Patents

Literature

200results about How to "Reduce the degree of reunion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic powder organic surface modifying method

ActiveCN101134852AImprove performanceAchieve chemical modification of organic surfacesPigment treatment with organosilicon compoundsOrganic solventOil water

The present invention provides process of organizing the surface to modify inorganic powder, and during the process, inorganic superfine particles are dispersed homogeneously in non-polar organic solvent and have the surfaces well organization modified. The process includes preparing water solution for dispersing inorganic powder, dissolving organic surface modifier, organic surface modifying, solid-liquid separating and washing, and post-treatment. The process features that oil-water interface and phase transfer are utilized for organic surface modification of inorganic superfine powder in non-polar organic solvent.

Owner:江苏河海纳米科技股份有限公司 +1

Method for preparing functionalized graphene and composite material of functionalized graphene

InactiveCN102862976AGood dispersionImprove interface performanceMaterial nanotechnologyCarbon compoundsEpoxyOrganic solvent

The invention discloses a method for preparing functionalized graphene and a composite material of the functionalized graphene. The method for preparing the functionalized graphene comprises the following steps of: performing Friedel-Crafts reaction on natural graphite which is taken as a raw material to obtain modified graphite, extracting, purifying, and uniformly dispersing in an organic solvent with ultrasonic to form stable graphene suspension liquid. The method for preparing the composite material comprises the following steps of: adding epoxy resin into the graphene suspension liquid, stirring for dissolving, uniformly mixing with ultrasonic, distilling under reduced pressure to remove the organic solvent to obtain a graphene / epoxy resin composite; and adding an epoxy resin curing agent, an accelerant and micrometer silver sheets sequentially, and heating for curing to obtain the composite material of a graphene polymer, namely a graphene / epoxy resin conducting composite material. The edge functionalized graphene has a high interaction between functional groups at the edge and a polymer matrix, so that the dispersion of the graphene in the polymer matrix can be promoted, the agglomeration degree can be reduced, and the interface performance of the composite material can be enhanced.

Owner:SOUTH CHINA UNIV OF TECH

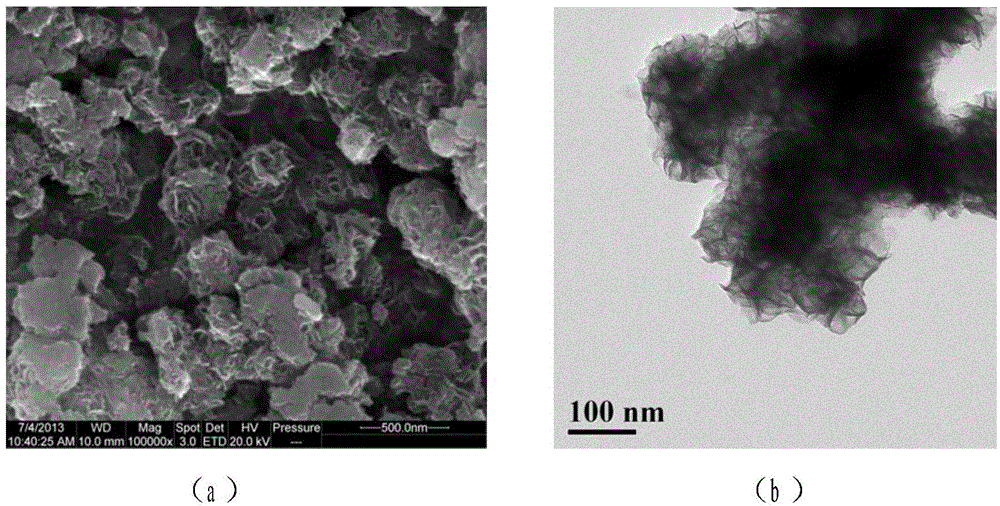

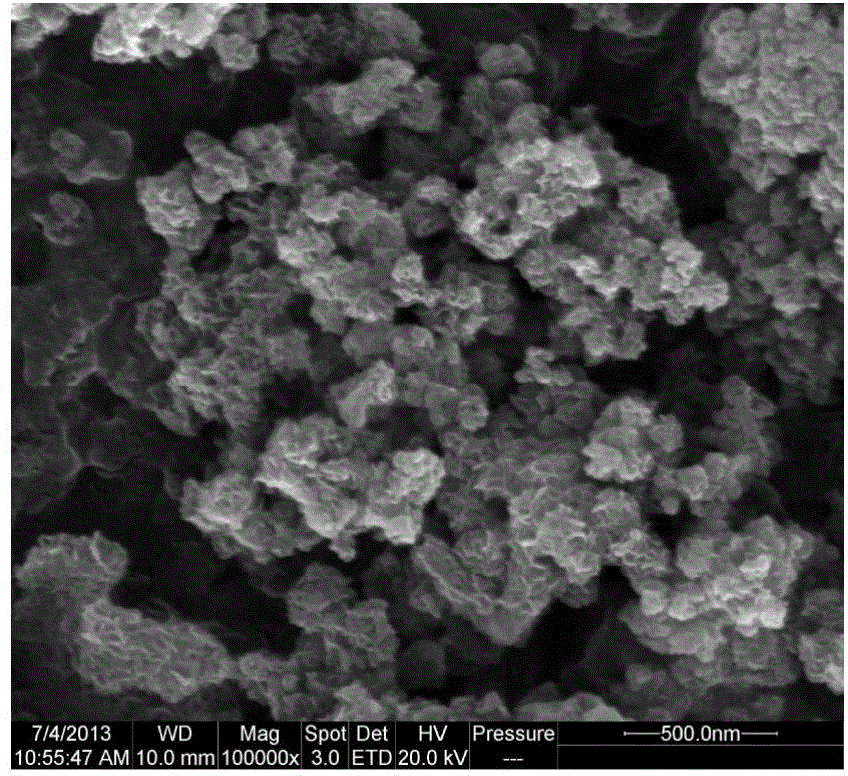

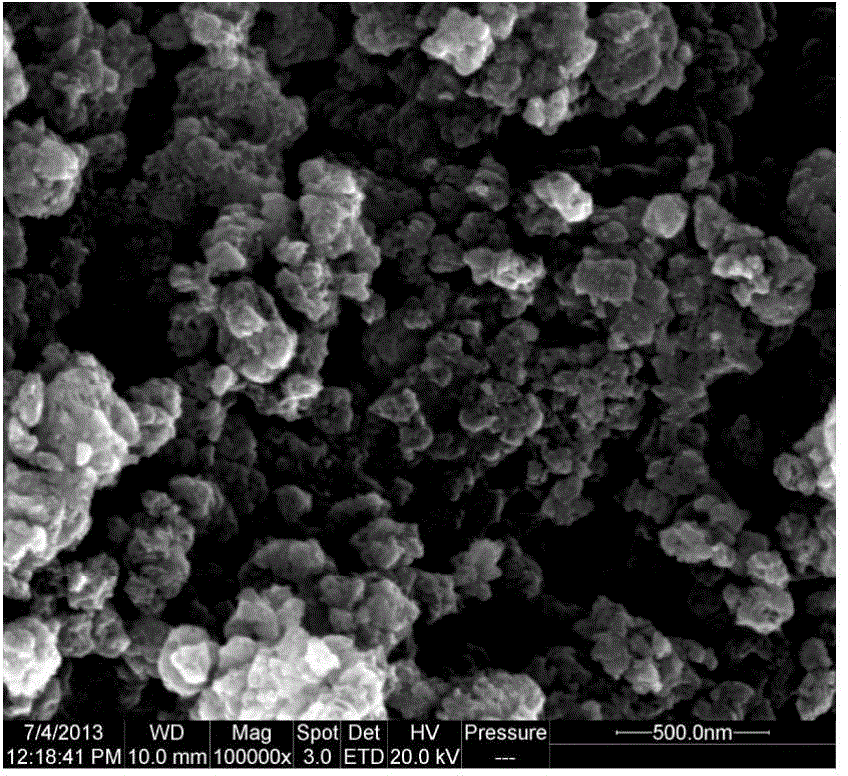

Method for hydro-thermally synthesizing MoS<2> nanoflower with sulfur-containing biological reagent as sulfur source

ActiveCN105366725AWide range of usesNot corrosiveMaterial nanotechnologyMolybdenum sulfidesFiltrationHydrogenation catalysis

The invention discloses a method for hydro-thermally synthesizing a MoS<2> nanoflower with a sulfur-containing biological reagent as a sulfur source. The method comprises the following steps of adding molybdate and L-cysteine or glutathione to deionized water separately for forming a uniform solution, wherein the concentration of the molybdate is 0.002-0.03 M, the mole ratio of S to Mo in raw materials is 4 to 1-2 to 1, and adjusting the pH value of the solution to be 1-7 with hydrochloric acid or ammonia water; shifting the compounded solution to a hydro-thermal reaction kettle with the volume being 100 ml for seal, and conducting a hydro-thermal reaction for 18-36 hours at the temperature of 180-220 DEG C; after the solution is cooled naturally, conducting suction filtration, washing and drying, and obtaining the MoS<2> nanoflower with slice layers accumulated and the surface rough. A MoS<2> product synthesized through the method is at the nanoscale in dimension, is good in dispersion property and has wide application on the aspects of electrode materials, solid lubricant and particularly oil product hydrogenation catalysis.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

