Refrigerator inner container, refrigerator inner container material and preparation method of refrigerator inner container material

A technology for a refrigerator liner and a toughening agent is applied in the refrigerator liner material and its preparation, and in the field of refrigerator liner, and can solve the problems of application limitation, inability to have ultra-low temperature, high toughness and grease resistance at the same time, and reducing the low temperature performance of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

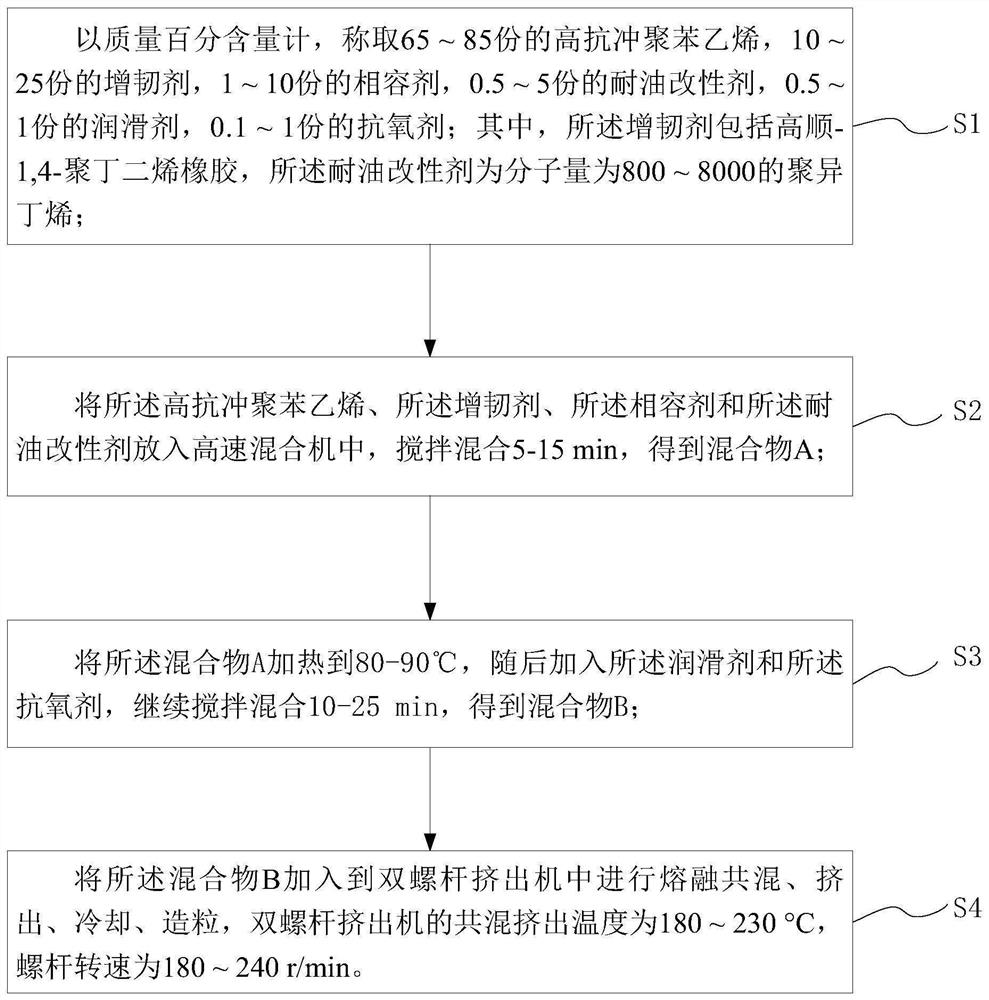

[0042] refer to figure 1 , figure 1 Shown is a flow chart of the preparation method of the inner liner material of the refrigerator of the present invention, the preparation method of the refrigerator liner material is as follows, comprising the following steps:

[0043] S1. In terms of mass percentage, weigh 65-85 parts of high-impact polystyrene, 10-25 parts of toughening agent, 1-10 parts of compatibilizer, and 0.5-5 parts of oil-resistant modifier , 0.5 to 1 part of lubricant, 0.1 to 1 part of antioxidant.

[0044] S2. Put the high-impact polystyrene, toughening agent, compatibilizer and oil-resistant modifier into a high-speed mixer, stir and mix for 5-15 minutes, and obtain mixture A.

[0045] S3. Heat mixture A to 80-90° C., then add lubricant and antioxidant, and continue stirring and mixing for 10-25 minutes to obtain mixture B.

[0046] S4. Add mixture B to a twin-screw extruder for melt blending, extrusion, cooling, and granulation. The blending extrusion tempera...

