Medium and low temperature p-type multi element pyroelectric alloy possessing high thermoelectric figure of merit (ZT)

A high-heat, multi-component technology, applied in the field of new materials, to achieve the effect of simple process, high thermoelectric performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

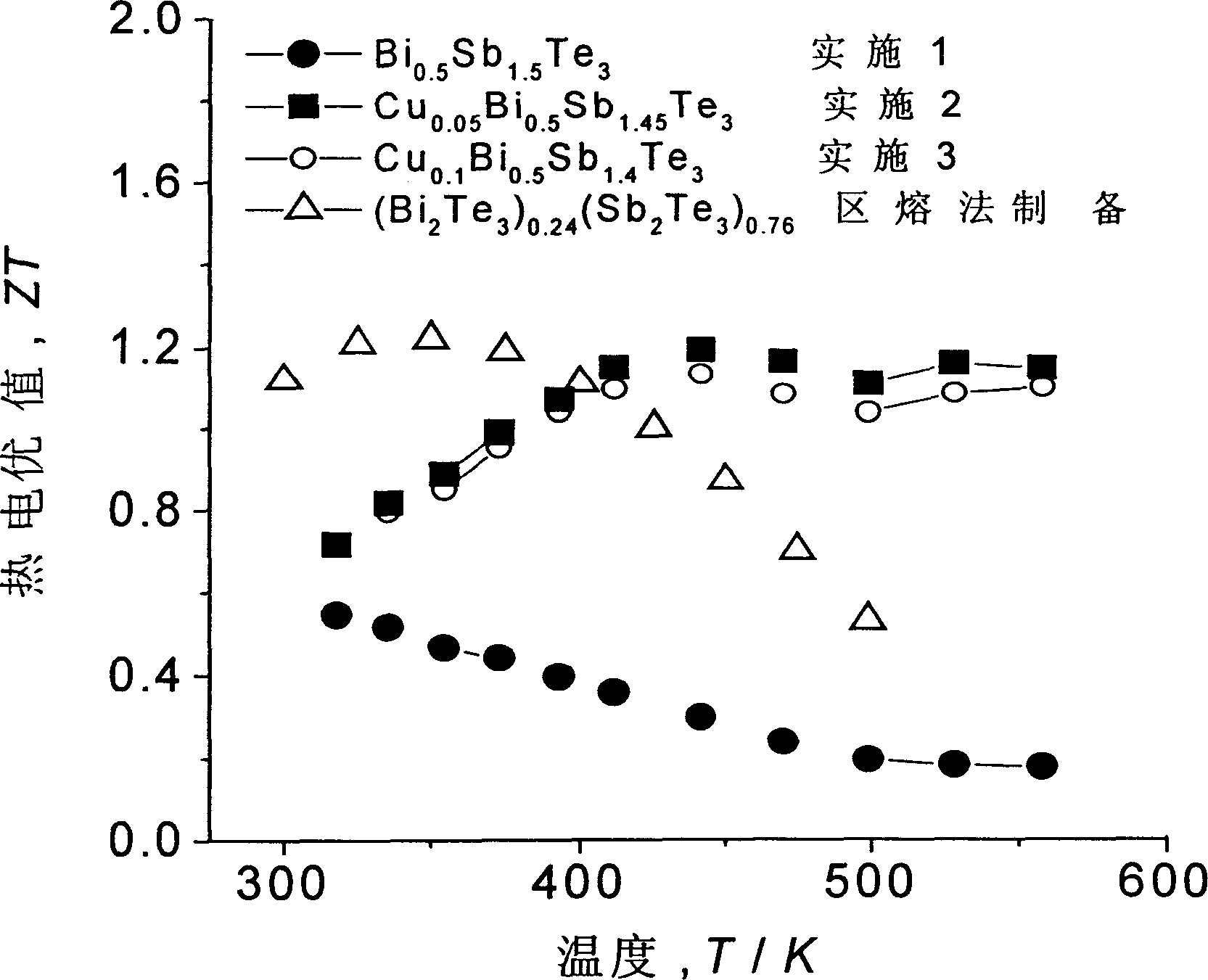

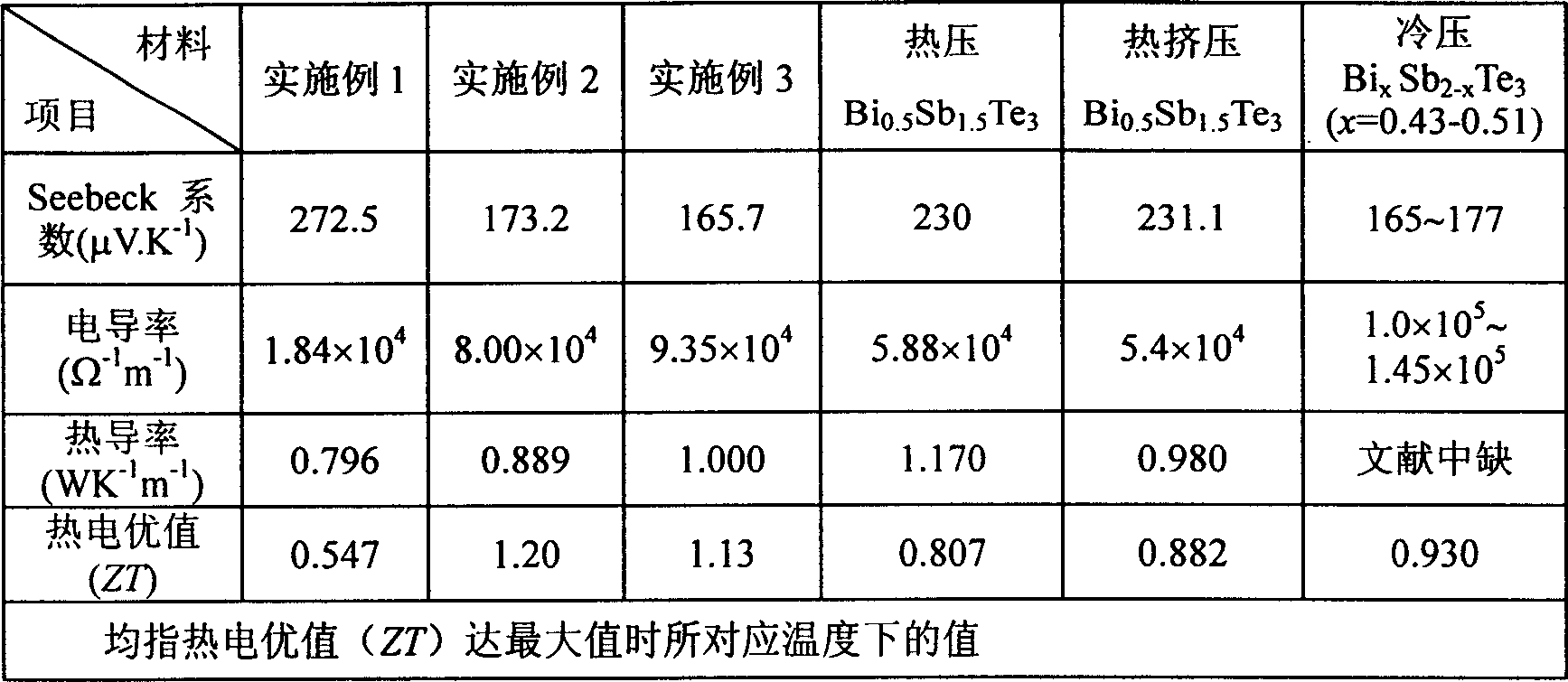

[0020] According to Bi 0.5 Sb 1.5 Te 3 The three elements of Bi, Sb and Te with a purity greater than 99.999wt% are weighed by the molecular formula and placed in a vacuum quartz tube, melted at a temperature of 1000° C. and maintained for 10 hours. Shake the tube every 1 hour during the melt to ensure a uniform reaction. After 10 hours, it was quenched in water to obtain a bulk metal telluride, which was then pulverized and ball milled. The ball milling time was controlled at 5 hours, and finally formed by discharge plasma spark sintering (SPS) under high vacuum.

Embodiment 2

[0022] In the pseudo binary alloy Bi 0.5 Sb 1.5 Te 3 The Cu element with a mole fraction of 0.05 is used to replace the Sb element with an equal mole fraction. According to the molecular formula Cu 0.05 Bi 0.5 Sb 1.45 Te 3 Weigh Cu, Bi, Sb and Te three elements with a purity greater than 99.999wt% and place them in a vacuum quartz tube, melt at 1000°C and keep for 10 hours. Shake the tube every 1 hour during the melt to ensure a uniform reaction. After 10 hours, it was quenched in water to obtain a block of quaternary metal telluride, which was then pulverized and ball milled. The ball milling time was controlled at 5 hours, and finally formed by discharge plasma spark sintering (SPS) under high vacuum.

Embodiment 3

[0024] In the pseudo binary alloy Bi 0.5 Sb 1.5 Te 3 The Cu element with a mole fraction of 0.1 is used to replace the Sb element with an equal mole fraction. According to the molecular formula Cu 0.1 Bi 0.5 Sb 1.4 Te 3 Weigh Cu, Bi, Sb and Te three elements with a purity greater than 99.999wt% and place them in a vacuum quartz tube, melt at 1000°C and keep for 10 hours. Shake the tube every 1 hour during the melt to ensure a uniform reaction. After 10 hours, it was quenched in water to obtain a block of quaternary metal telluride, which was then pulverized and ball milled. The ball milling time was controlled at 5 hours, and finally formed by discharge plasma spark sintering (SPS) under high vacuum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com