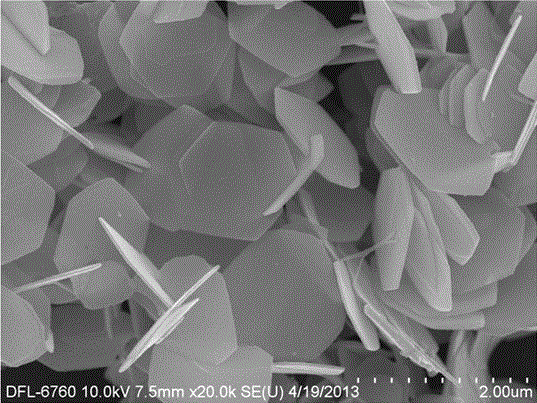

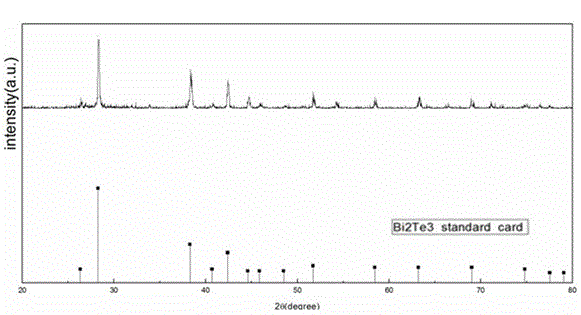

Manufacturing method of nanometer hexagonal sheet-shaped bismuth telluride thermoelectric material

A hexagonal flake, thermoelectric material technology, applied in nanotechnology, nanotechnology, binary selenium/tellurium compounds, etc., can solve the problems of high cost, uncontrollable product shape, many process links, etc. Thermoelectric effect, good thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a method for preparing nanoscale hexagonal flake Bi 2 Te 3 The synthetic method belongs to the solvothermal synthesis method. Solvothermal synthesis is a method of reacting raw materials in a closed reaction system with an organic solvent as a medium at a certain temperature and the autogenous pressure of the solvent to synthesize a compound that is difficult to form under normal reaction conditions. The method has the advantages of low reaction temperature, short time, high product purity, controllable shape and size, and the like.

[0041] 1. Tellurium bismuth mixing process:

[0042] The organic solvent in this process is necessary for the solvothermal synthesis method, and its main function is to provide a solvent and a reducing environment. The organic solvent is diethylene glycol (DEG) or triethylene glycol (Triethylene glycol), among which, triethylene glycol is suitable for a higher temperature range.

[0043] The dosage ratio of mixtu...

Embodiment 1

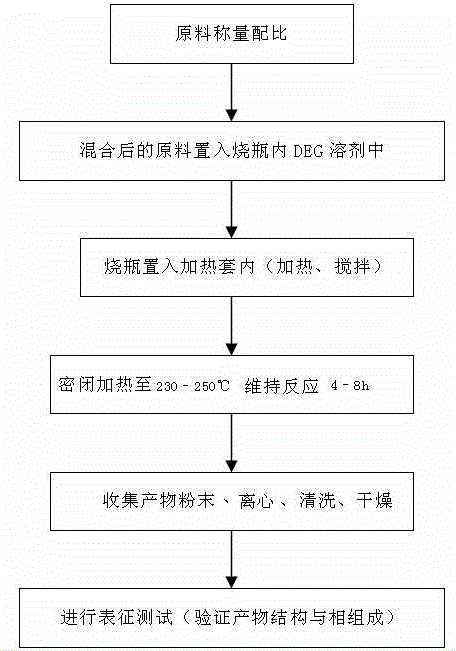

[0059] see image 3 , a method for manufacturing a nanoscale hexagonal bismuth telluride thermoelectric material, the method includes the following steps in sequence:

[0060] Tellurium-bismuth mixing process: first use an electronic balance to weigh and analyze pure bismuth-containing compounds and tellurium-containing compounds and mix them to obtain a mixture. The molar ratio of elements Bi and Te in the mixture is 2:3, and then dissolve the mixture into In an organic solvent to obtain a mixed solution, the amount ratio of the mixing material and the organic solvent is 0.2-0.4mol: 1L; the bismuth-containing compound is 99% Bi(NO 3 ) 3 , the tellurium-containing compound is K with a concentration of 98% by mass 2 TeO 3 ; The organic solvent is diethylene glycol or triethylene glycol;

[0061] Adjustment process: first add NaOH to the above mixed solution to make the pH of the mixed solution 11–13, and then add polyvinylpyrrolidone of the same quality as NaOH to obtain th...

Embodiment 2

[0066] The basic content is the same as that of Example 1, except that the temperature of the heat preservation is 240° C., and the time of heat preservation is 6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com