Patents

Literature

261 results about "Nanocrystalline composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Printhead heaters with a nanocrystalline composite structure

Owner:MEMJET TECH LTD +1

Ceramic-phase-containing iron-based amorphous nanocrystalline composite coating and preparation thereof

ActiveCN101298654AEasy to useExtended service lifeMolten spray coatingOxide ceramicsThermal spraying

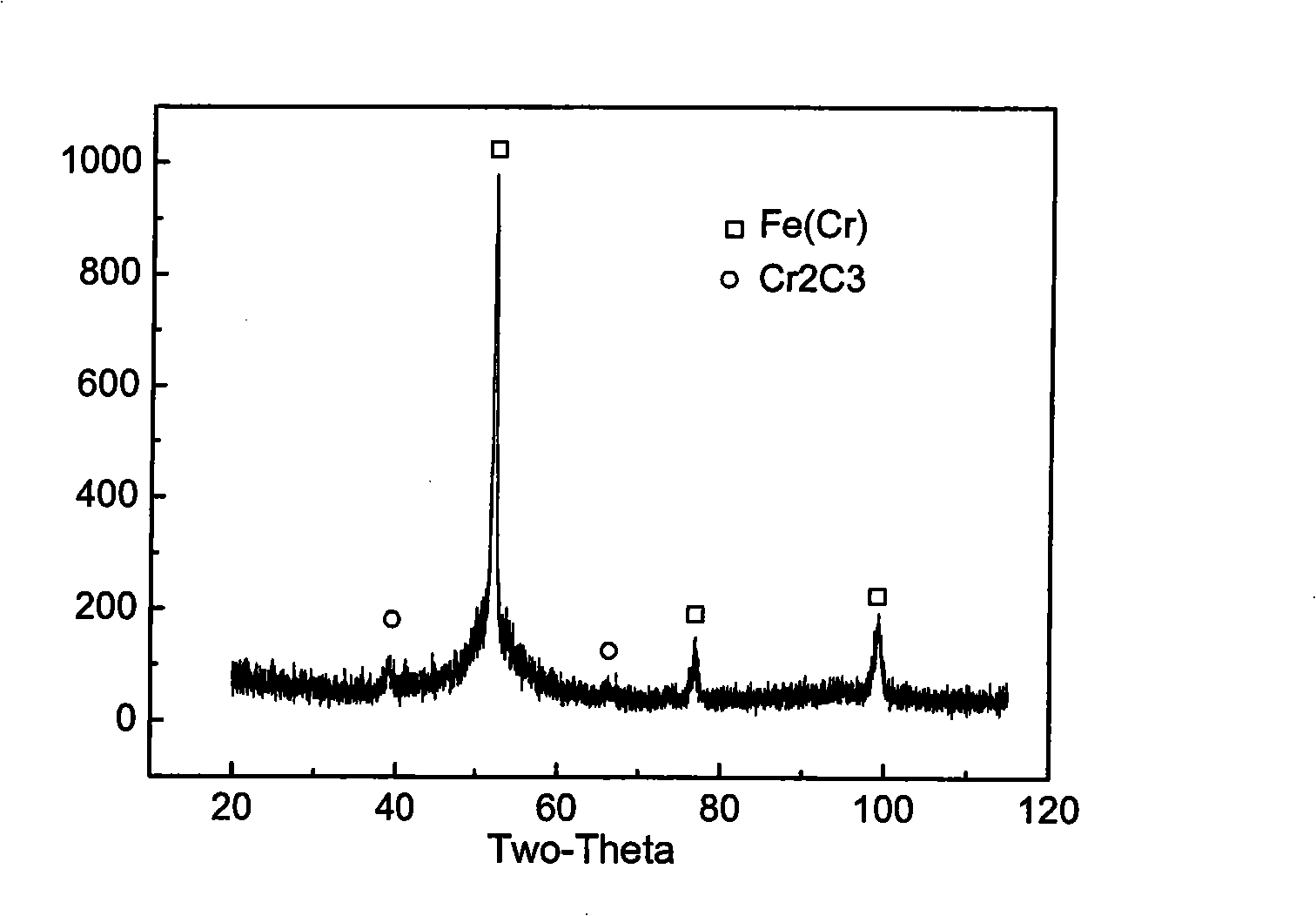

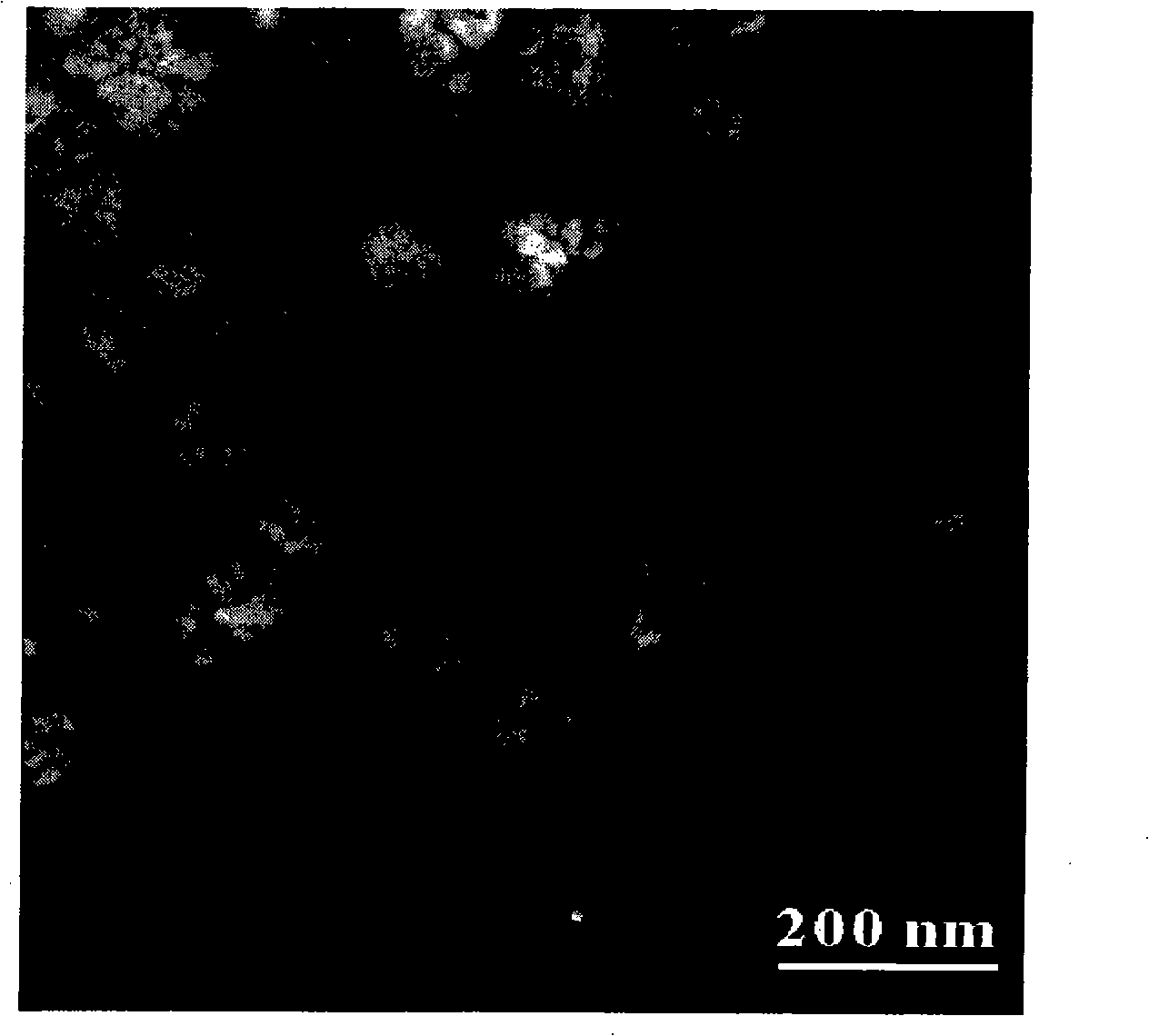

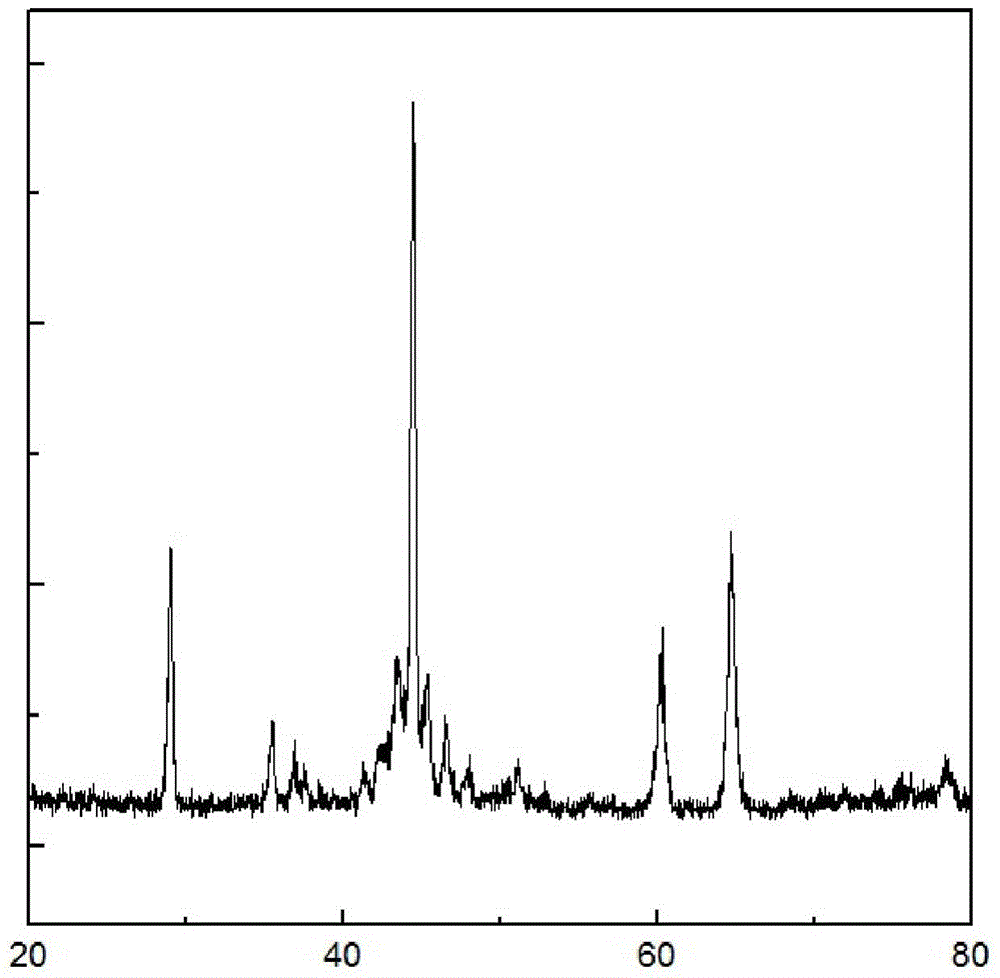

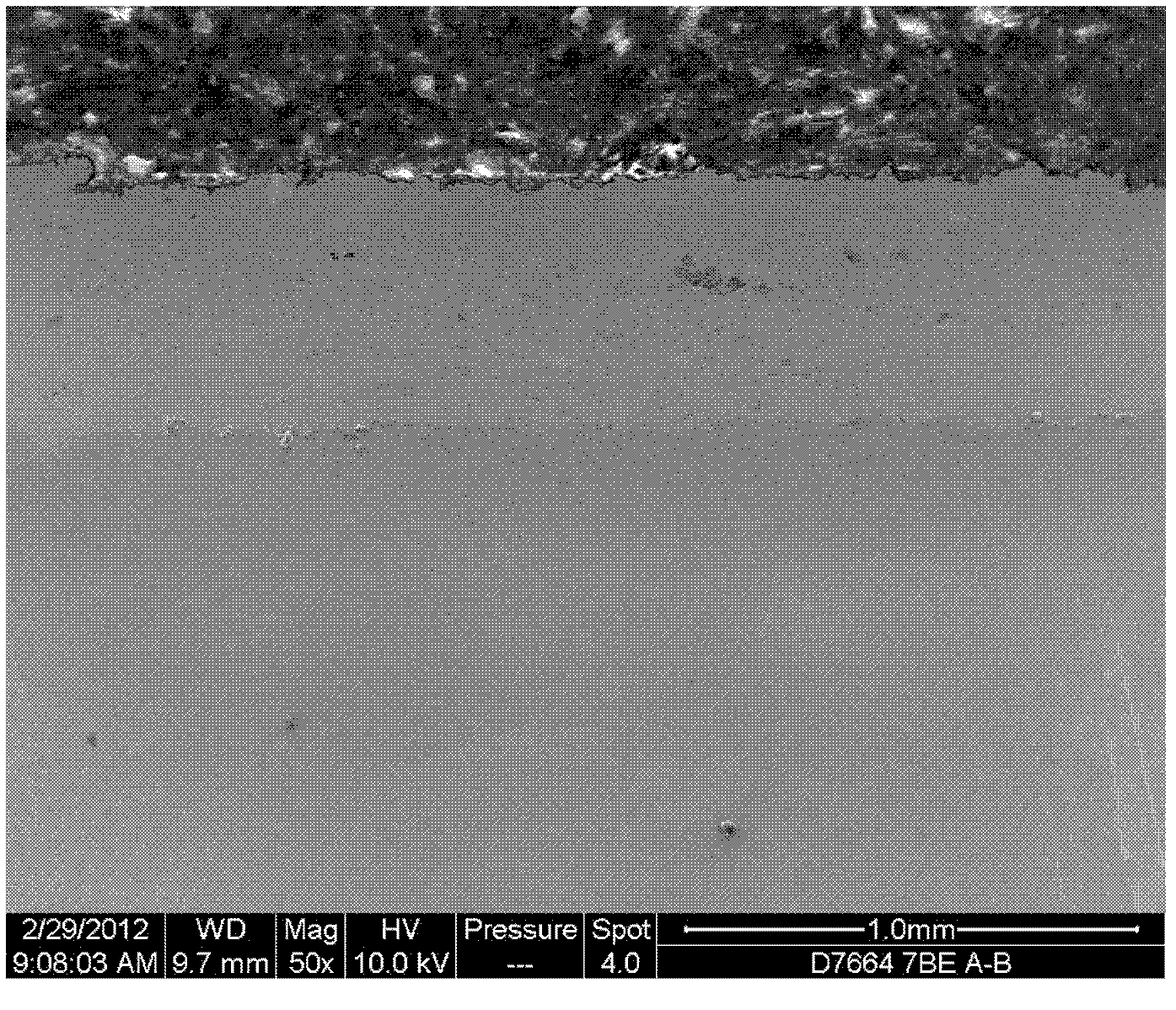

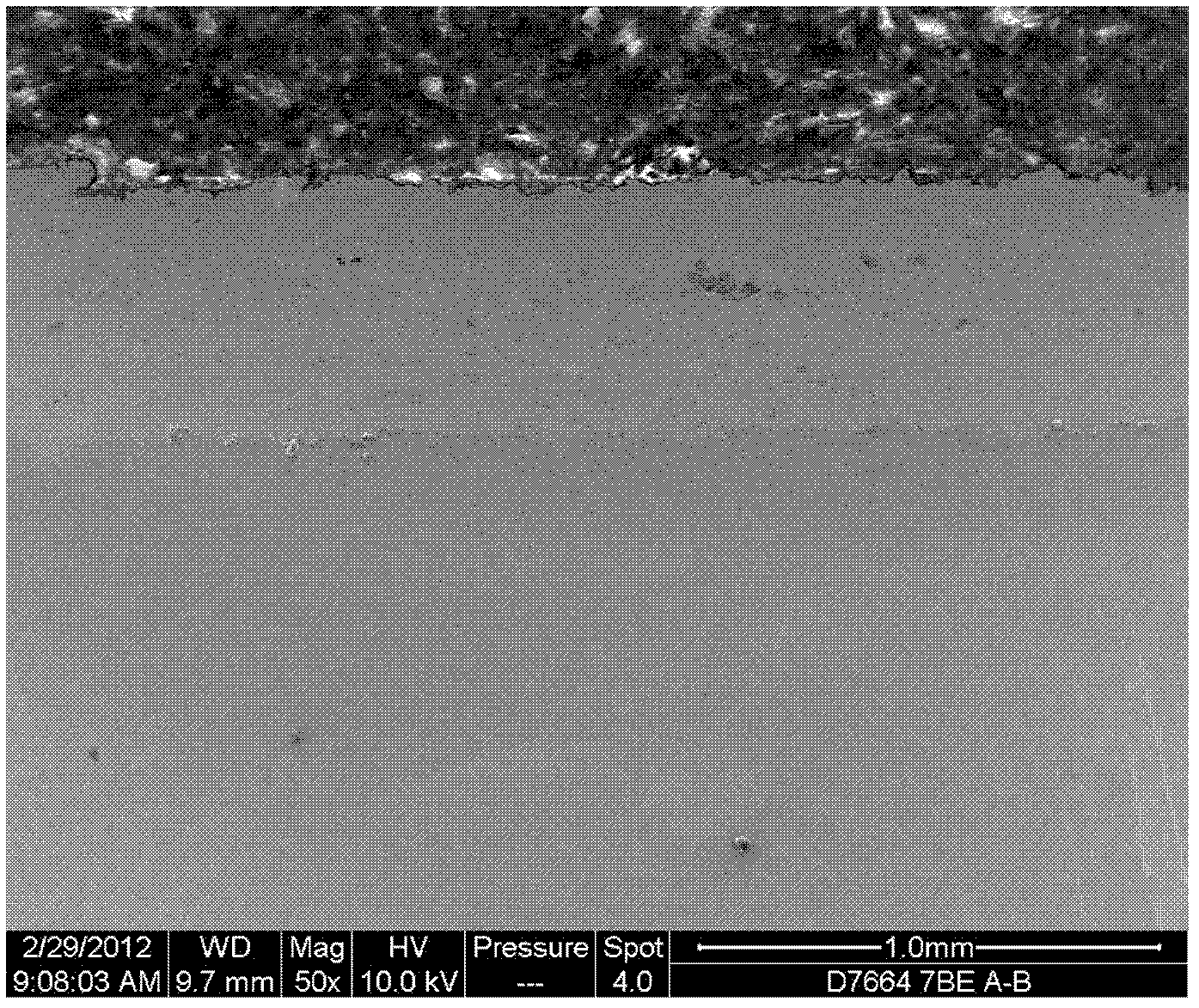

The invention belongs to the field of thermal spraying and particularly relates to a composite amorphous and nano-crystalline coating layer with ceramic phase and ferrum base and a preparation method thereof. Carbide or oxide ceramics of Co or Ni ladles are firstly added into a flux core, a flux-cored wire is prepared together with the flux core and a ferrum-base alloy with amorphous ingredients and used as a spraying material, and the electric arc spraying method is adopted for leading the flux-cored wire to be melted, atomized into fused drops and finally deposited on a substrate, thus preparing the composite amorphous and nano-crystalline coating layer with ceramic-phase structure and ferrum base, which has the performance of high bond strength, good wear resistance, corrosion resistance and oxidation resistance as well as remarkably prolonged service life of the substrate, and the composite amorphous and nano-crystalline coating layer with ceramic phase and ferrum base can be widely applied to the restoration and the protection of device parts in the fields of metallurgy, electric power and petroleum, etc.

Owner:CENT IRON & STEEL RES INST

CrTiAlSiN nano composite coating, cutter deposited with same and preparation method thereof

InactiveCN101879794AHigh bonding strengthHigh surface hardnessLayered productsVacuum evaporation coatingAdhesiveHardness

The invention relates to a CrTiAlSiN nano composite coating, a cutter deposited with the same and a preparation method thereof. The composite coating comprises a bonding layer, a supporting layer and a main wear layer, wherein the bonding layer consists of Cr, the supporting layer consists of CrN, and the main wear layer is a CrSiN / TiAlSiN nano multilayered composite coating formed by alternating CrSiN layers and TiAlSiN layers or an nc-CrTiAlN / a-Si3N4 nanocrystalline composite coating formed by embedding nanocrystalline CrTiAlN into amorphous Si3N4. The bonding layer is deposited on a cutter matrix, and then the supporting layer and the main wear layer are deposited to obtain the cutter deposited with the coating. The obtained CrTiAlSiN nano composite coating has the advantages of high hardness, low friction coefficient and strong adhesive force; and the cutter deposited with the coating has higher surface hardness, stronger film-matrix adhesive force and good wear-resisting property and high temperature resistance.

