High-bonding-force solid lubricating film layer used in wide temperature range environment, and preparation method of solid lubricating film layer

A solid lubricating, wide temperature range technology, applied in the field of high-binding solid lubricating film and its preparation, can solve the problems of low wear resistance, low hardness of sputtering film, easy to lose lubricating performance, etc. The effect of low layer friction coefficient, lower surface roughness, and better self-lubricating performance in a wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

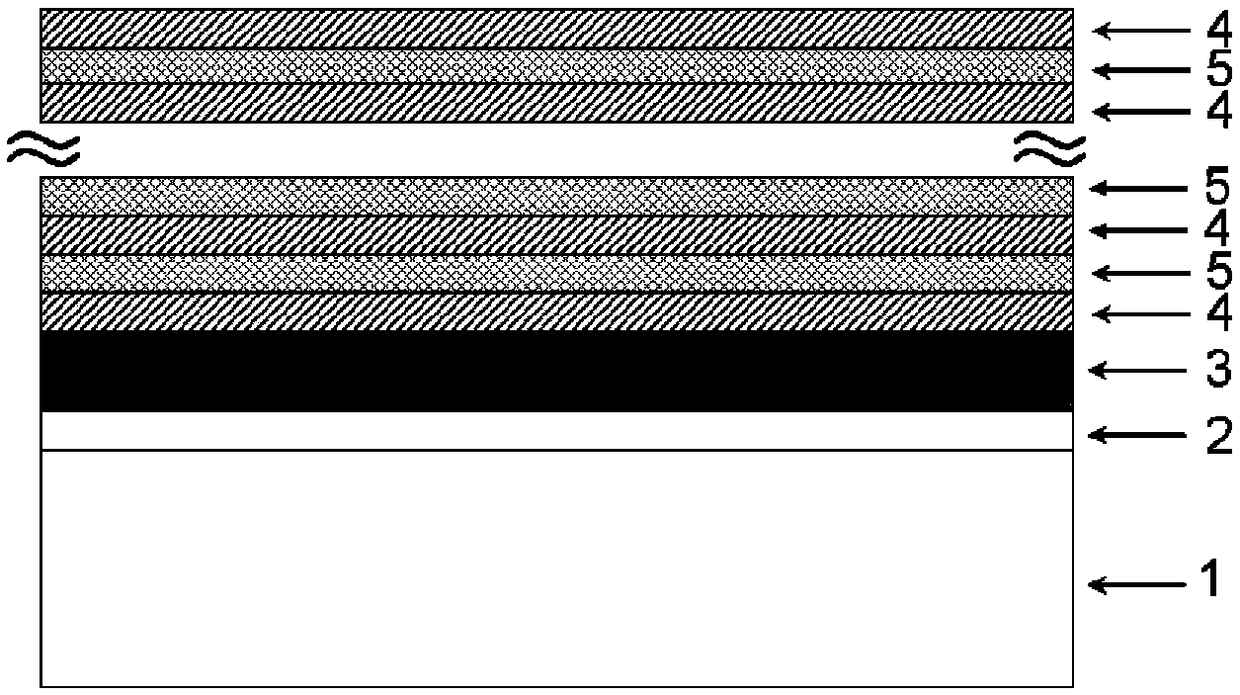

[0029] A solid lubricating film layer with high binding force in a wide temperature range environment, such as figure 1 Shown; where the substrate 1, bonding layer 2 (Ti), transition layer 3 (TiN / TiCN), functional layer 4 (TiN), functional layer 5 (MoS 2 -Ag), substrate 1 is TC4 alloy, Ti / TiN / TiCN / (TiN / MoS 2 -Ag) nanocomposite multilayer film.

