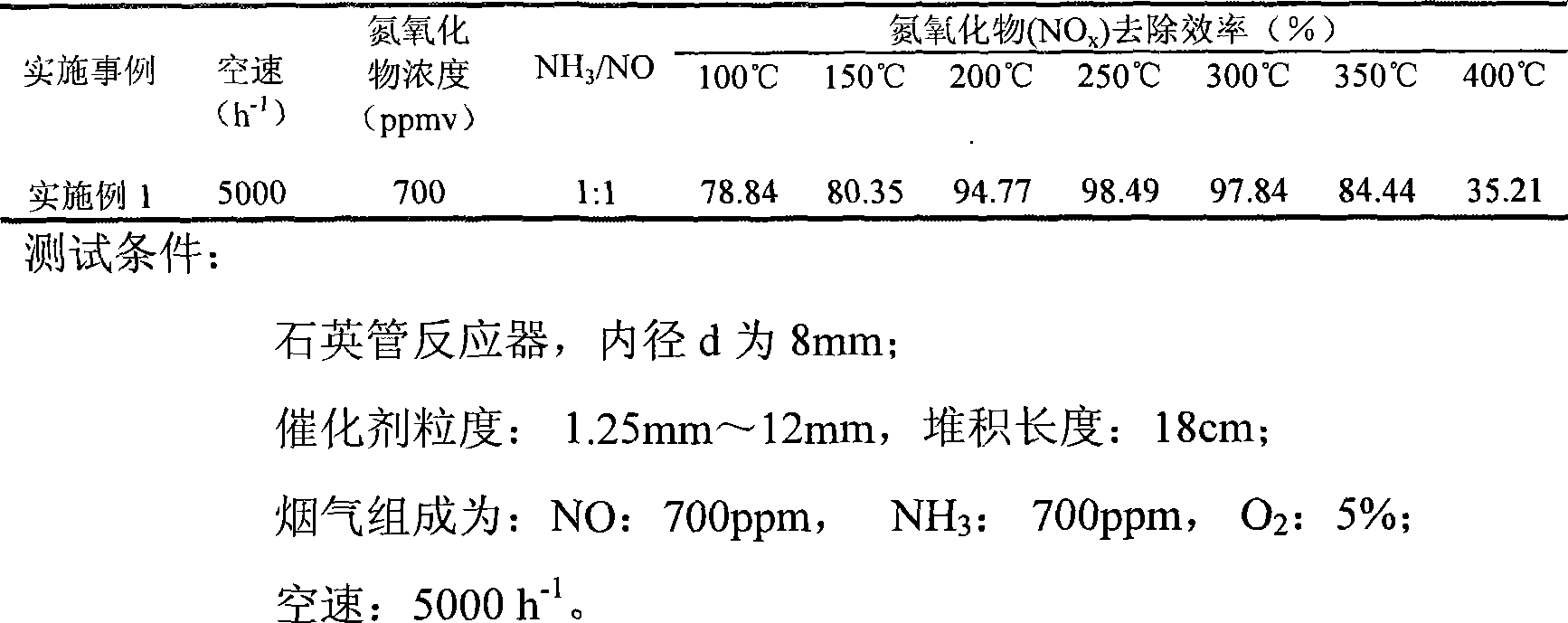

Denitration catalyst, and preparation method

InactiveCN1872413ALarge specific surface areaImprove stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHigh resistanceThermal stability

A denitrating catalyst for the reduction reaction of Nox / NH3 gas mixture to generate N2 and H2O is proportionally prepared from bentone, TiO2, Fe2O3, CuO and H2O. Its preparing process is also disclosed. It has high thermal stability and high resistance to steam.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

SCR flue gas denitration composite catalyst and preparation method thereof

ActiveCN101352678AGood chemical stabilityImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsTitanium zirconiumCerium

The invention relates to a compound catalyst for SCR flue gas denitration and a preparation method thereof, pertaining to the technical fields of environmental protection catalytic materials and atmosphere pollution controlling. The compound catalyst takes aluminum-based, titanium-based or zirconium-based ceramics as a carrier and titanium-zirconium-aluminum-cerium complex metal oxide as an active ingredient of the compound catalyst. The preparation method adopted includes: the aluminum-based, titanium-based or zirconium-based ceramics is impregnated in a titanium-zirconium-aluminum-cerium complex colloidal sol, and then dried and roasted to prepare compound catalyst active coatings. Compared with the prior art, the compound catalyst not only promotes the activity and the chemical stability of the catalyst and extends the temperature window of the catalytic activity, but also enhances the mechanical and thermal stability of a catalyst carrier, is environment protective and cheap without secondary pollution, prolongs the service life of the catalyst and lowers the load of the active ingredient.

