A semiconductor device and a manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of peeling, being easily affected by moisture, low mechanical strength, etc., and achieve the effect of improving peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

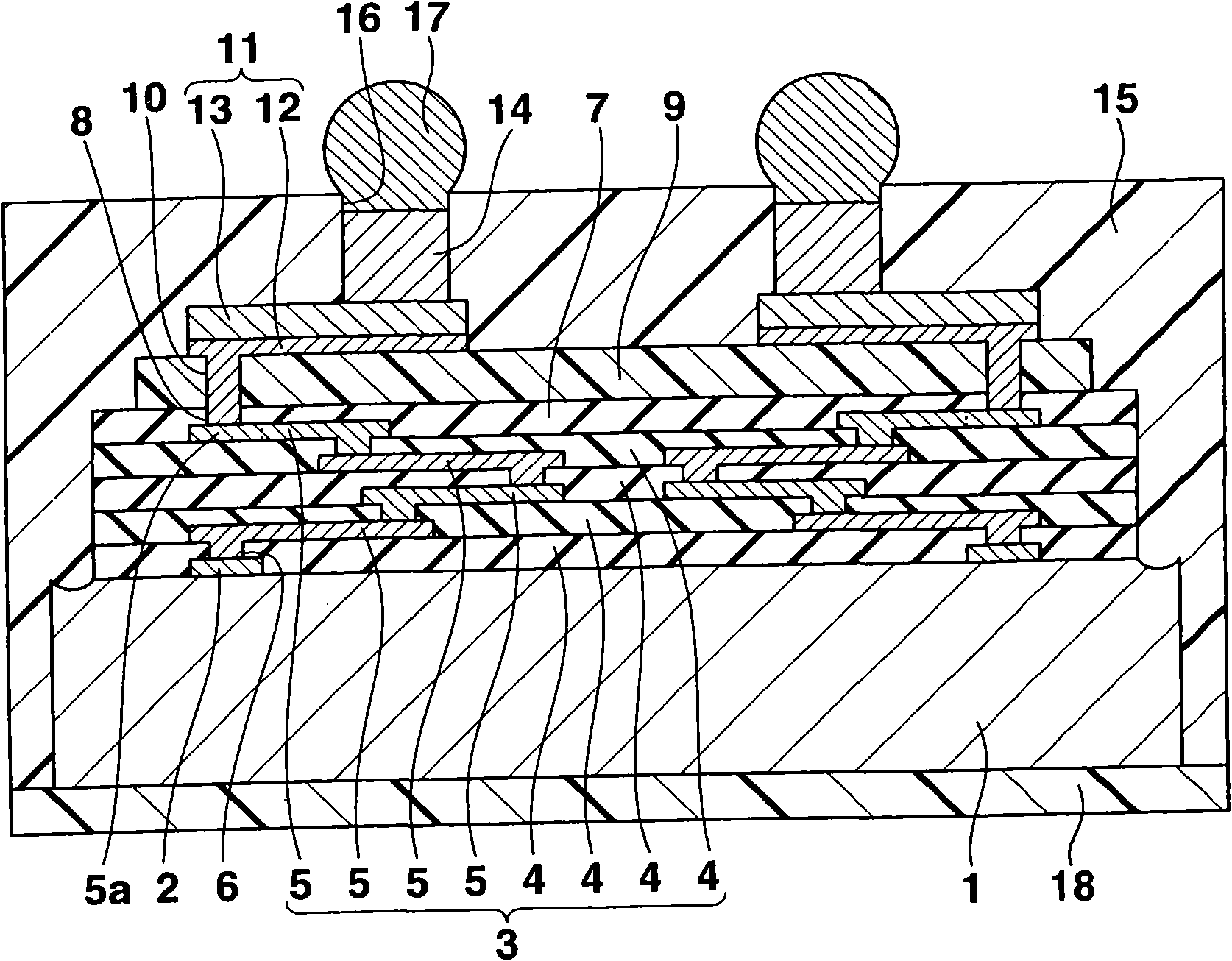

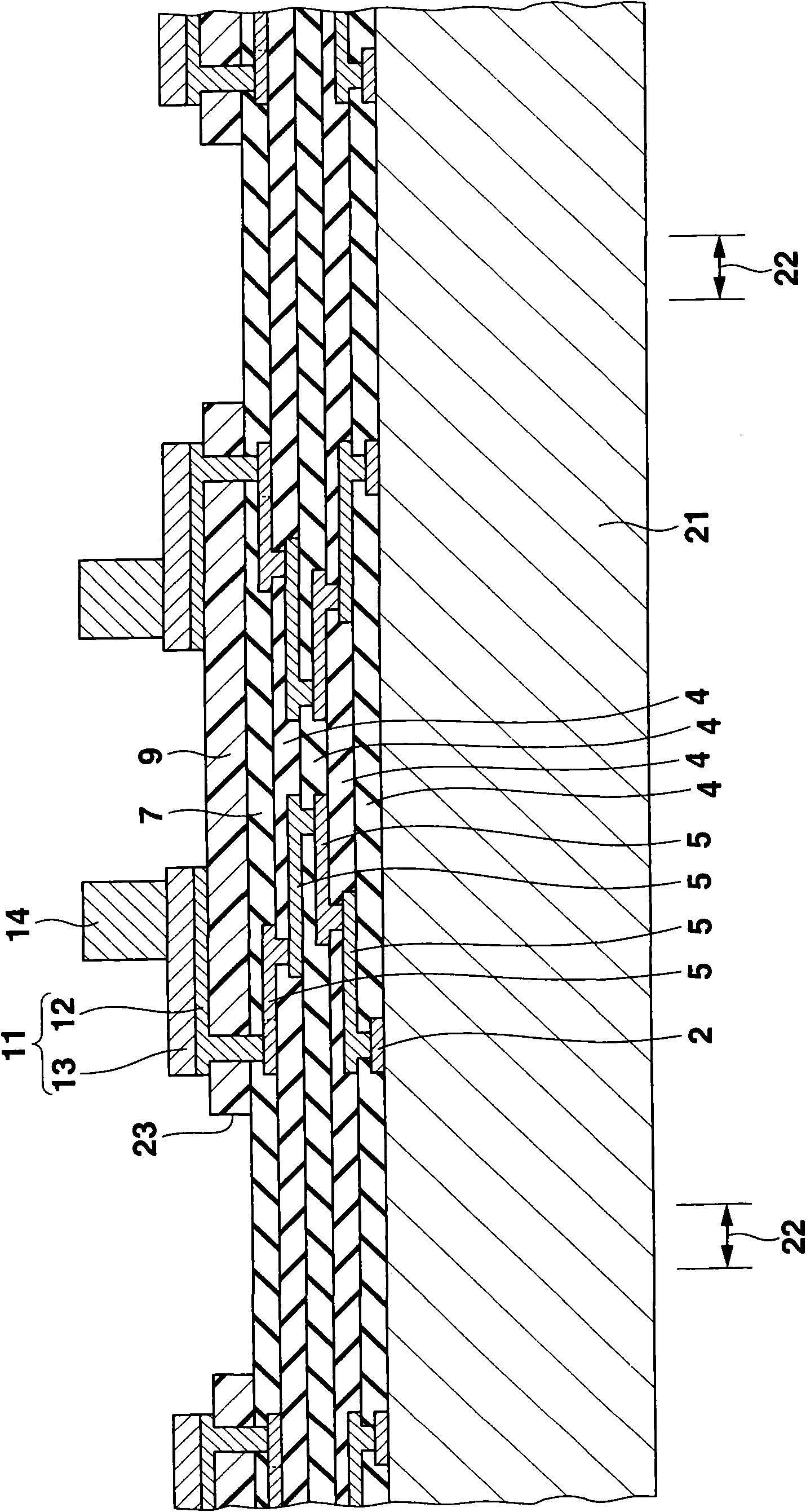

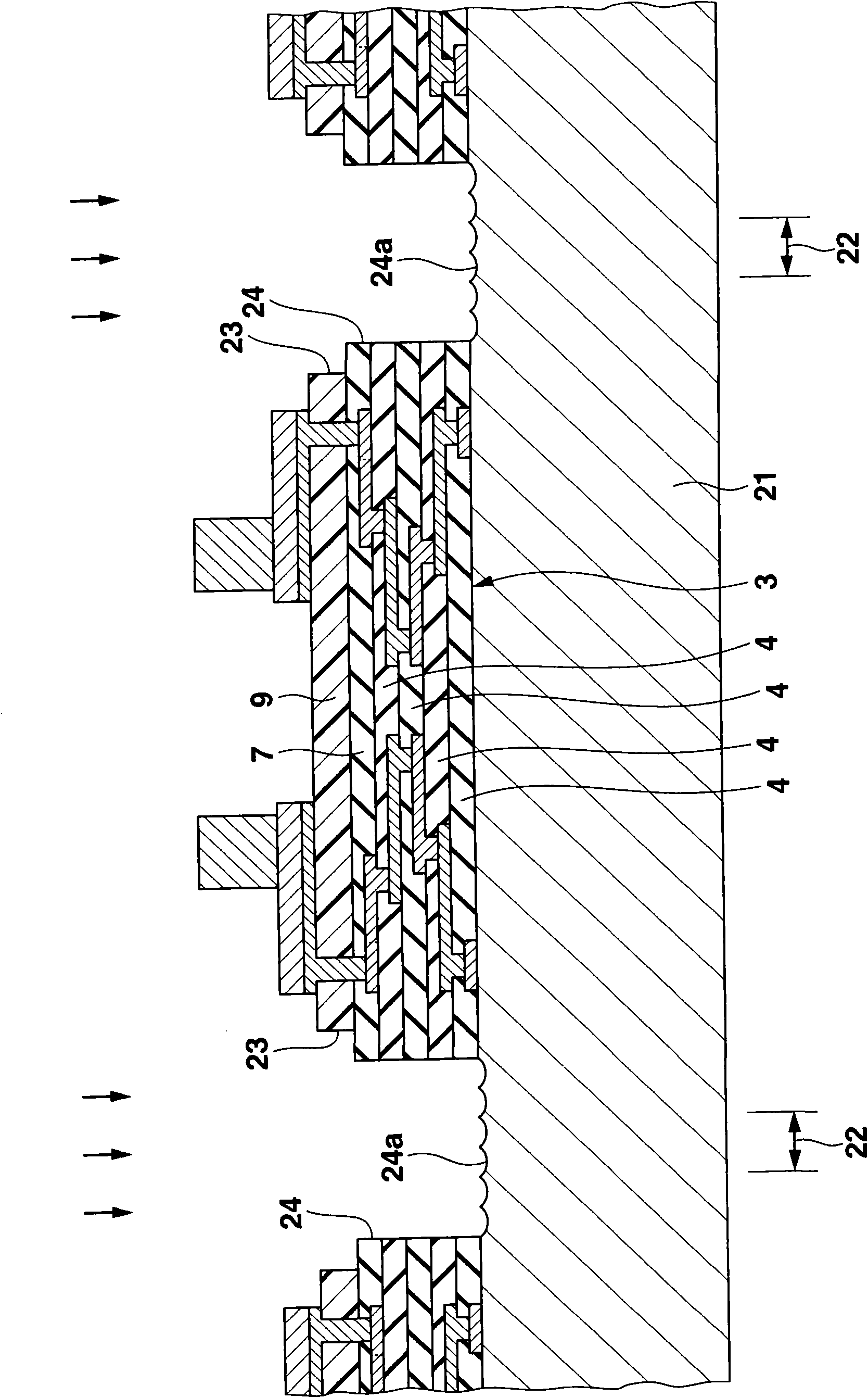

[0059] figure 1 A cross-sectional view showing a semiconductor device according to a first embodiment of the present invention. This semiconductor device includes a silicon substrate (semiconductor substrate) 1 . On the upper surface of the silicon substrate 1, integrated circuits with predetermined functions are provided, especially elements (not shown) such as transistors, diodes, resistors, capacitors, etc. Connection pads 2 made of aluminum-based metal or the like. Although only two connection pads 2 are shown in the figure, there are actually a plurality of connection pads 2 on the upper surface of the silicon substrate.