[0030] The specific preparation process of the high-binding force solid lubricating film layer in the above-mentioned space wide temperature range environment is carried out according to the following steps:

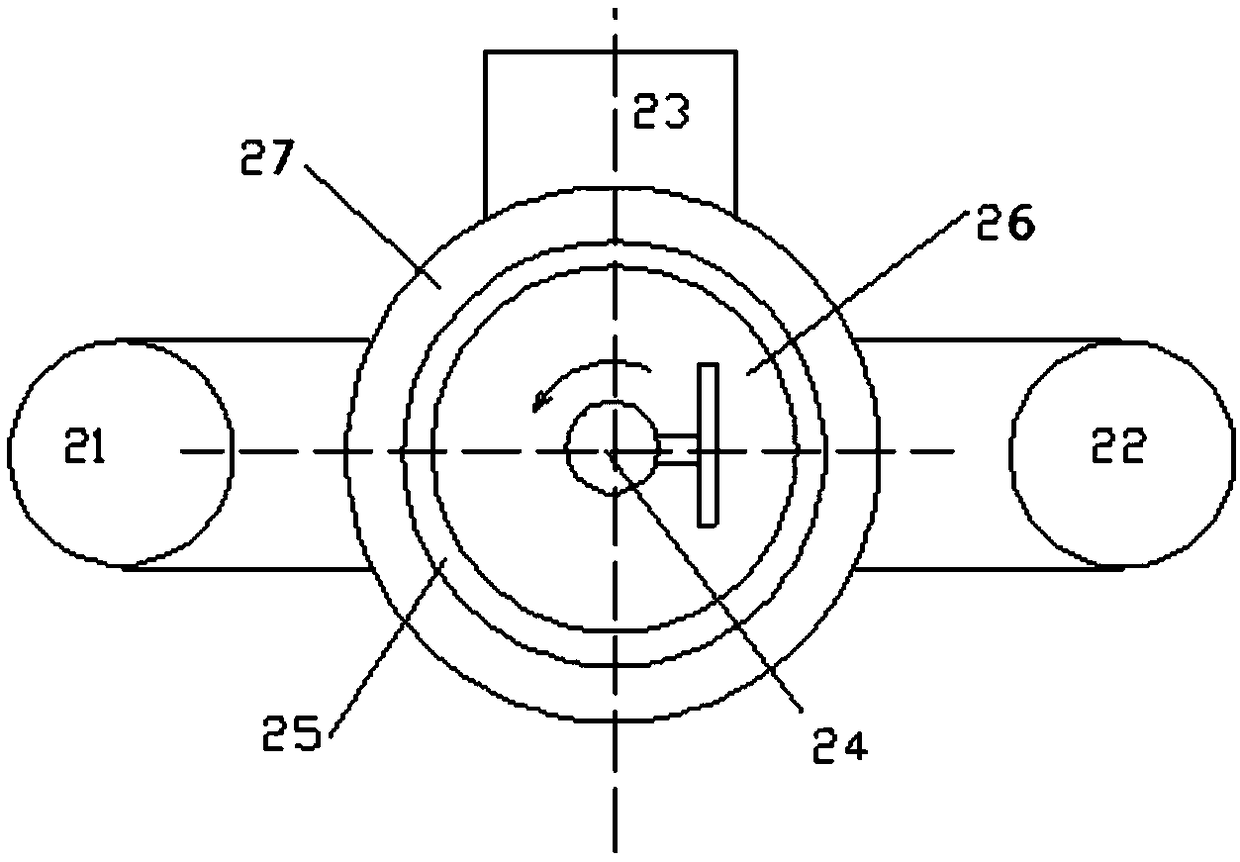

[0031] 1) Sputtering cleaning: After surface polishing, acetone ultrasonic cleaning, ethanol ultrasonic cleaning and drying, the coated samples are placed on the rotatable target stage in the coating equipment, and the vacuum chamber is evacuated to 4.0×10 -3 Pa, through Ar, the control air pressure is 3.0×10 -1 Pa, start the radio frequency to clean the sample by Ar plasma sputtering, the radio frequency power is 400W, and at...

Embodiment 2

[0038] The preparation time of TiN film layer in step 4 in embodiment 1 is shortened to 10min from 30min, MoS 2 - The preparation time of the Ag film layer was shortened from 9 minutes to 3 minutes, and the number of corresponding multi-layer layers was increased from 8 layers to 24 layers, and the total thickness of the film layer was kept consistent. Other steps were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com