A kind of preparation method of novel interfacial phase material

A technology of interfacial phase and composite materials, which is applied in the field of preparation of new interfacial phase materials, can solve the problems of poor oxidation resistance and inability to apply high-temperature water vapor and high-speed gas environments, etc., to achieve extended service life and good high temperature and oxidation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a high-temperature-resistant and anti-oxidation novel interface phase material, comprising the following steps:

[0034] Step 1: Degumming the SiC fiber preform at a temperature of 500-700° C. and nitrogen atmosphere for 0.5-1 hour.

[0035]Step 2. Mix ethyl orthosilicate and absolute ethanol in a ratio of 17:12 by volume under a magnetic heating stirrer, then add the mixture of dilute hydrochloric acid and deionized water drop by drop, and continue to stir at a constant temperature for two Hours, a stable, transparent silica sol was obtained.

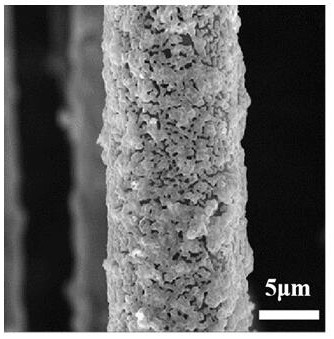

[0036] Step 3: Add an appropriate amount of SiC fibers treated in step 1 to the silica sol, impregnate, coat, and dry, and then keep it in a vacuum furnace at a constant temperature of 300~500°C for 1 hour to obtain a uniform SiO on the surface. 2 coated SiC fibers.

[0037] Step 4: Take 322.82g of concentrated phosphoric acid, add deionized water to dilute, and use a 500mL volumetric flask to constant v...

Embodiment 2

[0045] A method for preparing a high-temperature-resistant and anti-oxidation novel interface phase material, comprising the following steps:

[0046] Step 1: Degumming the SiC fiber preform at a temperature of 500-700° C. and nitrogen atmosphere for 0.5-1 hour.

[0047] Step 2. Mix ethyl orthosilicate and absolute ethanol in a ratio of 17:12 by volume under a magnetic heating stirrer, then add the mixture of dilute hydrochloric acid and deionized water drop by drop, and continue to stir at a constant temperature for two Hours, a stable, transparent silica sol was obtained.

[0048] Step 3: Add an appropriate amount of SiC fibers treated in step 1 to the silica sol, impregnate, coat, and dry, and then keep it in a vacuum furnace at a constant temperature of 300~500°C for 1 hour to obtain a uniform SiO on the surface. 2 coated SiC fibers.

[0049] Step 4: Take 322.82g of concentrated phosphoric acid, add deionized water to dilute, and use a 500mL volumetric flask to constant ...

Embodiment 3

[0057] A method for preparing a high-temperature-resistant and anti-oxidation novel interface phase material, comprising the following steps:

[0058] Step 1: Degumming the SiC fiber preform at a temperature of 500-700° C. and nitrogen atmosphere for 0.5-1 hour.

[0059] Step 2. Mix ethyl orthosilicate and absolute ethanol in a ratio of 17:12 by volume under a magnetic heating stirrer, then add the mixture of dilute hydrochloric acid and deionized water drop by drop, and continue to stir at a constant temperature for two Hours, a stable, transparent silica sol was obtained.

[0060] Step 3: Add an appropriate amount of SiC fibers treated in step 1 to the silica sol, impregnate, coat, and dry, and then keep it in a vacuum furnace at a constant temperature of 300~500°C for 1 hour to obtain a uniform SiO on the surface. 2 coated SiC fibers.

[0061] Step 4: Take 322.82g of concentrated phosphoric acid, add deionized water to dilute, and use a 500mL volumetric flask to constant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com