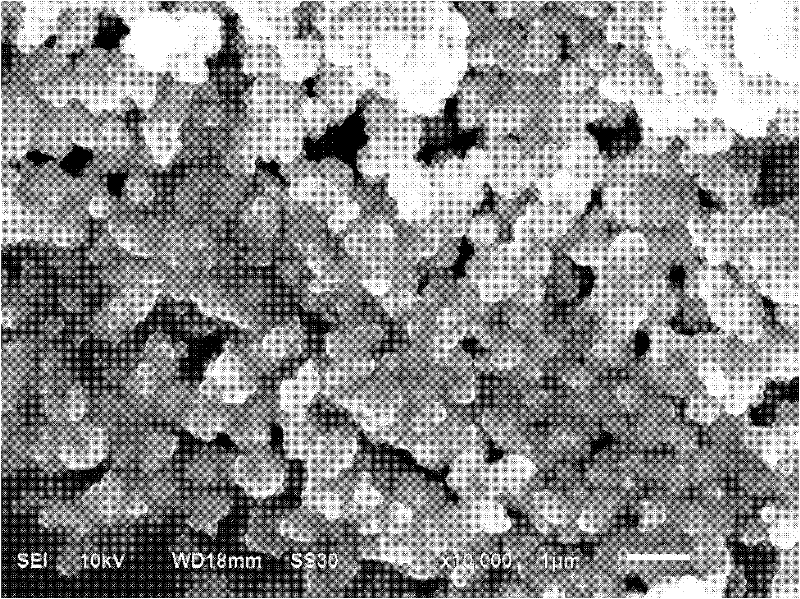

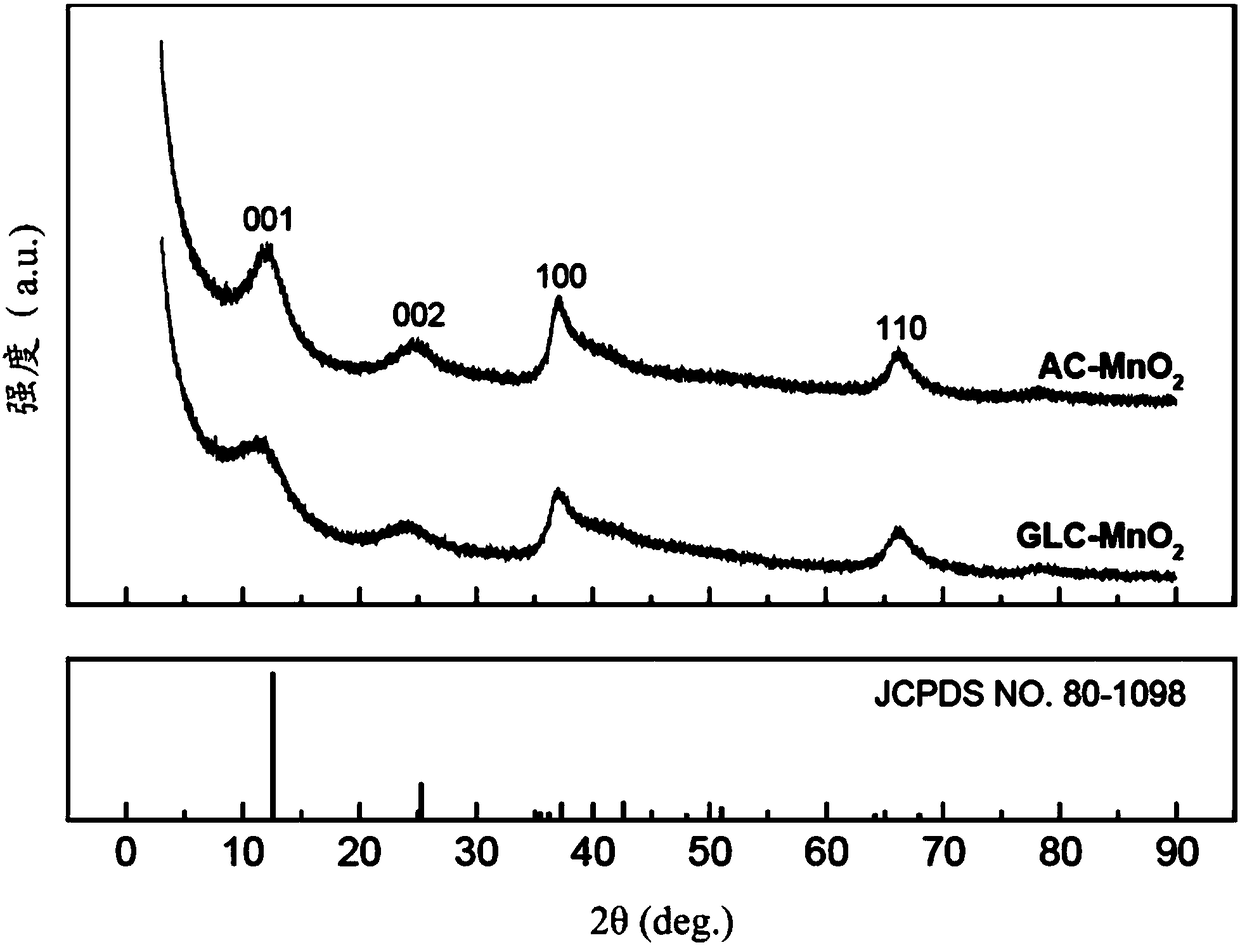

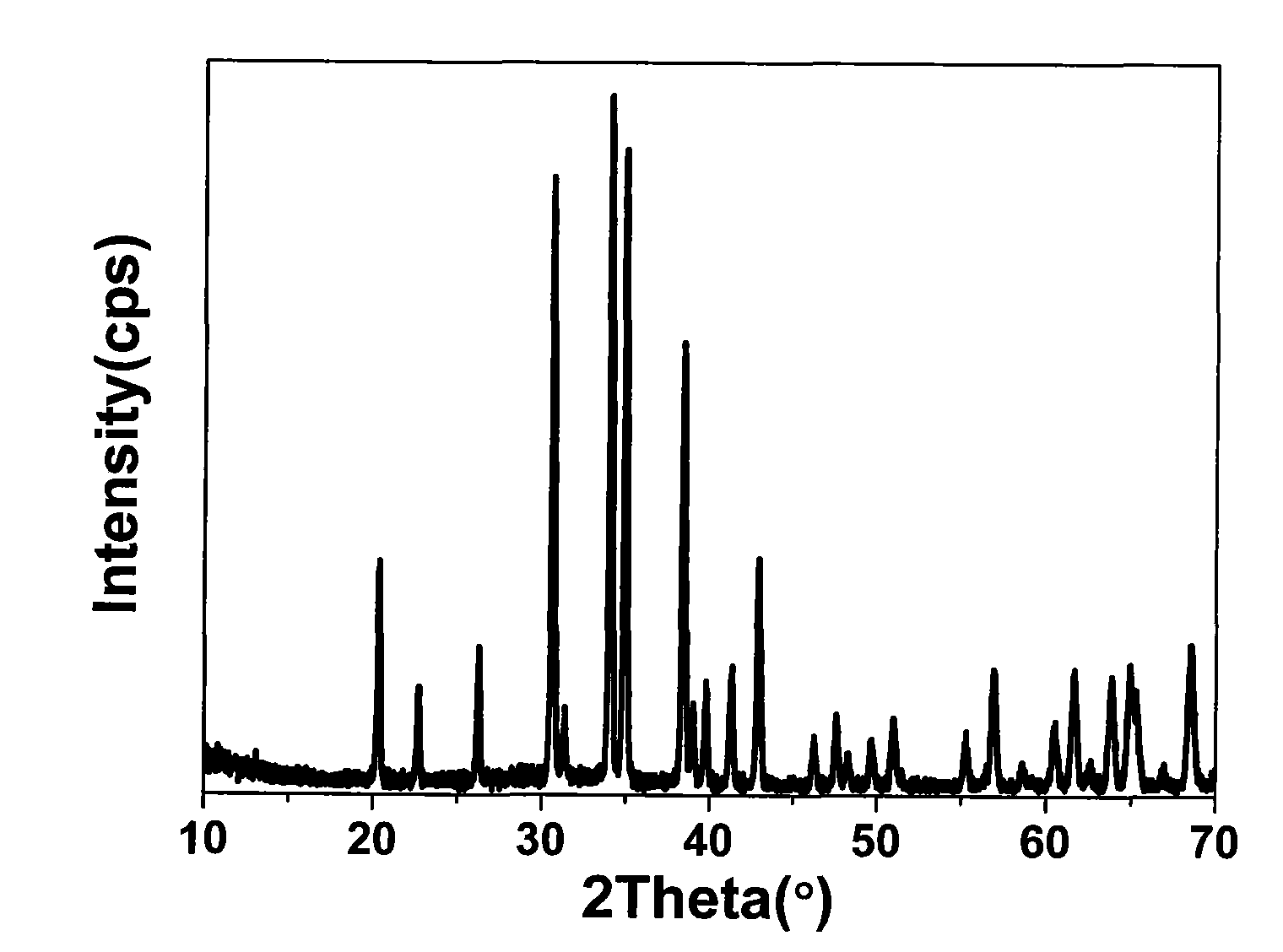

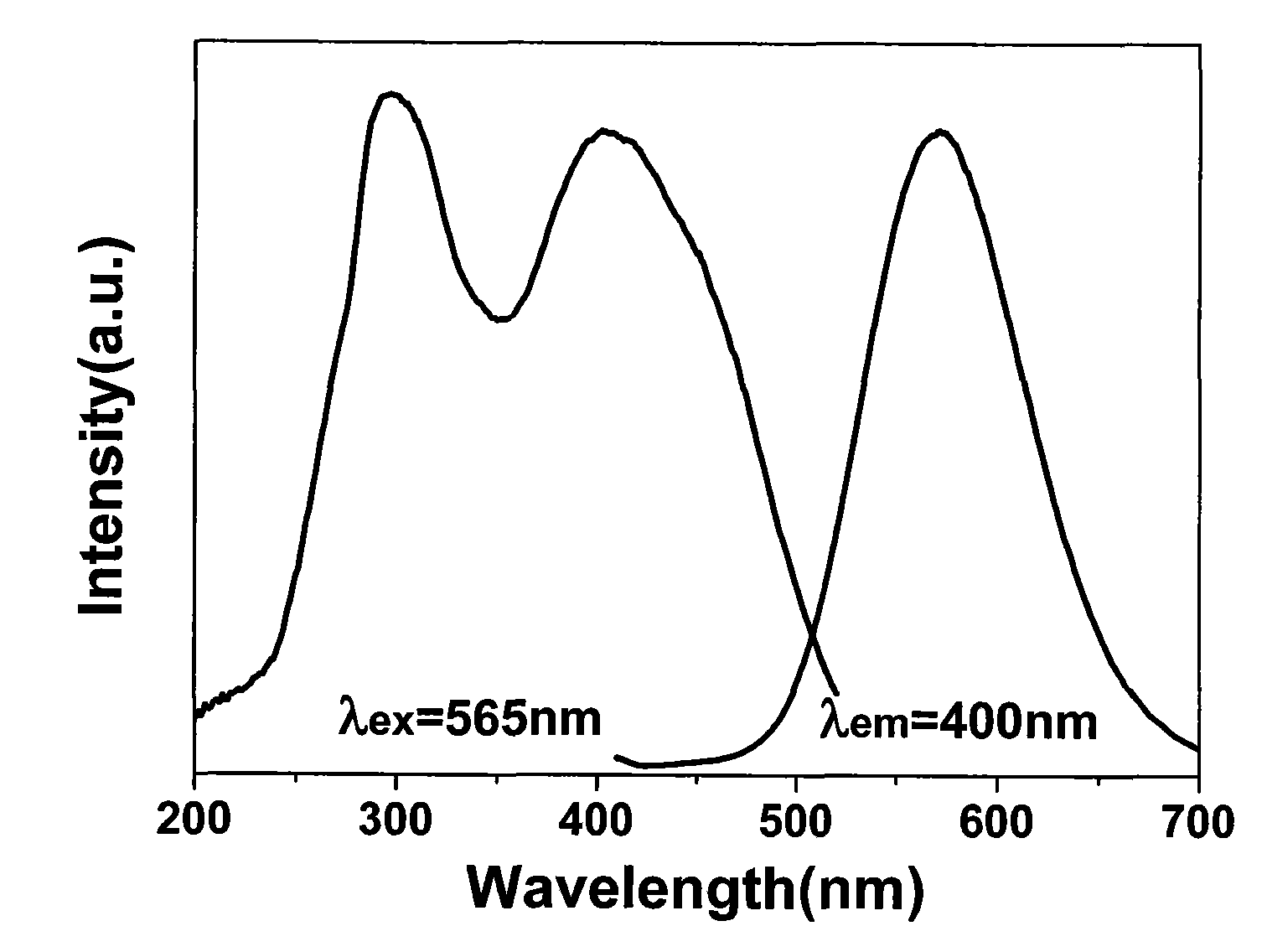

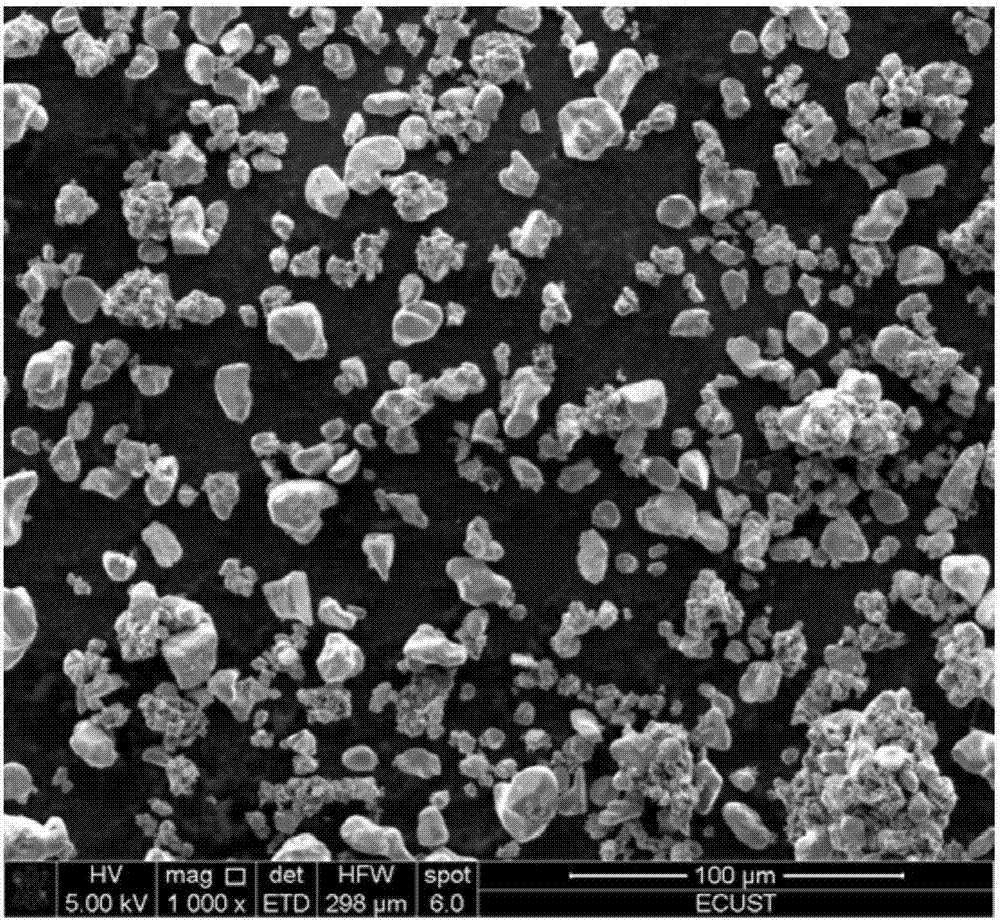

Method for preparing cerium-activated yttrium aluminium garnet fluorescent powder

The invention relates to a preparation method of yttrium aluminum garnet phosphor activated by cerium and a phosphor. The invention provides a generalized preparation method of yttrium aluminum garnet phosphor activated by cerium. A chemical formula is Y3-x-y-zRyAl5-mGamO12: Cex, R'z. The preparation method comprises the steps of: preparation of metal ions solutions, preparation of precipitant solutions, preparation of metal ions precipitants, addition of flux and solid phase reaction, sintering, grinding powders sintered under high temperature, pickling, alkali washing, water washing and drying, then the target product YAG:Ce phosphor, which has high luminous intensity, low agglomeration degree without ball milling, proper powder size and narrow particle size distribution, is obtained; besides, the phosphor has low agglomeration degree after being treaded under high temperature, and the phosphor can be packed and sealed without ball milling and can maximize the excellent optical property.

Owner:XIAMEN UNIV

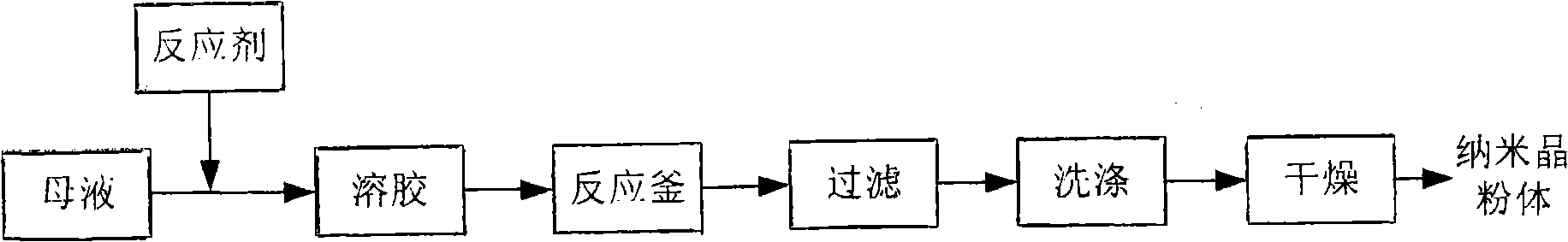

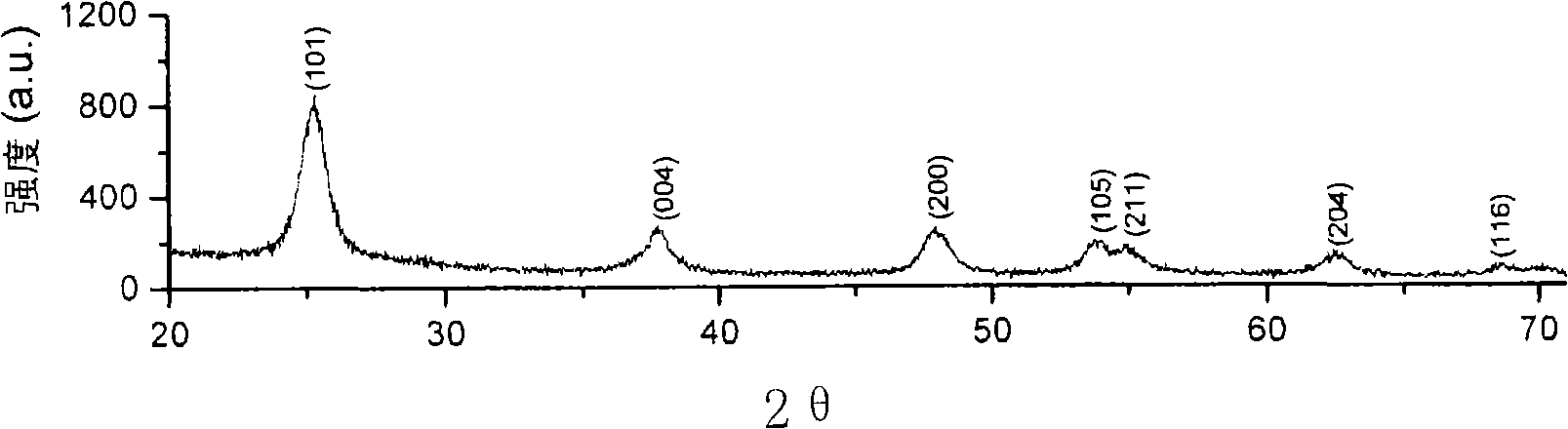

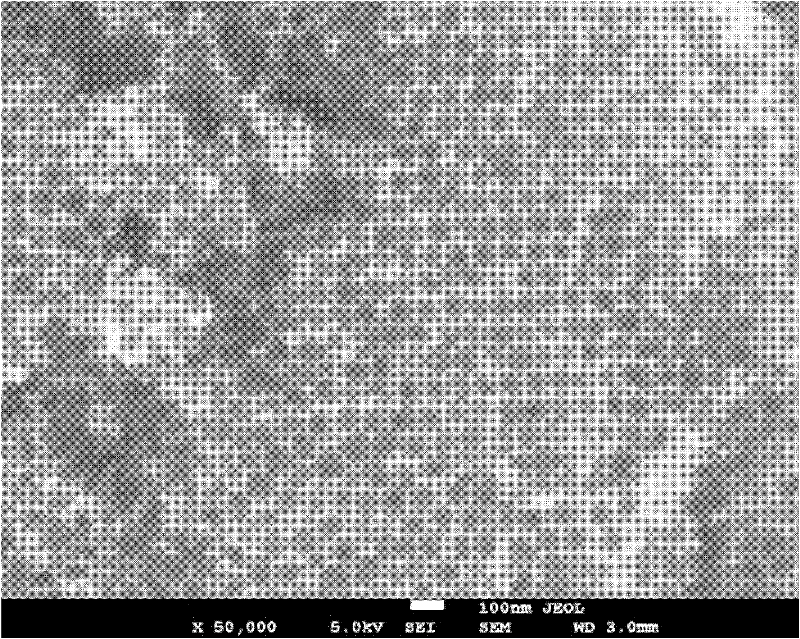

Sol-solvent-thermal method for synthesizing nanocrystalline oxide powder

InactiveCN101348240AUniform particle sizeNarrow distributionOxide/hydroxide preparationIron oxides/hydroxidesInorganic saltsLiquid medium

The invention provides a sol-solvent thermal method for synthesizing a nanocrystalline oxide powder. The method comprises the following: (1) a step of preparation of inorganic salt mother liquids, during which the inorganic salt taken as a material is dissolved in an organic liquid medium or water to prepare a mother liquid of the inorganic salt with definite concentration; (2) a step of preparation of a precipitation reactant liquid, during which alkali is dissolved in an organic liquid medium or water, proper quantity of surfactants are added to prepare the precipitation reactant liquid with definite concentration; (3) a step of preparation of sols, during which, at a certain temperature, while stirring, the prepared reactant liquid is slowly added in the prepared mother liquid of the inorganic salt, the reactant liquid and the mother liquid of the inorganic salt are kept reacting for a period of time after adding the reactant liquids in the mother liquid of the inorganic salt, and the transparent sols are obtained; and (4) a step of solvent thermal reaction of the sols, during which the prepared sols are put in a reaction kettle and reacted for a period of time under a certain temperature and pressure, the products obtained are subjected to filtering, washing and drying, and the nanocrystalline oxide powder is obtained.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

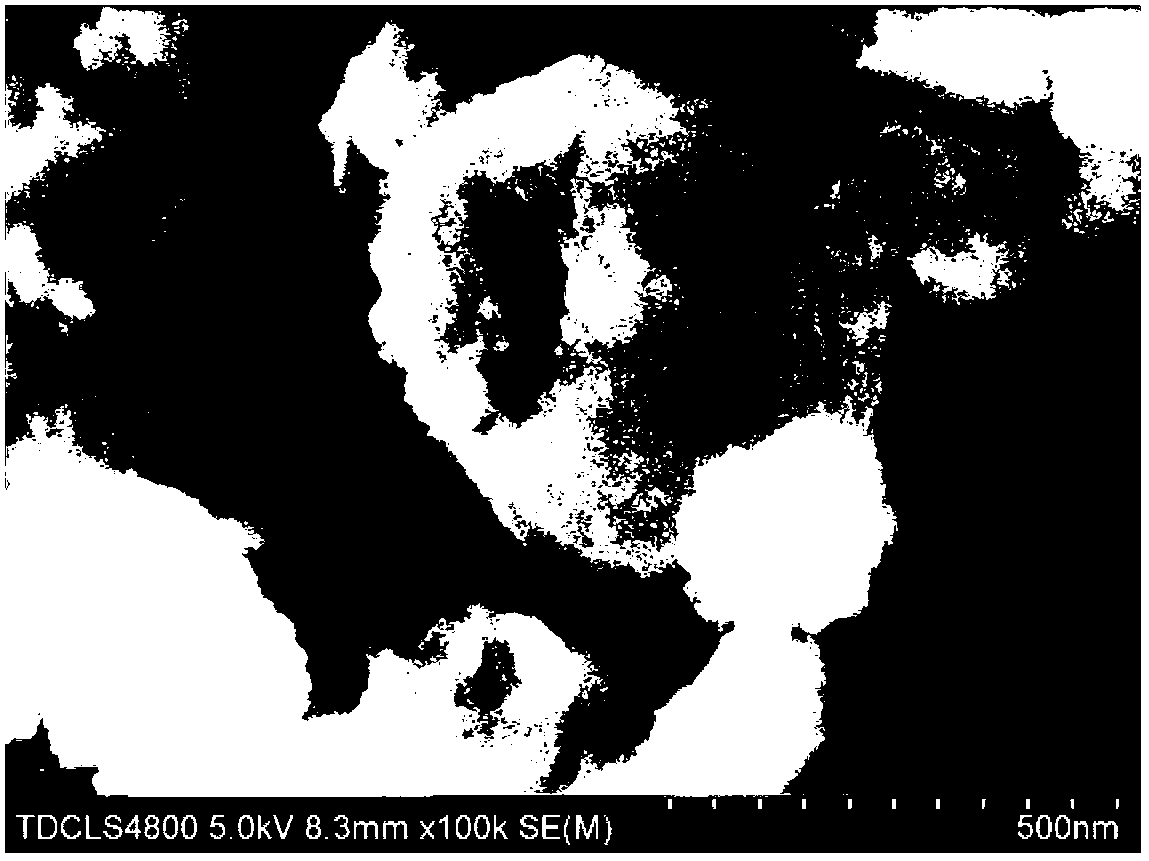

Porous carbon in situ composite lithium iron phosphate cathode material and preparation method thereof

InactiveCN102201576AImprove charge and discharge performanceImprove cycle performanceCell electrodesPorous carbonCharge discharge

The invention, which belongs to the technical field of lithium ion battery cathode materials, discloses a porous carbon in situ composite lithium iron phosphate cathode material and a preparation method thereof. A synthetic process mainly comprises the following steps: dispersing porous carbon; compositing a precursor FePO4.2H2O / porous carbon, and synthesizing the product of the porous carbon in situ coating lithium iron phosphate cathode material. The porous carbon in situ composite lithium iron phosphate cathode material comprises 0.5 to 15 wt% of the porous carbon, 85 to 99.5 wt% of lithium iron phosphate, and 0 to 10 wt% of residual carbon obtained after organic carbon source pyrolysis. Most lithium iron phosphate particles are restricted in the inner of pores of carbon through in situ coating, so obtained composite cathode material particles have small diameters and a good uniformity. Carbon walls of porous carbon allow uniform coating of the lithium iron phosphate particles to be realized and simultaneously particle agglomeration to be largely reduced. The porous carbon in situ composite lithium iron phosphate cathode material has the advantages of good charge-discharge performance, stable circular property, rate capability, novelty, simple synthetic technology and easy large-scale production.