Owner:NANJING UNIV OF TECH

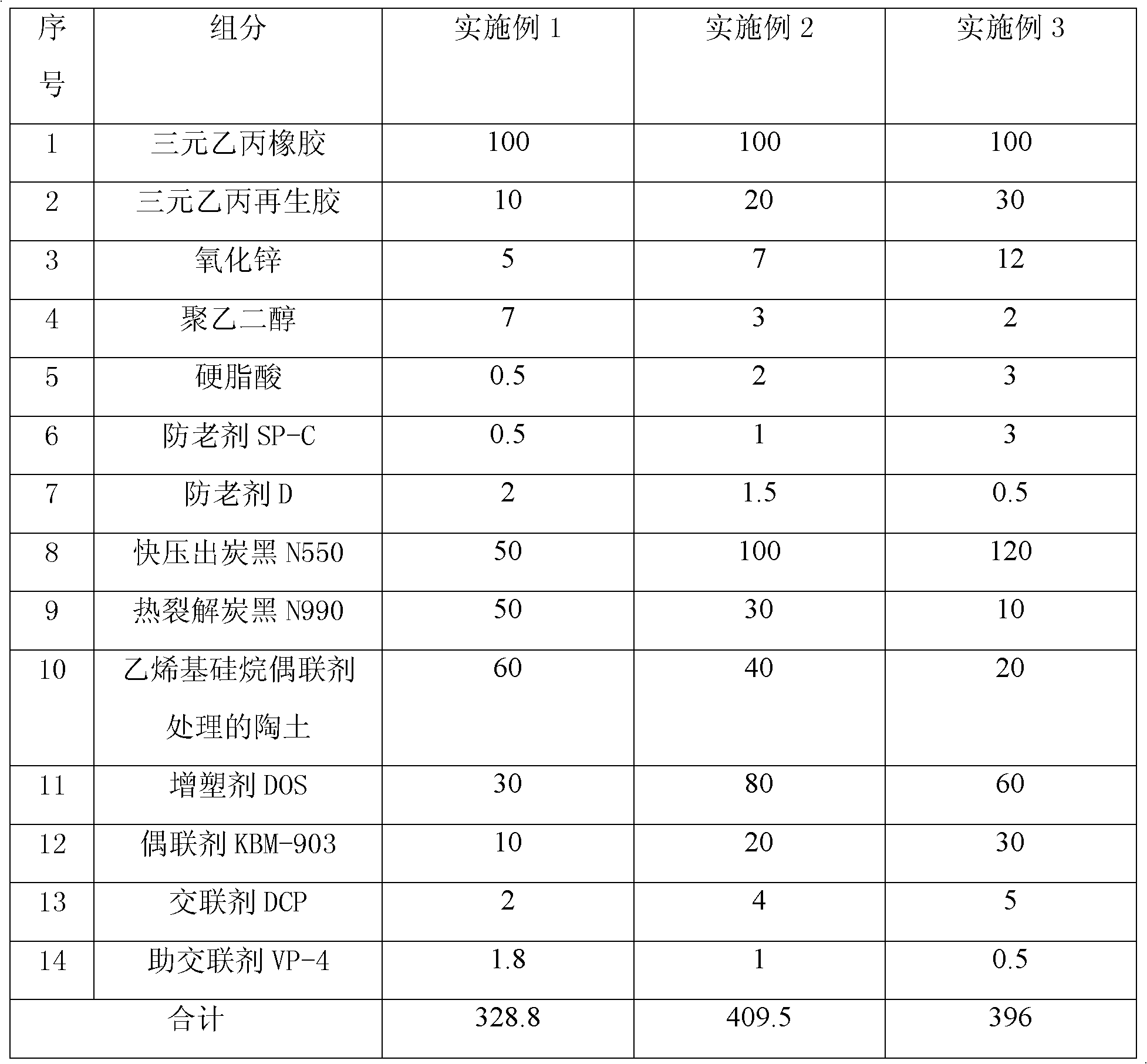

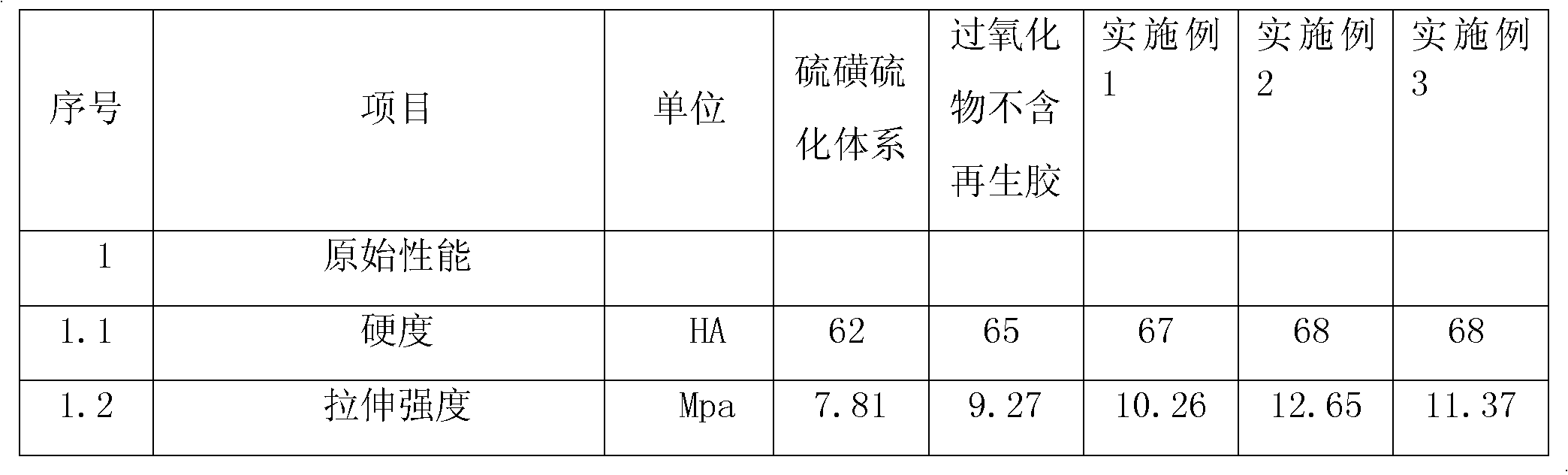

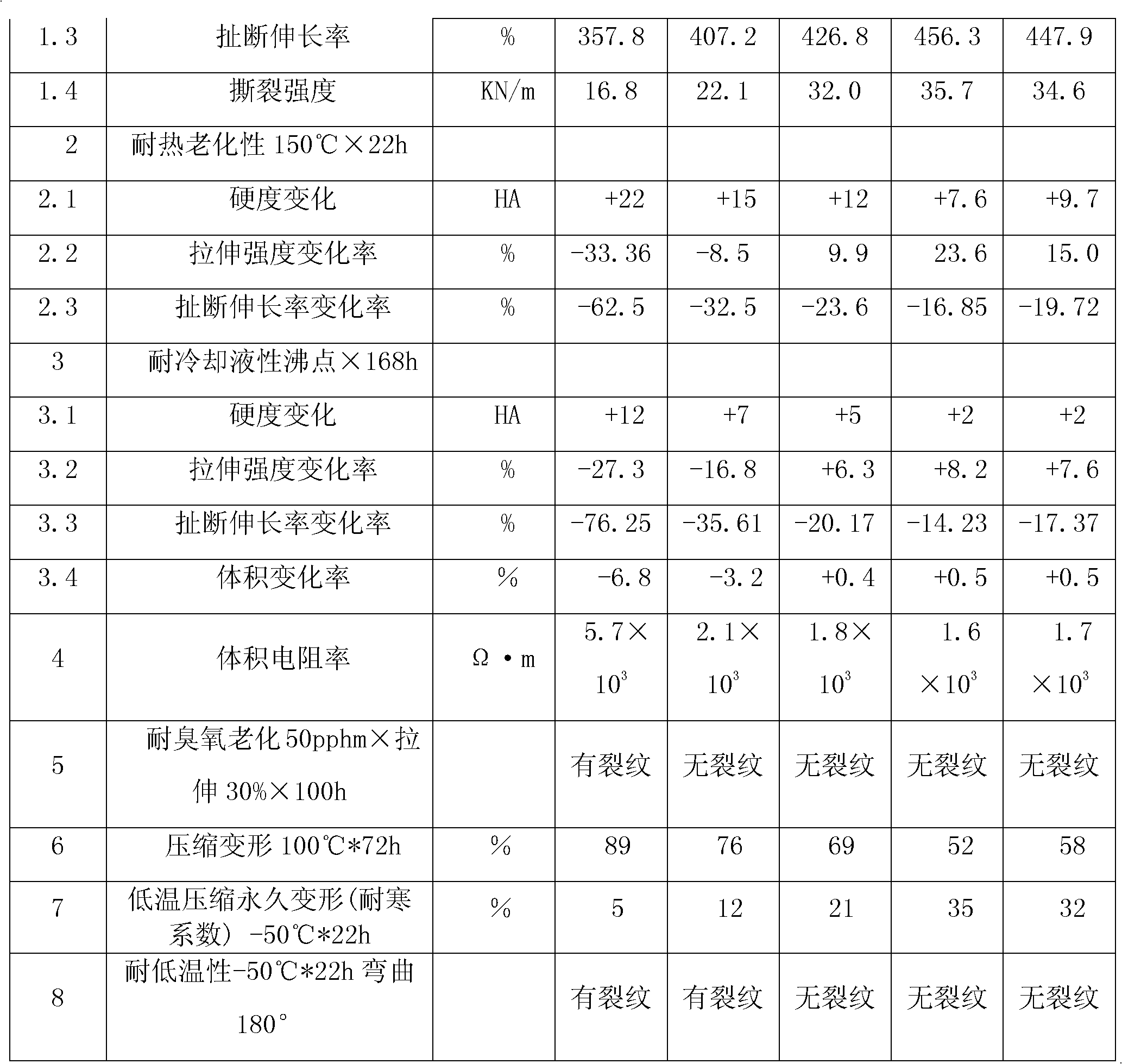

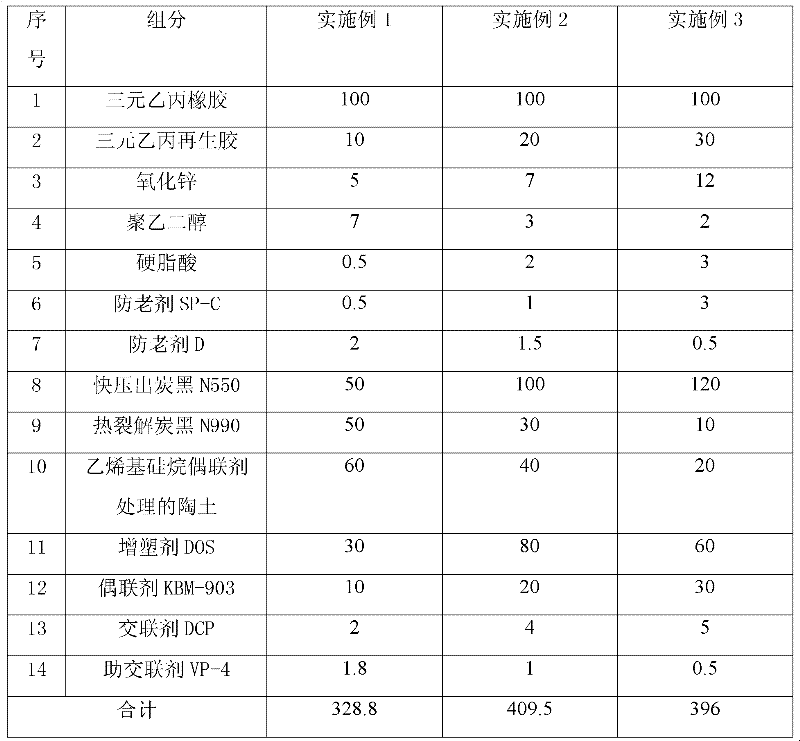

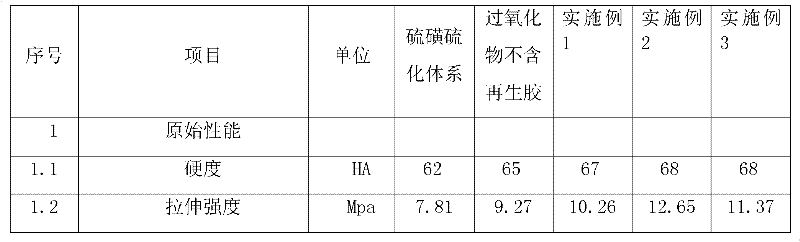

Cold-resistant rubber tube using both peroxide ternary ethylene-propylene rubber and reclaimed rubber

ActiveCN102093638AExcellent ozone resistanceImprove cold resistanceFlexible pipesThermal ageingCross-link

The invention relates to a cold-resistant rubber tube using both peroxide ternary ethylene-propylene rubber and a reclaimed rubber. The cold-resistant rubber tube comprises the following components: ternary ethylene-propylene rubber, ternary ethylene-propylene reclaimed rubber, zinc oxide, polyethylene glycol, stearic acid, an age resister SP-C, an age resister D, fast extruding carbon black N550, thermal cracking carbon black N990, china clay processed by a vinyl silane coupling agent, a plasticizer DOS, a coupling agent KBM-903, a cross-linking agent DCP and an auxiliary cross-linking agent VP-4. Compared with a sulfur vulcanizing system and a peroxide system which do not contain a reclaimed rubber tube, the formula of the cold-resistant rubber tube using both the peroxide ternary ethylene-propylene rubber and the reclaimed rubber has higher cold resistance, cooled liquid resistance, electric property resistance, ozone resistance and thermal ageing resistance, lower compression set, higher elongation, breaking strength and tearing strength and can better meet the requirements of a cooling system circulating water pipe and a connecting hose pipe which are used for a long time at a low temperature.

Owner:TIANJIN PENGYI GRP CO LTD

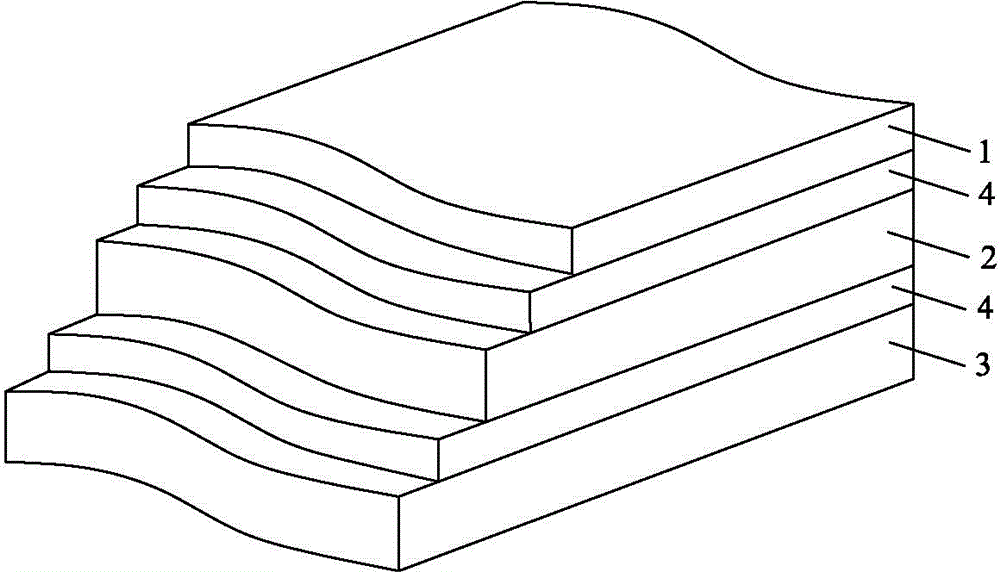

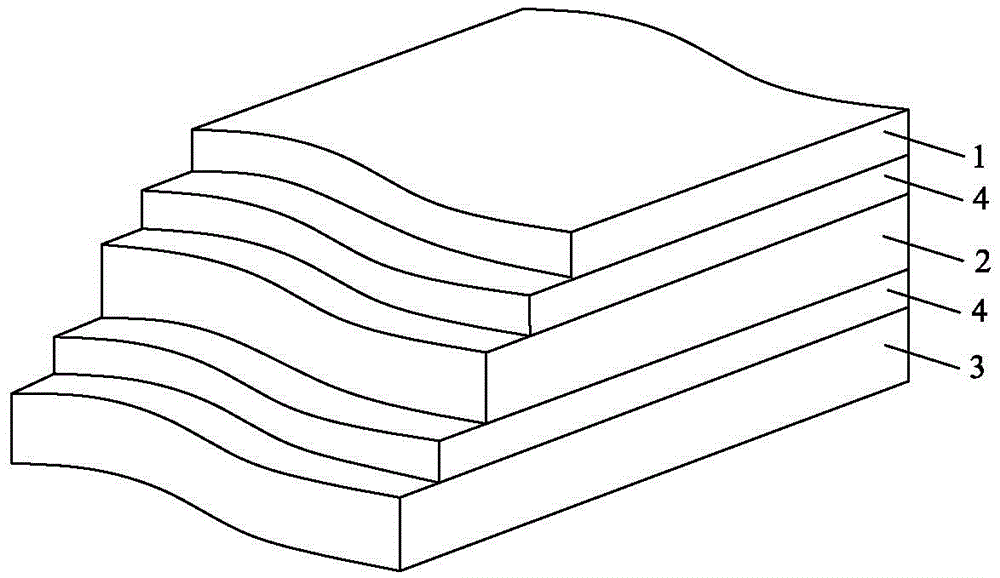

Solar photovoltaic battery assembly transparent backboard composite film and preparation method thereof

