Surface-functionalized BN nanosheet, and preparation method and application thereof

A technology of surface functionalization and nano-flakes, which is applied in the direction of dyeing polymer organic compound treatment, epoxy resin glue, adhesive type, etc., can solve problems such as complex process flow, achieve enhanced interfacial interaction, and improve mechanical properties and thermal conductivity, promoting peeling and dispersion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

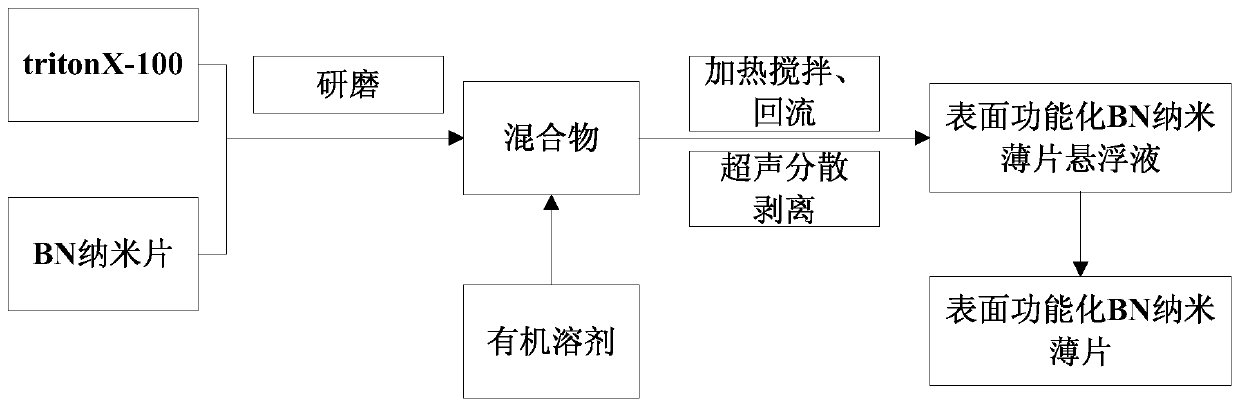

[0040] (1) A method for preparing surface functionalized BN nanosheets, the process flow chart is shown in figure 1 , including the following steps:

[0041] This example uses TritonX-100 to modify BN nanosheets:

[0042] 1) Mix 0.1-0.5g of BN nanosheets and 1-5mL of tritonX-100 in an agate grinding bowl, and manually grind for 30-40min to obtain a mixture.

[0043]2) Add the mixture of polyethylene glycol octylphenyl ether (tritonX-100) and BN nanosheets into acetone after mixing and grinding, and react for 2-3 hours under reflux under condensation and stirring at 50-60°C to obtain the heated solution, and then ultrasonically treat the heated solution below 20° C. for 60-80 min to obtain a suspension of surface-functionalized BN nano-flakes, which contains surface-functionalized BN nano-flakes (m-BN).