Owner:UNIV OF SCI & TECH BEIJING +1

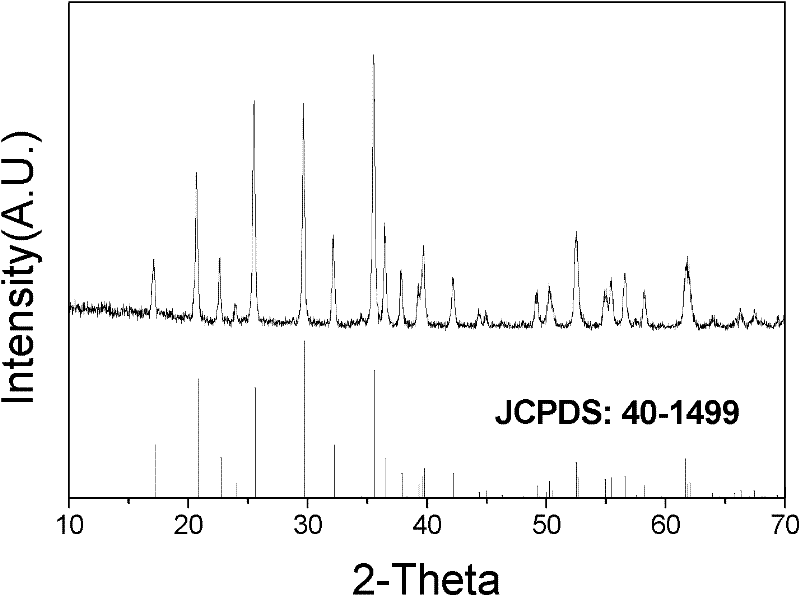

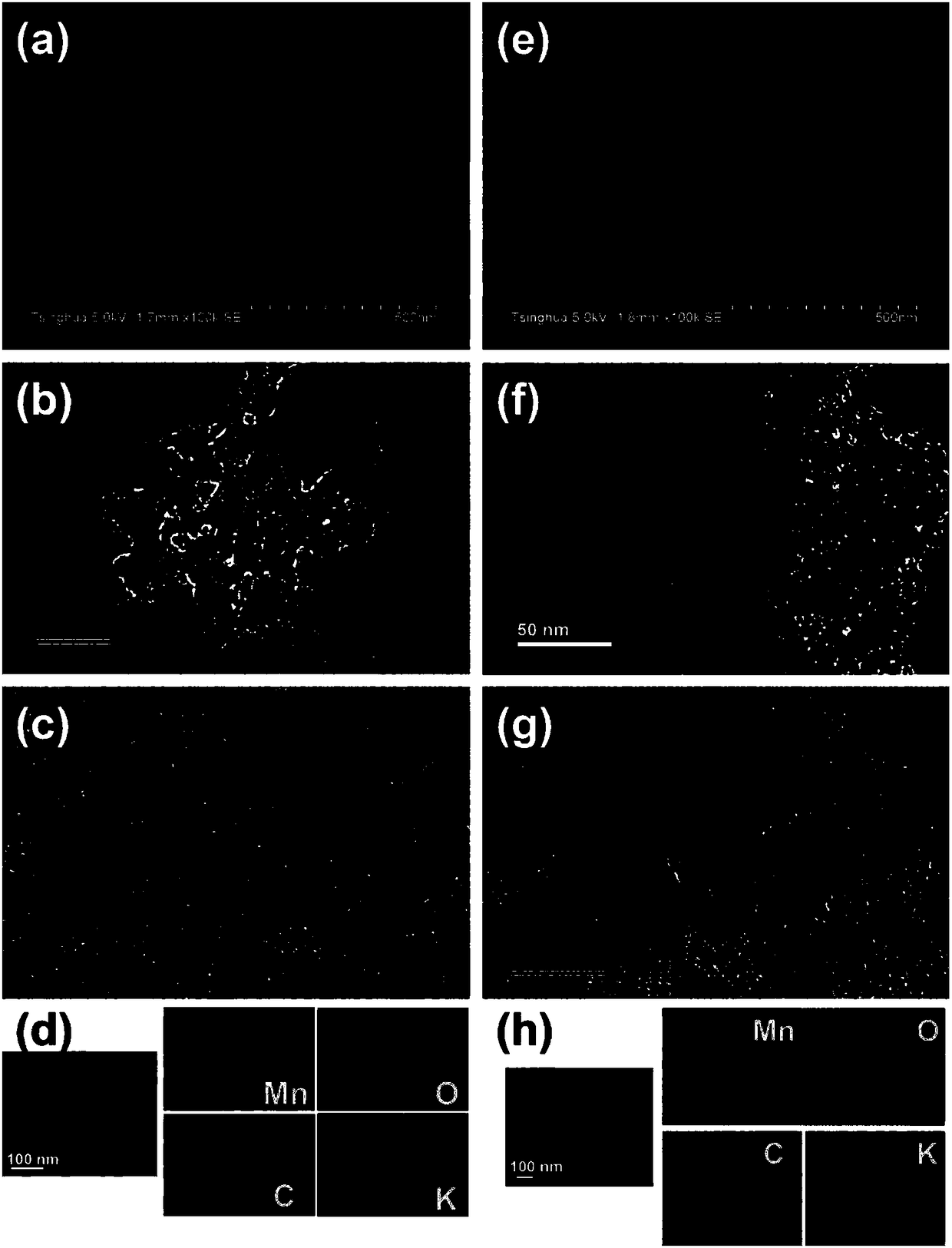

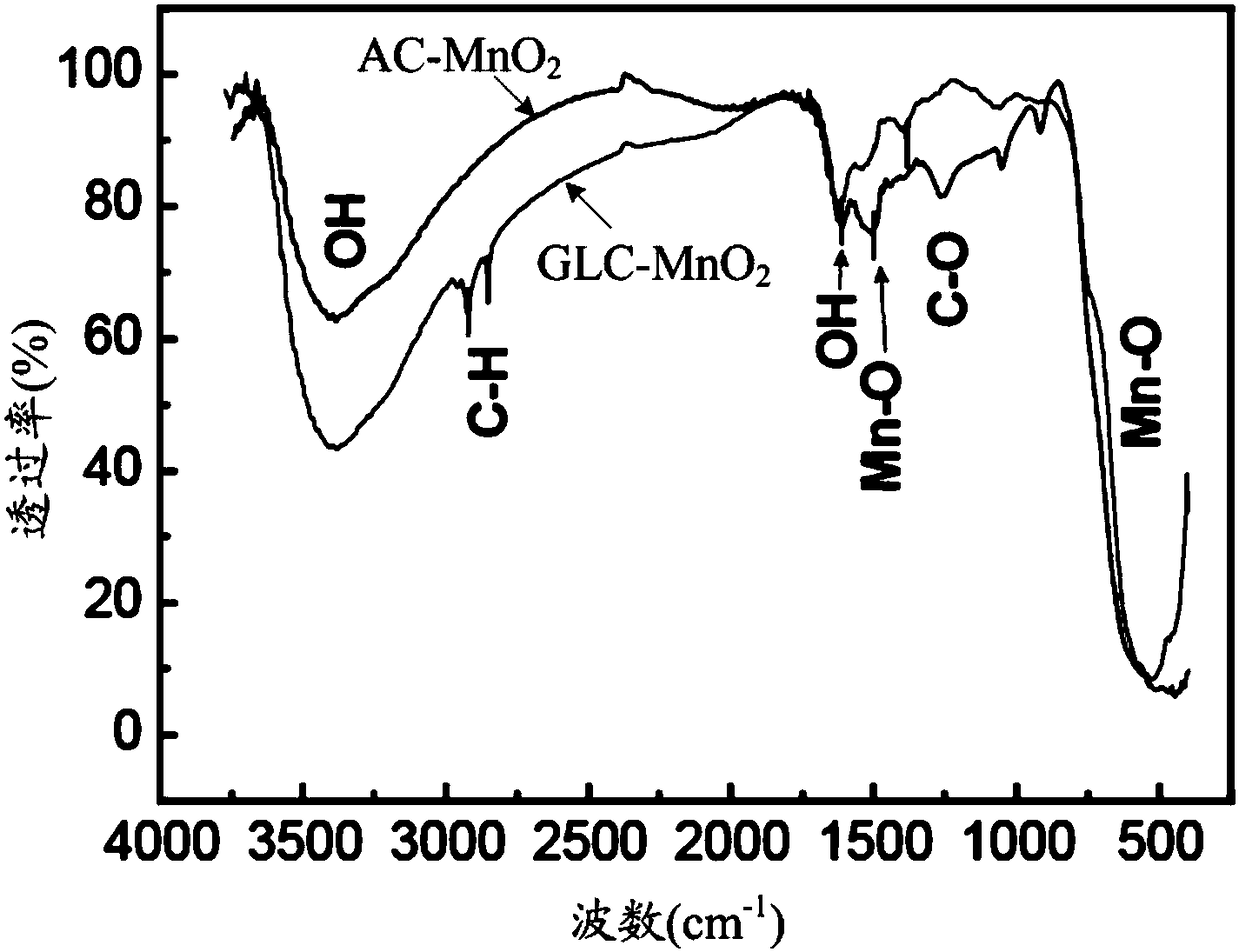

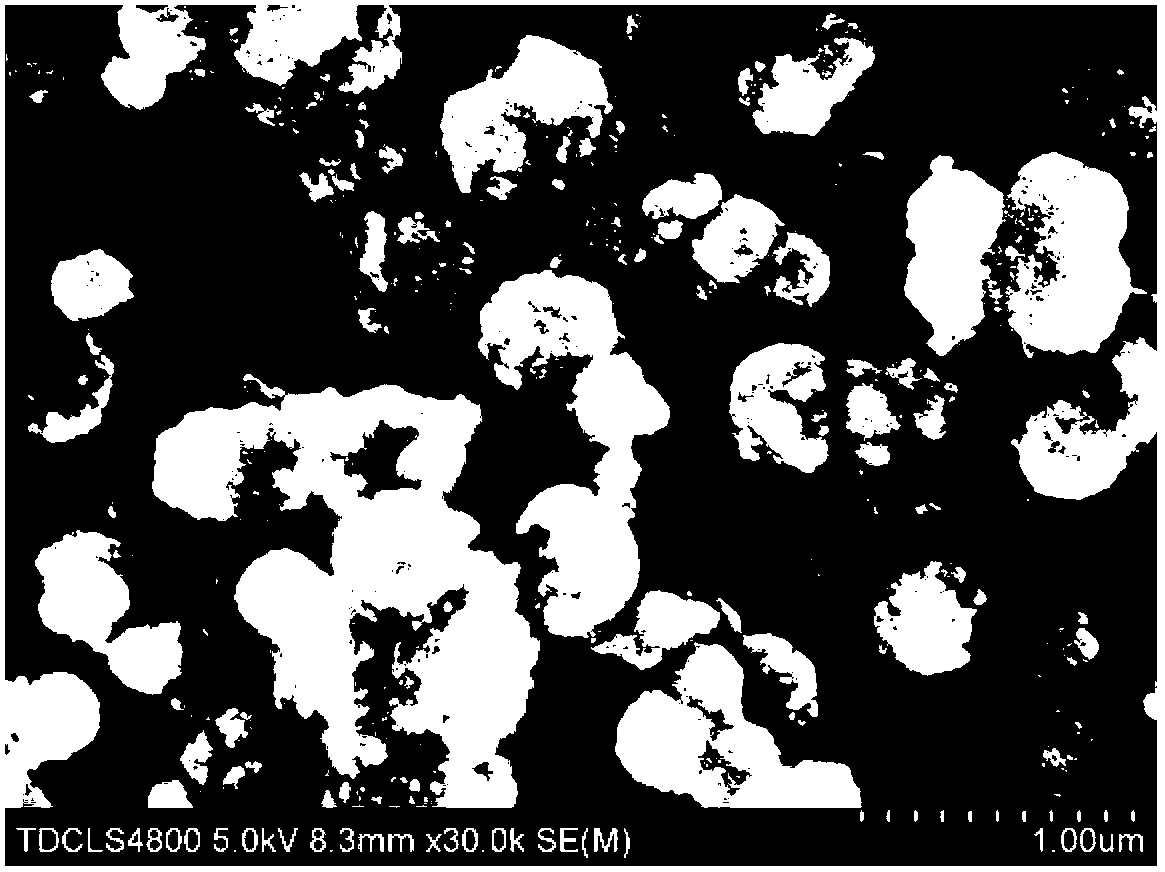

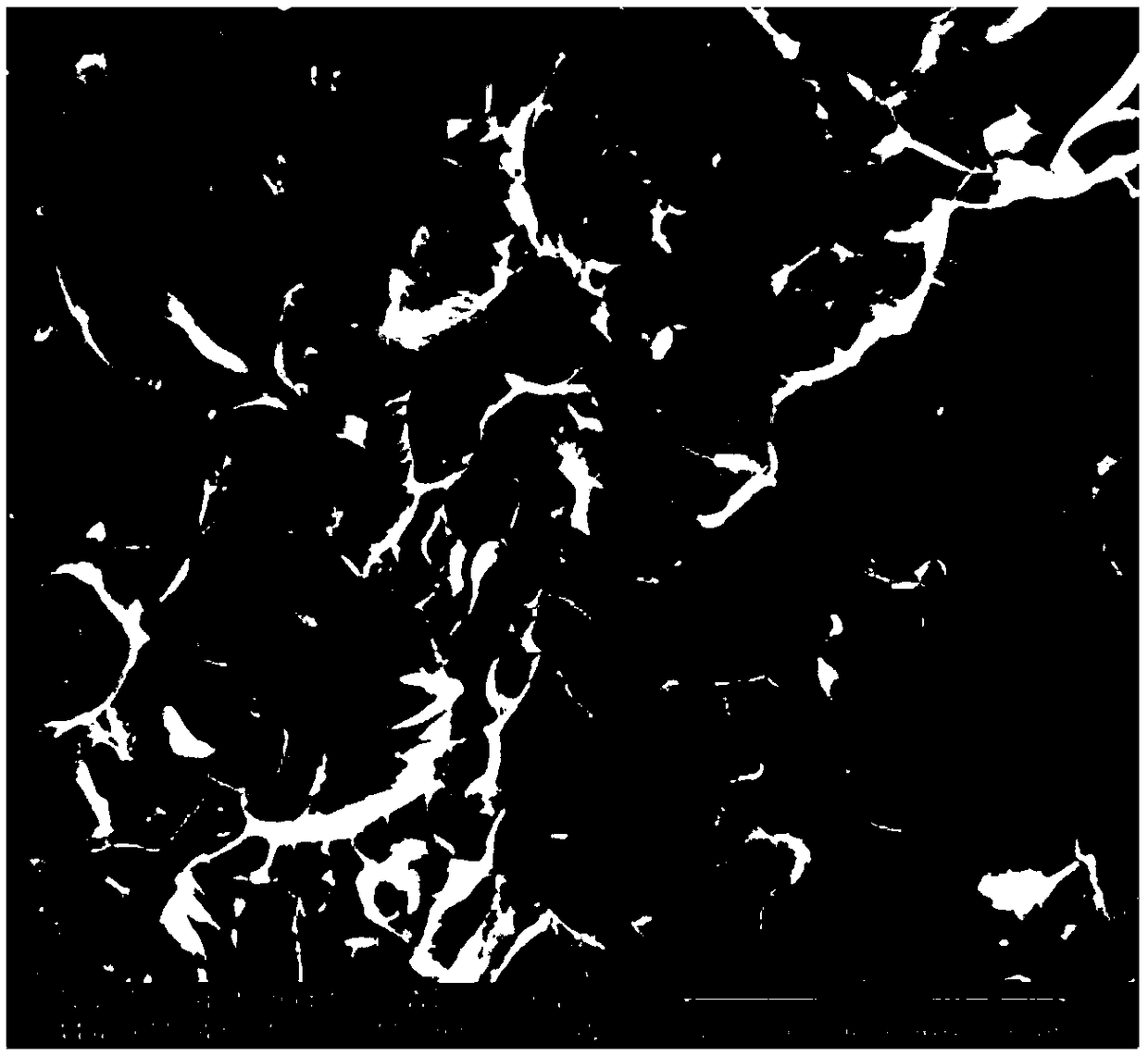

Manganese dioxide composite material, and preparation method and application thereof

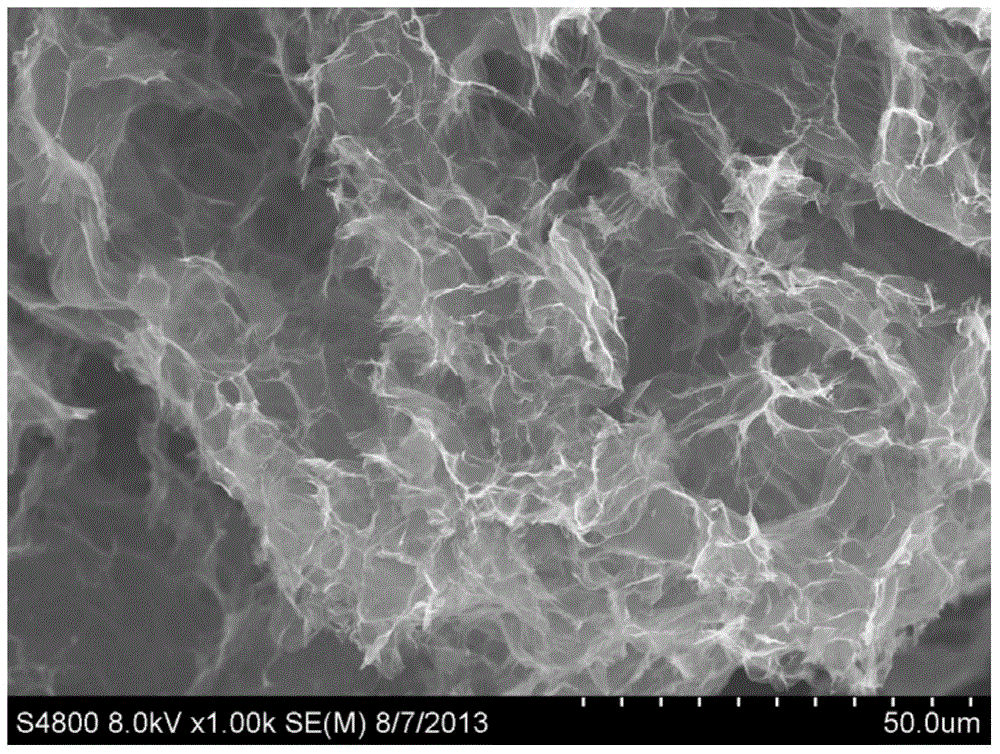

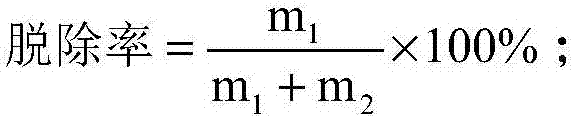

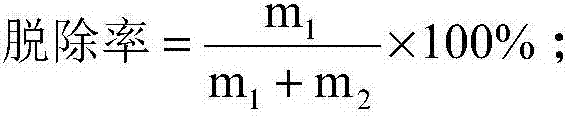

ActiveCN108421545AReduce the degree of reunionLarge apertureGas treatmentDispersed particle separationManganese oxideNanostructured carbon

The invention discloses a manganese dioxide composite material. The manganese dioxide composite material is composed of delta-MnO2 nano sheets and nano secondary particles assembled by nano carbon, wherein the nano secondary particles have a porous structure. The invention also provides a preparation method of the manganese dioxide composite material and an application of the manganese dioxide composite material in removing formaldehyde. The manganese dioxide composite material provided by the invention can rapidly catalyze the degradation of formaldehyde at a low temperature / room temperature,and the removal rate of formaldehyde is high. The preparation method of the manganese dioxide composite material provided by the invention is simple and is easy to operate, and the production cost islow.

Owner:TSINGHUA UNIV

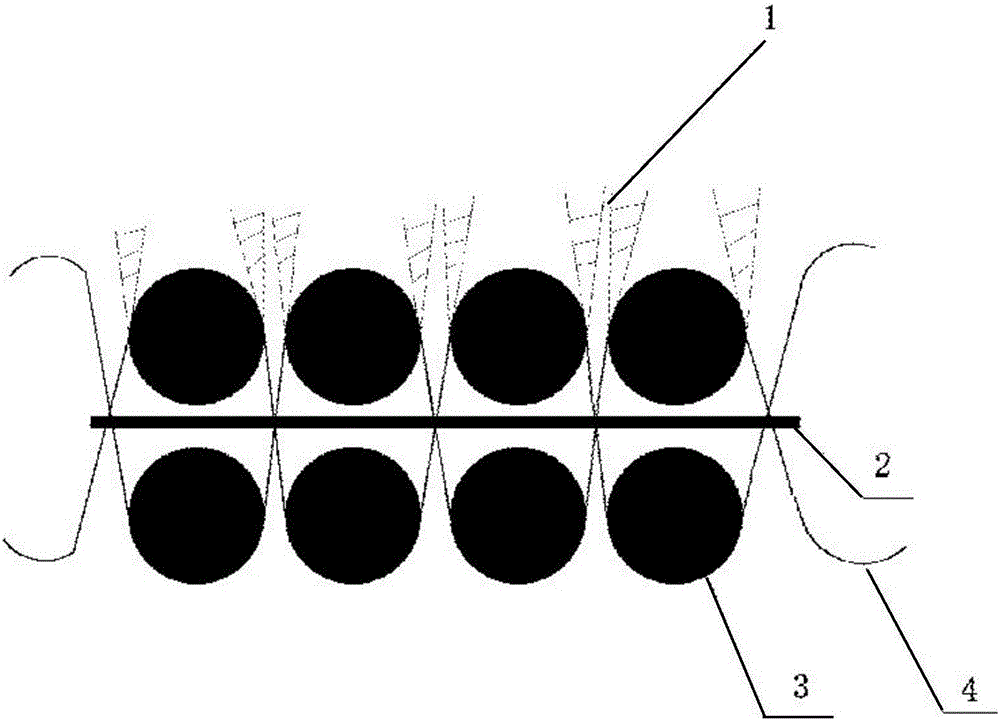

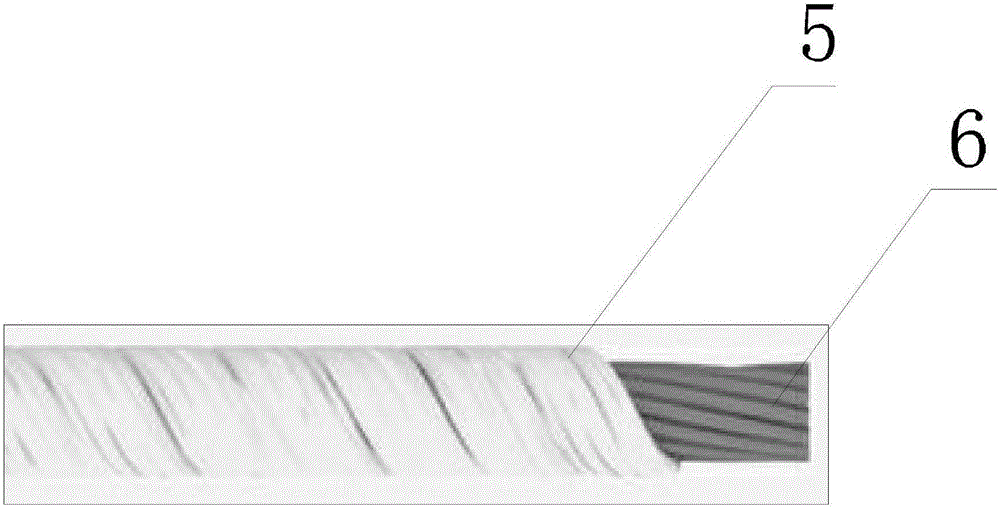

Preparation method of latex-free woven carpet

ActiveCN106012217ASolve pollutionTackle air pollutionFibre treatmentWoven fabricsYarnEnvironmental resistance

The invention discloses a preparation method of a latex-free woven carpet. The carpet is prepared from base cloth, fleece yarn, weft and warp, wherein the weft is composite yarn which is formed by core yarn and a wrapping layer, the wrapping layer is prepared from hot-melting fibers and a nano reinforcing material, a sizing agent of the nano reinforcing material is added to the hot-melting fibers with a blending modification method, a wrapping layer material is obtained and used for wrapping the core yarn, and then the weft is obtained; the warp, the weft and the fleece yarn are interwoven and heated, so that the hot-melting fibers are melted and bonded to pile yarn, and the carpet is obtained after cooling, solidification and post-processing. With the adoption of the preparation method, the waste water pollution problem and the air pollution problem are solved in the carpet production and recycling processes, environment protection is facilitated, and the wear resistance of the carpet is improved due to adoption of the nano reinforcing material.

