Nano zirconia/epoxy resin compound material and preparation method thereof

A technology of nano-zirconia and epoxy resin, which is applied in the field of nano-zirconia/epoxy resin composite materials and its preparation, can solve the problems of performance degradation, easy agglomeration of nano-zirconia particles, and damage to the compact structure of materials, and achieve shrinkage. Low, good adhesion, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

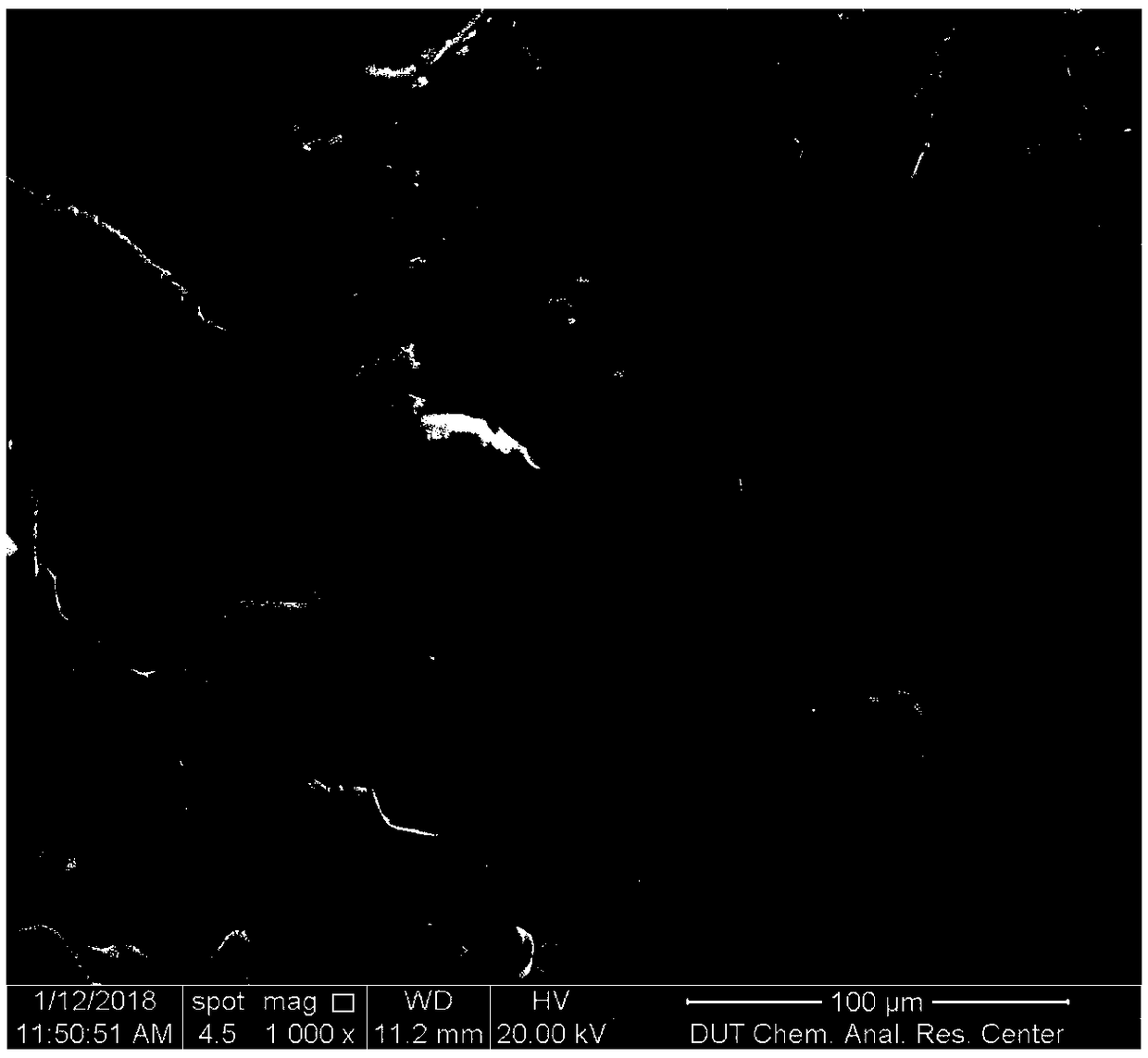

[0048] A nano-zirconia / epoxy resin composite material, comprising nano-zirconia particles and epoxy resin, the nano-zirconia particles are synthesized by an improved sol-gel combustion method, and the particle size is between 3 and About 10nm, the addition amount is 1wt% of the epoxy resin composite material; the epoxy resin is bisphenol A type epoxy resin.

[0049] The preparation method of described nanometer zirconia / epoxy resin composite material, comprises the following steps:

[0050] One, the ZrOCl 2 ·8H 2 O was dissolved in deionized water to form a 0.12mol / L solution; then NH was added to the solution 3 ·H 2 O generates a gel-like precipitate, which is centrifuged and washed several times with absolute ethanol to remove soluble impurities; the precipitate is dispersed in an organic solvent, and then added with Zr 4+ The molar ratios of HNO were 1.16 and 20, respectively 3 and H 2 o 2 Continue stirring for 24h to obtain a clear sol; then add urea and mix homogen...

