A kind of preparation method of high temperature resistance and anti-oxidation heat conduction carbon fiber/silicon carbide composite material

A composite material and carbon fiber technology, which is applied in the field of preparation of high-temperature resistant and oxidation-resistant thermally conductive carbon fiber/silicon carbide composite materials, can solve the problems of weak interaction and low thermal conductivity, and achieve simple methods, enhanced thermal conductivity, excellent high resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

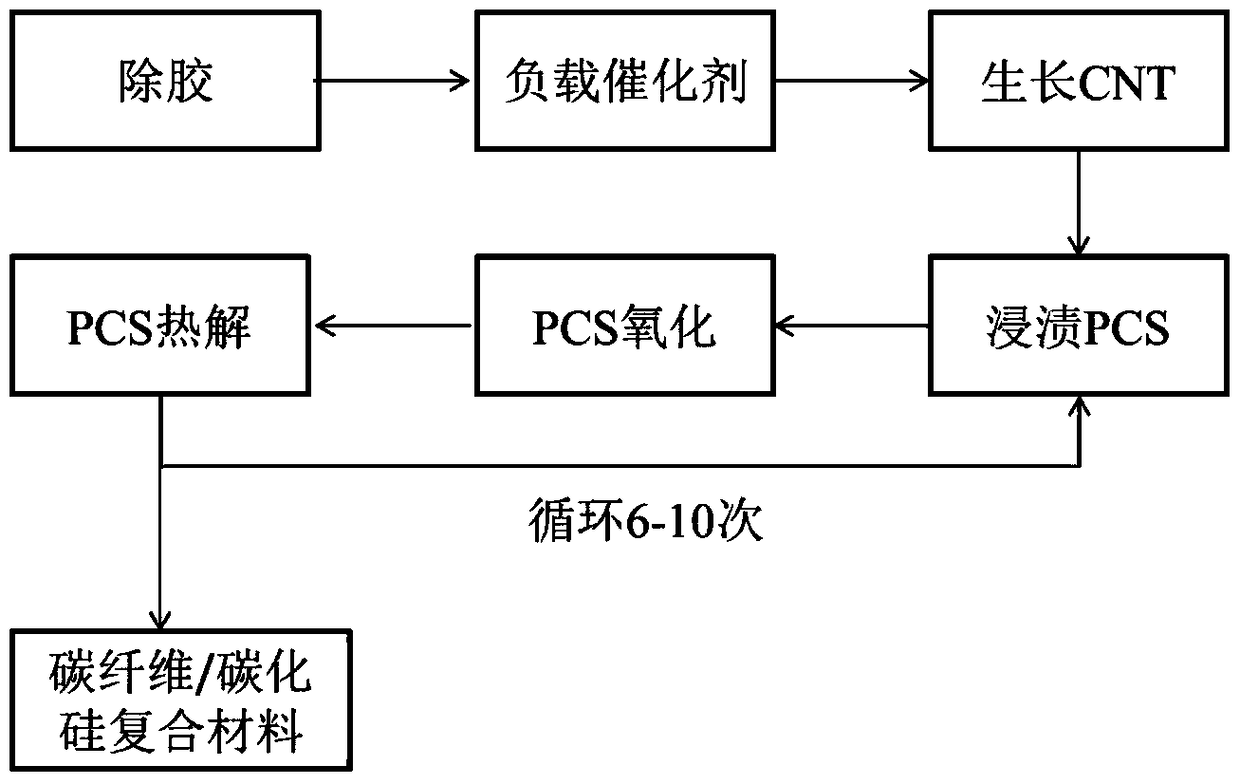

Method used

Image

Examples

Embodiment 1

[0032] After cleaning and drying the carbon fiber fabric, place it in a tube furnace, raise the temperature to 700°C at a rate of 5°C / min in an Ar atmosphere, and keep the temperature constant for 0.5h to remove the polymer coating on the surface of the carbon fiber fabric when it leaves the factory. Soak the degummed carbon fiber fabric in 0.05mol / L Fe(NO 3 ) 3 in solution. After soaking for 0.5h, take it out and dry it. The catalyst-loaded carbon fibers were placed in a tube furnace. Argon was introduced (the flow rate was 200 sccm), and the temperature was raised to 400° C. at a rate of 5° C. / min. Reduce the flow of Ar to 100sccm and feed H at the same time 2(The flow rate is 200 sccm). After 10 minutes, increase the Ar flow rate to 350 sccm and decrease the H 2 The flow rate is 20 sccm. The temperature was raised to 750°C at a rate of 5°C / min. The carbon source (ethanol:xylene = 1:1) was introduced, the injection speed was 20ml / h, and the growth time was 10min. Tu...

Embodiment 2

[0034] After cleaning and drying the carbon fiber fabric, place it in a tube furnace, raise the temperature to 750°C at a rate of 10°C / min in an Ar atmosphere, and keep the temperature for 1h to remove the polymer coating on the surface of the carbon fiber fabric when it leaves the factory. Soak the degummed carbon fiber fabric in 0.1mol / L Fe(NO 3 ) 3 in solution. After soaking for 1 hour, take it out and dry it. The catalyst-loaded carbon fibers were arranged in a tube furnace. Argon was introduced (the flow rate was 300 sccm), and the temperature was raised to 450° C. at a rate of 10° C. / min. Reduce the Ar flow rate to 150 sccm and feed H at the same time 2 (The flow rate is 250 sccm). After 20min, increase the Ar flow to 380sccm and decrease the H 2 The flow rate is 35 sccm. The temperature was raised to 800°C at a rate of 10°C / min. The carbon source (ethanol:xylene = 1:1) was introduced, the injection speed was 20ml / h, and the growth time was 30min. Turn off H aft...

Embodiment 3

[0036] After cleaning and drying the carbon fiber fabric, place it in a tube furnace, raise the temperature to 800°C at a rate of 15°C / min under an Ar atmosphere, and keep the temperature constant for 2 hours to remove the polymer coating on the surface of the carbon fiber fabric when it leaves the factory. Soak the degummed carbon fiber fabric in 0.3mol / L Fe(NO 3 ) 3 in solution. After soaking for 2 hours, take it out and dry it. The catalyst-loaded carbon fibers were placed in a tube furnace. Argon was introduced (the flow rate was 400 sccm), and the temperature was raised to 500° C. at a rate of 15° C. / min. Reduce the flow of Ar to 200sccm and feed H at the same time 2 (The flow rate is 300 sccm). After 30 minutes, increase the Ar flow rate to 400 sccm and decrease the H 2 The flow rate is 50 sccm. The temperature was raised to 850°C at a rate of 15°C / min. The carbon source (ethanol:xylene = 1:1) was introduced, the injection speed was 20ml / h, and the growth time wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com