Owner:湖北三环成套工业有限公司

Process for producing nanorcrystalline composites

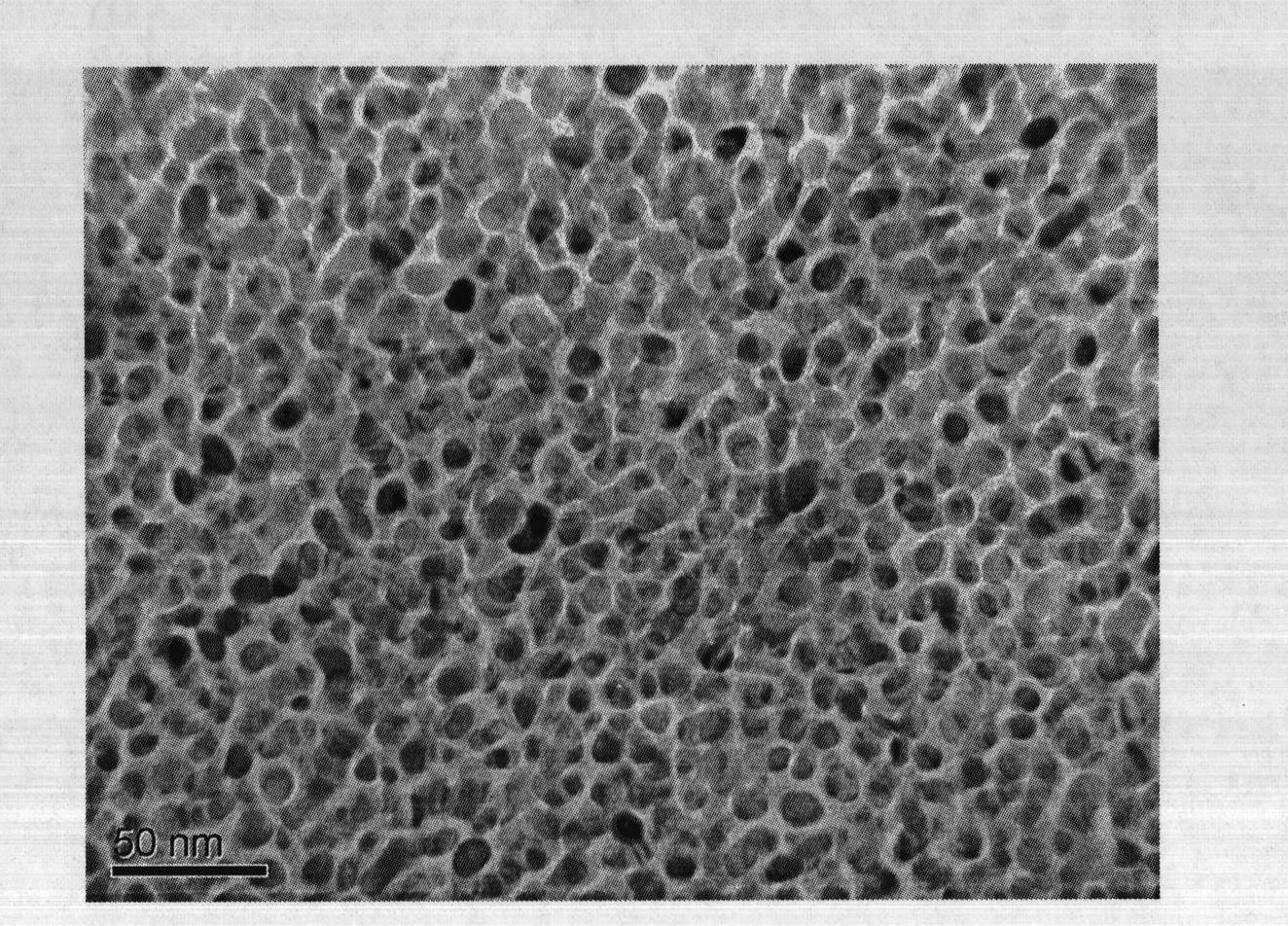

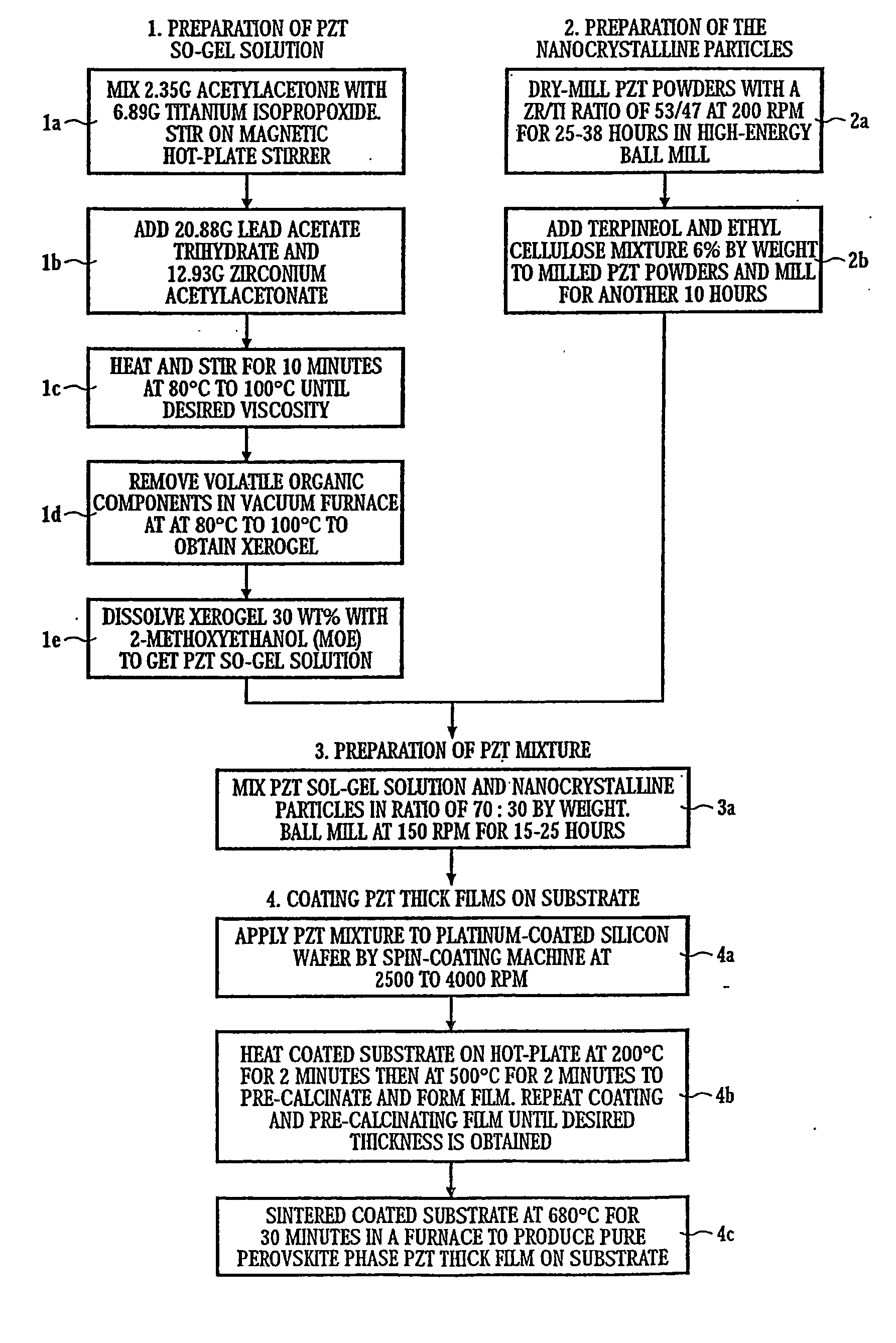

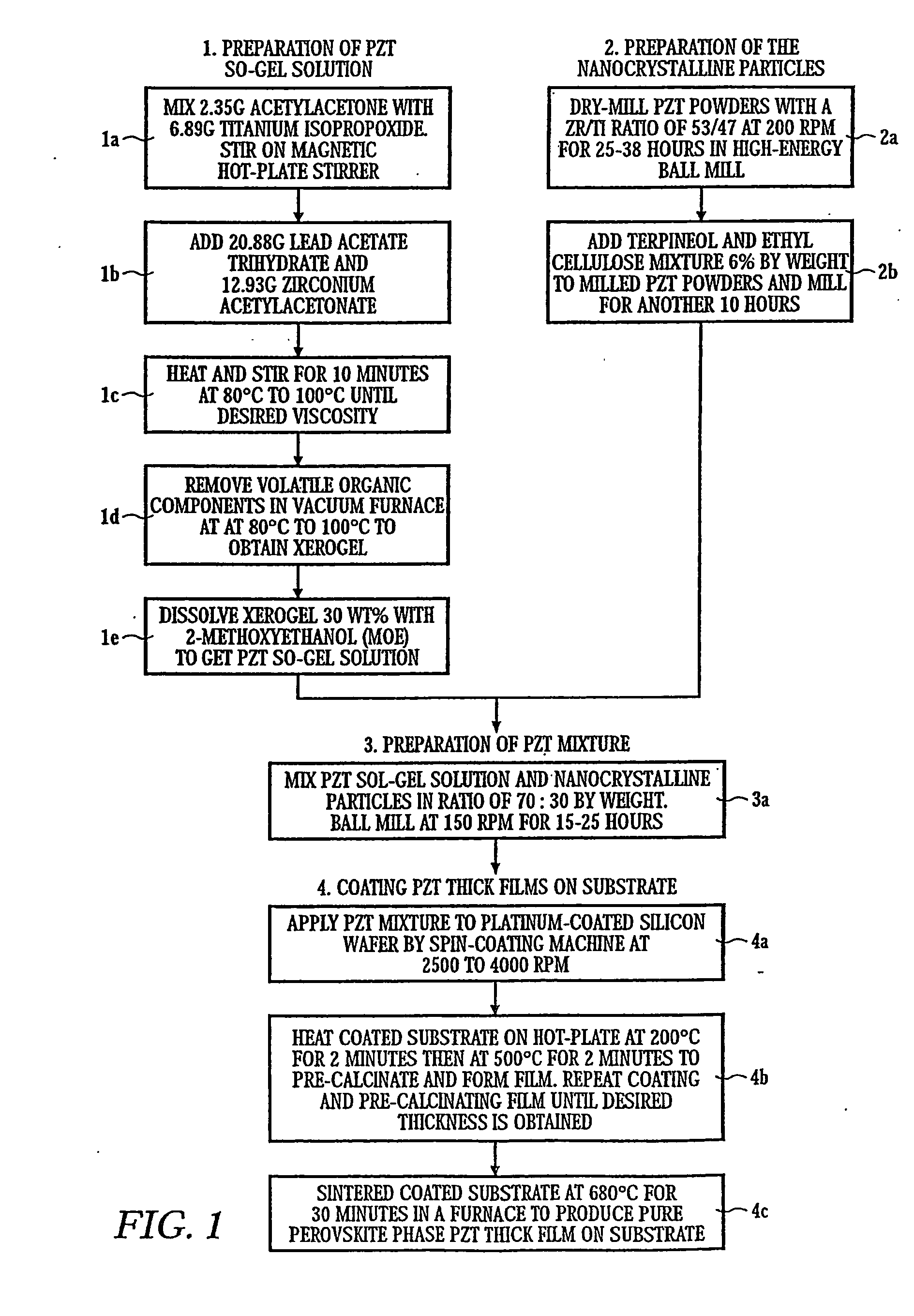

InactiveUS20050255239A1Reduce reunionHigh densityMaterial nanotechnologyLayered productsPorosityVolumetric Mass Density

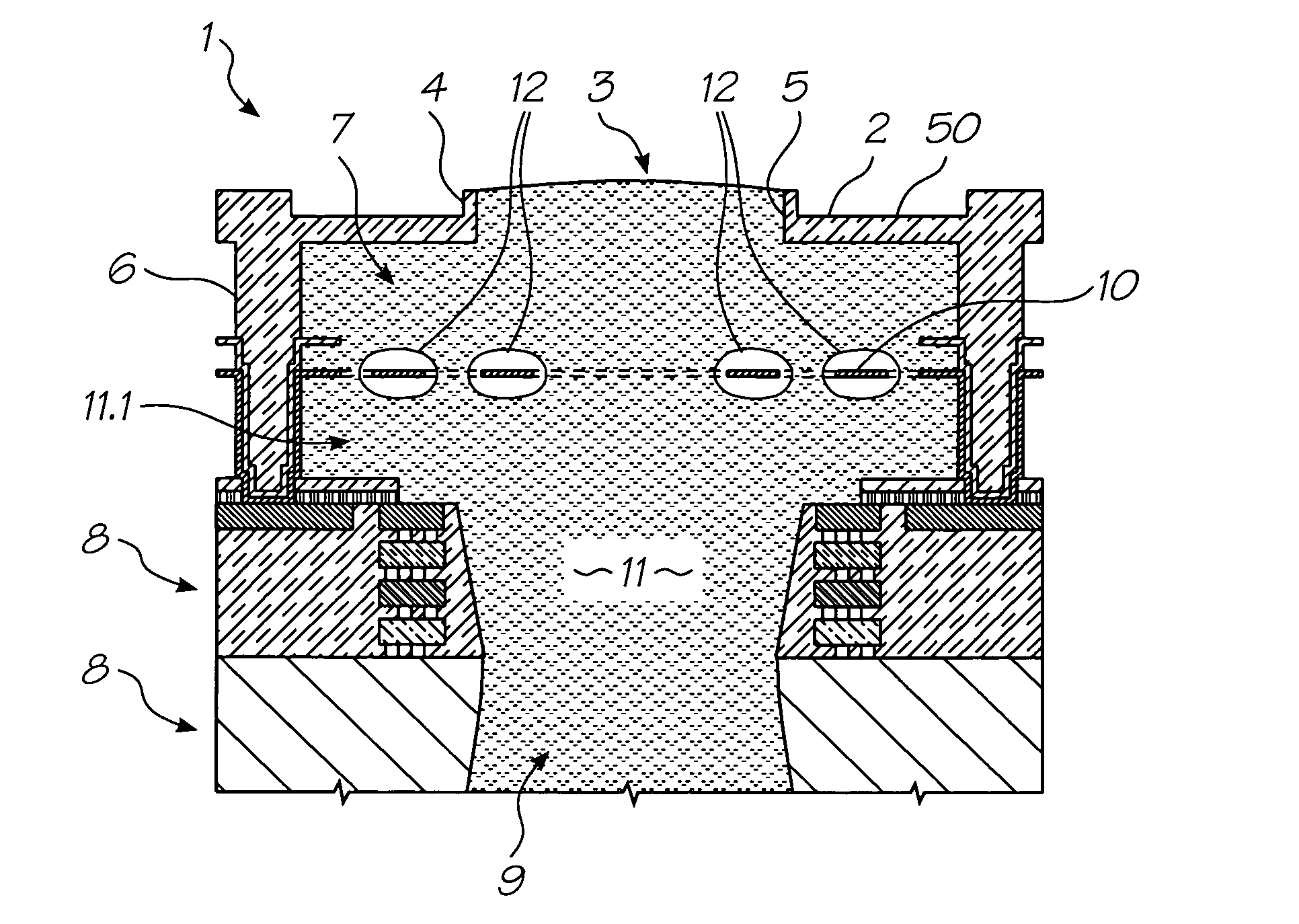

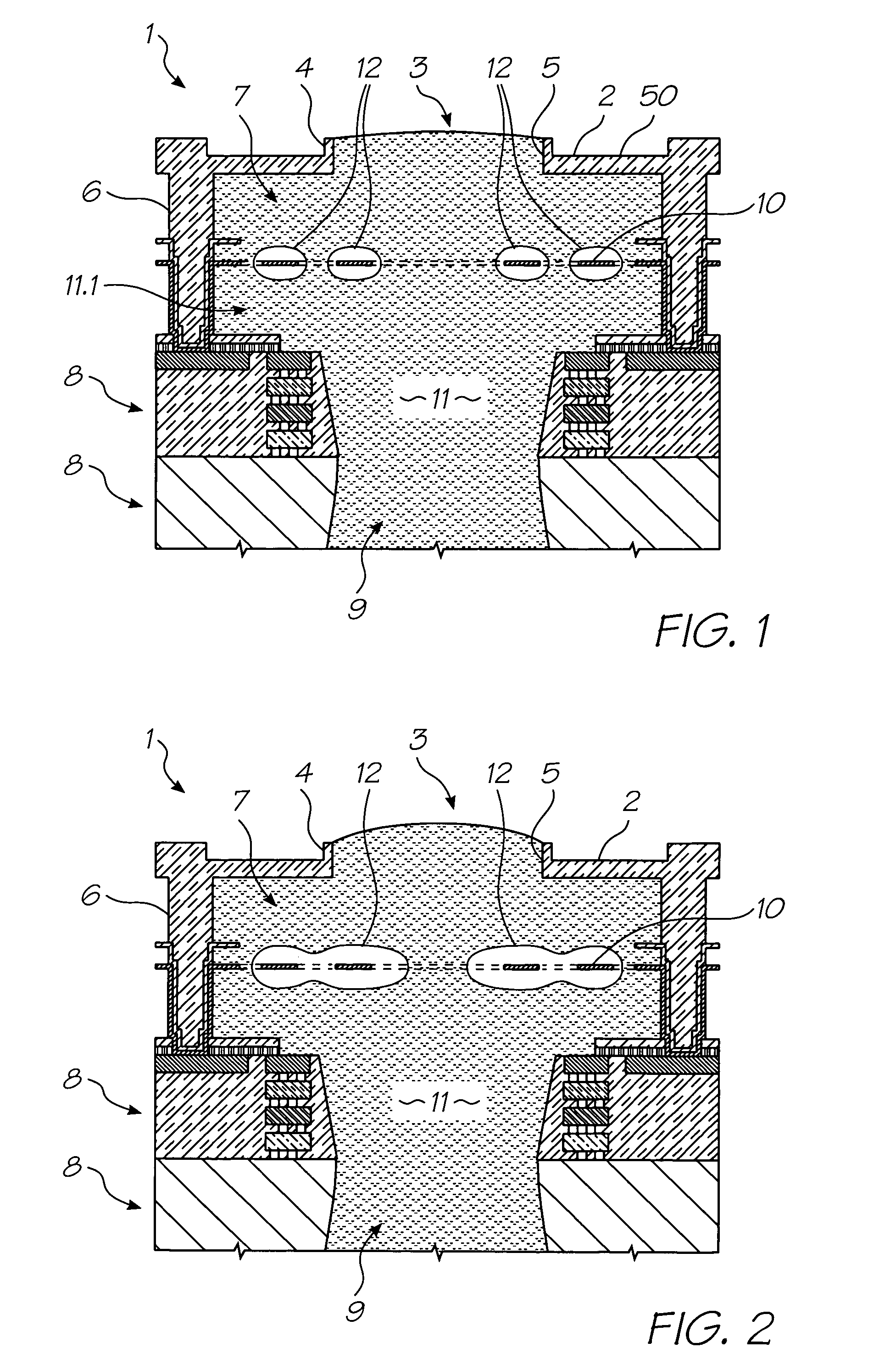

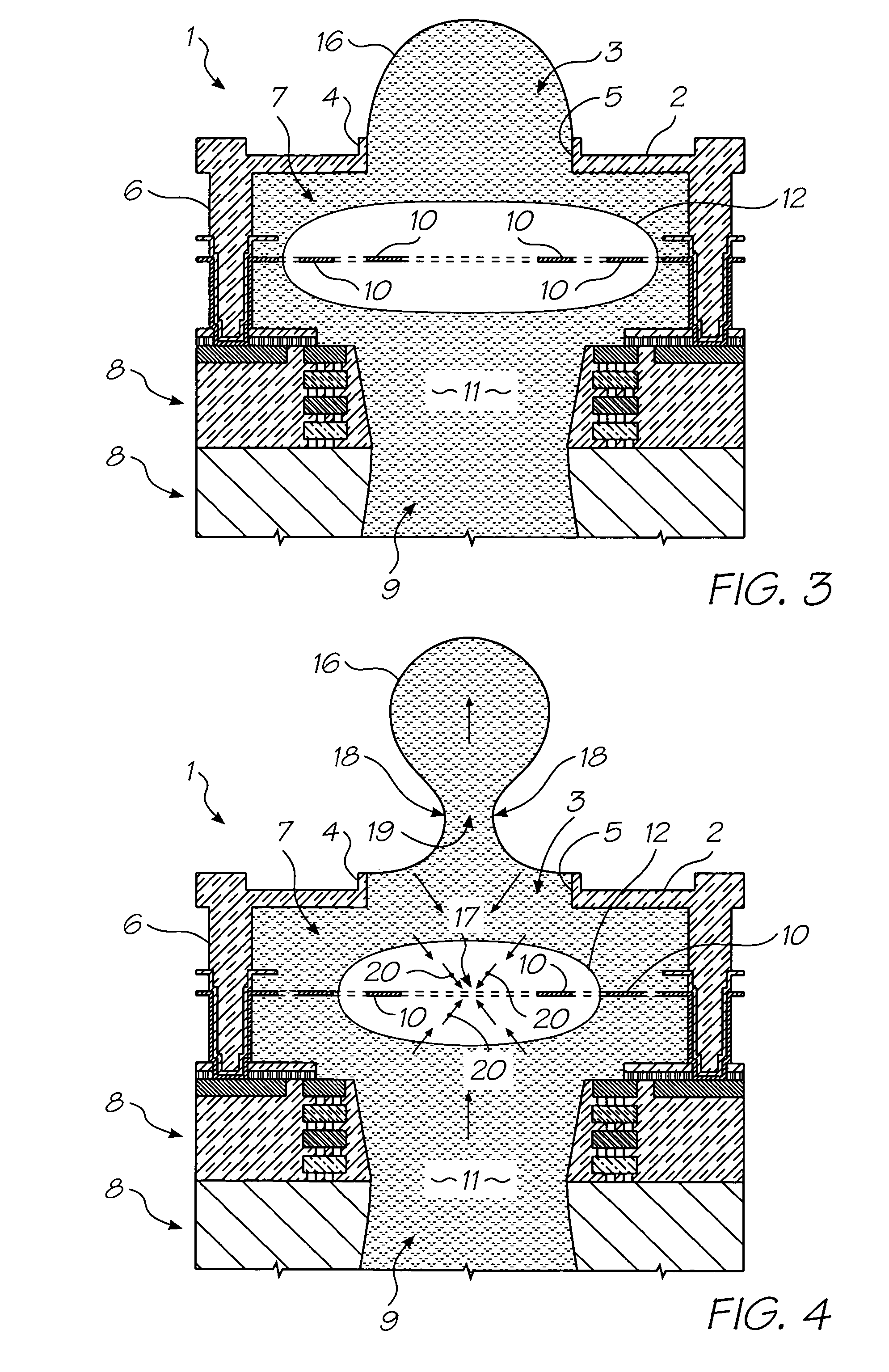

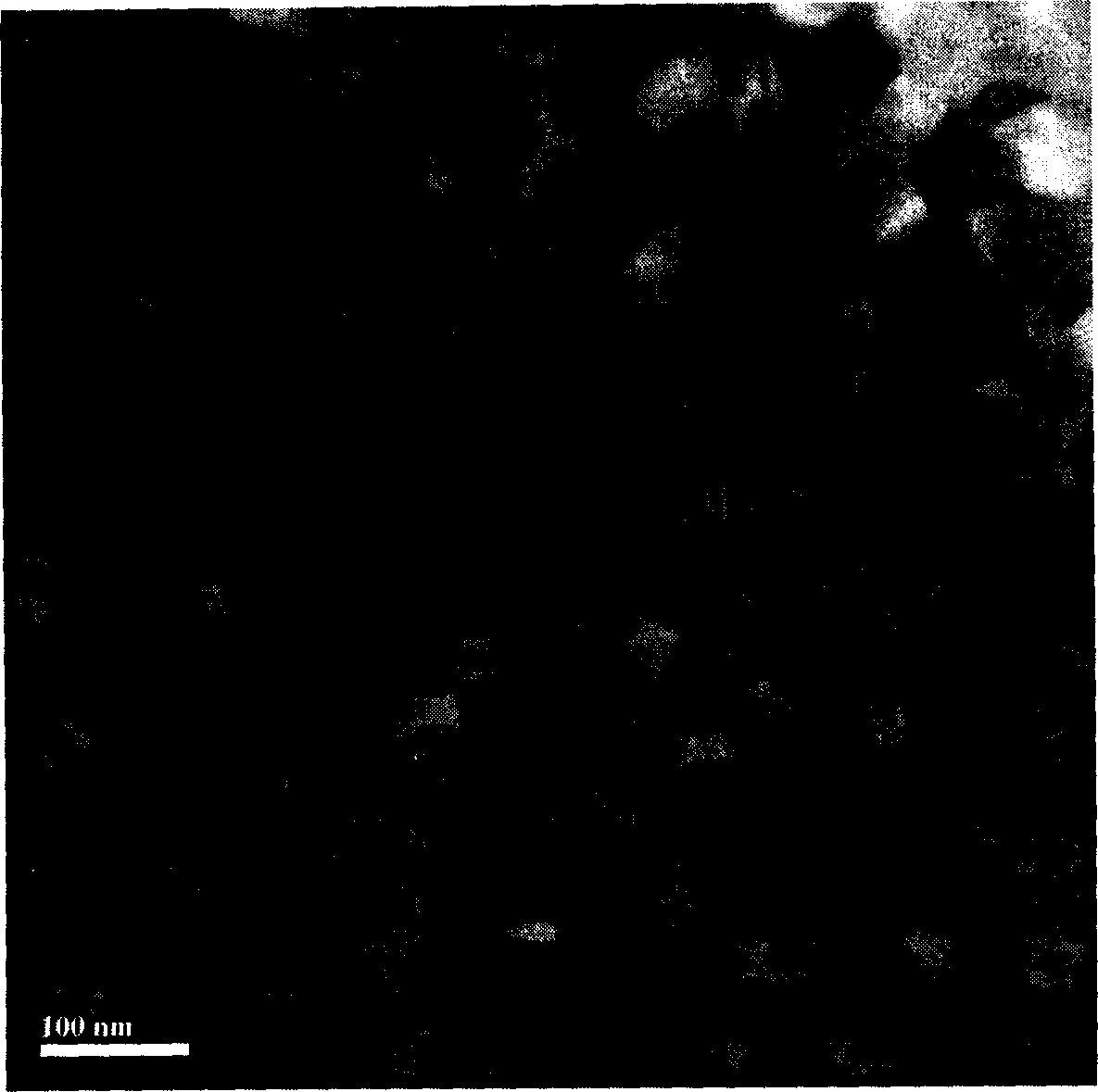

A process to produce dense nanocrystalline composites such as ceramic bodies, coatings and multi-layered devices with uniform microstructure is disclosed. The invention utilizes sol-gel solutions to reduce agglomeration of nanocrystalline powders in the production of “green bodies” or intermediate products. This novel use of sol-gel solutions also reduces grain growth and porosity in products during sintering. In finished products, final grain sizes are typically less than 100 nm with densities of the final products approaching 99.5% of theoretical densities. In addition, sintering temperatures required are lower than those in conventional methods, typically less than 1,100° C. While FIG. 1 shows one application of this novel process, this invention has wide application in the manufacture of many other products, particularly for composite coatings and in the production of nanodevices.

Owner:NANYANG TECH UNIV

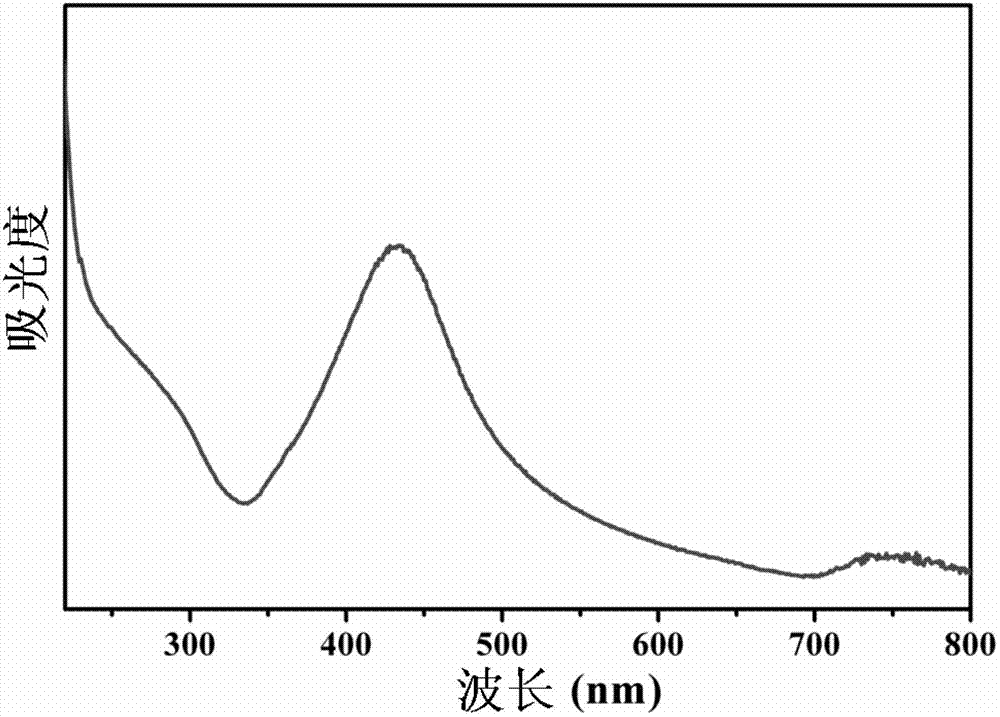

Preparation method for nano-sliver/cellulose nanocrystalline composite particle

InactiveCN102775643AIncrease loadDoes not destroy the glycosidic ring structureNanotechnologyCelluloseFree cooling

The invention relates to a preparation method for a nano-sliver / cellulose nanocrystalline composite particle. The preparation method comprises the following steps of: (1) adding a cellulose raw material into an acid-mixed solution and reacting at the temperature of 50-90DEG C for 1-20 hours; after the reaction is ended, washing a reaction product with deionized water to neutral and obtaining aldehyde cellulose nanocrystalline; and (2) adding the aldehyde cellulose nanocrystalline into a silver nitrate solution; reacting at the temperature of 60-105DEG C for 10-60 minutes; and after naturally cooling, diluting a reaction product with the deionized water, centrifuging and then carrying out free drying or vacuum drying to obtain a nano-silver / CNC (Cellulose Nanocrystalline) composite material. The preparation method disclosed by the invention is simple and convenient in process, easy in operation and environment friendly and can be used for shortening the preparation period; the prepared CNC / nano-silver has the advantages of small size, easy adjustment, large specific area, firmness in combination of the CNC and the nano-silver, durable antibacterial effect, antibacterial and enhancing functions and broad application prospect.