ActiveCN105428445AGood weather resistanceImprove aging resistanceFinal product manufactureSynthetic resin layered productsPolyesterWeather resistance

The invention relates to the technical field of a composite film, and particularly to a solar photovoltaic battery assembly transparent backboard composite film and a preparation method thereof. The solar photovoltaic battery assembly transparent backboard composite film comprises a first weather-resistant layer, a second weather-resistant layer and a substrate layer, wherein the first weather-resistant layer, the second weather-resistant layer and the substrate layer are successively arranged from top to bottom. The first weather-resistant layer is a transparent weather-resistant polycarbonate (PC) film and has a thickness of 25-100 [mu]m. The second weather-resistant layer is a transparent weather-resistant polyester (PET) film and has a thickness of 150-300 [mu]m. The substrate layer is a transparent linear low-density polyethylene (LLDPE) film and has a thickness of 50-150 [mu]m. According to the solar photovoltaic battery assembly transparent backboard composite film, a traditional poly(vinylidene fluoride) (PVDF) film is replaced by the transparent weather-resistant PC film, and weather resistance and light transmittance of the back board on which the solar photovoltaic battery assembly transparent backboard composite film is applied. Not only is cost reduced, but also environment pollution caused by a fluoride film is greatly reduced. Furthermore the solar photovoltaic battery assembly transparent backboard composite film has excellent binding property with a polyethylene vinylacetate (EVA) film.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

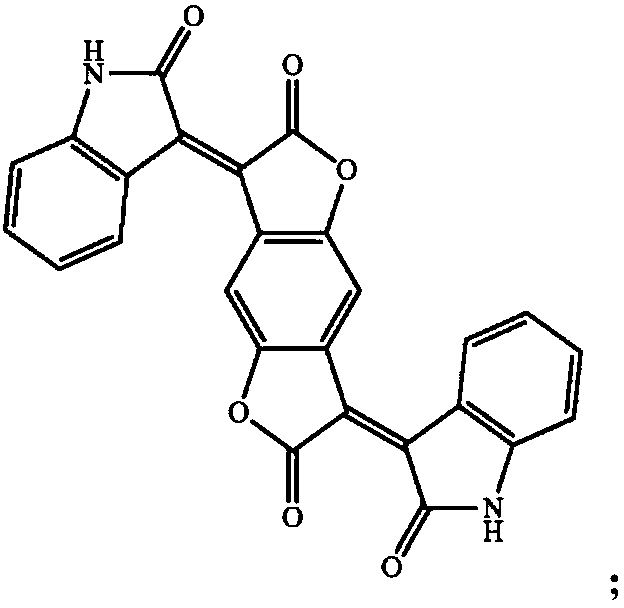

Side edge shading glue and no-border display device

ActiveCN106554650AHigh OD valueGood flexibilityNon-linear opticsElectrically-conductive paintsCross-linkPolymer science

The invention provides side edge shading glue and a no-border display device. The side edge shading glue comprises oligomer containing polymerizable groups, reactive monomers, photoinitiator, black dye, carbon black, graphene and additives. An adopted resin system composed of the oligomer containing the polymerizable groups, the reactive monomers and the photoinitiator has a high curing reaction speed under UV irradiation; by adding the carbon block for increasing black, the side edge shading glue has a high OD value, the color of the carbon black is fixed, and the situation that color fading is caused because of long time, and consequently insufficient shading is caused is avoided; a method that a dispersion agent is adopted for dispersing the carbon black and a polymer cross-linked network to fix the carbon black makes the side edge shading glue free of the conditions of precipitation and uneven dispersion of the carbon black; and in addition, by adding the graphene, the flexibility and the heat conduction performance of the side edge shading glue can be improved, and further, static electricity on the surface of a display panel can also be removed by means of the heat conduction performance of the graphene.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Chloride absorbent

InactiveCN101104142AWide temperature rangeImprove purification effectOther chemical processesDispersed particle separationAlkaline earth metalSorbent

The invention relates to the chlorine hydride adsorbent, which takes the metallic compounds and the mineral as main materials, and is prepared by roasting under the temperature between 350-800 DEG C, the invention is characterized in that the metallic compounds are composed of the alkali metal and / or alkaline earth metal compounds and transition metal oxide, the content of transition metal oxide is eight percent to twenty five percent according to the weight percentage; the compressive strength of chlorine hydride adsorbent is more than 80N / cm, breakthrough chlorine content is more than forty eight percent under the temperature of 500 DEG C. The chlorine hydride adsorbent of the invention has advantages of wide range of temperature suitability, good purifying degree, high chloride capacity, excellent water tolerance performance and high mechanical strength.

Owner:EAST CHINA UNIV OF SCI & TECH

High-density polyethylene sound-absorbing cotton and preparation method thereof

InactiveCN103757819AHigh strengthNon-hygroscopicSynthetic resin layered productsNon-woven fabricsLow-density polyethyleneNonwoven fabric

The invention discloses high-density polyethylene sound-absorbing cotton. The high-density polyethylene sound-absorbing cotton consists of a top surface layer, a back face layer and a fiber-cotton layer clamped between the top surface layer and the back face layer, wherein the top surface layer and the back face layer are made of a non-woven fabric. The high-density polyethylene sound-absorbing cotton is characterized in that the non-woven fabric is made from the following raw materials in parts by weight by means of melt blowing: 100 parts of isotactic polypropylene, 12-15 parts of EVA (Ethylene-Vinyl Acetate) resin, 5-8 parts of high-density polyethylene, 2-3 parts of glass fiber, 4-5 parts of barium sulfate, 10-12 parts of phthalic acid ester, 2-3 parts of silane coupling agent KH-550, 1-2 parts of melamine cyanurate, 1-2 parts of ethyl cellulose, 2-3 parts of rosin, 4-5 parts of oxidation castor oil, 10-12 parts of sawdust, 12-15 parts of active carbon, 3-4 parts of corncob, 2-3 parts of corydalis tuber, 1-2 parts of red-rooted salvia root, 1-2 parts of safflower and 4-5 parts of addition agent. The prepared high-density polyethylene sound-absorbing cotton has the advantages of non-hygroscopicity, high vapor resistance, high strength, high air permeability, chemical corrosion resistance and wide application field.

Owner:芜湖跃飞新型吸音材料股份有限公司

Building waterproof and heat-insulating coating for metal roofs and preparation method of building waterproof and heat-insulating coating

InactiveCN107573786AFlexible designImprove performanceAntifouling/underwater paintsPaints with biocidesWater basedPotassium

The invention discloses a building waterproof and heat-insulating coating for metal roofs and a preparation method of the building waterproof and heat-insulating coating. The building waterproof and heat-insulating coating is prepared by mixing the following two groups of components: first components: water, a first thickener, a first dispersant, a second dispersant, a wetting agent, a first defoamer, a second defoamer, multifunctional additives, a preservative, a mildew inhibitor, titanium dioxide, composite heat-insulating powder, filler and functional filler; second components: an antifreezing agent, film forming additives, an emulsifier, water, emulsion, a second thickener, a third thickener, a pH value regulator and tributyl phosphate, wherein the composite heat-insulating powder is acompound formed by mixing and dispersing rectorite powder and potassium hexatitanate whiskers and then performing surface modification. The preparation method comprises the following steps: firstly,pre-dispersing the first components to obtain slurry with a fineness of 40-80 microns, then adding the second components for paint mixing, and filtering to obtain a finished product. The building waterproof and heat-insulating coating provided by the invention has advantages of simple production process, low cost, easy construction, short construction period, water-based environmental protection,no toxicity and noninflammability, can be widely applied to water prevention and heat insulation of metal roofs.