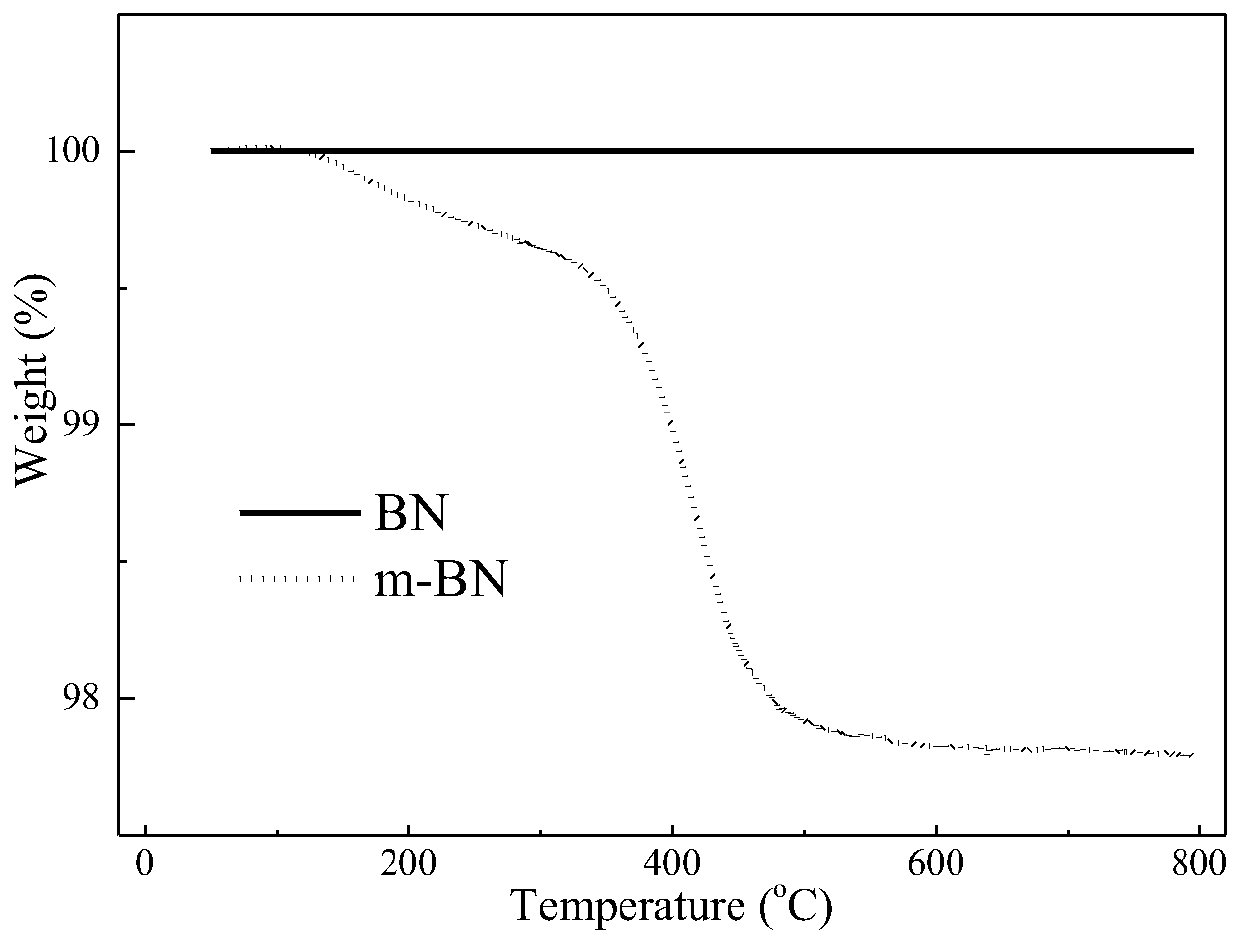

[0044] 3) Remove the organic solvent of the surface-functionalized BN nano-flake suspension, and carry out thermogravimetric and simultaneous thermal analysis (TGA) of the p...