Owner:DONGHUA UNIV

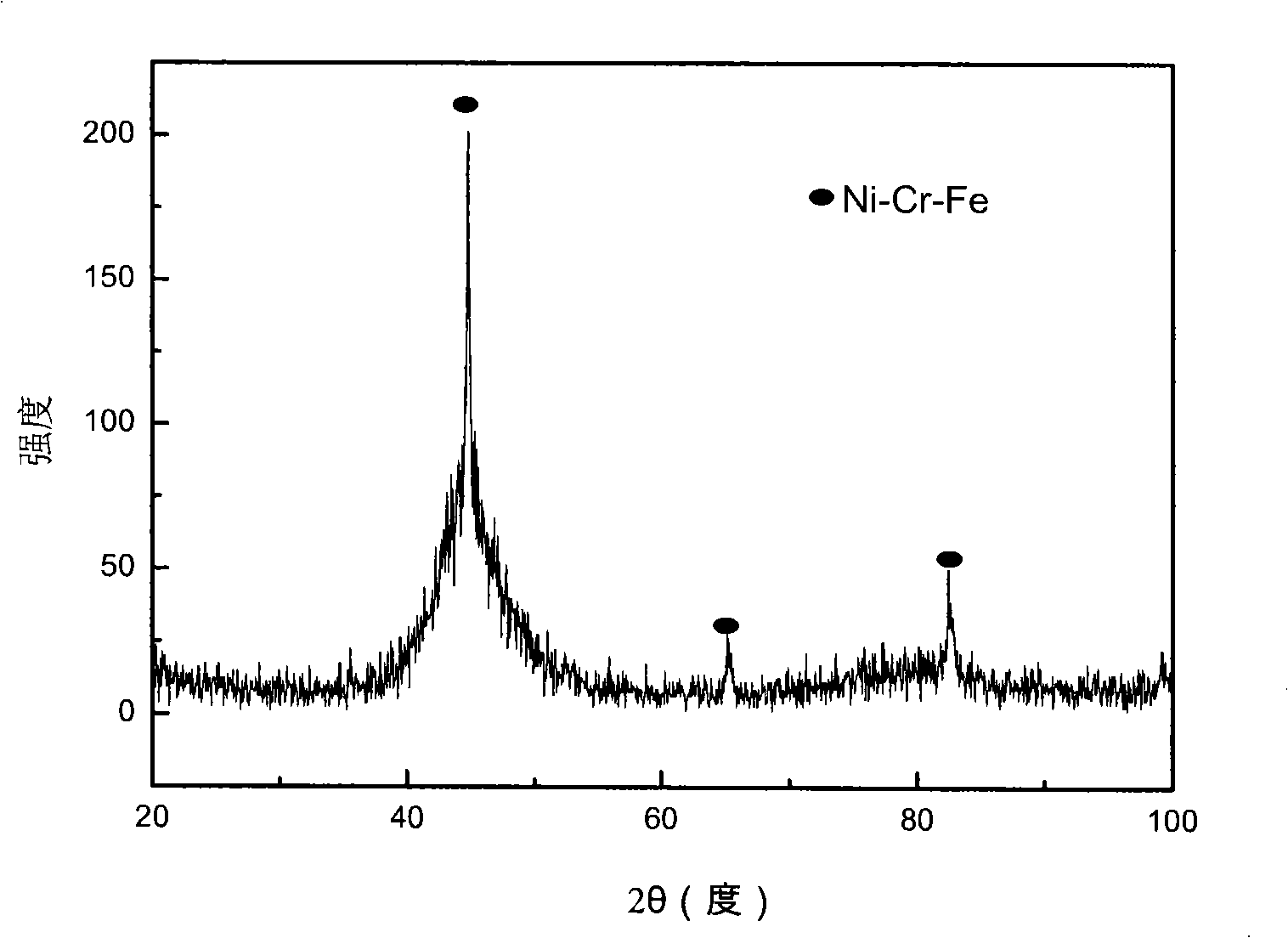

Highly corrosion-proof abrasion-proof iron matrix amorphous nanocrystalline coating and its preparation method

InactiveCN1730714AExcellent comprehensive performance of corrosion resistance and wear resistanceMolten spray coatingLiquid spraying apparatusThermal sprayingNanostructure

A highly corrosion-proof abrasion-proof iron matrix amorphous nanocrystalline coating and its preparation method consists of, integrating nano technique with non-crystallizing technique, and comprises using Fe-based multielement amorphous alloy powder as spraying powder, making amorphous coating through supersonic flame-spraying, then transforming into amorphous and nanocrystalline composite coating through heat treatment method.

Owner:UNIV OF SCI & TECH BEIJING

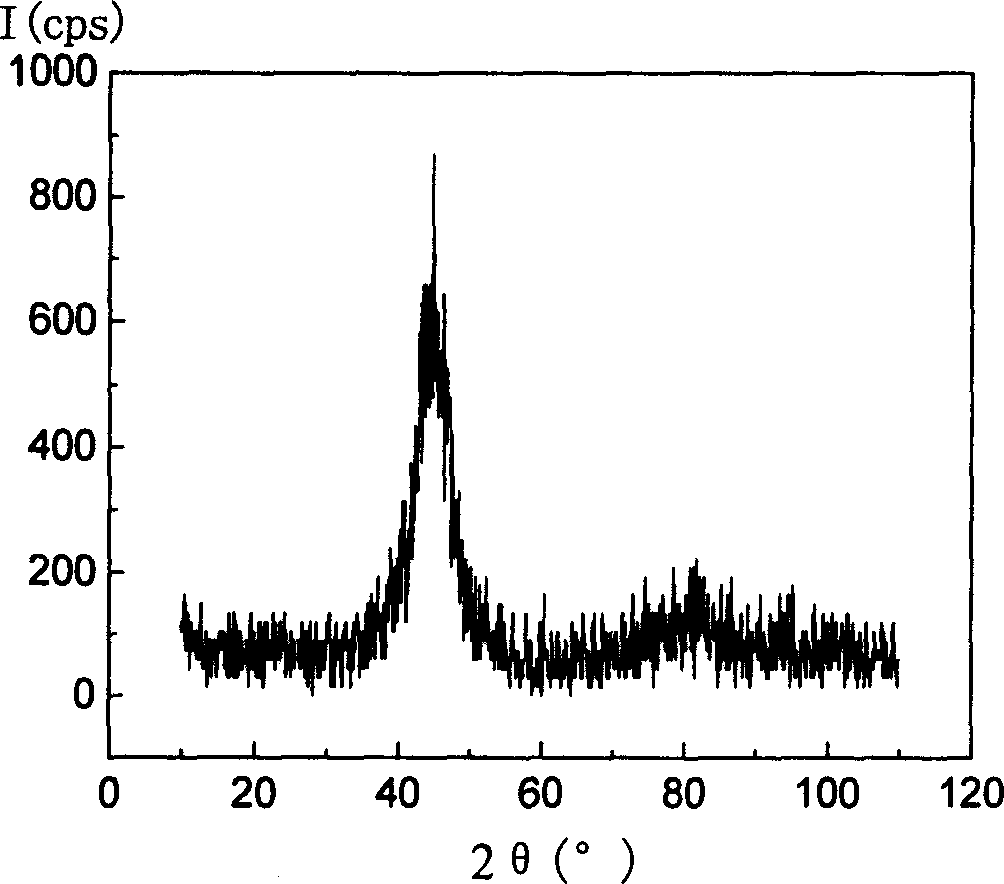

Iron based amorphous nanocrystalline composite coating

InactiveCN101492795ALow costSimple preparation processMolten spray coatingSpray coatingPlasma sprayed

The invention relates to a Fe-based amorphous nanocrystalline coating, the composition of the coating is expressed by atomic ratio as follows: Fe100-a-b-c-d-eNiaCrbPcTdDe, wherein, a is 0.5-8, b is 5-26, c is 3-15, d is 8-20 and e is 0-8; T is one or more of B, C and Si, and D is five or less of Y, V, Zr, Mo, Nb, Cu, Al, Ga, Sn, W and Mn. The coating can be hot spray coating, electric arc spray coating or plasma spray coating.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

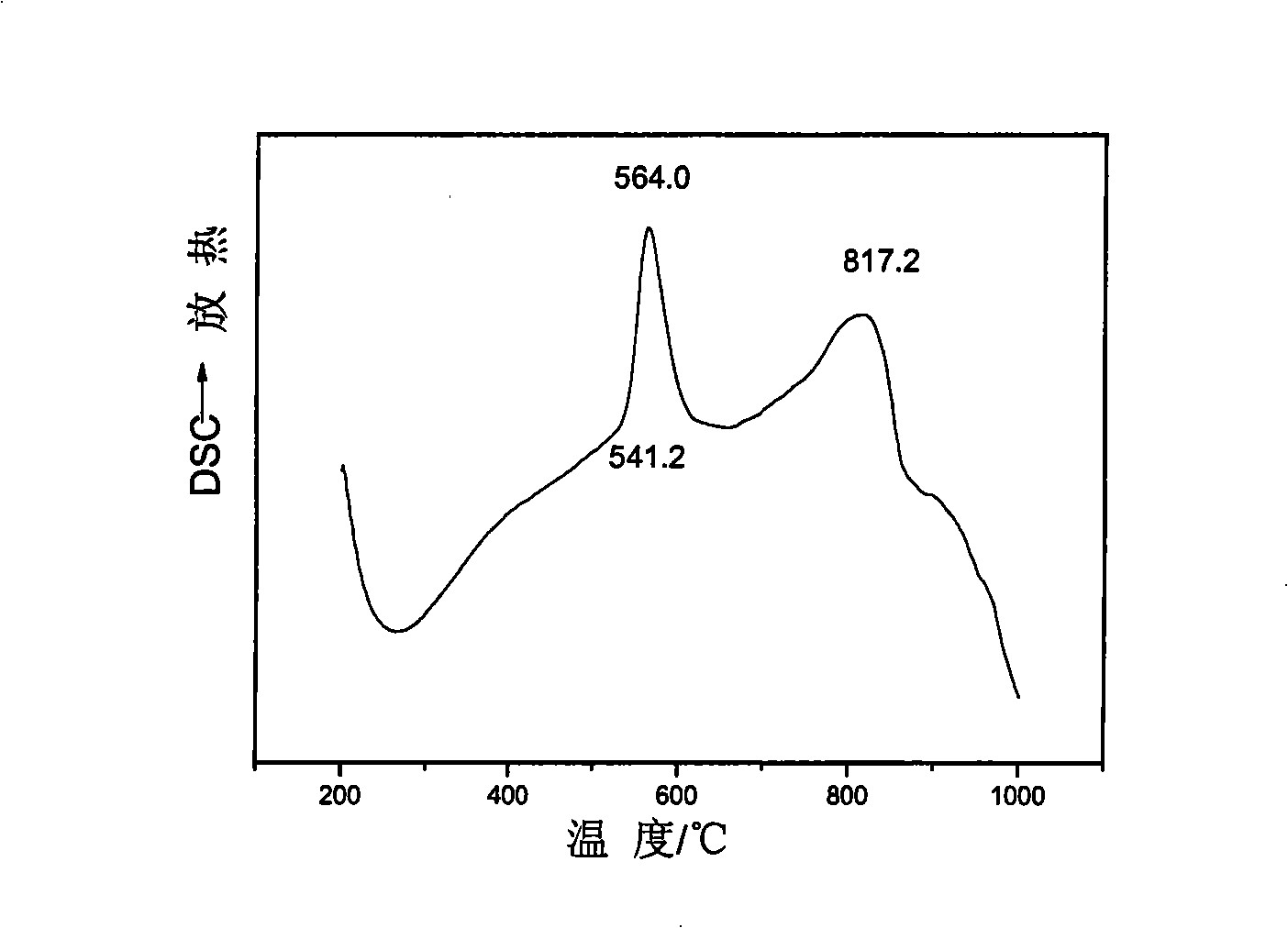

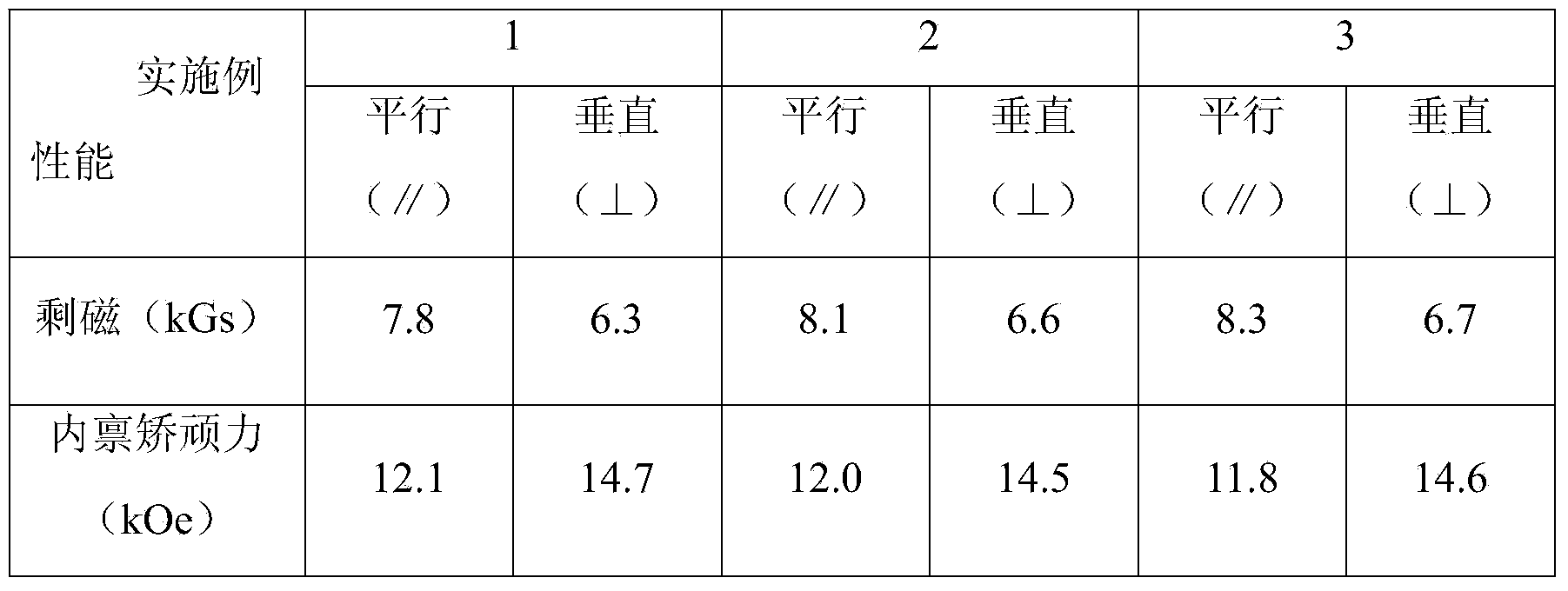

Method for preparing rare-earth iron series biphase nanocrystalline composite permanent-magnet material

InactiveCN1737955AHigh densityImprove magnetismInorganic material magnetismRare earthInduction furnace

The invention belongs to the field of magnetic material. At present much of the permanent magnet material is thin belt or powder, and since the custom sintering process for preparing block material will make the crystal grow, the magnetic property drops significantly. The steps of said invention comprises: the alloy whose component is RxFeyBz, in which R stands for rare-earth Nd or Pr element and the content of x is 4-10, y is 78-88, z is 6-18, is smelted for mother alloy in induction furnace in vacuum; Then preparing the quenched alloy in amorphous, nanometer crystalline state or amorphous-nanometer mixed state by smelting quick-quench method; the linear speed of smelting quick-quench is arranged between 10-50 m / s; under the protection of inertance gas, abrading the alloy into powder whose coarseness is lower than 80 items; encasing the powder into module to precompression and shaping, while range of pressure is 10-1000MPa; carrying the process of discharging plasma sintering, while the sintering temperature is 550Deg C.-700Deg C., the pressure is 30-1000MPa, the elevated temperature speed is 50-500Deg C. / min, the time of heat preservation is 0-10 min, the elevated temperature speed is 50-200Deg C. / min, Said invention can realize high magnetic property material with high degree of compactness, whose crystal grain is smaller than 100 nanometers, and it can be used in high temperature.