Owner:苏州市姑苏新型建材有限公司

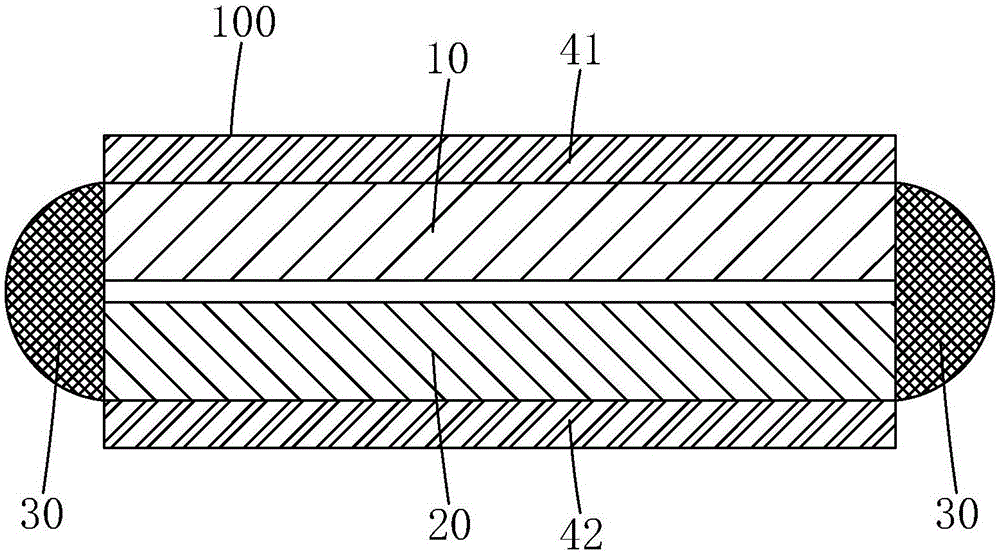

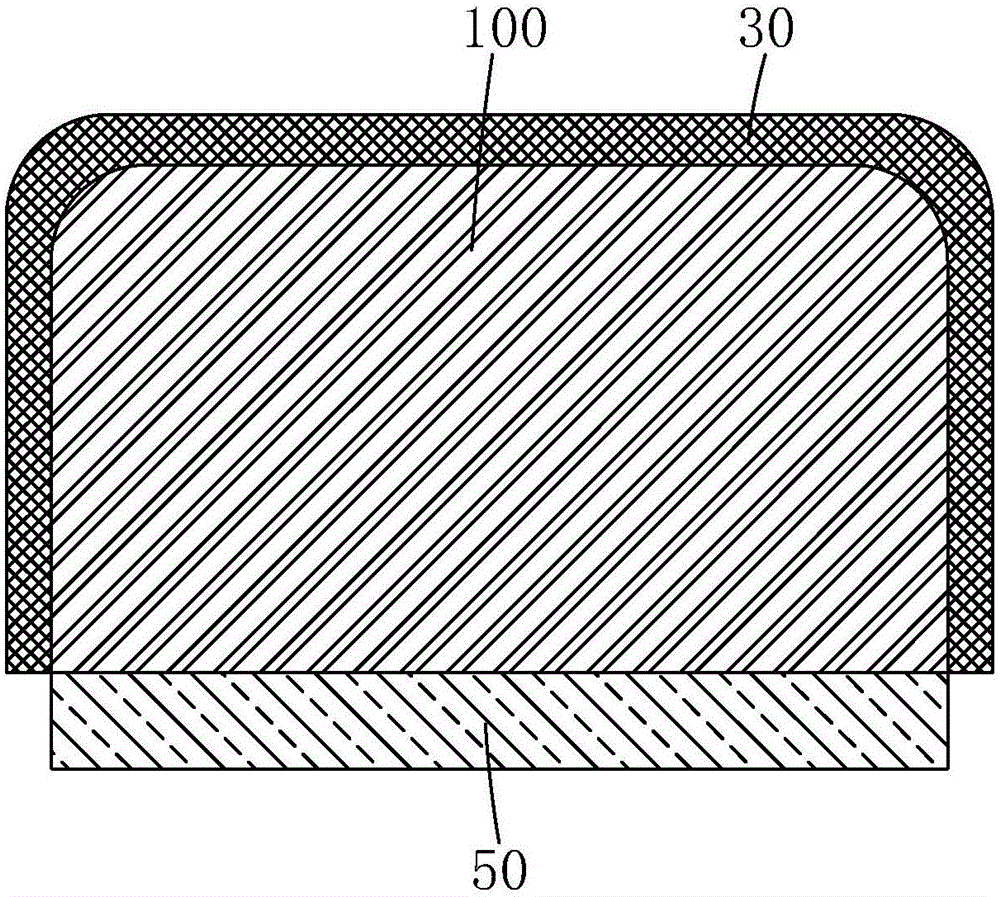

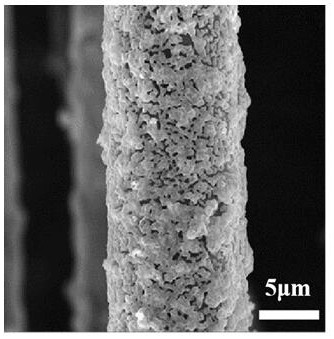

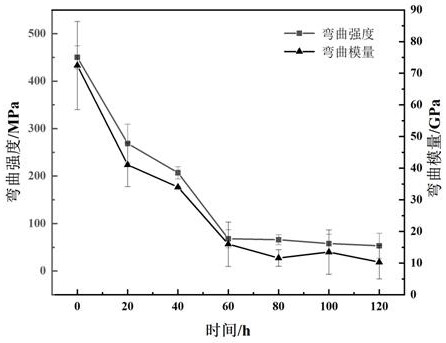

Preparation method of novel interface phase material

ActiveCN113248266AGood high temperature resistance and oxidation resistanceExtended service lifeO-Phosphoric AcidPhosphate

The invention provides a preparation method of a novel interface phase material. The method comprises the following steps: preparing silica sol, preparing a citrate stock solution from RE<3+> soluble nitrate and citric acid, and mixing the citrate stock solution with a phosphoric acid solution to obtain a mixed solution; pretreating SiC fibers; dipping the pretreated SiC fiber in the prepared silica sol, dipping, coating and drying, and then keeping in a vacuum furnace at a constant temperature for 1 hour to obtain the SiC fiber with a SiO2 coating on the surface; putting the SiC fiber with the SiO2 coating into the prepared mixed solution, keeping in a constant-temperature water bath for a period of time, washing, drying, and carrying out first heat treatment under the protection of inert gas to form a rare earth phosphate coating on the surface of the SiO2 coating; and performing secondary heat treatment on the prepared sample under the protection of inert gas to form an interface phase with a rare earth pyrosilicate coating on the surface of the SiC fiber.

Owner:NAT UNIV OF DEFENSE TECH

Zeolite-supported metal type hydrogen and tritium removal catalyst and application thereof

InactiveCN110560149AHigh reactivityGood water vapor resistanceGas treatmentMolecular sieve catalystsRadiation protectionTritium

The invention discloses a zeolite-supported metal type hydrogen and tritium removal catalyst and application thereof. The catalyst is composed of Metal / zeolite, zeolite is used as a carrier, a precious metal is used as an active component, and the weight percentage of the precious metal is less than or equal to 10%. The zeolite-supported metal type hydrogen and tritium removal catalyst is an inorganic hydrogen / tritium removal precious metal catalyst with high room-temperature reaction activity and good water vapor resistance under the condition of low-concentration hydrogen / tritium, and can beflexibly and conveniently applied to passive hydrogen removal in nuclear power stations, hydrogen removal of storage batteries and radiation protection in tritium-containing places.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Composite insulating material for coal mine cable

InactiveCN105315562AGood heat resistanceGood water vapor resistanceRubber insulatorsPlastic/resin/waxes insulatorsWaxParaffin oils

The invention discloses a composite insulating material for a coal mine cable. The composite insulating material is characterized by being prepared from, by weight, 40-60 parts of EPDM rubber, 40-60 parts of polyolefin elastomer, 60-90 parts of calcined kaolin, 5-10 parts of zinc oxide, 1-3 parts of coupling agent A-172, 2-4 parts of paraffin, 3-10 parts of anti-aging agent, 6-12 parts of paraffin oil, 0.5-1 part of polyethylene wax, 0.5-1 part of stearic acid and 2-10 parts of vulcanizing agents. The composite insulating material for the coal mine cable has the advantages of being good in ozone aging resistant performance and thermal oxygen aging resistant performance, high in elasticity, small in permanent deformation, high in tensile strength, good in calendering performance, low in cost and the like.

Owner:山东太平洋橡缆股份有限公司

Rigid polyurethane foam culture stone and production method thereof

InactiveCN101649674ASmall adjustment rangeHigh closed cell rateCovering/liningsThermal insulationEngineering

The invention aims at the shortcomings that the current culture stones are heavy in weight, high in cost or poor in thermal insulation properties and have poor bondability with the building blocks, masonries and the like, are easily spalled, have short service lives and the like, and provides a rigid polyurethane foam (RPUF) culture stone and a production method thereof. The RPUF product with goodbondability, good thermal insulation property, light materials and long service life is obtained by improving the culture stone raw materials, production steps and technological conditions, which issuitable for the indoor and outdoor decoration in various environments.

