Formula and production process for high-temperature-resistant conveyor belt

A production process and conveyor belt technology, applied in the formulation and production process of high-temperature-resistant conveyor belts, can solve problems such as low production efficiency, foaming, and high cost of high-temperature-resistant conveyor belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

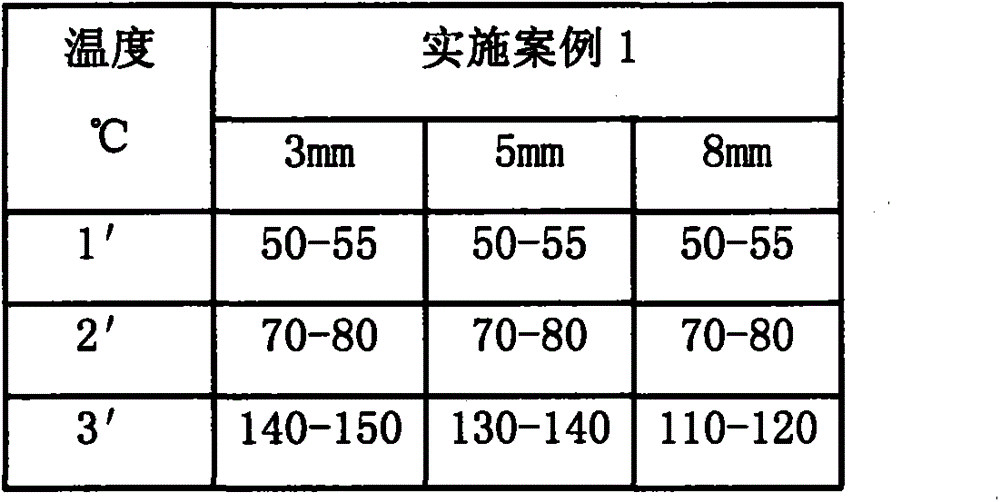

Embodiment example 1

[0025] A high temperature resistant conveyor belt, the surface rubber of the conveyor belt is added with the following material components: 100% EPDM rubber, 3% vulcanizing agent, 0.5% accelerator, 7% active agent, 2% anti-aging agent, 50% reinforcing agent , 20% softener, 20% aluminum silicate, 5% macroamide, and about 3% others.

[0026] Experimental equipment: calender standard 6 o'clock, 400*400*2 electric heating small plate, far infrared thermometer, Φ40 steel ball and bracket, etc.

[0027] Process flow:

[0028] 1. Mixing: After the rubber is masticated, the above-mentioned materials are weighed in proportion and mixed with the rubber after mastication;

[0029] 2. The middle layer: remove the dust from the canvas bristles, after drying, wipe the rubber layer by layer with the kneaded rubber, cool and coil, and then guide the tape to shape;

[0030] 3. Embryo making: extrude the rubber edge glue mixed in step 1, and use the film calendering as the upper covering glue...