Owner:BEIJING UNIV OF TECH

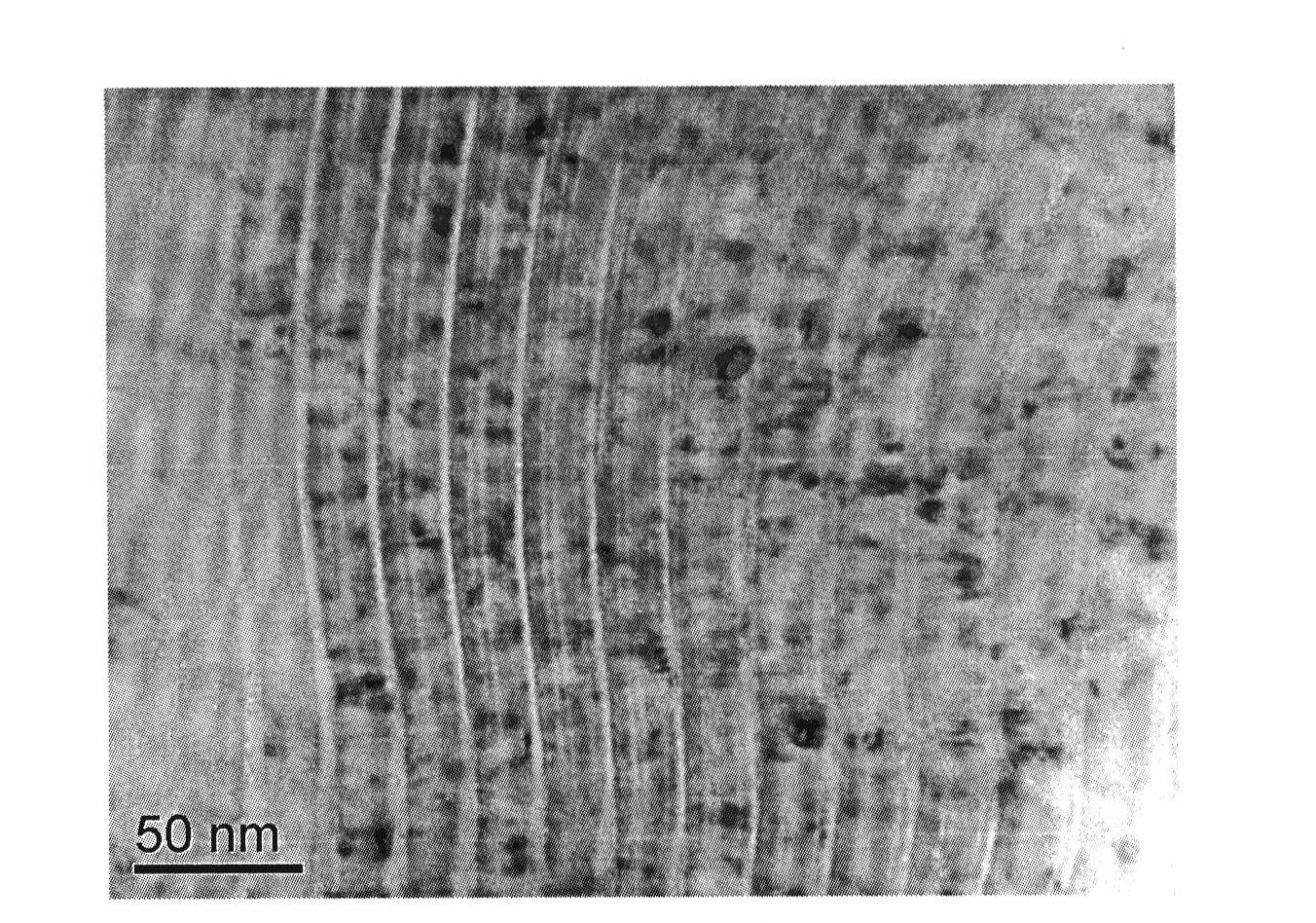

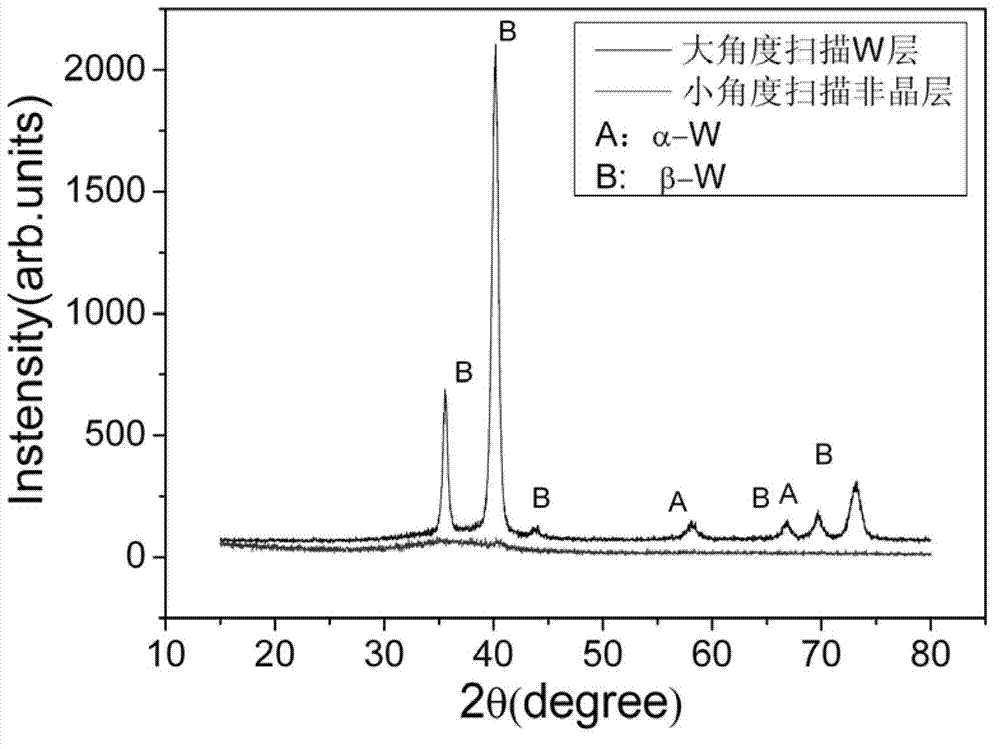

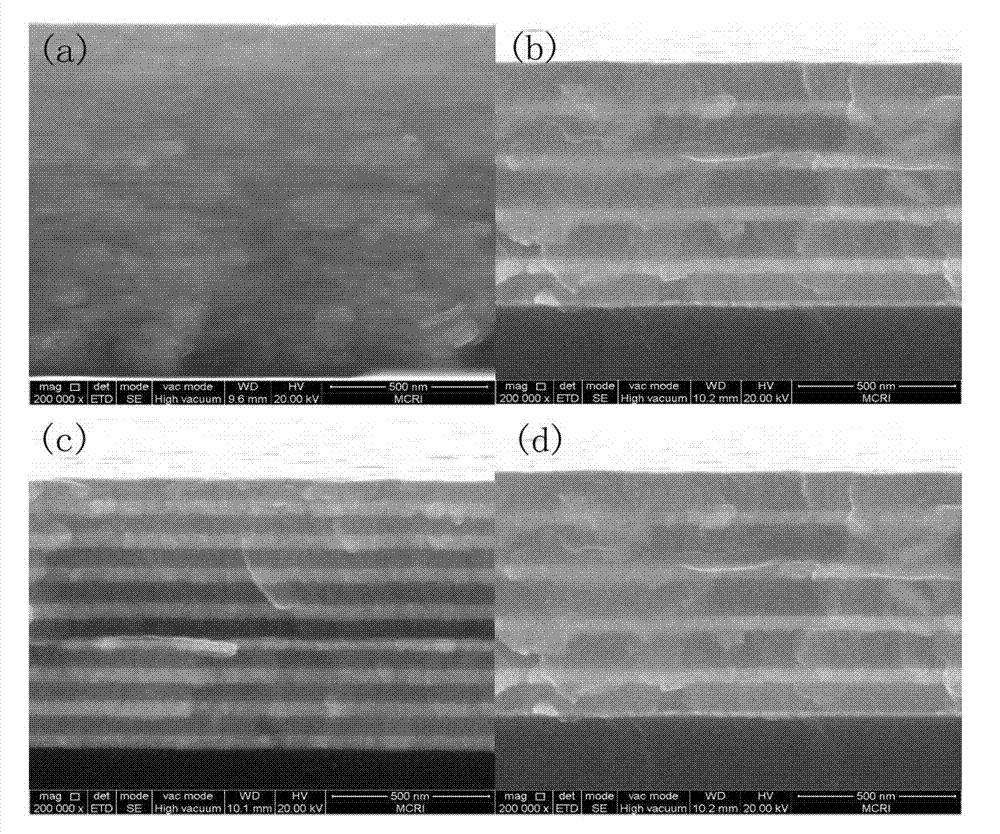

Method for preparing amorphous/nanometer crystal multilayer-structure film

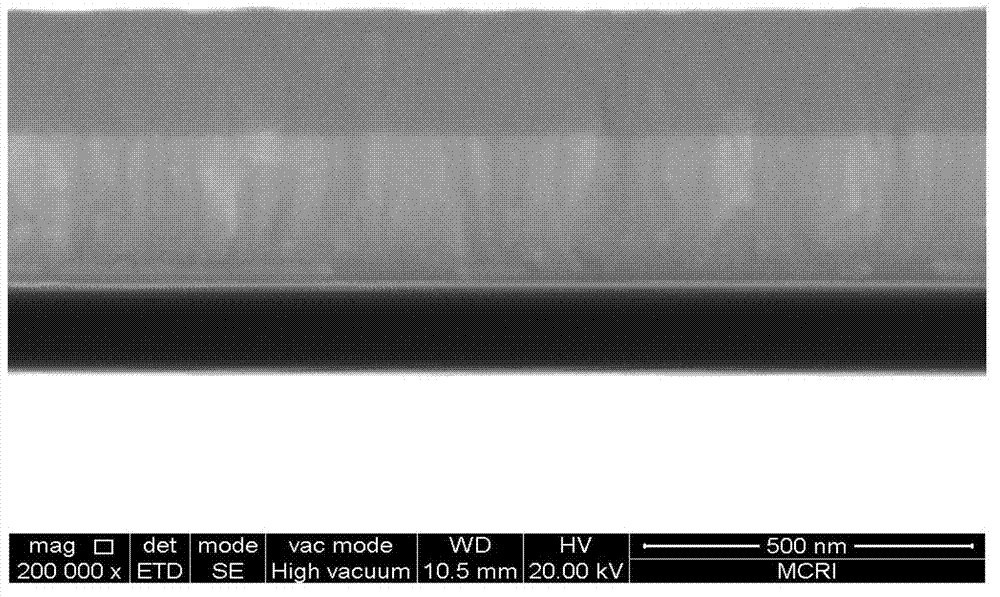

InactiveCN102925869AClear structureClear interfaceVacuum evaporation coatingSputtering coatingAlloyShear band

The invention discloses a method for preparing an amorphous / nanometer crystal multilayer-structure film. The amorphous / nanometer crystal multilayer-structure film is characterized in that the amorphous / nanometer crystal multilayer-structure film is composed of two entirely different crystal structures of a nanometer crystal structure and an amorphous structure, and has a multilayer structure composed of alternately overlapped amorphous layers and nanometer crystal layers. The amorphous / nanometer crystal multilayer-structure film prepared by the method has a compact film structure and clear interface layers. The method realizes control of a blending proportion of amorphous layers and nanometer crystal layers by control of thickness sizes (reaching to nanoscale) of different film layers thereby changing a blending proportion and even gradually changing a blending proportion, provides a novel research method for shear band deformation and size effects of a micro-amorphous alloy, provides a novel approach for improvement of mechanical properties such as ductility and toughness of an amorphous alloy thereby providing possibility for preparation of a mechanical property-controllable amorphous / nanometer crystal composite material, has simple processes and a low cost, and can be industrialized and popularized easily.

Owner:昆山昊盛泰纳米科技有限公司

Method for manufacturing zinc oxide-cellulose nanocrystalline composite fiber film with antibacterial characteristic and photocatalytic degradation characteristic at same time

InactiveCN104018235AProduce pollutionReduce typesFilament/thread formingNon-woven fabricsFiberOrganic solvent

The invention relates to a method for manufacturing a zinc oxide-cellulose nanocrystalline composite fiber film with the antibacterial characteristic and the photocatalytic degradation characteristic at the same time. The method includes the steps of enabling microcrystalline cellulose to be reacted for 5 hours to 10 hours under the 40 DEG C-95 DEG C mixed acid condition, adjusting the pH value to seven after the reaction is finished, and obtaining cellulose nanocrystalline powder; (2) preparing suspension liquid with the powder, mixing the suspension liquid with a zinc salt water solution, dropwise adding a sodium hydroxide solution at 30 DEG C to 95 DEG C, stirring to enable the mixture to be reacted for 5 min to 60 min after drop adding is finished, and carrying out washing and drying to obtain cellulose nanocrystalline-zinc oxide hybrid materials; (3) adding the materials and PHBV into organic solvents, raising the temperature to range 30 DEG C to 80 DEG C, and obtaining an electrostatic spinning solution; (4) carrying out electrostatic spinning on the electrostatic spinning solution, and obtaining the zinc oxide-cellulose nanocrystalline composite fiber film. According to the method, the preparing process is simple, and the obtained fiber film is a multifunctional full biodegradation product and has the antibacterial characteristic and the photocatalytic degradation characteristic.

Owner:ZHEJIANG SCI-TECH UNIV

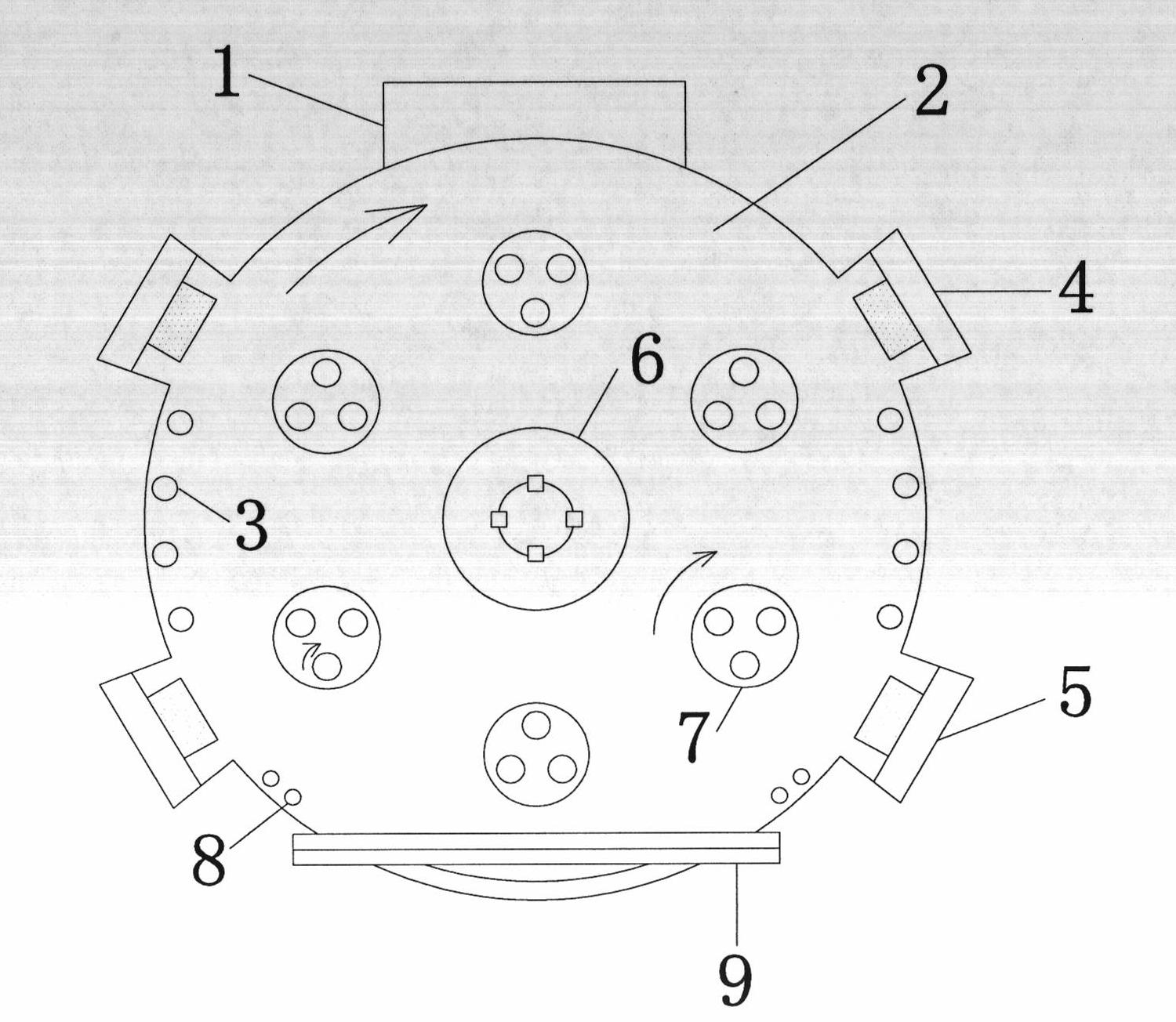

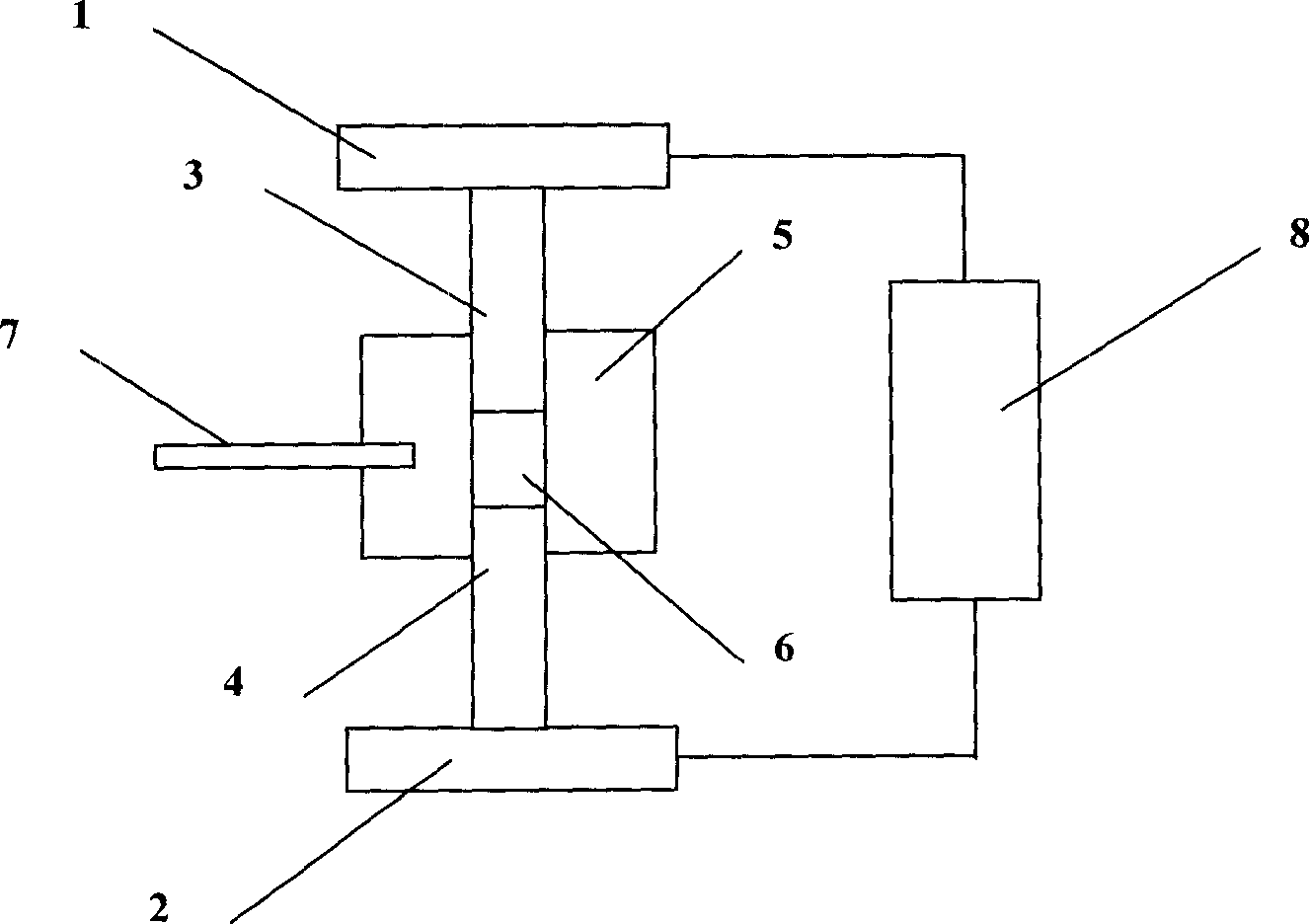

Bipolar plate of fuel cell and method for preparing carbon titanium nanocomposite film on surface thereof

The invention discloses a bipolar plate of a fuel cell and a method for preparing a carbon titanium nanocomposite film on the surface thereof, belongs to the technical field of surface modification of metallic materials and fuel cells, and relates to a bipolar plate of a regenerative fuel cell and a proton exchange membrane fuel cell and a preparation technology of a surface modified film of the bipolar plate. The bipolar plate consists of a metal thin plate substrate and carbon titanium nanocomposite films which are formed on the surfaces at two sides of the substrate, wherein the metal thin plate substrate is a titanium plate and a stainless steel plate; the carbon titanium nanocomposite film is an amorphous and nanocrystalline composite film which is prepared on an amorphous carbon substrate with an arc ion film plating method and on which titanium and titanium carbide nanocrystals are distributed; the thickness of the film is of micron dimension; and the size of the crystal grains of the nanocrystals is of micron dimension. The invention has the effects and advantages that: the bipolar plate is low in manufacturing cost, has prominent composite performance such as corrosion resistance, conductivity, hydrophobicity and the like, can be used for replacing a noble metal bipolar plate and a graphite bipolar plate, and can be used as a cell bipolar plate of the proton exchange membrane fuel cell and an electrolytic cell bipolar plate of the regenerative fuel cell.

Owner:DALIAN UNIV OF TECH

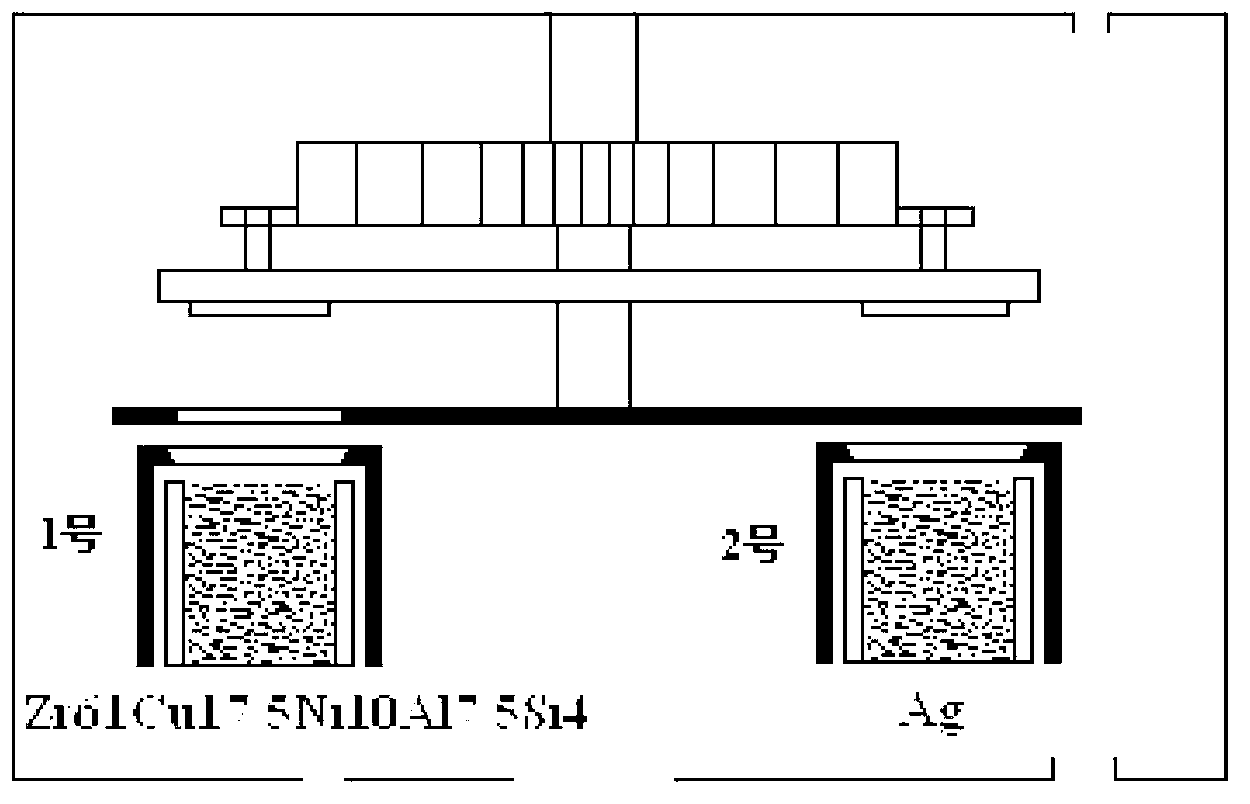

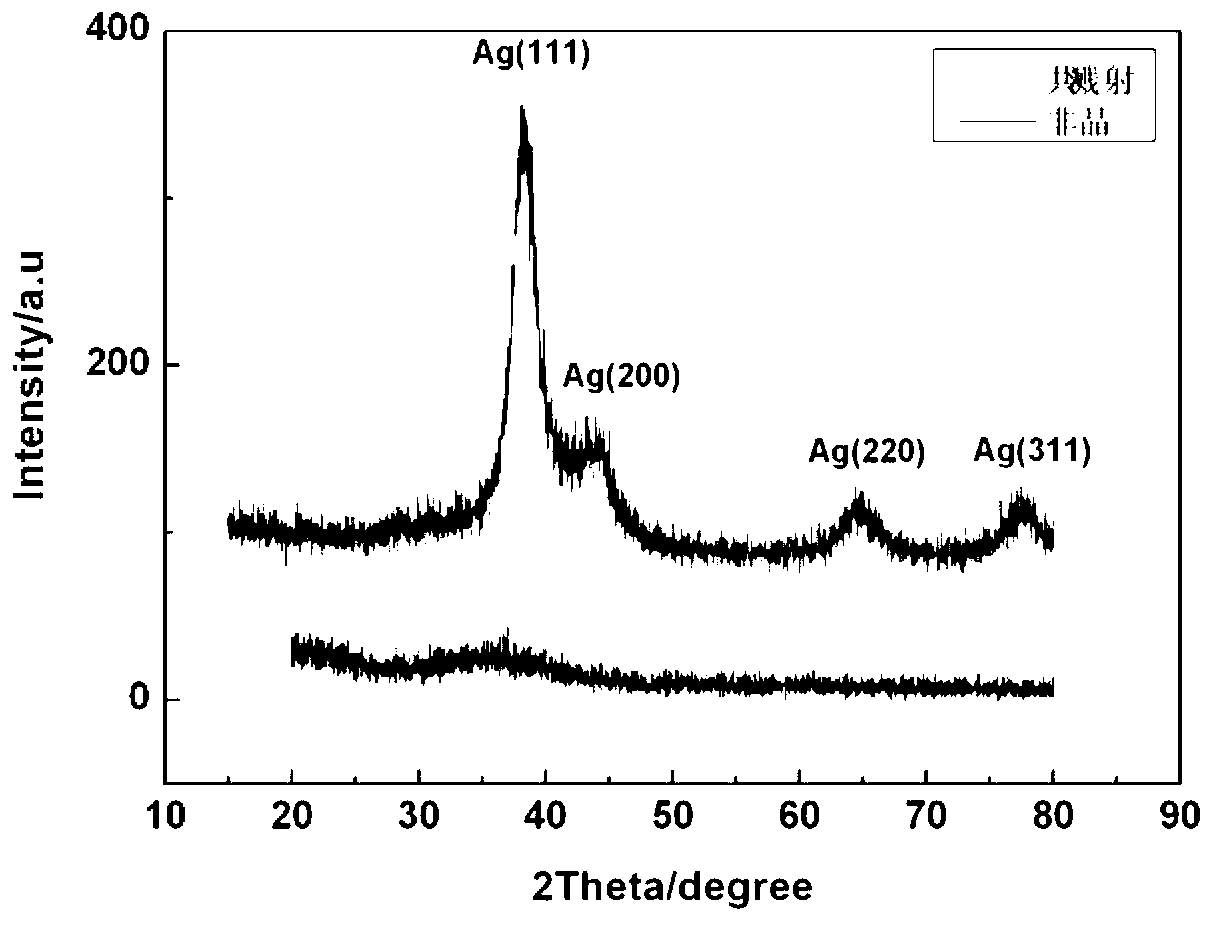

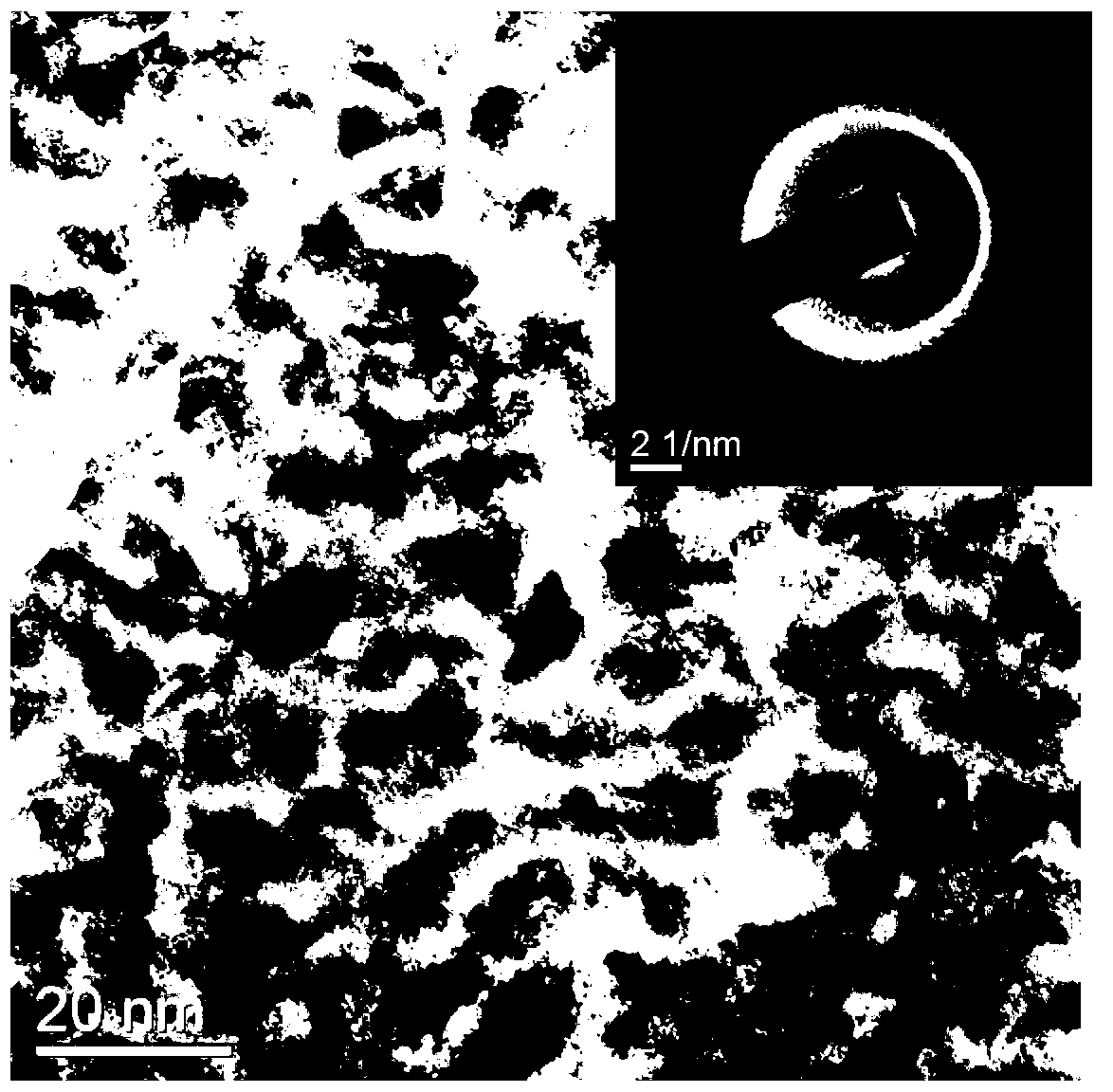

Method for preparing noncrystalline-nanocrystalline composite membrane by adopting co-sputtering method

InactiveCN103215555AAvoid secondary processingEasy to controlVacuum evaporation coatingSputtering coatingSputteringCreep strain

The invention discloses a method for preparing a noncrystalline-nanocrystalline composite membrane by adopting a co-sputtering method, wherein a mixture thin membrane with a noncrystalline phase and a crystalline phase coexisting is prepared by means of implementing double-target magnetron sputtering on a matrix and simultaneously depositing the noncrystalline phase and a nanocrystalline phase. The noncrystalline co-sputtered membrane prepared by the method has a high creep strain rate sensitive value, an excellent mechanical property and uniform plastic deformation. By virtue of the method which is simple and feasible, the noncrystalline mixture thin membrane with the noncrystalline phase and the crystalline phase coexisting is prepared. The thin membrane can be widely applied to the fields of protective coating, functional coating and the like of various precise instruments such as micro electro mechanical systems (MEMS) and nanometer electro mechanical systems (NEMS).