Owner:宿迁特力新材料有限公司

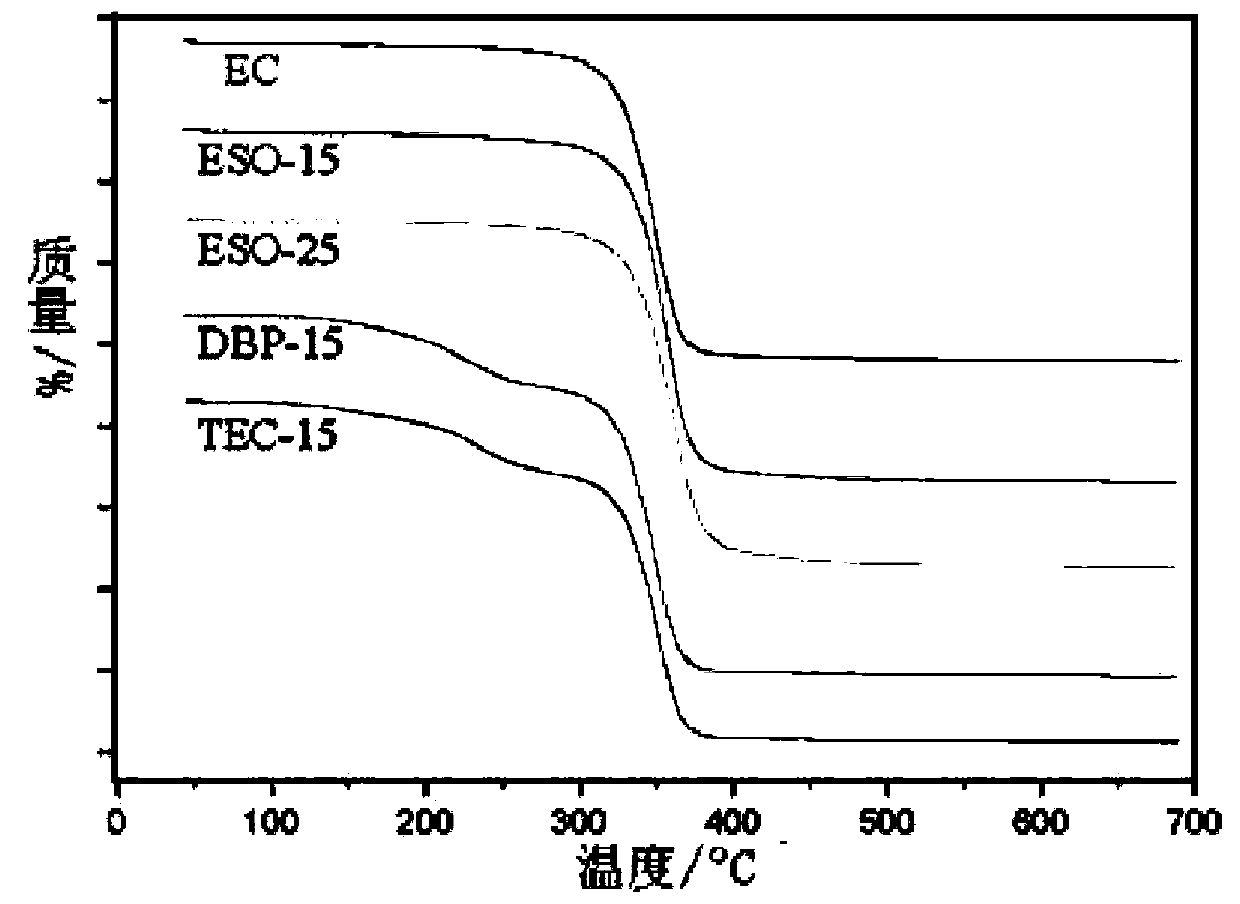

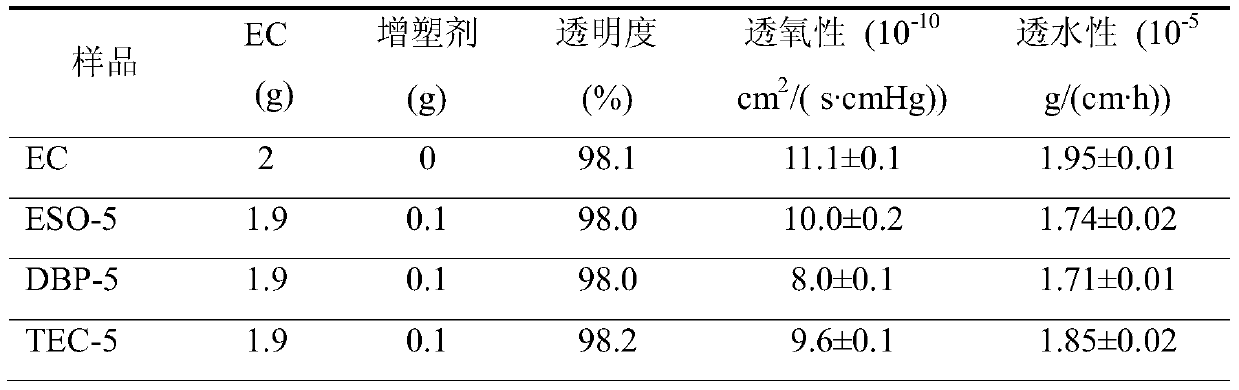

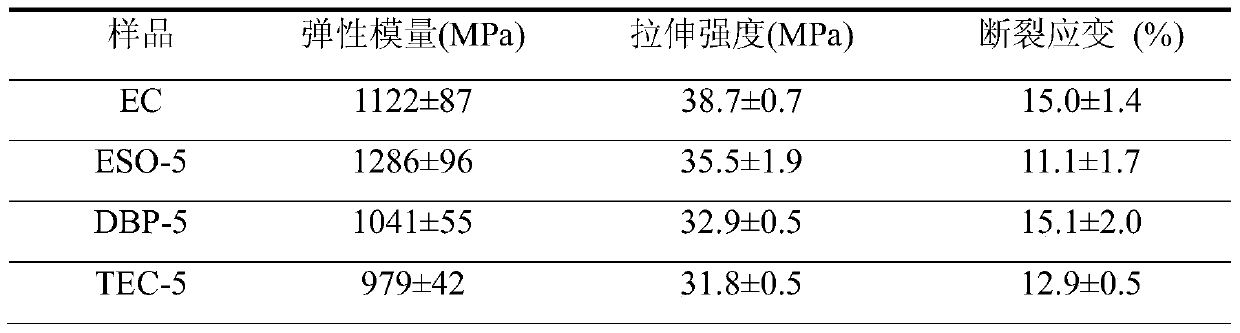

Epoxidized soybean oil plasticized ethyl cellulose membrane and method for preparing the same

The invention belongs to the technical field of natural polymer membrane materials and discloses an epoxidized soybean oil plasticized ethyl cellulose membrane and a method for preparing the same. The method comprises the steps of dissolving ethyl cellulose and epoxidized soybean oil in a solvent and obtaining a mixed solution after uniform mixing; pouring the mixed solution in a die to pour the mixed solution into the membrane, and obtaining the epoxidized soybean oil plasticized ethyl cellulose membrane. The membrane has good mechanical property, flexibility, folding resistance, breaking resistance, draining property, moisture resistance and oxygen resistance and does not burn, and can serve as a biodegradable membrane material and have wide application prospect in the fields of food preservation, packaging and medicines.

Owner:SOUTH CHINA UNIV OF TECH

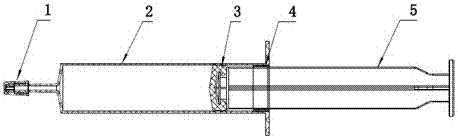

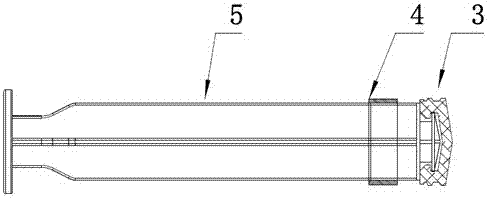

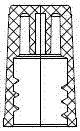

Pre-filled high-temperature sterilization syringe

PendingCN107469194AGuaranteed aseptic qualitySolving resource constraintsEnemata/irrigatorsIntravenous devicesInterference fitDrug injection

The invention belongs to the technical field of syringes, in particular suitable for a drug injection mode for animals, and discloses a pre-filled high-temperature sterilization syringe. The pre-filled high-temperature sterilization syringe comprises a tube cap, a needle tube, a push rod and a piston, wherein the part, near the handle end of the needle tube, of the needle tube is provided with a stop ring, and the front end of the needle tube is provided with an external thread; the tube cap is provided with an internal thread, and the tube cap and the needle tube are assembled through rotation of the threads; the outer diameter of the push rod is matched with the inner diameter of a handle, and the outer diameter of the piston and the inner diameter of the needle tube are in an interference fit for sealing; the stop ring is welded to the part, near the handle end of the needle tube, of the needle tube, and during assembly, the push rod runs through the inner hole of the handle and assembled with the piston so as to form a locking structure after assembly. According to the pre-filled high-temperature sterilization syringe, a filling machine is used to inject a certain amount of drug liquid through the top of the needle tube of the syringe, the tube cap and the needle tube are assembled through rotation of the threads so that sealing and locking can be achieved, and the syringe is delivered into a sterilization chamber for steam sterilization at a high temperature of 121 DEG C for 30 minutes.

Owner:石家庄鑫富达医药包装有限公司

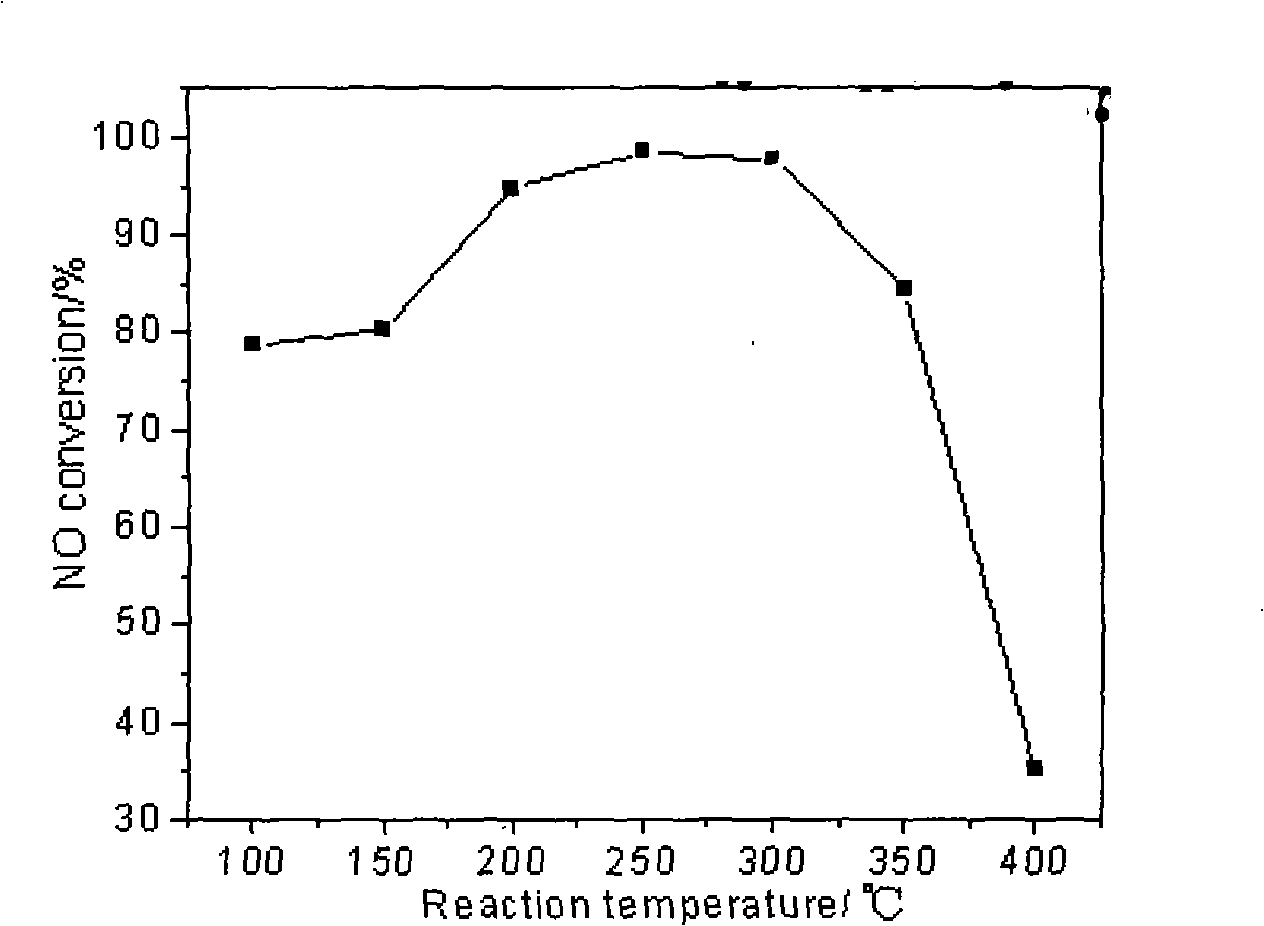

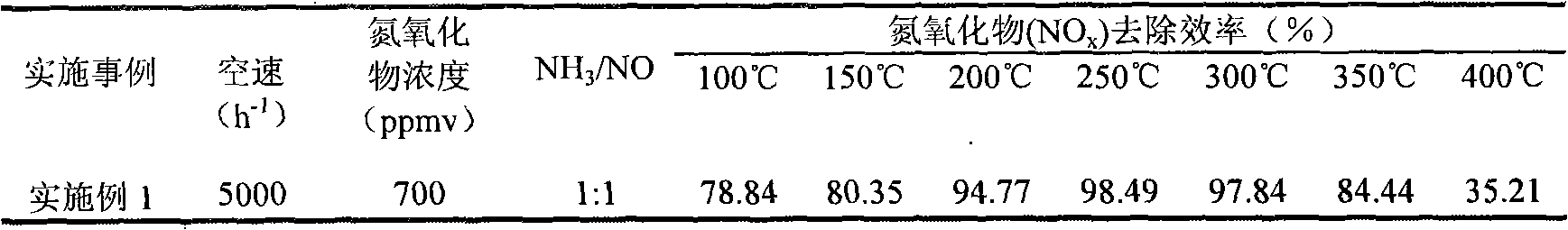

SCR flue gas denitration composite catalyst and preparation method thereof

ActiveCN101352678BGood chemical stabilityImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsTitanium zirconiumCerium

The invention relates to a compound catalyst for SCR flue gas denitration and a preparation method thereof, pertaining to the technical fields of environmental protection catalytic materials and atmosphere pollution controlling. The compound catalyst takes aluminum-based, titanium-based or zirconium-based ceramics as a carrier and titanium-zirconium-aluminum-cerium complex metal oxide as an active ingredient of the compound catalyst. The preparation method adopted includes: the aluminum-based, titanium-based or zirconium-based ceramics is impregnated in a titanium-zirconium-aluminum-cerium complex colloidal sol, and then dried and roasted to prepare compound catalyst active coatings. Compared with the prior art, the compound catalyst not only promotes the activity and the chemical stability of the catalyst and extends the temperature window of the catalytic activity, but also enhances the mechanical and thermal stability of a catalyst carrier, is environment protective and cheap without secondary pollution, prolongs the service life of the catalyst and lowers the load of the active ingredient.