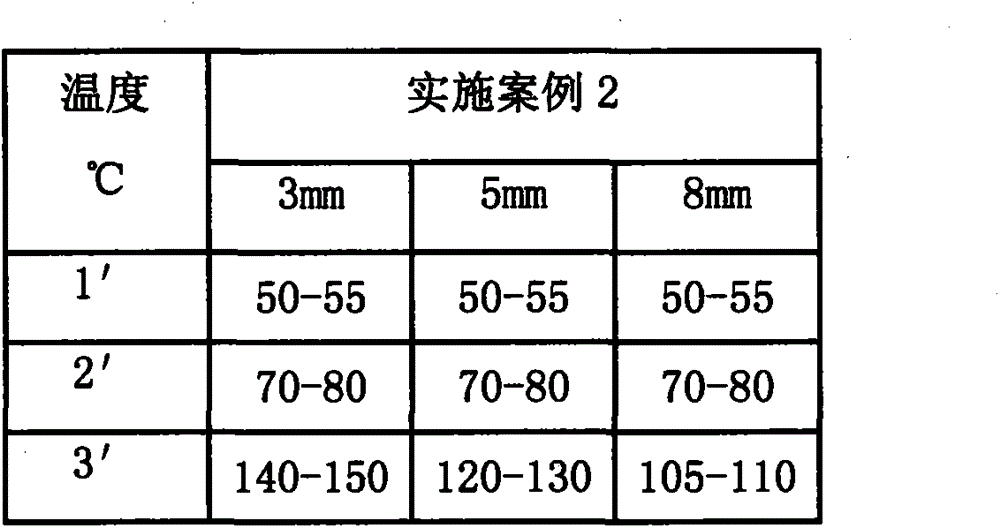

Embodiment example 2

[0039] A high temperature resistant conveyor belt, the surface rubber of the conveyor belt is added with the following material components: 100% EPDM rubber, 3% vulcanizing agent, 0.5% accelerator, 7% active agent, 2% anti-aging agent, 50% reinforcing agent , 20% softener, 30% aluminum silicate, 5% macroamide, and about 3% others.

[0040] Test equipment and instruments: calender standard 6 o'clock, 400*400*2 small electric heating plate, far infrared thermometer, Φ40 steel ball and bracket, etc.

[0041] Process flow:

[0042] 1. Mixing: After the rubber is masticated, the above-mentioned materials are weighed in proportion and mixed with the rubber after mastication;

[0043] 2. The middle layer: remove the dust from the canvas bristles, after drying, wipe the rubber layer by layer with the kneaded rubber, cool and coil, and then guide the tape to shape;

[0044] 3. Embryo making: extrude the rubber edge glue mixed in step 1, and use the film calendering as the upper cover...

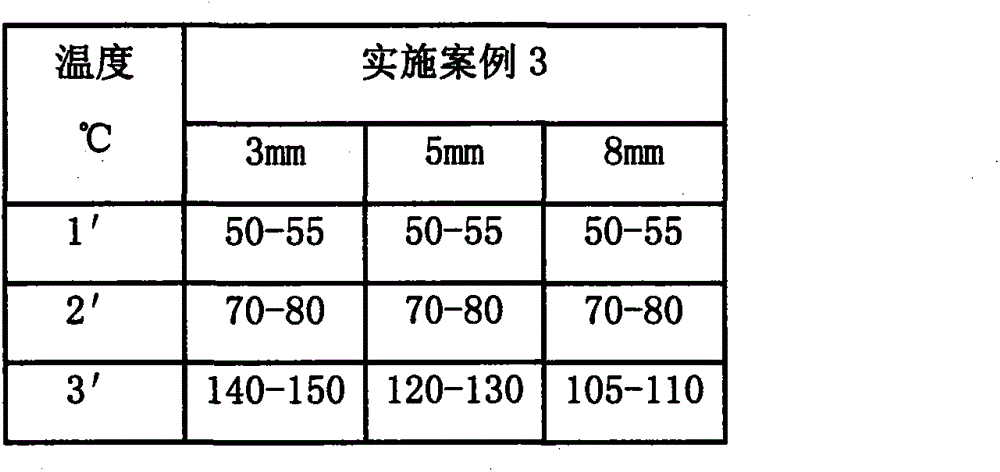

Embodiment example 3

[0053] A high temperature resistant conveyor belt, the surface rubber of the conveyor belt is added with the following material components: 100% EPDM rubber, 3% vulcanizing agent, 0.5% accelerator, 7% active agent, 2% anti-aging agent, 50% reinforcing agent , 20% softener, 40% aluminum silicate, 5% macroamide, and about 3% others.

[0054] Test equipment and instruments: calender standard 6 o'clock, 400*400*2 small electric heating plate, far infrared thermometer, Φ40 steel ball and bracket, etc.

[0055] Process flow:

[0056] 1. Mixing: After the rubber is masticated, the above-mentioned materials are weighed in proportion and mixed with the rubber after mastication;

[0057] 2. The middle layer: remove the dust from the canvas bristles, after drying, wipe the rubber layer by layer with the kneaded rubber, cool and coil, and then guide the tape to shape;

[0058] 3. Embryo making: extrude the rubber edge glue mixed in step 1, and use the film calendering as the upper cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com