Owner:昆山昊盛泰纳米科技有限公司

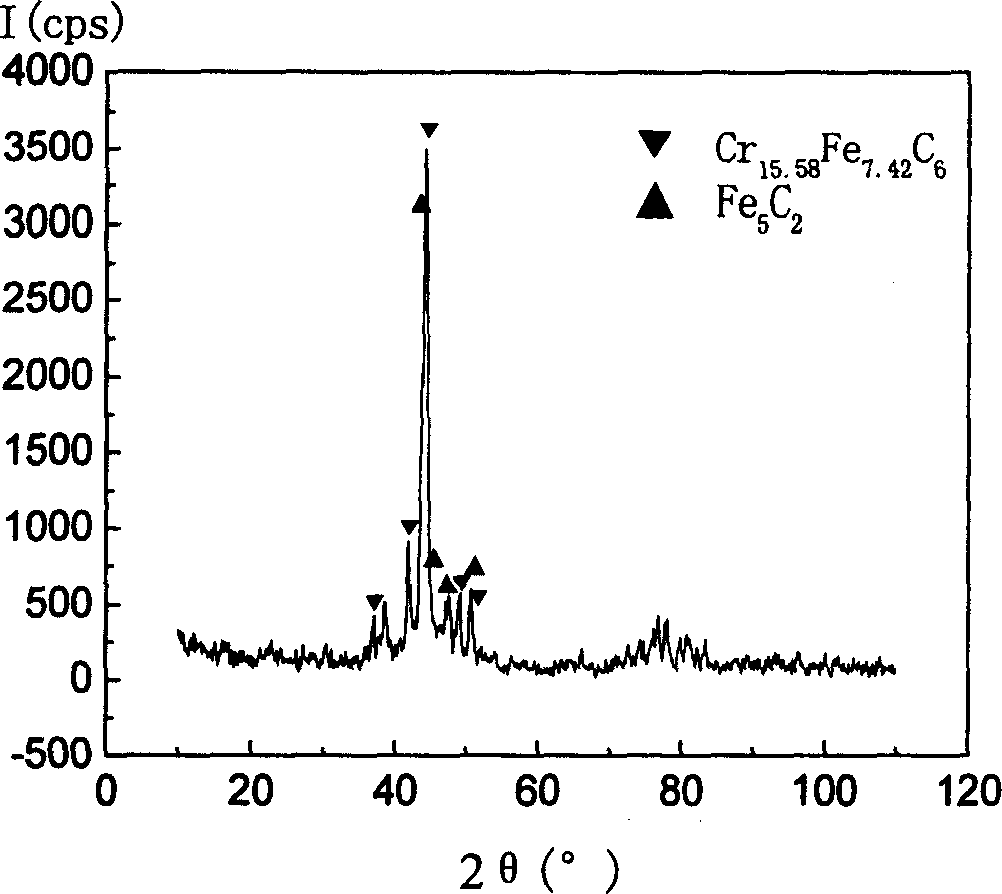

Iron-based nanocrystalline composite coating for protecting boiler tail heating surface and laser-cladding forming process of iron-based nanocrystalline composite coating

ActiveCN104357748AImprove wear and corrosion resistanceReduce corrosion wearMetallic material coating processesRare-earth elementAlloy

The invention discloses an iron-based nanocrystalline composite coating for protecting a boiler tail heating surface and a laser-cladding forming process of the iron-based nanocrystalline composite coating. The iron-based nanocrystalline composite coating comprises the following components in percentage by weight: 49.9-62.8% of Fe, 14.2-20.4% of Cr, 9.0-16.3% of Mo, 2.9-4.1% of B, 0.6-1.3% of C, 1.0-2.4% of Mn, 3.4-8.0% of W, 1.0-1.9% of Si and 0-3.9% of RE, wherein RE is a rare earth element. The forming process comprises the following steps: preparing alloy powder of the iron-based nanocrystalline composite coating; treating the surface of the boiler tail heating surface; preparing the iron-based nanocrystalline composite coating through a simultaneous powder feeding method and a laser-cladding method, wherein the laser cladding is performed for multiple times. The formed iron-based nanocrystalline composite coating is 1 mm above in thickness. The iron-based nanocrystalline composite coating can obviously enhance the wear resistance and corrosion resistance of the boiler tail heating surface, and reduce maintenance costs of worn and corroded parts and consumption of raw materials of a power plant.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

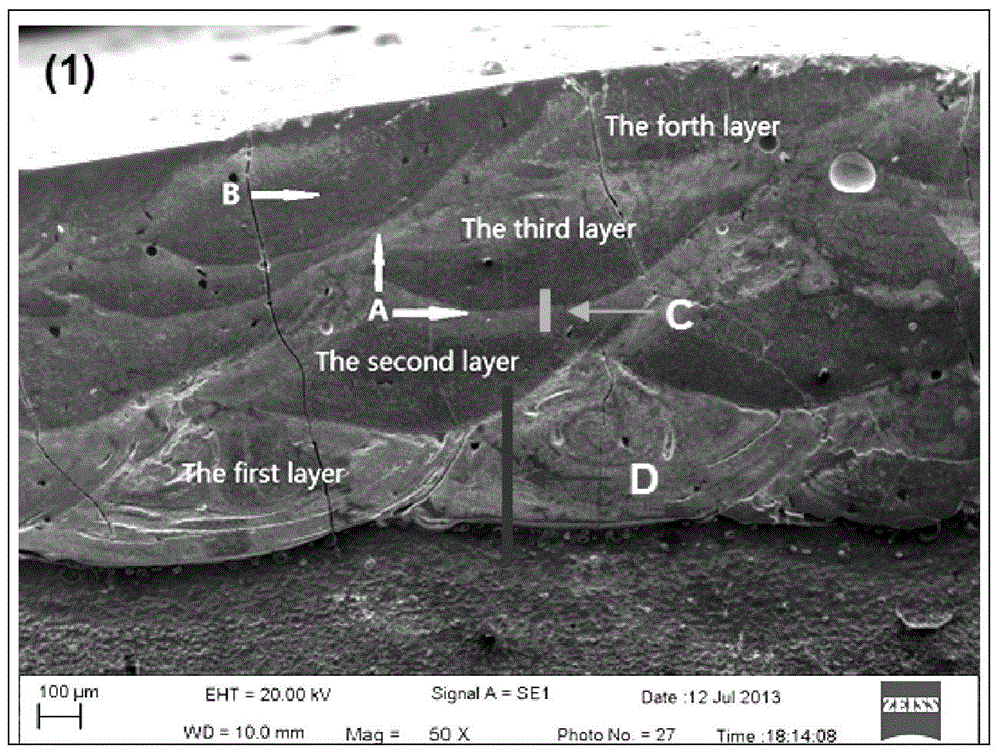

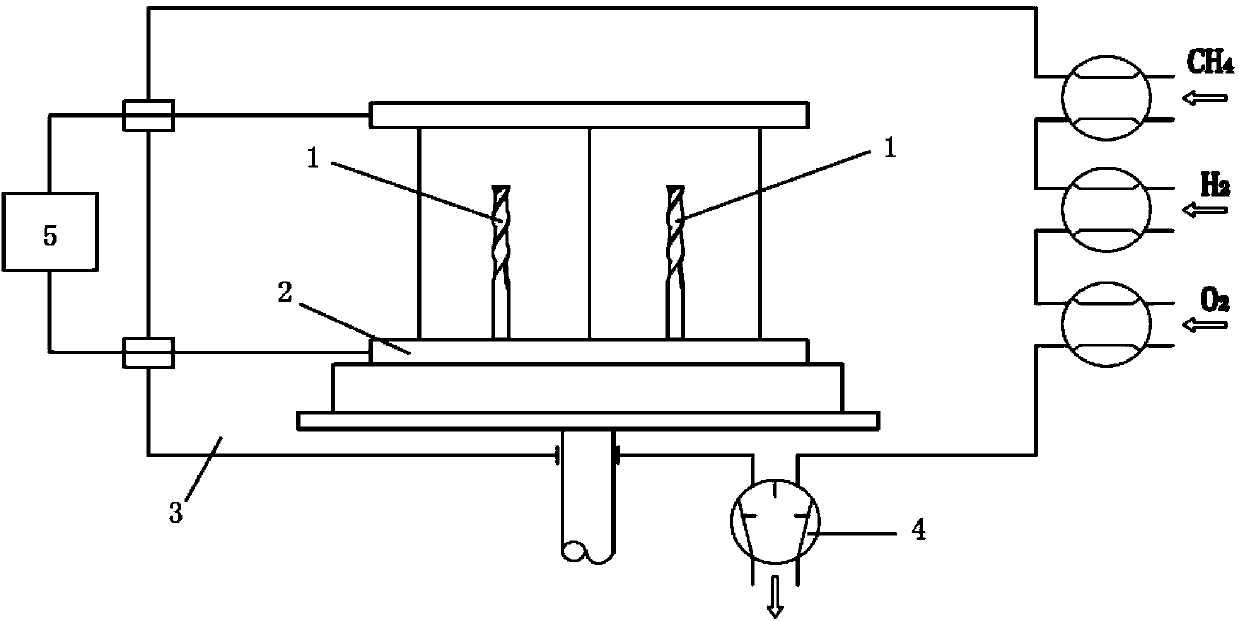

Preparation method of diamond composite coating of micro milling cutter

ActiveCN103436855AImprove display finishImprove wear resistanceChemical vapor deposition coatingMilling cutterGas phase

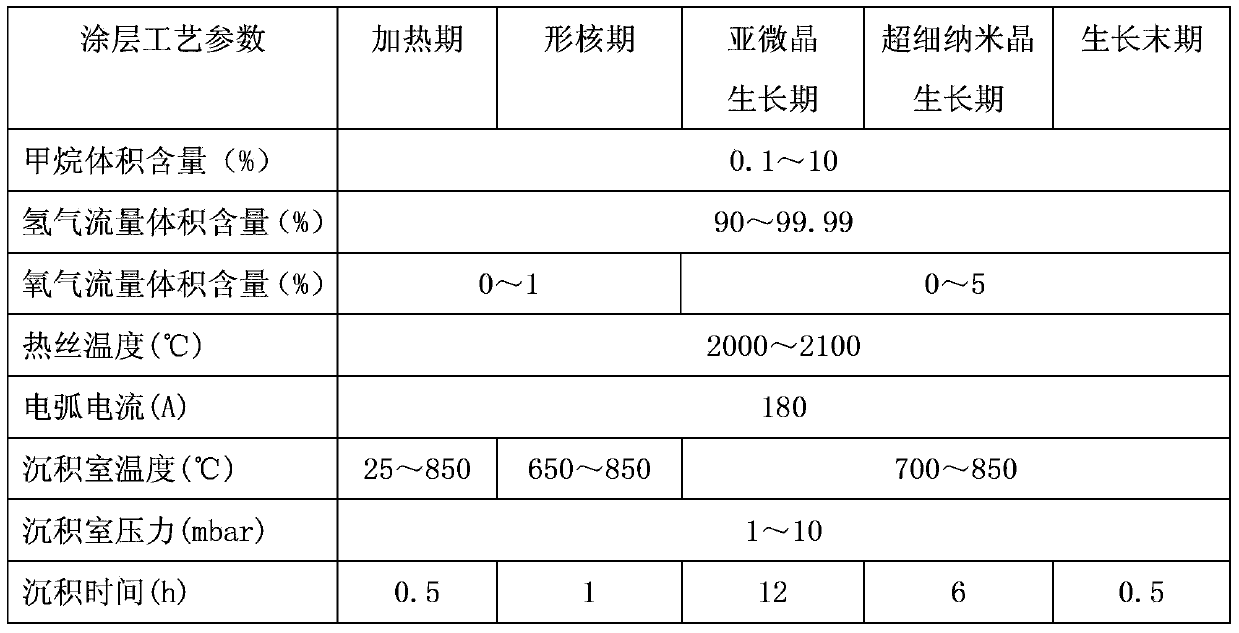

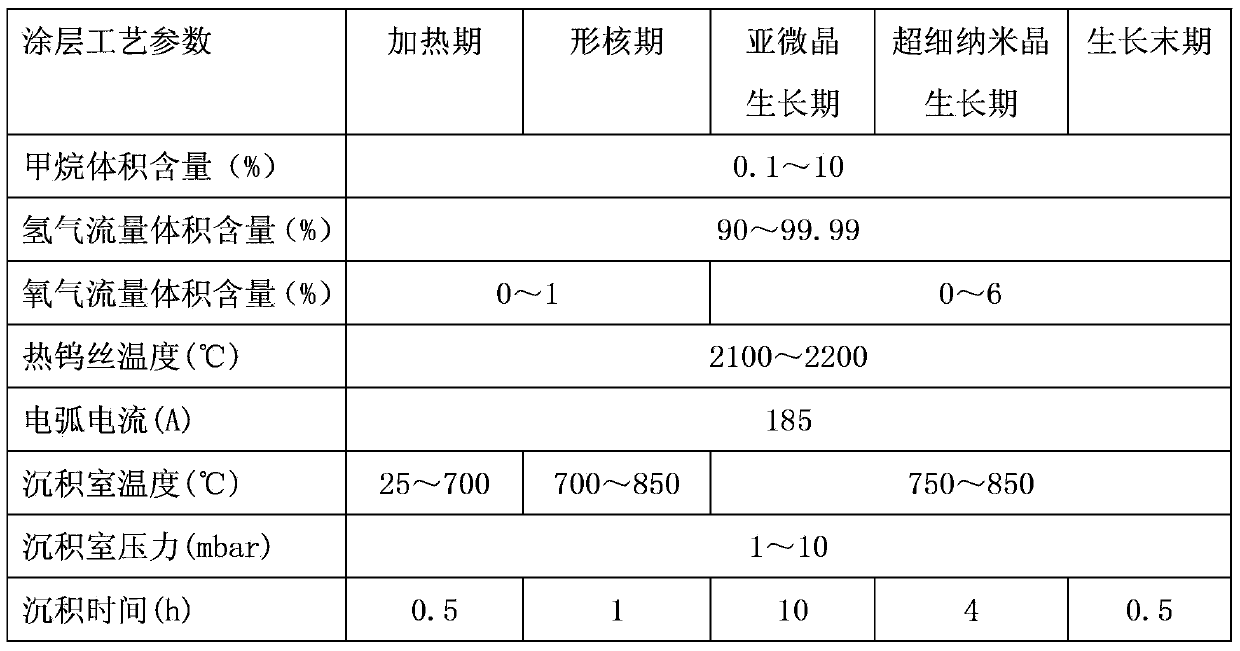

The invention discloses a preparation method of a diamond composite coating of a micro milling cutter, and relates to the micro milling cutter. The preparation method comprises the following steps of: placing a PCB (Printed Circuit Board) micro milling cutter into a tool and then placing into a deposition reaction chamber; evacuating the deposition reaction chamber, and introducing methane (CH4), hydrogen gas and oxygen gas into the deposition reaction chamber; applying direct-current electric arc to a heating wire which is installed in the deposition reaction chamber, wherein a deposition process in the deposition reaction chamber is divided into five stages including a heating stage, a nucleation stage, a submicrocrystal growth stage, a superfine nanocrystalline growth stage and a final growth stage, different gas-phase deposition conditions are adopted in the five stages, the submicrocrystal growth stage and the superfine nanocrystalline growth stage can be generated in a circulating manner to form a diamond submicrocrystal and superfine nanocrystalline composite coating, and the circulating generation number is N (N is not less than 1). The prepared diamond composite coating of the micro milling cutter can be used for keeping the cutting edge to be sharp for a longer time, obviously improving the machining effect, prolonging the service life of the cutter, reducing the cutter changing frequency, improving the machining efficiency and lowering the machining cost.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

Samarium-cobalt-base nanocrystalline permanent magnet material and preparation method thereof

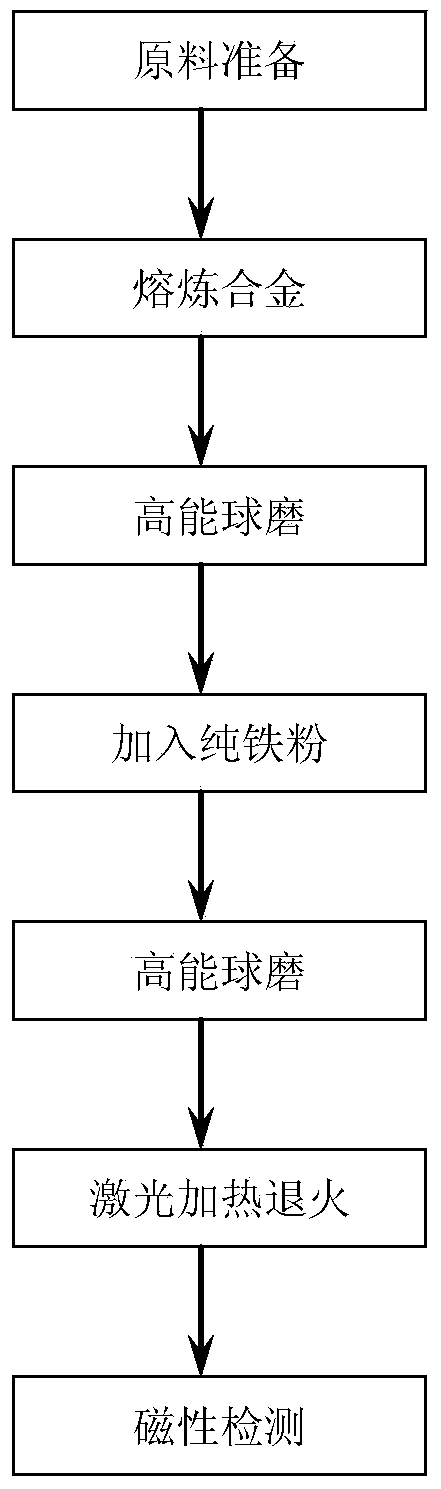

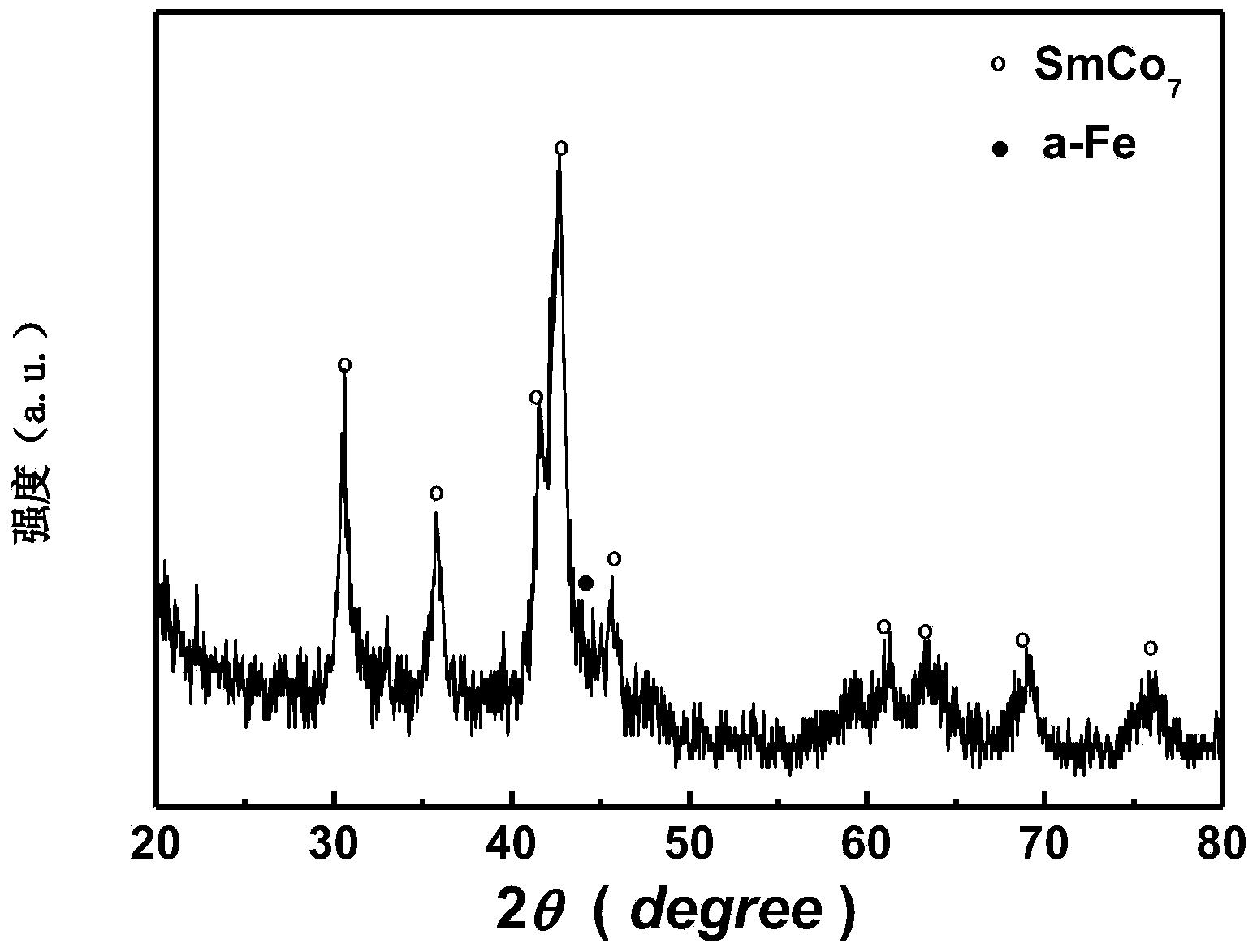

The invention relates to the metallurgy field and discloses novel samarium-cobalt-base nano-composite permanent magnetic material. The samarium cobalt base is (Sm, R)1(Co, Fe, Cu, Zr)7 in type and comprises a TbCu7 type structure, and Co is partially replaced by Fe, Cu and Zr; Re is any one of heavy rare earth Lu, Dy and Tb and partially replaces Sm. The preparation method includes steps that 1) mixing raw materials of the samarium cobalt base according to proportion, and smelting to obtain a 1: 7 type samarium cobalt base alloy ingot; 2) ball milling the alloy ingot through a high-energy ball milling technique, mixing with Fe powder according to proportion, and performing high-energy ball milling to obtain nanocrystalline composite magnetic powder; 3) carrying out annealing heat treatment on the nanocrystalline composite magnetic powder. According to the samarium-cobalt-base nanocrystalline permanent magnet material and the preparation method thereof, the soft / hard-magnetic phase composite magnetic powder is prepared through the high-energy ball milling, laser heat treatment and other techniques, a high magnetic energy product is obtained through exchange coupling between the nanocrystalline hard magnetic phase and nanocrystalline soft magnetic phase, and meanwhile, because rare-earth Fe phase is not used, the cost is lowered, and the operation technique is simplified.

