Nanocomposite structure Mg2Si-based thermoelectric material and preparation method thereof

A thermoelectric material and nano-composite technology, which is applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problem of inability to achieve microstructure controllability, limited improvement of thermoelectric performance, and difficulty in controlling nanophase distribution conditions and other issues, to achieve the effects of inhibiting oxidation and volatilization, improving production efficiency, and improving thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

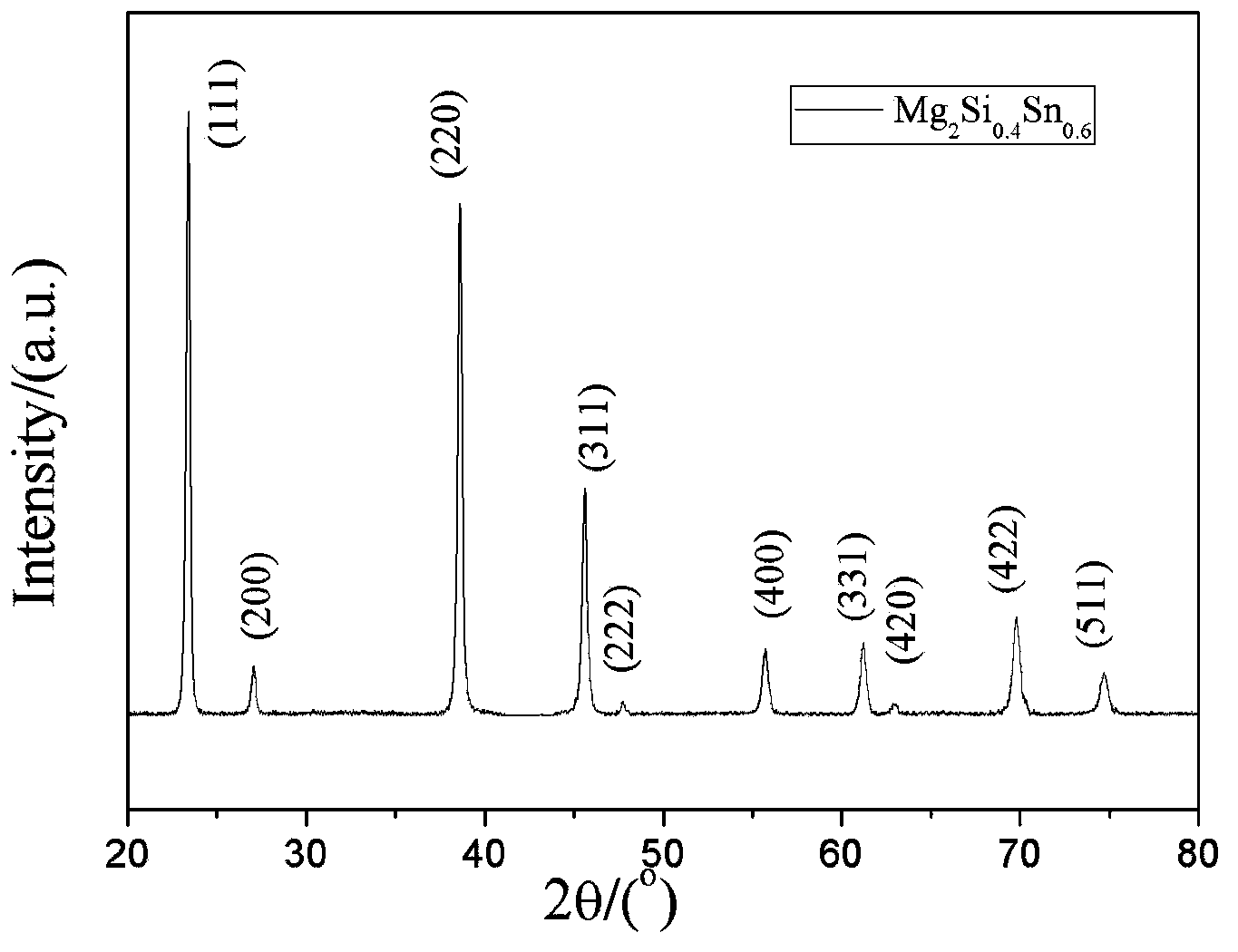

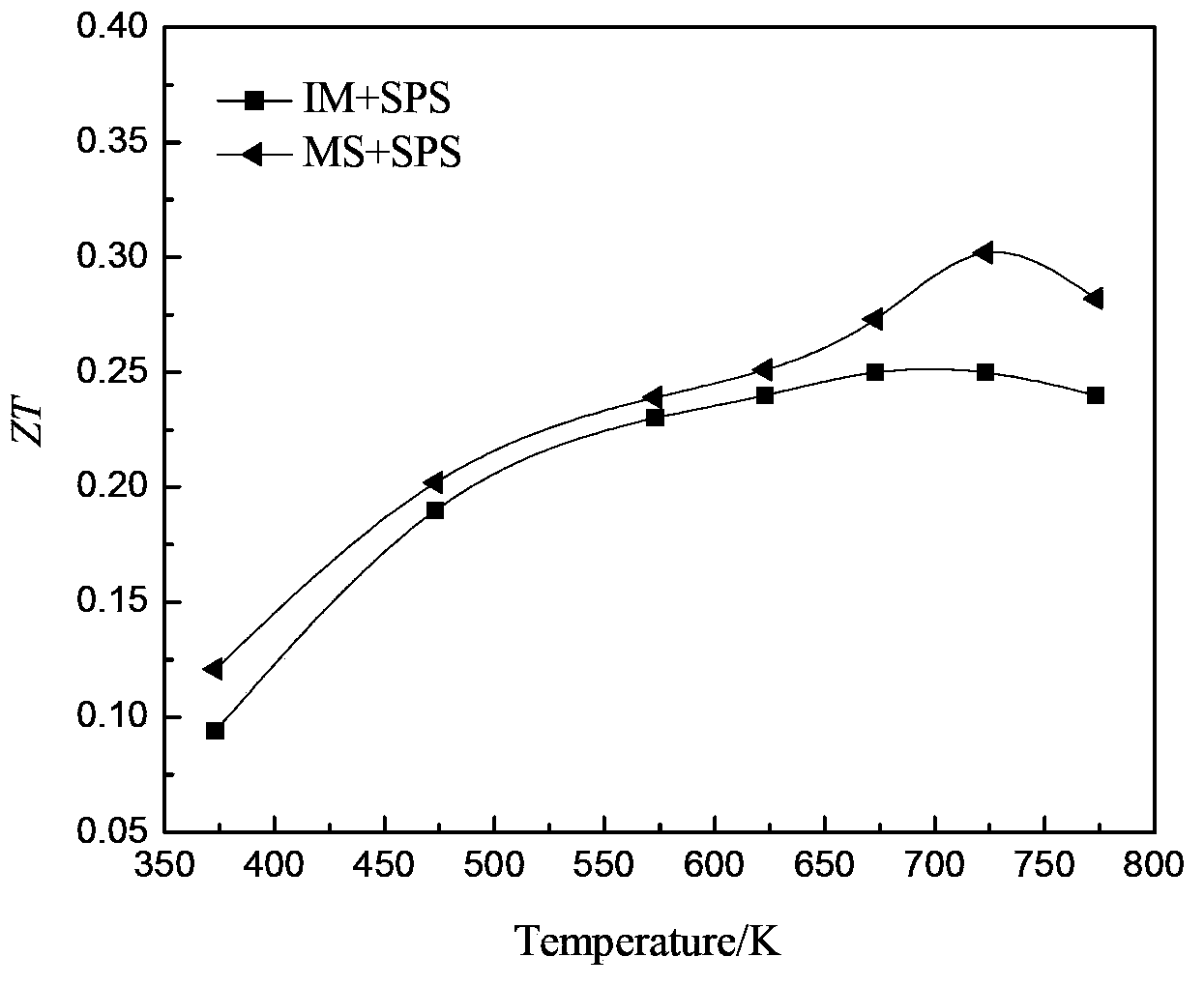

Embodiment 1

[0021] 1) Using high-frequency induction suspension melting equipment, using Mg block (purity 99.99%), Si block (purity 99.999%), Sn block (purity 99.99%) as raw materials, according to the chemical formula Mg 2 Si 0.4 sn 0.6 Proportionally weighed in an Ar atmosphere, the prepared raw materials were put into a red copper crucible for smelting, and the deoxidized argon was used as the protective atmosphere of the smelting process. The smelting time was 80s and the maximum power was 14kw.

[0022] 2) Using induction melting and rapid quenching furnace equipment, the smelted components are Mg 2 Si 0.4 sn 0.6 The ingot is loaded into a quartz tube with an open lower end, and then placed vertically in the induction melting coil of the cavity of the quick quenching equipment. The injection pressure is 0.02MPa, so that the induction smelting block reaches a molten state, and the melt is sprayed onto a copper roller with a speed of 40m / s and thrown out to form a strip and collect...

