A carbon fiber surface hfzrb 2 The preparation method of -sibnc composite coating

A composite coating and surface coating technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problem of not being suitable for preparing dense interfacial phase coating on the surface of fibers, not suitable for uniform coating on the surface of multi-dimensional fibers, difficult Problems such as industrial production, to achieve the effect of improving interface compatibility, reducing equipment requirements, and being easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

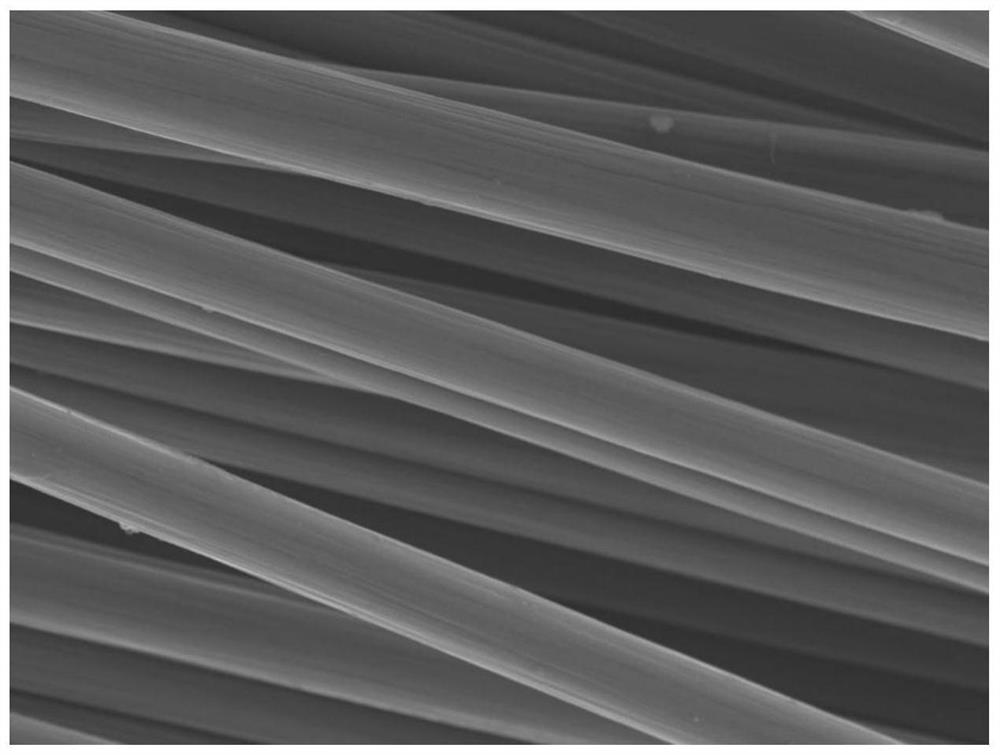

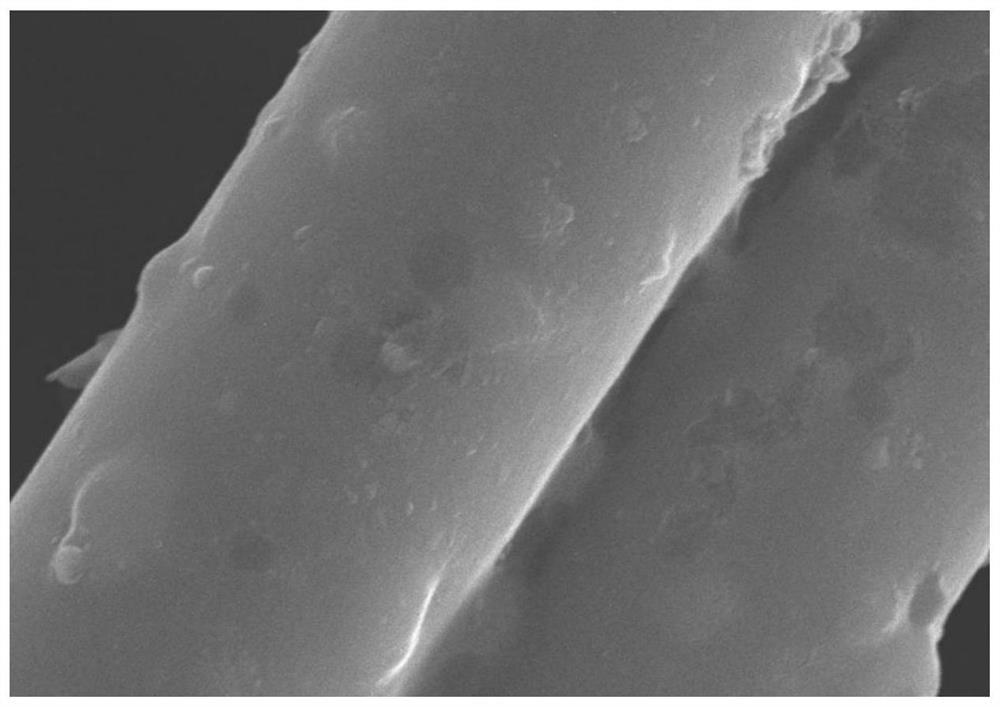

[0040] A carbon fiber surface HfZrB 2 -The preparation method of SiBNC composite coating, it comprises the following steps:

[0041] Use polyvinyl alcohol and deionized water as solvents, and prepare a polyvinyl alcohol solution with a concentration of 1mol / L under the condition of heating and stirring at 85°C; dissolve boric acid in deionized water and prepare a concentration of It is a boric acid solution of 0.6mol / L; the precursor raw materials of hafnium oxychloride octahydrate and zirconium oxychloride octahydrate are fully dissolved in deionized water, and ammonia water is added dropwise to the above solution while stirring at room temperature to form a white flocculent precipitate (pH =9.5), the above-mentioned white precipitate was centrifugally washed 4 times with deionized water, and then the white precipitate was dissolved in nitric acid (pH=1.5), to obtain a zirconium doped with a zirconium doping concentration of 50mol% and an ion concentration of 0.5mol / L. Misce...

Embodiment 2

[0043] Submerge the carbon fiber in the coating solution and ultrasonically immerse it for 45 minutes to obtain the coated carbon fiber. The rest of the process steps and conditions are the same as in Example 1.

[0044] Obtain coated with HfZrB through the above steps 2 - SiBNC-coated carbon fibers with a coating thickness of approximately 0.74 μm.

Embodiment 3

[0046] The treated carbon fibers were immersed in the coating solution, ultrasonically impregnated for 100 minutes, kept at 1250° C. for 3 hours and cooled in a furnace. The rest of the process steps and conditions were the same as in Example 1.

[0047] Obtain coated with HfZrB through the above steps 2 - SiBNC-coated carbon fibers with a coating thickness of approximately 1.63 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com