Owner:嘉兴市鹏程磁钢有限公司 +1

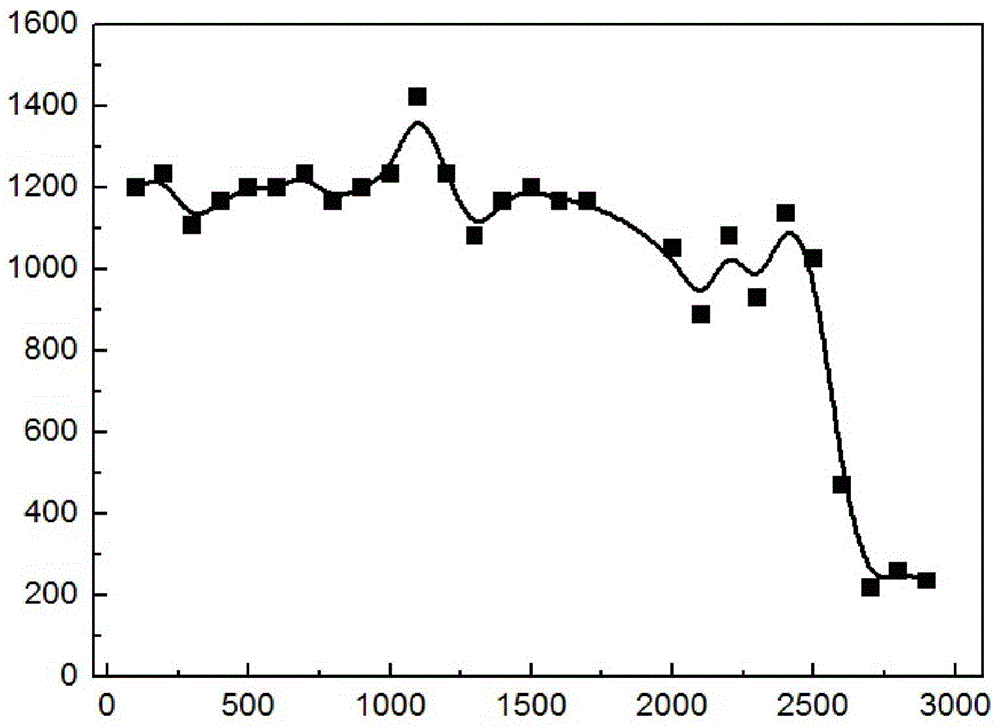

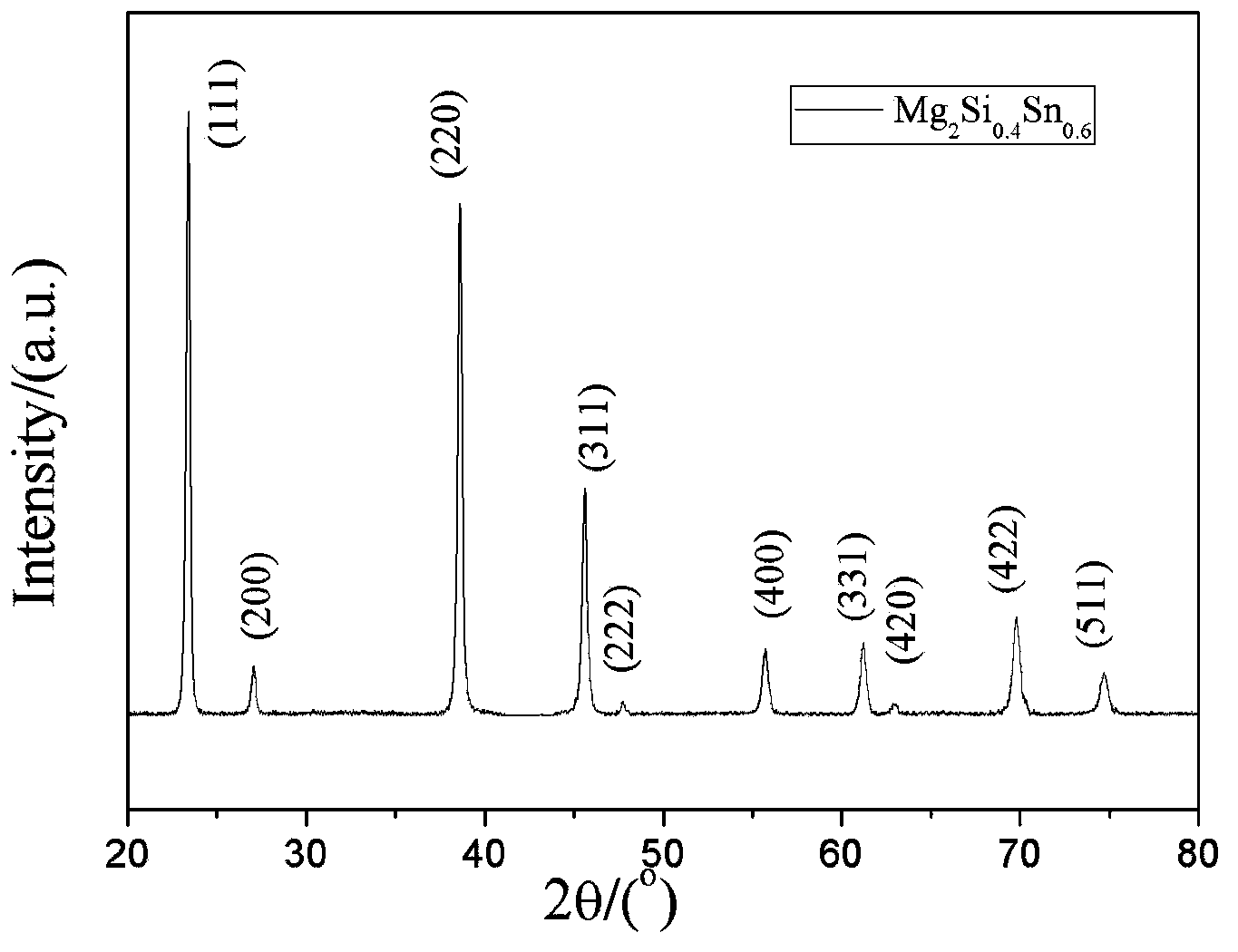

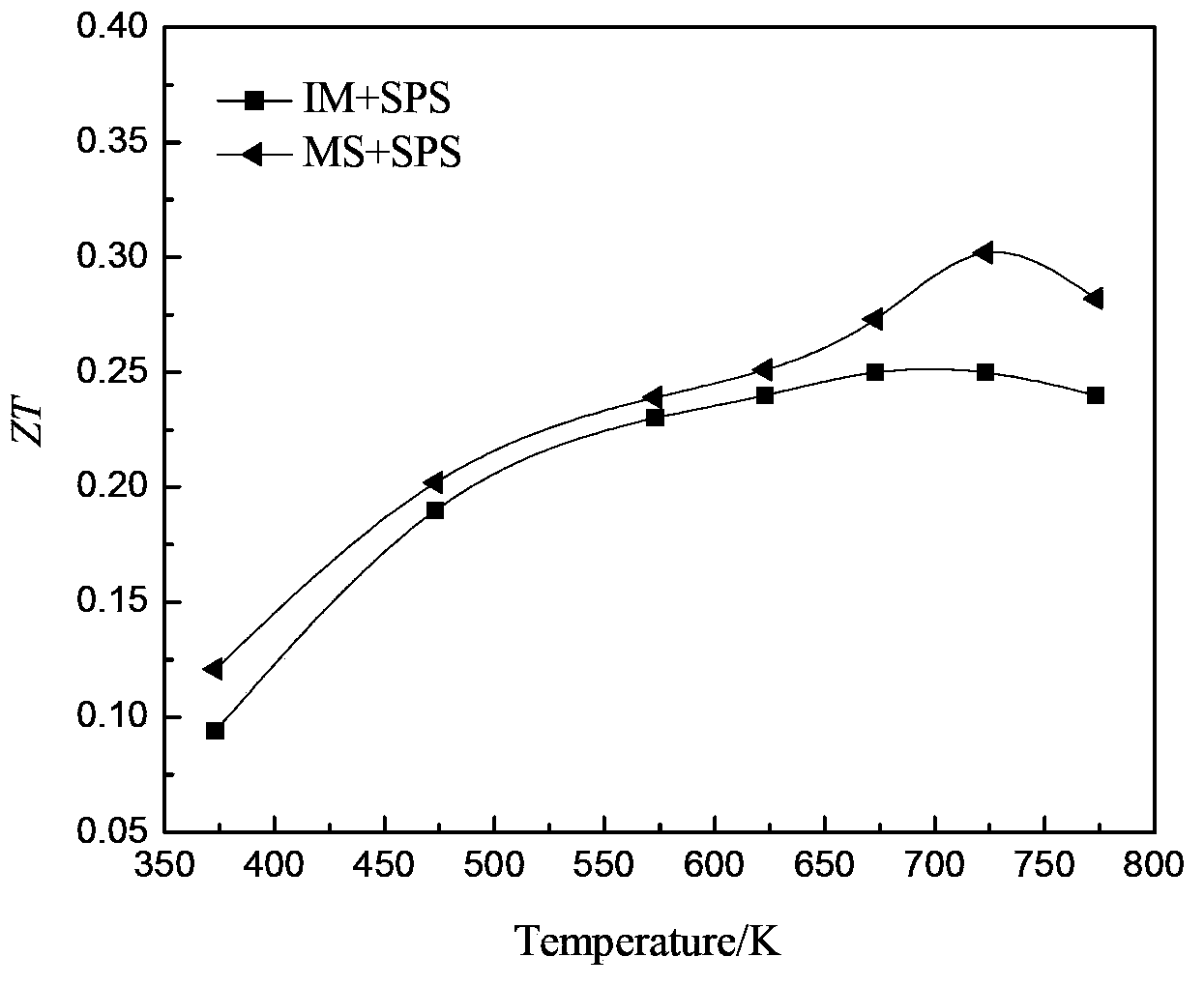

Nanocomposite structure Mg2Si-based thermoelectric material and preparation method thereof

InactiveCN103700759APrevent oxidationPrevent volatilizationThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsMolten state

The invention relates to a nanocomposite structure Mg2Si-based thermoelectric material and a preparation method thereof, and belongs to the technical field of preparation of semiconductor thermoelectric materials. The preparation method comprises the following steps: taking Mg, Si and Sn elementary substance materials according to a stoichiometric ratio and performing high-frequency induction smelting to form cast ingot; crushing the smelted cast ingots, filling into a quartz glass tube with a lower open end, vertically placing into an induction smelting coil, vacuumizing a cavity of a rapid quenching furnace, filling protective gas, performing induction smelting to enable the block to reach a molten state, spraying the melt to a copper rod, throwing out to form belt materials, and collecting the belt materials; placing the belt materials into a glove box under the argon protective atmosphere, grinding into powder, and performing spark plasma sintering into blocks. The preparation method is simple and feasible; the process flow is short; oxidation of Mg can be effectively inhibited; process parameters are easy to control. An amorphous / nanocrystalline composite structure exists in a sample, the grain size is obviously refined, the grain size distribution is controllable, scattering of electrons and phonons is increased, the Seebeck coefficient is greatly increased, and the thermoelectric property of the material is improved.

Owner:BEIJING UNIV OF TECH

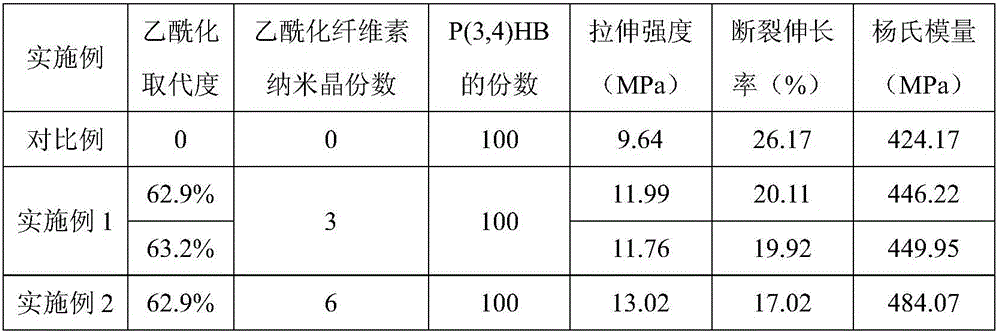

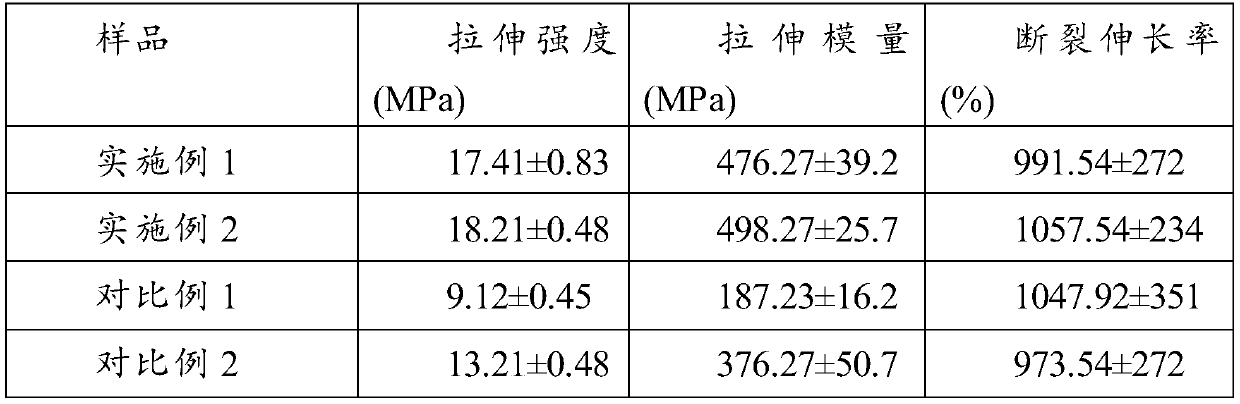

Acetylated cellulose nanocrystalline composite modified biomass-based polyester material and preparation method thereof

The invention belongs to the field of natural high polymer materials and particularly relates to an acetylated cellulose nanocrystalline composite modified biomass-based polyester material and a preparation method thereof. The acetylated cellulose nanocrystalline composite modified biomass-based polyester material is prepared from acetylated cellulose nanocrystalline and poly(3-hydroxybutyrate-co-4-hydroxybutyrate) in the weight ratio being (3-30):100 through compositing. The preparation method comprises steps as follows: poly(3-hydroxybutyrate-co-4-hydroxybutyrate) and an acetylated cellulose nanocrystalline solution are mixed and put into a polytetrafluoroethylene mold for film casting, a solvent is evaporated at the room temperature, and the acetylated cellulose nanocrystalline composite modified biomass-based polyester material is obtained after vacuum drying. The tensile strength and the Young modulus of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) are remarkably improved after composite modification by acetylated cellulose nanocrystalline, the strength and the rigidity of the material are improved, and the application range of the material is effectively broadened.

Owner:WUHAN UNIV OF TECH

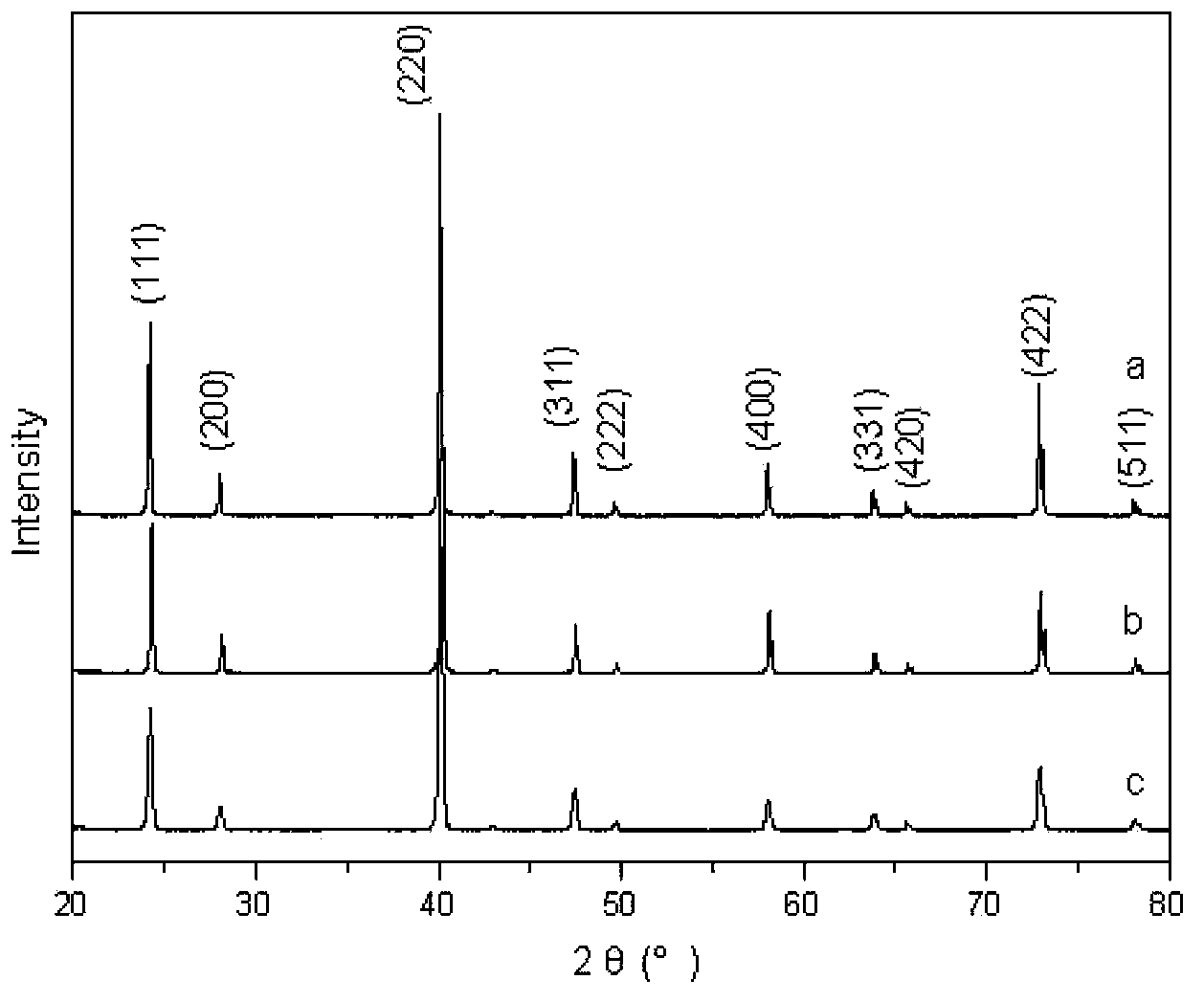

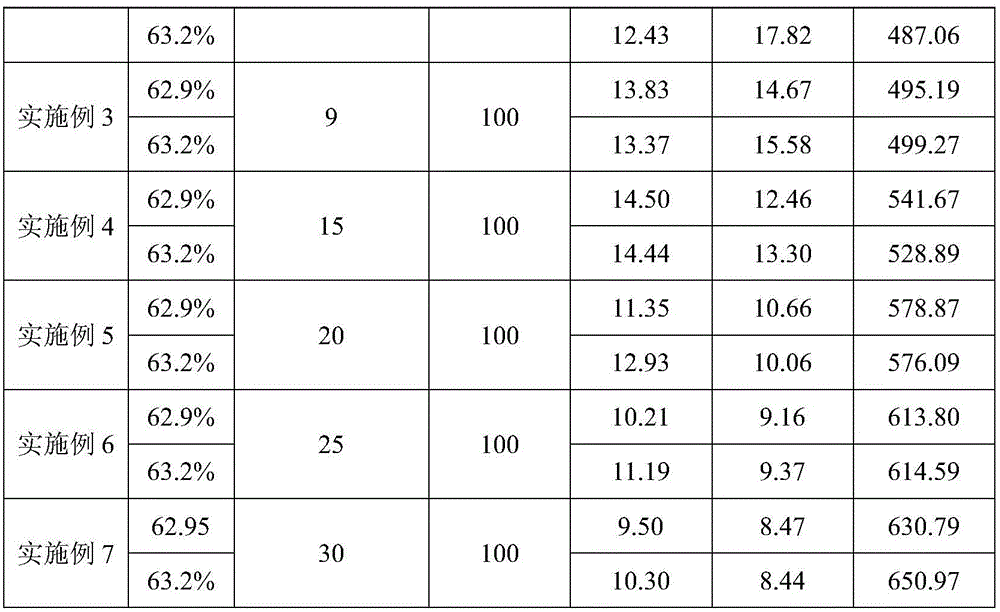

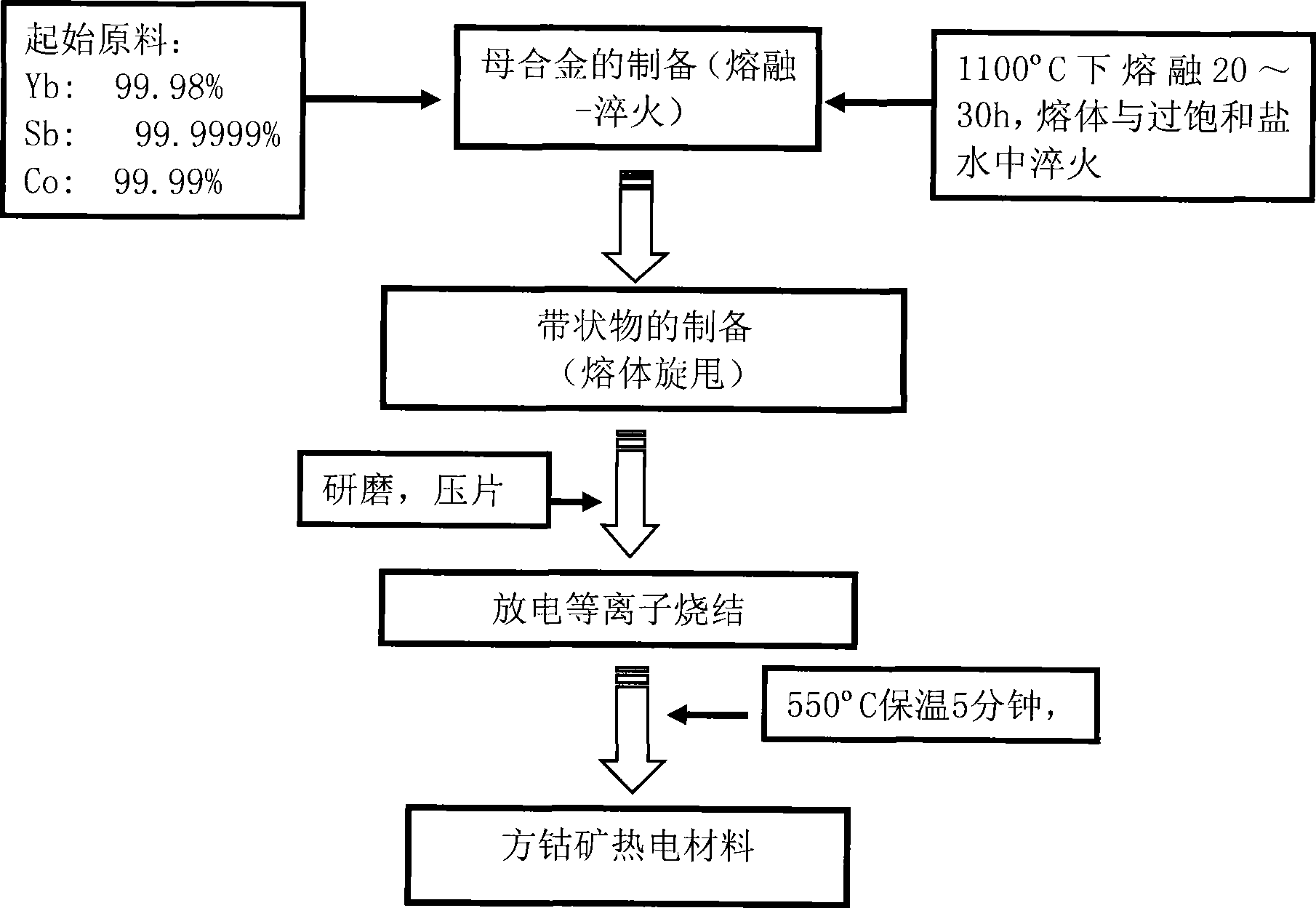

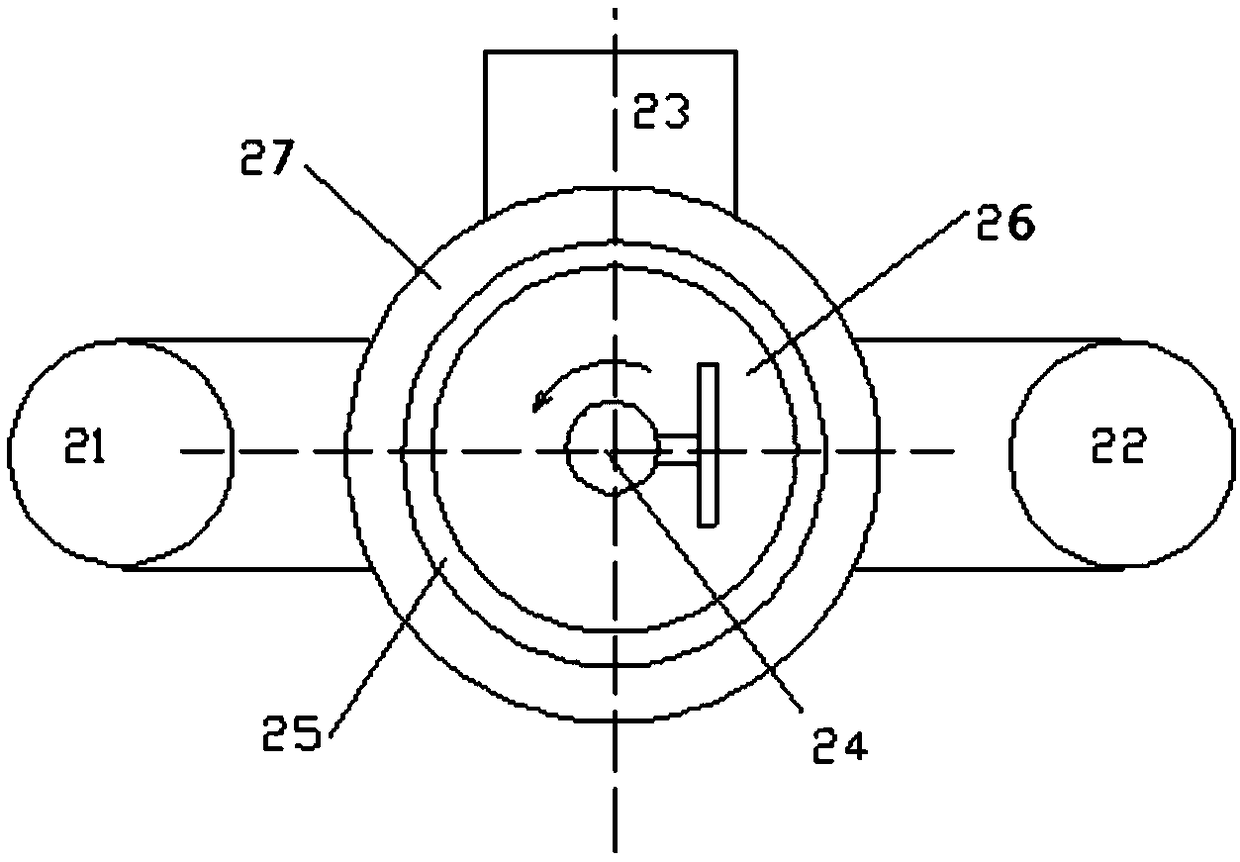

Rapid preparation of high performance nanostructured filling type skutterudite thermoelectric material