Embodiment 1

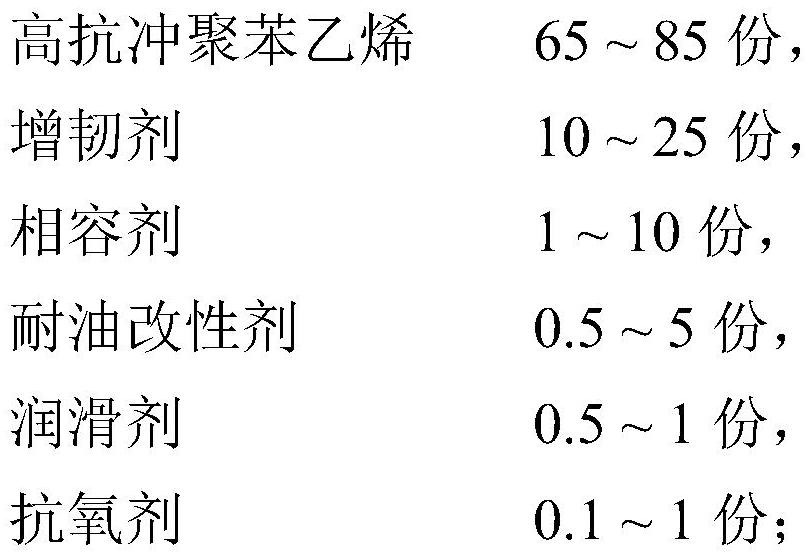

[0049] In terms of mass content, the refrigerator liner materials include:

[0050]

[0051] The preparation method of the refrigerator liner material comprises the following steps:

[0052] S11. According to the above ratio, weigh each component of the refrigerator liner material.

[0053] S12. Put high-impact polystyrene, high-cis-1,4-polybutadiene rubber, styrene-butadiene-styrene block copolymer and polyisobutylene into a high-speed mixer, and stir and mix for 15 minutes , to obtain mixture A.

[0054] S13. Heat mixture A to 80° C., then add solid paraffin and antioxidant 1076, and continue stirring and mixing for 10 minutes to obtain mixture B.

[0055] S14. Add the mixture B to the twin-screw extruder, and carry out melt blending, extrusion, cooling, and granulation at a blending extrusion temperature of 180-230°C and a screw speed of 180r / min to obtain the refrigerator. gall material.

Embodiment 2

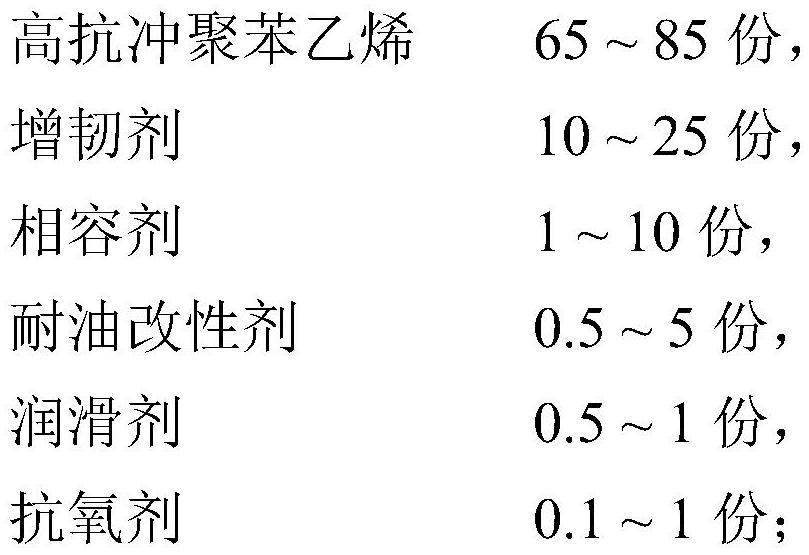

[0057] In terms of mass content, the refrigerator liner materials include:

[0058]

[0059] The preparation method of the refrigerator liner material comprises the following steps:

[0060] S21. According to the above ratio, weigh each component of the refrigerator liner material.

[0061] S22. Combine high-impact polystyrene, high-cis-1,4-polybutadiene rubber, styrene-butadiene rubber (SBR) with core-shell structure, block copolymer of styrene-butadiene-styrene and poly The isobutene was put into a high-speed mixer, stirred and mixed for 5 minutes, and a mixture A was obtained.

[0062] S23. Heat mixture A to 90° C., then add ethylene bis stearic acid amide and antioxidant 1076, and continue stirring and mixing for 20 minutes to obtain mixture B.

[0063] S24. Add the mixture B to a twin-screw extruder, and carry out melt blending, extrusion, cooling, and granulation at a blending extrusion temperature of 180-230°C and a screw speed of 200r / min to obtain a refrigerator....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com