Owner:BINZHOU COC CARPET

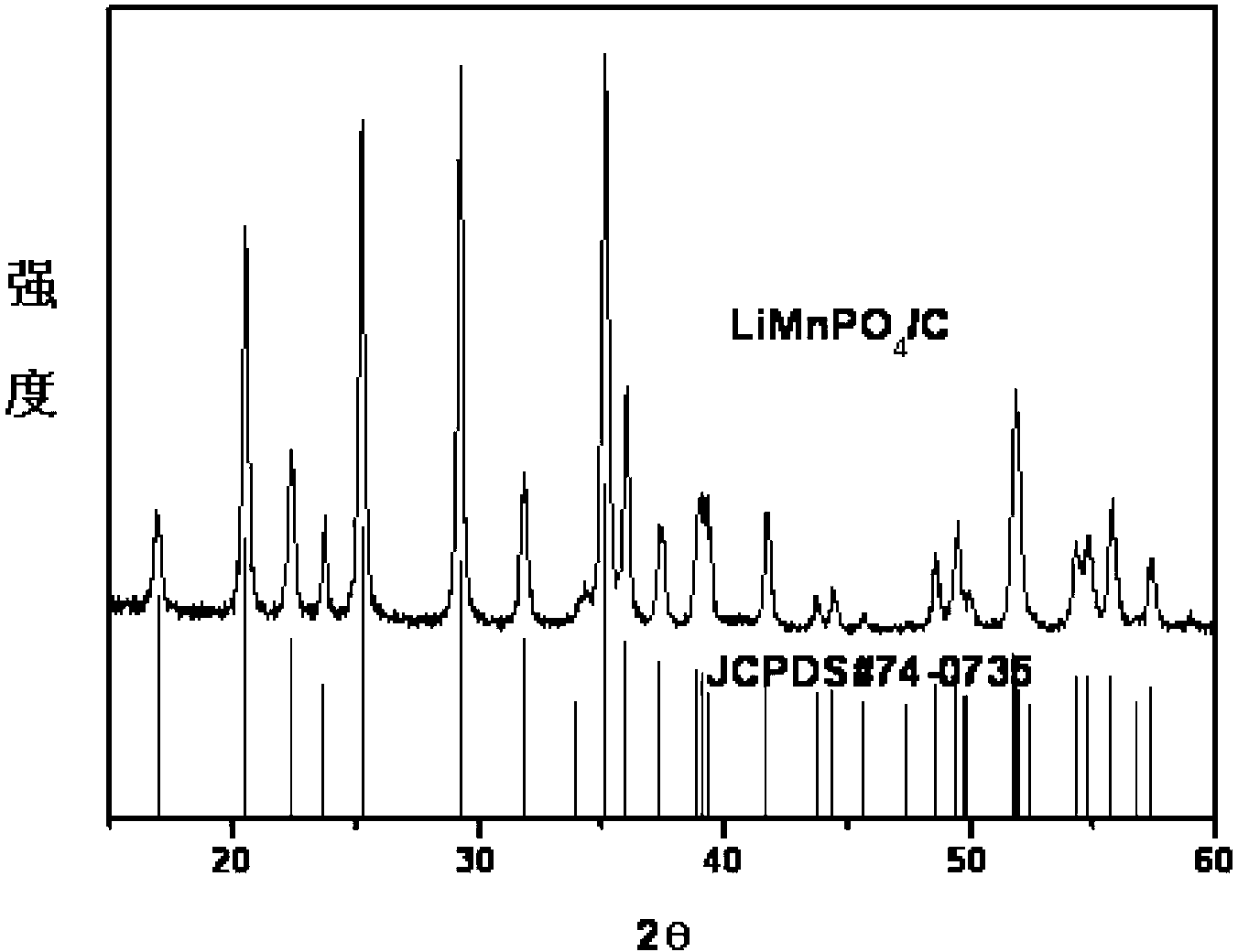

Positive material for lithium ion battery, preparation method of material, and lithium ion battery

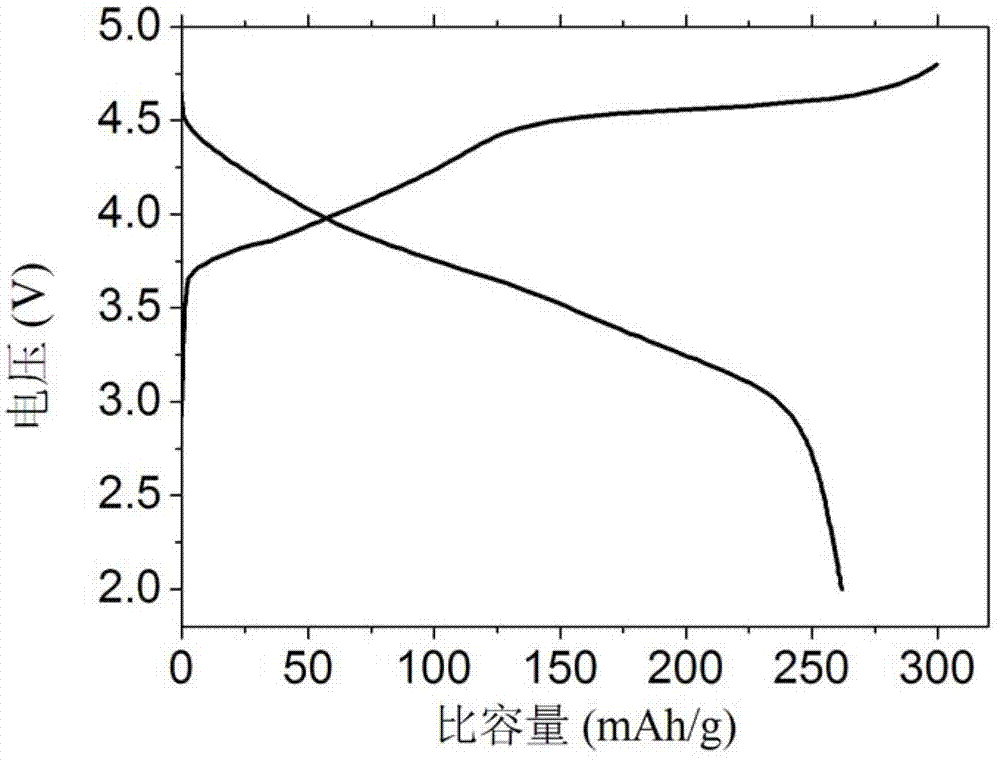

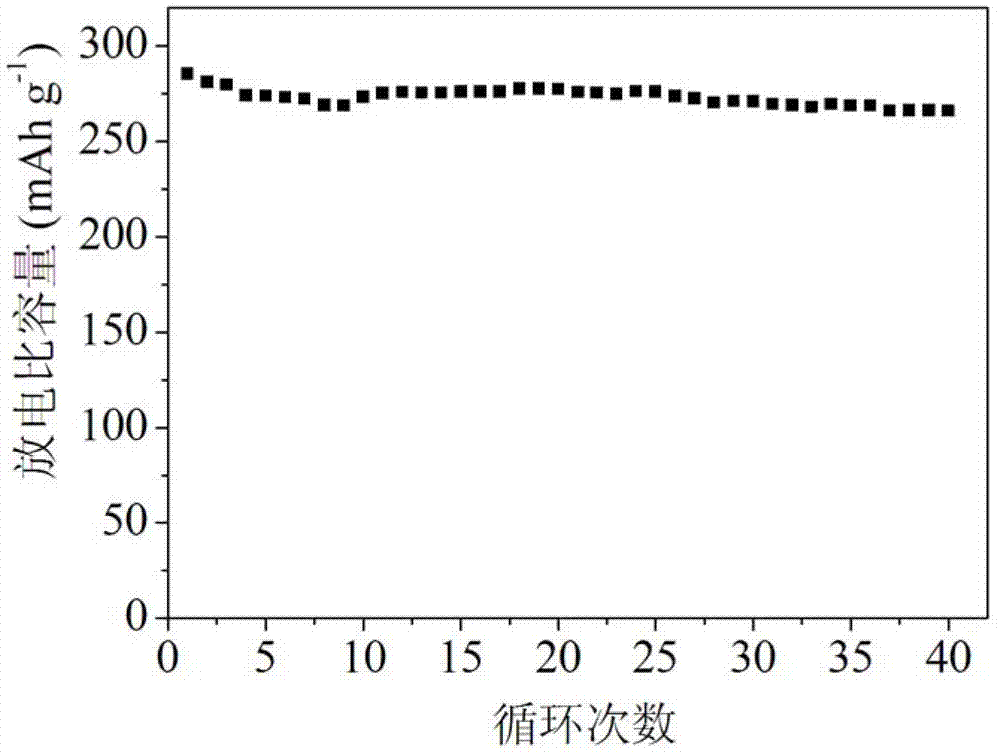

ActiveCN103258994AImprove performanceSmall particle sizeCell electrodesSecondary cellsSodium-ion batterySolvent

The invention provides a positive material for a lithium ion battery and a preparation method thereof. The method comprises the following steps of: providing nano lithium phosphate with a hollow structure; mixing the nano lithium phosphate, a soluble manganese source compound and an additive with a mixed solvent of water and polyhydric alcohol; carrying out ball milling to obtain a mixed solution; then keeping heat of the mixed solution in a closed reaction kettle filled with inert gas under the condition that the temperature is 150-230 DEG C to obtain lithium phosphate; mixing the lithium phosphate with a carbon source compound and carrying out the ball milling; and calcining to obtain the positive material for the lithium ion battery of carbon coated lithium phosphate. According to the positive material and the preparation method thereof disclosed by the invention, polyhydric alcohol-hydrothermal reaction between a solid and liquid can be carried out on the lithium phosphate and the soluble manganese source compound, so that the grain diameter of a lithium phosphate crystal is effectively reduced and a crystal form of the lithium phosphate crystal is integrally formed; and furthermore, the positive material for the lithium ion battery with high specific capacity and specific energy can be obtained and is good for popularization. The invention further provides the lithium ion battery.

Owner:TIANJIN B&M SCI & TECH

Preparation method for graphene rare earth aluminum alloy high-conductive material

ActiveCN107099708AReduce the degree of reunionLow densityConductive materialMetal/alloy conductorsRare earthConductive materials

The invention discloses a preparation method for a graphene rare earth aluminum alloy high-conductive material. The method comprises the following steps: adding aluminum scrap, silicon calcium alloy, copper aluminum alloy, zinc aluminum alloy, magnesium ingot, rare earth aluminum alloy and graphene into a smelting furnace for smelting; performing ladle analysis, thereby acquiring an aluminum alloy solution; casting and rolling the aluminum alloy solution, thereby acquiring aluminum alloy; performing homogenization treatment on the aluminum alloy; performing ageing treatment, thereby acquiring the graphene rare earth aluminum alloy high-conductive material. According to the preparation method for the graphene rare earth aluminum alloy high-conductive material, provided by the invention, the technical parameters are reasonably set, the graphene structure is optimized and the overall performance of the aluminum alloy is effectively improved, so that the acquired graphene rare earth aluminum alloy high-conductive material has excellent electric conductivity, heat resistance, arc altitude resistance and mechanical properties.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

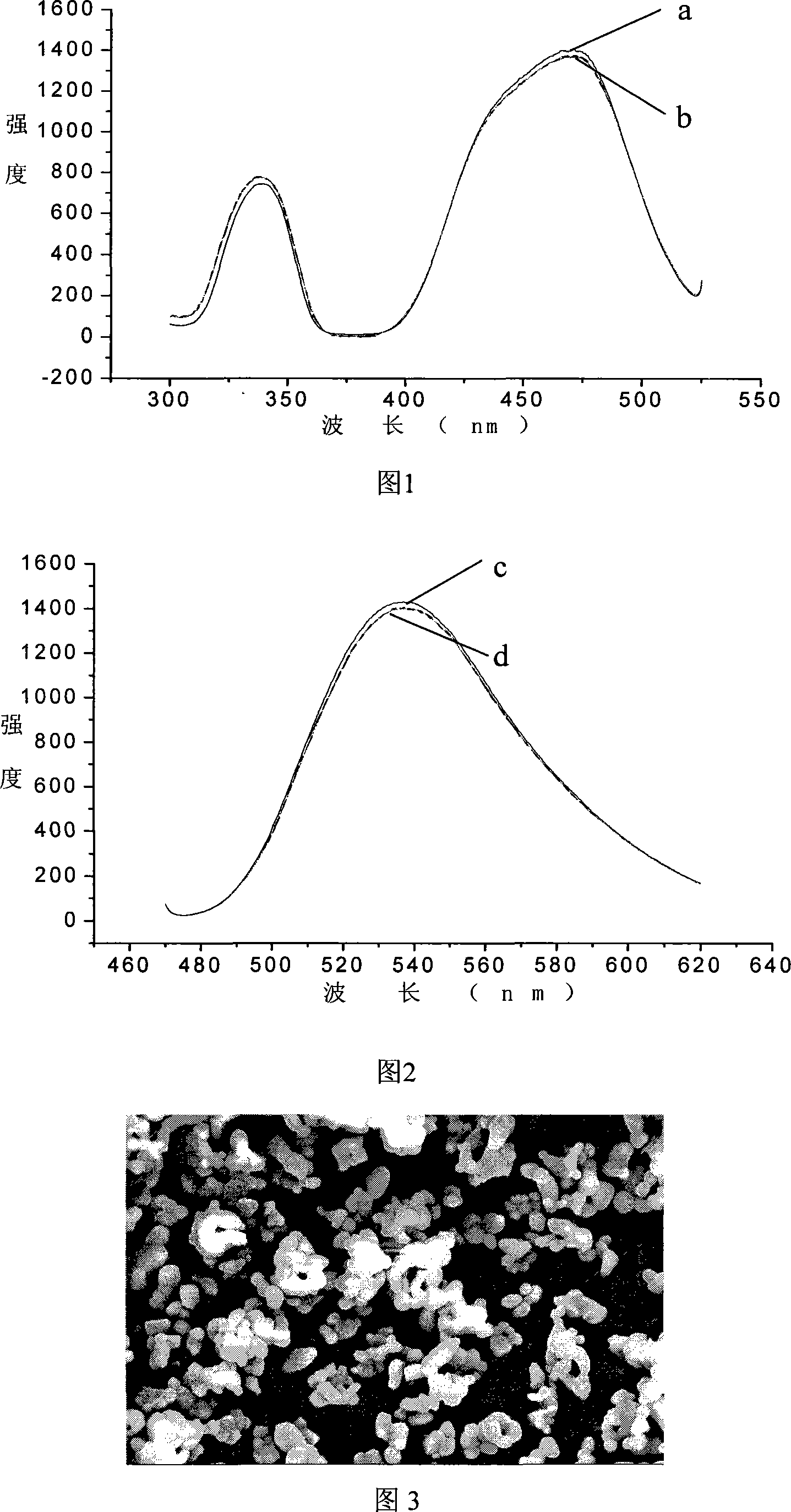

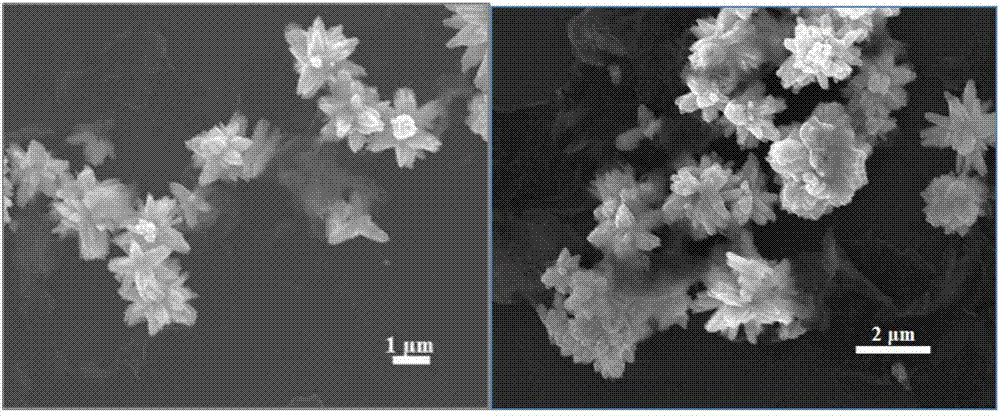

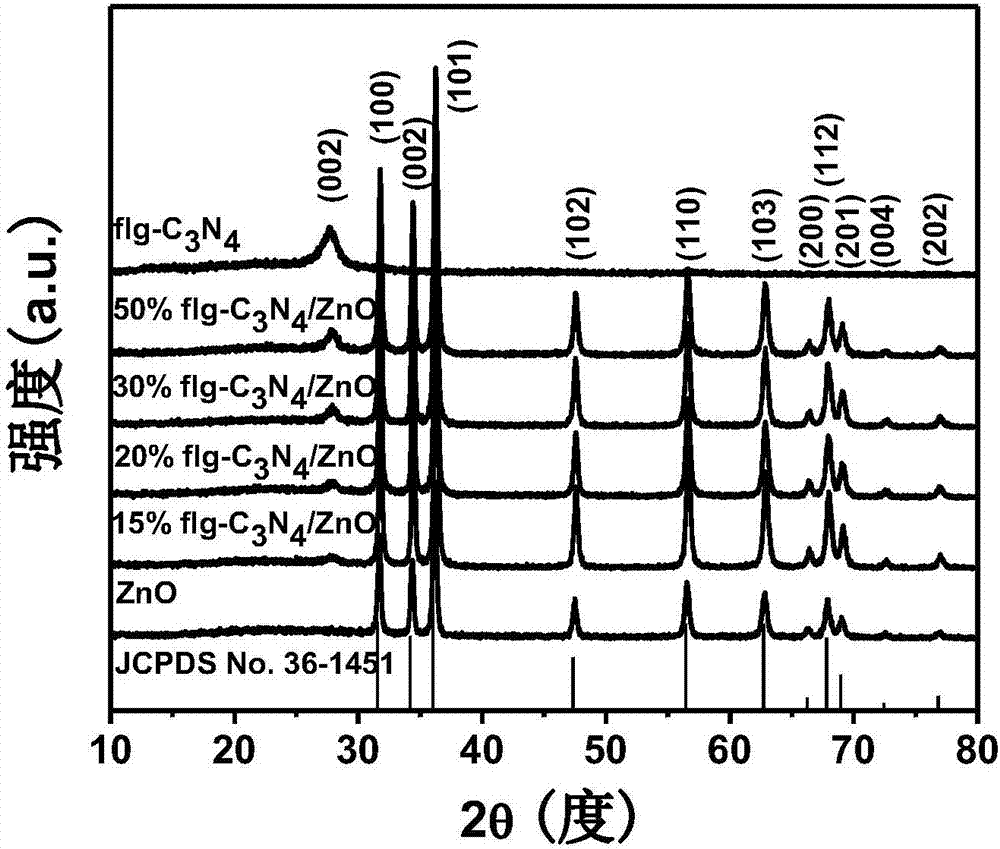

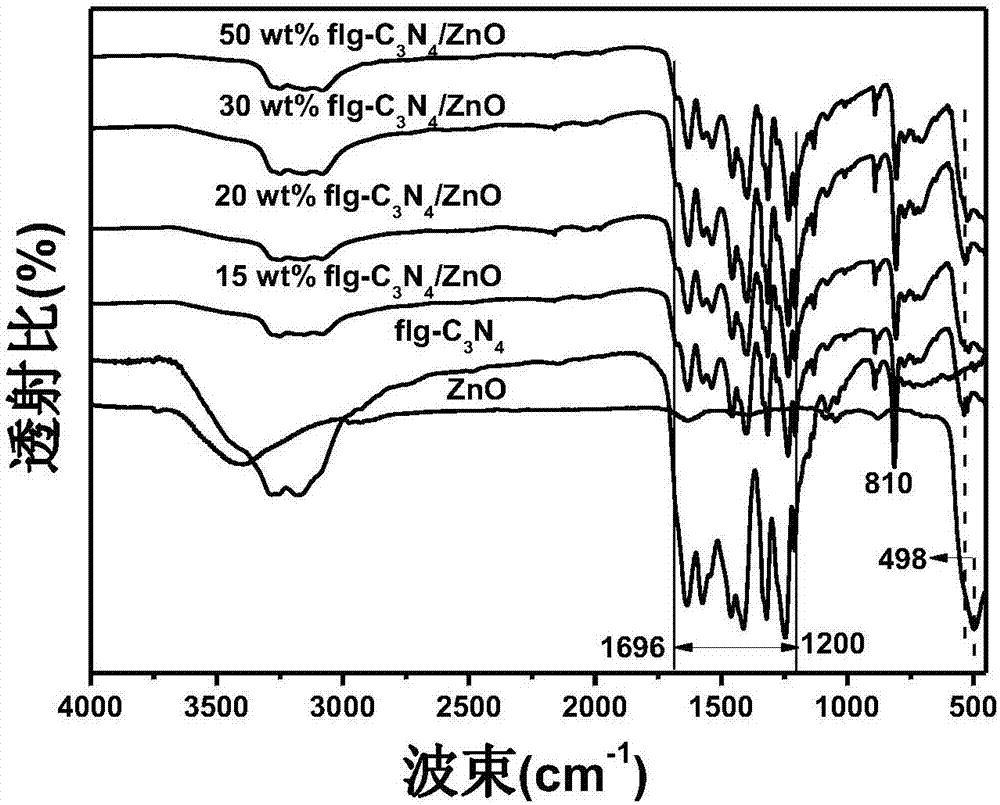

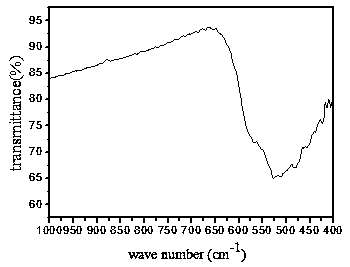

Preparation method for visible-light-responsive composite photocatalyst

InactiveCN106964386AReduce the degree of reunionHigh activityPhysical/chemical process catalystsWater/sewage treatment by irradiationEvaporationLight responsive

