Transformer shell material and preparation method thereof

A shell material and a technology for a transformer, applied in the field of transformer shell materials and their preparation, can solve the problems of poor sound insulation effect, poor heat transfer and heat dissipation effect, weak sound absorption effect, etc., achieve good insulation performance, excellent sound absorption effect, and improve sound absorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

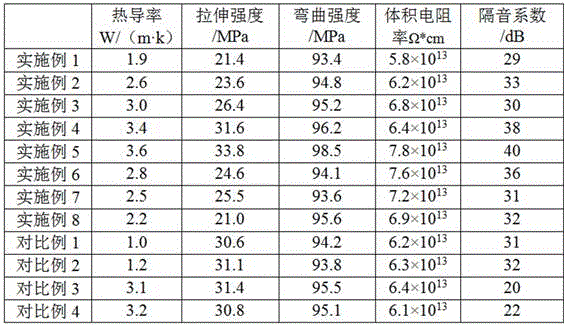

Examples

Embodiment 1

[0024] A transformer casing material, comprising the following raw materials in parts by weight: 40 parts of polyurethane resin, 30 parts of nitrile rubber, 10 parts of sound-absorbing material, 16 parts of aluminum nitride, 8 parts of magnesium oxide, 10 parts of glass fiber, and 1 part of antioxidant parts and 5 parts of silane coupling agent.

[0025] Wherein the sound-absorbing material is prepared by the following steps:

[0026] (1) The sound-absorbing material is prepared from the following raw materials in parts by weight: 30 parts of vermiculite powder, 15 parts of zeolite powder, 1 part of stearic acid, 2 parts of calcium carbonate, and 5 parts of water glass.

[0027] (2) Mix the weighed vermiculite powder, zeolite powder, stearic acid and calcium carbonate evenly, add water 0.2 times the weight of the total amount of raw materials and stir evenly, then add water glass and mix evenly, dry and crush to 100 mesh, Then keep it warm at 400°C for 60 minutes to prepare t...

Embodiment 2

[0034] A transformer casing material, comprising the following raw materials in parts by weight: 42 parts of polyurethane resin, 28 parts of nitrile rubber, 11 parts of sound-absorbing material, 15 parts of aluminum nitride, 7 parts of magnesium oxide, 11 parts of glass fiber, and 2 parts of antioxidant 4 parts and 4 parts of silane coupling agent.

[0035] Wherein the sound-absorbing material is prepared by the following steps:

[0036] (1) The sound-absorbing material is prepared from the following raw materials in parts by weight: 28 parts of vermiculite powder, 16 parts of zeolite powder, 2 parts of stearic acid, 3 parts of calcium carbonate, and 6 parts of water glass.

[0037] (2) Mix the weighed vermiculite powder, zeolite powder, stearic acid and calcium carbonate evenly, add water 0.25 times the weight of the total amount of raw materials and stir evenly, then add water glass and mix evenly, dry and crush to 120 mesh, Then keep it at 420° C. for 55 minutes to prepare...

Embodiment 3

[0044] A transformer casing material, comprising the following raw materials in parts by weight: 44 parts of polyurethane resin, 26 parts of nitrile rubber, 12 parts of sound-absorbing material, 14 parts of aluminum nitride, 6 parts of magnesium oxide, 12 parts of glass fiber, and 3 parts of antioxidant 3 parts and 3 parts of silane coupling agent.

[0045] Wherein the sound-absorbing material is prepared by the following steps:

[0046] (1) The sound-absorbing material is prepared from the following raw materials in parts by weight: 26 parts of vermiculite powder, 17 parts of zeolite powder, 1.5 parts of stearic acid, 4 parts of calcium carbonate, and 7 parts of water glass.

[0047](2) Mix the weighed vermiculite powder, zeolite powder, stearic acid and calcium carbonate evenly, add water 0.3 times the weight of the total amount of raw materials and stir evenly, then add water glass and mix evenly, dry and crush to 140 mesh, Then keep it at 440° C. for 50 minutes to prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com