Owner:NANJING TECH UNIV

Foamed HDPE plastic sheet

The invention relates to a foamed HDPE plastic sheet. The foamed HDPE plastic sheet comprises the following components in percentage by mass (%):70-80% of HDPE, 3-5% of PE foaming agent, 5-7% of white oil, 8-11% of ultraviolet absorber and 4-7% of antioxidant. A method for manufacturing the foamed HDPE plastic sheet comprises the following steps of stirring, drying and melting, carrying out mold stripping, setting and carrying out annealing treatment. The molded sheet has wide application range and has the advantages of ultraviolet resistance, no rot, no deformation, no color fading, insect pest repellence, wear resistance, water tightness, no cracks, no need of maintenance and the like. The preparation method of the foamed HDPE plastic sheet is simple in operation process and both time and labor are saved; and the prepared finished product has the advantages of relatively long service life and better application effects.

Owner:DANYANG CITY HENGDA PLASTIC

Load type ozone nanometer type reduction catalyst and manufacturing method thereof

ActiveCN101837295AGood water vapor resistanceAppropriate costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNano catalystActivated carbon

The invention relates to a reduction catalyst technology, in particular to a load type ozone nanometer type reduction catalyst and a manufacturing method thereof. The invention is characterized in that each kilogram of superfine or nano activated carbon is added with 27g-725g of manganous nitrate, 73g-590g of copper nitrate, 0.019g-0.093g of palladium nitrate and 650g-850g of deionized water, andthe mixture is dipped for 0.5 to 1 hour, dried in a constant temperature drying device, then roasted for certain time at set temperature and manufactured into the load type nano catalyst after being cooled.