The invention relates to a preparation method for a visible-light-responsive composite photocatalyst. The photocatalyst is a few-layer carbo nitride / zinc oxide compound. The composite photocatalyst is prepared by compounding a certain mass of few-layer carbo nitride (few-layer C3N4) and a certain mass of zinc oxide (ZnO). The preparation method comprises the following concrete steps: placing a prepared flower-like ZnO material in deionized water for ultrasonic treatment until uniform dispersion is realized; then adding a certain mass of few-layer C3N4 and continuing ultrasonic dispersion and stirring for a certain period of time; and then transferring a mixed solution to an oil-bath pan for heating under stirring until evaporation to dryness is realized so as to obtain the few-layer C3N4 / ZnO composite photocatalyst. The results of photocatalysis performance experiments prove that the composite photocatalyst has a wide visible light response range and high photocatalytic activity compared with a non-visible-light-responsive ZnO material with a wide band gap, and has good application prospects and economic benefits in conversion of solar energy, sewage treatment and the like.

Owner:JIANGSU UNIV

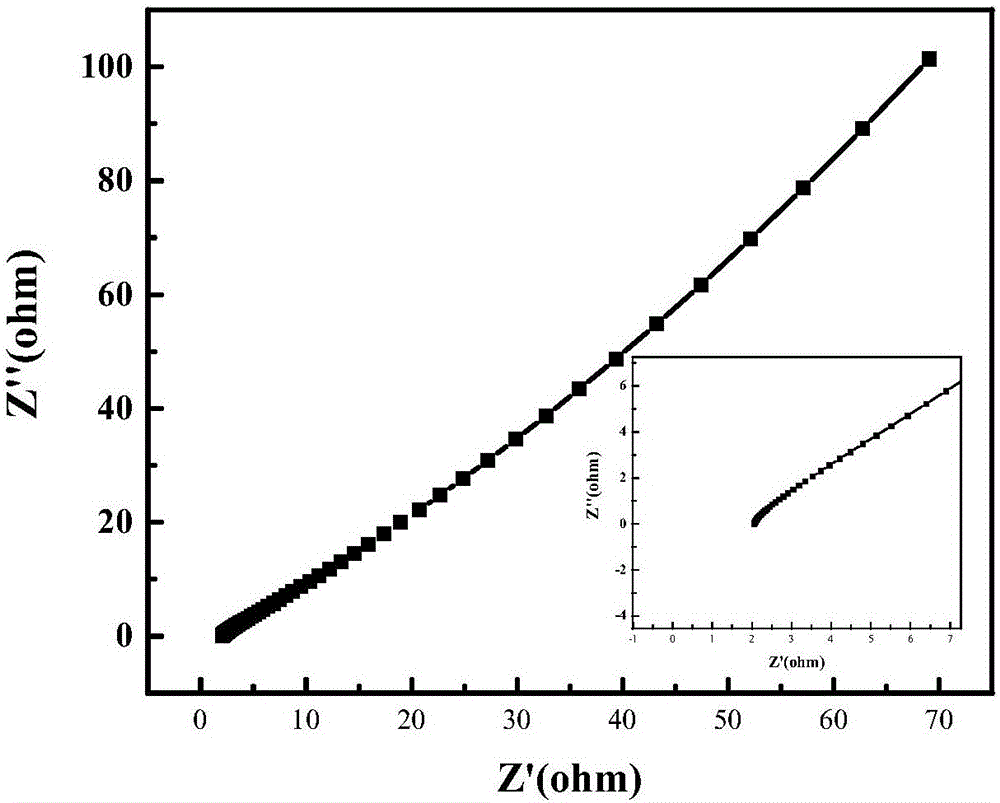

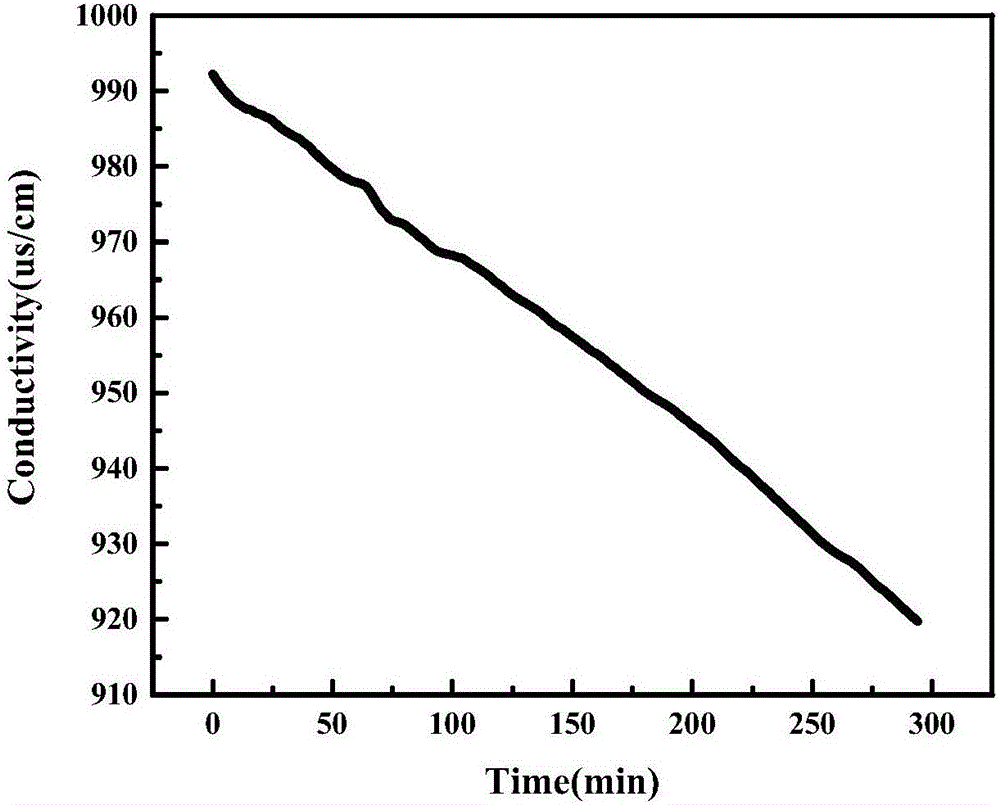

Preparation method of porous graphene/polypyrrole electrode material

ActiveCN107522269AImprove conductivityReduce the degree of reunionDispersed particle separationWater/sewage treatmentWater bathsPeristaltic pump

The invention discloses a preparation method of a porous graphene / polypyrrole electrode material. The preparation method of the porous graphene / polypyrrole electrode material comprises dissolving pyrrole in a water-ethanol mixed solution, and then adding in a certain amount of graphene oxide; in an ice-water bath, adding in and uniformly mixing ferrous chloride tetrahydrate, dropwise adding in hydrogen peroxide solution through a peristaltic pump and continuing to stirring the solution for 24 h; then, adding in a certain amount of reducing agent, performing treatment in a thermostatic water bath of 95 DEG C for 12 h; suction-filtering and washing the obtained mixture, and vacuum-drying the washed mixture at 40 DEG C for 12 h to obtain a porous graphene / polypyrrole sample. The prepared porous graphene / polypyrrole sample achieves good effects on the capacitive deionization technology.

Owner:TONGJI UNIV

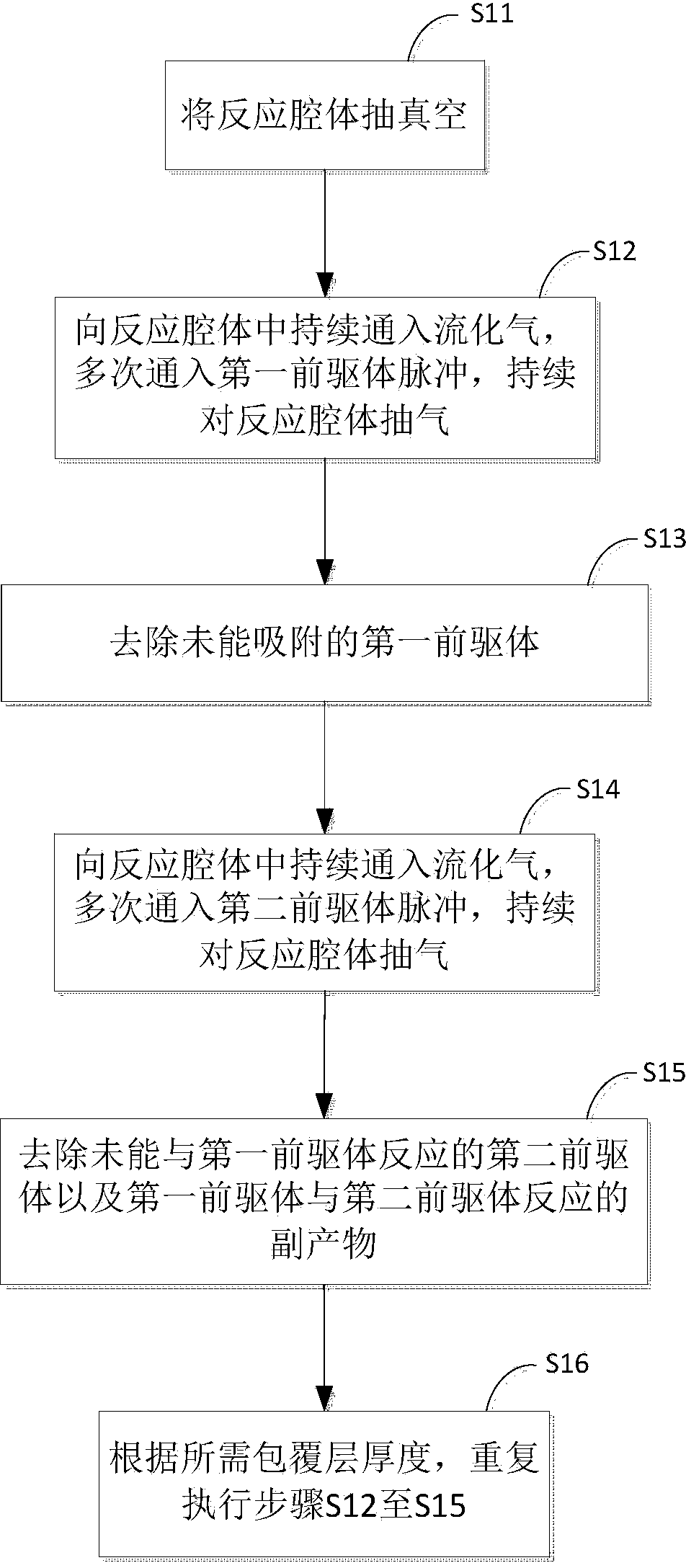

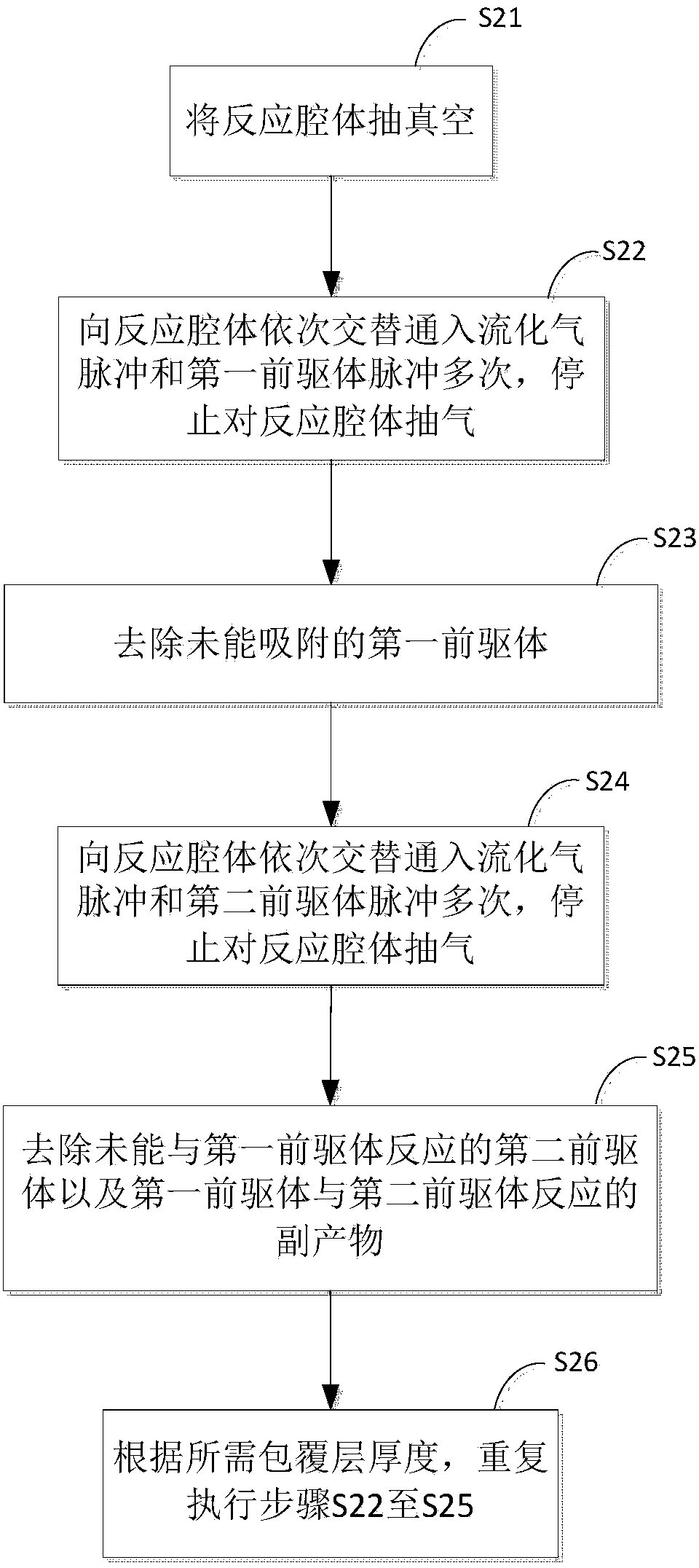

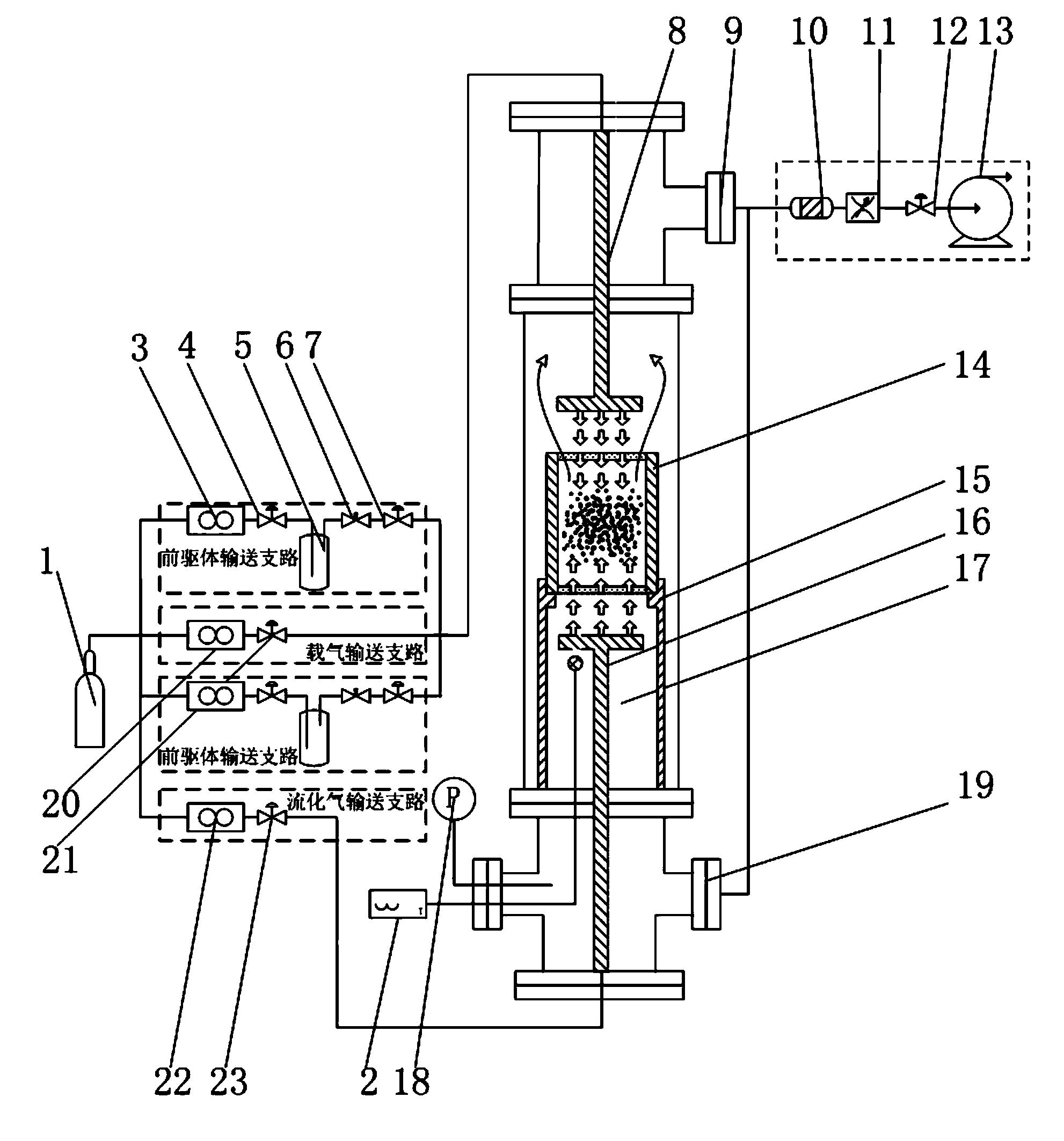

Atomic layer deposition method and atomic layer deposition device for coating ultrafine powder

ActiveCN103451623AReduce the degree of reunionIncrease coverageChemical vapor deposition coatingMetallurgyControl system