InactiveCN101435029AShort manufacturing cycleImprove thermoelectric performanceSkutteruditeSalt water

The invention relates to a preparing method of thermoelectric compound, in particular to a fast preparing method of filled type skutterudite thermoelectric material with high performance nanostructure. The invention is characterized in that the method comprises the following steps: 1) batching: granular Yb, granular Co and granular Sb are used as starting materials and weighed according to the chemical formula Yb0.3Co4Sb12.3; 2) preparing master alloy: the granular Yb, the granular Co and the granular Sb are mixed, then put into a melting furnace, heated slowly to 1100 DEG C by adopting rate of temperature increase of 2 DEG C / min and melted for 20 to 30h so as to obtain melt; the melt is quenched in supersaturated salt water so as to obtain the master alloy; 3) the master alloy is carried out cleaning processing, placed in an induction heating furnace to be melted to melt and then rotatablely throws the melt so as to obtain a strap product with an amorphous / nanocrystalline composite structure; and 4) the strap product with the amorphous / nanocrystalline composite structure is ground, tableted and then sintered by using discharging plasma so as to obtain filled type skutterudite thermoelectric material with high performance nanostructure. The method has short preparation period, low energy consumption, simple and easy-control technique, safety and no pollution.

Owner:WUHAN UNIV OF TECH

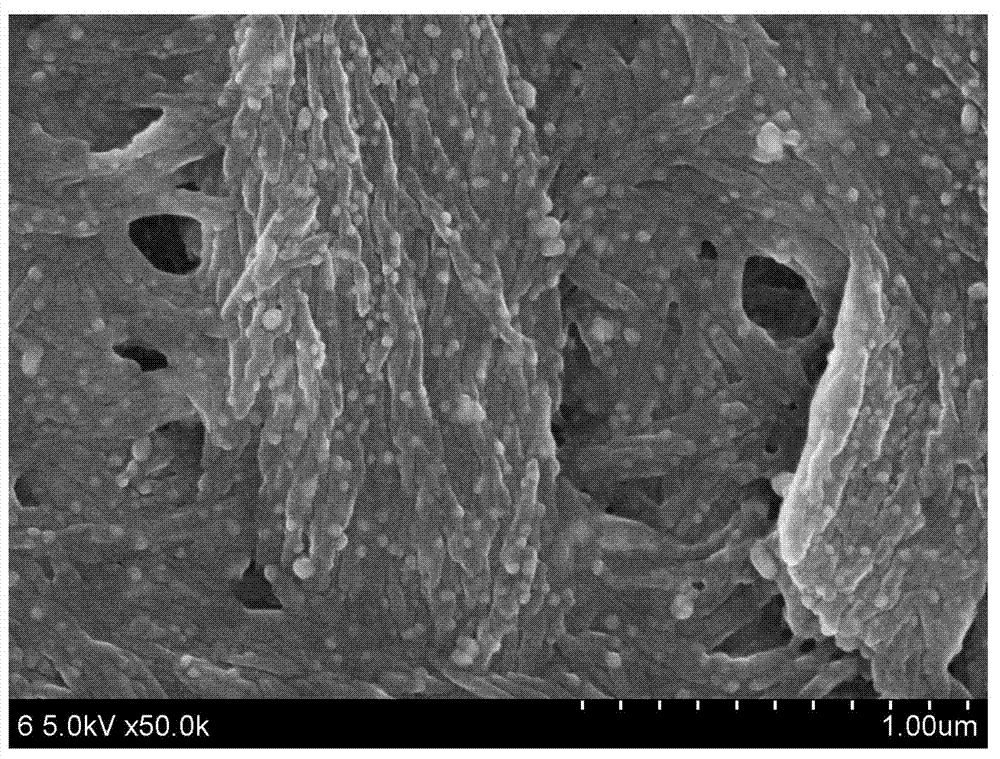

Method for manufacturing metal oxide nano-wire/noble metal nanocrystalline composite material

The invention relates to a method for manufacturing a metal oxide nano-wire / noble metal nanocrystalline composite material. The method comprises the following steps: uniformly dispersing noble metal nanocrystalline in a solvent, dripping the solvent in ethanol solution of 2-mercaptoethylphosphoric acid for reaction overnight so as to obtain solution of phosphoric acid functionalized noble metal nanocrystalline; adding metal oxide nano-wires into the solution of phosphoric acid functionalized noble metal nanocrystal for reaction overnight, filtering the solution, and washing the solution with ethanol and deionized water to obtain the metal oxide nano-wire / noble metal nanocrystal composite material. The method adopts the 2-mercaptoethylphosphoric acid (2-MEPA) as a bonder to ensure that the noble metal nanocrystalline and the metal oxide nano-wires can be bonded through a functional organic group, and regulates and controls light characteristic, electrical characteristic, catalytic characteristic and sensitivity characteristic of the metal oxide nano-wire / noble metal nanocrystalline composite material by regulating the size of the noble metal nanocrystalline and dispersed state thereof on the surface of the metal oxide nano-wires.

Owner:SHANGHAI UNIV

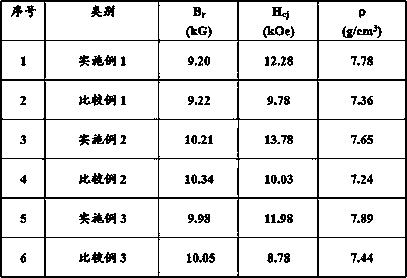

Apreparation method of SmCu alloy doped samarium-cobalt based nano composite permanent magnet

ActiveCN108962523AImprove textureImprove coercive forceTransportation and packagingMetal-working apparatusMagnetic phaseAlloy

The invention discloses a preparation method of a SmCu alloy doped samarium-cobalt-based nano composite permanent magnet, belonging to the technical field of magnetic materials. The material takes 1:5-type SmCo nanometer magnet and nanocrystalline alpha-Fe composite magnet as the base body, employs the magnetron sputtering and spark plasma sintering technology to take the low melting point Sm_6Cu_4 alloy as interface phase to improve the grain boundary and diffuse into the hard magnetic phase, , thus improving the magnet coercivity, and the Sm-Co based nanocrystalline composite permanent magnet with good magnetic properties was obtained. At that same time, the invention has the advantage of simple process and low cost, and is favorable for the application of samarium-cobalt-based nano composite permanent magnet in more permanent magnet device.

Owner:ZHEJIANG ZHONGKE MAGNETIC IND

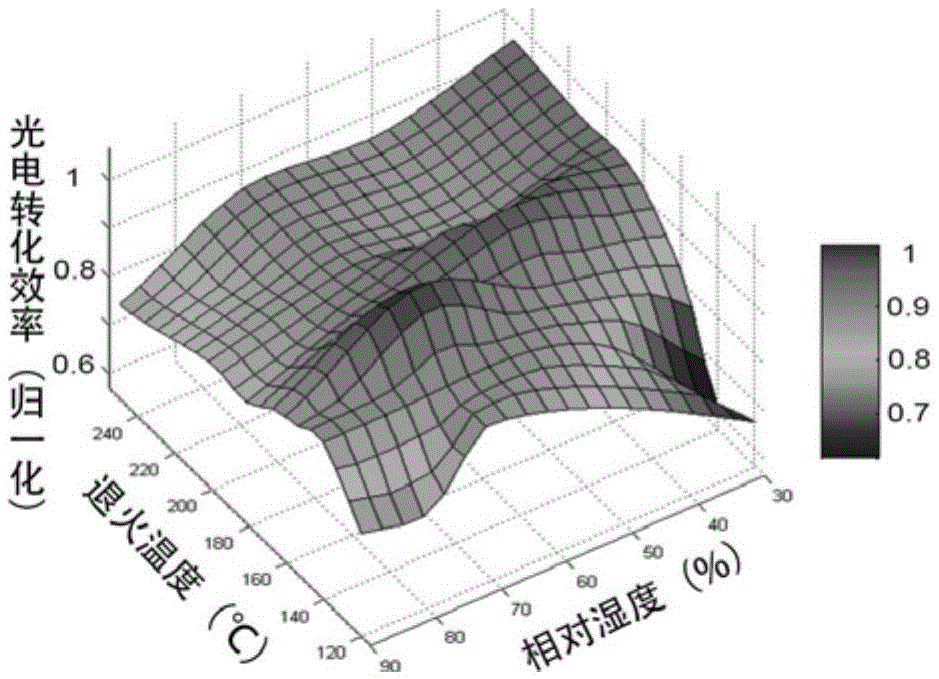

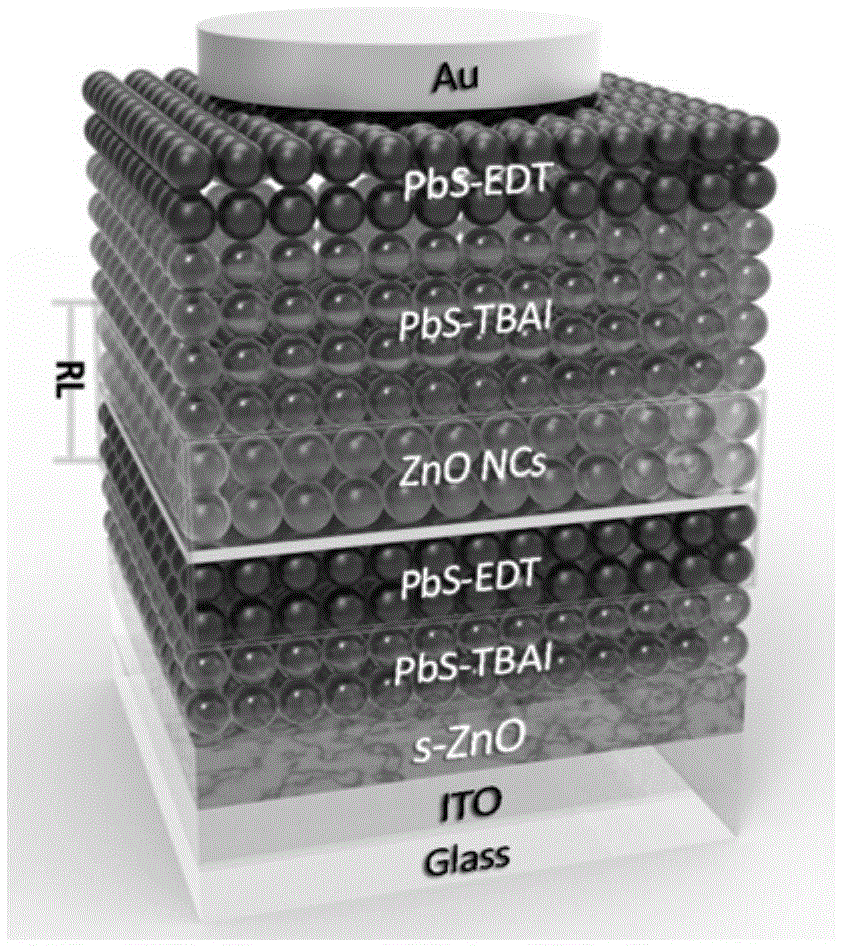

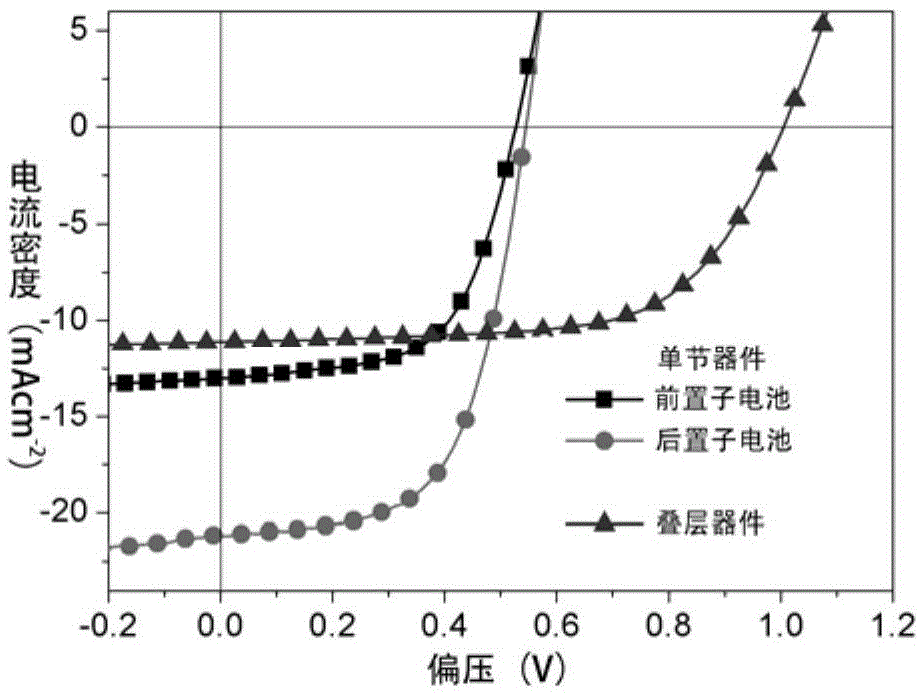

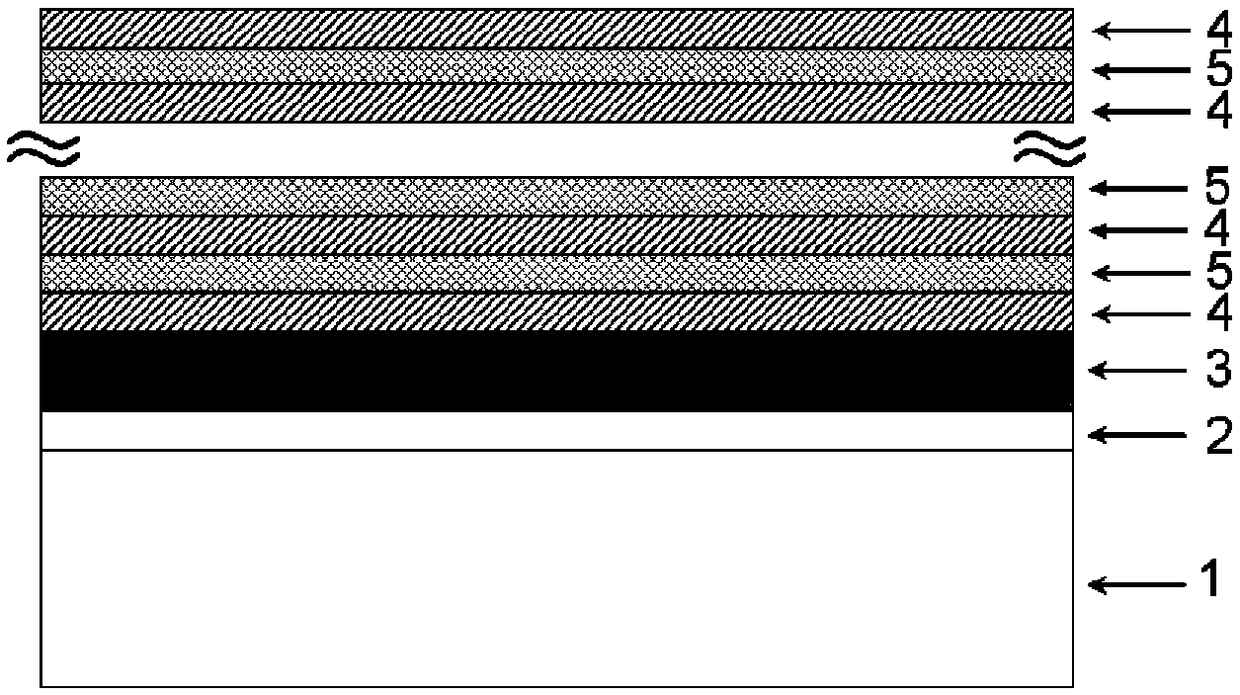

Nanocrystalline composite center-based stacked solar cell and preparation method thereof

InactiveCN105679858AStable performanceEasy to operateFinal product manufacturePhotovoltaic energy generationElectrical batteryEngineering

The invention discloses a nanocrystalline composite center-based stacked solar cell and a preparation method thereof. Specifically, the preparation method comprises the following three steps: (1) preparation of a front sub-cell; (2) preparation of a composite center; and (3) preparation of a back sub-cell. With lead sulfide nanocrystal as a hole transport layer of the composite center, the stacked solar cell has the characteristic that a solvent method process is simple in operation and has the device stability that a traditional solvent method material is short of. A novel composite center and lead sulfide colloidal quantum dot solar cell system has the compatibility; the efficiency is much higher than that of a lead sulfide quantum dot lamination device reported at present; the temperature of the overall preparation process is controlled within 140 DEG C; the whole preparation process is carried out in air; the technology is simple; and an inert gas atmosphere is not needed. The preparation method disclosed by the invention breaks through existing technical bottlenecks, and provides a certain guidance function for further improvement of the photoelectric conversion efficiency of the device and promotion of commercialized development.

Owner:SUZHOU UNIV

Graphene-cellulose nanocrystalline composite heat-conducting film with bionic structure and preparation thereof

The invention relates to a graphene-cellulose nanocrystalline heat-conducting film with a bionic structure and preparation thereof. The composite film has a shell-like brick-mud layered structure. A preparation method for the film comprises the following steps: (1) mixing a GO solution with a CNC solution in a certain ratio under stirring, and then successively carrying out coating and drying; and(2) subjecting a film obtained in the step (1) to annealing and reducing at a high temperature to obtain the target product graphene-cellulose nanocrystalline heat-conducting film. Compared with theprior art, the invention has the advantage that the thermal conductivity and electrical conductivity of the graphene film are improved by embedding CNC among layers of graphene through self-assemblingto construct the graphene layered shell-like structure.

Owner:SHANGHAI JIAO TONG UNIV

Self-repaired waterborne polyurethane/cellulose nanocrystalline composite material and preparation method thereof

The invention provides a preparation method of a self-repaired waterborne polyurethane / cellulose nanocrystalline composite material. The preparation method comprises the following steps: preparing a waterborne polyurethane emulsion; mixing cellulose nanocrystalline powder or an aqueous dispersion with carboxylic acid containing maleinimide radicals in deionized water, carrying out vacuum-pumping water removal during a heating reaction to obtain maleinimide grafted cellulose nanocrystallines; mixing the waterborne polyurethane emulsion with the maleinimide grafted cellulose nanocrystallines, carrying out ultrasonic dispersion uniformly, and heating to obtain the self-repaired waterborne polyurethane / cellulose nanocrystalline composite material. Furan rings are introduced into a waterborne polyurethane macromolecular chain structure through a furan ring chain extender and / or an end-capping reagent, the maleinimide radicals are grafted to the surfaces of the cellulose nanocrystallines through an esterification reaction, the two components are uniformly mixed and heated to obtain the novel self-repaired waterborne polyurethane / cellulose nanocrystalline composite material, so that direct and uniform fastening recombination of the waterborne polyurethane and cellulose nanocrystallines is facilitated, and mechanical properties and self-repair performance of the material are improved.

