Apreparation method of SmCu alloy doped samarium-cobalt based nano composite permanent magnet

A nano-composite, permanent magnet technology, used in magnetic objects, metal processing equipment, magnetic materials, etc., can solve problems such as magnetic properties gap, achieve good magnetic properties, improve coercivity, and improve the effect of grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

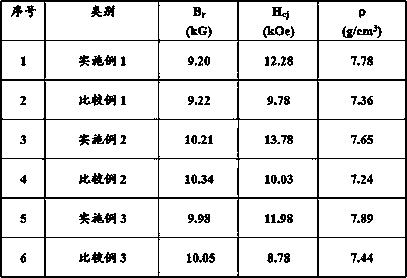

Examples

Embodiment 1

[0019] 1) Prepare the raw materials first, weigh the raw materials according to the following weight ratio: Sm: 20%, Ce: 6%, Co: 56%, Fe: 10%, Cu: 5%, Zr: 3%, mix the raw materials and carry out vacuum Melting, and then high-energy ball milling for 2 hours to make alloy powder;

[0020] 2) According to Sm 6 Cu 4 Alloy composition Weigh and mix each raw material, vacuum melt the mixed raw material, and then melt the melted Sm 6 Cu 4 After the alloy ingot is melted, it is poured into the magnetron sputtering target mold, and after cooling, it is ground and cut to obtain Sm 6 Cu 4 Alloy sputtering target;

[0021] 3) Using magnetron sputtering technology to make the Sm prepared in step (2) 6 Cu 4 The alloy target is plated with (Sm, Ce) prepared in step (1). 1 (Co, Fe, Cu, Zr) 5 A mixed powder is obtained on the alloy powder; the vacuum degree of the vacuum chamber during the sputtering process is 8×10 - 2 Pa, the magnetron sputtering current is 20A, and the magnetron ...

Embodiment 2

[0029] 1) Prepare the raw materials first, weigh the raw materials according to the following weight ratio: Sm: 25%, Ce: 2.5%, Co: 53.5%, Fe: 11%, Cu: 6%, Zr: 2%, mix the raw materials and vacuum Melting, and then high-energy ball milling for 3 hours to make alloy powder;

[0030] 2) According to Sm 6 Cu 4 Alloy composition Weigh and mix each raw material, vacuum melt the mixed raw material, and then melt the melted Sm 6 Cu 4 After the alloy ingot is melted, it is poured into the magnetron sputtering target mold, and after cooling, it is ground and cut to obtain Sm 6 Cu 4 Alloy sputtering target;

[0031] 3) Using magnetron sputtering technology to make the Sm prepared in step (2) 6 Cu 4 The alloy target is plated with (Sm, Ce) prepared in step (1). 1 (Co, Fe, Cu, Zr) 5 A mixed powder is obtained on the alloy powder; the vacuum degree of the vacuum chamber during the sputtering process is 8×10 - 2 Pa, the magnetron sputtering current is 20A, and the magnetron sputte...

Embodiment 3

[0039] 1) Prepare the raw materials first, weigh the raw materials according to the following weight ratio: Sm: 27%, Ce: 2.7%, Co: 50.8%, Fe: 11%, Cu: 5.5%, Zr: 3%, mix the raw materials and then vacuum Melting, and then high-energy ball milling for 4 hours to make alloy powder;

[0040] 2) According to Sm 6 Cu 4 Alloy composition Weigh and mix each raw material, vacuum melt the mixed raw material, and then melt the melted Sm 6 Cu 4 After the alloy ingot is melted, it is poured into the magnetron sputtering target mold, and after cooling, it is ground and cut to obtain Sm 6 Cu 4 Alloy sputtering target;

[0041] 3) Using magnetron sputtering technology to make the Sm prepared in step (2) 6 Cu 4 The alloy target is plated with (Sm, Ce) prepared in step (1). 1 (Co, Fe, Cu, Zr) 5 A mixed powder is obtained on the alloy powder; the vacuum degree of the vacuum chamber during the sputtering process is 8×10 - 2 Pa, the magnetron sputtering current is 20A, and the magnetron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com