The invention discloses an atomic layer deposition method and an atomic layer deposition device for coating ultrafine powder. The atomic layer deposition method is characterized in that fluidized gas is introduced into an adsorption process of a precursor, powder is blown away by utilizing the fluidized gas, and sufficient dispersion of the powder is realized. The atomic layer deposition device comprises a reaction cavity, a supply system, a vacuum system, a heating system, a monitoring system and a control system and is characterized in that the supply system comprises a fluidized gas source, and the fluidized gas enters a reaction cavity by virtue of a fluidized gas delivery branch and is used for blowing away the powder into the whole reaction region. By adopting the atomic layer deposition method and the atomic layer deposition device, powder coating rate and deposition uniformity can be effectively improved, and massive powder can be coated in each deposition process, so that the powder coating efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

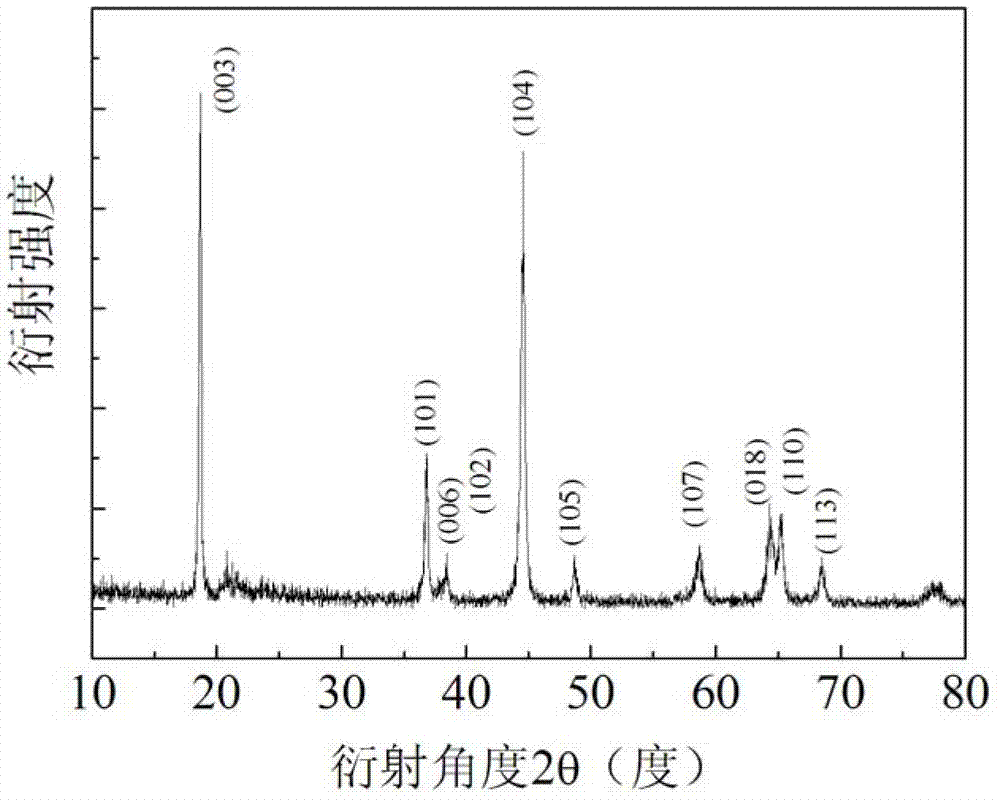

Carbon-coated lithium-rich positive electrode material as well as preparation method thereof

ActiveCN103545519AGood charge and discharge cycle performanceImproved magnification performanceCell electrodesCarbon layerLithium-ion battery

The invention belongs to the technical field of lithium ion battery positive electrode materials and discloses a carbon-coated lithium-rich positive electrode material as well as a preparation method thereof. The surface-coated lithium-rich material comprises a principal phase Li[LiaNi(1 / 2-3a / 2)M(n1 / 2+a / 2)]O2 (a being greater than 0 and less than 1 / 3) as well as a coated carbon layer. The preparation method of the material comprises the following steps: a step of preparing an intermediate phase of the lithium-rich material, namely Li[LiaNi(1 / 2-3a / 2)M(n1 / 2+a / 2)]O2 (a being greater than 0 and less than 1 / 3), a step of uniformly mixing the lithium-rich intermediate phase and a carbon source, and a step of quickly and thermally treating at a high speed. The lithium ion battery positive electrode material prepared by the preparation method disclosed by the invention greatly improves charging and discharging performances of the material under high multiplying power and can satisfy high-power development requirements. Moreover, the carbon-coated lithium-rich positive electrode material is low in material cost, simple in process, high in cost performance and suitable for industrial production.

Owner:SUZHOU QINGTAO NEW ENERGY TECH CO LTD

Filtration method of nanometer molecular screen

InactiveCN1541765ALife expectancyPromote flocculationMolecular sieve catalystsLoose filtering material filtersMolecular sieveFlocculation

The filtering method for nano molecular sieve features that the method includes adding alkali medium, non-electrolyte and water into molecular sieve slurry. The added amount of the alkali medium is such that the mixture has pH not lower than 12; and the volume ratio among molecular sieve slurry, non-electrolyte and water is 1 to 1-5 to 0-2. The said method can inhibit flocculation of un-crystallized SiO2 effectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing silicon-based oxynitride fluorescent powder

InactiveCN101818063ALow costSynthesis temperature is lowLuminescent compositionsLuminous intensityFluorescence

The invention discloses a method for preparing silicon-based oxynitride fluorescent powder, which comprises the following steps of: weighing corresponding raw materials and silica powder based on stoichiometric proportion of each element in the chemical formula of the silicon-based oxynitride fluorescent powder, after uniformly mixing the raw materials and the silica powder, raising the temperature to 800 to 1,000 DEG C under any one of the conditions of condition a to condition c, performing reduction reaction under the condition c or the condition d, and cooling the reaction product to roomtemperature to obtain the silicon-based oxynitride fluorescent powder, wherein the condition a is vacuum; the condition b is the atmosphere of inert gases; the condition c is the atmosphere of nitrogen-containing gases; and the condition d is the atmosphere of reductive gas. The silicon-based oxynitride fluorescent powder doped with various luminescent ions and prepared by the method has bright fluorescence under the excitation of ultraviolet ray, near ultraviolet or visible light. The method has the advantages of low preparation temperature of the product, high phase purity of the product, controllable particle size of the product, good luminous intensity of the product, low cost, simple process and the like, and is easy to enlarge industrialization.

Owner:UNIV OF SCI & TECH OF CHINA

Nano zirconia/epoxy resin compound material and preparation method thereof

The present invention discloses a nano zirconia / epoxy resin compound material and a preparation method thereof, and belongs to the technical field of material preparation. The nano zirconia / epoxy resin compound material comprises zirconia nanoparticles and an epoxy resin; and the zirconia nanoparticles can be uniformly dispersed in the epoxy resin matrix in an amount of 1-10 wt% of the epoxy resin. The method comprises the following steps: (1) the zirconia nanoparticles are prepared by a sol-gel combustion method; (2) a silane coupling agent is used to conduct surface-modifying of the zirconiananoparticles; (3) the modified zirconia nanoparticles are dispersed in the epoxy resin to form a uniform nano-zirconia / epoxy resin dispersion system; and (4) a curing agent is added to conduct curing. The ZrO2 nanoparticles synthesized by improving the sol-gel method are introduced into the epoxy resin dispersion system to significantly improve the toughness of the resin after the curing and greatly improve the mechanical properties of the epoxy resin. Besides, the nano zirconia / epoxy resin compound material is simple in preparation technology, low in production costs and mild in reaction conditions, can be subjected to batch production, and can meet the special requirements for the resin materials in various fields of aerospace, civil industry, etc.

Owner:DALIAN UNIV OF TECH

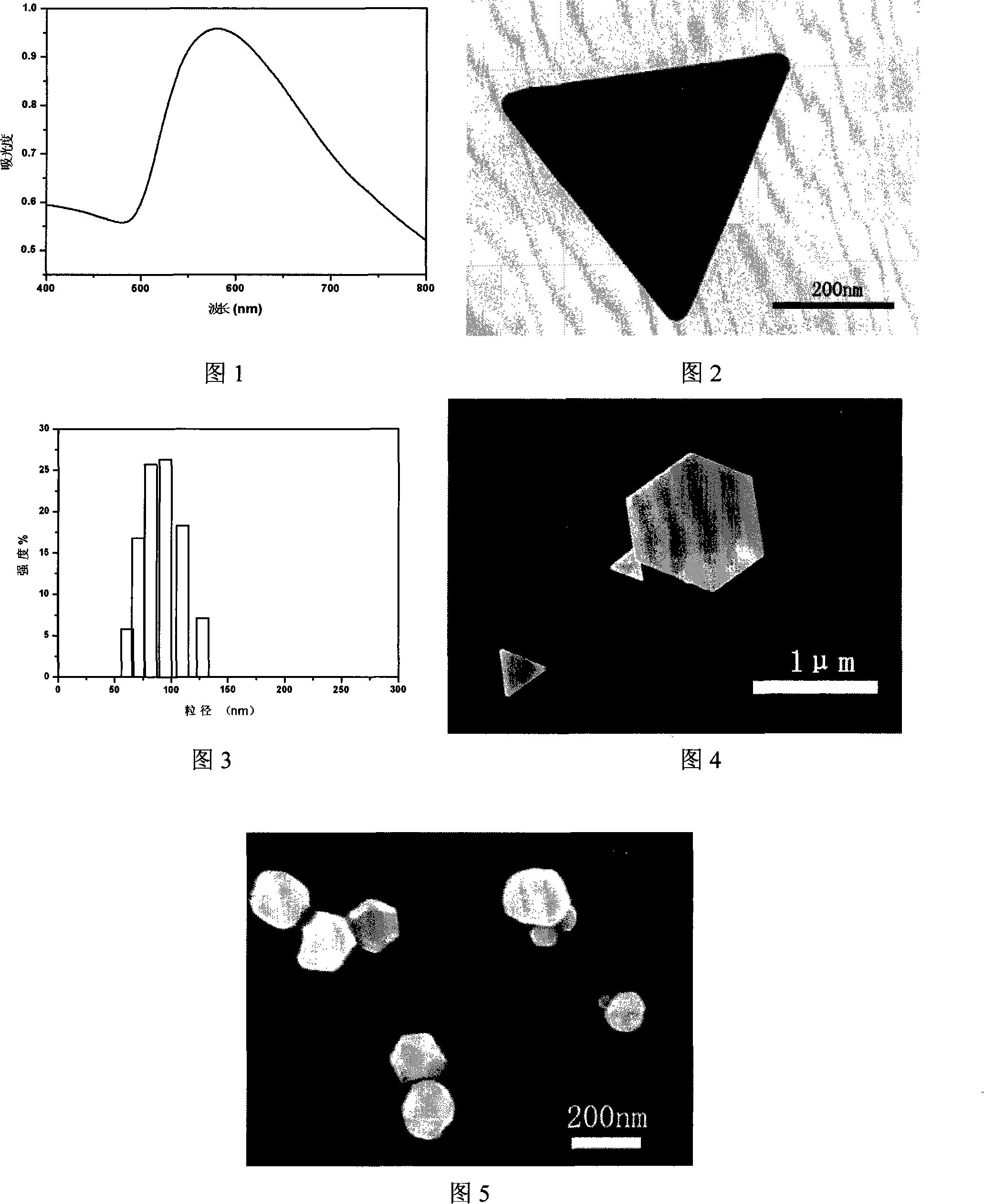

Method for hydrothermally synthesizing nano-Au with polyacrylic acid

The invention relates to a preparation method of gold-nano by poly-acrylic acid hydrothermal synthesis, relates to a gold-nano, which provides a gold-nano particle or gold-nano piece with form and shape can be changed through changing experimental conditions. The method is simple and applicable, has low cost and easy obtained material and is applicable for large-scale industrialization production. The production process has no pollution to environment, which is a method of gold-nano by poly-acrylic acid hydrothermal synthesis that meets the requirement of advocating 'green chemistry'. Water is added with polymer, stirred to dissolve; after the polymer is completely dissolved, auric chloride acid is added and stirred and before-reaction precursor solution is obtained; the before-reaction precursor solution is poured into polytetrafluoroethylene lining, put into a high pressure vessel and sealed to react; then the reaction device is cooled to room temperature and centrifugated, leading the gold-nano particle and the polymer to be separated; the gold-nano particle is washed with ethanol, and the gold-nano is obtained. The gold-nano generally comprises gold-nano particle or / and nano-glod piece.

Owner:XIAMEN UNIV

Method for preparing nano hydrotalcite and nano calcium carbonate composite modified polyvinyl chloride resin

The invention relates to a preparation method of a polyvinyl chloride resin modified in compound by nano-hydrotalcite and nano-calcium carbonate. The steps of the preparation method are as follows: (1) 1.0g of the nano-hydrotalcite and 1.0 to 5.0g of the nano-calcium carbonate are added into 10 to 50g of deionized water containing 0.1 to 0.5g of dispersant, and are sheared and dispersed in ultrasonic or high speed for 10 to 60 min in the temperature of 20 to 100 DEG C, and the compound dispersion solution of the nano-hydrotalcite and the nano-calcium carbonate is obtained; (2) the compound dispersion solution of the nano-hydrotalcite and the nano-calcium carbonate, 0.05 to 0.50g of the initiator, 0.1 to 0.5g of the dispersant, 100g of vinyl chloride and 100 to 250g of the deionized water are put into a polymerization reactor and polymerized with the temperature being raised to 45 to 65 DEG C after being mixed for 10 to 60 min in room temperature until system pressure falls 0.5 to 2.5kg / cm2. Unreacted vinyl chloride is removed when the polymerization is finished, and then the polyvinyl chloride resin modified in compound by nano-hydrotalcite and nano-calcium carbonate is obtained after the material in the polymerization reactor is discharged, filtered and dried. The modified polyvinyl chloride prepared with the invention can become polyvinyl chloride compound material with uniform dispersed nano particles, improved thermal stability and mechanical property and low dense burning smoke through being processed.

Owner:ZHEJIANG UNIV +1

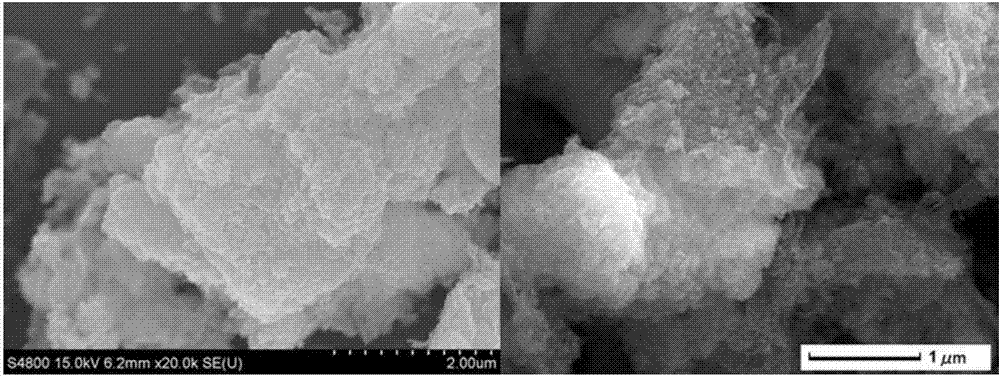

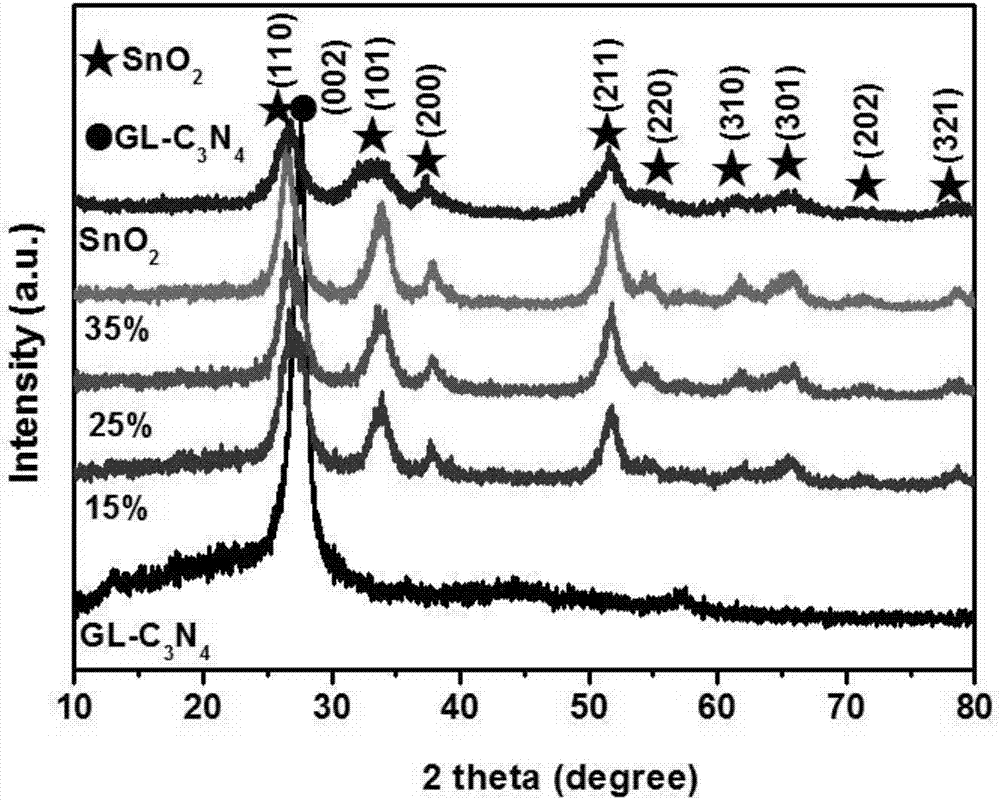

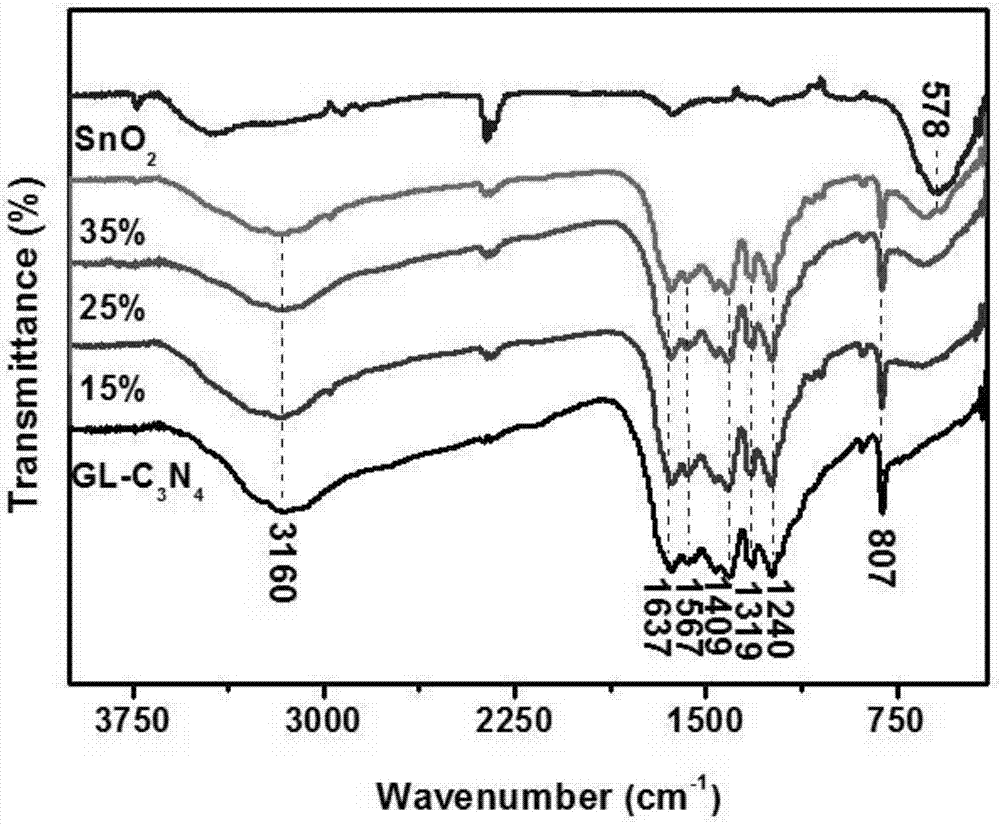

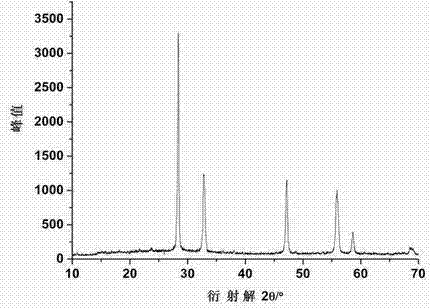

Stannic oxide/graphene carbon nitride composite photocatalytic material and preparation method thereof

InactiveCN107096558ASimple and fast operationLow costPhysical/chemical process catalystsTin dioxideGraphite carbon

The invention belongs to the field of photocatalysis and particularly relates to a stannic oxide / graphene carbon nitride composite photocatalytic material and a preparation method thereof. A composite photocatalyst is prepared by in-situ composition of stannic oxide (SnO2) and a certain mass of graphene carbon nitride (GL-C3N4) obtained by stripping graphite carbon nitride (g-C3N4) through ammonium chloride (NH4Cl). A photocatalytic performance experiment proves that the composite photocatalyst has relatively high photocatalytic activity in comparison with monomers carbon nitride and stannic oxide, and has good application prospect and economic benefit in the aspects of solar energy conversion and sewage treatment.

