Si<3>N<4>/SiON composite film, laser chip and preparation method

A composite film and laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problem that the passivation film layer cannot meet the performance requirements of high-speed laser chips, and achieve the reduction of stress superposition effect, low film layer stress performance, The effect of meeting performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

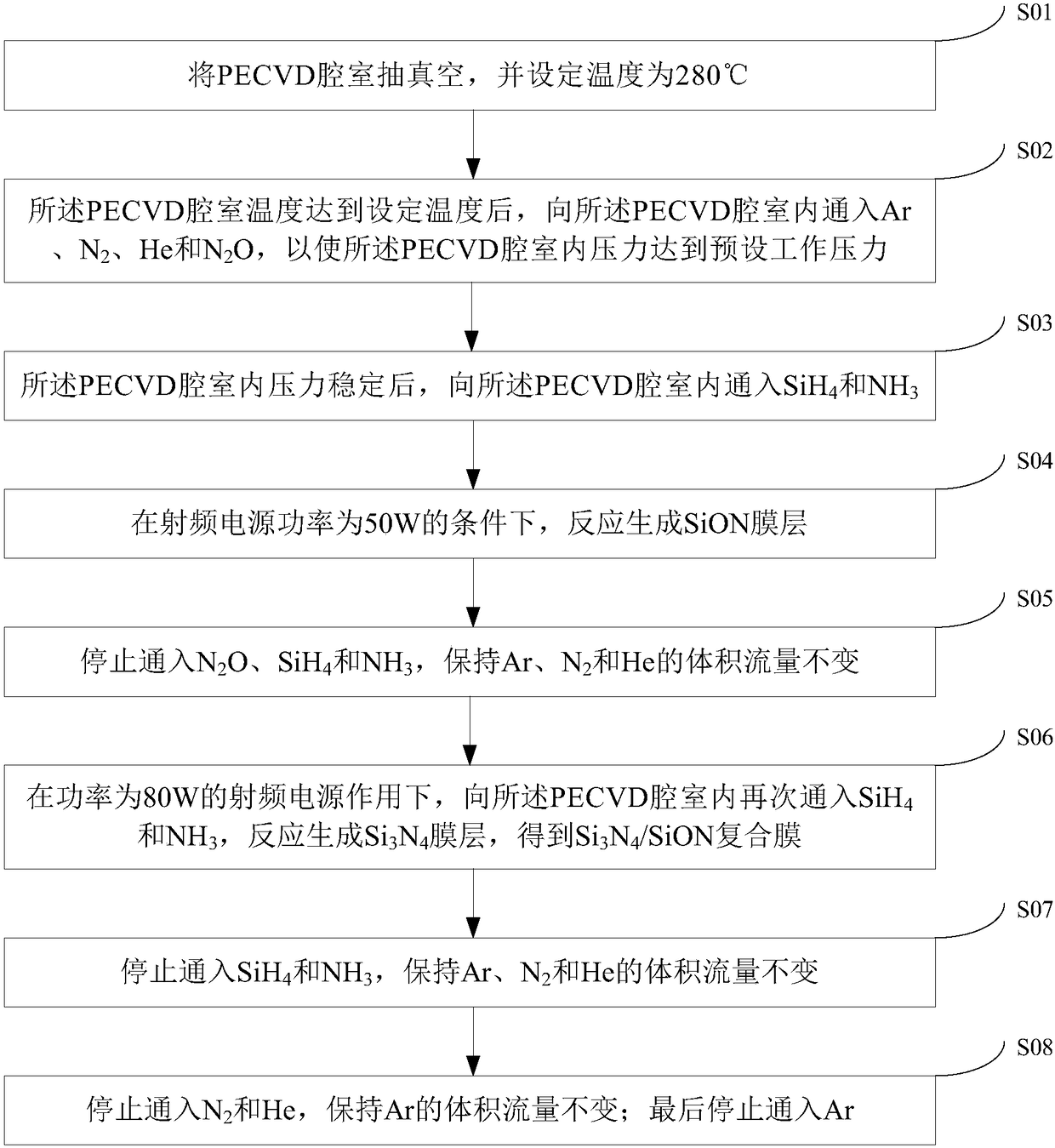

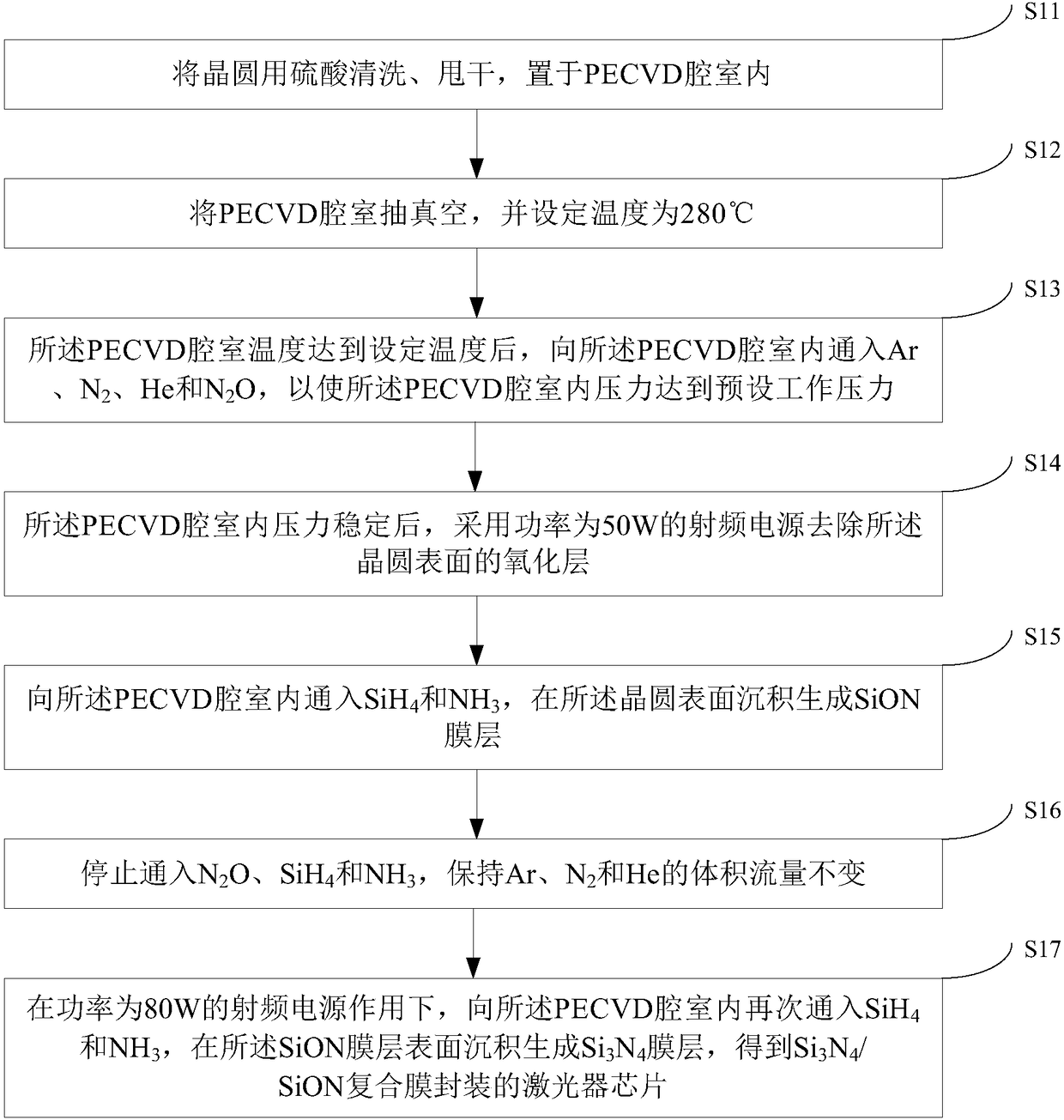

Method used

Image

Examples

Embodiment Construction

[0037]Although PECVD has the advantages of low substrate temperature, good film quality, and fewer pinholes, the passivation film formed by PECVD has a certain film stress, and the greater the thickness of the passivation film, the greater the film stress. Big. When the thickness of the passivation film is relatively thick, the passivation film is easy to crack and fall off, so that the passivation film cannot meet the performance requirements of the laser chip, which in turn leads to failure of the laser chip. However, if the passivation film formed by PECVD is thinner, its water vapor resistance will be poorer, which will cause the laser chip to be easily immersed in water, which will lead to its failure. It can be seen that the water vapor resistance and film stress performance of the passivation film are related to the thickness of the passivation film, and the greater the thickness of the passivation film, the better the water vapor resistance and the greater the film str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com