a kind of mosi 2 / al 2 o 3 High temperature resistant microwave absorbing material, preparation method and application thereof

A microwave-absorbing material and high-temperature-resistant technology, which is applied in the field of chemical material preparation, can solve problems such as high ductile-brittle transition temperature, high proportion of non-metallic bonds, and insufficient creep strength, and achieve good high-temperature resistance and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

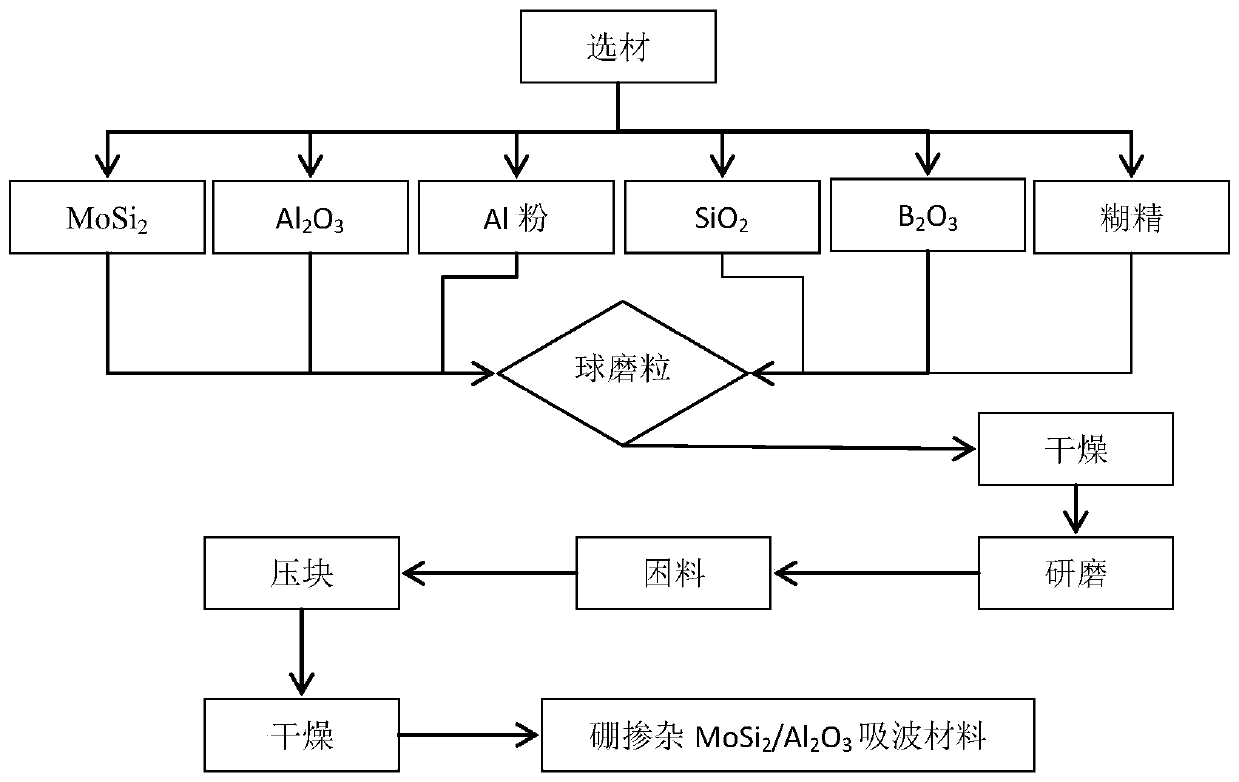

[0026] Select MoSi 2 , Al 2 o 3 , Al powder and SiO 2 As raw material, dextrin as binder, B 2 o 3 As a sintering aid, MoSi with a content of 6wt.% is selected in terms of mass percentage 2 , 35wt.% SiO 2 , 26wt.% Al powder, 15wt.% Al 2 o 3 , 8wt.% dextrin and 10wt.% B 2 o 3 , adding absolute ethanol and mechanically grinding for 8.5 hours with a full-range fine powder ball mill, the ball milling speed is 350rpm, to obtain a mixed slurry;

[0027] Place the mixed slurry in a constant temperature electric drying oven at 80°C to dry for 48 hours until it becomes a mixed powder;

[0028] Grind the mixed powder obtained by drying the slurry for 4 hours with an agate mortar, then add an appropriate amount of deionized water and stir evenly for 4 hours;

[0029] Use a hydraulic pressure testing machine to make a size of 250MPa on the press For the cylindrical sample, put the cylindrical sample in a constant temperature electric drying oven at 80°C for 48 hours;

[003...

Embodiment 2

[0033] Select MoSi 2 , Al 2 o 3 , Al powder and SiO 2 As raw material, dextrin as binder, B 2 o 3 As a sintering aid, MoSi with a content of 16wt.% is selected in terms of mass percentage 2 , 25wt.% SiO 2 , 21wt.% Al powder, 20wt.% Al 2 o 3 , 9wt.% dextrin and 9wt.% B 2 o 3 , adding absolute ethanol and mechanically grinding for 10 hours with a full-range fine powder ball mill, the ball milling speed is 350rpm, to obtain a mixed slurry;

[0034] Place the mixed slurry in a constant temperature electric drying oven at 80°C to dry for 48 hours until it becomes a mixed powder;

[0035] Grind the mixed powder obtained by drying the slurry for 4 hours with an agate mortar, then add an appropriate amount of deionized water and stir evenly for 4 hours;

[0036] Use a hydraulic pressure testing machine to make a size of 250MPa on the press For the cylindrical sample, put the cylindrical sample in a constant temperature electric drying oven at 80°C for 48 hours;

[0037...

Embodiment 3

[0040] Select MoSi 2 , Al 2 o 3 , Al powder and SiO 2 As raw material, dextrin as binder, B 2 o 3 As a sintering aid, MoSi with a content of 24wt.% is selected in terms of mass percentage 2 , 15wt.% SiO 2 , 17wt.% Al powder, 25wt.% Al 2 o 3 , 9wt.% dextrin and 10wt.% B 2 o 3 , adding absolute ethanol and mechanically grinding with a full-range fine powder ball mill for 8 hours, the ball milling speed is 350rpm, to obtain a mixed slurry;

[0041] Place the mixed slurry in a constant temperature electric drying oven at 80°C to dry for 48 hours until it becomes a mixed powder;

[0042] Grind the mixed powder obtained by drying the slurry for 4 hours with an agate mortar, then add an appropriate amount of deionized water and stir evenly for 4 hours;

[0043] Use a hydraulic pressure testing machine to make a size of 250MPa on the press For the cylindrical sample, put the cylindrical sample in a constant temperature electric drying oven at 80°C for 48 hours;

[0044...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com