Owner:JIANGSU UNIV

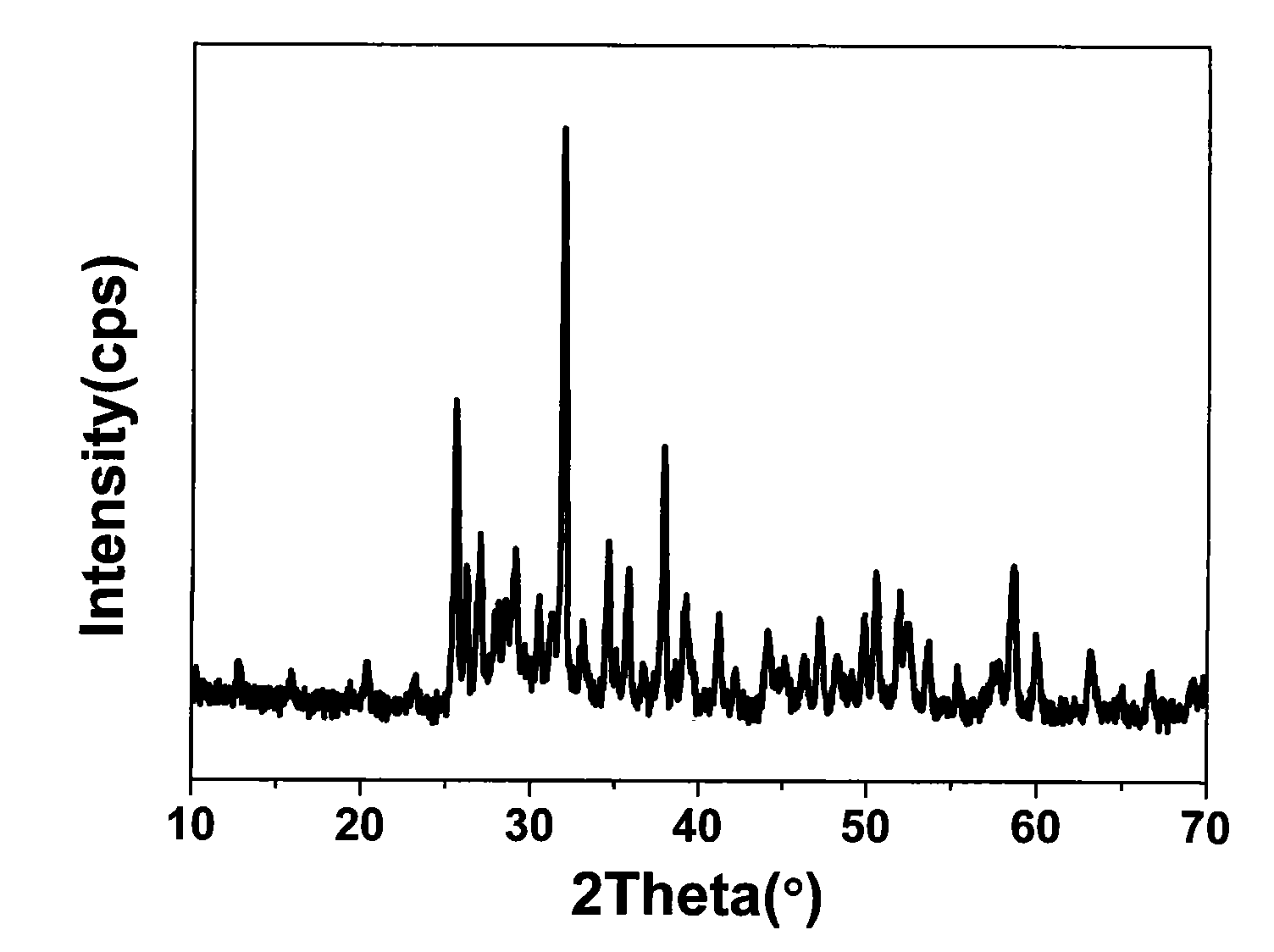

Sol-gel-hydrothermal method for preparing bismuth tungstate and indium-doped bismuth tungstate

InactiveCN102765758AHigh crystallinityLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsTungsten compoundsIndiumTungstate

The invention discloses a sol-gel-hydrothermal method for preparing bismuth tungstate and indium-doped bismuth tungstate. The technical scheme point of the invention is to respectively disclose a sol-gel-hydrothermal method for preparing a bismuth tungstate catalyst and a sol-gel-hydrothermal method for preparing an indium-doped bismuth tungstate catalyst. The preparation method disclosed by the invention has the advantages of simple operation and low cost; and the prepared bismuth tungstate catalyst and the indium-doped bismuth tungstate catalyst have excellent photocatalysis performance.

Owner:HENAN NORMAL UNIV

Graphene powder and preparation method thereof

ActiveCN104787751ALower decomposition temperatureConducive to the degree of oxidationState of artCvd graphene

The present invention provides a graphene powder preparation method, which comprises: a, carrying out a reaction of graphite oxide and a dispersant to obtain an intermediate product, wherein the dispersant comprises an ammonium salt; and b, carrying out a heat treatment on the intermediate product to obtain the graphene powder. According to the present invention, the close contact degree of the graphite oxide sheet layers can be weakened through the dispersant, such that the obtained graphene powder of the present invention has characteristics of low agglomeration degree and good dispersion property; the dispersant is subjected to thermal decomposition to produces gas during the heat treatment process and the gas makes the graphite oxide be peeled, such that the agglomeration degree of the obtained graphene powder of the present invention is further weakened so as to obtain the graphene powder having the good dispersion property; and the graphene powder having the good dispersion property can be obtained without the spray drying compared with the method in the prior art, such that the graphene powder preparation method of the present invention has characteristics of high efficiency and low energy consumption, and can be used for large-scale production of the graphene powder.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

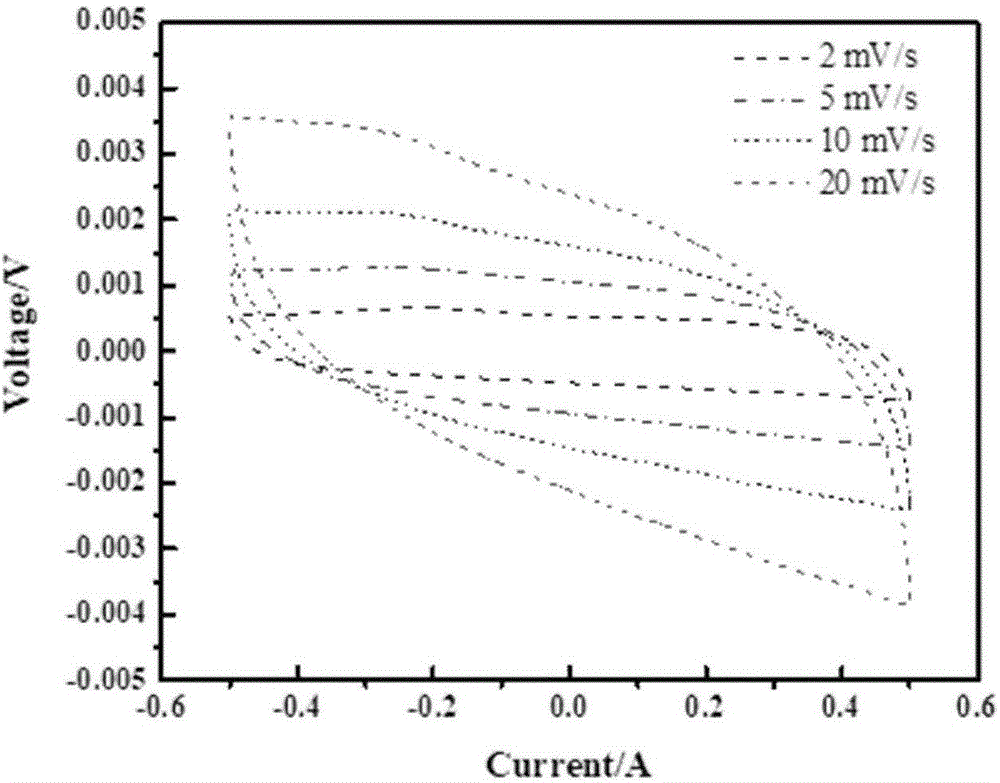

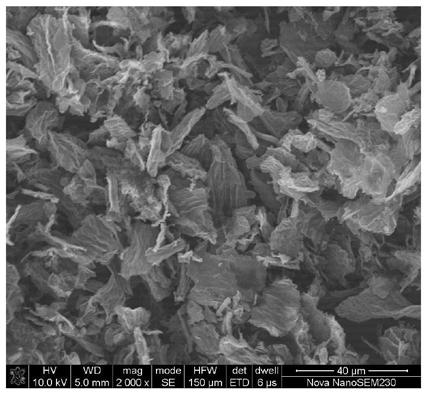

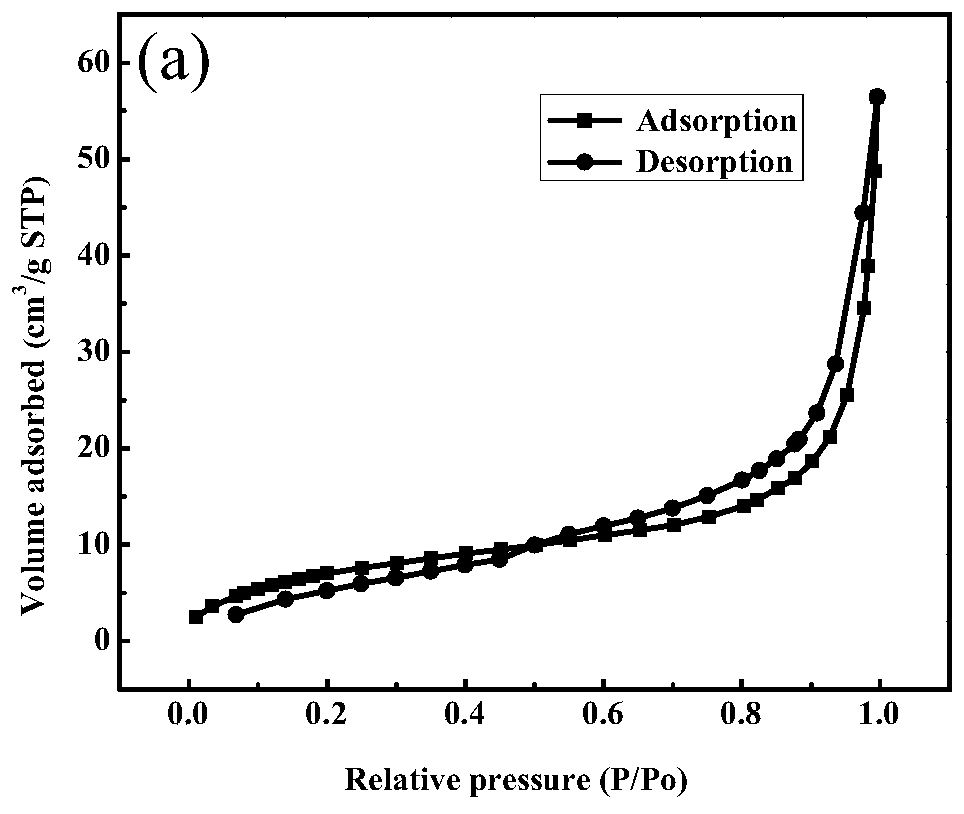

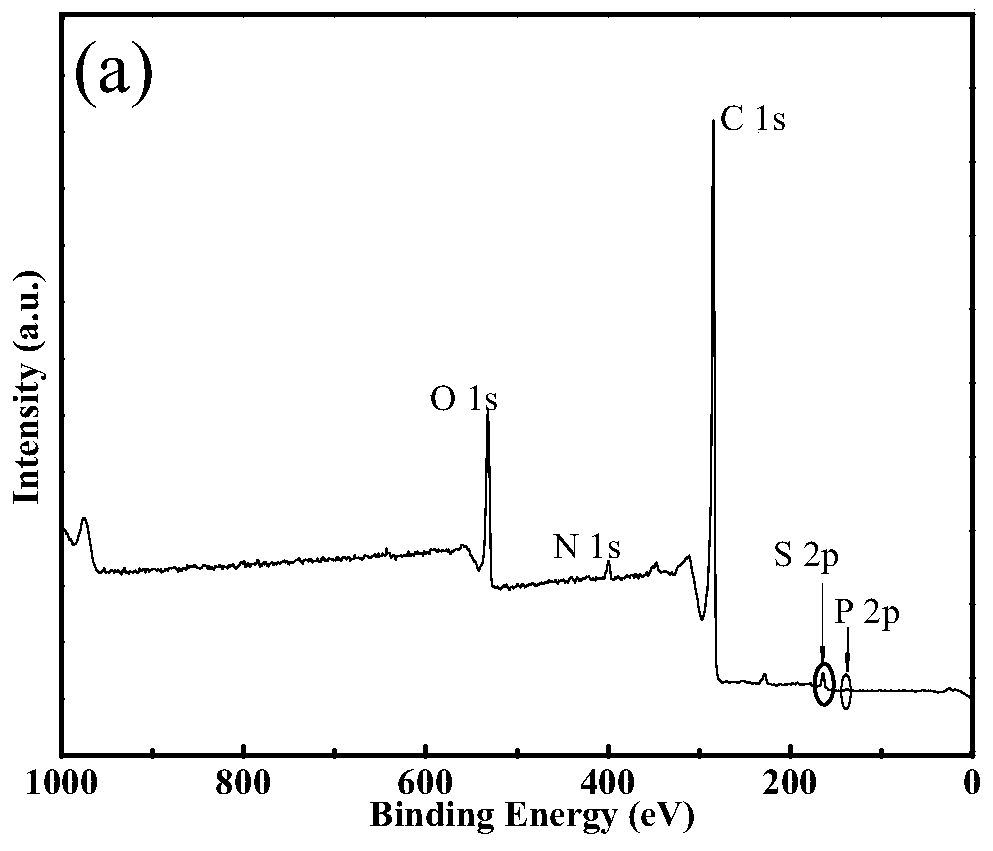

Preparation method of nitrogen-sulfur-phosphorus doped porous graphene oxide material and application of nitrogen-sulfur-phosphorus doped porous graphene oxide material

InactiveCN110391087AImprove performanceHigh densityCarbon compoundsHybrid capacitor electrodesCapacitancePorous graphene

The invention discloses a preparation method of a nitrogen-sulfur-phosphorus doped porous graphene oxide material and application of a nitrogen-sulfur-phosphorus doped porous graphene oxide material.According to the invention, a porous graphene oxide material doped with three elements is prepared by taking graphene oxide as a raw material, adding hydrogen peroxide in a hydrothermal condition forpore-forming and adding a dopant containing three elements of nitrogen,sulfur and phosphorus, and is applied to the electrode material of a supercapacitor. The three-dimensional porous structure is etched on the surface of graphene by using hydrogen peroxide with the strong oxidizing property, so that the specific surface area of a graphene material is further improved, the obtained porous graphene oxide is subjected to ultrasonic dispersion and then is fully mixed with a doping agent containing three elements of nitrogen, phosphorus and sulfur, nitrogen, sulfur and phosphorus heteroatoms areintroduced into the porous graphene oxide to improve the electrochemical performance of the graphene, and the porous graphene oxide is loaded on a conductive current collector to prepare a supercapacitor electrode, so that the capacitor obtains the better capacitance performance and has the good circulation stability.

Owner:HUNAN UNIV OF TECH

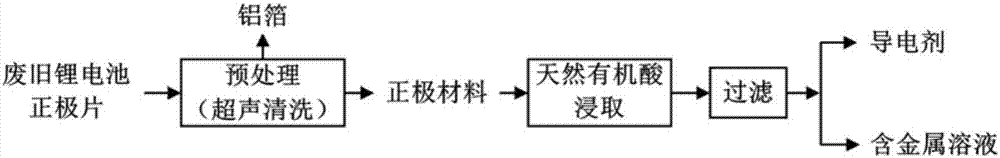

Method for recycling lithium, nickel, cobalt and manganese from waste lithium ion battery

InactiveCN107546437AWon't happenNo secondary pollutionWaste accumulators reclaimingProcess efficiency improvementManganeseLithium-ion battery

The invention provides a method for recycling lithium, nickel, cobalt and manganese from a waste lithium ion battery. The method for recycling lithium, nickel, cobaltand manganese from the waste lithium ion battery comprises the following steps of performing pretreatment of the positive electrode plate of the waste lithium ion battery to enable an aluminium foilto be separated from the positive electrode active material to obtain positive electrode active material powder; by taking a mixed liquid which consists of organic polyatomic acid and a reducing agentas a leaching agent, performing leaching of the positive electrode active material powder to obtain the leaching liquid; and extracting metal elements from the leaching liquid. Compared with the prior art, the method has the difference that the positive electrode active material is leached by adopting the organic polyatomic acid and the reducing agent instead of toxic inorganic acid, so that themethod disclosed in the invention does not generate toxic gas; and in addition, the recycled waste acid liquid can be subjected to biological degradation easily, without causing secondary pollution; and furthermore, the leaching efficiency is also improved.

Owner:EAST CHINA UNIV OF SCI & TECH

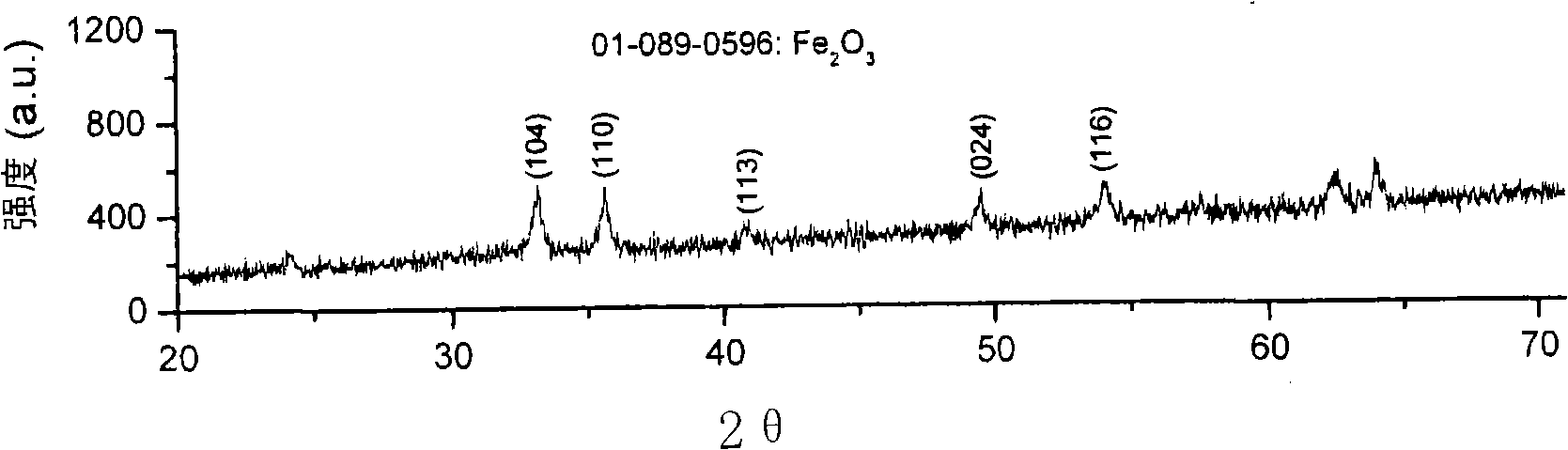

Method for preparing nano ferrous acid copper

InactiveCN101134599AImprove refinementReduce the degree of reunionNanostructure manufactureIron compoundsCombustionRoom temperature

The present invention relates to preparation process of nanometer copper ferrite, and belongs to the field of superfine copper ferrite powder preparing technology. The preparation process includes the following steps: dissolving malic acid in water, adding ferric nitrate nonahydrate and copper nitrate trihydrate, stirring at room temperature, dropping ammonia water to regulate pH value, evaporating solvent, drying and heating for self-spreading combustion to obtain nanometer copper ferrite powder. The process has facile material, low cost, simple operation, high yield and low power consumption.

