Lithium ion battery negative electrode piece using hard carbon and soft carbon as active materials and lithium ion battery

A lithium-ion battery and active material technology, applied in the field of lithium-ion battery manufacturing, can solve the problems of hard carbon and soft carbon without very systematic research and analysis, low initial charge and discharge efficiency of graphite system, and poor processing performance of graphite system, etc., to achieve The effect of improving high current rate performance, improving charging performance, improving cycle performance and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

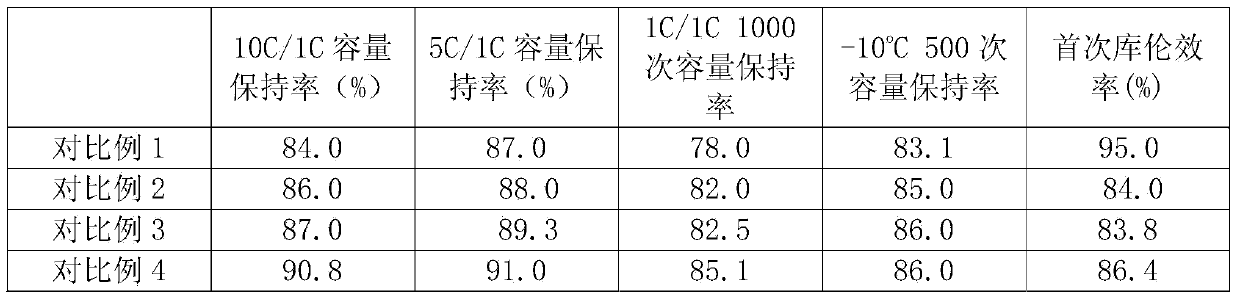

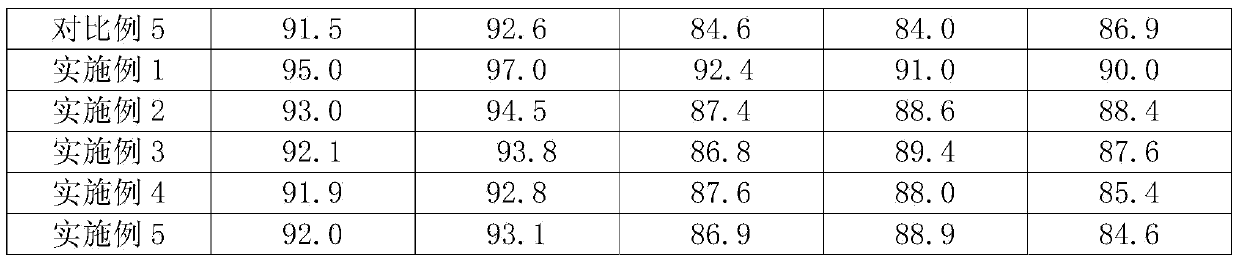

Examples

Embodiment 1

[0024] Embodiment 1: artificial graphite, Super P (graphite), KS-6 (carbon black), sodium carboxymethyl cellulose, and SBR emulsion with a mass content of 40% are according to the weight of 91.5: 1.5: 1.0: 2.0: 4.0 Proportional mixing, as the first layer of graphite layer material, according to 40g / m on one side 2 The areal density is coated on both sides of the metal foil current collector, and dried to make a pole piece; the hard carbon material, soft carbon material, Super P (graphite), KS-6 (carbon black), carboxymethyl Sodium cellulose and SBR emulsion with a mass content of 40% are mixed to make a slurry, and the mass ratio of each component is 45.0:46.5:1.5:1.0:2.0:4.0, according to 90g / m on one side 2 The surface density of the primary pole piece is coated on both sides of the primary pole piece to make a secondary pole piece; artificial graphite, Super P (graphite), KS-6 (carbon black), sodium carboxymethyl cellulose, and 40% of the mass content SBR emulsion is mixed...

Embodiment 2

[0025] Embodiment 2: the SBR emulsion of artificial graphite, Super P (graphite), KS-6 (carbon black), sodium carboxymethyl cellulose, mass content 40% is according to the weight of 91.5:1.5:1.0:2.0:4.0 Proportional mixing, as the first layer of graphite layer material, according to 40g / m on one side 2 The areal density of the metal foil is coated on both sides of the metal foil current collector, and dried to make a pole piece; the hard carbon material, Super P (graphite) KS-6 (carbon black), sodium carboxymethyl cellulose, SBR emulsion with a mass content of 40% is mixed to make a slurry, and the mass ratio of each component is 91.5:1.5:1:2:4, according to 90g / m on one side 2 The surface density of the primary pole piece is coated on both sides of the primary pole piece to make a secondary pole piece; artificial graphite, Super P (graphite), KS-6 (carbon black), sodium carboxymethyl cellulose, and 40% of the mass content SBR emulsion is mixed according to the weight ratio o...

Embodiment 3

[0026] Embodiment 3: the SBR emulsion of artificial graphite, Super P (graphite), KS-6 (carbon black), sodium carboxymethylcellulose, mass content 40% is according to the weight of 91.5:1.5:1.0:2.0:4.0 Proportional mixing, as the first layer of graphite layer material, according to 40g / m on one side 2 The areal density of the metal foil is coated on both sides of the metal foil current collector, and dried to make a pole piece; the soft carbon material, Super P (graphite) KS-6 (carbon black), sodium carboxymethyl cellulose, SBR emulsion with a mass content of 40% is mixed to make a slurry, and the mass ratio of each component is 91.5:1.5:1:2:4, according to 90g / m on one side 2 The surface density of the primary pole piece is coated on both sides of the primary pole piece to make a secondary pole piece; artificial graphite, Super P (graphite), KS-6 (carbon black), sodium carboxymethyl cellulose, and 40% of the mass content SBR emulsion is mixed according to the weight ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com