Embodiment 2

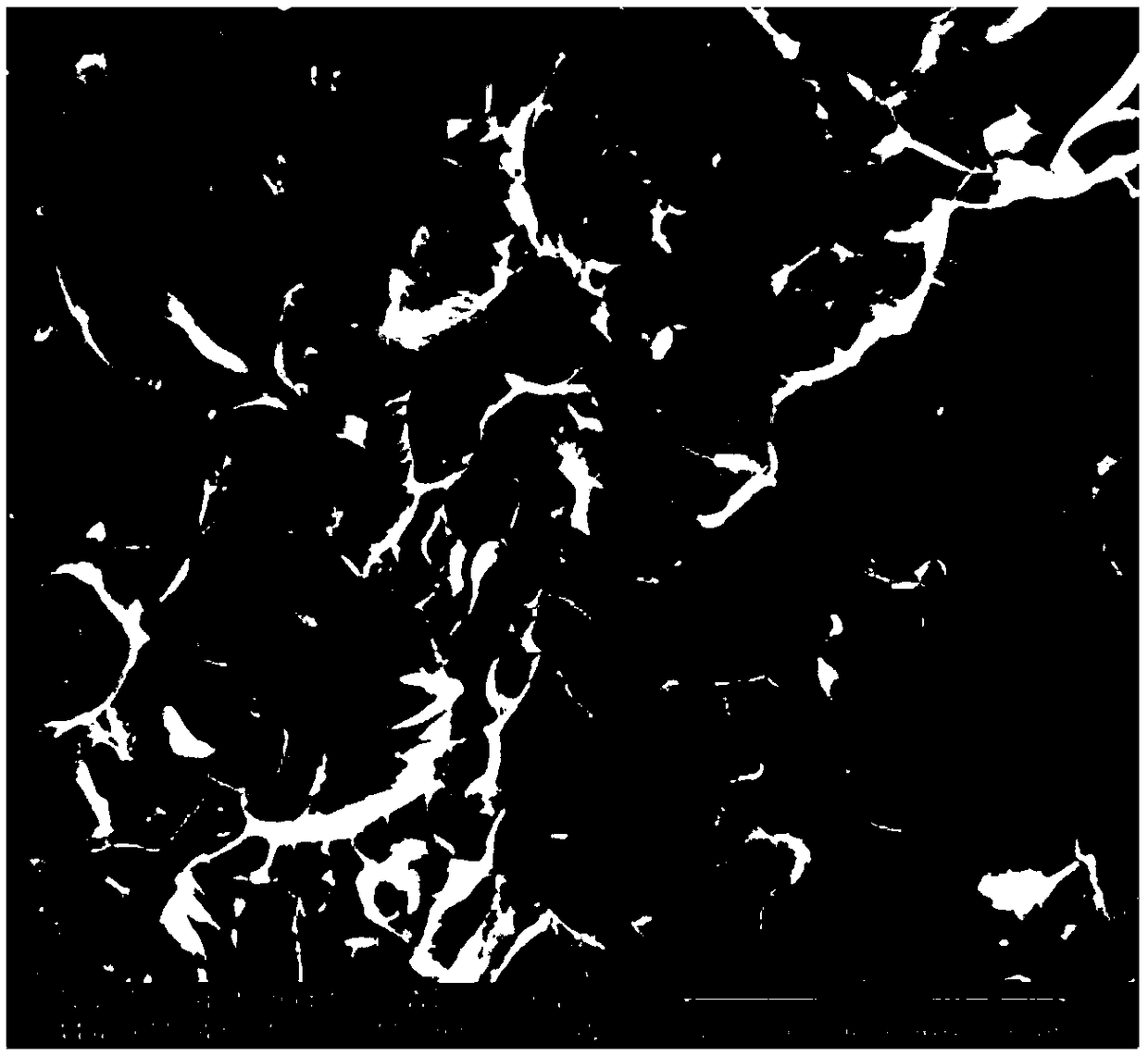

[0055] A nano-zirconia / epoxy resin composite material, comprising nano-zirconia particles and epoxy resin, the nano-zirconia particles are synthesized by an improved sol-gel combustion method, and the particle size is between 3 and About 10nm, the addition amount is 3wt% of the epoxy resin composite material; the epoxy resin is bisphenol A type epoxy resin.

[0056] The preparation method of described nanometer zirconia / epoxy resin composite material, comprises the following steps:

[0057] One, the ZrOCl 2 ·8H 2 O was dissolved in deionized water to form a 0.12mol / L solution; then NH was added to the solution 3 ·H 2 O generates a gel-like precipitate, which is centrifuged and washed several times with absolute ethanol to remove soluble impurities; the precipitate is dispersed in an organic solvent, and then added with Zr 4+ The molar ratios of HNO were 1.16 and 20, respectively 3 and H 2 o 2 Continue stirring for 24h to obtain a clear sol; then add urea and mix homogen...

Embodiment 3

[0062] A nano-zirconia / epoxy resin composite material, comprising nano-zirconia particles and epoxy resin, the nano-zirconia particles are synthesized by an improved sol-gel combustion method, and the particle size is between 3 and About 10nm, the addition amount is 4wt% of the epoxy resin composite material; the epoxy resin is bisphenol A type epoxy resin.

[0063] The preparation method of described nanometer zirconia / epoxy resin composite material, comprises the following steps:

[0064] One, the ZrOCl 2 ·8H 2 O was dissolved in deionized water to form a 0.12mol / L solution; then NH was added to the solution 3 ·H 2 O generates a gel-like precipitate, which is centrifuged and washed several times with absolute ethanol to remove soluble impurities; the precipitate is dispersed in an organic solvent, and then added with Zr 4+ The molar ratios of HNO were 1.16 and 20, respectively 3 and H 2 o 2 Continue stirring for 24h to obtain a clear sol; then add urea and mix homogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com