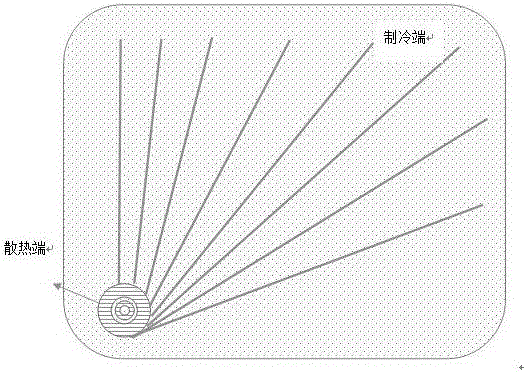

Polymer sheath-core composite fiber with thermoelectric effect as well as preparation method and application thereof

A composite fiber and thermoelectric effect technology, applied in the direction of conjugated synthetic polymer artificial filament, fiber treatment, fiber chemical characteristics, etc., can solve the problems of low thermoelectric power factor, low conductivity and Seebeck coefficient of organic thermoelectric materials, etc., Achieve excellent thermoelectric properties, good industrialization prospects, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

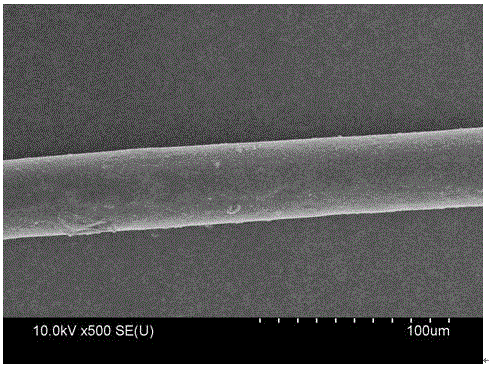

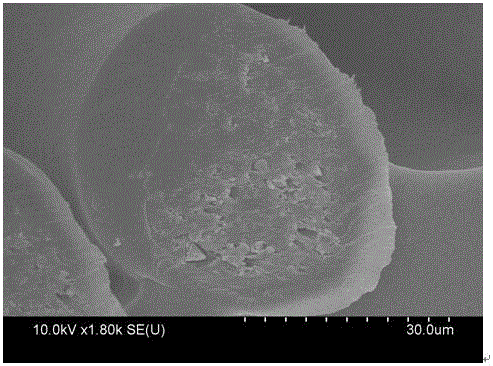

[0036] Using high-purity bismuth telluride and graphene (3-6 layers) powder as raw materials, according to the stoichiometric ratio of 50 g bismuth telluride and 30 g graphene, weigh a total of 80 g of powder and put it into a ball mill tank. Perform ball milling with a ball-to-material ratio of 13:1, a rotating speed of 350 r / min, and a ball milling time of 12 hours to obtain micron-sized powders. After mixing the obtained micron-sized powder with PP (20g), put it into a twin-screw blender, set the screw temperature at 180°C, and the extrusion speed at 5 kg / h, and then immerse the extruded material in a water bath to cool down , pelletized, and dried to obtain a thermoelectric masterbatch.

[0037] Two-component compound spinning screw extruder In the process, the thermoelectric masterbatch is put into the core material hopper, the cortex is put into pure PP, and the mass ratio of the cortex to the core is 1:2; the spinning process parameters are set as follows: spinning te...

Embodiment 2

[0039]Using high-purity bismuth telluride and graphene (3-6 layers) powder as raw materials, according to the stoichiometric proportion of 20 g of bismuth telluride and 5 g of graphene, weigh a total of 25 g of powder and put it into a ball mill tank. Perform ball milling with a ball-to-material ratio of 13:1, a rotating speed of 350 r / min, and a ball milling time of 12 hours to obtain micron-sized powders. Mix the obtained micron-sized powder with PA6 (75 g), put it into a twin-screw blender, set the screw temperature at 270°C, and the extrusion speed at 5 kg / h, and then immerse the extruded material in a water bath Cool down, pelletize, and dry to obtain thermoelectric masterbatch.

[0040] Two-component compound spinning screw extruder In the process, the thermoelectric masterbatch is put into the core material hopper, the cortex is put into pure PA6, and the mass ratio of the cortex to the core is 1:1; the spinning process parameters are set as follows: spinning temperat...

Embodiment 3

[0042] Using high-purity bismuth telluride and graphene (3-6 layers) powder as raw materials, according to the stoichiometric proportion of 40 g bismuth telluride and 20 g graphene, weigh a total of 60 g of powder and put it into a ball mill tank. Perform ball milling with a ball-to-material ratio of 13:1, a rotating speed of 350 r / min, and a ball milling time of 12 hours to obtain micron-sized powders. After mixing the obtained micron-sized powder with PET (40 g), put it into a twin-screw blender, set the screw temperature at 220 ° C, and the extrusion speed at 5 kg / h, and then the extruded material is immersed in a water bath Cool down, pelletize, and dry to obtain thermoelectric masterbatch.

[0043] Two-component compound spinning screw extruder In the process, the thermoelectric masterbatch is put into the core material hopper, the cortex is put into pure PET, and the mass ratio of the cortex to the core is 2:1; the spinning process parameters are set as follows: spinni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com