Owner:EAST CHINA NORMAL UNIV

Preparation method and application of flaky nano copper oxide

ActiveCN110436508ASimple preparation processReduce manufacturing costNanotechnologyCopper oxides/halidesPhotocatalytic degradationCopper salt

The invention discloses a preparation method and application of flaky nano copper oxide. The preparation method of the flaky nano copper oxide mainly comprises the following steps: accurately weighingcopper salt and oxalic acid or oxalate, uniformly mixing the copper salt and the oxalic acid or the oxalate, then grinding, adding a proper amount of distilled water in the grinding process to enablethe mixture to be in a fluid state, heating, cleaning and drying after grinding to obtain a precursor copper oxalate, and calcining the precursor copper oxalate to obtain the flaky nano copper oxide.A preparation technology is simple, no organic solvent except ethanol is used in a preparation process, the preparation method is environment-friendly and safe, and prepared flaky nano copper oxide particles are uniform in size and small in particle size, and have good photocatalytic degradation performance on a methylene blue solution.

Owner:GANSU AGRI UNIV

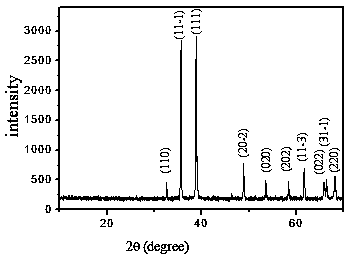

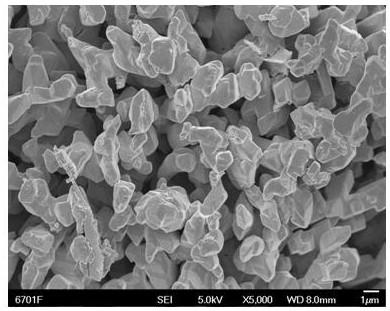

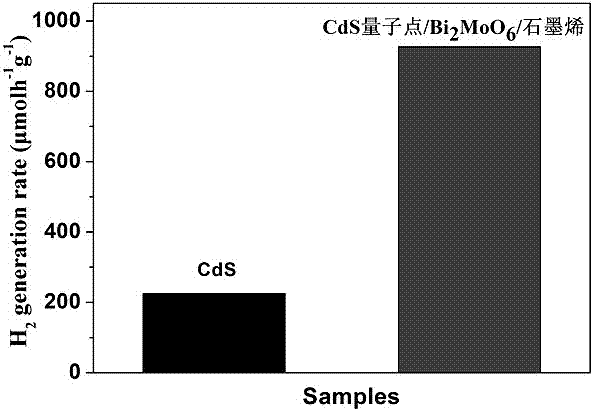

Method for preparing CdS quantum dot/Bi2MoO6/graphene composite photocatalyst

InactiveCN107233899AImprove hydrogen production performanceImprove separation efficiencyMaterial nanotechnologyMolybdeum compoundsPhotocatalytic water splittingQuantum dot

The invention discloses a method for preparing a CdS quantum dot / Bi2MoO6 / graphene composite photocatalyst and belongs to the technical field of synthesis of inorganic environmental-friendly photocatalytic materials. According to key points of the technical scheme of the present invention, the method for preparing the CdS quantum dot / Bi2MoO6 / graphene composite photocatalyst disclosed by the invention comprises the following step: compounding CdS quantum dots, Bi2MoO6 and graphene, to obtain the CdS quantum dot / Bi2MoO6 / graphene composite photocatalyst, wherein a molar ratio of the CdS quantum dot to Bi2MoO6 is 1:(0.1-0.5); and the mass ratio of the graphene to Bi2MoO6 is (0.03-0.15):1. According to the CdS quantum dot / Bi2MoO6 / graphene composite photocatalyst prepared by the method disclosed by the invention, the recombination rate of photo-induced electrons and holes is effectively reduced, photocatalytic water splitting hydrogen production catalytic activity of the CdS quantum dots is improved, and a light etching phenomenon of the CdS quantum dots in the photocatalytic water splitting process is retarded. Moreover, the method has the advantages of mild operating conditions, low agglomeration degree of the prepared product and high photocatalytic activity.

Owner:HENAN NORMAL UNIV

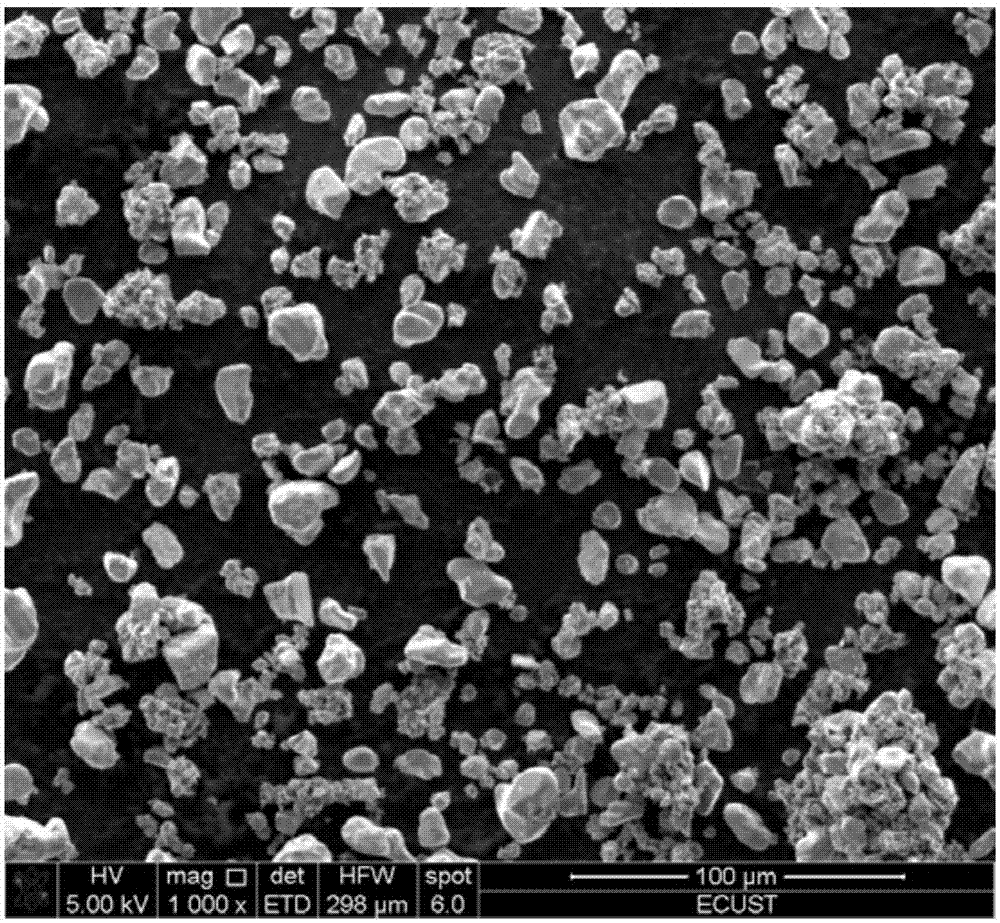

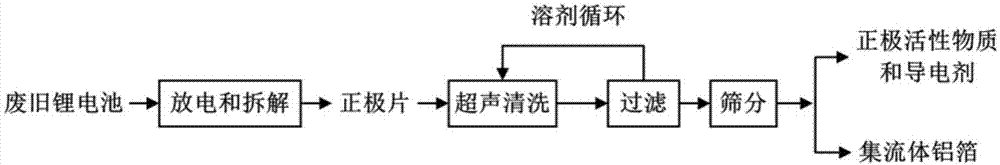

Method for recovering aluminum foil and positive active material from waste lithium ion battery

InactiveCN107579303AHigh recovery rateImprove separation efficiencyWaste accumulators reclaimingBattery recyclingOrganic solventPhysical chemistry

The invention provides a method for recovering an aluminum foil and a positive active material from a waste lithium ion battery. The method comprises the following steps: performing ultrasonic cleaning on a positive plate of the waste lithium ion battery in a solvent, then filtering and collecting a solid and enabling the solid to pass through a sieve of 50-100 [mu]m to respectively obtain the aluminum foil and the positive active material; the solvent is a non-proton polar organic solvent; and the ultrasonic cleaning conditions are as follows: 20-70 kHz and 20-100 DEG C. The method provided by the invention solves the problem of extremely-high loss rate of the positive active material in a traditional method.

Owner:EAST CHINA UNIV OF SCI & TECH

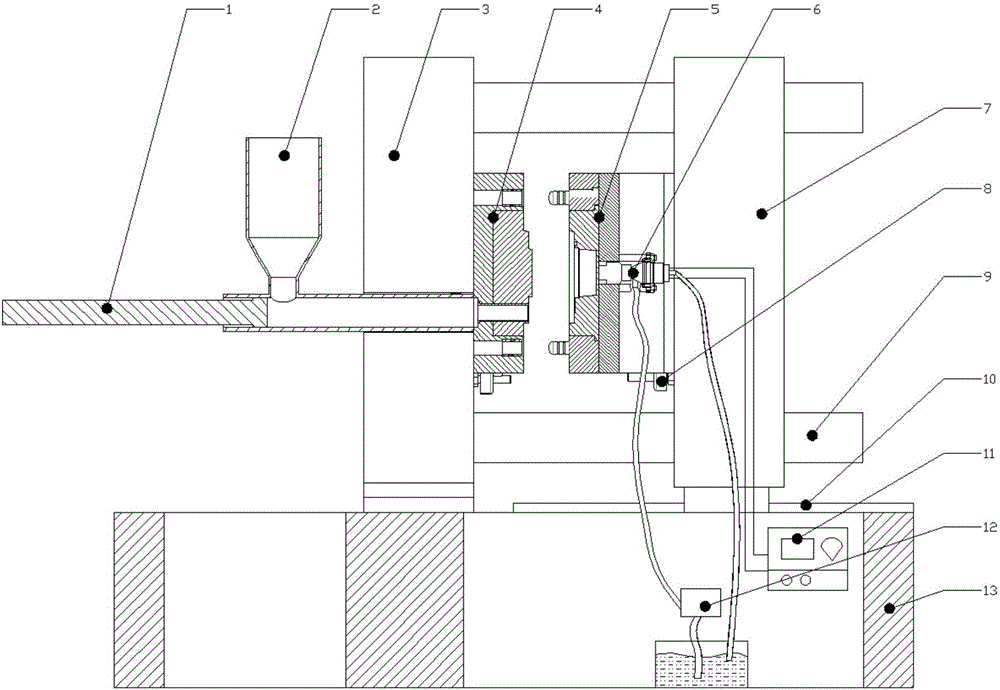

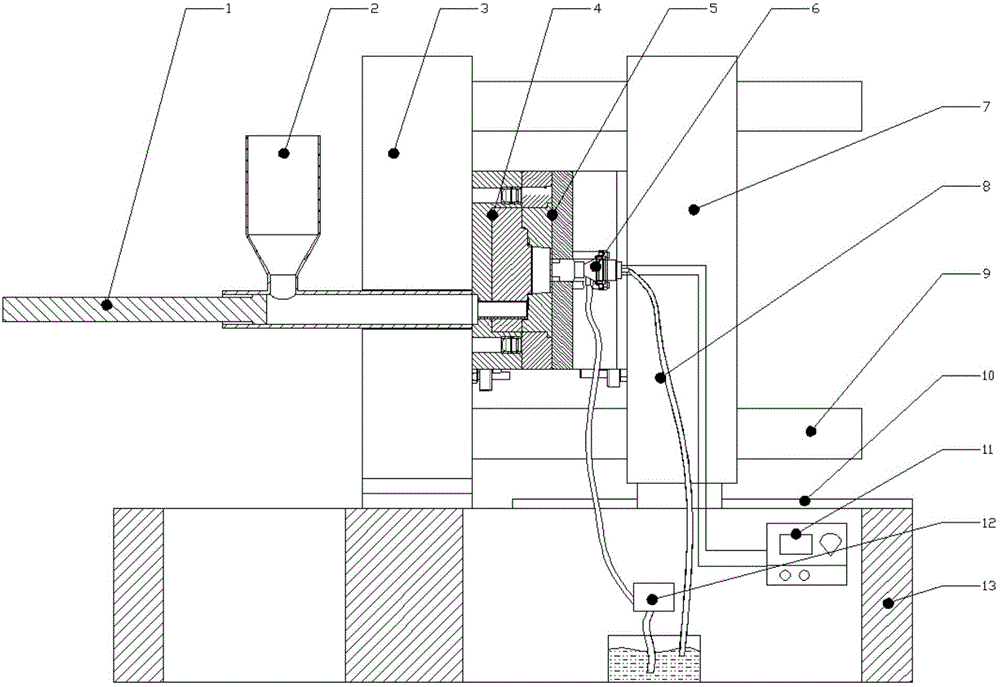

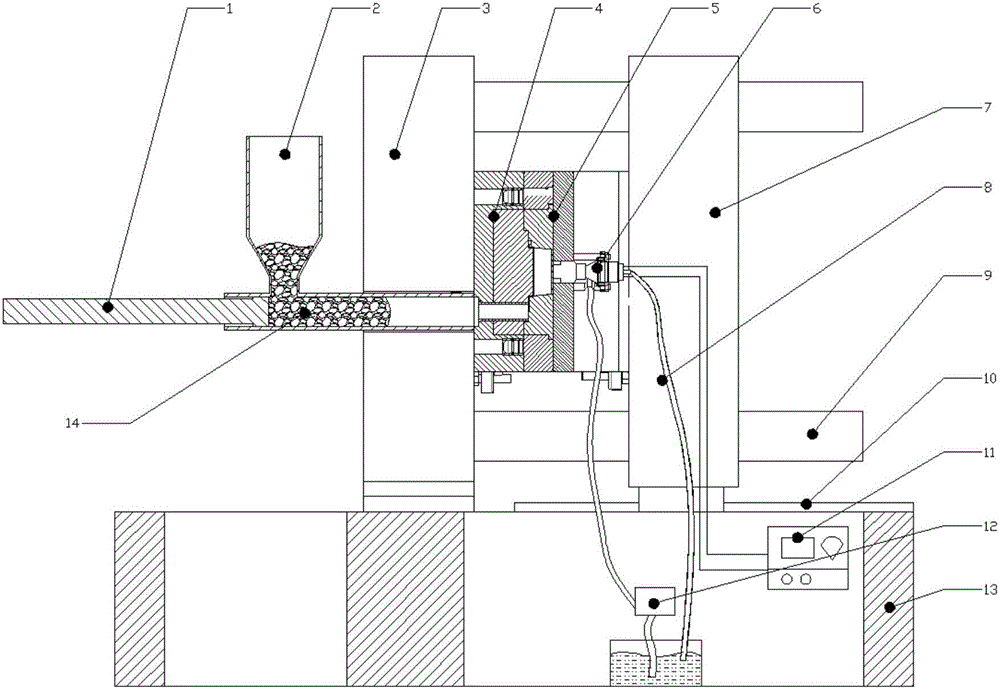

Ultrasound-assisted semisolid die-casting molding device and method for complex thin-wall aluminum alloy pieces

The invention discloses an ultrasound-assisted semisolid die-casting molding device and method for complex thin-wall aluminum alloy pieces. The ultrasound-assisted semisolid die-casting molding device comprises a die-casting machine, a die-casting die, an ultrasonic vibration system and a cooling system. The die-casting die is mounted on the die-casting machine. A press-jet assembly penetrates through a static die fixing plate and is connected with the die-casting die. The ultrasonic vibration system is connected to a movable die of the die-casting die and directly acts on the movable die for semisolid die-casting molding through ultrasonic assistance. The movable die is provided with the cooling system connected with the ultrasonic vibration system. By adoption of the ultrasound-assisted semisolid die-casting molding device and method, the solid phase agglomeration degree can be effectively lowered, the flowing capacity and mold-filling capacity of semisolid metal are improved, grains can be refined, the density of the castings is improved, the mechanical property and heat conductivity of the aluminum alloy castings are further improved, and a novel molding method is provided for the complex thin-wall aluminum alloy piece casting.

Owner:ZHEJIANG UNIV

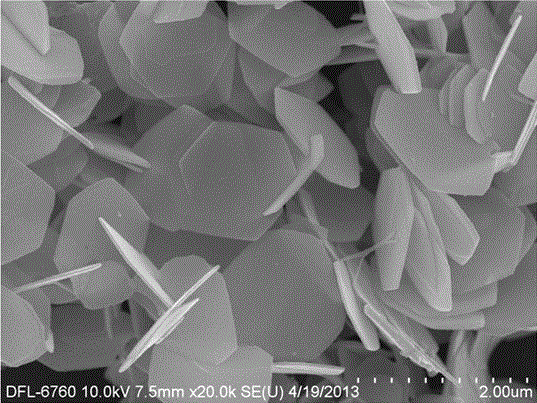

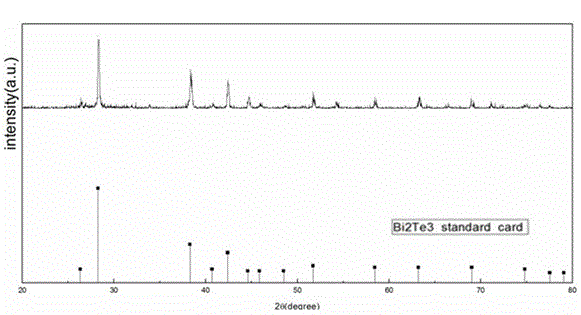

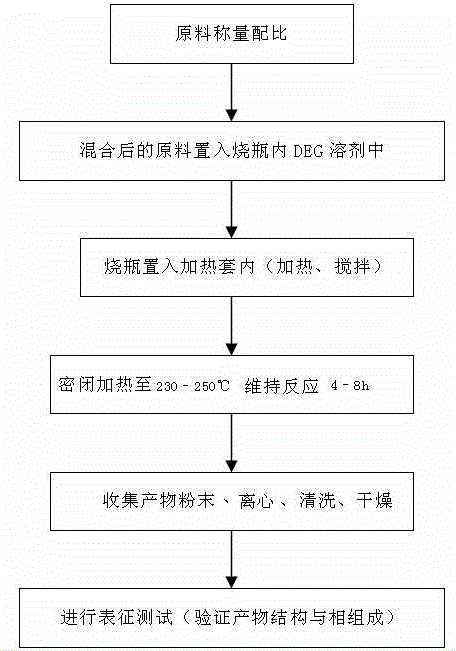

Manufacturing method of nanometer hexagonal sheet-shaped bismuth telluride thermoelectric material

ActiveCN103910341AImprove thermoelectric performanceIncreased ZT valueMaterial nanotechnologyBinary selenium/tellurium compoundsOrganic solventBismuth telluride

A manufacturing method of a nanometer hexagonal sheet-shaped bismuth telluride thermoelectric material orderly comprises: a tellurium bismuth mixing process, an adjusting process, a sealing heating stirring process, and a purification process. The tellurium bismuth mixing process comprises: preparing a mixture of Bi and Te with a mol ratio of 2:3, and dissolving the mixture in an organic solvent to obtain a mixed solution; the adjusting process comprises: adding NaOH and polyvinylpyrrolidone to adjust the shape and size of the product; the sealing heating stirring process comprises: heating and performing heat insulation of the product under a sealing and stirring condition; the purification process comprises: purifying the product by centrifugation, cleaning, and drying. The design of the invention not only prepares the nanometer hexagonal sheet-shaped bismuth telluride thermoelectric material with a controllable product shape, but also is few in process links, short in period, low in energy consumption, and low in cost.

Owner:DONGFENG COMML VEHICLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com