Owner:NINGBO YOUMING ELECTRICAL APPLIANCE CO LTD

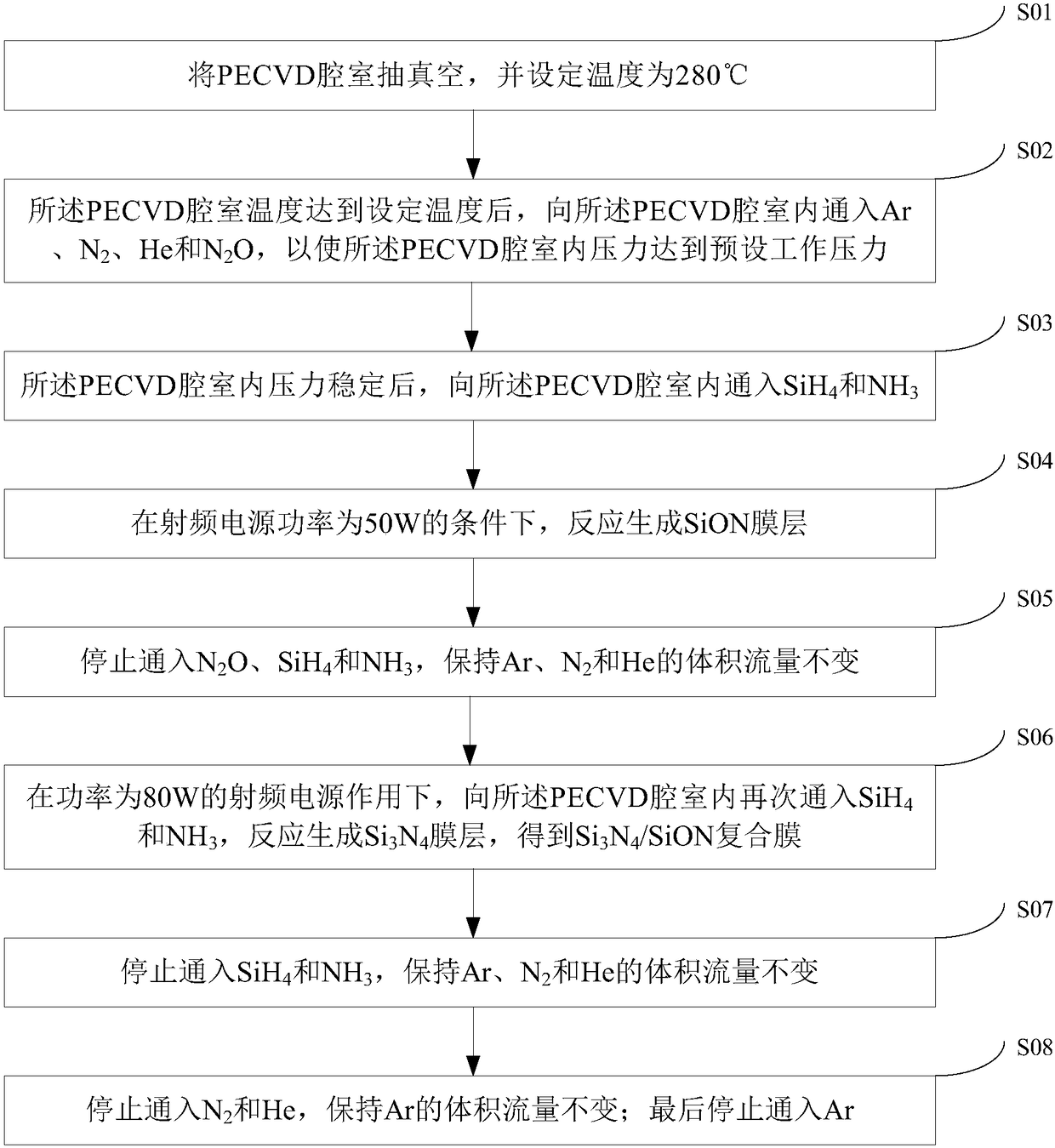

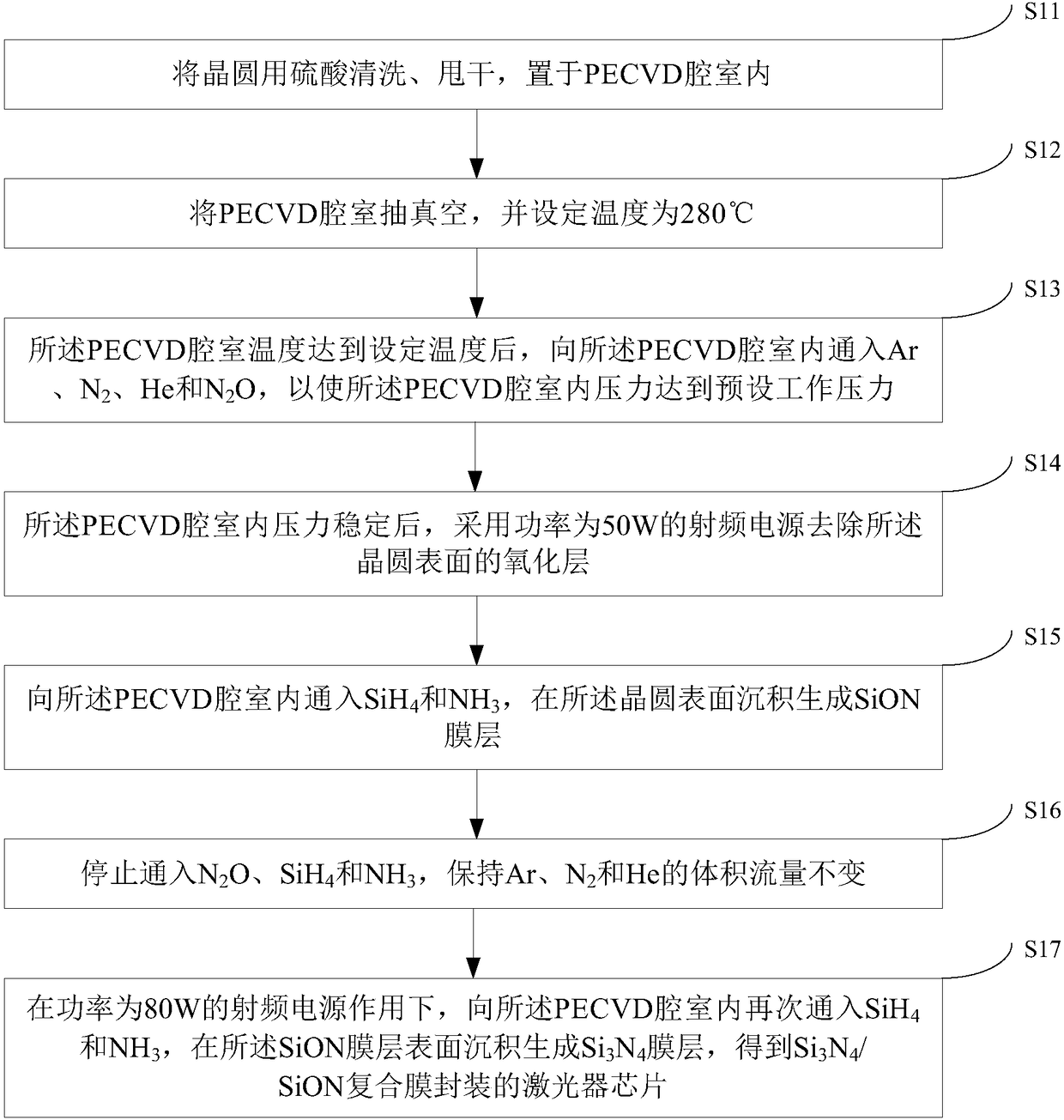

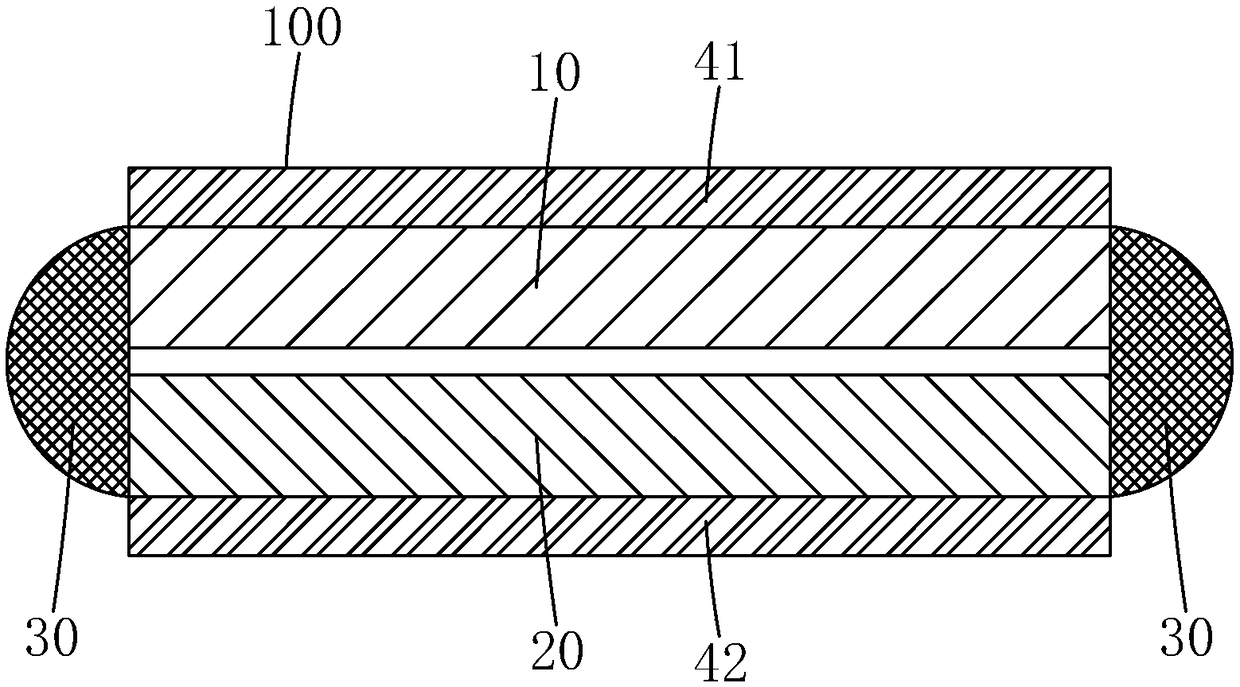

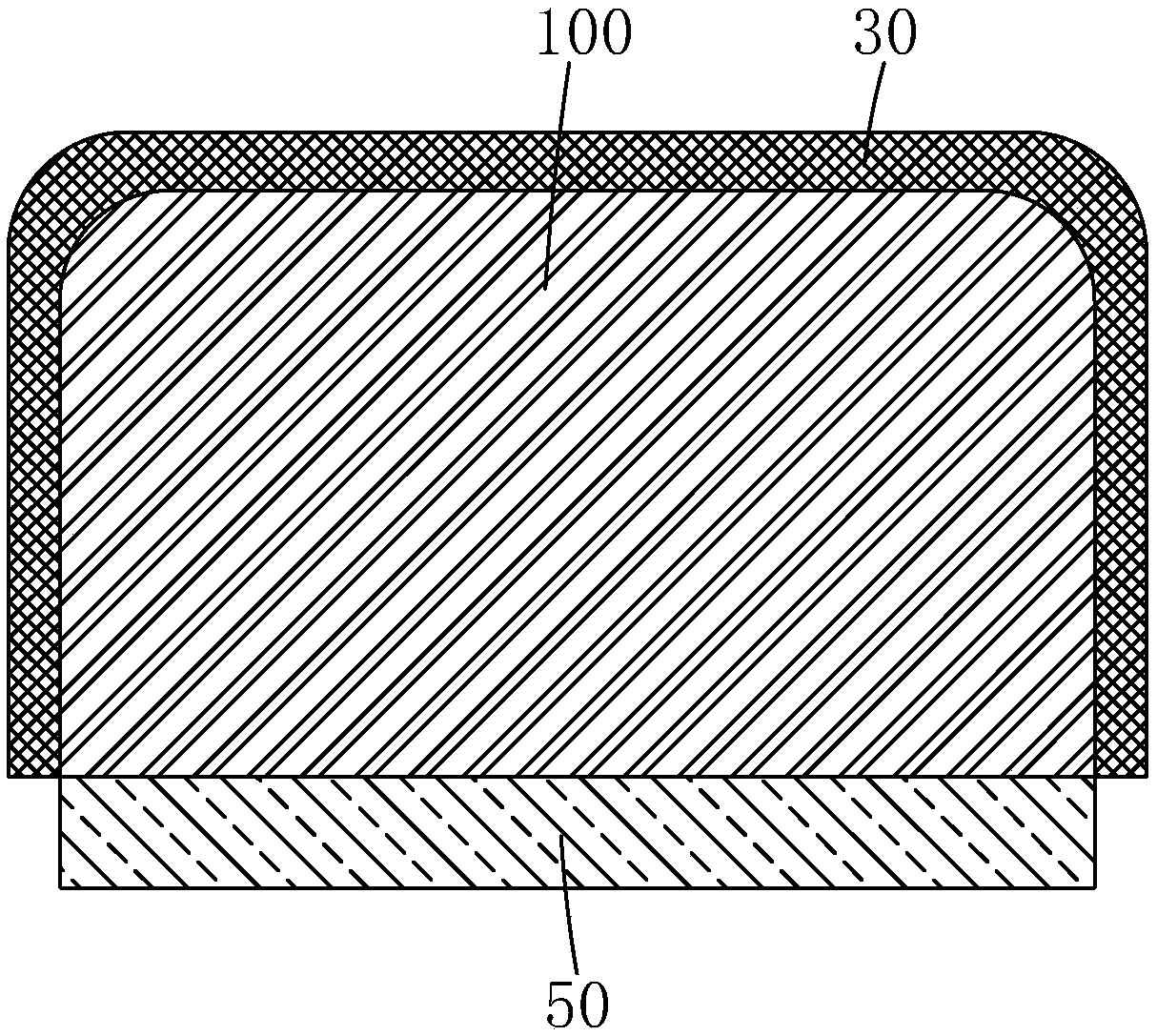

Si<3>N<4>/SiON composite film, laser chip and preparation method

InactiveCN108493760AReduce stress superposition effectGood water vapor resistanceLaser detailsSemiconductor lasersOptoelectronicsLow stress

The invention provides a Si<3>N<4> / SiON composite film, a laser chip and a preparation method. The film layer stress of a Si<3>N<4> film layer prepared by a PECVD method is negative stress, while thefilm layer stress of a SiON film layer prepared by the PECVD method is positive stress. By enabling the Si<3>N<4> film layer with negative stress to be compounded with the SiON film layer with positive stress, the Si<3>N<4> / SiON composite film with relatively low stress is formed, thereby lowering a stress overlaying effect in the chip preparation process; and in addition, the Si<3>N<4> film layerand the SiON film layer both have relatively high water vapor resistance performance, so that the prepared Si<3>N<4> / SiON composite film obtains both of water vapor resistance performance and low film stress performance, so that performance requirement of a high-speed laser chip is satisfied.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

Cold-resistant rubber tube using both peroxide ternary ethylene-propylene rubber and reclaimed rubber

ActiveCN102093638BSmall compression deformationImprove corrosion resistanceFlexible pipesThermal ageingCross-link

The invention relates to a cold-resistant rubber tube using both peroxide ternary ethylene-propylene rubber and a reclaimed rubber. The cold-resistant rubber tube comprises the following components: ternary ethylene-propylene rubber, ternary ethylene-propylene reclaimed rubber, zinc oxide, polyethylene glycol, stearic acid, an age resister SP-C, an age resister D, fast extruding carbon black N550, thermal cracking carbon black N990, china clay processed by a vinyl silane coupling agent, a plasticizer DOS, a coupling agent KBM-903, a cross-linking agent DCP and an auxiliary cross-linking agentVP-4. Compared with a sulfur vulcanizing system and a peroxide system which do not contain a reclaimed rubber tube, the formula of the cold-resistant rubber tube using both the peroxide ternary ethylene-propylene rubber and the reclaimed rubber has higher cold resistance, cooled liquid resistance, electric property resistance, ozone resistance and thermal ageing resistance, lower compression set,higher elongation, breaking strength and tearing strength and can better meet the requirements of a cooling system circulating water pipe and a connecting hose pipe which are used for a long time at a low temperature.

Owner:TIANJIN PENGYI GRP CO LTD

Modified polyphenyl ether-enhanced plastic

InactiveCN105802223AGood dimensional stabilityImprove insulation performanceLow-density polyethylenePolystyrene

The invention discloses modified polyphenyl ether-enhanced plastic, which is prepared from the following components in parts by mass: 50 parts of polyphenyl ether, 8-10 parts of glass fiber, 3-5 parts of polystyrene, 3-5 parts of a hydrogenated styrene-butadiene segmented copolymer, 2-3 parts of polybutadiene, 1-2 parts of low-density polyethylene and 1-2 parts of phenyl benzoyl carbinol. In the manner, the modified polyphenyl ether-enhanced plastic has the advantages of good dimensional stability, good electrical insulating property, wide using temperature range, good moisture resistance, high strength, high hardness, good rigidity, high impact strength, good corrosion resistance, good self-lubricating property, good solvent resistance, safety, practicability and the like, and has a wide market prospect in popularization of the modified polyphenyl ether-enhanced plastic.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

A kind of solar photovoltaic cell module transparent back plate composite film and preparation method thereof

ActiveCN105428445BGood weather resistanceImprove aging resistanceFinal product manufactureSynthetic resin layered productsComposite filmWeather resistance

The invention relates to the technical field of composite films, in particular to a composite film for a transparent back plate of a solar photovoltaic cell module and a preparation method thereof. The solar photovoltaic cell module transparent backboard composite film of the present invention comprises a first weather-resistant layer, a second weather-resistant layer and a base layer in sequence from top to bottom, and the first weather-resistant layer is a transparent weather-resistant PC film with a thickness of 25-100 μm; The second weather-resistant layer is a transparent weather-resistant PET film with a thickness of 150-300 μm; the base layer is a transparent linear low-density LLDPE film with a thickness of 50-150 μm. The present invention replaces the traditional PVDF film with a transparent weather-resistant PC film, which improves the weather resistance and light transmittance of the backboard it is applied to, not only reduces the cost, but also greatly reduces the environmental pollution caused by the fluorine film. EVA film has excellent adhesion.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