Owner:芜湖万隆新材料有限公司

High-bonding-force solid lubricating film layer used in wide temperature range environment, and preparation method of solid lubricating film layer

ActiveCN108977776AReduce surface roughnessReduce coefficient of frictionVacuum evaporation coatingSputtering coatingBatch processingTitanium alloy

The invention discloses a high-bonding-force solid lubricating film layer used in a wide temperature range environment, and a preparation method of the solid lubricating film layer. A nanocrystallinecomposite coating, sequentially formed by a bonding layer (Ti), a transition layer (TiN / TiCN) and a functional layer (TiN / MoS2-Ag), is separately deposited on titanium alloy, aluminum alloy, stainlesssteel and a bearing steel substrate by using an ion implantation and deposition combined magnetron sputtering technology. The prepared nanocrystalline composite coatings can reliably service in the wide temperature range environment of -150 to 300 DEG C, and are strong in adhesion and low in friction coefficient, thus greatly prolonging the service life of moving parts of a spacecraft and improving the reliability of the spacecraft. Furthermore, the preparation method provided by the invention has the characteristics of being high in ionization rate, simple in membrane layer equipment structure, capable of realizing batch processing, and the like, thus being suitable for industrial production and having a good application prospect.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Alginic acid fluorescent fiber material and preparation and application

InactiveCN105155038AHigh strengthGood fluorescenceAlginate artificial filamentsWet spinning methodsFiberFluorescence

The invention discloses an alginic acid fluorescent fiber material and preparation and application, and belongs to the field of the printing and packaging technology and the anti-counterfeit technology. Alginic acid / cadmium telluride (CdTe) nanocrystalline composite fluorescent fiber is adopted. A method includes the steps of firstly, preparing a blend spinning solution of cadmium telluride (CdTe) nanocrystalline and sodium alginate; secondly, preparing the fluorescent fiber; thirdly, preparing the alginic acid / cadmium telluride (CdTe) nanocrystalline composite fluorescent fiber through a wet spinning method; fourthly, conducting spinning through the blend spinning solution in the first step by means of a spinning head; fifthly, conducting stretching in stretching liquid after a coagulating bath; sixthly, conducting washing to form the fluorescent fiber. The alginic acid fluorescent fiber material can be applied to various types of anti-counterfeit paper and cloth.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

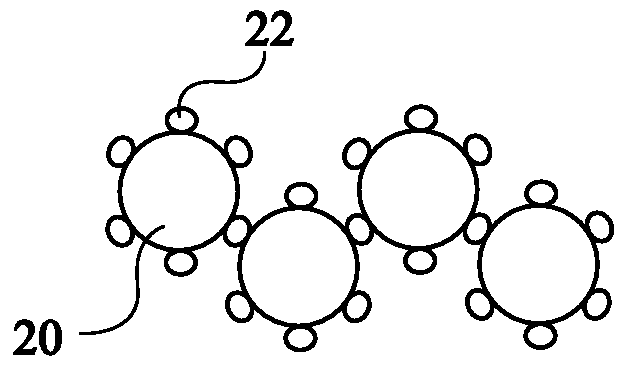

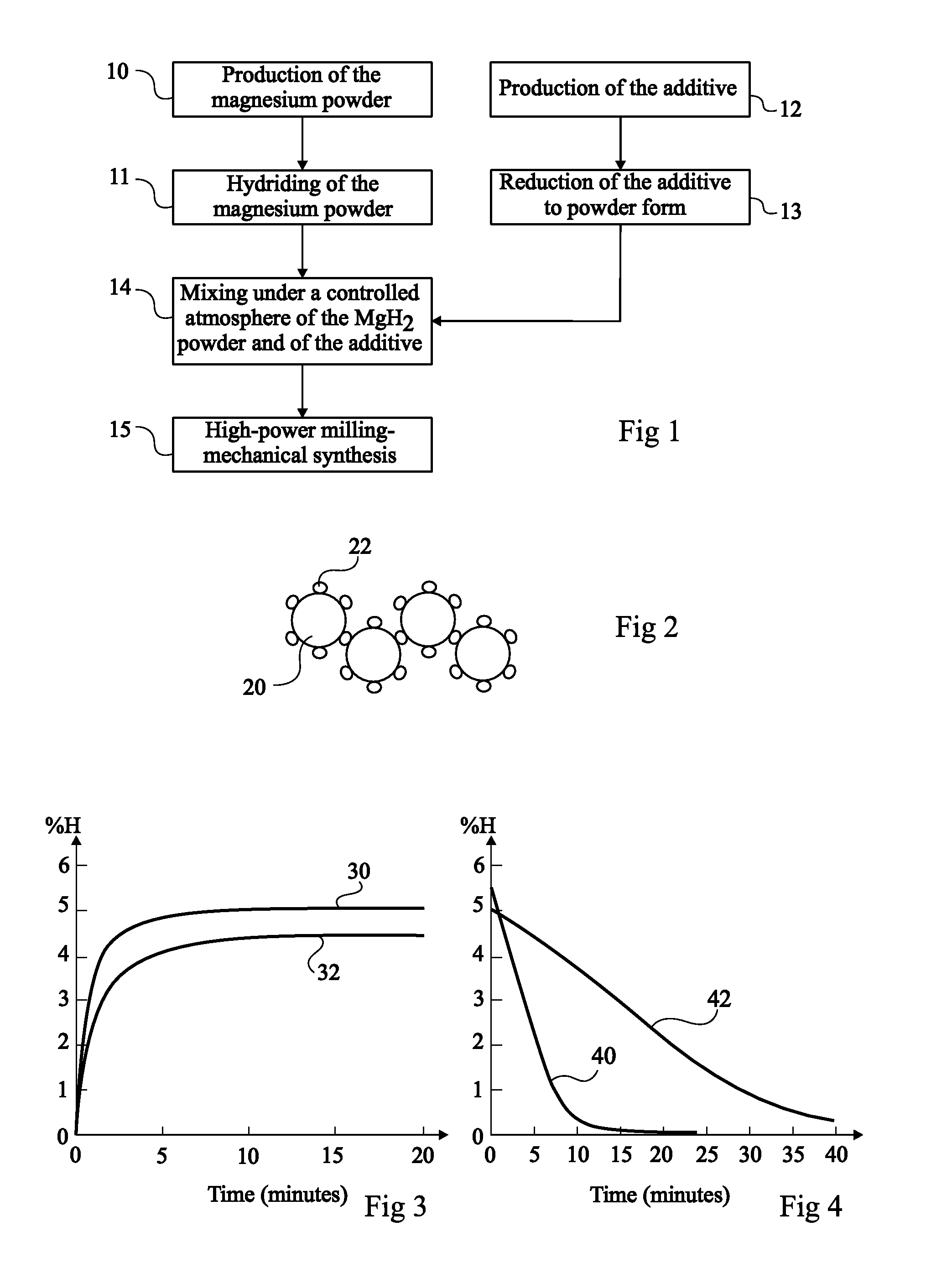

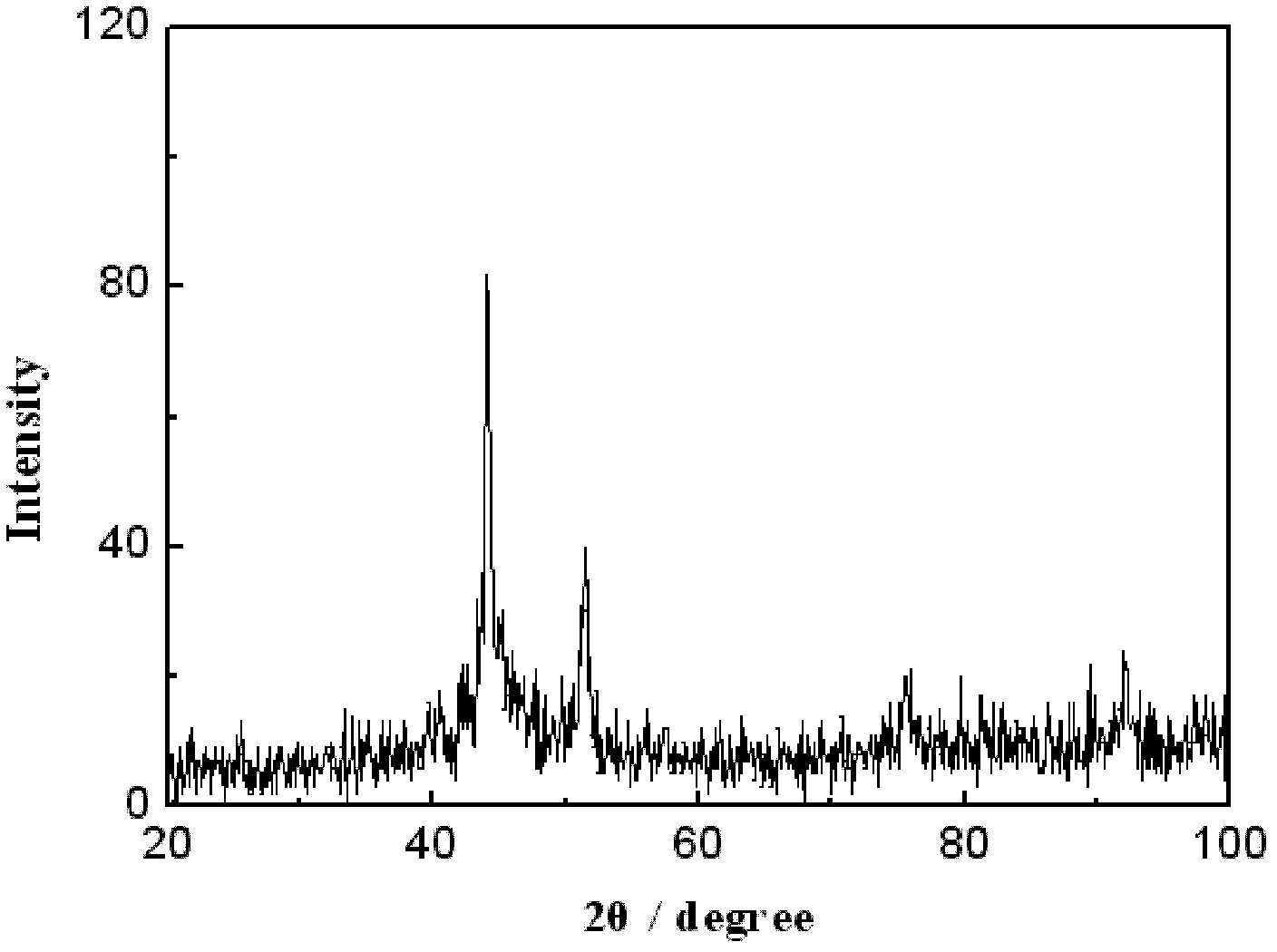

Nanocrystalline Composite for Storage of Hydrogen

ActiveUS20090278086A1Promote absorptionImproved desorption kineticsHydrogenOther chemical processesManganeseAlloy

The invention relates to a method for preparation of a material adapted to reversible storage of hydrogen, including steps consisting of providing a first powder of a magnesium-based material, hydrogenating the first powder to convert at least part of the first powder into metal hydrides, mixing the first hydrogenating powder with a second powder additive, the proportion by mass of the second powder in the mix obtained being between 1% and 20% by mass, wherein the additive is formed from an alloy with a centred cubic structure based on titatnium, vanadium and at least one other metal chosen from chromium or manganese, and grinding the mix of first and second powders.

Owner:CENT NAT DE LA RECHERCHE SCI

Cored wire of high-speed electric arc spraying nickel-base amorphous nanocrystalline antifriction coating

A cored wire of a high-speed electric arc spraying nickel-base amorphous nanocrystalline antifriction coating is characterized in that a core of the cored wire is wrapped by a pure-Ni cover, the mass percent of the core accounting for the wire ranges from 27% to 40%, the core consists of components including, in mass percent, from 3 to 5% of metal Cr, from 10 to 12% of B-Cr alloy, from 2 to 5% of Si-Fe alloy, from 10 to 15% of Mo and from 0 to 10% of BaF2 and CaF2 eutectic powder. In order to resolve the problem that a traditional high-speed electric arc spraying wear-resistant coating is poor in antioxidation and corrosion prevention, the cored wire is reasonable in ingredient design, the nickel-base amorphous nanocrystalline composite antifriction coating with the thickness of 0.5-1mm, low porosity and high bonding strength is prepared on a 20G low-carbon steel matrix by means of high-speed electric arc spraying, the hardness of the coating is larger than HV600, amorphous phase content is 20-50%, antioxidation and wear-resisting antifriction effects of the coating are remarkable, and the cored wire can be used for preparing antioxidative, anti-corrosion, wear-resistant and antifriction coatings with the work environment temperature within 750 DEG C.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

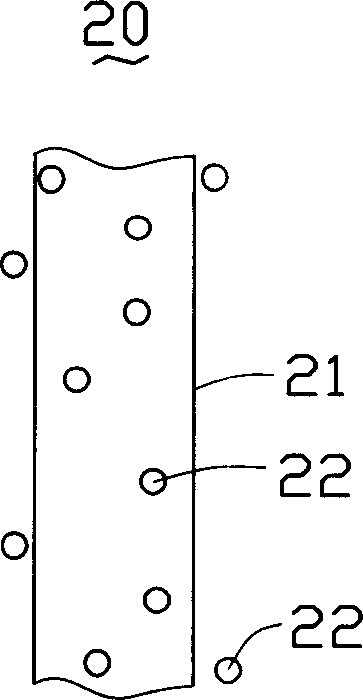

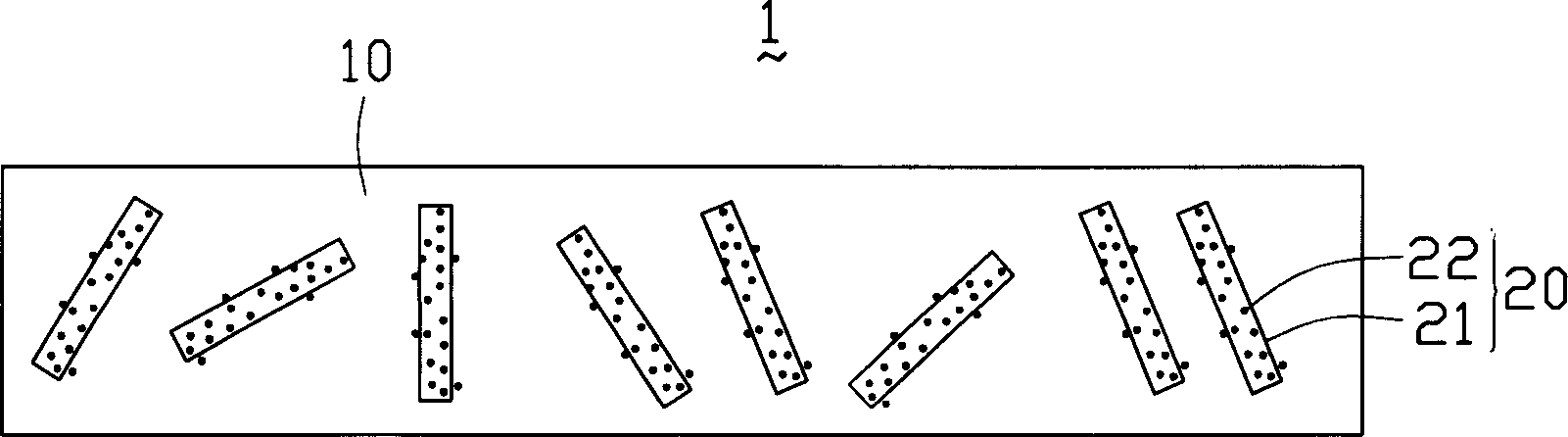

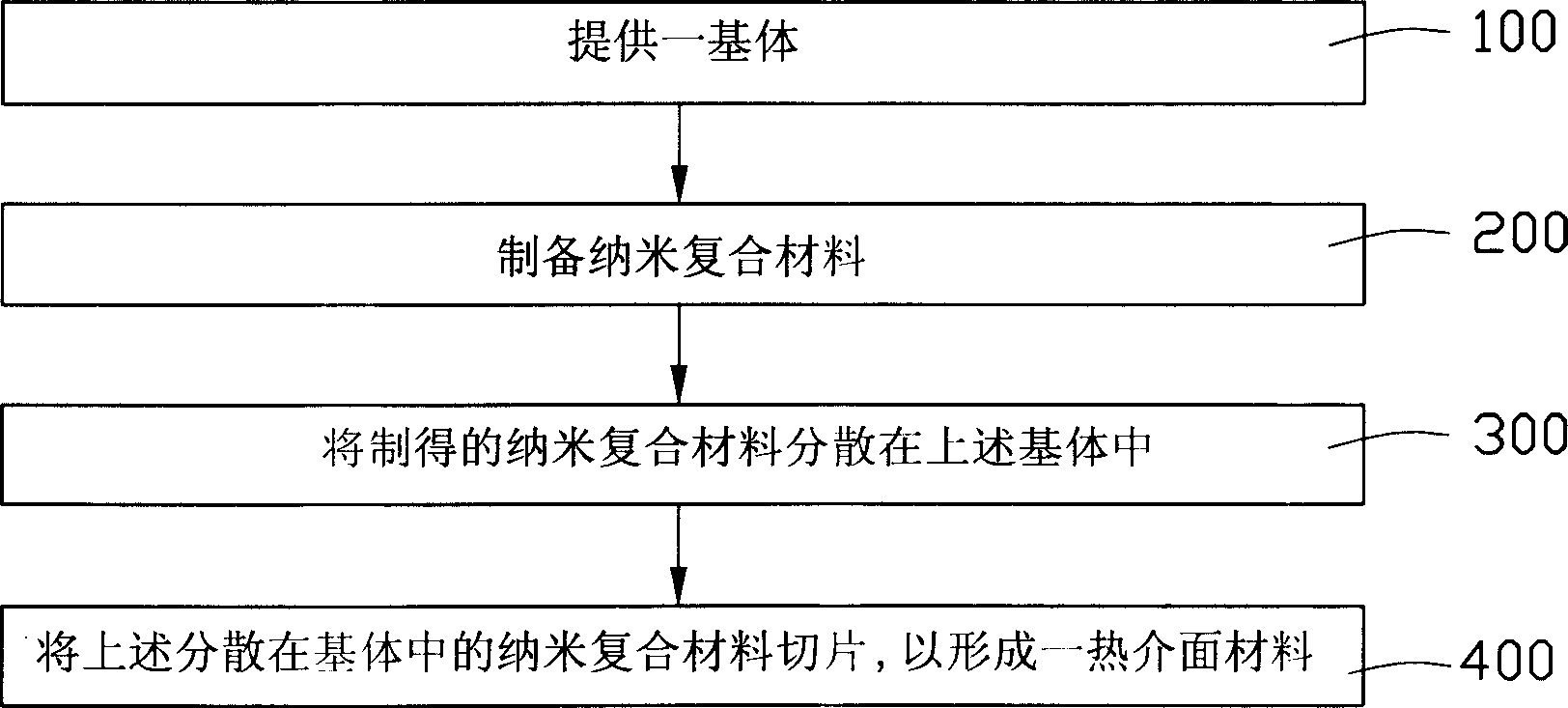

Thermal interface material and its production

InactiveCN1854241AHigh thermal conductivityImprove thermal conductivityHeat-exchange elementsFiberHeat conducting

The invention includes a kind of hot interface material and the method of preparing it. This kind of hot interface material contains parent materials and nanocrystalline composite materials in the base stock. The nanocrystalline composite materials includes nanometer fiber and heat-conducting granules which disperse inside the nanometer fiber pipe and outside.This nanometer fiber comes from carbon nanometer pipe, carbon nanometer line or carbon fiber. The size of heat-conducting granules can be micron level, but the nanometer level is better. This invention also provides the method of preparing the hot interface material.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

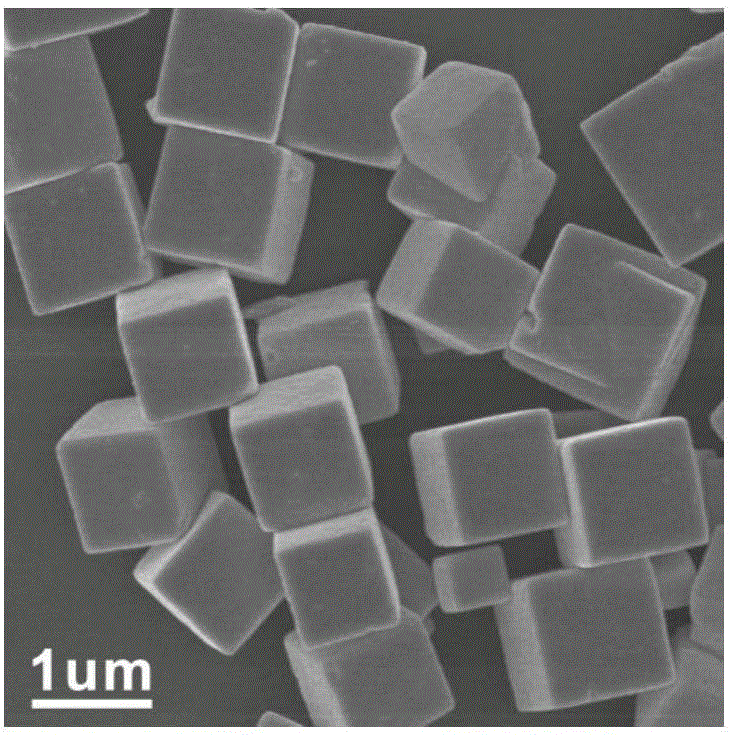

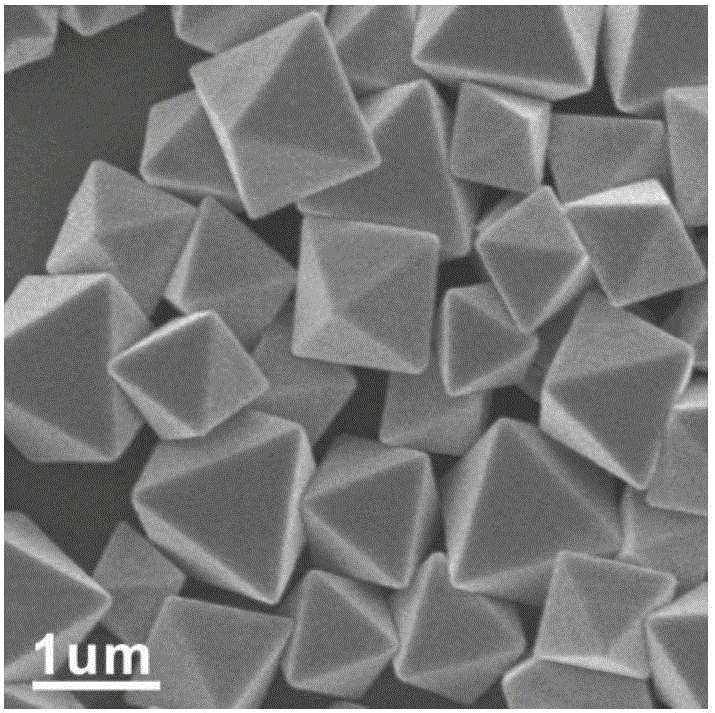

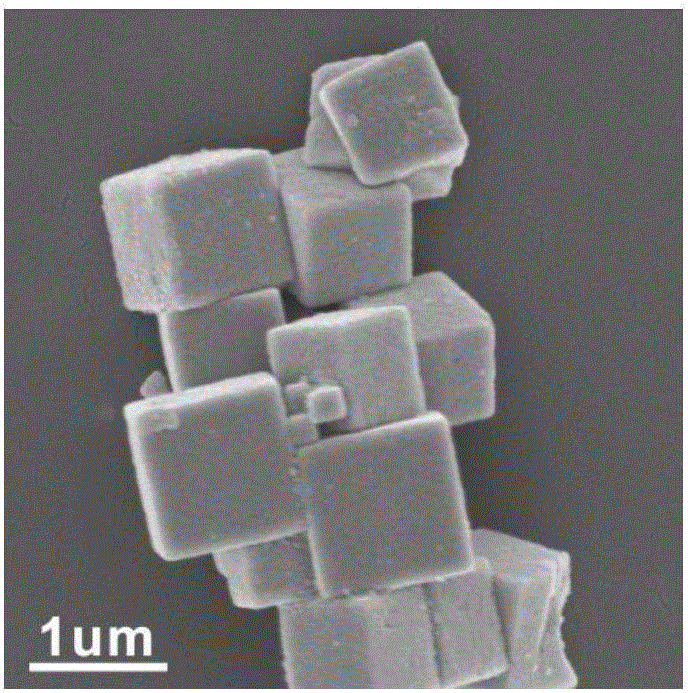

ZnO/Cu nanometer crystal composite material, and preparation method and application thereof

ActiveCN106378141AHigh catalytic performance boostImprove catalytic performanceHydrogenMetal/metal-oxides/metal-hydroxide catalystsOctahedronNanotechnology

The invention provides a ZnO / Cu nanometer crystal composite material. ZnO is loaded on the surface of Cu nanometer crystals; the ZnO / Cu nanometer crystal composite material is of a cube or octahedron structure. When the ZnO / Cu nanometer crystal composite material is applied to water gas conversion reaction, compared with the Cu nanometer crystals, the ZnO / Cu nanometer crystal composite material has the advantages that the high catalysis performance promoting effect is shown; meanwhile, for ZnO / Cu nanometer crystal materials with different appearances, great catalytic performance differences are also shown. Experiments show that the cube ZnO / Cu has good catalytic performance on the water gas conversion reaction.

Owner:UNIV OF SCI & TECH OF CHINA

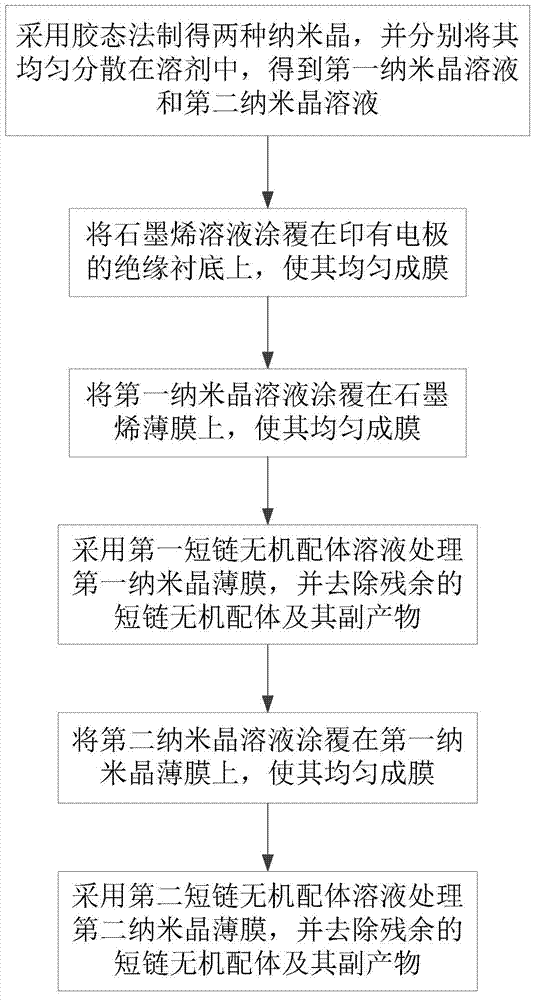

Semiconductor resistance gas sensor and production method thereof

ActiveCN104713914ALower initial resistanceReduce the difficulty of detectionMaterial resistanceWorking temperatureEngineering

The invention discloses a semiconductor resistance gas sensor and a production method thereof. The gas sensor comprises an insulation substrate, a signal electrode and a gas sensitive layer; and the gas sensitive layer is formed by a semiconductor nanocrystal composite material and graphene. A semiconductor nanocrystal solution is synthesized through a colloidal state technology, and can directly form a film at room temperature without high temperature treatment, so the energy consumption is small, agglomeration of nanoparticles is avoided, the large specific area advantages of the nanoparticles is maximally performed, gas adsorption is facilitated, and the sensitivity of the sensor is improved, thereby the sensor can be used to detect a target gas with a low concentration at a low work temperature and even normal temperature. The production method is simple, and can easily realize large scale batch production.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com