Embodiment 1

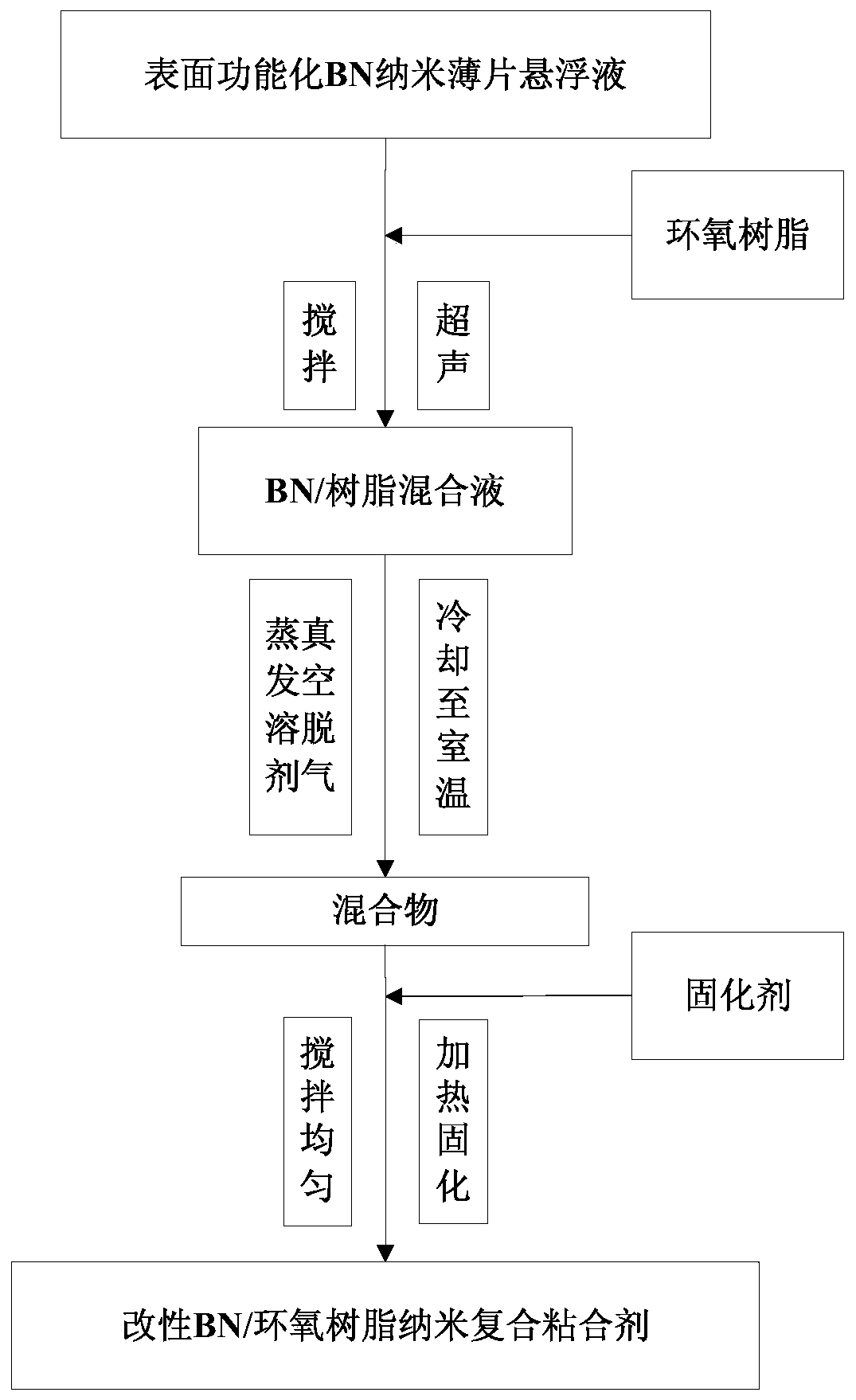

[0056] A preparation method of modified BN / epoxy resin nano composite adhesive, comprising the following steps:

[0057] (1) Mix 0.2 g of BN nanosheets and 2 mL of tritonX-100 in an agate grinding bowl, and manually grind for 30 min to obtain a mixture.

[0058] (2) The mixture of tritonX-100 and BN nanosheets was mixed and ground into 20 mL of acetone, and condensed and refluxed, and reacted for 2 hours under stirring at 50° C. to obtain a heated solution. Then, the heated solution was ultrasonically treated below 20° C. for 60 min to obtain a uniformly dispersed surface-functionalized BN nanosheet (m-BN) suspension, wherein the ultrasonic frequency was 35 KHz.

[0059] (3) Stir by magnetic force for 20 minutes, and then ultrasonically treat for 30 minutes, mix 3.5 g of epoxy resin (E-51) and m-BN suspension evenly to obtain a BN / resin mixture.

[0060] The BN / resin mixture was then evaporated with acetone at 70°C using a hot plate and magnetic stirring. Air bubbles and res...

Embodiment 2

[0066] A preparation method of modified BN / epoxy resin nano composite adhesive, comprising the following steps:

[0067] (1) Mix 0.2 g of BN nanosheets and 2 mL of tritonX-100 in an agate grinding bowl, and manually grind for 30 min to obtain a mixture.

[0068] (2) The mixture of tritonX-100 and BN nanosheets was mixed and ground into 30 mL of acetone, and condensed and refluxed, reacted for 2 hours under stirring at 50° C. to obtain a heated solution. Then, the heated solution was ultrasonically treated below 20° C. for 60 min to obtain a uniformly dispersed surface-functionalized BN nanosheet (m-BN) suspension, wherein the ultrasonic frequency was 40 KHz.

[0069] (3) Stirring by magnetic force for 20 minutes, and then ultrasonic treatment for 30 minutes, 4.9 g of epoxy resin (E-51) and m-BN suspension were uniformly mixed to obtain a BN / resin mixture.

[0070] The BN / resin mixture was then evaporated with acetone at 70°C using a hot plate and magnetic stirring. Air bubbl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com