Side shading glue and borderless display device

ActiveCN106554650BHigh OD valueGood flexibilityNon-linear opticsElectrically-conductive paintsCross-linkPolymer science

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

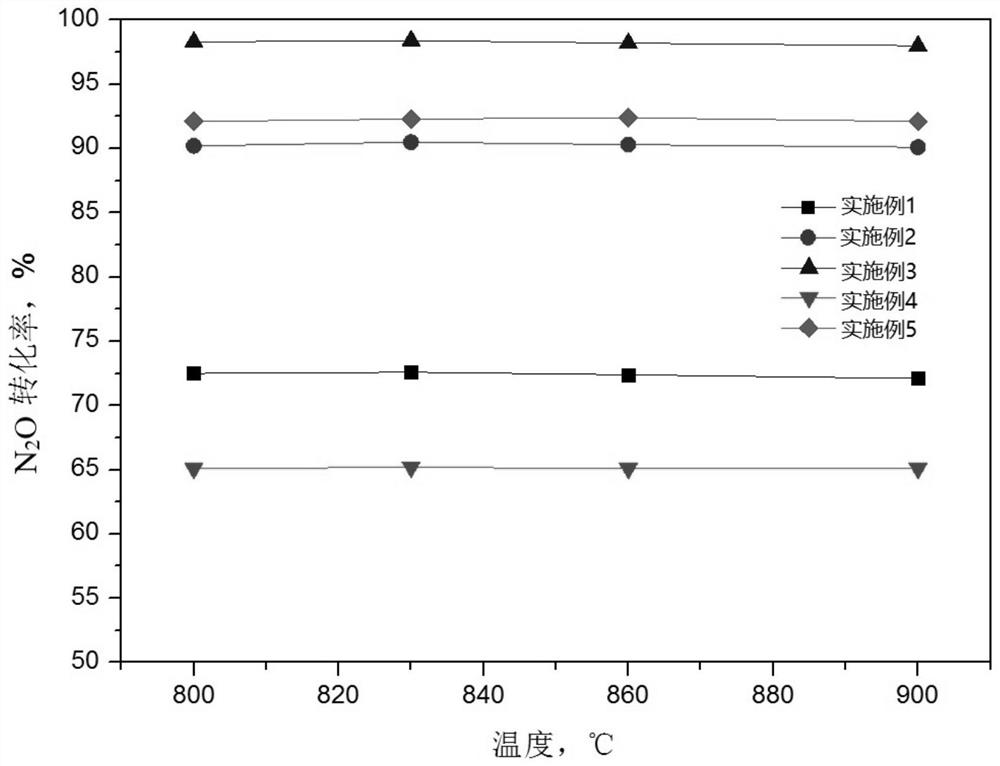

Preparation method of nitric acid industrial carbon emission reduction catalyst

PendingCN114160159AHigh activityImprove high temperature stabilityNitrous oxide captureHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

The invention discloses a preparation method of a nitric acid industrial carbon emission reduction catalyst. The method comprises the following steps: 1, dissolving an active component precursor and an auxiliary agent precursor in deionized water to obtain a transparent dipping solution; 2, adding the cerium dioxide powder into a dipping solution for dipping treatment, and drying to obtain a catalyst precursor; 3, uniformly mixing an adhesive, a pore forming agent and the catalyst precursor, adding water, kneading, and carrying out extrusion molding to obtain a catalyst blank; and 4, drying the catalyst blank, and roasting to obtain the nitric acid industrial carbon emission reduction catalyst. According to the present invention, the types and the proportions of the active components and the auxiliary agent are designed, and the roasting treatment process and the process parameters are controlled so as to obtain the catalyst with the relatively dispersed active components and the high crystallinity, such that the number of the effective active centers in the catalyst is increased so as to improve the activity of the catalyst, and the catalyst has better high-temperature stability and is suitable for N2O emission reduction in the nitric acid production process.

Owner:XIAN ORIGIN CHEM TECH

Ethylene-propylene-diene rubber thermal shrinkable tube and preparation method thereof

ActiveCN102030950BExcellent ozone resistanceGood weather resistanceRubber insulatorsHigh resistancePolymer science

The invention provides an ethylene-propylene-diene rubber thermal shrinkable tube to solve the problem that the conventional thermal shrinkable tube has low performance in the aspects of high-temperature resistance, oil resistance and solvent resistance and cannot meet the performance requirements of the industries such as automobiles, high-speed trains, military projects and aerospace on high oil resistance and high solvent resistance. The ethylene-propylene-diene rubber thermal shrinkable tube is made from the following materials: ethylene-propylene-diene rubber, thermal shrinkable resin and a reinforcing agent. The zinc oxide, zinc stearate, a softener and an age resister can be added selectively. When chemical crosslinking is adopted, a crosslinker is required. Meanwhile, the invention provides three methods for producing the thermal shrinkable tubes from the materials, namely a two-step mixing electronic crosslinking method, a one-step mixing electronic crosslinking method and a chemical crosslinking method. The ethylene-propylene-diene rubber thermal shrinkable tube provided by the invention has high ozone resistance, weather-aging resistance, high heat resistance, high vapor resistance, high electric insulation and high chemical medium resistance and can be applied in the connector protection and sealing of power supply lines.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

A chloride absorbent

InactiveCN100464837CImprove performanceGood water vapor resistanceOther chemical processesDispersed particle separationAlkaline earth metalSorbent

The invention relates to the chlorine hydride adsorbent, which takes the metallic compounds and the mineral as main materials, and is prepared by roasting under the temperature between 350-800 DEG C, the invention is characterized in that the metallic compounds are composed of the alkali metal and / or alkaline earth metal compounds and transition metal oxide, the content of transition metal oxide is eight percent to twenty five percent according to the weight percentage; the compressive strength of chlorine hydride adsorbent is more than 80N / cm, breakthrough chlorine content is more than forty eight percent under the temperature of 500 DEG C. The chlorine hydride adsorbent of the invention has advantages of wide range of temperature suitability, good purifying degree, high chloride capacity, excellent water tolerance performance and high mechanical strength.

Owner:EAST CHINA UNIV OF SCI & TECH

Rigid polyurethane foam culture stone and production method thereof

InactiveCN101649674BHigh closed cell rateLow thermal conductivityCovering/liningsNatural patternsThermal insulationEngineering

The invention aims at the shortcomings that the current culture stones are heavy in weight, high in cost or poor in thermal insulation properties and have poor bondability with the building blocks, masonries and the like, are easily spalled, have short service lives and the like, and provides a rigid polyurethane foam (RPUF) culture stone and a production method thereof. The RPUF product with good bondability, good thermal insulation property, light materials and long service life is obtained by improving the culture stone raw materials, production steps and technological conditions, which issuitable for the indoor and outdoor decoration in various environments.

Owner:宿迁特力新材料有限公司

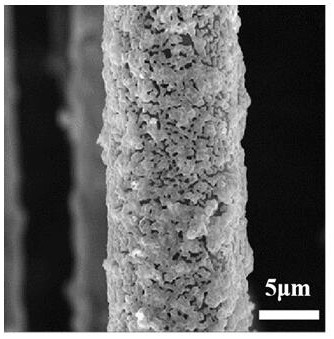

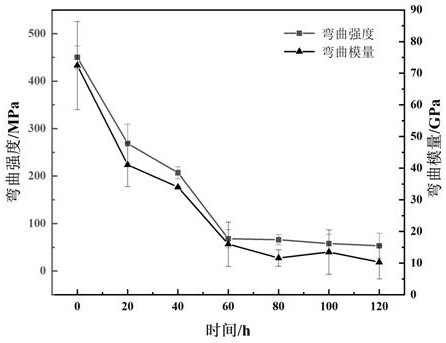

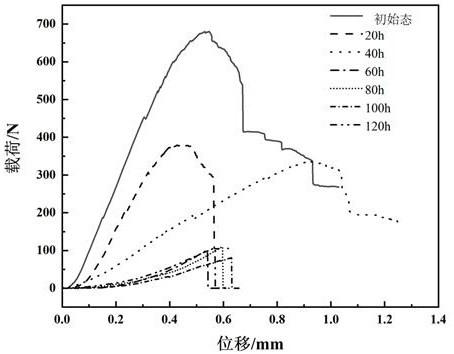

A kind of preparation method of novel interfacial phase material

ActiveCN113248266BGood high temperature resistance and oxidation resistanceExtended service lifeO-Phosphoric AcidPhosphate

The invention provides a preparation method of a novel interface phase material, comprising: preparing silica sol, and using RE 3+ Soluble nitrate and citric acid were used to prepare a citrate stock solution, and the citrate stock solution and phosphoric acid solution were mixed to obtain a mixed solution; the SiC fiber was pretreated; the pretreated SiC fiber was immersed in the prepared silica sol, and passed After impregnation, coating, and drying, keep the temperature in a vacuum furnace for 1 hour to obtain a surface with SiO 2 Coated SiC fibers; will have SiO 2 The coated SiC fiber is placed in the prepared mixed solution, kept in a constant temperature water bath for a period of time, washed, dried, and subjected to the first heat treatment under the protection of an inert gas. 2 A rare earth phosphate coating is formed on the surface of the coating; then the prepared sample is subjected to a second heat treatment under the protection of an inert gas to form an interface phase with a rare earth pyrosilicate coating on the surface of the SiC fiber.

Owner:NAT UNIV OF DEFENSE TECH

Formula and production process for high-temperature-resistant conveyor belt

InactiveCN105315559ALow water absorptionReduce coefficient of frictionConveyorsHeat resistanceActive agent

The invention provides a formula and a production process for a high-temperature-resistant conveyor belt. The conveyor belt is prepared by adding the following material components into surface rubber: 100% of EPDM rubber, 2 to 5% of a vulcanizing agent, 0.2 to 0.7% of a promoter, 5 to 9% of an active agent, 1 to 5% of an antiaging agent, 4 to 55% of a reinforcing agent, 10 to 20% of a softening agent, 20 to 50% of aluminum silicate, 4 to 5% of polyamide and about 3% of other material components. According to the invention, due to the selection of the heat-resistant material EPDM rubber and the addition of aluminum silicate and polyamide in the surface rubber of the high-temperature-resistant conveyor belt, heat resistance of the rubber is improved; heat-insulating effect is exerted to the surface rubber and cloth; the temperature of the cloth can be protected from improving, so foaming between the cloth and the rubber is prevented from occurrence, and the conveyor belt can be still used; heat insulation is improved; service life is prolonged; and work efficiency is increased.

Owner:江苏天丰橡塑制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com