[0060] On the upper surface of the silicon substrate 2 except for the outer peripheral portion of the connection pad 2, a low dielectric constant film wiring multilayer structure portion 3 for connecting the various elements of the above-mentioned integrated circuit is provided. The low-dielectric-constant film wiring laminated structure portion 3 ha...

no. 2 approach

[0086] Figure 13 It is a cross-sectional view of a semiconductor device as a second embodiment of the present invention. In this semiconductor device, with figure 1 The semiconductor device shown differs in having the second trench 26 with a depth ratio Figure 4 The case shown is a shallow construction. Therefore, in the lower portion of the peripheral side surface of the silicon substrate 1, between the lower surface of the silicon substrate 1 and the second groove 26, a remaining portion of the silicon substrate 1 is formed as a protrusion 31 whose side surface is exposed (exposed) to the outside. The side surface of the protruding portion 31 exposed to the outside is flush with the side surface of the sealing film 15 . In this way, the lower protective film 18 formed on the lower surface of the silicon substrate 1 covers the lower surface of the protrusion 31 .

[0087] Next, an example of a method of manufacturing the semiconductor device will be described. At this ...

no. 3 approach

[0094] Figure 18 It is a cross-sectional view of a semiconductor device as a third embodiment of the present invention. In this semiconductor device, with Figure 13 The semiconductor device shown is different in that the protrusion 31 is removed by forming the third groove 32 in the shape of a track until the sealing film 15 is exposed on the peripheral portion of the lower surface of the silicon substrate 1 including the protrusion 31, and the third The lower protective film 18 is provided in the groove 32 .

[0095] Next, an example of a method of manufacturing the semiconductor device will be described. At this time, at Figure 15 After the procedure shown, as Figure 19 As shown, a cutting knife 33 is prepared. The cutting blade 33 is made of a disc-shaped whetstone, the cross-sectional shape of the cutting edge is substantially U-shaped, and the thickness is larger than the width of the second groove 26 . Then, using the cutting knife 33, will include the second g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com