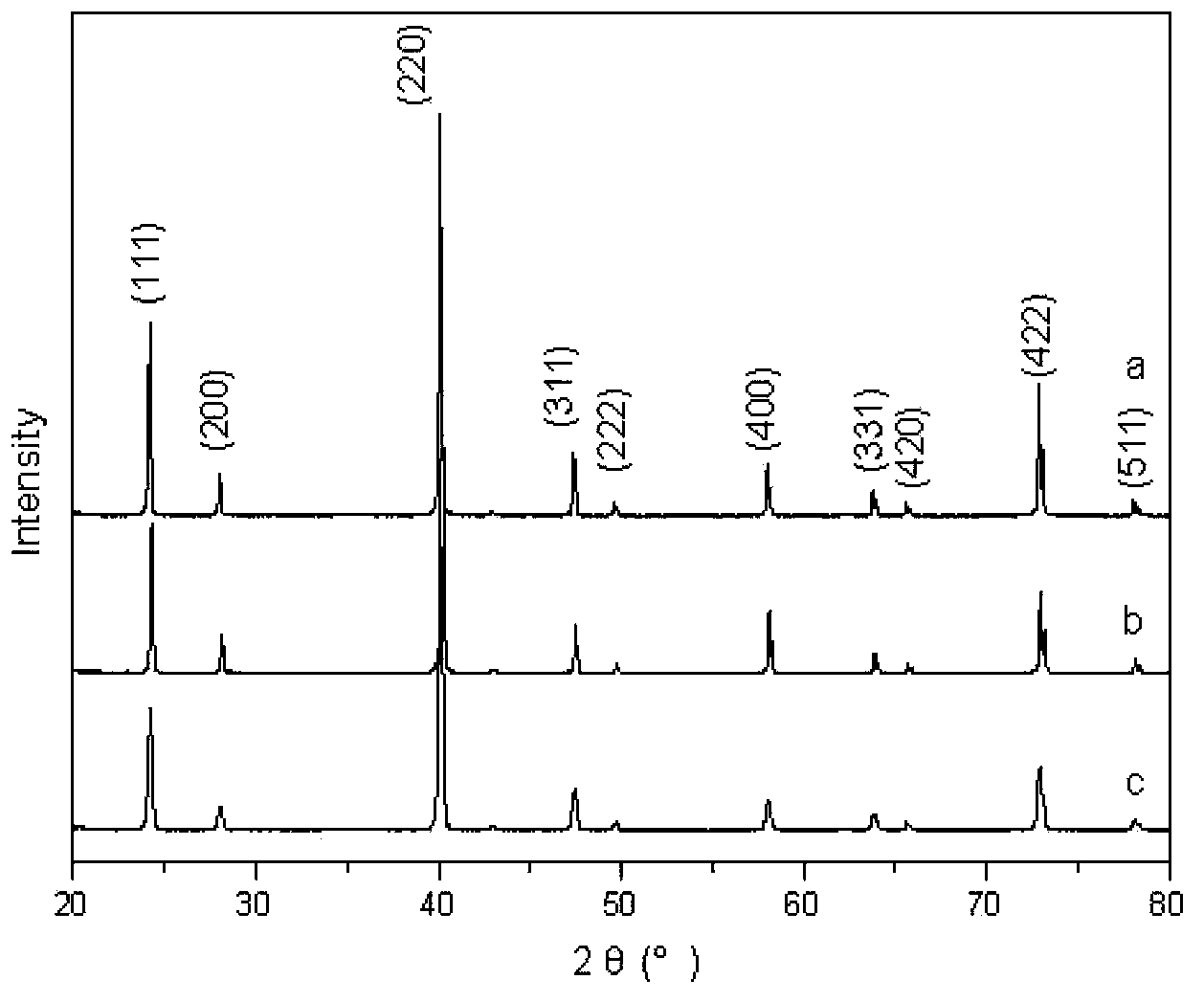

Embodiment 2

[0025] 1) Using high-frequency induction suspension melting equipment, using Mg block (purity 99.9%), Si block (purity 99.999%), Sn block (purity 99.9%) as raw materials, according to the chemical formula Mg 2 Si 0.5 sn 0.5 Proportionally weighed in an Ar atmosphere, the prepared raw materials were put into a copper crucible for smelting, and the deoxidized argon was used as the protective atmosphere of the smelting process. The smelting time was 90s and the maximum power was 16kw.

[0026] 2) Using induction melting and rapid quenching furnace equipment, the smelted components are Mg 2 Si 0.5 sn 0.5 The ingot is loaded into a quartz tube with an open lower end, and then placed vertically in the induction melting coil of the cavity of the quick quenching equipment. The injection pressure is 0.03MPa, so that the induction smelting block reaches a molten state, and the melt is sprayed on a copper roller with a speed of 30m / s and thrown out to form a strip and collect the str...

Embodiment 3

[0029] 1) Using high-frequency induction suspension melting equipment, using Mg block (purity 99.9%), Si block (purity 99.999%), Sn block (purity 99.9%) as raw materials, according to the chemical formula Mg 2 Si 0.6 sn 0.4 Proportionally weighed in an Ar atmosphere, the prepared raw materials were put into a red copper crucible for smelting, and the deoxidized argon was used as the protective atmosphere of the smelting process. The smelting time was 100s and the maximum power was 17kw.

[0030] 2) Using induction melting and rapid quenching furnace equipment, the smelted components are Mg 2 Si 0.6 sn 0.4 The ingot is loaded into a quartz tube with an open lower end, and then placed vertically in the induction melting coil of the cavity of the quick quenching equipment. The injection pressure is 0.05MPa, so that the induction smelting block reaches a molten state, and the melt is sprayed onto a copper roller with a speed of 20m / s and thrown out to form a strip and collect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com